Page 1

ACCESSORIES

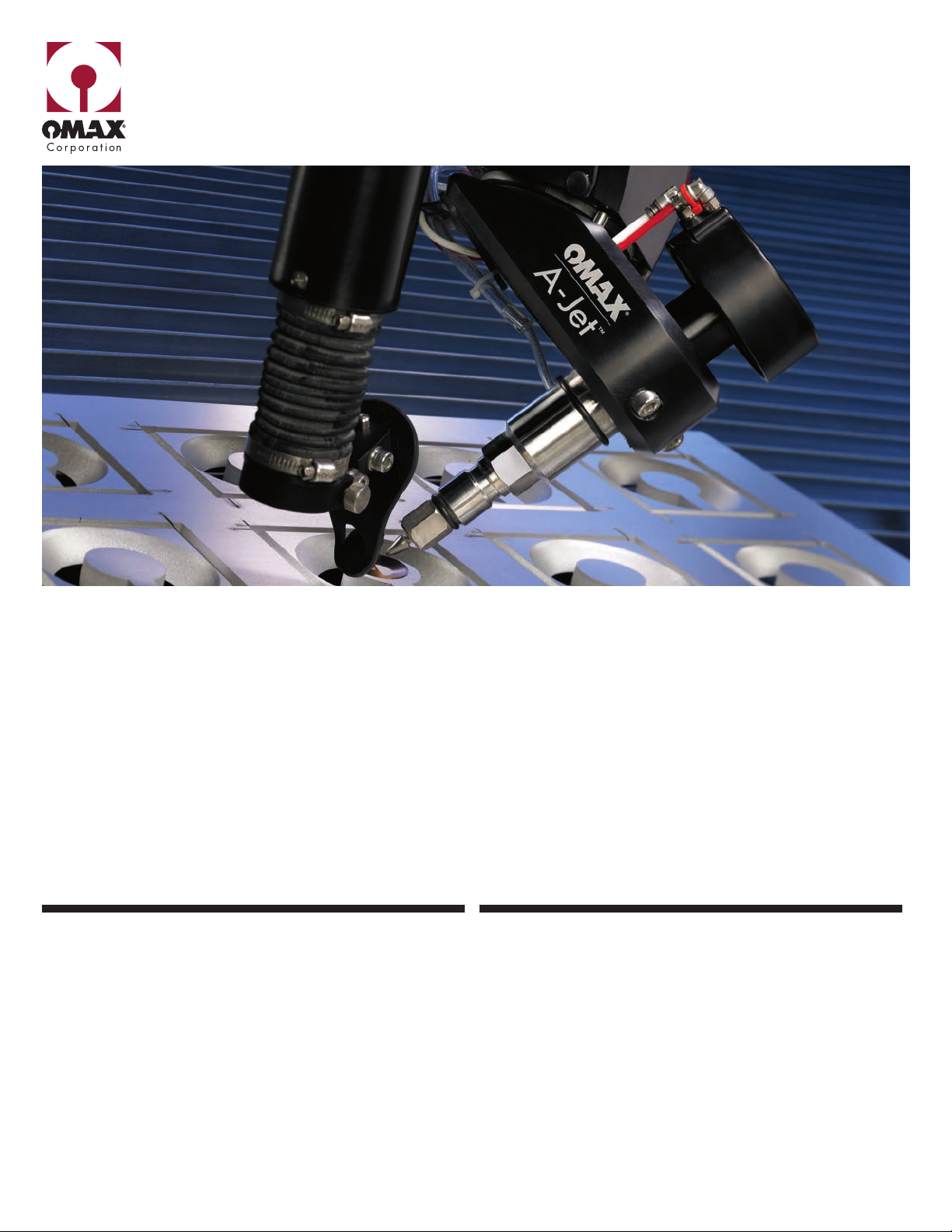

A-JET

Shown with optional terrain follower

OMAX A-Jet

The patent-pending A-Jet® is a complete software-controlled, multi-axis accessory that features the exibility to automatically

compensate for taper, as well as cut severe angles up to 60° off vertical. The A-Jet cuts countersunk holes and precision shapes with

beveled edges at angles specied by the user. The accessory supplies additional axes of motion, allowing the operator to fabricate

and shape metal edges for weld preparation. The dynamic A-Jet is capable of a high level of positioning accuracy, resulting in

parts that need no secondary nishing.

FEATURES

• Cutting angle ranges from 0° to 60°

• Three modes of taper compensation

• Supplied with a MAXJET® 5i Nozzle, which includes an

OMAX High Angle Fusible Mixing Tube

• Designed for high ow/high power abrasive waterjet

applications with multiple pumps by using large diameter

tubing with minimal pressure loss

• Features a xed focal point design, where the XYZ axes do

not need to move as the head tilts

BENEFITS

• Eliminates secondary machining and grinding for fabrication processes,

ideal for common welding projects

• Easily creates countersinks and weld-ready edges

Precision angular motion can create unique 3D parts

•

• Fully automatic taper compensation to minimize taper on nished parts

• OMAX-unique High Angle Fusible Mixing Tube protects precision

mechanism

Made in the USAWWW.OMAX.COM

Page 2

A-JET

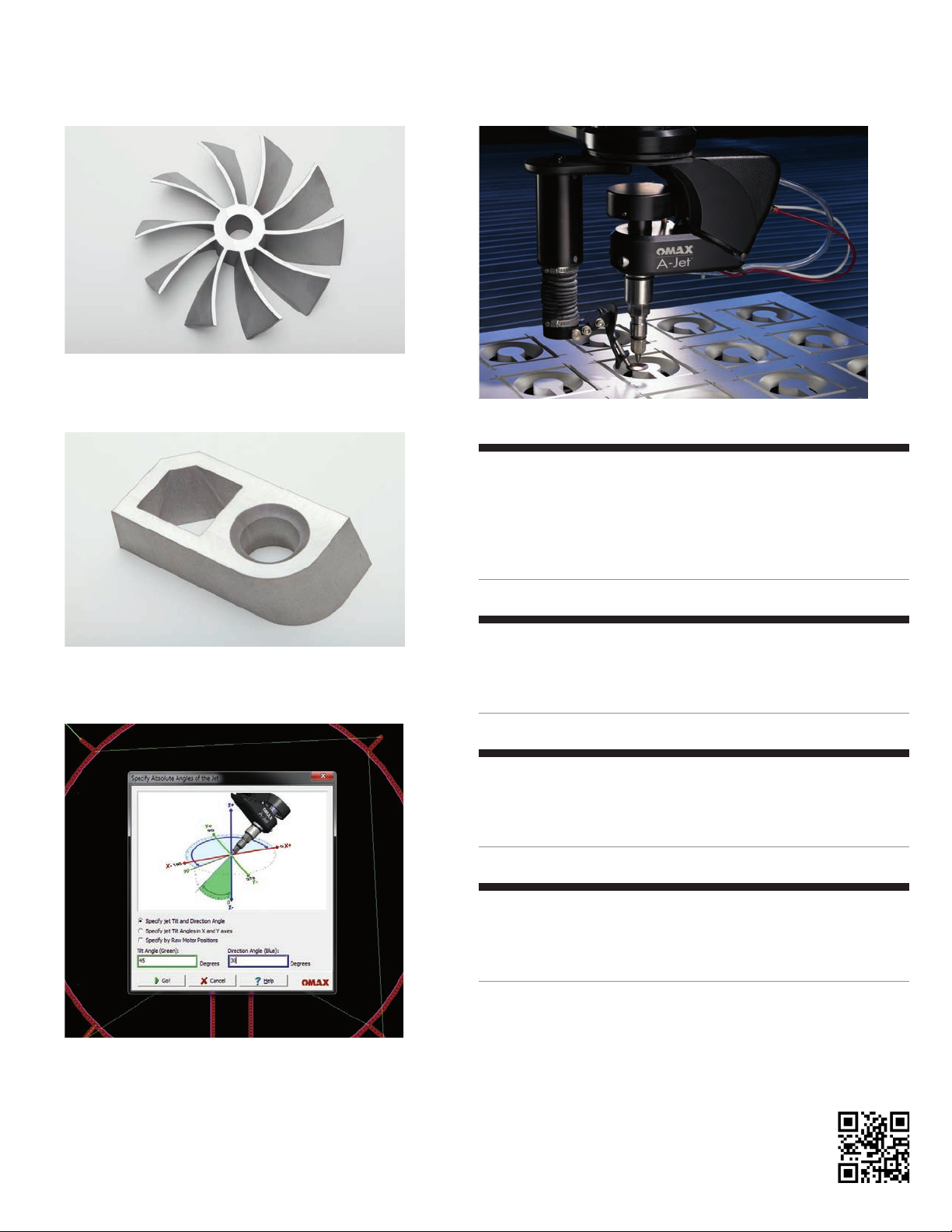

Precise and complex three dimensional parts become a

reality with the OMAX A-Jet.

3D FUNCTIONALITY

With the A-Jet, 3D parts are now possible on an abrasive waterjet.

The continuous precision 5-axis movement of the A-Jet cutting head allows

for detailed 3D shapes to be cut from a wide variety of materials. With the

combination of the A-Jet and the optional Rotary Axis, the OMAX JetMachining

Center becomes even more versatile, allowing for complex and challenging 3D

shapes to be cut, such as beveled pipe ttings.

The A-Jet makes cutting bevels simple, and software controls

help to eliminate taper.

The Intelli-MAX Software provides full control over the A-Jet,

including manual tilt and direction angle input.

OPTIONS

• Terrain Follower automatically adjusts to accommodate warped at plate

• Rotary Axis allows for complex 6-axis 3D parts and precision beveled pipe

ttings

• 0.030” Fusible Mixing Tube for ner kerf size*

REQUIREMENTS

• A bridge-style OMAX JetMachining® Center (for cantilever-style OMAX

JetMachining Centers, contact an OMAX sales representative for details)

• OMAX 9-axis PC-based controller

• OMAX Intelli-MAX 18 Software Suite or later for taper compensation

SPECIFICATIONS

• Positioning Accuracy: ±0.09° (±6 arc minutes)

• 0.042” High Angle Fusible Mixing Tube standard

• Z-axis travel: 6” (152mm), up to 8” (203mm) when using shorter table slats in

the Catcher Tank

*Using the 0.030” size greatly reduces mixing tube life in exchange for higher

precision kerf size.

Specications subject to change without notice.

600050B January 2014

WWW.OMAX.COM

Made in the USA

OMAX CORPORATION

21409 72nd Avenue South

Kent, WA 98032

TEL 1-253-872-2300 / 1-800-838-0343

FAX 1-253-872-6190

Loading...

Loading...