OMC AD10, AM10, TD10, TM10 Maintenance Manual

Installaon, Operaon and Maintenance Manual TD10/…‐en Rev.03/2018

INSTALLATION, OPERATION AND

MAINTENANCE MANUAL

ENGLISH

Three-way valves

Diverter valves Series AD10 - TD10

Mixing valves Serie AM10 - TM10

Our products are manufactured under ISO-9001 Quality Assurance System, approved by CSQ certified under no.9190.OMC2 - FIRST ISSUE 1994/08/04

OMC s.r.l. Via G. Galilei, 18 - 20060 - Cassina de Pecchi (MI) - ITALY - www.omcsrl.com - Tel.: (+39) 02.95.28.468

Page 1

TABLE OF CONTENTS

1.0 SAFETY INFORMATION

Installaon, Operaon and Maintenance Manual TD10/…‐en Rev.03/2018

ENGLISH

1.01 INTENDED USE

1.02 ACCESS

1.03 LIGHTING

1.04 HAZARDOUS FLUIDS IN THE PIPE

1.05 ENVIRONMENTAL SITUATIONS

1.06 TEMPERATURE

1.07 SYSTEM

1.08 PRESSURIZED SYSTEMS

1.09 TOOLS AND CONSUMABLE PARTS

1.10 PROTECTION CLOTHES

1.11 QUALIFICATION OF OPERATORS IN CHARGE OF THE WORKS

1.12 HANDLING

1.13 FREEZING

1.14 OTHER RISKS

1.15 DISPOSAL

1.16 RISK OF CORROSION AND/OR EROSION

2.0 INSTALLATION

2.01 ASSEMBLY OF THE VALVE ON THE PIPE

3.0 ACTUATOR CONNECTION

3.01 PNEUMATIC ACTUATOR CONNECTION

3.02 ELECTRIC ACTUATOR CONNECTION

4.0 MAINTENANCE

4.01 VALVE/ACTUATOR SEPARATION

4.02 REPLACEMENT OF THE PLUG SEAT OF THE DIVERTER VALVE

4.03 REPLACEMENT OF THE PLUG SEAT OF THE MIXING VALVE

4.04 REPLACEMENT OF THE PLUG SEAT OF THE DIVERTER VALVE WITH BELLOWS

4.05 REPLACEMENT OF THE PLUG SEAT OF THE MIXING VALVE WITH BELLOWS

4.06 REPLACEMENT OF THE STEM PACKING GLAND

5.0 TIGHTENING TORQUES

6.0 SIZES OF PLUG CONNECTION

7.0 PERIODICAL OPERATIONS

8.0 AVAILABLE SPARE PARTS

9.0 PRESSURE/TEMPERATURE REPORT OMC-TUV-00 Rev.03/2018

Page 2

Our products are manufactured under ISO-9001 Quality Assurance System, approved by CSQ certified under no.9190.OMC2 - FIRST ISSUE 1994/08/04

OMC s.r.l. Via G. Galilei, 18 - 20060 - Cassina de Pecchi (MI) - ITALY - www.omcsrl.com - Tel.: (+39) 02.95.28.468

Installaon, Operaon and Maintenance Manual TD10/…‐en Rev.03/2018

1.0 SAFETY INFORMATION

The safe operation of this product is ensured only if it is installed, commissioned, used and maintained in an

appropriate way by qualified personnel in compliance with the operating instructions.

1.01 INTENDED USE

Verify that the actuator is suitable for the intended use and application by controlling:

- that the material of which the valve is made up of is compatible with the process fluid;

- that the valve is suitable to the pressures and temperatures of the process fluid;

- to have arranged a suitable safety device which prevents, in case of valve malfunctioning, any hazardous

overpressures or overtemperatures.

The OMC valves are not intended to withstand any external stresses which can be induced by the systems in

which they are inserted. The installer must take account of these stresses and take the appropriate measures.

1.02 ACCESS

Ensure a safe access and, if required, a safe working platform (with a suitable protection) before operating on the

product. Arrange the suitable lifting means, if required.

1.03 LIGHTING

Ensure a lighting which is suitable to the required type of work.

1.04 HAZARDOUS FLUIDS IN THE PIPE

Take account of the content of the pipe or anything it may have previously contained. Be careful to: flammable

materials, substances hazardous for the health, temperature extremes.

1.05 ENVIRONMENTAL SITUATIONS

ENGLISH

Take account of: areas at risk of explosion, lack of oxygen (such as tanks, wells, etc.…), hazardous gases,

temperature limits, high or low temperature surfaces, risk of fire (for example during welding operations),

excessive noise, moving machines.

1.06 TEMPERATURE

Wait until the temperature normalizes after the interception to prevent any risks of burn or freezing.

1.07 SYSTEM

Take account of the possible effects on the whole expected working system.

May the intended measure put the other parts of the system or the personnel at risk?

Make sure that the shut-off valves are gradually activated in order to prevent any abrupt variations to the system.

1.08 PRESSURIZED SYSTEMS

Make sure that the pressure is isolated and discharged to the atmospheric pressure in safe conditions. Take

account of a double insulation (double block and vent) and the blocking or the labelling of the closed valves. Do

not consider the system depressurized even if the pressure gauge indicates zero pressure.

During the operation the valve is pressurized. Before performing any maintenance operation or action on

the flanges and closing caps, make sure that the line is depressurized (0 bar) and at ambient temperature.

Our products are manufactured under ISO-9001 Quality Assurance System, approved by CSQ certified under no.9190.OMC2 - FIRST ISSUE 1994/08/04

OMC s.r.l. Via G. Galilei, 18 - 20060 - Cassina de Pecchi (MI) - ITALY - www.omcsrl.com - Tel.: (+39) 02.95.28.468

Page 3

Installaon, Operaon and Maintenance Manual TD10/…‐en Rev.03/2018

1.09 TOOLS AND CONSUMABLE PARTS

Before starting the work, make sure to have at your disposal all the tools required to perform it, do not make use

of inappropriate tools. Use only OMC original spare parts.

ENGLISH

1.10 PROTECTION CLOTHES

Take account of whether you and/or others need some clothes against the hazards, such as chemical products,

temperatures, radiations, noise, fall of objects, risks for eyes and face.

1.11 QUALIFICATION OF THE OPERATORS IN CHARGE OF THE WORKS

All works must be performed and supervised by some skilled, trained and competent personnel.

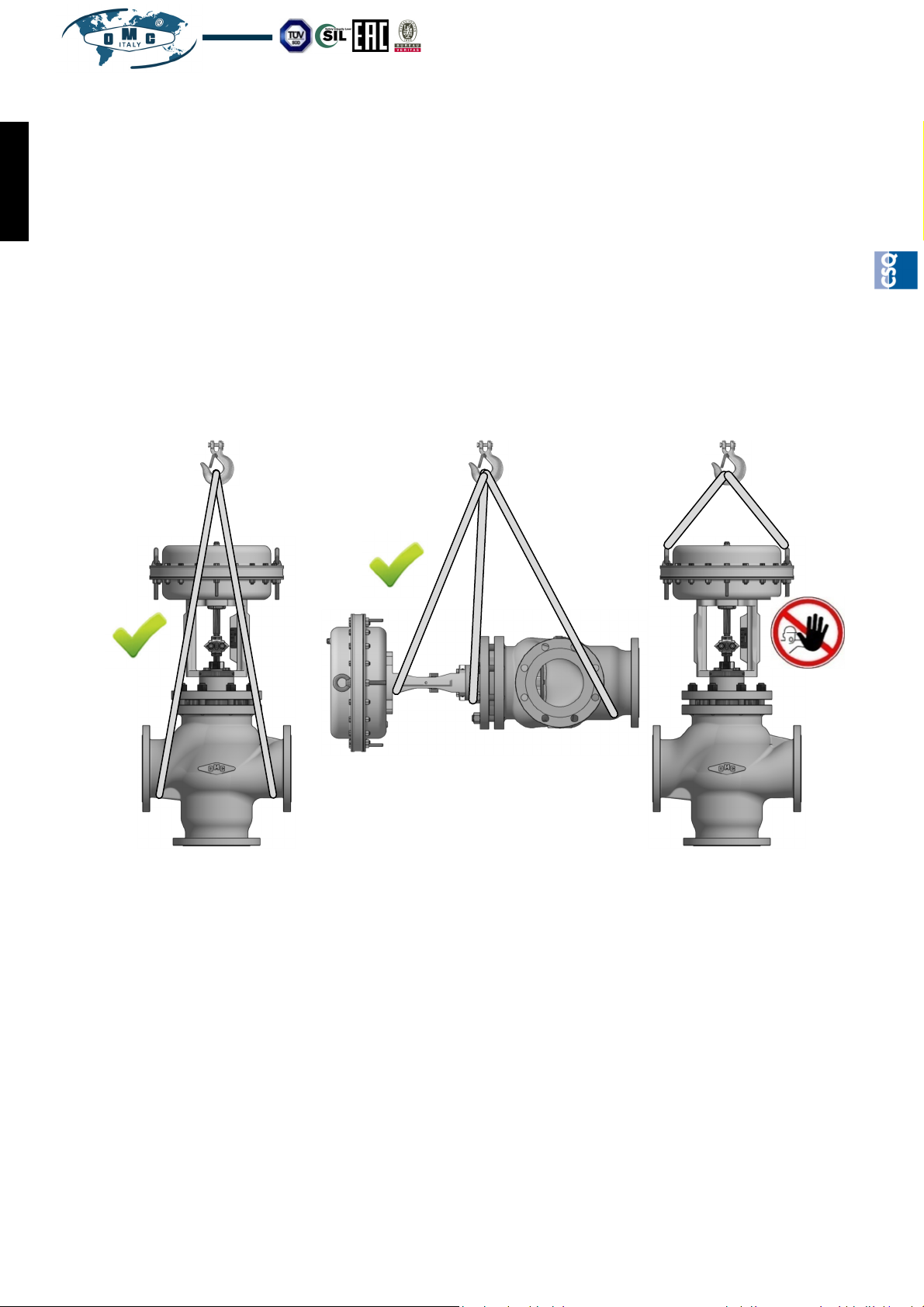

1.12 HANDLING

Use suitable lifting means for the handling of the products by assessing all the risks concerning the lifting, the

environment load, the individual and the circumstances of the work which is about to be performed.

CORRECT

CORRECT WRONG

1.13 FREEZING

Protect the products against frozen in environments with temperatures lower than the freezing point of the

process fluid.

1.14 OTHER RISKS

During the operation, the external surface of the product can be at temperatures which are hazardous to touch.

Take account of this risk.

1.15 DISPOSAL

For the disposal respect the legislation in force in the State/Country/Nation where the product should be disposed

of.

1.16 RISK OF CORROSION AND/OR EROSION

Periodically verify any phenomena of internal and/or external corrosion and/or erosion as they may

significantly damage the pressurized parts by locally reducing the thickness and as a consequence the

safety degree.

Our products are manufactured under ISO-9001 Quality Assurance System, approved by CSQ certified under no.9190.OMC2 - FIRST ISSUE 1994/08/04

Page 4

OMC s.r.l. Via G. Galilei, 18 - 20060 - Cassina de Pecchi (MI) - ITALY - www.omcsrl.com - Tel.: (+39) 02.95.28.468

Installaon, Operaon and Maintenance Manual TD10/…‐en Rev.03/2018

2.0 INSTALLATION

All works must be performed and supervised by skilled, trained and competent personnel.

The fusion of the OMC valves’ body highlights the flow direction, the maximum operating pressure and the

material.

Before installing the valve, make sure that the pipe which channels the process fluid is clean, by performing, if

required, an energetic blowing with steam or compressed air.

The installation of the filter upstream the valve will prevent the entrance of any dirt in the plug.

To perform periodical maintenance operations of the valves installed on continuous-operation systems, it is

recommended to install three shut-off valves, located upstream and downstream of the three-way valve. The three

shut-off valves must have the same internal diameter of the control valve. During the installation of the valve,

make sure that the flow in the pipe goes in the same direction as indicated by the arrow on the valve body.

ENGLISH

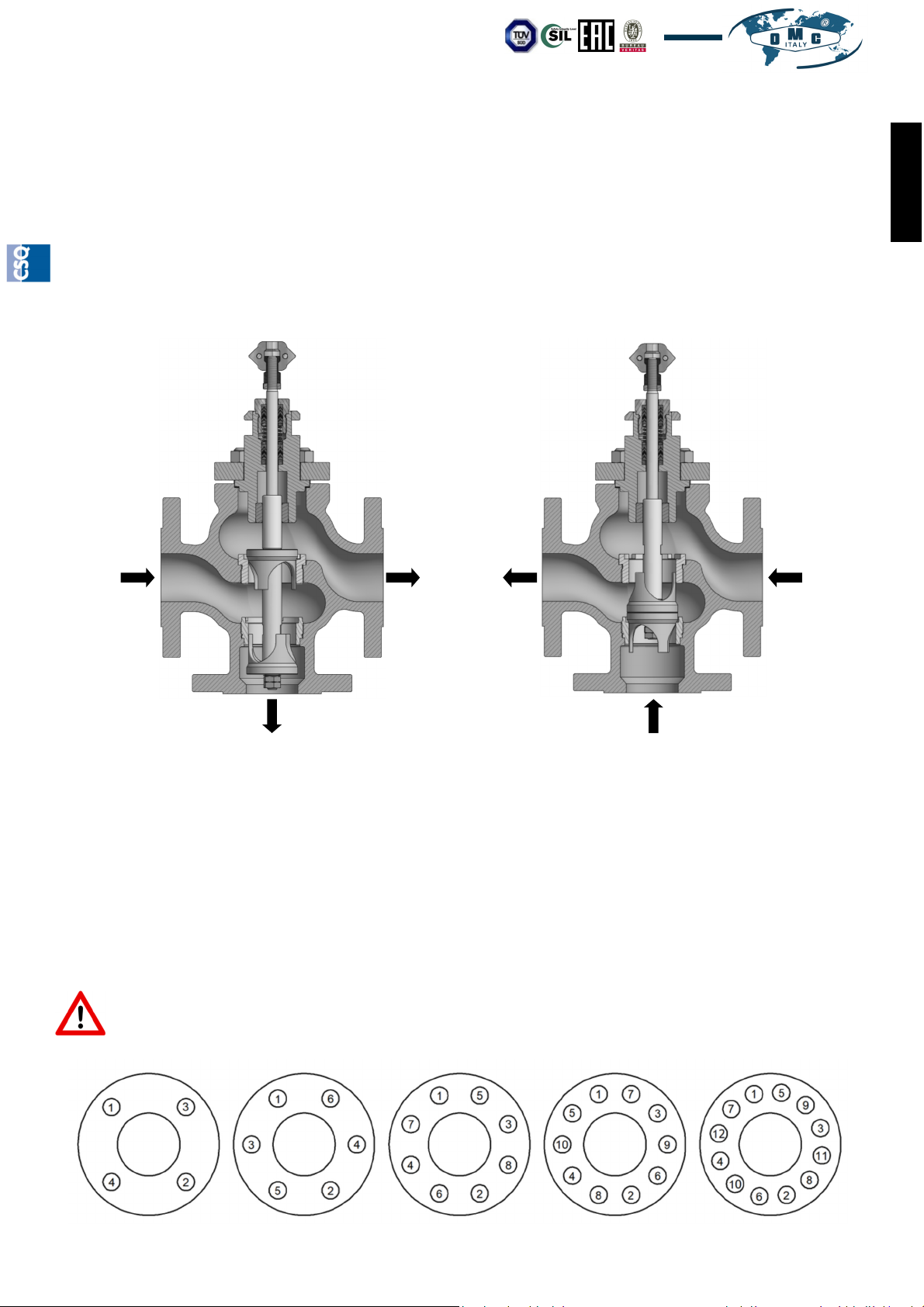

A-B B

A

A-B B

A

Pic. 1.1 Diverter valve flows Pic. 1.1 Mixing valve flows

The assembling position of the valve does not limit its operation, but it is recommended to assemble the valve

with the actuator pointed upward as other positions might allow the accumulation of any impurities which are

contained in the fluid thus damaging the valve itself.

2.01 ASSEMBLY OF THE VALVE ON THE PIPE

To ensure a uniform load and a uniform alignment, the flange bolts must be gradually tightened in criss-cross

sequence, as indicated in Pic.2

Prevent any excessive tightening. Use the recommended tightening torques. Prevent any pipe

misalignment. Choose the flange gaskets according to the operating conditions.

ATTENTION!!! For valves with braze-on connections, the welding operation must be performed

only by qualified personnel and, in order to prevent any damages to the valves, keep the valve

body cold during the above-mentioned operation.

Our products are manufactured under ISO-9001 Quality Assurance System, approved by CSQ certified under no.9190.OMC2 - FIRST ISSUE 1994/08/04

OMC s.r.l. Via G. Galilei, 18 - 20060 - Cassina de Pecchi (MI) - ITALY - www.omcsrl.com - Tel.: (+39) 02.95.28.468

Pic. 2 Tightening sequence

Page 5

Loading...

Loading...