Page 1

Accessory Specifications

PRECISION ABRASIVE WATERJET ACCESSORIES

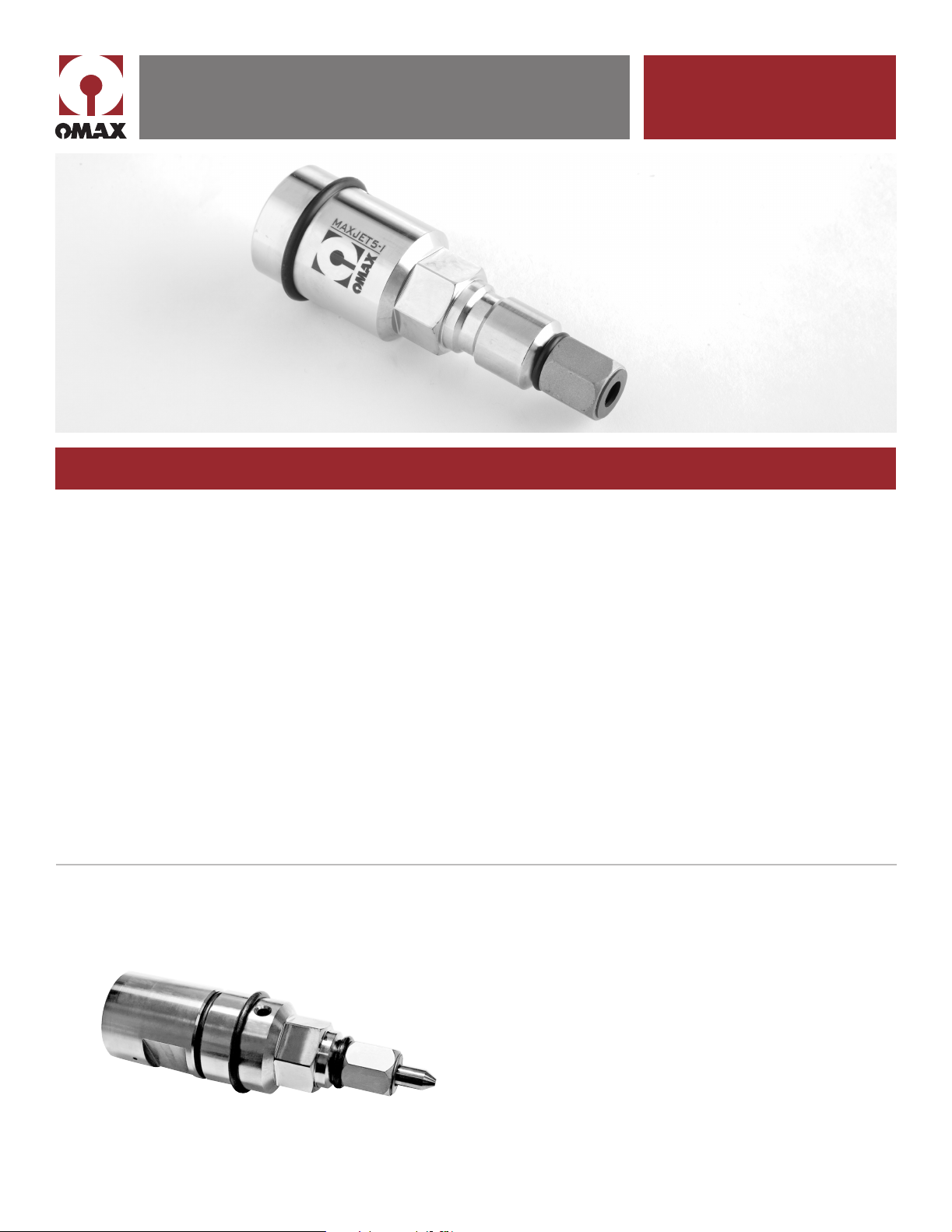

OMAX® MAXJET®5i Nozzle

The standard long-life integrated nozzle

Warranted to last 500 hours or more*, the

MAXJET 5i combines OMAX precision with

rugged durability and convenience. This onepiece factory-aligned, integrated assembly

eliminates the need to rebuild the nozzle body

– simply replace the entire nozzle body when

necessary. The MAXJET 5i also provides more

accurate and consistent jet alignment over the

life of the nozzle.

* Warranty prorated for use

NOZZLES

MAXJET 5i Standard Feature

• High quality nozzle components - diamond orifice

and carbide disc are permanently fixed inside the

mixing chamber and nozzle body to ensure precise

internal component alignment

MAXJET 5i Benefits

• Get better quality cut parts

• Completely integrated nozzle body comes ready to

install

• Reduce downtime – no more nozzle body rebuilds!

• Experience overall lower operating cost compared to

traditional nozzles

• Prolong mixing tube life by generating a more accurate

jet stream to reduce internal contact with abrasive

OPTIONAL NOZZLES

MAXJET 5i MINIJET Standard Features

• High quality nozzle components include mixing cham-

ber, carbide disc, and diamond orifice permanently

integrated and aligned within the nozzle body

• Cuts at a narrower width (between 0.020" and

0.025")

MAXJET 5i MINIJET Benefits

• No more nozzle body rebuilds!

• Cut intricate, delicate parts with no distortion or

secondary machining

• Reduce wasted material when cutting precious materials

• Expected life 500 hours or more (limited warranty*)

Page 2

PRECISION ABRASIVE WATERJET ACCESSORIES

OMAX® 7/15 MINI MAXJET®5 NOZZLE

• Nozzle kit includes an excess flow dump valve

assembly, abrasive orifice, dump valve orifice

for the pump, abrasive feed tubing, and

abrasive agitator

7/15 MINI MAXJET 5 Benefits

• Generates less wasted material by making narrower

cuts – a distinct cutting advantage when working

7/15 MINI MAXJET 5 Standard Features

• Achieves finer precision cutting with a 0.007"

orifice and a 0.015" mixing tube

• Narrower jet stream can carry finer abrasive such

as 220 HPA

OMAX® MAXJET®5 WATER ONLY NOZZLE

with precious metals and materials

• Cut intricate, delicate parts with no distortion or

secondary machining

• Designed to be a compact nozzle with a single

abrasive feed tube

MAXJET 5 Water Only Standard Features

• Since there is no mixing tube in the assembly,

the kerf width is based on the diameter of the

orifice (available orifice sizes range from 0.010" to

0.014")

About OMAX

OMAX has the industry leading patented

abrasivejet controller with a built-in expert system. Our

exclusive “Compute First-Move Later” motion control system

automates most programming and tool setup work, virtually

eliminating the need for extensive operator training. Plus,

with free OMAX Intelli-MAX® Software upgrades for the life

of the machine and our ongoing commitment to advance

the efficiency of our technology and software, OMAX saves

you time and money.

• Jewel orifice is positioned lower in the nozzle

assembly, therefore closer to the work piece

• With Intelli-MAX® Software, you can select the

“water only” cutting quality to deactivate the

abrasive valve

MAXJET 5 Water Only Benefits

• Effectively cut soft material (such as rubber, foam,

wood, etc.) without abrasive

• Save on consumable costs by not using wear

components such as mixing tube, mixing chamber,

or chamber disc

Connect and follow OMAX for the latest news

in waterjet technology.

The OMAX Technology

Guarantee entitles you, as

the original owner, to free

OMAX software upgrades

for the life of the machine.

OMAX Corporation

21409 72nd Ave South, Kent, WA 98032

253-872-2300 tel 253-872-6190 fax

1-800-838-0343 toll-free

WWW.OMAX.COM website

Printed in the U.S.A © January 2012 All rights reserved. S-0055

Loading...

Loading...