Page 1

Accessory Specifications

PRECISION ABRASIVE WATERJET ACCESSORIES

OMAX POL installed next to a Tilt-A-Jet

BEST APPLICATIONS:

• Locatetoolpathwithexistingfeatureswhenmaterialislarger

thanthecuttingareaofthemachine

• Reverseengineerormeasureexistingparts

OMAX® Precision Optical Locator

The Precision Optical Locator (POL), an

POL

Standard Features

• USB camera with microscope lens to

zoom in on material features, locate,

and select points with software’s

precision crosshair alignment tool

• Video image of featured location can

be saved for quality control records

• Light ring illuminates viewing area

• When used with OMAX Watcher utility,

the accessory allows remote machine

monitoring and shut down

• Includes two USB extension cables;

two camera tripods; and accessory

carrying case

• Camera resolution: 1280 x 1024

pixels*

®

* Subject to change without notice

Requirements

• Video/optical locating system

eliminates the need for cumbersome

point location using time consuming

dial indicators

• Video monitoring and software

functions measure the location of

material features to prepare for

secondary machining, such as drilling

in the center of a disk

• Pick up locating points without the

operator leaving the control console

accessory combining hardware and software

technology, allows you to determine the location

of parts on the machining table or features on

existing parts or materials.

The POL includes a compact video camera

mounted to the Z-axis to precisely locate points,

edges, or holes on a piece of material placed

on the OMAX cutting table. The accessory’s

software is integrated with Intelli-MAX® Make,

providing you the interface to view the live video

feed from the camera and apply application

tools to measure and locate features.

POL

Connect and follow OMAX for the latest news

in waterjet technology.

The OMAX Technology

Guarantee entitles you, as

the original owner, to free

OMAX software upgrades

for the life of the machine.

OMAX Corporation

21409 72nd Ave South, Kent, WA 98032

253-872-2300 tel 253-872-6190 fax

1-800-838-0343 toll-free

WWW.OMAX.COM website

Printed in the U.S.A © April 2012 All rights reserved. S-0016

Page 2

PrecisionAbrasiveWaterjetAccessories

Requirements

• Motorized Z-Axis or Tilt-A-Jet

• Remove accessory from Z-Axis

during cutting operations

Contact an OMAX Sales

Representative for more details

Software Interface

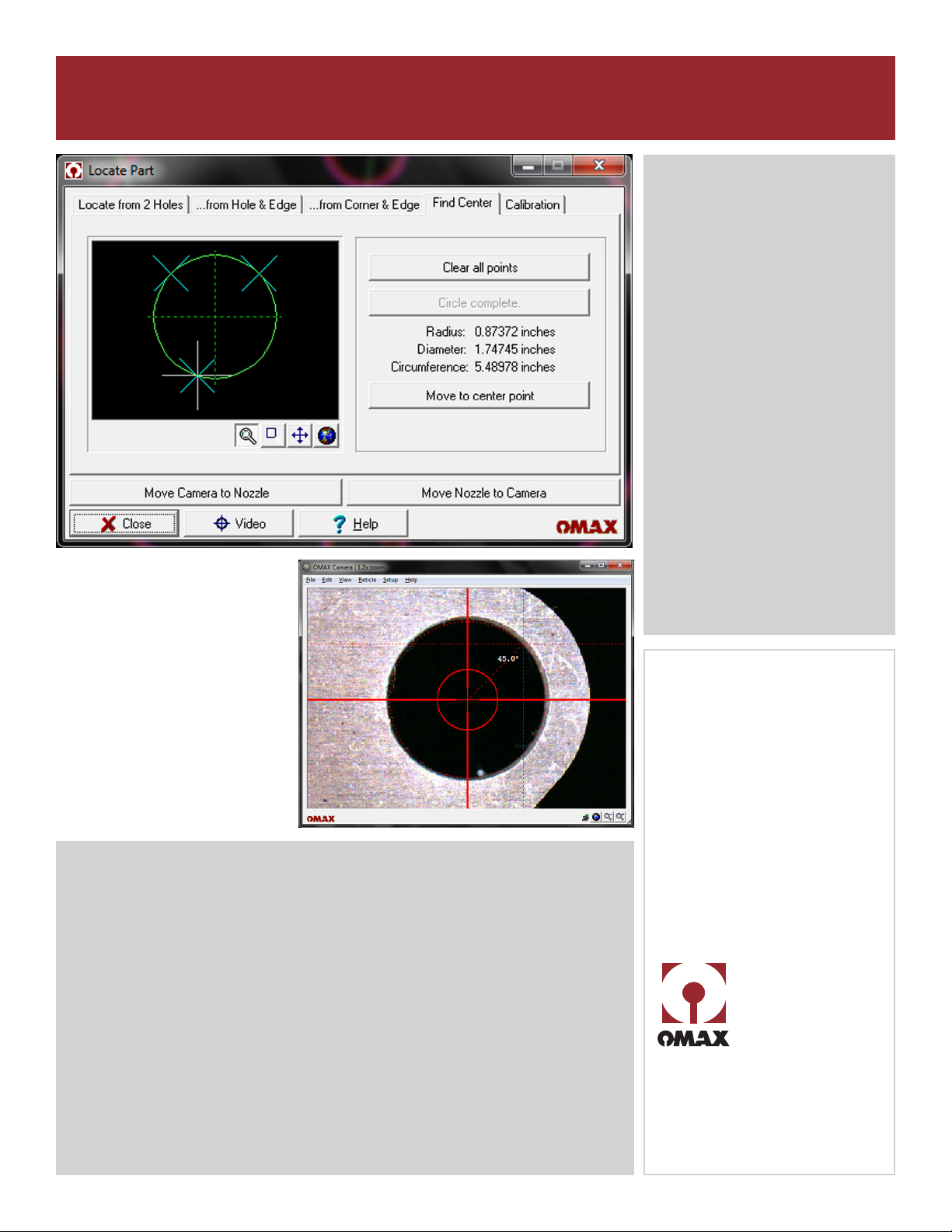

(Above) From the POL’s Locate

Part window, select a method

tab to determine the location of

a part, such as “Find Center.”

(Right) From the OMAX

Camera window, use the

application’s precision crosshairs to locate specific part

features, such as a center of a

circle, an edge, or corner.

POL software capabilities include

• Locating a part’s feature from two reference holes

• Locating a part’s feature from a hole and an edge

• Locating a part’s feature from a corner and an edge

• Finding the exact center of a circle

• An instructional wizard for rotating part tool paths to align with existing material

• Digital zoom and full screen views

• Interaction with the Intelli-MAX Software Suite

• Measurement tools

• Reverse engineering tools

Contact an OMAX Sales Representative for more details

NOTE: All specifications subject to change without notice

About OMAX

OMAX has the industry leading patented

abrasivejet controller with a built-in

expert system. Our exclusive “Compute

First-Move Later” motion control system

automates most programming and tool

setup work, virtually eliminating the need

for extensive operator training. Plus,

with free OMAX Intelli-MAX® Software

upgrades for the life of the machine and

our ongoing commitment to advance the

efficiency of our technology and software, OMAX saves you time and money.

For information on what other OMAX

products and accessories can do for you,

call us today at 800-838-0343 or visit

our website at www.omax.com.

OMAX Corporation

21409 72nd Ave South, Kent, WA 98032

253-872-2300 tel 253-872-6190 fax

1-800-838-0343 toll-free

WWW.OMAX.COM website

Printed in the U.S.A © April 2012 All rights reserved. S-0044

Loading...

Loading...