Page 1

PRECISION ABRASIVE WATERJET SYSTEMS

OMAX 160X Series JetMachining Center

160X SERIES

The OMAX 160X Series JetMachining Center is the largest OMAX machine, with lengths exceeding fty feet. Utilizing the

innovative and precise Intelli-TRAX® linear drive technology designed exclusively for the abrasive waterjet environment, the

160X Series is a robust and reliable system that maximizes both machine time and prot margins. Innovative accessories such

as the DualBRIDGE, A-Jet®, and Rotary Axis greatly expand the versatility of the 160X Series with multi-axis, multi-head cutting

capabilities.

FEATURES BENEFITS

• Fastest cutting speeds and best precision compared to any abrasivejet in

the industry and is backed by our exclusive Intelli-MAX® Software with real

world cutting data

• Programmable Motorized Z-Axis with a precision OMAX MAXJET®5i Nozzle

Assembly can boost cutting productivity and process efciency

• Increase machining capacity with optional DualBRIDGE system

• Low maintenance, high reliability scissor-style hard plumbing

• Drive system sealed against water, dirt, and grit.

• High efciency Generation 4 EnduroMAX pump systems available up to

100 hp with operating efciencies up to 90%

• Rapid Water Level Control for quiet and clean submerged cutting

• Bulk Abrasive Feed Assembly transports garnet from the assembly’s large

hopper into the Zero Downtime Hopper located at the Motorized Z-Axis

• Factory-tested for quality and precision

• Machines a wide range of materials and thicknesses, from metals to glass

• Does not create heat-affected zones or mechanical stresses

• No tool changes and minimal xturing reduces setup by 50% or more

• No additional water required for pump cooling

• Efcient footprint for minimal oorspace utilization

• Leaves behind a satin-smooth edge, reducing secondary operations

• No noxious gases, liquid and oils used in, or caused by, the machining process

• EnduroMAX pump technology delivers the highest nozzle horsepower in the

industry for faster and more efcient cutting

• Completes most work below 80 dBA

• Environmentally “green” system with quiet and clean operation with low

electrical consumption

• High reliability pump design capable of over 1,000 hours between

maintenance

Made in the USAWWW.OMAX.COM

Page 2

160X SERIES

MACHINE DIMENSIONS

Footprint (with controller)

Weight (tank empty)

Height (with scissor plumbing) 10’ 0” (3,658 mm)

Operating Weight

35’ 0” x 22’ 6” to 55’ 0” x 22’ 6”

(10,688 mm x 6,858 mm to

16,764 mm x 6,858 mm)

21,000 lbs to 51,000 lbs

(9,525 kg to 23,133 kg)

83,000 lbs to 199,000 lbs

(37,648 kg to 90,265 kg)

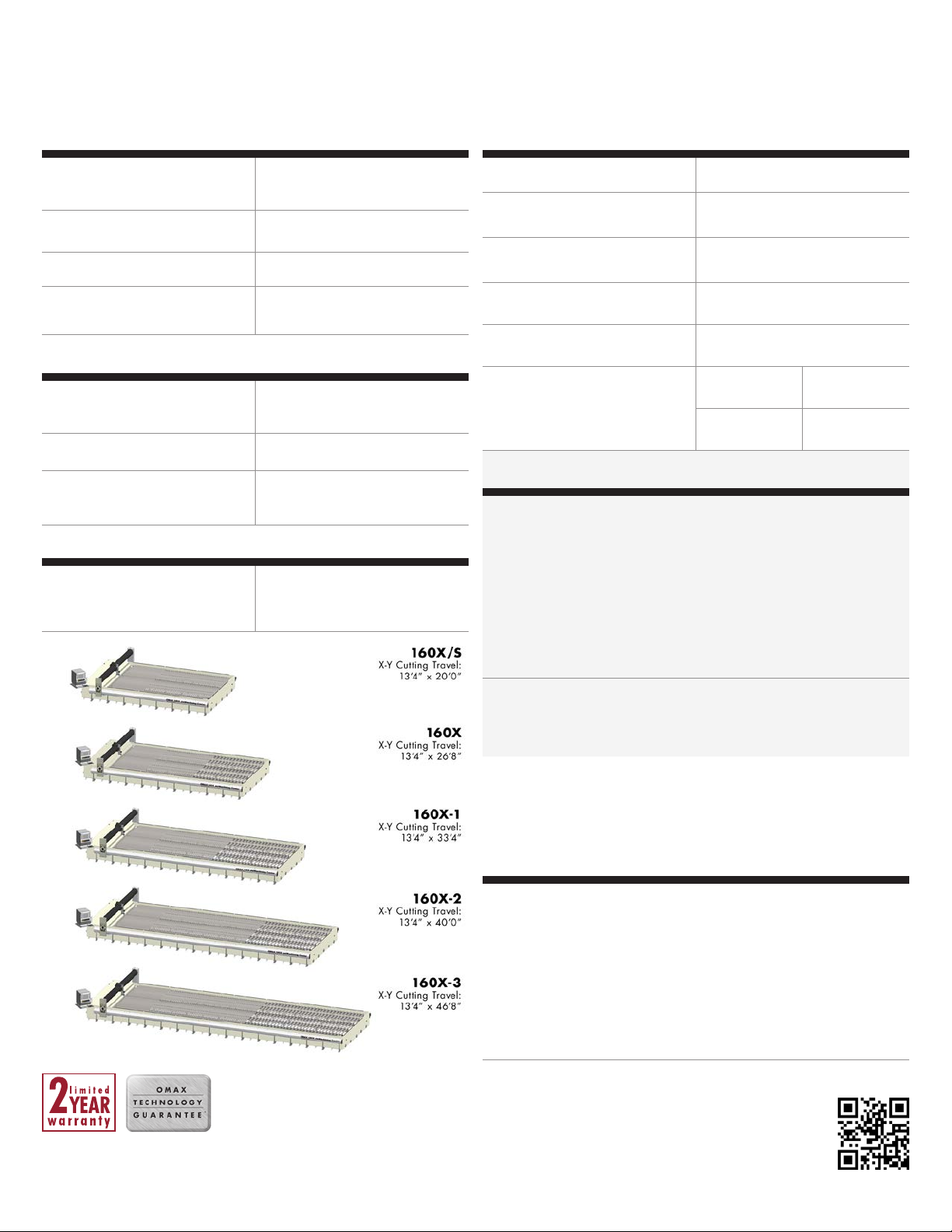

WORK ENVELOPE

X-Y Cutting Travel*

Z-Axis Travel (with Motorized Z-Axis)* 8” (203 mm)

Table Size

26’ 8” x 13’ 4” to 46’ 8” x 13’ 4”

(8,128 mm x 4,064 mm to

14,224 mm x 4,064 mm)

28’ 3” x 14’ 9” to 48’ 6” x 14’ 9”

(4,572 mm x 4,496 mm to

14,783 mm x 4,496 mm)

DRIVE DESCRIPTION

• Closed loop, digital drives

• Brushless servo motors

• Intelli-TRAX drive technology with

linear encoders in X-Axis

• Precise Motorized Z-Axis

STANDARD MODEL SPECIFICATIONS

Material Support Slats 4" x 1/8" Galvanized Steel

Maximum Supported Material Load 400 lbs/sq ft (1,950 kg/sq meter)

Electrical Requirements

Noise Level

Speed 180 in/min (4,572 mm/min)

Accuracy of Motion at 70˚ F

3-Phase, 380-480 VAC ±10%,

50-60 Hz

Below 80 dBA at one meter for

submerged cutting

Ballbar Circularity

(Over 12”)

Repeatability

±0.005”

(±0.076 mm)

±0.002”

(±0.051 mm)

OPTIONAL ACCESSORIES

• Tilt-A-Jet® Cutting Head for taper

compensation

• DualPUMP Package (redundant dual

EnduroMAX option up to 100 hp)

• Variable Speed SRS (VS-SRS)

• Collision Sensing Terrain Follower

• OMAX Drill Head

• Rotary Axis

• A-Jet Articulated Cutting Head

• Water-only MAXJET 5 for cutting soft

materials

• OMAX Mini MAXJET 5i Nozzle

• Precision Optical Locator (POL)

• Manual Tilt Z-Axis

• Stone Cutting Kit

• Laminar Filter

• Waterjet Brick Kit

• Catcher Tank Armor Plating

• Material Holding Kit

• Laser Feature Finder

The OMAX Technology Guarantee

entitles you, as the original owner, to

free OMAX software upgrades for the

life of the machine.

Specications subject to change without notice.

600042B January 2014

*Optional accessories may reduce travel. Images may show optional

accessories. For a complete list of accessories, contact an OMAX sales

representative. Pumps are built to meet UL and CE specications. Contact

OMAX for detailed utility requirements.

ABOUT OMAX

OMAX is the global total solutions provider in advanced abrasive waterjet

systems. Our intuitive Intelli-MAX Software Suite simplies programming and

reduces setup times, increasing your productivity. OMAX engineers continue

to innovate technology for waterjet machining, from proven 4th generation

pump designs to cutting edge drive systems with micron-level accuracy. With

the largest abrasive waterjet support network in the world, OMAX continues to

shape the future of waterjets.

To see how an OMAX JetMachining Center can save you time and money, call

or visit our website and request a free part analysis today.

WWW.OMAX.COM

Made in the USA

OMAX CORPORATION

21409 72nd Avenue South

Kent, WA 98032

TEL 1-253-872-2300 / 1-800-838-0343

FAX 1-253-872-6190

Loading...

Loading...