Page 1

Accessory Specifications

PRECISION ABRASIVE WATERJET SYSTEMS

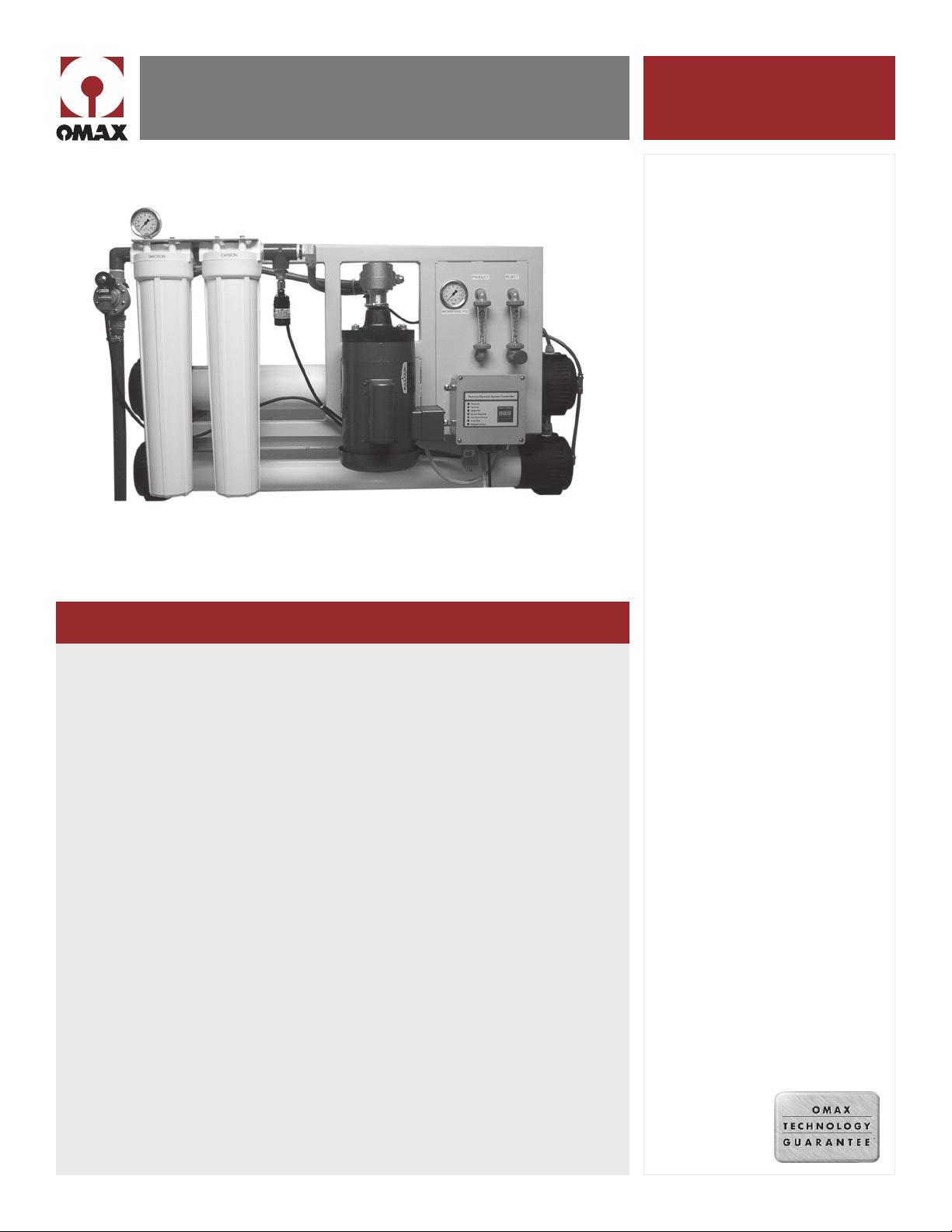

OMAX® Reverse Osmosis System

Why would your facility consider using a reverse

osmosis system?

Water quality varies depending on location.

In some areas, total dissolved solids can be

RO

What is Reverse

Osmosis?

To understand reverse osmosis, you must

first understand osmosis. During natural

osmosis, water flows from a less concentrated solution through a semipermeable

membrane to a more concentrated saline

solution until concentrations on both sides

of the membrane are equal.

Reverse Osmosis

Reverse osmosis requires external pressure to reverse natural osmotic

flow. As pressure is applied to the

saline solution, water flows from a more

concentrated saline solution through

the semipermeable membrane.

Reverse Osmosis

Membrane

A reverse osmosis membrane has

a thin microporous surface that rejects

impurities, but allows water to pass

through. The membrane rejects 85%-95%

of inorganic solids. Reverse osmosis is a

percent rejection technology. The purity

of the product water depends on the

purity of the inlet water. The purity of

reverse osmosis product water is much

higher than the purity of the feedwater.

Reject Water

A large percentage (50%-75%)

of the feedwater does not pass through

the membrane but flows across the membrane surface, constantly cleaning it and

carrying the inorganic and organic solids

to drain. This water is called “reject.”

sustained at or below 250 ppm, eliminating

pre-treatment measures for effective waterjet

operation. However, in areas where the total

dissolved solids (TDS) rise in excess of 250 ppm,

an OMAX Pressure Reverse Osmosis System can

be just the assurance you need to provide clean,

pure water to your equipment.

RO

When to consider

a water softener?

In some locations you will find the

hardness (calcium and magnesium)

in your water to be high but the TDS

to be below 250. In situations like this

a water softener is recommended. You

will gain many of the same benefits that

a reverse osmosis system would give

you but at a lower cost.

The OMAX Technology

Guarantee entitles you, as

the original owner, to free

OMAX software upgrades

for the life of the machine.

Page 2

Brine/Salt

Tank

Softener

Customer Supplied Drain

Pump

Station

City Water

Feed

60 psi

Reverse Osmosis Unit

(Wall Mounted)

High Level

Switch

Reject

Product

Gray Level Control Wire

OMAX Pressure Reverse Osmosis System

Power Requirements

110V, 60 Cycle, 10AMP

Quality Monitor

Digital Total Dissolved Solids Meter

Pre-Treatment

5 Micron Filter 20”

Carbon Block Filter 20”

Membranes

Membranes (2) 4” x 40”

Max. Operating Pressure 125 psi

Feed Temperature 95° F

Recommended pH 6 to 12

Free Chlorine Tolerance <0.1 ppm

Average Rejection 96%

Gallons per Day 2500 at 77 psi

Membrane Vessels

Number of Vessels 2

Vessel Rating 240 psi

Vessel Construction PVC

Max. Temperature 130° F

Frame

Construction Powder-coated steel

Dimensions 18”H x 38”W x 6”D

Mounting Wall

Water Softener

Type Time clock initiated

Grains Removed 45,000

Flow Rate 10 gpm

Resin 1.5 cubic feet total

Pipe Size 3/4”

Resin Tank Dimensions 10” x 54”

Brine Tank Dimensions 18” x 30”

Note: Specifications subject to change without notice.

Benefits

• A reverse osmosis system removes

90% to 95% of the total dissolved

solids in your water. Dissolved particles are the primary source of damage

to OMAX waterjet equipment.

• A reverse osmosis system protects your

waterjet equipment so you don’t have

to replace your expendables nearly

as often.

• Virtually hands-free operation.

• Pure water can be used for other

equipment in shop (EDM, etc.).

• More hours of running time between

maintenance.

• Inexpensive filter changes on reverse

osmosis once per month.

• Most cities only charge $2.50 per

1000 gallons making the cost for

water minimal.

About OMAX

OMAX has the industry leading patented

abrasivejet controller with a built-in

expert system. The OMAX Software

makes it easy to machine precision parts

as fast as possible at the lowest cost.

JetMachining is ideal for short-run part

production, just-in-time manufacturing,

tooling, and prototype part development.

It requires no tool changes or complex

fixturing, so you can reduce setup times

by at least 50%.

For more information on what other

OMAX products and accessories can do

for you, call us today at 800-838-0343

or visit our website at www.omax.com.

OMAX Corporation

21409 72nd Ave South, Kent, WA 98032

253-872-2300 tel 253-872-6190 fax

1-800-838-0343 toll-free

WWW.OMAX.COM website

Printed in the U.S.A © June 2007 All rights reserved. OC-009

Loading...

Loading...