Page 1

Accessory Specifications

PRECISION ABRASIVE WATERJET ACCESSORIES

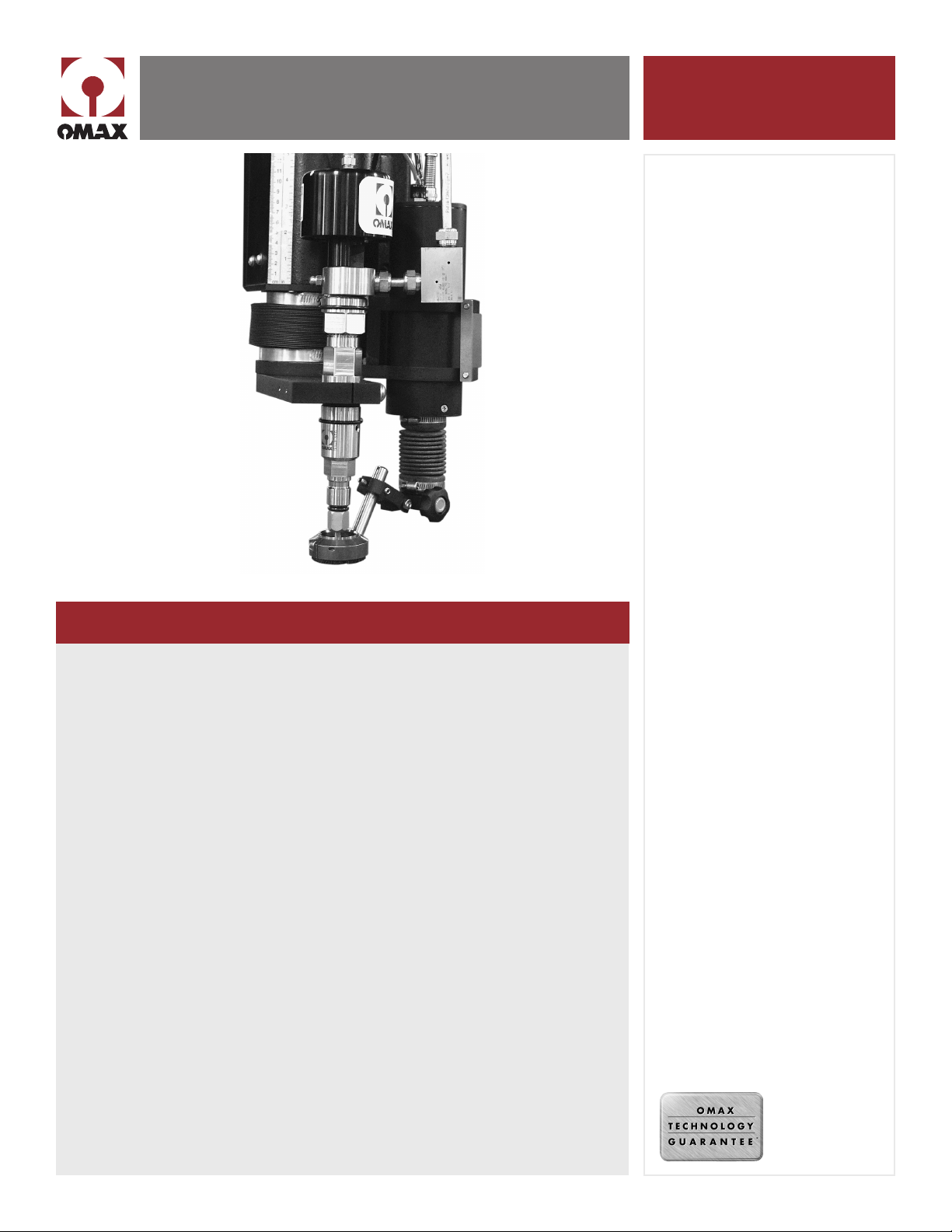

Shown on the Motorized Z-Axis

OMAX® Collision Sensing Terrain Follower

The OMAX Collision Sensing Terrain Follower

allows a JetMachining® Center to automatically and

accurately cut parts from materials with irregular

or warped surfaces without the need for special

programming.

The Terrain Follower attaches directly to the

machine’s Z-axis. Changes in a material’s height

are detected and the Z-axis automatically makes

CSTF

Standard Features

• Linear encoder senses changes

in material height during cutting

operations

• A collision detector protects the nozzle

and related hardware from damage

• Built-in containment guard minimizes

nozzle splash and spray during

machining

• Easy field retrofit to a Motorized Z-Axis

or Tilt-A-Jet®

• Heavy duty liquid-tight electrical fitting

with spring-type strain relief

• O-ring seal bulk-head air fittings

with protective boots

Benefits

• Automatically maintains the correct

nozzle standoff throughout the

cutting process

• Adjusts automatically to uneven

surfaces; reduces need for

additional programming

• Constantly senses necessary height

adjustments when activated, unlike

other contour following products on

the market

• Reduces potential equipment damage

from nozzle collisions

• Simple setup and operation

• No special programming required

• No requirement to map the elevation

of your material—simply move the

nozzle to where you want to begin

cutting and push start

• Electrical connections armored

for durability

• Robust sealing to withstand the

abrasive waterjet environment

• No matter where you are located

in the world, you’ll receive effective

technical support to ensure your CSTF

is operating at its highest levels. With

hundreds of active units in the field,

our technicians are strategically

located to meet customer needs.

the required height adjustments, maintaining

the necessary cutting standoff (typically within

± 0.020”). A collision detector pauses jet motion

if obstructions are in the path of the nozzle.

CSTF

The OMAX Technology

Guarantee entitles you, as

the original owner, to free

OMAX software upgrades

for the life of the machine.

Page 2

OMAX Collision Sensing Terrain Follower

Shown on the Tilt-A-Jet

Best Applications

• Great for large sheets of nested parts

• Great for materials that stress relieve while cutting

• Ideal for cutting large parts on uneven or warped sheets

• Assists in cutting hard, smooth, or non-cosmetic surfaces

Requirements

• Microsoft Windows

Contact OMAX Customer Service

for information if you are running DOS

• Motorized Z-Axis or Tilt-A-Jet

• OMAX Software version 11 or greater

May experience reduction in travel with

OMAX Models 55100, 5555, 2652, and

2626. Contact OMAX for more information.

®

About OMAX

OMAX has the industry leading patented

abrasivejet controller with a built-in expert

system. Our exclusive “Compute FirstMove Later” motion control system

automates most programming and tool

setup work, virtually eliminating the need

for extensive operator training. Plus,

with free OMAX Intelli-MAX® Software

upgrades for the life of the machine and

our ongoing commitment to advance the

efficiency of our technology and software,

OMAX saves you time and money.

For information on what other OMAX

products and accessories can do for you,

call us today at 800-838-0343 or visit

our website at www.omax.com.

Improvements

• Offers a more robust sensing mechanism

• Equipped with more stable sensor mounting

• Auto-disables during machine shutdown

• Foot is more rigid and easily removed without tools

Note: Specifications subject to change without notice.

OMAX Corporation

21409 72nd Ave South, Kent, WA 98032

253-872-2300 tel 253-872-6190 fax

1-800-838-0343 toll-free

WWW.OMAX.COM website

Printed in the U.S.A © October 2010 All rights reserved. S-0030

Loading...

Loading...