Page 1

ACCESSORIES

DUALBRIDGE

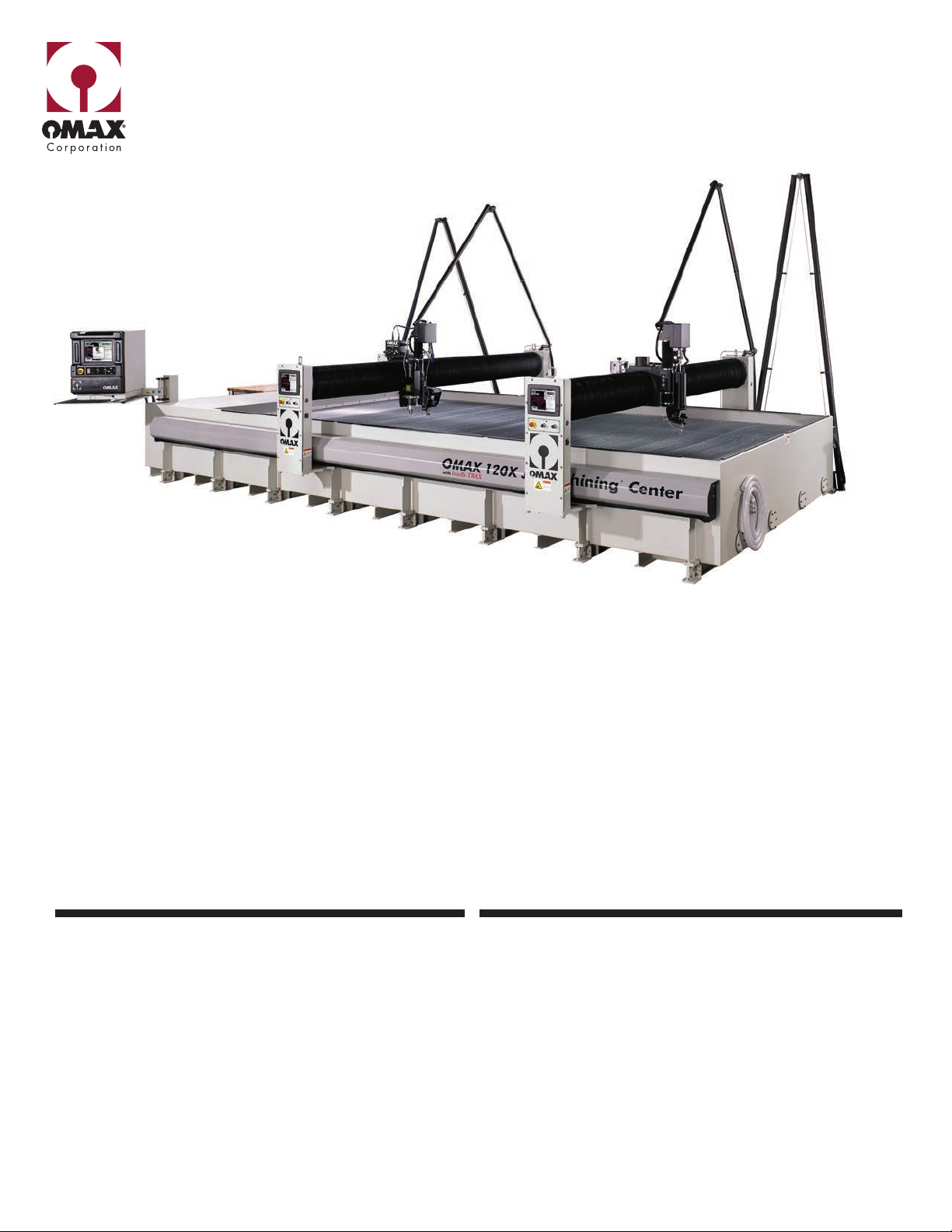

OMAX DualBRIDGE

Signicantly increase productivity with the addition of a second bridge: simultaneously cut separate jobs on a single bed with a

single operator. Available on the 80X Series, 120X Series and 160X Series, the OMAX DualBRIDGE option is ideal for highoutput, high-capacity jobs, or shops with limited facility space. Retrottable to existing 80X Series, 120X Series, and 160X

Series, two sets of the Intelli-MAX® Software Suite on two computers control each bridge autonomously, allowing for two discrete,

independent cutting jobs to take place simultaneously.

FEATURES

• Each bridge has the same precision as the standard single

bridge OMAX JetMachining® Center

• Automatic bridge collision detection

• Each bridge can use any of the precision OMAX cutting head

options for maximum versatility

• You can have different accessories on each bridge, e.g.,

a Tilt-A-Jet

• Up to four cutting heads on one machine

®

on one bridge and an A-Jet® on the other bridge

BENEFITS

• Eliminate down times & setup times: With a DualBRIDGE System

you don’t need to stop cutting to load or unload material

• Redundancy increases productivity: one bridge can continue cutting while the

other undergoes annual inspection

Can use both bridges to cut one large part at the same time, greatly reducing

•

cutting times

•

Small footprint: all the features of a second waterjet machine for

the space of a pump

• Acquire the fastest cutting conguration with multiple cutting

heads and pumps on one machine

Made in the USAWWW.OMAX.COM

Page 2

DUALBRIDGE

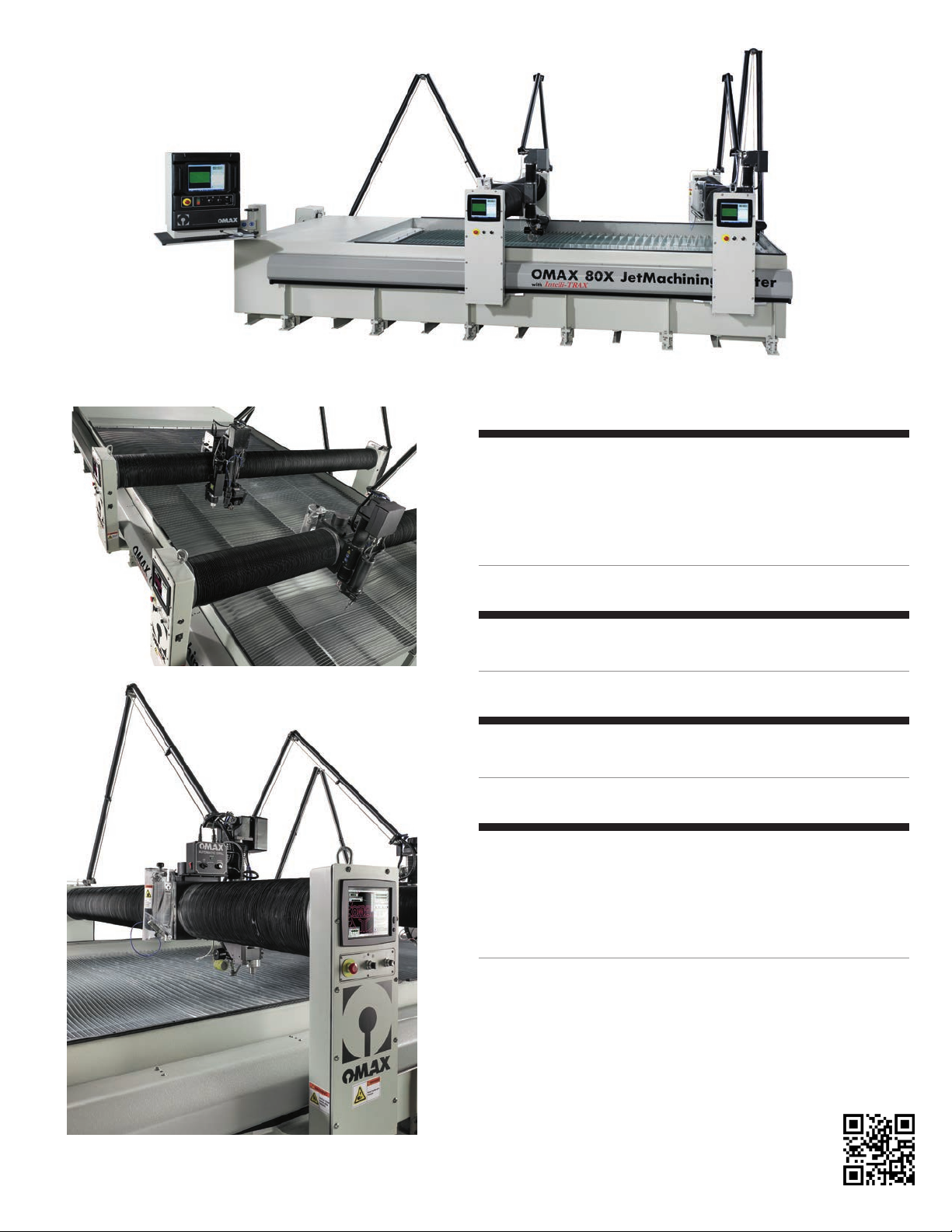

EXPANDED VERSATILITY

With the DualBRIDGE option, your JetMachining Center becomes

much more versatile. By taking advantage of the extensive accessories OMAX

has for its JetMachining Centers, you can cut high precision taper-free parts with

a Tilt-A-Jet on one bridge, while the second

bridge, equipped with the A-Jet and Rotary Axis, cuts complex

6-axis 3D shapes.

OPTIONS

• Touch Screen Monitors for each Y-Bridge

• Second Z-Axis for each Y-Bridge for up to four cutting heads

REQUIREMENTS

• 80X Series, 120X Series, or 160X Series JetMachining Center

• Separate EnduroMAX® Pump for second Y-Bridge

ACCESSORIES

• Auto Feed Pneumatic Drill

• Tilt-A-Jet taper removal cutting head

• A-Jet 5-axis articulated cutting head

• Rotary Axis

• Precision Optical Locator

• DualPUMP for each bridge

Specications subject to change without notice.

600060B January 2014

WWW.OMAX.COM

Made in the USA

OMAX CORPORATION

21409 72nd Avenue South

Kent, WA 98032

TEL 1-253-872-2300 / 1-800-838-0343

FAX 1-253-872-6190

Loading...

Loading...