Page 1

SOFTWARE

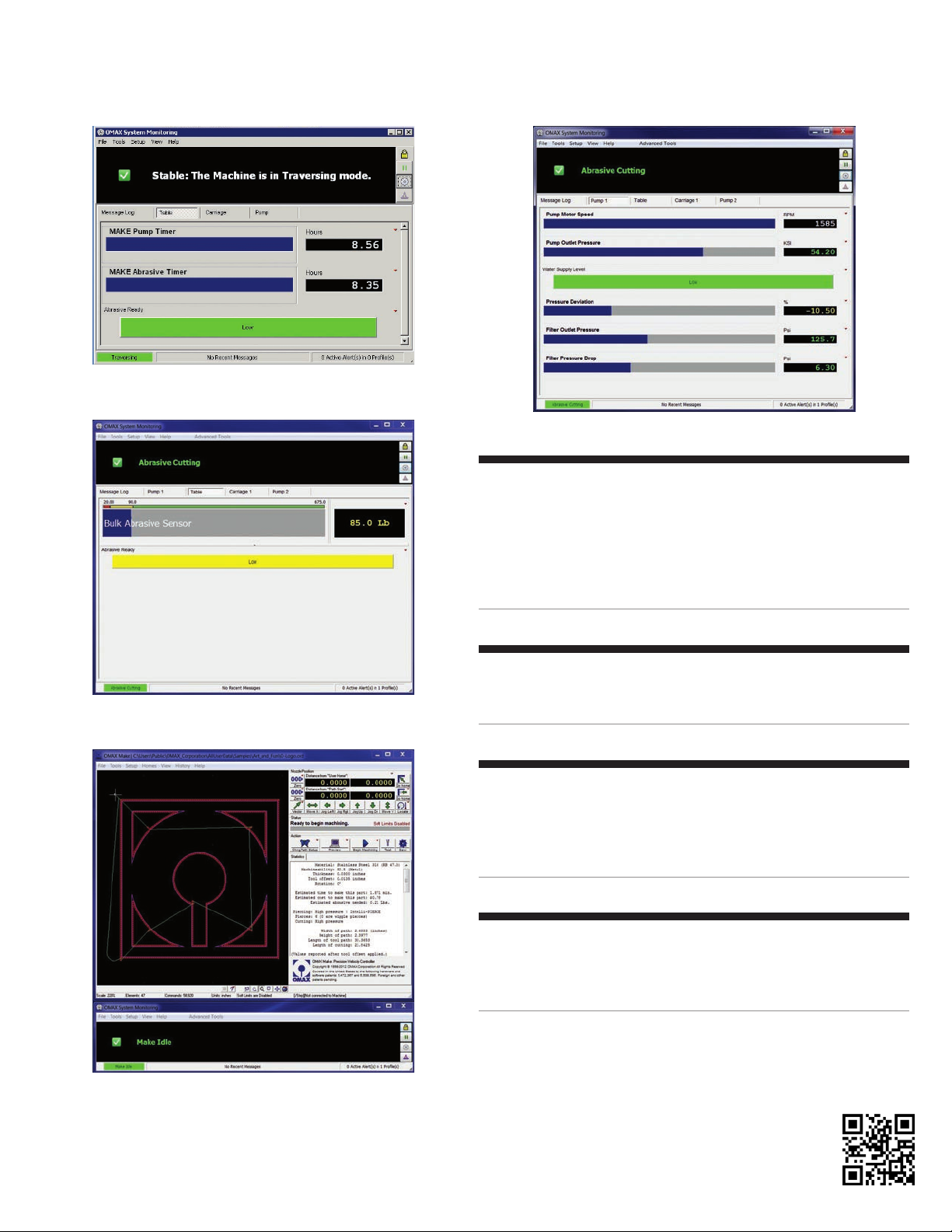

INTELLI-VISOR

OMAX Intelli-VISOR System Monitoring

With the OMAX Intelli-VISOR System Monitoring Package, you can increase efciency and reduce downtime by connecting

operation controls with machine maintenance and upkeep. Intelli-VISOR integrates real-time cutting data from different devices

across the OMAX JetMachining® Center through its streamlined software interface and robust machine sensor network. Running in

parallel with other programs in the Intelli-MAX® Software Suite, Intelli-VISOR is both simple and highly adaptable for the end user.

A comprehensive alert system keeps you connected and aware of your machine’s status to maximize productivity.

FEATURES

• Multi-User Notication System including email and

SMS text messaging*

• Advanced Data Logging with export functionality

• Customizable pause and alert triggers

• Software Display Interface can be customized

• Industry-standard ModBus® communications protocol

The OMAX Technology Guarantee

entitles you, as the original owner, to

free OMAX software upgrades for the

life of the machine.

BENEFITS

• Preventative maintenance planning to reduce production downtime

• Monitor pump pressure, abrasive levels, and cutting activity to improve production

• Proactively pauses the machine before resources are exhausted

• Ensure proper pressure at the pump for optimal performance

• Predict potential interruptions before starting a cut

Made in the USAWWW.OMAX.COM

Page 2

INTELLI-VISOR

The Intelli-VISOR display can present Module information in

user-customizable formats.

ENHANCED CONTROL

The heart of the Intelli-VISOR System Monitoring Package is its Modules.

Modules are custom-programmed parameters that gather data from the sensor

suite and process it according to the limits set by the user. When a limit is

reached, the Module logs the data and can send an alert to the controller PC,

an email address, or a cell phone text message.*

The Modules can also pause the machine to protect the cutting head and the

part being cut.

Different checkpoints can be set in each Module, providing

multiple levels of alerts and responses.

MAINTENANCE TRACKING

• Preloaded with maintenance tracking Modules

• Can notify up to 4 people via email or SMS text message*

• Integrates maintenance into the Intelli-MAX Software Suite

PUMP MONITORING

• Improved communications with the pump controller

• Pauses machine when pump fault occurs or water pressure is outside

specied window

• Provides feedback for charge pump pressure, lter pressure drop, pump water

temperature, and supply water tank level

ABRASIVE MONITORING

• Comprehensive abrasive monitoring improves reliability and usability

of machine

• Constant feedback on abrasive levels help manage supply

• Sensors monitor the Bulk Hopper Supply and Carriage Hopper Level

* Requires an Internet connection. Additional setup needed.

OMAX Intelli-VISOR runs alongside Make, working together

to ensure productivity and uptime.

Specications subject to change without notice.

600088B January 2014

WWW.OMAX.COM

Made in the USA

OMAX CORPORATION

21409 72nd Avenue South

Kent, WA 98032

TEL 1-253-872-2300 / 1-800-838-0343

FAX 1-253-872-6190

Loading...

Loading...