OMAS Air-Fi AFT7, Air-Fi AFT9, Air-Fi AFT77 DUAL, Air-Fi AFT99 DUAL Installer And User Instruction Manual

Page 1

CLIMATIZZATORE DA PARETE CON POMPA DI CALORE

WALL TYPE AIR CONDITIONER WITH HEATING PUMP

MANUALE DI INSTALLAZIONE E USO

INSTALLER AND USER INSTRUCTION MANUAL

GAS REFRIGERANTE R410A

COOLING GAS R410A

Page 2

1. GENERAL INFORMATION

1.1 GENERAL ADVICES

1.2 RECEIVING THE PRODUCT

1.3 HANDLING

1.4 OPERATING CONDITIONS

1.5 DISPOSAL OF THE PRODUCT

2. INSTALLATION

2.1

CHOOSING THE AIR FLOW DIRECTION

2.2 WHERE TO INSTALL THE AIR CONDITIONER

2.3 INTERNAL UNIT INSTALLATION

2.4

2.5

PREPARING THE COOLING LINES

CONNECTING THE PIPES ON THE INTERNAL UNIT

2.6 EXTERNAL UNIT INSTALLATION

2.7 REFRIGERANTS CIRCUITS

2.8

INDOOR/OUTDOOR UNIT MULTIFILAR WIRING DIAGRAM

2.9 EXTERNAL UNIT CONNECTION PIPES

2.10 VACUUM AND FILLING OPERATION

3. USE AND MAINTENANCE

3.1 REMOTE CONTROL FUNCTIONS

3.2 INSTRUCTIONS FOR USE

3.3 RESET OPERATION

3.4

3.5

MAINTENANCE

PROBLEM - POSSIBLE CAUSES / REMEDIES

ENVIRONMENTAL INFORMATION : this equipment contains fluorinated

greenhouse gases covered by the Kyoto Protocol. It should only be serviced or

dismantled by professional trained personnel.

GAS R410A,GWP( GlobalWarming Potential ) = 1975

INDEX

Page 3

1 GENERAL INFORMATION

1.1 GENERAL ADVICES

After having removed the packing, check that all the

content is intact and complete. In the event of noncompliance, contact the Retailer which sold you the

appliance.

The appliance should be installed and the

maintenance should be effected by a qualified

Company in accordance with the laws and

regulations in force in the country of installation.

Upon work accomplishing, this Company should

issue the owner the declaration of compliance of

installation with current regulations and standards

and with instructions given on this booklet.

These appliances have been designed to heat or

cool the air of rooms and should only be used for this

purpose, in compatibility with their performances

features. The manufacturer cannot be held liable for

damage caused to property or injury to persons or

animals due to incorrect installation, regulation and

maintenance or to improper use.

This air-conditioner contains R410-A refrigerant : at

the end of its use, operate with caution during the

disposal, in order to not damage the cooling

connections and the battery.

Do not switch on the unit before having totally

assembled it and before having put it in its correct

operating position.

Before starting the appliance, check that it is

correctly earthed, according to the legislation in force

in the country concerned.

BASIC SAFETY RULES

Using electrical appliances implies the observance of

basic safety rules, such as those given below:

Children and unassisted handicapped persons are

not allowed to use the air-conditioner.

Do not touch the air-conditioner when foot or parts

of the body are wet or damp.

Do not carry out any cleaning operation until the airconditioner has been disconnected from the mains

electricity supply by putting the installation on/off

switch to “off”.

Do not pull, remove or twist the electric cable

connected to the air-conditioner, even if

disconnected from the mains electricity supply.

A too low temperature is harmful to health as well as

being a useless waste of energy.

Avoid prolonged direct contact with the flow of the

air. Avoid the room being closed for a long time.

Periodically open the windows to guarantee a correct

change of air. During storms put the on/off switch to

“off” position.

This instruction booklet is an integral part of the

appliance and should be therefore carefully

preserved and always accompany the appliance,

also in the event of transfer to another owner or user

or another installation. Should the booklet be

damaged or lost, please request a copy to your

Technical Assistance.

Repair or maintenance works must be carried out by

Technical Assistance or by qualified technicians in

compliance with the instructions given in this booklet.

Do not alter the appliance, since hazardous

situations could be created while the manufacturer of

the appliance will not be liable for any damage or

injury caused.

Before staring the installation it is suggested to

foresee an omnipolar switch, fixed in accessible

position, with contacts opening distance equal or

superior to 3 mm.

This machine has been submitted to a 40MPa

testing pressure.

Do not sit or stand on the appliance or put anything

at all on top of it.

Do not spay or throw water directly into the airconditioner.

Do not introduce sharp or pointed objects through

the air intake or outlet grids.

Do not access internal parts of the air-conditioner

without having put the on/off switch to “off” position.

Do not leave the packing material ( cardboard,

staples, plastic bags, etc..) to be taken by of children,

but dispose it properly since it could be a source of

danger.

Do not alter the safety or regulating devices without

the permission and instructions of the air-conditioner

manufacturer.

ENGLISH -2-

Page 4

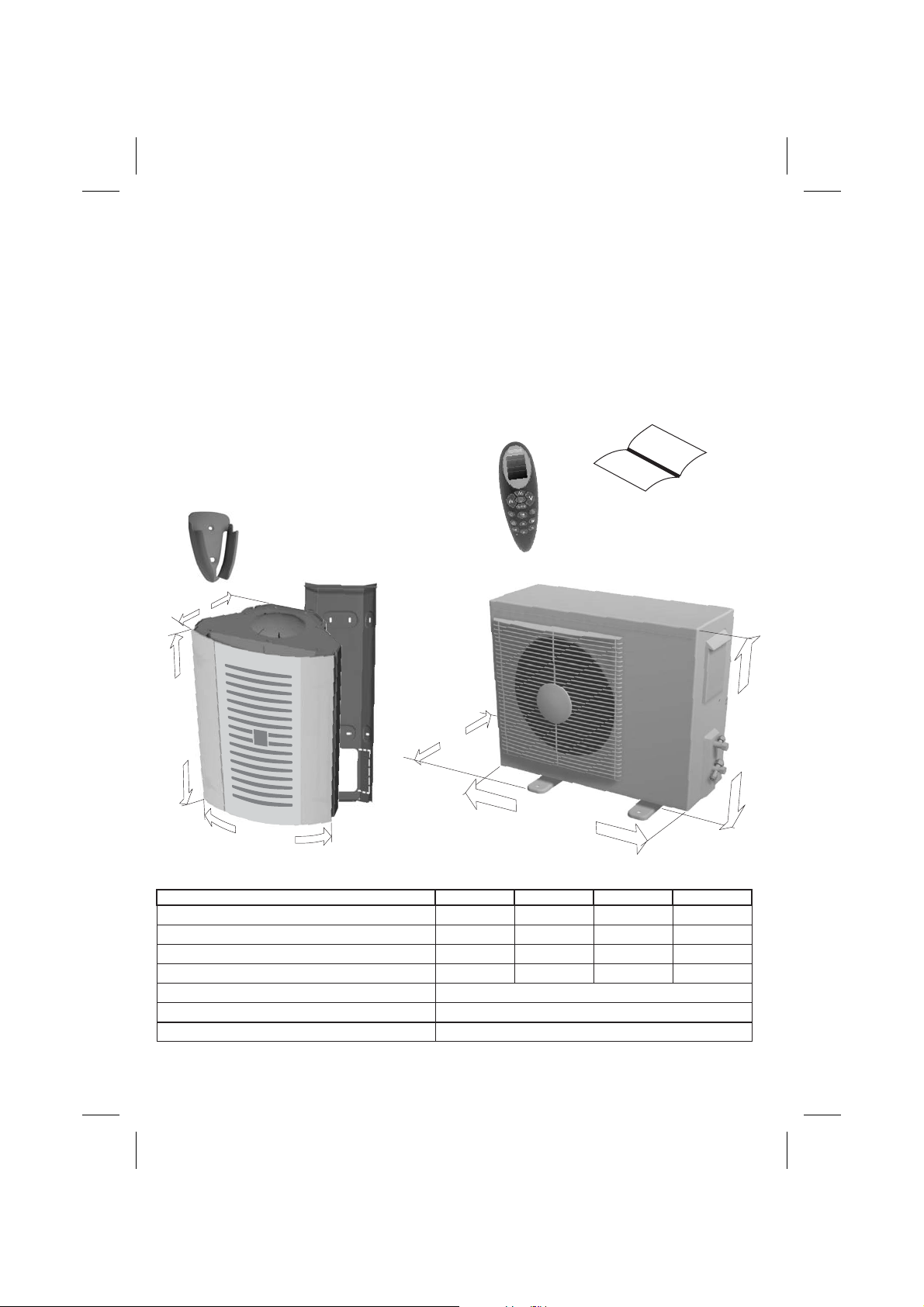

1.2 RECEIVING THE PRODUCT 1.3 HANDLING

The air-conditioner is delivered in two different

packings protected by card-board and is

accompanied by:

- Instruction booklets.

- Wall-mounting support.

- Supplied accessories for installation

operation.

- Remote control.

- Connection pipes.

- Drainage pipes

- Electrical connection cables.

Packaging components must be disposed

correctly and not left without control to

children, since they are a potential source

of danger

REMOTE CONTROL WALL

MOUNTING SUPPORT

WALL MOUNTING SUPPORT

D

The air-conditioner should be handled by

technical staff using suitable equipment for

the appliance weight.

It is advisable to remove the packing only when

the air-conditioner has been located in the point

of installation.

During transportation the outdoor unit must be

kept in UPRIGHT position.

USER AND INSTALLER

BOOKLET

REMOTE CONTROL

H

W

INTERNAL UNIT

Model

Internal unit dimensions H/W/D(cm)

Internal Unit weight (Kg)

External Unit dimensions H/W/D(cm)

External Unit weight (Kg)

Rated voltage (V)

Cooling gas

Additional cooling gas per each meter ( more than 5m ) g/m

D

W

EXTERNAL UNIT

AFT7

54,5/35/25

7,1 7,1 7,1

49,5/67/30

27,5 28,5 52

ENGLISH -3-

AFT9

54,5/35/25 54,5/35/25

49,5/67/30

220-240

R410 A

20

AFT77 DUAL

61/91/34,5

H

AFT99 DUAL

54,5/35/25

7,1

61/91/34,5

53

Page 5

1.4 OPERATING CONDITIONS

COOLING MODE

- Internal temperature from 18°C 47% R.H. to 32°C 47% R.H.

- External temperature from 18°C 41% R.H. to 43°C 41% R.H.

HEATING MODE

- Internal temperature from 18°C 47% R.H. to 27°C 47% R.H.

- External temperature from -5°C to 24°C 41% R.H.

1.5 IMPORTANT INFORMATION FOR CORRECT DISPOSAL OF THE

PRODUCT IN ACCORDANCE WITH EC DIRECTIVE 2002/96/EC

.

At the end of its working life, the product must not be disposed of as urban waste.

It must be taken to a special local authority differentiated waste

collection centre or to a dealer providing this service.

Disposing of a household appliance separately avoids possible negative

consequences for the environment and health deriving from inappropriate

disposal and enables the constituent materials to be recovered to obtain

significant savings in energy and resources.

As a reminder of the need to dispose of household appliances separately,

the product is marked with a crossed-out wheeled dustbin.

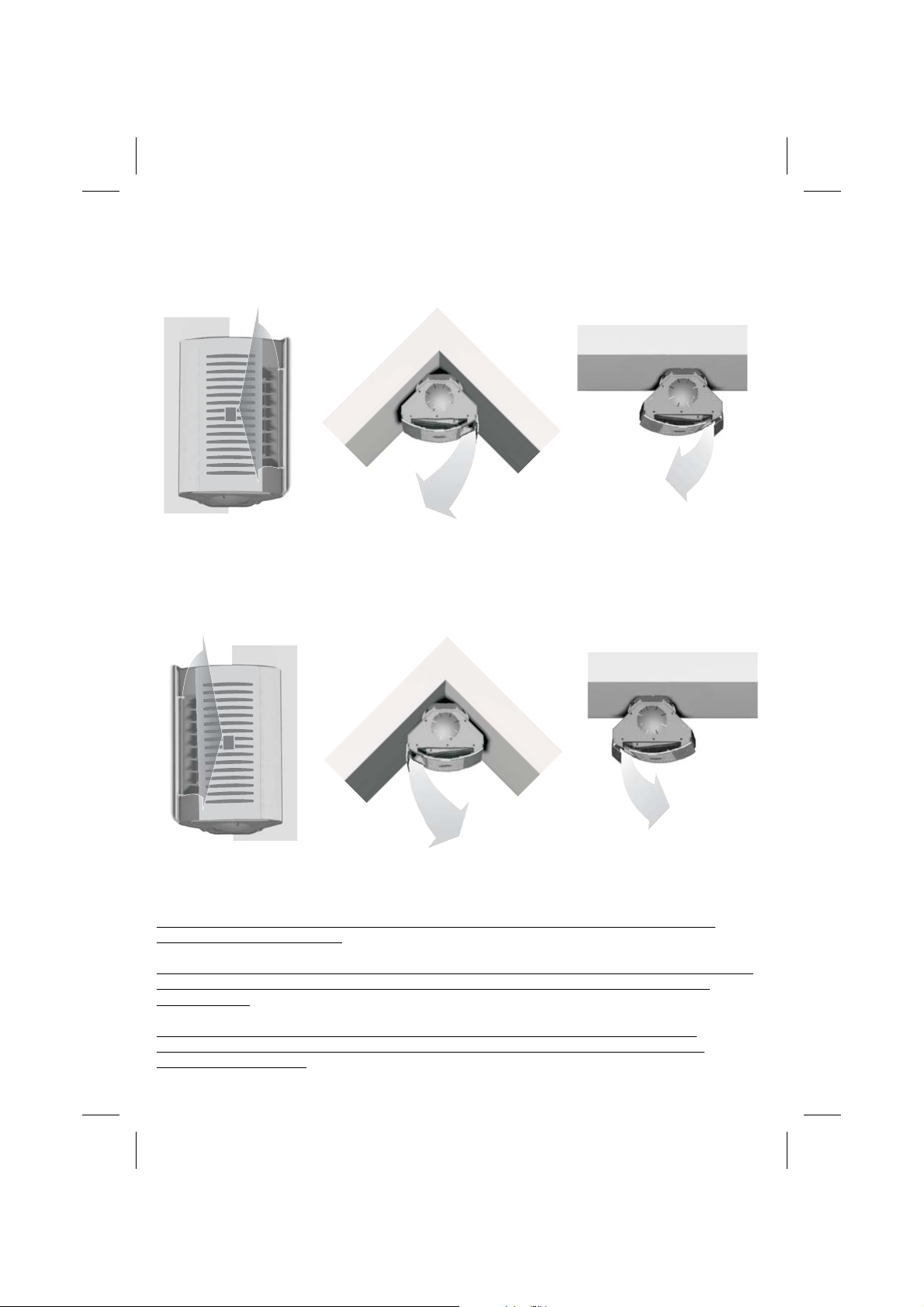

BS PLUG WIRING

Wiring Instructions: Should it be necessary to change the plug please note the wires in the

mains lead are coloured in accordance with the following code :

BLUE - NEUTRAL

BROWN - LIVE

GREEN AND YELLOW - EARTH

As the colours of the wires in the mains lead of this appliance may not correspond with the

coloured markings identifying the terminals in your plug, proceed as follows:

1. The wire is the and must be connected to the terminal which is marked with

BLUE NEUTRAL

the letter or coloured .

2. The wire is the and must be connected to the terminal which is marked with the

letter or coloured

3. The is the and must be connected to the terminal which is marked

with the letter or or coloured .

4. Always ensure that the cord grip is positioned and fastened correctly.

If a fused plug is used it must be fitted with a fuse.

If in doubt consult a qualified electrician.

Wiring for a 13 Amp Plug (BS1363)

Please note. The Earth Terminal is

Marked with the letter or Earth Symbol .

N BLACK

BROWN LIVE

L RED.

GREEN/YELLOW EARTH

E GREEN OR GREEN/YELLOW

13A (BS 1363) 13A

E

Earth(Green/Yellow)

13 AMP

ENGLISH -4-

Neutral - N

(Blue)

Live - L

(Brown)

Page 6

2.1 CHOOSING THE AIR FLOW DIRECTION.

THE UNIT IS SUPPLIED WITH THE AIR FLOW EXIT POSITIONED IN THE RIGHT SECTOR:

THIS ALLOWS THE AIR DIFFUSION FROM RIGHT TO LEFT SIDE.

IN CASE THE USER WANTS TO MODIFY THIS STANDARD AND DIRECT THE AIR DIFFUSION

FROM LEFT TO RIGHT SIDE

FOLLOW THE INSTRUCTIONS CONTAINED INSIDE THE INSTALLER PARAGRAPH.

ATTENTION: THESE OPERATIONS CAN BE EFFECTED ONLY BY A QUALIFIED AND

AUTHORIZED TECHNICIAN.

FOR SAFETY AND PRACTICAL REASONS, WE SUGGEST TO ANALYSE THE POSSIBILITY

OF MODIFYING THE AIR EXIT DIRECTION BEFORE STARTING THE INSTALLATION

PROCEDURE.

IF THE MODIFICATIONS NECESSARY TO CHANGE THE AIR EXIT OCCUR AFTER

INSTALLATION, BEFORE STARTING THE OPERATION ALWAYS DISCONNECT THE

ELECTRICAL SUPPLY.

ENGLISH -5-

Page 7

!

Remove the screws that fix the upper and lower

closing caps.

!

Remove the screws that fix the left side frontal

panel on the upper and lower part of the indoor unit.

!

Extract the front panel by pulling it out.

!

Remove carefully the central panel, by rolling it

from right to left side.

ENGLISH -6-

Page 8

!

Remove the screws fixing the display

support and rotate it of 180°. Pay attention to

place in the correct position the electrical

cables.

!

Position the display back by using the

screws previously removed. Rotate the indoor

unit of 180°, by maintaining the air exit on the

left side.

!

By maintaining the front panel with the brand

plate in the lower part, insert it back by rolling

it from right to left side.

!

Both the pipes located in the rear part of the

indoor unit must be rotated up to 180°:

!

Remove the 4 screws (A) that fix the plastic

protection covering the cooling circuit.

A SPECIAL ATTENTION SHOULD BE PAID

DURING THE FOLLOWING STEPS :

!

Take the indoor unit pipes out of 15°

(PHASE 1)

(A)

!

Rotate the terminal part, gently, up to 180°,

avoiding possible bendings on the curve

(PHASE 2) by maintaining the pipes blocked

in the (B) position.

The internal unit is equipped with condense

drainage connection option both on the upper

and lower part. If the air exit position should

be changed, the condense drainage position

must be modified too : take the pipe and the

plug positioned on the drainage connection off

and then invert their position.

!

Put all the removed platics parts back to their

original position and fix them with the screws.

!

Position the indoor unit on the upper part of

the wall mounting bracket and rotate it up to

45°.

After these operations the air conditioner is

ready to be installed with air exit located on its

left side.

ENGLISH -7-

Page 9

IMPORTANT:

To not compromise the air-conditioner integrity, do not install it among windows or doors.

If this installation is however necessary, put a stop system on the door/window, in order

to avoid any inconvenience.

·

To not compromise the operating of the air-conditioner, do not install it near curtains or

similar

ENGLISH -8-

Page 10

2.2 SELECTING THE LOCATION

The place of installation should be arranged by the

installation designer or by a technically competent

person and should take into account technical

requirements as well as relevant current laws and

regulations which envisage the obtaining of specific

permits (e.g. town-planning, architectural, fire,

environmental pollution regulations, etc. ); it is

therefore advisable to apply for and obtain the

necessary permits before installing the airconditioner.

The air-conditioner should be installed by a qualified

Company in compliance with relevant laws and

regulations in force inthe country of installation.

Before starting installation take intoconsideration:

- The position of the indoorandoutdoor unit,

- The minimum technicalspaces,

- The maximum lengthof the refrigerant lines

- The difference inlevel between the appliances

- The presence ofother heating sources.

- The possibility of draning the moisture.

.

2.3 INTERNAL UNIT INSTALLATION

The wall-mounting support allows two different

solutions:

A) Wall mounting installation

B) Corner area installation.

A) WALL MOUNTING INSTALLATION

!

Unscrew the two screws in the inferior part of the

unit to remove the wall mounting support (Fig.1)

!

Lean on the wall the support, in the foreseen

installation area, check the level and the distances

(Fig.2)

!

Mark with a pencil inside the fixing holes

(B). (Fig.2)

Remove the support.

!

Make two holes in correspondance to the pencil

!

marks.

If the pipes have to pass through the wall in X

!

direction (Fig.4), drill a hole ø 70/80 mm inclined of

3-5° downward in correspondance to the (B)

area (Fig.2).

If the direction is Y, (Fig.4), take away the pre-

!

sheared metal part, in the selected direction.

!

In case the upper pre-shared part should be

removed too, the mounting bracket must be fixed

through the holes located in C position and the

supplied washers must be interposed between the

bracket and the wall.

Fix the support through the 4 screws anchors and

!

the provided screws.

Avoid bending the copper pipes several times in

the same point, otherwise they could be

damaged

(Fig.3),

only

.

(A) and

ENGLISH -9-

ceiling

90°

20 cm

(A) (A)

20 cm 20 cm

wall

(A) (A)

180/200 cm

floor

X

Y

(C)

Fig.1

wall

(B)

Fig.2

3-5°

Fig.3

Y

Fig.4

Page 11

B) CORNER INSTALLATION

!

Unscrew the two screws in the inferior part of the

unit to remove the wall mounting support (Fig.1)

!

Lean on the wall the support, in the foreseen

installation area, check the level and the distances

(Fig.2)

!

Mark with a pencil inside the fixing holes

(B). (Fig.2)

Remove the support.

!

Make two holes in correspondance to the pencil

!

marks.

If the pipes have to pass through the wall in X

!

direction (Fig.4), drill a hole ø 70/80 mm inclined of

3-5° downward in correspondance to the (B)

area (Fig.2).

If the direction is Y, (Fig.4), take away the pre-

!

sheared metal part, in the selected direction.

In case the upper pre-shared part should be

!

removed too, the mounting bracket must be fixed

through the holes located in C position and the

supplied washers must be interposed between the

bracket and the wall.

Fix the support through the 4 screws anchors and

!

the provided screws.

Avoid bending the copper pipes several times in

the same point, otherwise they could be

damaged

(Fig.3),

only

.

(A) and

Fig.1

ceiling

20 cm

Corner area

(A) (A)

(A) (A)

3-5°

Fig.3

ENGLISH -10-

180/200 cm

floor

X

(B)

Fig.2

(C)

Y

50 mm

Fig.4

Page 12

2.4 PREPARING THE COOLING LINES:

- The cooling lines between the two units should be in

special copper pipes forcooling installation.

- Check the internal part of the pipes and eventually

remove dirt or dampness as they can interfere with

proper operation.

- The cooling lines should be singularly insulated with

polyurethane foam with closedcells.

- Plan theroute of thepipeline to reduce the length and

the number of bends as much as possible for best

performance of the system.Alwaysuse a pipe folder.

- After having cut the connection pipes, eliminate the

slight defects by maintaining the pipe opening

downward.

- For a correct flange operation, use a flange tool for

pipes and eliminate the eventualdefects.

- Check that the flangesdo not have anydefect.

- Removethe connectionslocated onthe indoorunit. A

little quantity of air will be expelled to show the good

condition of the circuit.

Not correct !

Correct !

- Screw andtighten the pipe unionwith manometric key

as per the followingdata:

OUTSIDE DIAMETER THIGHTENING COUPLE

mm

ø 6,35

ø 9,52

Inch

¼”

3/8”

Kg/m

1,8

4,2

During this operation keep the connections with

another key in order to avoid possible pipes twistin

g.

Attention:

Check the flanging with the above mentioned

images.

If the section is not correct, cut it away and

proceed with another one.

ENGLISH -11-

Copper

tube

1,3/2mm

Page 13

2.5 CONNECTING THE PIPES ON THE

INTERNAL UNIT

Hook the unit on the wall mounting support, by

matching intoAB.

Line up the pipes of the indoor unit together with the

ones of the outdoor unit and screw manually the

unions.

DO NOT FORCE THE SCREWING WITH TOOLS IF

THE LINE UP OPERATION ON THE THREAD

PARTS IS NOT PERFECTLY EFFECTED.

Then, tighten with the help of a dynamometric key by

respecting the details quoted in the previous page.

Put then the pipe insulating back to its position and

complete the operation by adding polyethylene tape.

It is advisable to insulate the moisture drainage pipe

with the cooling pipes in order to have the pipes all

together in one block (FIg.3).

B

A

Position back the unit and fix it on the wall mounting

support with the fixing screws placed in the bottom

part (Fig.4).

ENGLISH -12-

Page 14

CONDENSE DRAINAGE

The indoor unit is fitted with condense drain pipe

which a drainage hose ( inside 16 mm) should be

connected, leading to a suitable drainage outlet area.

Fasten the condensate drain pipe to the refrigerant

pipes with adhesive tape whenever the lines cross

through a wall; this is to prevent the condensate drain

pipes from being crushed.

The drainage pipe should have a 3-5° inclination

down towards the drain; it should never be inclined

upwards.

Check all the joints for leaks.

The condensate drain pipe should be inserted into the

couplings located on the bottom left or right part of the

indoor unit.

Carefully check the condensed water

outflows from thepipeeasily.

ENGLISH -13-

3-5°

Page 15

2.6 EXTERNAL UNIT

INSTALLATION.

The outdoor unit should be put in a position

that guarantees the minimum space for air

circulation and for allowing maintenance work

and connection of the refrigerant and electrical

lines.

30 Cm

70 Cm

100 Cm

8cm8

cm

30 Cm

70 Cm

IT IS ADVISABLE TO AVOID:

- Installation in cavitiesor air vents;

- Installation where obstacles or barriers could

cause recirculation of the expelledair.

- Installation in place with an aggressive

atmosphere.

- -Installation in confined places in which the

sound level of the outdoor unit could be

increased by reverberation orresonance.

- Installation in corners where dust, leaves or

similar could reduce the efficiency of the airconditioner by obstructing theair circulation.

- Installation in places where the air expelled by

the outdoor unit could enter inhabited rooms

through windows or doors, thereby causing

inconveniences to other people.

- Installation in a place where the air expelled

from the outdoorunit is againsta prevailing wind;

- Installation in aplace that is directsunlighted.

The outdoor unit can be installed on a floor or

on a flat surface or wall-mounted, by checking

if its weight is properly supported and there is

no transmission of vibration to the nearest

As the unit also operates in heating

rooms.

mode, during this operation, the condensed

water may be drained from the outdoor unit.

For this reason it is advisable to check if the

moisture drainage directly on the floor is

acceptable. If not, it is possible to collect the

moisture through a union elbow ( supplied

together with the unit ) connected to a drainage

pipe. In this way the moisture will be

discharged in a specific area.

In case of floor installing, before connecting the

drainage pipe to the union elbow, it is before

necessary to insert below the unit some

spacers to avoid vibrations: the spacers also

allow the necessary space to insert the union

elbow.

ENGLISH -14-

Page 16

2.7 REFRIGERANT CIRCUITS

ENGLISH -15-

Page 17

2.9

CONNECTING THE PIPES ON

THE EXTERNAL UNIT

Line up the pipes of the internal unit together

with the ones of the external unit and screw

manually the unions.

Do not force the screwing with tools if the

line up operation it is not perfectly effected.

Tighten then with the help of a dynamometric

key by respecting the details quoted in the

previous page :

After this, put the pipe insuting back and

complete the insulating operation with

polyethylene tape.

It is advisable to insulate the moisture drainage

pipe with the cooling pipes in order to have the

pipes all together.

Pipes length

The maximum length of the connection pipes is

20m. For more than 5m, pay attention to the

cooling quantity to add for each additional meter

of pipe ( Seesection 1.2 ).

If the vertical distance between indoor and

outdoor unit is more than 3m (max. 10m ), the oil

plug phenomenon can occur. To avoid this

phenomenon it is advisable the presence of a

siphon into the pipeline.

max 10 m

ENGLISH -16-

max 10 m

Page 18

2.10 VACUUM AND FILLING

OPERATION

Vacuumand filling of the circuit

The air-conditioner must be switched off.

- See Fig.(1):

1. Valvesplug.

2. Coolant cylinder valve.

3. Pin valve.

4. Vacuumline.

5. Connection pipe.

6. 3-way valve.

7. Vacuumpump.

8. Manometers group.

B Cooling tap.

C High pressure valve.

- Check the 2-way and 3-way valves

locks are closed Fig.(2)

- Take away the plug from the valve n°1

on the gas line coupling.

- Connect the vacuum line n°4 coming

from the manometers group n°8.

- Empty the installation, until the nominal

pressure of 0.3mBar is reached.

- Close the tap on the manometers group

n° 8 connected to the vacuum pump n°

7 and switch it off.

- Take away the plugs on the taps n°2

Fig.(2) and open the taps with the allen

spanner and let the cooling gas

contained in the outdoor unit circulating

Fig.(3).

- Screw and tighten the plugs n°2 on the

taps Fig.(2).

- Take away the vacuum line from the

valve n°3 and screw and tighten the

relative plug n°1.

Check with the leaking tester there are no

gas cooling leakages, particularly in

proximity of the couplings.

Check the correct operation of the airconditioner

Check the operating pressure through the

3-ways valve with the indoor unit set at the

following conditions :

Cooling mode;

High ventilation speed.

The correct pressure must be between 8

and 9 kg/cm2, with external temperature

more than 27°C.

ENGLISH -17-

Page 19

3. USE AND MAINTENANCE

3.1 REMOTE CONTROL

INSTALL AND CHANGE THE BATTERY

-Open the cover of battery case.

-Insert the battery (AAA, 2 pcs),

the positive must be same with the

mark on the plastic surface.

-Reinstall the cover of battery.

- Important: if pressing ON/OFF

button no icons are displayed, please

install the battery in the correct position.

- The exhausted battery must be

disposed responsibly.

REMOTE CONTROL FUNCTIONS

All the air-conditioners functions can be controlled, set

Or adjusted through the infrared remote control.

ICON

°C

FUNCTION

Automatic mode

Cooling mode

Dehumidifying

Heating mode

Time

--

Fan speed

Air direction

Timer off

Timer on

Sleep mode

Temperature

DISPLAY FUNCTIONS

RED LED switched on:

GREEN LED switched on:

YELLOW LED switched on:

BLUE LED switched on:

To switch on the unit, direct the remote

control toward the indoor unit.

power supply is connected.

compressor is on.

timer is on.

night mode is on.

ENGLISH -18-

Page 20

3.2 ISTRUCTION FOR USE WITH REMOTE CONTROL

- Press the button to switch on the unit.

COOLING FUNCTION

- Press the button until the cooling mode is set.

- Press the buttons to adjust the setting temperature.

- Press the button and select the fan speed among

high , middle , low or auto.

(In case AUTO is chosen, the fan speed is automatically

adjusted to keep it as high as needed to reach the setting

temperature).

SLEEPING FUNCTION

- Press the button until cooling /heating /auto .

- Press the buttons to select the temperature (not possible

in AUTO function).

- Press the button : when this icon in displayed, the

function is automatically set.

- Press again to cancel this function setting.

HEATING FUNCTION

- Press the button until the heating mode is set.

- Press the buttons to adjust the temperature.

- Press the button and select the fan speed among

high , middle , low or AUTO.

(In case AUTO is chosen, the fan speed is automatically

adjusted to keep it as high as needed to reach the setting

temperature).

DEHUMIDIFYING FUNCTION

- Press the button until the dehumidifying mode is set.

- Press the button to adjust the temperature.

- The fan speed is automatically set.

FAN FUNCTION

- Press the button until the fan mode is set.

- Press the buttons to adjust the temperature.

- Press the button and select the fan speed among

high , middle , low or AUTO.

ENGLISH -19-

Page 21

AUTO MODE

- Press the button until the AUTO mode is set.

The unit will work automatically to create an optimal comfort

temperature in the room.

AUTOMATIC SWITCHING OFF

- Press the button until the desired function.

- Press the buttons to select the temperature.

- Press the button and select the fan speed among

high , middle , low or auto.

(In case AUTO is chosen, the fan speed is automatically

adjusted to keep it as high as needed to reach the setting

temperature).

- Press the button.

- Adjust the switching off time pressing the button (hours) and

(Minutes).

Press again to confirm the setting.

- Once the time is over, the unit will switch off automatically.

To confirm the set function press the button again.

The setting will be cancelled if the button is pressed again.

AUTOMATIC SWITCHING ON

- With the unit switched on, select the desired function by

pressing the button..

- Switch off the unit.

- Press the button.

- Set up the switching time pressing the button (hours) and

(minutes).

- To confirm the operating mode, press the button.

The unit will start to work automatically according to the

selected time.

- To cancel the setting, press again the button.

CHOOSING THE AIR DIRECTION

- With unit switched on and while the the fan is working:

Press the button to obtain a wide ray of air diffusion.

If a fixed angle of ventilation is desired, press again the

button and choose the desired inclination of the flap.

To reach the best cooling effects, the internal unit is equipped

with deflectors to adjust the air diffusion in order to reach all the

possible areas.

ENGLISH -20-

Page 22

3.4 MAINTENANCE

INTERNAL UNIT

The maintenance should be done by cleaning

the indoor unit and the air filters.

FILTERS CLEANING:

The filters cleaning is necessary to keep the

unit efficiency. Clean the filters at least every

week.

How to proceed:

Disconnect the unit from the electrical supply.

!

Extract the filter through the practical handle

!

and pull it down until it is completely out.

As the filter has three different compositions,

the cleaning operations should be done as

follows:

Extract the filters B/C from their case.

!

Clean the / filters only with a vacuum

!

cleaner,paying the maximum attention.

Clean the filter by washing it with warm

!

water (max 40°C) and neutral detergent .

Rinse with water only and and let it dry in a

!

shadowy place (do not expose it to direct sun

rays).

When the filter is perfectly dry, insert it back

!

together with the other filters in their original

position.

!

Insert the filters inside the unit until they are

perfectly blocked.

BC

A

It is advisable to change theB/Cfilters

during the annual ordinary maintenance

( performed by a qualified technicain ) to

guarantee the best cooling performances.

ATTENTION: Do not use the air-conditioner

without filters: there is risk to seriously

damage the unit.

CLEANING THE INTERNAL UNIT:

Disconnect the unit from the electrical supply.

!

Take a cloth and wet it with some water and a

!

little quantity of neutral detergent: then clean

the external surfaces.

Do not use abrasive cloth, alcohol or gasoline

!

as the surfaces could be damaged.

Do not use cloths or sponges excessively

!

wet, to not create water stagnation that could

damage the unit and compromise the safety.

EXTERNAL UNIT MAINTENANCE

How to proceed

!

Disconnect the unit from the electrical supply.

!

Take a cloth and wet it with some water and a

little quantity of neutral detergent: then clean

the external surfaces.

!

Do not use abrasive cloth, alcohol or gasoline

as the surfaces could be damaged.

!

Do not use cloths or sponges excessively

wet, to not create water stagnation that could

damage the unit and compromise the safety.

!

Check the presence of leaves or similar

inside the aspiration grids and remove them.

!

Do not insert tools inside the external unit to

remove dirty residues or similar: if necessary,

call a qualified technician to run this operation.

!

Do not splash water inside the unit.

ENGLISH -22-

Page 23

3.5 PROBLEM

POSSIBLE CAUSE / REMEDIES

The air-conditioner does not work.

The air-conditioner does not refrigerate the

room

Strange smell in the room.

.

The air-conditioner makes noise as a liquid

flux.

Water losses from the air-conditioner.

The remote control does not work.

The air-conditioner does not work for 3' when

switched on.

- Wrong setting of the timer / Check it.

- Problems on the power supply/Verify the

Presence of voltage.

- The filter could be dirty / Clean it.

- The room temperature is too high / Wait until

the temperature goes down.

- The temperature is not properly set / Check

it.

- The grids could be obstructed / Check and

remove the eventual obstacles.

- Dampness in the room, coming from walls,

carpets, furnishing or similar

- Freon flux inside the air-conditioner.

- Dehumidifying water on the indoor unit of the

air-conditioner.

- Wrong installation of the air-conditioner.

- Wrong connection of the drainage pipe.

- Exhausted batteries.

- Wrong insertion of the batteries inside the

remote control

- Protection of the air-conditioner. Wait for 3'

and the air-conditioner will start to work

again.

The remote control is broken.

- To force the air-conditioner working, press

the RESET button. If pressed one time the

unit will start to work in AUTO mode, if

pressed twice the unit will stop working.

.

The Company is not responsible of possible

mistakes on this instruction manual.

The Company can change without official

notice the features of the products

ENGLISH -23-

Loading...

Loading...