Page 1

Hot Chocolate Dispensers

Models DI-CN-0005, 0010

Items 39482, 31840

Instruction Manual

Revised - 12/18/2018

Toll Free: 1-800-465-0234

Fax: 905-607-0234

Email: service@omcan.com

www.omcan.com

Page 2

Table of Contents

Model DI-CN-0005 / Model DI-CN-0010

Section

General Information

Safety and Warranty

Technical Specications

Installation

Operation

Maintenance

--------------------------------------------------------------------------------------- 8 - 9

--------------------------------------------------------------------------------------- 9 - 11

--------------------------------------------------------------------------------- 11 - 21

--------------------------------------------------------------------------- 3 - 4

--------------------------------------------------------------------------- 4 - 6

Page

-------------------------------------------------------------------------- 7

Troubleshooting

Parts Breakdown

Electrical Schematics

Warranty Registration

----------------------------------------------------------------------------- 22 - 23

---------------------------------------------------------------------------- 23 - 25

---------------------------------------------------------------------------- 26

---------------------------------------------------------------------------- 27

2

Page 3

General Information

Omcan Manufacturing and Distributing Company Inc., Food Machinery of America, Inc. dba Omcan

and Omcan Inc. are not responsible for any harm or injury caused due to any person’s improper or

negligent use of this equipment. The product shall only be operated by someone over the age of 18, of

sound mind, and not under the inuence of any drugs or alcohol, who has been trained in the correct

operation of this machine, and is wearing authorized, proper safety clothing. Any modication to the

machine voids any warranty, and may cause harm to individuals using the machine or in the vicinity of

the machine while in operation.

CHECK PACKAGE UPON ARRIVAL

Upon receipt of an Omcan shipment please inspect for external damage. If no damage is evident on the

external packaging, open carton to ensure all ordered items are within the box, and there is no concealed

damage to the machine. If the package has suffered rough handling, bumps or damage (visible or concealed),

please note it on the bill of lading before accepting the delivery and contact Omcan within 24 hours, so we may

initiate a claim with the carrier. A detailed report on the extent of the damage caused to the machine must be

lled out within three days, from the delivery date shown in the shipping documents. Omcan has no recourse

for damaged products that were shipped collect or third party.

Before operating any equipment, always read and familiarize yourself with all operation and safety

instructions.

Omcan would like to thank you for purchasing this machine. It’s of the utmost importance to save

these instructions for future reference. Also save the original box and packaging for shipping the

equipment if servicing or returning of the machine is required.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Fabrication et distribution Companie Limité et Food Machinery d’Amerique, dba Omcan et

Omcan Inc. ne sont pas responsables de tout dommage ou blessure causé du fait que toute personne

ait utilisé cet équipement de façon irrégulière. Le produit ne doit être exploité que par quelqu’un de

plus de 18 ans, saine d’esprit, et pas sous l’inuence d’une drogue ou d’acohol, qui a été formé pour

utiliser cette machine correctement, et est vêtu de vêtements de sécurité approprié. Toute modication

de la machine annule toute garantie, et peut causer un préjudice à des personnes utilisant la machine

ou des personnes à proximité de la machine pendant son fonctionnement.

VÉRIFIEZ LE COLIS DÈS RÉCEPTION

Dès réception d’une expédition d’Omcan veuillez inspecter pour dommages externes. Si aucun dommage

n’est visible sur l’emballage externe, ouvrez le carton an de s’assurer que tous les éléments commandés

sont dans la boîte, et il n’y a aucun dommage dissimulé à la machine. Si le colis n’a subi aucune mauvaises

manipulations, de bosses ou de dommages (visible ou cachée), notez-le sur le bond de livraison avant

d’accepter la livraison et contactez Omcan dans les 24 heures qui suivent, pour que nous puissions engager

une réclamation auprès du transporteur. Un rapport détaillé sur l’étendue des dommages causés à la machine

doit être rempli dans un délai de trois jours, à compter de la date de livraison indiquée dans les documents

d’expédition. Omcan n’a aucun droit de recours pour les produits endommagés qui ont été expédiées ou cueilli

par un tiers transporteur.

3

Page 4

General Information

Avant d’utiliser n’importe quel équipement, toujours lire et vous familiariser avec toutes les opérations

et les consignes de sécurité.

Omcan voudrais vous remercier d’avoir choisi cette machine. Il est primordial de conserver ces

instructions pour une référence ultérieure. Également conservez la boîte originale et l’emballage pour

l’expédition de l’équipement si l’entretien ou le retour de la machine est nécessaire.

---------------------------------------------------------------------------------------------------------------------------------------------------

Omcan Empresa De Fabricacion Y Distribucion Inc. Y Maquinaria De Alimentos De America, Inc. dba

Omcan y Omcan Inc. no son responsables de ningun daño o perjuicío causado por cualquier persona

inadecuada o el uso descuidado de este equipo. El producto solo podra ser operado por una persona

mayor de 18 años, en su sano juicio y no bajo alguna inuencia de droga o alcohol, y que este ha sido

entrenado en el correcto funcionamiento de esta máquina, y ésta usando ropa apropiada y autorizada.

Cualquier modicación a la máquina anúla la garantía y puede causar daños a las personas usando la

máquina mientras esta en el funcionamiento.

REVISE EL PAQUETE A SU LLEGADA

Tras la recepcion de un envio Omcan favor inspeccionar daños externos. Si no hay daños evidentes en el

empaque exterior, Habra el carton para asegurararse que todos los articulos solicitados ésten dentro de la

caja y no encuentre daños ocultos en la máquina. Si el paquete ha sufrido un manejo de poco cuidado, golpes

o daños (visible o oculto) por favor anote en la factura antes de aceptar la entrega y contacte Omcan dentro

de las 24 horas, de modo que podamos iniciar una reclamación con la compañia. Un informe detallado sobre

los daños causados a la máquina debe ser llenado en el plazo de tres días, desde la fecha de entrega que se

muestra en los documentos de envío. Omcan no tiene ningun recurso por productos dañados que se enviaron

a recoger por terceros.

Antes de utilizar cualquier equipo, siempre lea y familiarizarse con todas las instrucciones de

funcionamiento y seguridad.

Omcan le gustaría darle las gracias por la compra de esta máquina. Es de la mayor importancia para

salvar estas instrucciones para futuras consultas. Además, guarda la caja original y el embalaje para el

envío del equipo si servicio técnico o devolución de la máquina que se requiere.

Safety and Warranty

GENERAL SAFETY RULES

Carefully read the entire instruction manual before use. The connection to the electricity main socket must

comply with the current safety standards. The machine must be connected to an electric outlet that is:

• Compatible with the plug provided with the machine.

• Of dimensions conforming to the data shown on the rating plate on the side of the machine.

• Properly grounded.

4

Page 5

Safety and Warranty

• Connected to a system provided with a differential switch and circuit breaker.

• Connected to a system that has been certied according to the current standards and regulations in the

country of use.

The power cord must not be:

• Allowed to come into contact with any kind of liquid: danger of electric shocks and/or re.

• Crushed and/or brought into with sharp surfaces.

• Used to move the machine.

• Used if it shows any damage.

• Handle with dent or wet hands.

• Would into a coil when the machine is on.

• Tampered with.

Do not:

• Install the machine in a manner other than that described in installation.

• Install the machine in a place where it may be exposed to sprays of water.

• Use the machine near inammable and/or explosive substances.

• Leave plastic bags, polystyrene, nails etc. within children’s reach, since they are potential sources of

danger.

• Allow children to play or stay near the machine.

• Use spare parts other than those recommended by the manufacturer.

• Make any technical changes to the machine.

• Immerse the machine in any kind of liquid.

• Spray water to the machine to wash it.

• Use the machine other than as directed in this manual.

• Use the machine when not in full possession of your mental and physical faculties; Under the inuence of

the drugs, alcohol, etc.

• Install the machine on top of other equipment.

• Use the machine in an explosive aggressive atmosphere or in the presence of a high concentration of dust

or oily substances suspended in the air.

• Use the machine in a place where there is a risk of re.

• Use the machine to dispense substances that are not compatible with the machine’s specications.

• Clean and service the machine when the main switch is set to –ON- or with the plug inserted into the mains

outlet.

The appliance is not intended for use by persons (including children) with reduced physical, sensor or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety. Before cleaning the machine, make

sure it is unplugged; wait until the machine has cooled down sufciency. Do not clean the machine with

gasoline and/or solvents of any kind. Repair work may be performed only by a Service Center authorized

by the Manufacturer and/or specialized, trained personnel. Do not site the machine near heating equipment

(stoves or radiators). In case of re, use carbon dioxide (C02) extinguishers. Do not use water or powder

extinguishers. In the event of improper use, all warranty rights will be forfeited and the manufacturer will accept

no liability for injury or damage to persons and/or property.

5

Page 6

Safety and Warranty

The following are to be considered improper use:

• Any use other than the intended use and/or with methods other than those described herein.

• Any operation on the machine that is in contrast with the directions provided herein.

• Use of the machine after any components have been tampered with and/or safety devices have been

changed.

• Use of the machine after it has undergone repair with components not authorized by the manufacturer.

• Outdoor installation of the machine.

Stop Functions

The machine is shut down by turning off the on/off switch.

Plates

None of the plates or labels applied on the machine must be removed, covered or damaged, especially those

relating to safety. In the event of damage to any of the rating plates on the machine, contact the manufacturer

for a replacement.

EMERGENCY SITUATIONS

Warning: to stop the machine in any emergency situation, rmly press the main switch so that it sets to OFF.

In the event of re, it is necessary to clear the area in order to allow trained staff, with the proper protective

equipment to intervene. Always use approved extinguishers and never use water or substances of an uncertain

nature.

1 YEAR PARTS AND LABOR BENCH WARRANTY

Within the warranty period, contact Omcan Inc. at 1-800-465-0234 to schedule a drop off to either

an Omcan authorized service depot in the area, or to an Omcan Service warehouse to repair the

equipment.

Unauthorized maintenance will void the warranty. Warranty covers electrical and part failures, not

improper use.

Please see https://omcan.com/disclaimer for complete info.

WARNING:

The packaging components (cardboard, polyethylene, and others) are classied as normal solid urban waste

and can therefore be disposed of without difculty.

In any case, for suitable recycling, we suggest disposing of the products separately (differentiated

waste) according to the current norms.

DO NOT DISCARD ANY PACKAGING MATERIALS IN THE ENVIRONMENT!

6

Page 7

Technical Specications

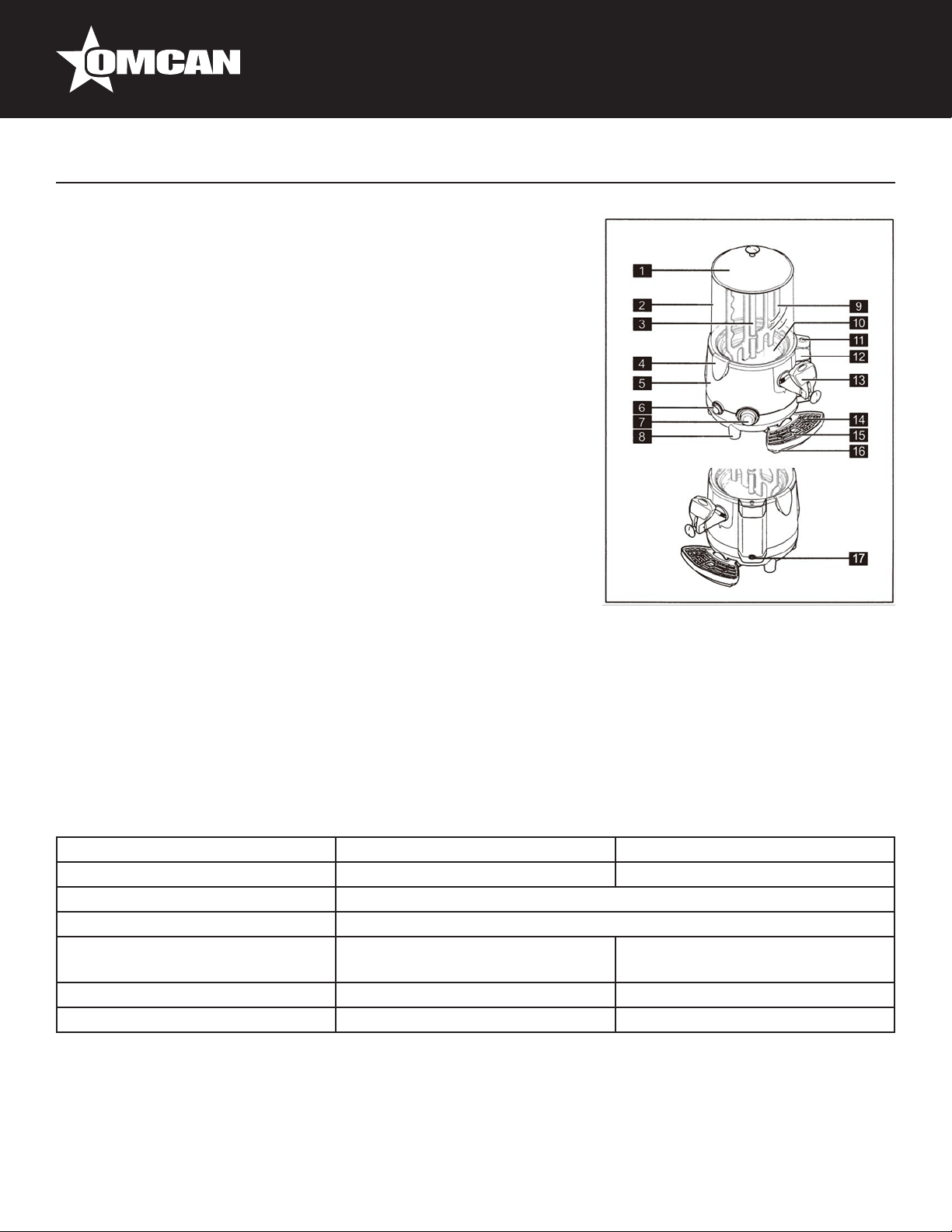

MACHINE DESCRIPTION

Use of the Machine

The machine for professional use you have purchased is intended to

produce hot chocolate drinks.

MAIN COMPONENTS

The main components making up the machine are:

1. Bowl lid.

2. Bowl (5 or 10 liters [1.32 or 2.64 US gals]).

3. Mixing auger.

4. Bowl hook-on handles.

5. Machine body.

6. Main switch.

7. Chocolate temperature adjustment thermostat (°C - °F).

8. Lower body.

9. Mixer.

10. Pan.

11. Lid for boiler tank water level indicator tray.

12. Boiler tank water level indicator tray.

13. Product dispenser unit (tap).

14. Drip tray maximum level indicator.

15. Drip tray grid.

16. Drip tray.

17. Boiler tank drainage cap.

TECHNICAL DATA

The technical data and features are listed below:

Model DI-CN-0005 DI-CN-0010

Capacity 5L / 5.28 QT 10L / 10.57 QT

Power 1000 W

Electrical 110/60/1

Dimensions

Weight 15 lbs. / 6.8 kgs. 16.5 lbs. / 7.5 kgs.

Item Number 39482 31840

Note: The manufacturer reserves the right to make changes to the machine without notice.

Important: Any changes and/or additions of accessories must be explicitly approved and implemented by the

manufacturer.

16.1” x 11” x 18.3”

410 x 279 x 465mm

16.1” x 11” x 22.8”

410 x 279 x 579mm

7

Page 8

Installation

The machine must be installed indoors in a well-lit and well-ventilated room with a rm, solid, level oor

(slope less than 20°); during installation, place the machine well out of the reach of children and unauthorized

persons.

The machine may only operate in places with an ambient temperature ranging between 10°C (50°F) and 32°C.

(89,6°F).

Accessories Supplied

Pipe cleaner: for correct cleaning of the hot chocolate dispensing channel.

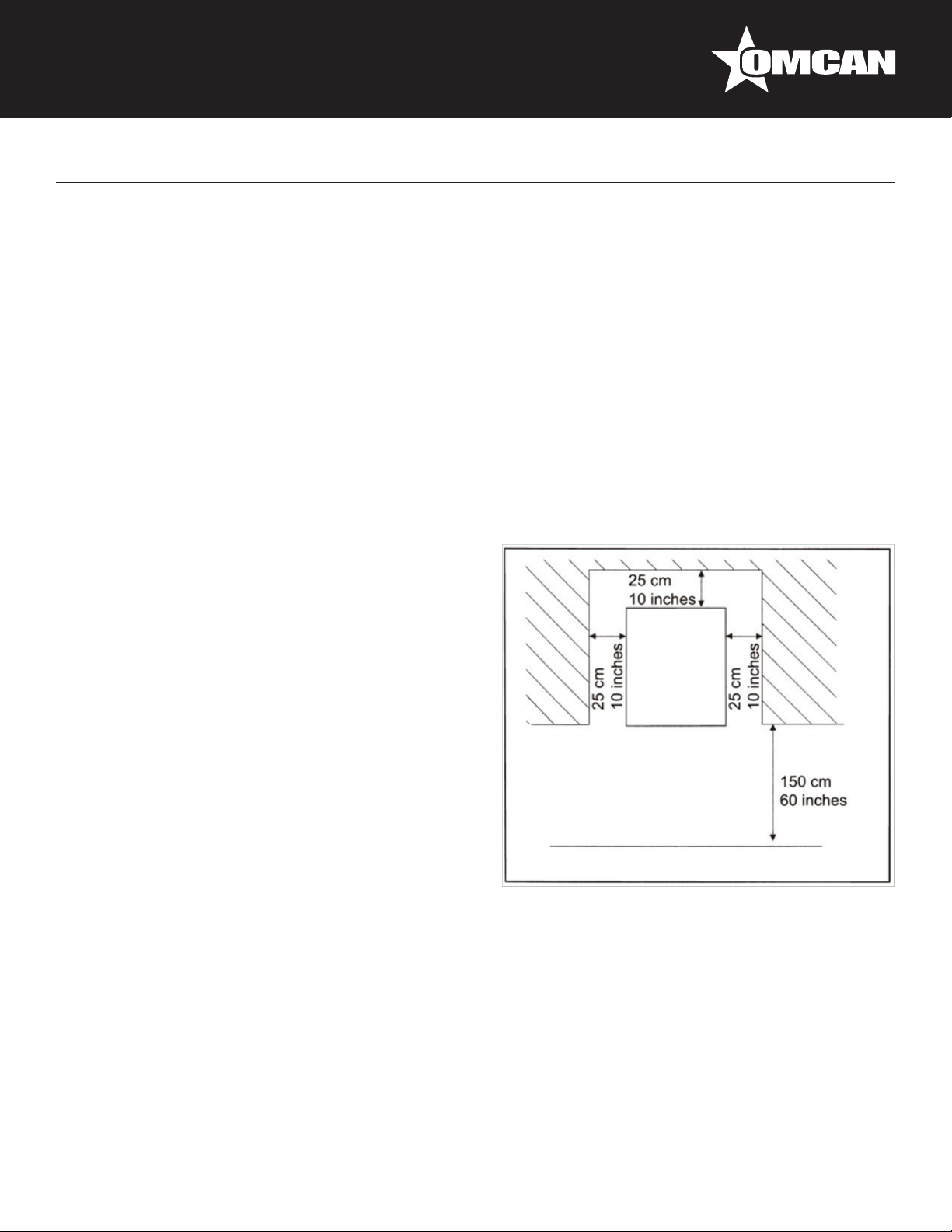

POSITIONING

It is necessary to check the following:

• The site has been duly prepared for machine installation.

• That the premises are suitably well lit, aired, clean and hygienic, and that the power socket is within easy

reach.

• The surface the machine will be installed on is rm,

at and solid.

• That the machine is placed at least 20 cm {7.8

inches) from the edge of the top used.

Adequate clearance must be left around the machine

to enable personnel to work without any constraints

and also to leave the work area immediately in case

of need. The image to the right shows the minimum

clearances for installation.

The image shows the clearances required for accessing:

• The controls situated on the left side.

• Machine parts so that they may be serviced in the

event of a fault.

Important note: when lifting the machine, do not use

the product dispenser unit (tap), drainage pipe, water

level indicator tray, bowl hook on handles or the bowl itself; grip the bottom machine body. Any damage to the

machine deriving from failure to follow these rules will not be covered by the warranty.

After positioning the packing container in the vicinity of the installation site, proceed as follows:

• Open the front pad of the packing container.

• Lift the machine and remove it from its packing.

• Then position it on the prepared site.

Before the machine is operated the rst time, its components must be thoroughly cleaned; for further details

see the relevant section herein.

8

Page 9

Installation

DISPOSAL OF PACKING MATERIALS

After opening the box, make sure to separate the packing materials according to type and dispose of them

in accordance with the current regulations in the user’s country. We recommend keeping the box for future

conveyance or transport.

ELECTRICAL CONNECTION

This job may be performed only by specialized technical personnel. Before inserting the plug into the mains

power socket, make sure that:

• The line voltage used is the same as the value indicated on the manufacturer’s rating plate.

• The main switch is set to OFF.

If the machine is being connected to the electricity mains for the rst time, this operation must be performed by

a specialized technician, while the Customer will be responsible for and have to take care of any subsequent

connections. The machine must be connected to the electricity main socket by means of the plug tted on the

power cord. Be sure to comply with:

• The technical regulations and standards in force at the time of installation.

• The data shown on the rating plate on the side of the machine.

Warning: the electric outlet must be situated in a place easily within reach of the user, so that no effort is

required in order to disconnect the machine from the power supply when necessary. If the power cord is

damaged, you must have it replaced either by the manufacturer or a specialized technician.

It is forbidden:

• To use extension cords of any type.

• To replace the original plug.

• To use adaptors.

Operation

Before the machine may be started up for the rst time, specialized

technical personnel must check that it functions properly.

STARTING UP

To start up the machine carry out the following steps:

• Make sure that the switch is set to off.

• Take off the lid.

• Fill the boiler tank with water using the boiler tank level indicator

tray, until it reaches the maximum value indicated on the tray itself,

which is marked MAX.

9

Page 10

Operation

Warning: ll the boiler tank by pouring in water slowly and check for a

few seconds to make sure that the water level has reached the MAX

level and that it is stable.

When lling an empty boiler rank for the rst time, the amount of water

needed to completely ll the tank is approximately 3.25 liters(0.86

GAL US).

• Remove the lid and pour the beverage prepared according to the

manufacturer’s instructions into the bowl.

• Never exceed the maximum level, which is marked MAX on the

tray itself.

• After pouring the product into the bowl,t the lid back in place.

• Make sure that the plug has been inserted into the mains socket.

• Press the main switch to start the machine; the product inside the

bowl will start to be mixed.

LIT LED: MACHINE ON.

LED OFF: MACHINE OFF.

• Set the thermostat to the required temperature to heat the product inside the bowl.

• The machines with LCD offer the opportunity to make a visual check to see when the product has reached

the required temperature inside the bowl.

Warning: during bowl and/or boiler switch off the machine using the main switch (LED off). There is a

temperature sensor, if the water is boiled up and the heating element is over heated. The temperature sensor

will shut down the machine. Then you need to press the reset button to restart the machine.

DISPENSING THE PRODUCT

Warning: The products dispensed from the machine has a very high temperature; risk of scalding.

10

Page 11

To dispense hot chocolate proceed as follows:

Note: It is advisable to keep the rod in the maximum dispensing

position to help the product to ow at the required rate.

• Place a cup beneath the tap.

• Use the lever on the tap (the product is dispensed when the level

is pressed or pulled) until the required amount of product has been

poured inside the cup.

• Gradually release the tap level so that it returns to the standby

position(tap off).

• If the product is especially think, it is advisable to keep the rod

pulled out at the maximum position; any clogging in the spout may

be removed by sliding the rod back and forth while keeping the

machine.

Warning: never touch the bowl or lid while the machine is operating,

since they are very hot, Always use the knob when moving the bowl

lid.

Operation

Maintenance

CLEANING AND MAINTENANCE

Machine cleaning and maintenance must be performed with the main switch set to OFF and the machine

unplugged from the main socket.

Warning: each time that the bowl is lled with any type of product (food or sanitizing product), make sure that

the mixing rod is present.

Warning: before carrying out any cleaning job wait until the machine has cooled down sufciently.

Warning: the use of abrasive and/or metal sponges to clean the machine or its components is completely

prohibited; only use ad amp cloth and/or non-abrasive sponge for cleaning.

Warning: only use the cleaning brush provided to clean the channel connecting between the tank and the tap;

never use this brush to clean other parts.

Before performing any cleaning and maintenance operation on the machine, wear the personal protections

(gloves, glasses,etc.), which are recommended by the safety standards in force in the country where the

11

Page 12

Maintenance

machine is used.

When performing the Cleaning and Maintenance operations, follow these instructions:

• Wear protection accident-proof gloves.

• Do not use solvents or in ammable materials.

• Do not use abrasive and/or metal sponges to clean the machine and its components.

• Do not wash machine components in a dishwasher.

• Do not dry parts of the machine in a conventional and/or microwave oven.

• Do not immerse the machine in water.

• Do not expose the machine to direct sprays of water.

• Clean only with warm water and a sanitizing product made from sodium hypochlorite diluted in water to

obtain an active chloride concentration.

• On completing work, make sure that all protective covers and guards that have been removed or opened

are set back in place and properly secured.

Cleaning and sanitization are operations that must be performed with utmost care and on a regular basis to

guarantee the quality of the beverages dispensed and compliance with mandatory hygiene standards.

Each bowl must be cleaned and sanitized for a product change at least every 2 days and in any case in

compliance with the current hygiene regulations in the user’s country. These operations must be made

more frequently if demanded by the characteristics of the product used; for further details, contact the

product supplier.

The metal, plastic and rubber materials used to make these parts, combined with their specic shapes

make cleaning easier but do not prevent the formation of bacteria and mould in the event of insufcient

cleaning.

CLEANING AND SANITATION PROCEDURES

EMPTYING THE BOWL

Before cleaning out the bowl, it is rst necessary to empty out any

production inside it.

With the machine switched on, empty out all of the product still

inside the bowl, using the level on the tap. Fill the bowl with water

and set thermostat to 50°C(122°F),Operate the appliance for at

least 15-20 minutes; increasing this amount of time will release any

product residues that may be stuck to the sides of the bowl. Empty

out the entire contents of the bowl, using the lever on the tap.

Warning: the product dispensed from the machine has a very high temperature; risk of scalding.

12

Page 13

Maintenance

REMOVING THE BOWL

Warning: before removing the bowl, make sure that the main switch is off and that the machine is unplugged

from the mains electricity and sufciently cooled down.

Removing the bowl is prohibited if it contains the product or any other liquid. It Is fundamentally important to

remove the bowl and its component parts if the machine is to be correctly cleaned and sainted.

To remove the bowl correctly proceed as follows:

• Take off the lid.

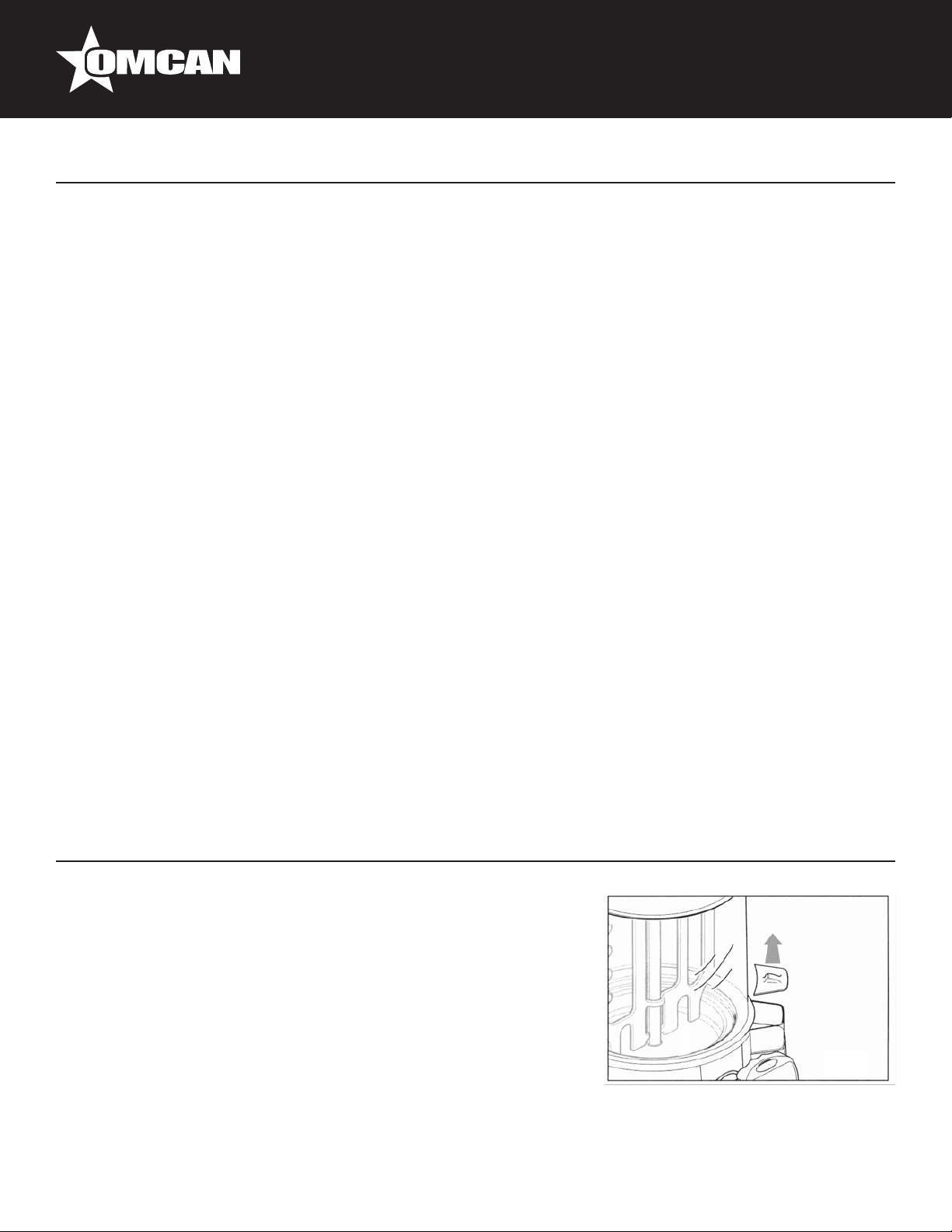

• Slide the mixer upwards to remove it, keeping it in line with the central rod until the bottom slot of the mixer

itself is level with the rotation pin.

• Tilt the mixer and slide it upwards, as illustrated in the gure, to remove it completely.

• Unlock the bowl hook-on handles, as illustrated in the gure, to free the bowl from the machine body.

13

Page 14

Maintenance

• Release the bowl from the machine body, using two ngers to pry it away from the xed steel part of the

mixer auger(A) and the others to grip the outlet edge of the bowl(B): Gradually pull the bowl harder until it

comes away from its seating.

• Slide the bowl upwards using both hands.

• Slide the mixing auger upwards with one hand, taking care to grip it by the rotation pin.

• Place the bowl on a at surface and using both hands, remove the gasket by sliding it upwards in the

direction shown by the arrow.

REMOVING THE TAP

Removing the tap is prohibited if the bowl contains the product or any other liquid.

To remove the tap, proceed as follows:

• Move the rod to the maximum dispensing position.

• Press the button(A) securing the tap to the machine and then remove the tap(B) with both hands.

14

Page 15

Maintenance

CLEANING THE PAN

It is necessary to remove all parts tted to the pan:

• Remove any product left in the bowl.

• Remove the bowl from the machine.

• Remove the tap from the machine.

• Clean the entire surface of the pan using a damp cloth and/or a non-abrasive sponge.

• Clean the channel connecting the bowl and the tap, using a cleaning brush.

• Ret the tap.

• Pour a little water inside the pan.

• Use the tap to drain out all water from the pan so as to eliminate any small product residues inside the

dispensing channel.

DISASSEMBLING THE TAP

To clean the inside of the tap more thoroughly, disassemble it as follows:

• Remove the tap.

• Place the tap on a clean, at surface, then loosen and remove the screw(A) fastening the button to the

machine, then slide out the pin(B) and relevant spring(C)from the seating.

• Pull the(D) all the way out from the knob(E) then push the lever(F) upwards from the bottom until it comes

out from the pin guide.

15

Page 16

Maintenance

• Unscrew the knob(E) by turning it counterclockwise while holding the rod in place.

• Pull out the rod(G) and spring(H) from the tap body (the pin/gasket assembly(I) will slide out together with

the rod).

• Detach the rod(G) from the pin/gasket assembly(I).

• Disassemble (by pulling) the pin(L) from the gasket(M).

WASHING AND SANITIZING THE COMPONENTS

All of the component parts previously disassembled (tap, mixer, mixing auger, gasket and bowl) must be

carefully washed and sanitized.

To carry out this procedure correctly proceed as follows:

• Fill a container with detergent and hot water with a temperature of 50~60°C(122~140°F).

• Wash the disassembled components with the detergent solution.

• Rinse with hot water.

• Clean only with warm water and a sanitizing product made from sodium hypochlorite diluted in water to

obtain an active chloride concentration of 0.02%.

• Immerse the disassembled component parts in the sanitizing solution for about 30 minutes.

• Rinse with clean water.

• Clean the bowl lid.

• Place the components on a clean surface and dry them.

16

Page 17

Maintenance

ASSEMBLING THE WASHED COMPONENTS

All washed and sanitized component parts must be re-assembled with care and then subsequently retted to

the machine, following the relevant steps.

Assembling the Bowl

Warning: make sure that the gasket is correctly assembled.

The rst image shows a seal correctly assembled; here the seal perfectly adheres to the bowl edge. The

second image shows a seal which is not correctly assembled; here the seal does not perfectly adhere to the

bowl edge.

• Fit the bowl back into place rmly downward, after moistening the seal with water.

DO NOT USE GREASE OR VASELINE.

Warning: make sure that the bowl is correctly tted to the machine; an incorrectly tted bowl will cause the

product to leak out; risk of scalding!

OK NO

17

Page 18

Maintenance

• Fix the bowl to the machine body using the relevant hook-on handles.

• Insert the mixer auger into its seating.

• Insert the mixer into its seating following the steps described in “Removing the Bowl” in reverse order.

Assembling the bowl

To assemble the tap, carry out in reverse all of the disassembly steps illustrated previously.

To t the level(F) push the rod(D) from the inside until the guides protrude; the insert the level(F) and slowly

release the rod(D).

Fitting the tap

To t the lap correctly back in place proceed as follows;

1. Hold down the button, making sure that the road is completely extracted.

2. Introduce the tap into the seat provide and push until the push button returns to its initial position.

INTERNAL SANITIZATION

Warning: The thermostat must be set to OFF.

18

Page 19

Maintenance

Carry out the following steps:

• Prepare the sanitizing solution.

• Fill the bowl with the sanitizing solution.

• Leave the solution to act for about 30 mins.

• Empty out the sanitizing solution from the bowl.

• Then rinse out the bowl and inside surfaces thoroughly to eliminate all residues of sanitizing solution.

CLEANING THE DRIP TRAY

The drip tray should be emptied and cleaned daily.

Note: the tray needs to be emptied out and cleaned every time that the red oat tted to the grid rises, this is to

stop liquid from leaking out.

• Lift the tray with grid and pull it outwards to remove it from its seating.

• Wash the tray and grid separately with lukewarm water.

• Dry all of the components.

• Reposition the grid on top of the tray.

• Fit the tray back in place and press down to secure it to the machine.

CLEANING THE BOWL LID

• Remove the bowl lid from the machine.

• Clean the surface using a damp cloth and / or a non-abrasive sponge soaked in sanitizing product.

• Rinse thoroughly using clean water.

EMPTYING THE BOILER

Warning: while the boiler is being emptied, the machine must be unplugged.

19

Page 20

Maintenance

Warning: The boiler may be emptied only when the bowl is empty and the machine has cooled down

sufciently.

The use of water from the boiler tank for food purposes is prohibited.

To empty the boiler proceed as follows:

• Unplug the machine.

• Remove the drip tray.

• Remove the cap(A).

• Place the machine on a at surface and with the boiler tank water level indicator tray turned towards to the

outer edge of the support surface.

• Place a container(B) with a capacity of more than 3 liters (0.8 US gals) underneath the bleeder cap(C).

• Use a coin or Allen wrench to unscrew the bleeder cap(C).

• Pull out the cap(C) with a rm movement and wait for all the water to empty out from the boiler tank.

CLEANING AND DE-SCALING THE BOILER TANK

The boiler tank needs to be de-scaled on a regular basis; this operation is recommended at least once every 3

months.

• Follow the steps for draining out the boiler tank.

• Insert and secure the boiler tank bleeder cap.

• Insert water plus scale remover for coffee machines into the tank (follow the instructions on the scale

remover package).

• Insert and secure the boiler tank bleeder cap.

• Leave the solution to act for the time indicated in the instruction of the solution itself.

• Empty out the solution from inside the boiler tank.

• Rinse out the tank with plenty of water, by lling and emptying it.

RESETTING THE TEMPERATURE SENSOR

The temperature sensor can only be reset by a specialized technician, who must organize all of the operating

sequences and the use of the correct equipment to operate in strict compliance with the current laws to this

regard.

20

Page 21

Maintenance

Warning: after the temperature sensor has intervened to shut down the machine, it is indispensable to drain

out any product contained inside the bowl and to clean all components before restoring the machine function.

Warning: before resetting the temperature sensor, switch off the machine using the relevant switch and unplug

it from the electrical main socket, then wait for the machine to cool down.

The operator is strictly prohibited from resetting the boiler tank minimum water level temperature sensor.

• Use a suitable tool to loosen and remove the protective screw.

• Use a suitable tool to press the button inside to restore normal machine operation.

PERIODIC MAINTENANCE

The machine must be periodically checked (at least once a year) by a specialized technician, this periodic

check serves to ensure that all the components installed and the machine itself are maintained at a high level

of safety. Any worn components must be replaced by an original spare part. It is forbidden to use the machine

when even only one of its components is faulty or worn. Users are forbidden to perform periodic maintenance.

SCRAPPING

Electrical and electronic equipment needs to be disposed of according to the European Directive 2002/96/

CE and in compliance with the standards and regulations in force for the country in which the machine is

used. Such equipment may not be disposed of as normal municipal solid waste but must rather be separately

collected to optimize recovery and recycling of the materials used to manufacture them. All products are

marked with the crossed out wheeled bin, symbol as a reminder of separate collection obligations. Correct

observance of all of the provisions for the disposal of end-of –life products will contribute to safeguarding the

environment.

21

Page 22

Troubleshooting

Problem Cause Remedy

Does not heat. No power. Make sure that the machine is

plugged in properly.

Switch set to OFF. Set the switch to ON.

Thermoprobe intervention. Reset the thermal protector.

Thermostat on “0”. Adjust the thermostat.

Mixing Paddle does not turn. No power. Make sure the machine is plugged

in properly.

The driving shaft is not properly in

place.

Motor fault. Contact service personnel.

On/Off switch on (0). Press the switch on.

Tap leaks. It has not been t correctly. Empty the machine and t the tap.

The outlet and rubber are dirty. Empty the machine and clean the

The sealing gasket needs

replacing.

Water is escaping from the level

tank.

Product leaks from the bottom of

the transparent bowl.

The thermometer does not show

the temperature.

Machine shutdown. The water level in the boiler tank

If the machine malfunctions due to causes other than those listed in this table or the proposed remedies do

not solve the problem, contact a specialized technician.

Temperature too high. Lower the temperature.

The sealing gasket of the level

tube needs replacing.

The water level is above the MAX

indication when the machine is at

room temperature.

The bowl has not been t correctly

in place.

The seal needs replacing. Contact service personnel.

Dead Battery. Replace the battery.

Probe malfunction. Call a specialized technician.

has fallen below the minimum

level.

No water in boiler tank. Top up the boiler tank, if a

Remove the shaft and then inset it

correctly.

entire tap thoroughly, t back on

the machine.

Contact service personnel.

Contact service personnel.

Allow the machine to cool down

and empty the boiler until reaching

the level indicated.

Empty the machine, remove the

bowl and t it in place.

Top up the boiler tank, if a

level sensor is tted, call for a

specialized technician to reset the

machine.

level sensor is tted, call for a

specialized technician to reset the

machine.

22

Page 23

Troubleshooting

REFERENCE

Item Number Model Number Description Manufacturer Model Number

39482 DI-CN-0005

31840 DI-CN-0010

Hot Chocolate Dispenser 5 L / 1 GAL

1.3 HP / 1000 W 110V/60/1

Hot Chocolate Dispenser 10 L / 3 GAL

1.34 HP / 1000 W 110V/60/1

CHOCOFAIRY5L

CHOCOFAIRY10L

Parts Breakdown

Model DI-CN-0005 39482

Item

No.

73902 Tank Cover for CHOCOFAIRY5L 1-A 73918

73903 Knob of Tank Lid for CHOCOFAIRY5L 1-B 73919

76453 Paddle for CHOCOFAIRY5L 2 73920

73905 Lid of Stirring Rod for CHOCOFAIRY5L 3-A 73921 Tank Hinge for CHOCOFAIRY5L 18 73937 Tap Handle for CHOCOFAIRY5L 34

76455 Stirring Rod for CHOCOFAIRY5L 3-B 73922 Upper Exterior for CHOCOFAIRY5L 19 73938 Screw of Faucet for CHOCOFAIRY5L 35

76456 PC Tank for CHOCOFAIRY5L 4 73923 Lower Exterior for CHOCOFAIRY5L 20 73939 Pin Spring for CHOCOFAIRY5L 36

73908 Gasket of PC Tank for CHOCOFAIRY5L 5 73924 Power Switch for CHOCOFAIRY5L 21 73940 Pin for CHOCOFAIRY5L 37

76458

73910 Gasket for CHOCOFAIRY5L 7 73926 Foot for CHOCOFAIRY5L 23 73942 Water Bin for CHOCOFAIRY5L 39

73911

73912 Heater Element for

73913 Boiler Gasket for CHOCOFAIRY5L 10 73929

73914

73915 Supporter for CHOCOFAIRY5L 12 73931

73916 Motor for CHOCOFAIRY5L 13 73932

76466 Back Cover for CHOCOFAIRY5L 14 76482

Description Position

Stainless Steel Boiler (Upper Part) for

CHOCOFAIRY5L

Overheat Protector for

CHOCOFAIRY5L

CHOCOFAIRY5L 9 73928

Stainless Steel Boiler (Lower Part) for

CHOCOFAIRY5L

6 73925 Thermostat for CHOCOFAIRY5L 22 73941 Lid of Water Bin for CHOCOFAIRY5L 38

8 73927 Ventilation Grill for CHOCOFAIRY5L 24 73943 Drainage Plug for CHOCOFAIRY5L 40

11 76479 Gasket of Faucet for CHOCOFAIRY5L 27 73946 Water Tray for CHOCOFAIRY5L 43

Item

No.

Description Position

Cover of Overheat Protector for

CHOCOFAIRY5L

Button of Overheat Protector for

CHOCOFAIRY5L

Button Stop of Protector for

CHOCOFAIRY5L

Washer of Faucet (Interior) for

CHOCOFAIRY5L

Nut of Faucet (Interior) for

CHOCOFAIRY5L

Nut of Faucet (Exterior) for

CHOCOFAIRY5L

Gasket of Faucet Screw for

CHOCOFAIRY5L

Gasket Inside the Faucet for

CHOCOFAIRY5L

15 73934 Moving Pin for CHOCOFAIRY5L 31

16 73935 Faucet Spring for CHOCOFAIRY5L 32

17 73936 Cleaner Shaft for CHOCOFAIRY5L 33

25 73944

26 73945 Floater for CHOCOFAIRY5L 42

28 73947

29 39257 Fan for CHOCOFAIRY5L 45

30

Item

No.

Description Position

Lid of Water Tray for

CHOCOFAIRY5L

Supporter of Fan for

CHOCOFAIRY5L

41

44

23

Page 24

Parts Breakdown

Model DI-CN-0010 31840

Item

No.

73902 Tank Cover for CHOCOFAIRY10L 1-A 73918

73903 Knob of Tank Lid for CHOCOFAIRY10L 1-B 73919

73904 Paddle for CHOCOFAIRY10L 2 73920

73905

73906 Stirring Rod for CHOCOFAIRY10L 3-B 73922 Upper Exterior for CHOCOFAIRY10L 19 73938

73907 PC Tank for CHOCOFAIRY10L 4 73923 Lower Exterior for CHOCOFAIRY10L 20 73939 Pin Spring for CHOCOFAIRY10L 36

73908

73909

73910 Gasket for CHOCOFAIRY10L 7 73926 Foot for CHOCOFAIRY10L 23 73942 Water Bin for CHOCOFAIRY10L 39

73911

73912 Heater Element for CHOCOFAIRY10L 9 73928

73913 Boiler Gasket for CHOCOFAIRY10L 10 73929

73914

73915 Supporter for CHOCOFAIRY10L 12 73931

73916 Motor for CHOCOFAIRY10L 13 73932

76466 Back Cover for CHOCOFAIRY10L 14 76482

Description Position

Lid of Stirring Rod for CHOCOFAIRY10L

Gasket of PC Tank for CHOCOFAIRY10L

Stainless Steel Boiler (Upper Part) for

CHOCOFAIRY10L

Overheat Protector for CHOCOFAIRY10L

Stainless Steel Boiler (Lower Part) for

CHOCOFAIRY10L

3-A 73921 Tank Hinge for CHOCOFAIRY10L 18 73937 Tap Handle for CHOCOFAIRY10L 34

5 73924 Power Switch for CHOCOFAIRY10L 21 73940 Pin for CHOCOFAIRY10L 37

6 73925 Thermostat for CHOCOFAIRY10L 22 73941

8 73927 Ventilation Grill for CHOCOFAIRY10L 24 73943 Drainage Plug for CHOCOFAIRY10L 40

11 76479 Gasket of Faucet for CHOCOFAIRY10L 27 73946 Water Tray for CHOCOFAIRY10L 43

Item

No.

Description Position

Cover of Overheat Protector for

CHOCOFAIRY10L

Button of Overheat Protector for

CHOCOFAIRY10L

Button Stop of Protector for CHOCOFAIRY10L

Washer of Faucet (Interior) for CHOCOFAIRY10L

Nut of Faucet (Interior) for CHOCOFAIRY10L

Nut of Faucet (Exterior) for CHOCOFAIRY10L

Gasket of Faucet Screw for CHOCOFAIRY10L

Gasket Inside the Faucet for CHOCOFAIRY10L

15 73934 Moving Pin for CHOCOFAIRY10L 31

16 73935 Faucet Spring for CHOCOFAIRY10L 32

17 73936 Cleaner Shaft for CHOCOFAIRY10L 33

25 73944

26 73945 Floater for CHOCOFAIRY10L 42

28 73947

29 39257 Fan for CHOCOFAIRY10L 45

30

Item

No.

Description Position

Screw of Faucet for CHOCOFAIRY10L

Lid of Water Bin for CHOCOFAIRY10L

Lid of Water Tray for CHOCOFAIRY10L

Supporter of Fan for CHOCOFAIRY10L

35

38

41

44

24

Page 25

Model DI-CN-0005 39482

Model DI-CN-0010 31840

Parts Breakdown

25

Page 26

Electrical Schematics

Model DI-CN-0005 39482

Model DI-CN-0010 31840

ITEM DESCRIPTION

S POWER SWITCH

Ts SAFETY THERMOSTAT

M MIXER MOTOR

Tr ADJUSTMENT THERMOSTAT

R HEATING ELEMENT

26

Page 27

Warranty Registration

Thank you for purchasing an Omcan product. To register your warranty for this product, complete the information below, tear off the card at

the perforation and then send to the address specied below. You can also register online by visiting:

Merci d’avoir acheté un produit Omcan. Pour enregistrer votre garantie pour ce produit, complétez les informations ci-dessous, détachez la

carte au niveau de la perforation, puis l’envoyer à l’adresse spécié ci-dessous. Vous pouvez également vous inscrire en ligne en visitant:

Gracias por comprar un producto Omcan usted. Para registrar su garantía para este producto, complete la información a continuación,

cortar la tarjeta en la perforación y luego enviarlo a la dirección indicada a continuación. También puede registrarse en línea en:

https://omcan.com/warranty-registration/

For mailing in Canada

Pour postale au Canada

Por correo en Canadá

OMCAN

PRODUCT WARRANTY REGISTRATION

3115 Pepper Mill Court,

Mississauga, Ontario

Canada, L5L 4X5

PRODUCT WARRANTY REGISTRATION

4450 Witmer Industrial Estates, Unit 4,

For mailing in the US

Pour diffusion aux États-Unis

Por correo en los EE.UU.

OMCAN

Niagara Falls, New York

USA, 14305

or email to: service@omcan.com

Purchaser’s Information

Name: Company Name:

Address:

Telephone:

City: Province or State: Postal or Zip: Email Address:

Country: Type of Company:

Restaurant Bakery Deli

Dealer from which Purchased: Butcher Supermarket Caterer

Dealer City: Dealer Province or State: Institution (specify):

Invoice: Other (specify):

Model Name: Model Number: Serial Number:

Machine Description:

Date of Purchase (MM/DD/YYYY): Date of Installation (MM/DD/YYYY):

Would you like to extend the warranty? Yes No

Thank you for choosing Omcan | Merci d’avoir choisi Omcan | Gracias por elegir Omcan

27

Page 28

Since 1951 Omcan has grown to become a leading distributor of equipment and supplies to the North

American food service industry. Our success over these many years can be attributed to our commitment

to strengthen and develop new and existing relationships with our valued customers and manufacturers.

Today with partners in North America, Europe, Asia and South America, we continually work to improve

and grow the company. We strive to offer customers exceptional value through our qualied local sales

and service representatives who provide convenient access to over 5,000 globally sourced products.

Depuis 1951 Omcan a grandi pour devenir un des “leaders” de la distribution des équipements et

matériel pour l’industrie des services alimentaires en Amérique du Nord. Notre succès au cours de ces

nombreuses années peut être attribué à notre engagement à renforcer et à développer de nouvelles

et existantes relations avec nos clients et les fabricants de valeur. Aujourd’hui avec des partenaires en

Amérique du Nord, Europe, Asie et Amérique du Sud, nous travaillons continuellement à améliorer et

développer l’entreprise. Nous nous efforçons d’offrir à nos clients une valeur exceptionnelle grâce à

nos ventes locales qualiées et des représentants de service qui offrent un accès facile à plus de 5000

produits provenant du monde entier.

Desde 1951 Omcan ha crecido hasta convertirse en un líder en la distribución de equipos y suministros

de alimentos en América del Norte industria de servicios. Nuestro éxito en estos años se puede atribuir

a nuestro compromiso de fortalecer y desarrollar nuevas relaciones existentes con nuestros valiosos

clientes y fabricantes. Hoy con socios de América del Norte, Europa, Asia y América del Sur, que trabajan

continuamente para mejorar y crecer la empresa. Nos esforzamos por ofrecer a nuestros clientes valor

excepcional a través de nuestro local de ventas y representantes de los servicios que proporcionan un

fácil acceso a más de 5,000 productos con origen a nivel mundial.

Loading...

Loading...