Page 1

DIRECT DRIVE PUMPS

Specific ations subje ct to chang e without no tice. Printe d in the U.S.A. April 2008 All ri ghts reser ved. PB -001

The OMAX Technology Guarantee

entitles you, as the original owner,

to free OMAX software upgrades for

the life of the machine.

The OMAX Commitment: Superior

care before, during, and after the sale.

OMAX JetMachining® Centers are sold through a well established

and growing network of distributors, both domestic and international,

with representation in over 40 countries. Each distributor is carefully

selected to provide superior customer care before, during, and after the

sale. Additionally, OMAX Service Technicians are available for expert

installation, training, maintenance, and repair assistance.

OMAX is strongly committed to innovation in the field of precision

abrasivejet machining. Our substantial investment in engineering

and R&D enables us to maintain the technology lead through

continued product development.

The OMAX Pump Guide

Page 2

Effi cient

OMAX V-Series Pumps

P3050V Specifi cation

Designed for machine shops that cut thick materials

or require faster cutting speeds.

Power 30 hp (22 Kw)

Rated Output Pressure 50 ksi (3450 bar)

Rated Orifi ce Size 0.014 in (0.355 mm)

Rated Flow Rate 0.42 – 0.84 gpm (1.5 – 3.2 Lpm)

P3055V Specifi cation

Designed for shops that require high precision and

primarily utilize MAXJET® 5 MiniJet nozzles.

Power 30 hp (22 Kw)

Rated Output Pressure 55 ksi (3790 bar)

Rated Orifi ce Size 0.010 in (0.254 mm)

Rated Flow Rate 0.3 – 0.43 gpm (1.1 – 1.6 Lpm)

P4055V Specifi cation

Designed for shops with high production or multiple

nozzle requirements.

Power 40 hp (30 Kw)

Rated Output Pressure 55 ksi (3790 bar)

Rated Orifi ce Size 0.015 in (0.381 mm)

Rated Flow Rate 0.45 – 1.05 gpm (1.7 – 4.0 Lpm)

Dual Pump Package Specifi cation

Designed for shops that cut thick materials and have

high capacity production or multiple nozzle requirements.

Power

* 80 hp (80 Kw)

Rated Output Pressure 55 ksi (3790 bar)

Rated Orifi ce Size 0.020 in (0.508 mm)

Rated Flow Rate 0.90 – 2.10 gpm (3.4 – 8.0 Lpm)

* Increase depends on geometry and cutting conditions. Recommended operation of

one cutting head with 0.020” orifi ce and 0.042” mixing tube, or two cutting heads

with 0.014” orifi ce and 0.030” mixing tube.

Utility Requirements:

Electrical Power 3-Phase, 380 – 480 VAC +/- 10%, 50-60 Hz

Water Supply 1.3 gpm (5 Lpm)

Contact OMAX for detailed utility requirements. Pumps built to meet UL and CE specifi cations.

Effi ciencies of Direct

Drive Technology

Compact & Quiet

High Power Effi ciency

Lower Water Usage

Easy Maintenance

Low Operating Cost

The future is here.

From the recognized leader in the high-pressure industry comes

the latest innovation in direct drive plunger pump technology,

the OMAX

®

V-Series Pump.

Designed for optimal effi ciency, the OMAX V-Series Pump

delivers more than 90% of the electrical input power to the

cutting nozzle. This translates into less water usage, faster

cutting speed per unit of input power, and lower cost per

fi nished part than other pump technologies.

In comparison, intensifi er pumps deliver less than 70% of the

electrical input power to the nozzle. To learn more about the

differences between intensifi er pumps and direct drive plunger

pumps, visit the product section at www.omax.com and read

“A Comparison Between Intensifi er and Crank Drive Pumps,”

by Dr. John Olsen.

OMAX V-Series Pump Benefi ts

•

Highest effi ciency abrasive waterjet pump on the market

•

No in-rush current at starting

•

With Chiller, cooling water is recycled

•

Long lifetime of all components

•

Easy access to all components for maintenance

•

Low noise levels

•

Runs on tap water*

•

Ergonomic design

•

Small footprint

•

2-year warranty

Standard Features

•

Variable speed electric motor for different cutting situations

•

Automated on/off cycles so pump runs only during part processing

•

Automatic latched safety shut-off switch in case of power failure

•

Pressure safety blow down valve included

•

Charge pump provided

•

Inlet fi lters (0.2 microns) provided

•

Auxiliary power supply to operate waterjet machine provided

•

Key-pad with digital display

•

Variable frequency drive

•

110VAC (220VAC) auxiliary power supply

•

On/off and emergency switches

•

Remote and local control

•

Wooden workbench top

* Note: For water temperatures in excess of 70° F, a Chiller

is recommended. Extreme mineral content or acidity may

require treatment.

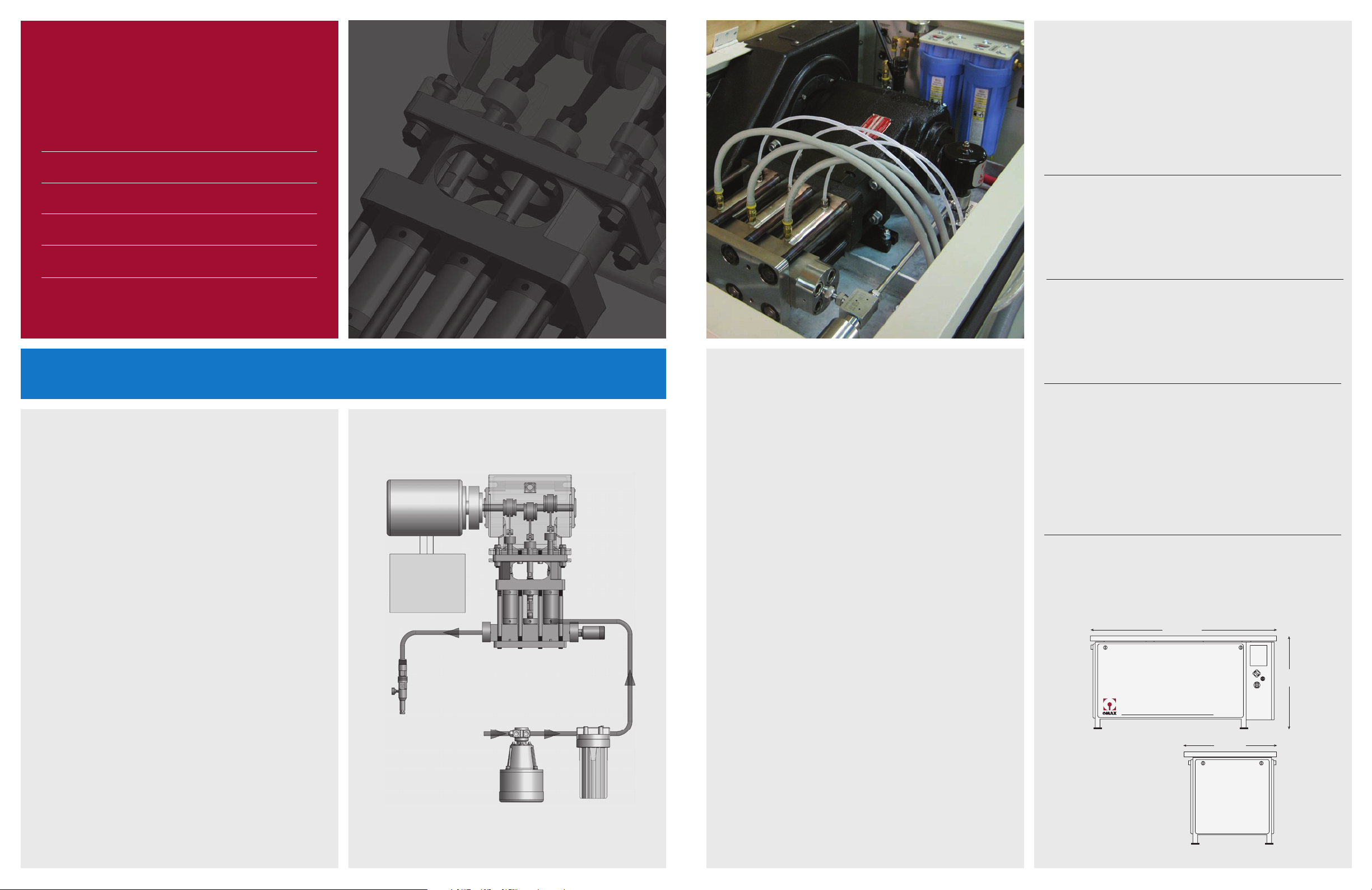

ADVANCED PUMP TECHNOLOGY

Designed for Tough

Industrial Use

Variable

Frequency

Drive

Electric Motor

OMAX Pump

OMAX Nozzle

Ultra High

Water Pressure

Inlet

Water

Charge

Pump

Filtration

Robust

Pump Unit

66”

(1676 mm)

38.5”

(978 mm)

36”

(915 mm)

Pressure

Speed

Low RPM

Run Time

Hours

·

·

·

·

Loading...

Loading...