Page 1

888-273-5303

www.durobrick.com

888-273-5303

www.durobrick.com

The Most Durable

Waterjet Brick

Available.

The Most Durable

Waterjet Brick

Available.

6112 East 32nd Place

Tulsa, OK 74135

• DuroPro™ Polypropylene material

will not separate like laminated

versions, allowing for more cuts and

a greater savings.

• Easily drains water away from the

cutting area, reducing splashback.

• Unique design creates an even, flat

cutting surface that prevents smaller

parts from falling through the brick.

• DuroPro™ Polypropylene material

reduces cutting noise creating a

quieter workspace.

• DuroPro™ Polypropylene material is

100% recyclable.

Distributed By:

Page 2

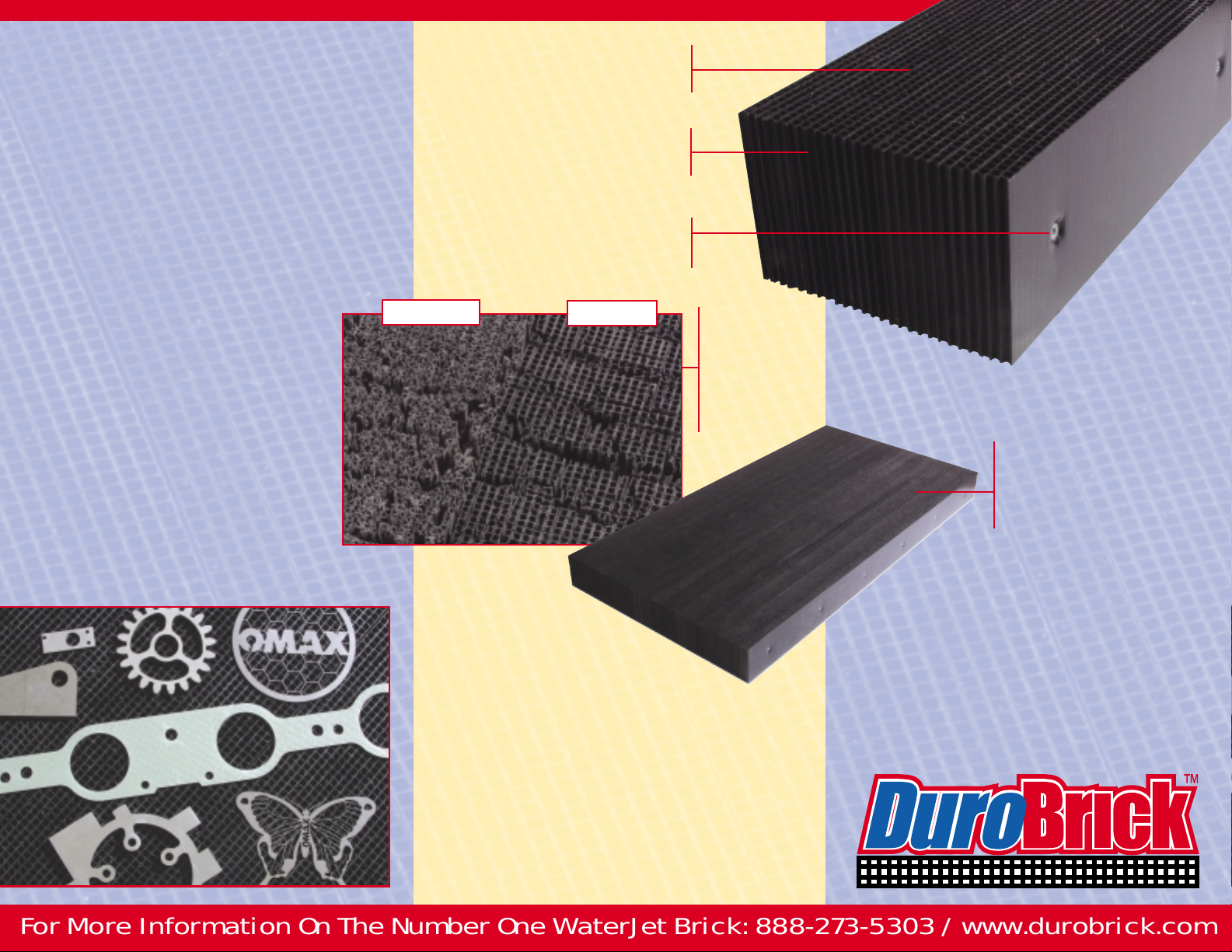

DuroBricks’s special design drains

water away from cutting area while

preventing splashback during cutting.

Thicker DuroPro™ material allows

DuroBrick™ to accept more cuts, while

retaining the original shape.

12 extra long screws hold DuroBrick™

together longer during cutting and help

increase the life of the product.

Durobricks are used together

to form a foundation bed as

needed for any cutting

application, both abrasive or

straight water jet cutting.

DuroBrick’s

unique design

allows them to

hold up longer

and take more

cuts than their

competition.

DuroBrick

Competitor

For More Information On The Number One WaterJet Brick: 888-273-5303 / www.durobrick.com

“

Our two waterjet

machines operate constantly,

sometimes 24 hours per day. Over many

years we have tried all of the different

waterjet bricks available. The DuroBrick™

is by far the longest lasting brick we have

ever used. We are sold on the DuroBrick™,

and I think you will be too.

”

Sid Holman / President

Holman Mfg. Co. / Locust Grove, OK

Material:

Exclusive super-tough, DuroPro™ polypropylene

material. DuroPro™ material does not de-laminate

and lose shape like many other waterjet bricks do.

Size and Weight:

Dimensions: 4” x 6” x 48” / Weight: 11 lbs.

Dimensions: 6” x 6” x 48” / Weight: 16.5 lbs.

DuroBrick waterjet brick is the most durable, long lasting

waterjet brick available in the marketplace today.

Made from a proprietary polypropylene material

manufactured specifically for the production of waterjet

bricks, DuroBrick™ waterjet bricks hold up to the rigors

of waterjet cutting better than any other brand.

DuroBrick™ waterjet bricks are manufactured using the

latest CNC equipment. Each brick is inspected under

strict quality control procedures to ensure a flat even

cutting surface. This procedure also allows cutting on

both sides, thereby increasing the life of the waterjet

brick. The tight-tolerance surfaces make an

excellent foundation bed for cutting parts from

materials such as:

• Aluminum

• Brass

• Ceramics

• Copper

• Fabric

• Foam

• Gaskets

• Glass

• Inconel

• Laminates

• Limestone

• Marble

• Plastics

• Phenolic

• Steel

• Titanium

• Wood

• Etc...

Specifications:

* Both bricks cut at

40,000 PSI

*

*

Loading...

Loading...