Page 1

Citrus Juicer

Model EX

Instruction Manual

3115 Pepper Mill Court, Mississauga, ON, L5L 4X5

1889 Maryland Avenue, Niagara Falls, NY, 14305

51659.7 - Version 01

1-800-465-0234

www.omcan.com

Page 2

Table of Contents

Model EX

Section

General Information

Safety & Warranty

-------------------------------------------------------------------------------- 3

------------------------------------------------------------------------------ 3 - 4

Technical Specications

Installation

Operation

Maintenance

-------------------------------------------------------------------------------------------- 5

--------------------------------------------------------------------------------------------- 5

------------------------------------------------------------------------------------- 5 - 6

Page

-------------------------------------------------------------------------- 4

Parts Breakdowns

Electrical Schematics

Warranty Registration

------------------------------------------------------------------------------ 7 - 8

------------------------------------------------------------------------------ 9

---------------------------------------------------------------------------- 11

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc. and Food Machinery Of America, Inc. dba Omcan

are not responsible for any harm or injury caused due to any person’s improper or negligent use of

this equipment. The product shall only be operated by someone over the age of 18, of sound mind, and

not under the inuence of any drugs or alcohol, who has been trained in the correct operation of this

machine, and is wearing authorized, proper safety clothing. Any modication to the machine voids any

warranty, and may cause harm to individuals using the machine or in the vicinity of the machine while

in operation.

The EX juice extractor is designed to process food products safely and efciently. Unless the operator is

properly trained and supervised, there is the possibility of a serious injury. It is the responsibility of the owner to

ensure that this machine is used properly and in a safe manner. It is mandatory to strictly follow the instructions

contained in this manual and any requirements of local law.

Safety and Warranty

The juice extractor model EX is simple to use and to operate, however read the following precautions to avoid

injury or damage to the unit:

• BEFORE cleaning always disconnect the machine from the power supply.

• NEVER use tools not intended to assist the unit in operation.

• BEFORE turning the unit ON, make sure the crown is rmly tted in its position.

• NEVER wear loose clothes during operation. Make sure hair is tied up at all times.

• REMOVE all jewelry and bracelets and roll up loose sleeves prior to use.

• NEVER turn the unit ON with wet clothes or feet.

• NEVER spray water or other liquid substances directly at motor, power switch or any other electrical

components. Do not use pressurized jets to clean the machine.

• ALWAYS install the unit in working area with adequate light and space away from children and other

objects.

• NEVER operate without all warning labels attached and owner/operator manual available to operator.

• NEVER leave unattended while operating.

• ALWAYS ground the unit properly.

• ALWAYS turn machine off before cleaning and maintenance.

• PROVIDE enough space around unit for safe operation.

• ALWAYS keep the oor dry. Wet oors may cause injury.

• ALWAYS turn the unit OFF in the case of a electrical problem.

• NEVER let dust or water to get into the electrical and mechanical components of the machine.

• DO NOT modify original features of the machine.

• DO NOT take out or tear off any safety or identication labels.

WARNING:

1 YEAR BENCH WARRANTY

3

Page 4

Safety and Warranty

The packaging components are classied as normal solid urban waste and can therefore be disposed of

without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

Technical Specications

01

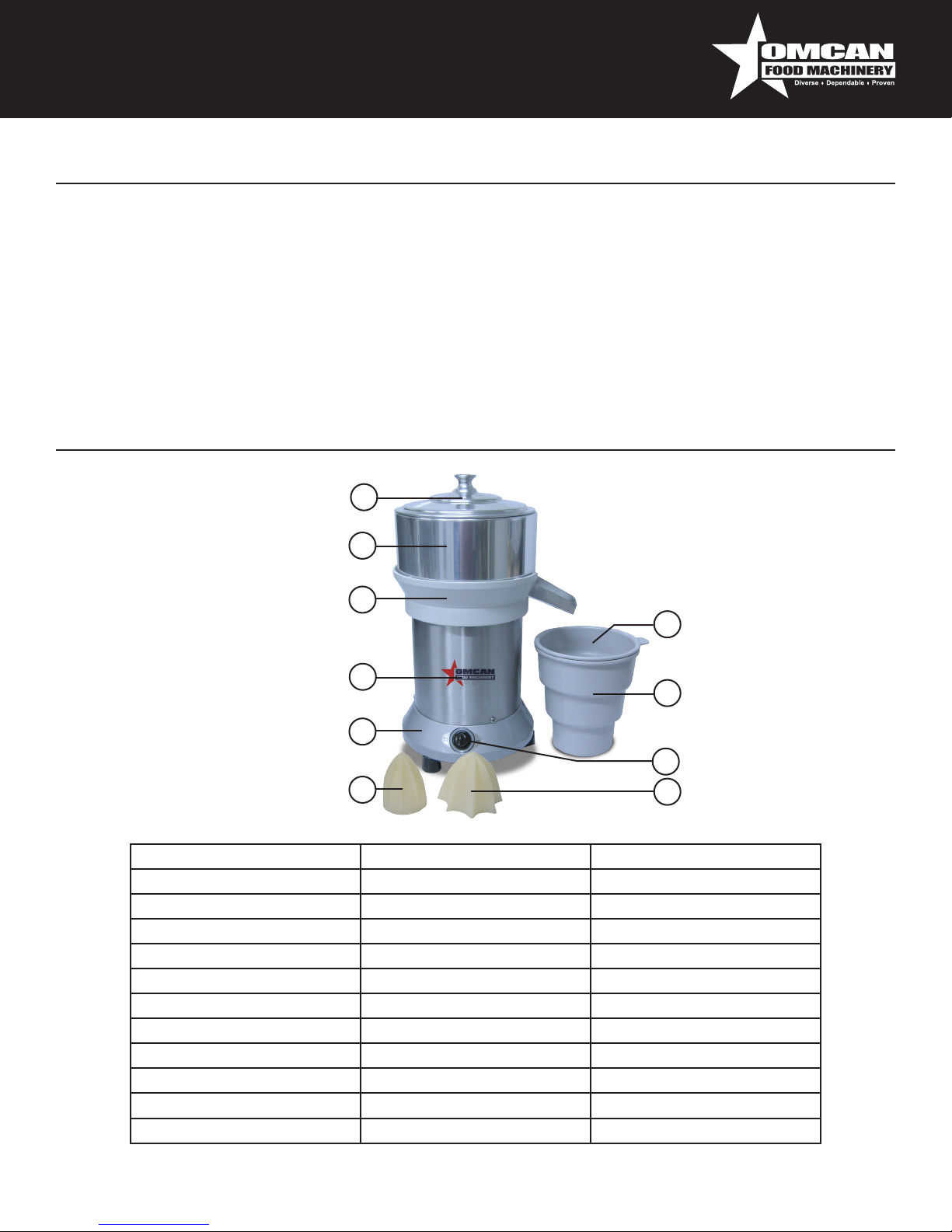

PICTURE 1

02

MAIN COMPONENTS

1. Lid.

2. Juice Chamber.

3. Motor Support Flange.

4. Motor Housing.

5. ON/OFF Switch.

6. Base.

7. Sieve.

8. Juice Vessel.

9. Big Crown.

10. Small Crown.

Technical Data Units EX

Voltage V 110

Frequency Hz 60

Rating HP 0.25

Consumption Kw/h 0.20

Height mm 380

Width mm 240

Depth mm 195

Net Weight kg 4.6

Gross Weight kg 5.5

Average Production Orange/min. 15

Rotation rpm 1750

03

04

06

10

07

08

05

09

4

Page 5

Installation

The juice extractor must be installed on a at, non-skid work surface with a maximum recommended height

of 85 cm. This equipment is equipped with a three pin electric cable. All pins must be connected before

the machine is turned on. This ensures the machine is properly grounded. Check if the machine voltage

corresponds with the power source.

Operation

PRE-OPERATION

Check if the machine is stable and that there is no movement s on the supporting surface. Wash all food

contact parts with hot water and neutral soap. Check if crown is properly tted. Place sieve (Pic. 1, #7) inside

the juice vessel (Pic. 1, #8) and put it below output opening (Pic. 1, #2). The extractor is now ready to operate.

IMPORTANT

Always disconnect the unit from power source before changing the crown. Place the crown on motor shaft and

make sure it is properly tted. To start operating, press the black push-button switch to the ON position. How to

feed the machine:

1. The juice extractors work very quickly, therefore they should be equally fed.

2. First of all cut fruit in two halves. With one hand, hold the cut fruit and press it down rmly against the

crown #9 or #10 (Pic. 1).

3. The juice will ow to the vessel through the chamber and the sieve.

IMPORTANT

Before cleaning disconnect the unit from power source. Before taking out the crown, be sure motor is

completely stopped. To remove the parts for cleaning, do as follows:

1. Turn the machine OFF, and disconnect it from power source.

2. Take out the lid, juice chamber, crown and juice vessel.

3. Wash all the above parts with warm water and neutral soap. Wipe dry.

4. With a damp cloth wipe the motor housing.

To reassemble the parts reverse the procedure.

Maintenance

5

Page 6

Maintenance

ATTENTION

Always unplug the machine before cleaning or maintenance.

6

Page 7

Model EX 10865

Parts Breakdown

28767.9

7

Page 8

Parts Breakdown

Model EX 10865

Descripon Item No.

PRESSION RIVET AD-423-S 00045.0

PRESSION RIVET AD-440-S 00220.8

RUBBER SEAL MOL 085375 00293.3

CUP LID LSP-04 00308.5

LIQUID CHAMBER 00386.7

SIEVE 00391.3

CUP 00392.1

CHAMBER BASE - ESB 00396.4

INSULATING TERM. EF-4228 01213.0

NYLON COVER CN-4472 02031.1

PFS M4x8 DIN 7985 ZB 03130.5

CRAMP T-18R-SMALL 04203.0

SCREW M3X6 DIN 84 ZB 04208.0

EXTERNAL PONT. 3/4" 04859.3

LARGE CROWN (FOR ORANGE) 08162.0

SMALL CROWN (FOR LEMON) 08163.9

CABLE 3X0,75MM 09103.0

CABLE HOLDER BLACK FC PG 7 09192.8

TUBO TERMO ENCOL.1/8x20mm 09533.8

SWITCH 16123 M2FTFE3B 10A 10116.8

ID LABLE MOTOR/RESIST 10204.0

ON/OFF LABEL 10491.4

ABRACADEIRA K22-LM(T-80I) 12469.9

STICKER CLIP 13757.0

NUT M4 DIN 934 14175.5

WASHER L.A4,3 16798.3

BASE EX/EXB 17434.3

LIQUID CHAMBER EX/EXB 17436.0

Descripon Item No.

POSITIVE TERMINAL LOCK 0,5A1,5 17581.1

TERMINAL COVER 17582.0

CABLE 3X1.0MM WITH PLUG 17898.5

MOTOR COMPL.0,25CV 60HZ W 18860.3

MOTOR 0,25CV 60HZ 18861.1

MOTOR SUPPORT EX 18874.3

NUT M4 DIN 1587 19091.8

CABINET EX/EXB 20080.8

CHAVE SELET.COMPL. 10594 24373.6

CB.3x0,75mm2 2PC1PR OMCAN 24592.5

OMCAN LOGO (MACHINES) 27154.3

LOGOTIPO OMCAN(EMBALAGEM) 27155.1

MOTOR 0,25CV 60HZ W 28767.9

MOTOR COMPL.0,25CV 60HZ 29067.0

HUBBER COVER 29538.8

MOTOR 0,25CV 60HZ 110/220 31631.8

MOTOR COMPL.0,25CV 60HZ G 31633.4

SCREW B.3,5X19 DIN 7981 ZB 33185.6

SCREW B.3,5X10 ZB PLAST.C/P 36366.9

SUPORTE DA CHAVE SELETORA 38193.4

CLOSURE SHEET 38267.1

BASE RING EX/EXB 38361.9

SUPORTE DO CAPACITOR 60Hz 38415.1

SWITCH 16123 M5FT5FE3B 10A 38416.0

MOTOR BEARER FLANGE 38877.7

MOTOR COMPL.0,25CV 60HZ G 38949.8

HOUSING SET EXB 39268.5

ETIQ.LIMPEZA/MANUTENCAO 50665.6

8

Page 9

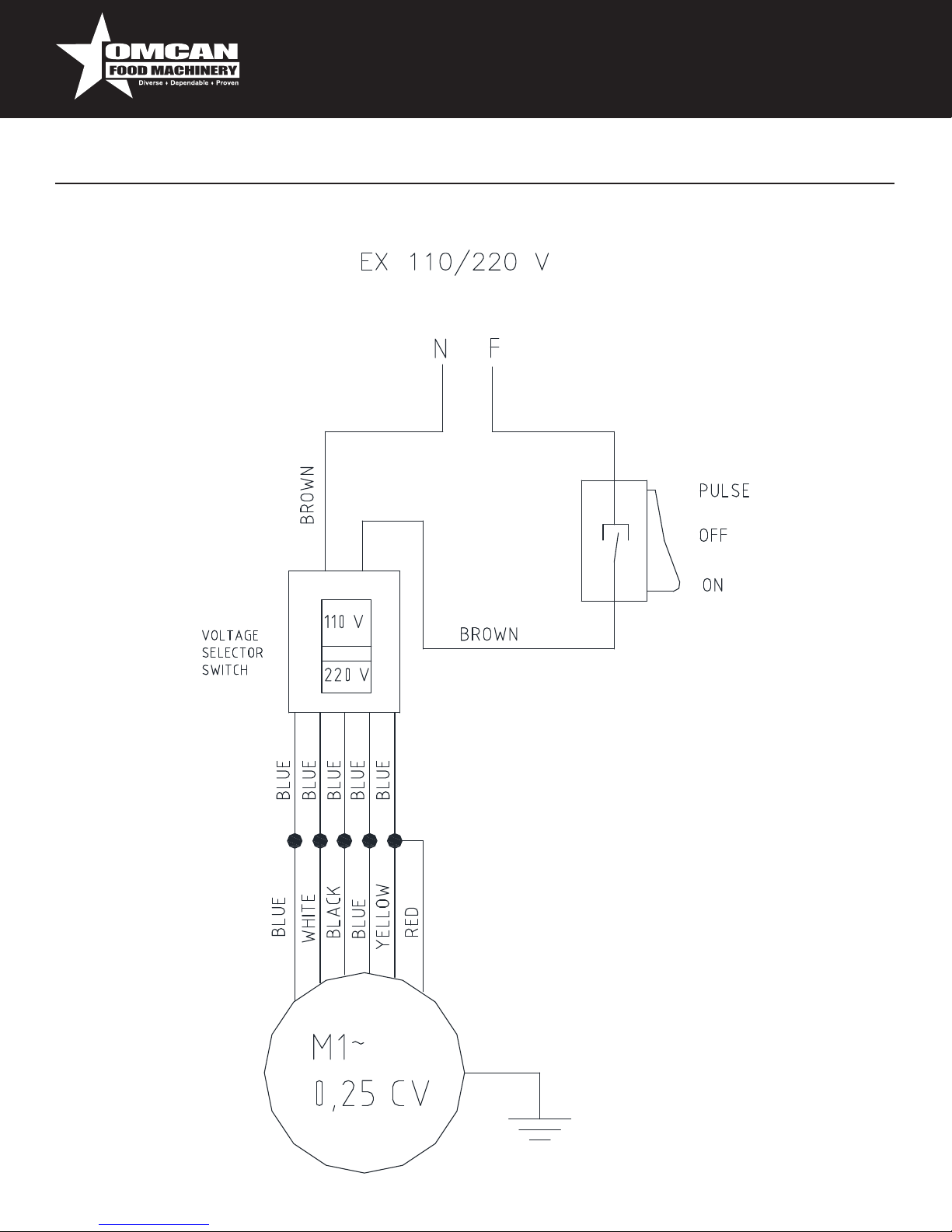

Model EX 10865

Electrical Schematics

9

Page 10

10

Page 11

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

www.omcan.com/warrantyregistration.html

For mailing in Canada For mailing in the US

OMCAN INC.

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

1889 Maryland Avenue,

Niagara Falls, New York

OMCAN

USA, 14305

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Thank you for choosing Omcan

11

Page 12

Over the last 60 years, Omcan has grown to become a leading supplier to the food

service industry in Canada and the USA. Our success over these many years is

directly attributed to our established relationships with all of our valued customers

and through providing them with Diverse, Dependable and Proven products.

Omcan continues to help our customers remain competitive.

With associates in North America, Europe, and Asia, our global footprint continues

to expand as we hold to the principle that clients benet from the accessibility

and familiarity of our sales team. In 2013 as our geography and brand recognition

continued to grow, we changed to one name Omcan Food Machinery.

In over 200,000 sq ft of warehouse space we stock over 2,500 quality food

equipment and supplies for the food preparation market.

Loading...

Loading...