Page 1

Accessory Specifications

PRECISION ABRASIVE WATERJET ACCESSORIES

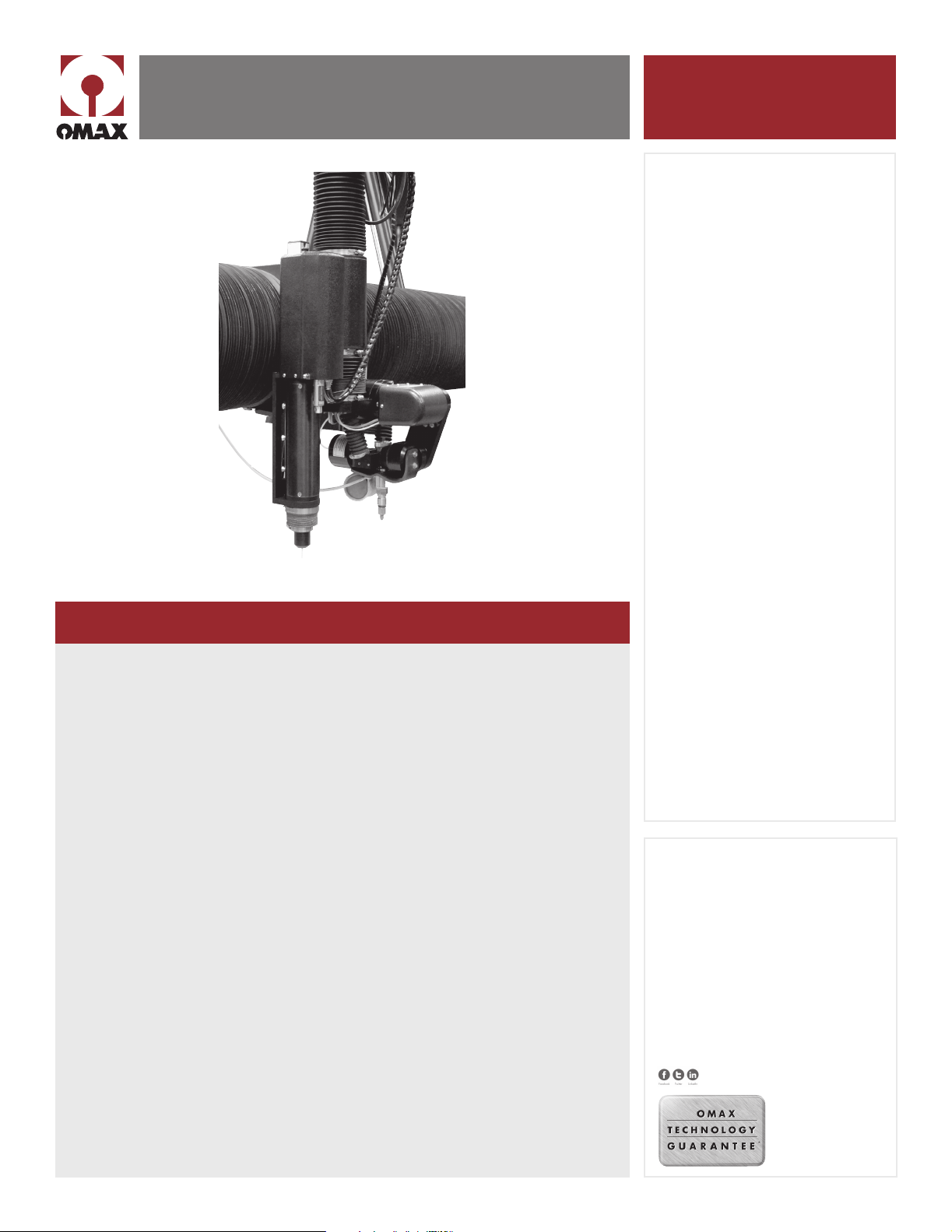

OMAX Drill Head installed next to a Tilt-A-Jet

®

OMAX® Drill Head

Achieve reliable piercing of composites and

laminates with an OMAX-engineered pneumatic drill

specifically designed for the waterjet environment.

Solely customized for OMAX machining, the robust

DRILL HEAD

Standard Features

• Chrome-plated and hard alloy steel

components enclosed inside waterresistant cases and bellows to protect from

a waterjet environment

• Corrosion-resistant cylinder wall will not

rust in moist air

• Highly efficient 5,000 RPM air motor

provides maximum power with minimum

air consumption. Air motor design

promotes longer drill bit life and quality

drilled holes.

• Drill equipped with a collet holder and

collet to hold a 1/16" drill bit

• Fully adjustable pneumatic feed rate and

depth of feed up to 3" of travel and 112

lbs of thrust with 85 psi air

• Automatically controlled by OMAX

Windows® PC-based control system

Benefits

• Successfully pre-drill brittle and sensitive

materials

• Reliably produce parts without

delamination

• Eliminate the process of tedious hand

drilling with customized registration

templates. When used with the OMAX

PC-based controller, the Drill Head can

quickly and automatically drill holes in

desired locations before cutting material

with a jet stream.

Requirements

• Windows PC-based controller installed

with Intelli-MAX® Software Suite Version

18.0 or higher

• Motorized Z-Axis, Tilt-A-Jet, or A-Jet

• Routinely apply air line lubrication and

gear train grease

• Filtration system (40 microns max.) for the

air feed connected to the drill

NOTE: Check with OMAX Sales for more details.

NOTE: Optional accessories installed on an OMAX may

reduce cutting travel. Contact OMAX for consultation.

®

Drill Head permits repeatable piercing of laminates

and composites prior to abrasive waterjet cutting and

accurately pierces small diameter holes in thick material.

With Intelli-MAX® innovation, no separate programming

is required.

The OMAX Drill Head is mounted to the Y-axis carriage

and is easily adjustable in the Z-direction to move the

accessory out of the way when not in use. No external

power is required.

Drill Head

About OMAX

OMAX is the leader in designing and

manufacturing precision abrasive waterjet

machining equipment. For more information on what other OMAX products and

accessories can do for you, call us today.

OMAX Corporation

21409 72nd Ave South, Kent, WA 98032

253-872-2300 tel 253-872-6190 fax

1-800-838-0353 toll-free

WWW.OMAX.COM website

Connect and follow OMAX for the latest news

in waterjet technology.

The OMAX Technology

Guarantee entitles you, as

the original owner, to free

OMAX software upgrades

for the life of the machine.

Printed in the U.S.A © January 2012 All rights reserved. S-0019

Loading...

Loading...