Page 1

OmniScan SX

User’s Manual

DMTA-20043-01EN [U8778624] — Revision B

May 2013

This instruction manual contains essential information on how to use this Olympus product safely and effectively.

Before using this product, thoroughly review this instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Page 2

Olympus NDT, 48 Woerd Avenue, Waltham, MA 02453, USA

Copyright © 2013 by Olympus. All rights reserved. No part of this publication may

be reproduced, translated, or distributed without the express written permission of

Olympus.

This document was prepared with particular attention to usage to ensure the

accuracy of the information contained therein, and corresponds to the version of

the product manufactured prior to the date appearing on the title page. There

could, however, be some differences between the manual and the product if the

product was modified thereafter.

The information contained in this document is subject to change without notice.

Part number: DMTA-20043-01EN [U8778624]

Revision B

May 2013

Printed in Canada

All brands are trademarks or registered trademarks of their respective owners and

third party entities.

Page 3

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table of Contents

List of Abbreviations ...................................................................................... vii

Labels and Symbols ........................................................................................... 1

Important Information — Please Read Before Use ..................................... 7

Intended Use .......................................................................................................................... 7

Instruction Manual ................................................................................................................ 7

Instrument Compatibility ..................................................................................................... 7

Repair and Modification ....................................................................................................... 8

Safety Symbols ....................................................................................................................... 8

Safety Signal Words ............................................................................................................... 9

Note Signal Words ................................................................................................................. 9

Safety ..................................................................................................................................... 10

Warnings ............................................................................................................................... 10

Battery Precautions .............................................................................................................. 11

Equipment Disposal ............................................................................................................ 12

WEEE Directive .................................................................................................................... 12

China RoHS .......................................................................................................................... 12

Korea Communications Commission (KCC) ................................................................... 13

EMC Directive Compliance ................................................................................................ 13

FCC (USA) Compliance ...................................................................................................... 13

ICES-001 (Canada) Compliance ........................................................................................ 14

Warranty Information ......................................................................................................... 14

Technical Support ................................................................................................................ 15

Introduction ...................................................................................................... 17

1. Package Content ......................................................................................... 19

Table of Contents iii

Page 4

DMTA-20043-01EN [U8778624], Rev. B, May 2013

2. Overview of the OmniScan SX ............................................................... 21

2.1 Display Touch Screen ............................................................................................... 22

2.2 Main Control Area .................................................................................................... 22

2.3 Power Key .................................................................................................................. 23

2.4 Help Key ..................................................................................................................... 23

2.5 Indicator Lights ......................................................................................................... 23

2.5.1 Power Indicator Light .................................................................................... 23

2.5.2 Acquisition Indicator Light ........................................................................... 24

2.5.3 Alarm Indicator Lights .................................................................................. 24

2.6 Left Side Panel ........................................................................................................... 24

2.7 Right Side Panel ........................................................................................................ 26

2.8 Top Panel .................................................................................................................... 27

2.9 Rear Panel ................................................................................................................... 28

3. Basic Operation .......................................................................................... 33

3.1 Turning On and Off the OmniScan SX ................................................................... 33

3.2 Sleep Mode ................................................................................................................. 34

3.3 Automatic Start-Up Mode ....................................................................................... 35

3.4 Power Supply Management .................................................................................... 35

3.4.1 DC Power Adaptor ........................................................................................ 36

3.4.2 Lithium-Ion Battery ....................................................................................... 37

3.4.2.1 Battery Status Indicators .................................................................... 38

3.4.2.2 Battery Discharge ................................................................................ 38

3.4.2.3 Battery Removal and Installation ...................................................... 39

3.4.2.4 Battery Charging ................................................................................. 40

3.4.2.5 Maximizing the Performance of Lithium-Ion Batteries ................. 41

3.4.2.6 Used Battery Disposal ......................................................................... 42

3.4.2.7 Warnings on Battery Use .................................................................... 43

3.5 Peripheral Connection .............................................................................................. 43

3.6 OmniScan SX Software Installation ........................................................................ 45

4. Maintenance ................................................................................................ 47

4.1 Preventative Maintenance ....................................................................................... 47

4.2 Instrument Cleaning ................................................................................................. 47

4.2.1 Casing Cleaning ............................................................................................. 47

4.2.2 Screen and Screen Protector Cleaning ........................................................ 48

4.3 Replacing the Touch-Screen Protector ................................................................... 48

5. Troubleshooting ......................................................................................... 51

5.1 Start-Up Problems ..................................................................................................... 51

5.2 Battery Charging Problems ..................................................................................... 51

iv Table of Contents

Page 5

DMTA-20043-01EN [U8778624], Rev. B, May 2013

5.3 Battery Life Problems ............................................................................................... 52

6. Specifications .............................................................................................. 53

7. Connector References ................................................................................ 61

7.1 Scanner Interface Connector ................................................................................... 62

7.2 Scanner Interface Adaptor ....................................................................................... 66

Appendix: Compatibility Tables ................................................................... 69

List of Figures ................................................................................................... 71

List of Tables ..................................................................................................... 73

Index ................................................................................................................... 75

Table of Contents v

Page 6

DMTA-20043-01EN [U8778624], Rev. B, May 2013

vi Table of Contents

Page 7

List of Abbreviations

DMTA-20043-01EN [U8778624], Rev. B, May 2013

DC direct current

EFUP environment-friendly use period

IATA International Air Transport Asso-

ciation

ICAO International Civil Aviation Orga-

nization

IMO International Maritime Organiza-

tion

LCD liquid crystal display

NDT nondestructive testing

PA phased array

RH relative humidity

SDHC secure digital high capacity

TFT thin film transistor

USDOT US Department of Transportation

UT ultrasonic testing

WEEE waste electrical and electronic

equipment

List of Abbreviations vii

Page 8

DMTA-20043-01EN [U8778624], Rev. B, May 2013

viii List of Abbreviations

Page 9

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Location of rating and

identification labels

(see Table 1 on page 2).

Labels and Symbols

Safety-related labels and symbols are attached to the instrument at the locations

shown in Figure i-1 on page 1. If any or all of the labels or symbols are missing or

illegible, please contact Olympus.

Figure i-1 Labels location

Labels and Symbols 1

Page 10

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 1 Content of the rating label

The CE marking is a declaration that this product conforms to

all the applicable directives of the European Community. See

the Declaration of Conformity for details. Contact your Olympus

representative for more information.

Content

2 Labels and Symbols

The C-Tick label indicates that the product complies with the

applicable standard, and establishes a traceable link between

the equipment and the manufacturer, importer, or agent

responsible for compliance, and for placing it on the

Australian market.

The WEEE symbol indicates that the product must not be

disposed of as unsorted municipal waste, but should be

collected separately.

Page 11

Table 1 Content of the rating label (continued)

The China RoHS mark indicates the product’s EnvironmentFriendly Use Period (EFUP). The EFUP is defined as the

number of years for which listed controlled substances will not

leak or chemically deteriorate while in the product. The EFUP

for the OmniScan SX has been determined to be 15 years.

Note: The Environment-Friendly Use Period (EFUP) is not

meant to be interpreted as the period assuring functionality

and product performance.

Seller and user shall be noticed that this equipment is suitable

for electromagnetic equipment for office work (class A) and it

can be used outside home.

The direct current symbol.

The DC adaptor polarity symbol.

M/N Model number

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Mfg. Date Manufacturing date

S/N Serial number

Labels and Symbols 3

Page 12

DMTA-20043-01EN [U8778624], Rev. B, May 2013

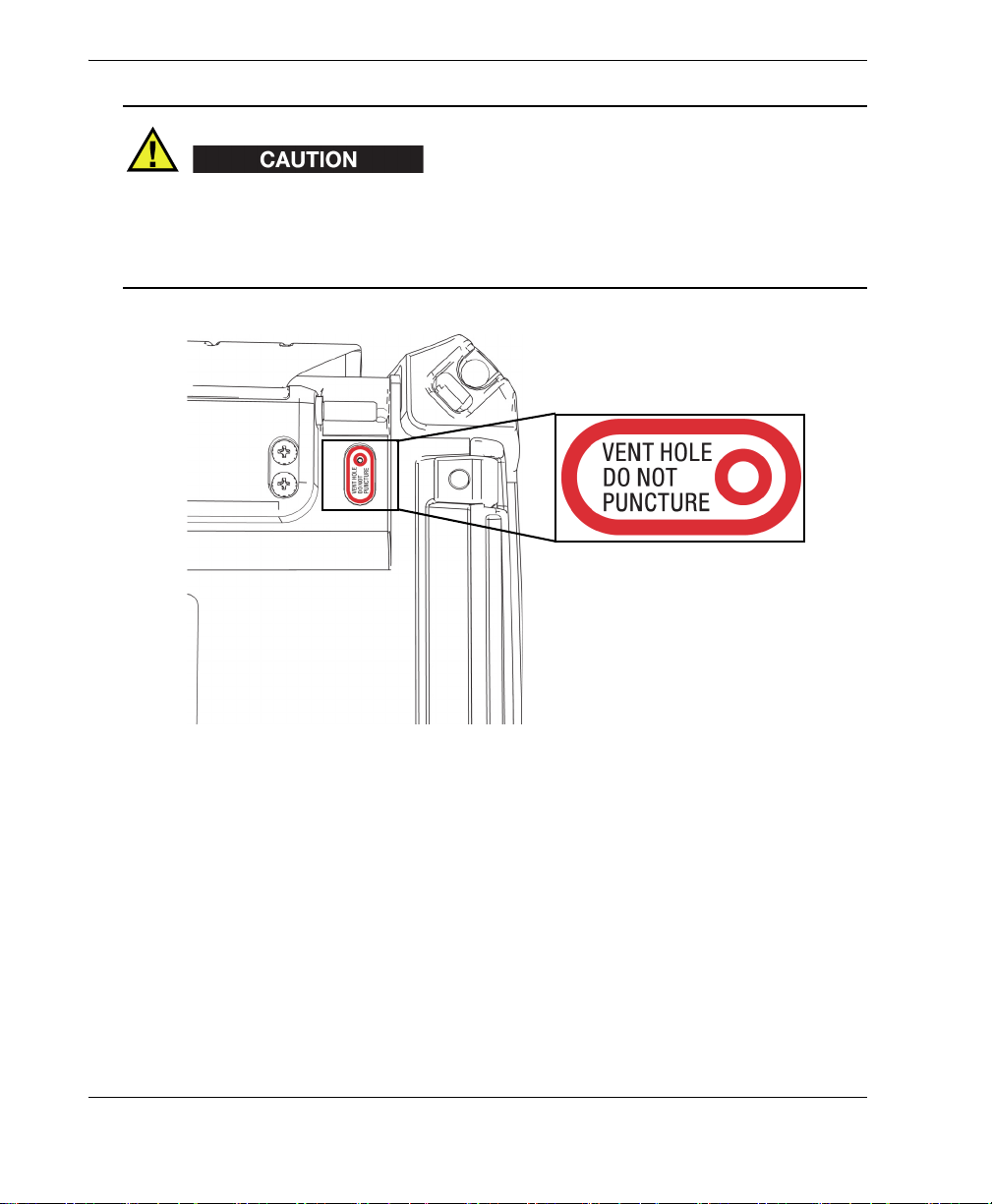

The membrane vent (see Figure i-2 on page 4) is used to counterbalance the internal

and external pressures and to maintain the instrument watertightness. Do not

puncture the membrane vent. When the membrane vent is punctured, the instrument

fails to comply with the IP66 rating.

4 Labels and Symbols

Figure i-2 Membrane vent location

Page 13

DMTA-20043-01EN [U8778624], Rev. B, May 2013

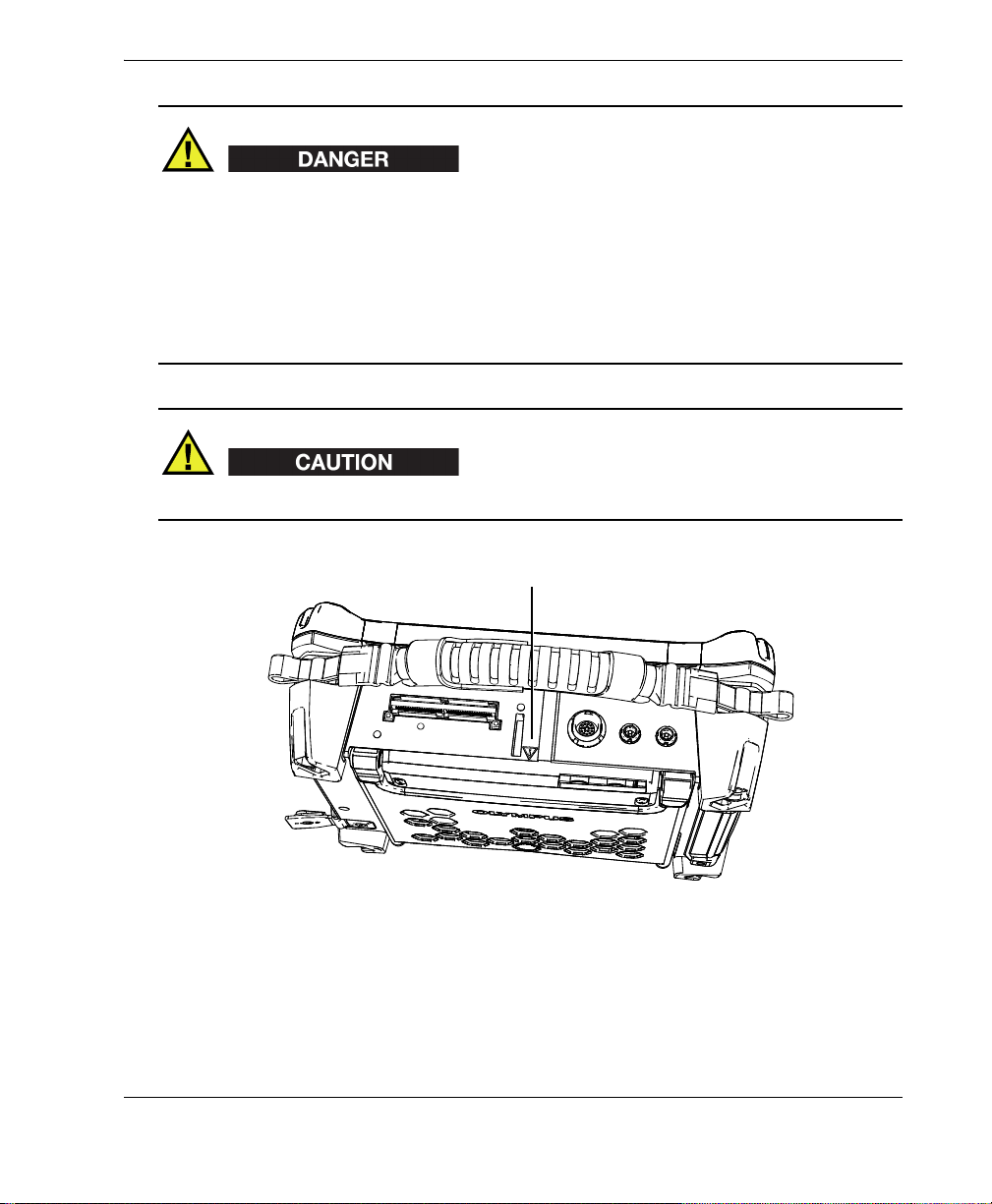

Warning symbol

• To reduce the risk of electric shock, avoid touching the inner conductor of the

probe connectors. Up to 340 V can be present on the inner conductor of the

ultrasonic testing (UT) connectors, and up to 115 V can be present on the phased

array (PA) connector. The warning symbol near the PA and UT connectors signals

this electric shock risk (see Figure i-3 on page 5).

• Reinforced insulation must be provided for the probes connected to the

OmniScan SX instrument.

Use only compatible Olympus probes.

Figure i-3 Warning symbol on top of the OmniScan SX

Labels and Symbols 5

Page 14

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Warning symbol

The warning symbol on the battery compartment door (see Figure i-4 on page 6)

signals that precautions must be taken concerning the battery. See section 3.4.2.7 on

page 43.

6 Labels and Symbols

Figure i-4 Warning symbol on battery compartment door

Page 15

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Important Information — Please Read Before Use

Intended Use

The OmniScan SX is designed to perform nondestructive inspections on industrial

and commercial materials.

Do not use the OmniScan SX for any purpose other than its intended use. It must

never be used to inspect or examine human or animal body parts.

Instruction Manual

This instruction manual contains essential information on how to use this Olympus

product safely and effectively. Before using this product, thoroughly review this

instruction manual. Use the product as instructed.

Keep this instruction manual in a safe, accessible location.

Instrument Compatibility

Refer to the Appendix on page 69 to confirm that the OmniScan SX is compatible with

the auxiliary equipment being used.

Important Information — Please Read Before Use 7

Page 16

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Always use equipment and accessories that meet Olympus specifications. Using

incompatible equipment could cause malfunction and/or equipment damage, or

injury.

Repair and Modification

The OmniScan SX does not contain any user-serviceable parts. Opening the

instrument might void the warranty.

In order to prevent human injury and/or equipment damage, do not disassemble,

modify, or attempt to repair the instrument.

Safety Symbols

The following safety symbols might appear on the instrument and in the instruction

manual:

General warning symbol

This symbol is used to alert the user to potential hazards. All safety messages that

follow this symbol shall be obeyed to avoid possible harm or material damage.

High voltage warning symbol

This symbol is used to alert the user to potential electric shock hazards greater

than 1000 volts. All safety messages that follow this symbol shall be obeyed to

avoid possible harm.

8 Important Information — Please Read Before Use

Page 17

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Safety Signal Words

The following safety symbols might appear in the documentation of the instrument:

The DANGER signal word indicates an imminently hazardous situation. It calls

attention to a procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in death or serious personal injury. Do not proceed beyond a

DANGER signal word until the indicated conditions are fully understood and met.

The WARNING signal word indicates a potentially hazardous situation. It calls

attention to a procedure, practice, or the like, which, if not correctly performed or

adhered to, could result in death or serious personal injury. Do not proceed beyond a

WARNING signal word until the indicated conditions are fully understood and met.

The CAUTION signal word indicates a potentially hazardous situation. It calls

attention to an operating procedure, practice, or the like, which, if not correctly

performed or adhered to, could result in minor or moderate personal injury, material

damage, particularly to the product, destruction of part or all of the product, or loss of

data. Do not proceed beyond a CAUTION signal word until the indicated conditions

are fully understood and met.

Note Signal Words

The following safety symbols could appear in the documentation of the instrument:

The IMPORTANT signal word calls attention to a note that provides important

information, or information essential to the completion of a task.

Important Information — Please Read Before Use 9

Page 18

DMTA-20043-01EN [U8778624], Rev. B, May 2013

The NOTE signal word calls attention to an operating procedure, practice, or the like,

which requires special attention. A note also denotes related parenthetical

information that is useful, but not imperative.

The TIP signal word calls attention to a type of note that helps you apply the

techniques and procedures described in the manual to your specific needs, or

provides hints on how to effectively use the capabilities of the product.

Safety

This instrument is an instrument of Class 1 and installation category II. Before turning

on the instrument, verify that the correct safety precautions have been taken (see the

following warnings). In addition, note the external markings on the instrument,

which are described under “Safety Symbols”.

Warnings

General Warnings

• Carefully read the instructions contained in this instruction manual prior to

turning on the instrument.

• Keep this instruction manual in a safe place for further reference.

• Follow the installation and operation procedures.

• It is imperative to respect the safety warnings on the instrument and in this

instruction manual.

• If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment could be impaired.

• Do not install substitute parts or perform any unauthorized modification to the

instrument.

10 Important Information — Please Read Before Use

Page 19

DMTA-20043-01EN [U8778624], Rev. B, May 2013

• Service instructions, when applicable, are for trained service personnel. To avoid

the risk of electric shock, do not perform any work on the instrument unless

qualified to do so. For any problem or question regarding this instrument, contact

Olympus or an authorized Olympus representative.

Electrical Warnings

• Before turning on the instrument, you must connect the protective earth terminal

of the instrument to the protective conductor (mains) of the power cord. The

mains plug shall only be inserted into a socket outlet provided with a protective

earth contact. Never negate the protective action by using an extension cord

(power cable) without a protective conductor (grounding).

• Only use fuses with the required rated current, voltage, and specified type

(normal-blow, slow-blow, quick-acting, etc.). Do not use repaired fuses or shortcircuited fuse holders. Doing so could cause electric shock or create a fire hazard.

• If there is any possibility that the ground protection could be impaired, you must

make the instrument inoperative and secure it against any unintended operation.

• The instrument must only be connected to a power source corresponding to the

type indicated on the rating label.

Battery Precautions

Transportation of lithium-ion batteries is regulated by the United Nations under the

United Nations Recommendations on the Transport of Dangerous Goods. It is

expected that governments, intergovernmental organizations, and other international

organizations shall conform to the principles laid down in these regulations, thus

contributing to worldwide harmonization in this field. These international

organizations include the International Civil Aviation organization (ICAO), the

International Air Transport Association (IATA), the International Maritime

Organization (IMO), the US Department of Transportation (USDOT), and others.

Please contact the transporter and confirm current regulations before transportation

of lithium-ion batteries.

Important Information — Please Read Before Use 11

Page 20

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Equipment Disposal

Before disposing of the OmniScan SX, check your local laws, rules, and regulations,

and follow them accordingly.

WEEE Directive

In accordance with European Directive 2002/96/EC on Waste Electrical

and Electronic Equipment (WEEE), this symbol indicates that the

product must not be disposed of as unsorted municipal waste, but

should be collected separately. Refer to your local Olympus distributor

for return and/or collection systems available in your country.

China RoHS

China RoHS is the term used by industry generally to describe legislation

implemented by the Ministry of Information Industry (MII) in the People’s Republic

of China for the control of pollution by electronic information products (EIP).

The China RoHS mark indicates the product’s EnvironmentFriendly Use Period (EFUP). The EFUP is defined as the number of

years for which listed controlled substances will not leak or

chemically deteriorate while in the product. The EFUP for the

OmniScan SX has been determined to be 15 years.

Note: The Environment-Friendly Use Period (EFUP) is not meant

to be interpreted as the period assuring functionality and product

performance.

12 Important Information — Please Read Before Use

Page 21

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Korea Communications Commission (KCC)

A 급 기기 ( 업무용 방송통신기자재 )

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판 매자 또는 사용자는 이 점을주의하시

기 바라 며 , 가정외의 지역에서 사용하는 것을 목적으로 합니다 .

EMC Directive Compliance

This equipment generates and uses radio-frequency energy and, if not installed and

used properly (that is, in strict accordance with the manufacturer’s instructions), may

cause interference. The OmniScan SX has been tested and found to comply with the

limits for an industrial device in accordance with the specifications of the EMC

directive.

To maintain OmniScan SX compliance with the emissions requirements of the EMC

directive, the following conditions must be met:

• All cables used to connect the equipment must have an overall shielding to ensure

electromagnetic compatibility and optimal performance.

• Ferrite clamp filters must be attached to the cables connected to the OmniScan SX.

For details, see “Ferrite clamp filters” on page 43.

FCC (USA) Compliance

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy, and if not installed and used in accordance with the

instruction manual, might cause harmful interference to radio communications.

Important Information — Please Read Before Use 13

Page 22

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Operation of this equipment in a residential area is likely to cause harmful

interference, in which case you will be required to correct the interference at your own

expense.

ICES-001 (Canada) Compliance

This Class A digital apparatus complies with Canadian ICES-001.

Cet appareil numérique de la classe A est conforme à la norme NMB-001 du Canada.

Warranty Information

Olympus guarantees your Olympus product to be free from defects in materials and

workmanship for a specific period, and in accordance with conditions specified in the

Olympus NDT Terms and Conditions available at http://www.olympusims.com/en/terms/.

The Olympus warranty only covers equipment that has been used in a proper

manner, as described in this instruction manual, and that has not been subjected to

excessive abuse, attempted unauthorized repair, or modification.

Inspect materials thoroughly on receipt for evidence of external or internal damage

that might have occurred during shipment. Immediately notify the carrier making the

delivery of any damage, because the carrier is normally liable for damage during

shipment. Retain packing materials, waybills, and other shipping documentation

needed in order to file a damage claim. After notifying the carrier, contact Olympus

for assistance with the damage claim and equipment replacement, if necessary.

This instruction manual explains the proper operation of your Olympus product. The

information contained herein is intended solely as a teaching aid, and shall not be

used in any particular application without independent testing and/or verification by

the operator or the supervisor. Such independent verification of procedures becomes

increasingly important as the criticality of the application increases. For this reason,

Olympus makes no warranty, expressed or implied, that the techniques, examples, or

procedures described herein are consistent with industry standards, nor that they

meet the requirements of any particular application.

Olympus reserves the right to modify any product without incurring the

responsibility for modifying previously manufactured products.

14 Important Information — Please Read Before Use

Page 23

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Technical Support

Olympus is firmly committed to providing the highest level of customer service and

product support. If you experience any difficulties when using our product, or if it

fails to operate as described in the documentation, first consult the user’s manual, and

then, if you are still in need of assistance, contact our After-Sales Service. To locate the

nearest service center, visit the Service Centers page at: http://www.olympusims.com.

Important Information — Please Read Before Use 15

Page 24

DMTA-20043-01EN [U8778624], Rev. B, May 2013

16 Important Information — Please Read Before Use

Page 25

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Introduction

Olympus is a long-standing leader in NDT (nondestructive testing) test platforms,

with thousands of OmniScan units in use throughout the world. With the

OmniScan SX, the user benefit from a lighter, smaller, and more portable solution that

meet requirements for single group fully encoded phased array inspection.

Refer to the OmniScan MXU Software User’s Manual for information on software

functions.

The illustrations used in this manual were prepared with the instrument version

available at the time of publication, and may differ slightly in appearance from the

version of the OmniScan SX instrument that you are using.

Introduction 17

Page 26

DMTA-20043-01EN [U8778624], Rev. B, May 2013

18 Introduction

Page 27

1. Package Content

Models

The OmniScan SX is available in two different models:

OMNISX-PA1664PR

Portable 16:64PR phased array acquisition unit (including one UT conventional

channel)

OMNISX-UT

Portable one-channel conventional UT acquisition unit

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Accessories

The OmniScan SX comes standard with the following accessories:

• Cable ferrite clamp — Internal diameter of 4.8 mm

• Cable ferrite clamp — Internal diameter of 6.6 mm

• Cable ferrite clamp — Internal diameter of 9.0 mm

• 16-GB USB Flash drive

• 16-GB SDHC card

• Anti-glare screen protectors (2)

•Stylus

• Li-ion battery

• DC power adaptor

• Power cord (model varies according to country)

• Transport case

• USB Flash drive, which contains:

Package Content 19

Page 28

DMTA-20043-01EN [U8778624], Rev. B, May 2013

—MXU software

— OmniScan SX Getting Started Guide

— OmniScan SX User’s Manual

— OmniScan MXU Software User’s Manual

For a list of accessories and part numbers, see “Compatibility Tables” on page 69.

20 Chapter 1

Page 29

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Main control

area

Function keys

Power key

Power

indicator light

Alarm indicator

lights

Display touch

screen

Acquisition

indicator

light

Help key

2. Overview of the OmniScan SX

The front panel of the OmniScan SX (see Figure 2-1 on page 21) contains all the main

controls and indicators, which are explained further in the following sections.

Figure 2-1 Front panel controls of the OmniScan SX

Overview of the OmniScan SX 21

Page 30

DMTA-20043-01EN [U8778624], Rev. B, May 2013

2.1 Display Touch Screen

The display touch screen acts as a pointing device. To click an interface element, touch

the screen surface lightly with your finger. Refer to the OmniScan MXU Software User’s

Manual for advanced operating instructions for the touch screen.

2.2 Main Control Area

The main control area is shown in Figure 2-1 on page 21. You can control the

OmniScan SX completely from this area if you wish. The main control area contains

three elements, which are described in Table 2 on page 22.

Table 2 Main control area

Element Name Description

Scroll knob Used to navigate through selections without

the need for a keyboard, mouse, or touch

screen. Turning the scroll knob in a clockwise

direction shifts a selection to the left

(horizontal list) or upward (vertical list). For

more information about using the scroll knob

with the OmniScan software, refer to the

OmniScan MXU Software User’s Manual.

22 Chapter 2

Accept key Used to confirm a selection.

Cancel key Used to cancel the current selection, or to go

back one level in the menu hierarchy.

Page 31

DMTA-20043-01EN [U8778624], Rev. B, May 2013

2.3 Power Key

The Power key (see Figure 2-1 on page 21) is used to start or shut down the

OmniScan SX, but also to enable or disable the sleep mode.

2.4 Help Key

The Help key (see Figure 2-1 on page 21) is located on the upper-right side of the

OmniScan SX front panel. Pressing this key displays the online help for the currently

selected function.

2.5 Indicator Lights

There are three types of indicator lights on the OmniScan SX front panel: power,

acquisition, and alarm. Each indicator light is described below.

2.5.1 Power Indicator Light

The power indicator light is located above the Power key. The color of this light

identifies the power status of the OmniScan SX (see Table 3 on page 23).

Table 3 Power indicator light statuses

Off The OmniScan SX is turned off.

Flashing orange The OmniScan SX is turned off. Battery is charging.

Orange The OmniScan SX is turned off. Battery charging is

complete.

Green • The OmniScan SX is turned on.

• The OmniScan SX is turned on and battery is charging.

Flashing

green/orange

The OmniScan SX is in sleep mode. The battery is

charging.

Overview of the OmniScan SX 23

Page 32

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 3 Power indicator light statuses (continued)

Flashing green • The OmniScan SX is in sleep mode.

• The OmniScan SX is in sleep mode and battery

charging is complete.

Flashing red A critical factor (excessive temperature, very weak battery,

etc.) requires immediate attention.

2.5.2 Acquisition Indicator Light

The acquisition indicator light is located below the Play key ( ). The color of this

light indicates the operating mode of the OmniScan SX (see Table 4 on page 24).

Table 4 Acquisition indicator light statuses

Off Inspection mode

Orange Analysis mode

2.5.3 Alarm Indicator Lights

There are three alarm indicator lights located on the upper right corner of the

OmniScan SX. These lights only flash one color (red) and indicate the trigger status of

their respective alarms (set within the software).

For more details about the alarm indicator lights, refer to the OmniScan MXU Software

User’s Manual.

2.6 Left Side Panel

The left side panel of the OmniScan SX (see Figure 2-2 on page 25) contains various

input and output ports.

24 Chapter 2

Page 33

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Memory card slot

Battery compartment door

SVGA output connector

USB ports

Battery compartment door

This door provides access to the battery compartment. Battery replacement is

covered in section 3.4.2.3 on page 39.

SVGA output

An external VGA or SVGA monitor that mirrors the OmniScan SX display may be

connected to this DB-15 port.

Memory card slot

Slot for inserting the Secure Digital High Capacity (SDHC) memory card.

USB ports (2)

The USB ports (see Figure 2-2 on page 25) accommodate USB peripherals such as

external keyboards, mice, storage devices, or printers.

Figure 2-2 Left side panel of the OmniScan SX

Overview of the OmniScan SX 25

Page 34

DMTA-20043-01EN [U8778624], Rev. B, May 2013

DC power adaptor plug

2.7 Right Side Panel

The right side panel of the OmniScan SX (see Figure 2-3 on page 26) contains the DC

power adaptor plug.

DC power adaptor plug

Used to connect an external DC power adaptor to the OmniScan SX.

26 Chapter 2

Figure 2-3 Right side panel of the OmniScan SX

Page 35

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Scanner interface

UT connectors

PA connector

2.8 Top Panel

• To reduce the risk of electric shock, avoid touching the inner conductor of the

probe connectors. Up to 340 V can be present on the inner conductor of the UT

connectors, and up to 115 V can be present on the PA connector. The warning

symbol near the PA and UT connectors signals this electric shock risk.

• Reinforced insulation must be provided for the probes connected to the

OmniScan SX instrument.

Use only compatible Olympus probes.

There are four connectors located on the top panel of the OmniScan SX (see Figure 2-4

on page 27).

Figure 2-4 Top panel of the OmniScan SX (OmniSX-PA1664PR shown)

Overview of the OmniScan SX 27

Page 36

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Phased array probe connector

LEMO connector

P1 (UT connector)

LEMO connector used for the transmission of ultrasonic signals when using the

pitch-catch inspection technique.

R1 (UT connector)

LEMO connector used for the reception of ultrasonic signals when using the

pitch-catch inspection technique.

Scanner interface

Used as an alarm output and control input.

PA connector

Used to connect a phased array probe.

The compatible probe connectors are presented in Figure 2-5 on page 28.

2.9 Rear Panel

28 Chapter 2

Figure 2-5 LEMO and phased array probe connectors

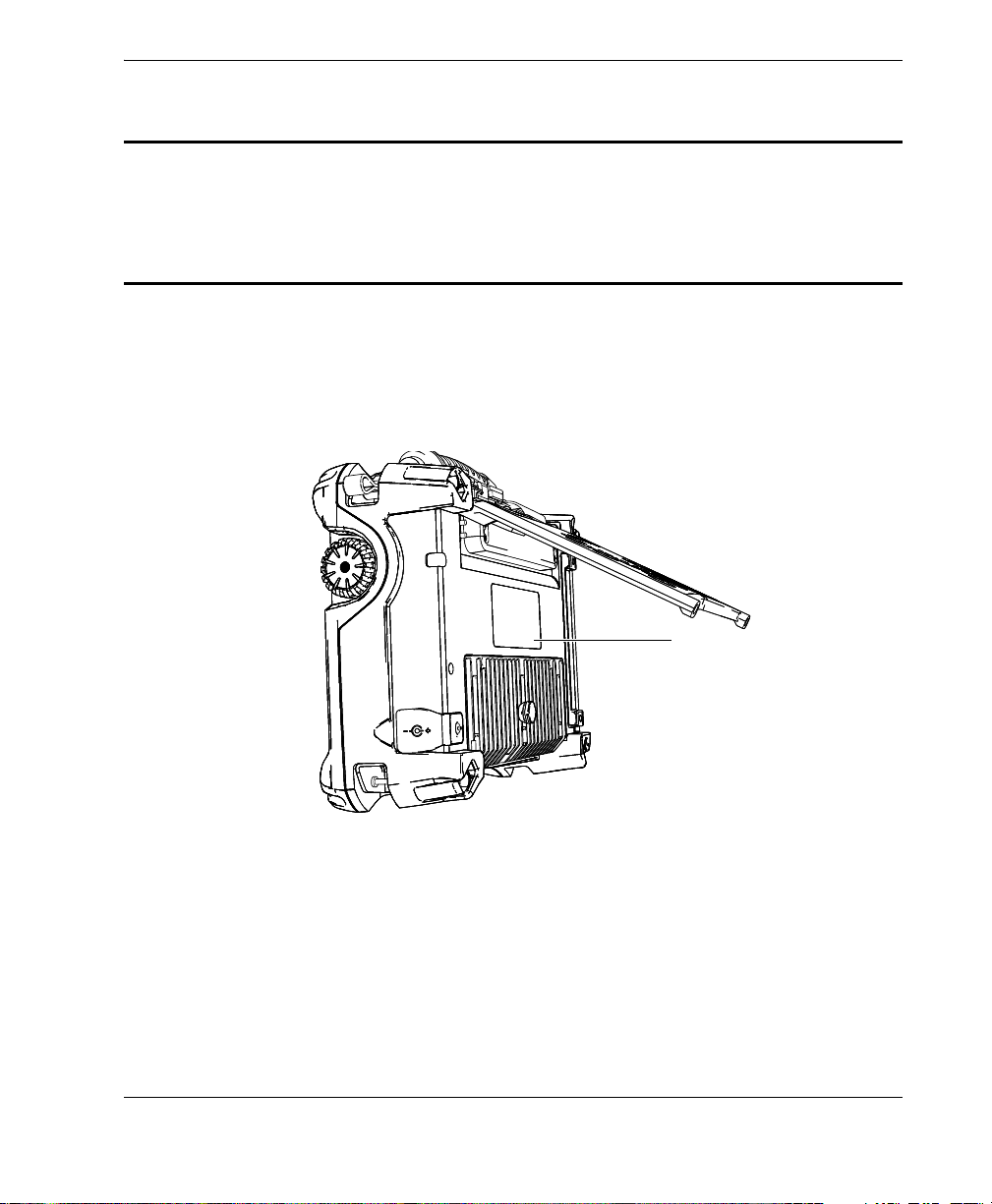

The rear panel consists of the heat sink and the support stand (see Figure 2-6 on

page 29).

Page 37

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Support stand

Heat sink

Support stand fastener

Figure 2-6 Rear panel of the OmniScan SX

• To prevent the OmniScan SX from falling over, the support stand must be opened

to its maximum position when the instrument is desktop mounted.

• In order to prevent injury, do not place your fingers between the rear panel and

the instrument’s support stand (when unfolded).

• Injury can result when support stand is folded in stored position.

• Do not use the support stand as a handle. Using the support stand as a handle

could cause equipment damage or injury.

Overview of the OmniScan SX 29

Page 38

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Fastening hole

Fastening hole

The rear panel is equipped with two fastening holes that can be used for attaching

accessories or for instrument mounting purposes (see Figure 2-7 on page 30 and

Figure 2-8 on page 31).

Figure 2-7 Fastening holes

30 Chapter 2

Page 39

DMTA-20043-01EN [U8778624], Rev. B, May 2013

44 mm 97 mm

92 mm

33 mm

59 mm

2 × M4

Figure 2-8 Fastening hole location and specifications

To prevent equipment damage, apply the following instructions when attaching

accessories to the OmniScan SX or when mounting the OmniScan SX to any surface.

• Use M4 × 0.7 mm screws with a nominal penetration length (into the instrument)

of 8 mm.

• Make sure that air can circulate freely between the OmniScan SX’s heat sink and

the accessory or mounting surface.

• When mounting the OmniScan SX to any surface:

— Always use the two fastening holes.

— Make sure that there is at least a 12 mm diameter surface contact area (see

Figure 2-9 on page 32) between the OmniScan SX and the supporting surface.

Overview of the OmniScan SX 31

Page 40

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Minimum 12 mm

diameter surface

contact

• Only attach accessories weighing 3.4 kg (the weight of the OmniScan SX) or less.

Figure 2-9 Surface contact requirements

32 Chapter 2

Page 41

DMTA-20043-01EN [U8778624], Rev. B, May 2013

3. Basic Operation

This chapter describes the basic principles and procedures involved in operating the

OmniScan SX instrument.

3.1 Turning On and Off the OmniScan SX

This section explains how to turn on and off the OmniScan SX.

To turn on the OmniScan SX

Press the Power key for one second.

The system starts up and performs a memory check.

If the system encounters a problem during the start-up phase, the power indicator

light will indicate the nature of the problem using a color code (for details, see “Power

Indicator Light” in section 2.5 on page 23).

To turn off the OmniScan SX

1. Quickly press the Power key.

The “Select a command” message appears (see Figure 3-1 on page 34).

Basic Operation 33

Page 42

DMTA-20043-01EN [U8778624], Rev. B, May 2013

The Shut Down button

Figure 3-1 The Shut Down button

2. Select Shut Down (see Figure 3-3 on page 35).

A message asking you if you want to save your setup appears (see Figure 3-2 on

page 34).

Figure 3-2 Saving the setup

3. To save your setup, select Yes .

You can also turn off the OmniScan SX by pressing and holding the Power key for ten

seconds. However, your setup will NOT be saved.

3.2 Sleep Mode

The OmniScan SX can be put into sleep mode when not in use to conserve power.

To use the sleep mode

1. With the OmniScan SX turned on, quickly press the Power key.

34 Chapter 3

Page 43

DMTA-20043-01EN [U8778624], Rev. B, May 2013

The Sleep button

The “Select a command” message appears (see Figure 3-3 on page 35).

2. Select Sleep.

Figure 3-3 Sleep mode selection

3. To disable the sleep mode, quickly press the Power key.

The OmniScan SX returns to its previous state (inspection or analysis mode).

3.3 Automatic Start-Up Mode

The OmniScan SX has an automatic start-up mode: auto-boot. Use the auto-boot

mode to remotely start the OmniScan SX unit. When this mode is enabled, you do not

need to press the Power key to start the OmniScan SX. The OmniScan SX starts up

automatically when connected to a DC power adaptor. This mode is disabled by

default.

To activate the auto-boot

1. Turn off the OmniScan SX unit, remove the batteries, and then disconnect the DC

power adaptor.

2. Press and hold the Power key.

3. Connect the OmniScan SX to a DC power adaptor.

4. Wait for the power indicator light to blink two times, and then release the Power

key.

5. To deactivate the auto-boot, repeat steps 1 to 4.

3.4 Power Supply Management

The OmniScan SX is a portable instrument that can draw power from either a lithiumion battery or a DC power adaptor.

Basic Operation 35

Page 44

DMTA-20043-01EN [U8778624], Rev. B, May 2013

3.4.1 DC Power Adaptor

You can operate the OmniScan SX on AC power using the DC power adaptor (P/N:

OMNI-A-AC [U8767093]). The OMNI-A-AC has a universal AC power input, which

operates with any line voltage from 100 VAC to 120 VAC or from 200 VAC to

240 VAC, and at 50 Hz to 60 Hz line frequency.

The DC power adaptor is for indoor use only.

To use AC power

1. Connect the AC power cord to the DC power adaptor (P/N: OMNI-A-AC

[U8767093]) and to an appropriate power outlet.

• Use only the AC power cord supplied with the OmniScan SX. Do not use this AC

power cord with other products.

• The OmniScan SX must only be connected to a power source corresponding to the

type indicated on the rating plate. Therefore, use only the DC power adaptor that

is delivered with the OmniScan SX.

2. On the right-hand side of the OmniScan SX, lift the rubber seal covering the DC

adaptor connector plug (see Figure 3-4 on page 37).

36 Chapter 3

Page 45

DMTA-20043-01EN [U8778624], Rev. B, May 2013

DC power adaptor plug

Figure 3-4 The OmniScan SX DC power adaptor plug

3. Connect the DC power adaptor to the OmniScan SX DC power adaptor plug (see

Figure 3-4 on page 37).

4. Press the power key to start the OmniScan SX.

3.4.2 Lithium-Ion Battery

The OmniScan SX holds one lithium-ion battery (P/N: OMNI-A-BATT2 [U8760059]).

The lithium-ion battery can be inserted and removed without needing to shut down

the OmniScan SX, provided that there is another valid power source available (DC

power adaptor).

The OmniScan SX also includes a lithium coin battery that does not need to be

removed or replaced by the user. The coin battery keeps the instrument clock and

masterboard configuration running.

Basic Operation 37

Page 46

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Replace the battery only with an Olympus battery (P/N: OMNI-A-BATT2

[U8760059]).

3.4.2.1 Battery Status Indicators

The battery status indicators located on the upper left corner of the display screen use

one of the following two methods to indicate the amount of power remaining in each

battery (see Figure 3-5 on page 38):

• The remaining operation time is displayed on the battery status indicator. The

OmniScan SX must be operated for approximately 15 minutes before it is able to

accurately display this information.

• The charge indicator (bar) on the battery status indicator shows the approximate

amount of remaining power in the battery.

If you attempt to start the OmniScan SX using a battery with an insufficient charge,

the power indicator light will flash red for approximately three seconds. To operate

the OmniScan SX, replace the battery or plug in the DC power adaptor.

Figure 3-5 Battery charge status

3.4.2.2 Battery Discharge

The battery status indicator displays the amount of time needed to discharge the

battery.

The OmniScan SX software informs the user of the remaining power status. The

battery status indicator variations are described in Table 5 on page 39.

38 Chapter 3

Page 47

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 5 Battery status indicator variations

Indicator Outline Fill Meaning

Dotted N/A There is no battery in the compartment.

Blue Blue The battery is functioning properly.

Blue Orange The battery is too hot for use.

Yello w

(blinking)

Orange Blue The battery is too hot to be charged, or

Red

(blinking)

N/A Yellow The OmniScan SX is being powered

Blue The battery is charging.

the internal system temperature is too

high to enable charging (over 60 °C).

Blue The battery charge is critically low (less

than 10 %). A beeping noise is emitted.

externally through the DC adaptor.

3.4.2.3 Battery Removal and Installation

To remove or install a battery

1. On the left side panel, turn the two quarter-turn latches to open the battery

compartment door.

2. Pull the tab to remove the battery (see Figure 3-6 on page 40).

Basic Operation 39

Page 48

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Battery compartment door

Lithium-ion battery

3. Insert a new battery. Make sure that the groove on the battery is aligned with the

small edge inside the battery compartment.

4. Close the battery compartment door.

The battery is recharged inside the OmniScan SX when it is connected to a DC power

adaptor. Connecting an adaptor automatically starts the recharging process. The

battery can also be recharged using an optional external charger.

3.4.2.4 Battery Charging

To charge the OmniScan SX battery

Connect the OmniScan SX to a proper DC power adaptor.

Battery charging is performed as follows:

• When the OmniScan SX is turned off:

40 Chapter 3

Figure 3-6 Removing a lithium-ion battery

Page 49

DMTA-20043-01EN [U8778624], Rev. B, May 2013

When the OmniScan SX is connected to a proper DC power source and is

turned off, it will automatically recharge the battery.

The power indicator light flashes orange to indicate that the battery is

currently being recharged. When the charge is complete, the power indicator

light emits a steady orange light. The battery can take up to 3 hours to fully

charge from a completely discharged state (less than 5 % remaining charge).

• When the OmniScan SX is running:

When the OmniScan SX is running and connected to a proper DC power

source, it will automatically recharge the battery. The indicator for the battery

is green.

Because the OmniScan SX is running, less power is available from the DC

source to recharge the battery. As such, it could take a minimum of 8 hours to

charge a completely discharged battery. For more information about battery

charge status, see Table 5 on page 39.

• When the OmniScan SX is in sleep mode:

When the OmniScan SX is in sleep mode and connected to a proper DC

power source, it will automatically recharge the battery. The indicator for the

battery flashes green and orange. When the charge is complete, the power

indicator light flashes green.

3.4.2.5 Maximizing the Performance of Lithium-Ion Batteries

This section describes lithium-ion battery care and maintenance.

Storage instructions for rechargeable batteries

1. Before recharging, drain the battery by running the OmniScan SX on battery

power until it shuts down, or until you get a low-battery warning. Do not leave

the battery dormant for long periods of time. Olympus recommends using the

battery at least once every two to three weeks. If a battery has not been used for a

long period of time, perform the “New battery procedure” on page 42.

If you do not plan to use the OmniScan SX on battery power within three or more

weeks, charge the battery to between 40 % and 80 % capacity (three or four bars

on the battery charge indicator), and then remove and store the battery in a clean,

cool, and dry place.

Basic Operation 41

Page 50

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Even when the OmniScan SX is turned off and unplugged, it draws a small amount of

power from the battery, which could completely discharge the battery in about

3 months at room temperature (25 °C).

2. Because lithium-ion batteries self-discharge over time, remember to check the

remaining charge of any stored batteries approximately once a month to ensure

that they have 40 % to 80 % remaining capacity, and recharge any that do not.

Failure to do so may render a battery permanently unusable if it falls below a

critical level (less than 1 %).

3. After an extended period of storage, the batteries should be recharged before use.

New battery procedure

1. Anytime you acquire a new rechargeable battery, use it four to eight times

consecutively in the OmniScan SX, and ensure that you completely discharge and

recharge it after each use. Doing so will enable it to reach maximum capacity,

providing maximum run time.

2. It is good practice to completely discharge and recharge the battery after the first

10 to 15 periods of normal use (or after two to three weeks) in order to drain the

battery, thus maintaining good run time and maximizing battery life.

3. Frequently switching from external DC power to battery power and vice versa

may result in shorter battery life, because the charge/discharge cycles are limited

(approximately 300 cycles). Please note that even a partial discharge and recharge

of the battery accounts for one cycle.

4. To maximize battery life, before charging, always run the OmniScan SX on battery

power until it shuts down, or until you get a low-battery warning. Recharge the

battery with the OmniScan SX in turned-off mode for a shorter recharge time, or

with the external charger if provided.

3.4.2.6 Used Battery Disposal

Although lithium-ion batteries do not contain any environmentally hazardous

components such as lead or cadmium, the batteries should be disposed of in

accordance with local regulations. Batteries should be disposed of in a discharged

state to avoid heat generation, and if applicable, in accordance with the European

Directive on Waste Electrical and Electronic Equipment (WEEE). Refer to your local

Olympus distributor for return and/or collection systems available in your country.

42 Chapter 3

Page 51

DMTA-20043-01EN [U8778624], Rev. B, May 2013

3.4.2.7 Warnings on Battery Use

Carefully read and observe the following warnings on battery use.

• Do not open, crush, or perforate batteries; doing so could cause injury.

• Do not incinerate batteries. Keep batteries away from fire and other sources of

extreme heat. Exposing batteries to extreme heat (over 80 °C) could result in an

explosion or personal injury.

• Do not drop, hit, or otherwise abuse a battery, as doing so could expose the cell

contents, which are corrosive and explosive.

• Do not short-circuit the battery terminals. A short circuit could cause injury and

severe damage to a battery, making it unusable.

• Do not expose a battery to moisture or rain; doing so could cause an electric

shock.

• Only use the OmniScan SX or an external charger approved by Olympus to

charge the battery.

• Do not recharge a battery unless the indicators light up when the capacity check

button on the battery is pressed. Doing so could be dangerous.

• Do not store batteries that have less than 40 % remaining charge. Recharge

batteries to between 40 % and 80 % capacity before storing them.

• During storage, keep the battery charged to between 40 % and 80 %.

• Do not leave the battery in the OmniScan SX during instrument storage.

3.5 Peripheral Connection

This section explains the peripherals that can be used with the OmniScan SX.

Ferrite clamp filters

Before using the OmniScan SX, attach the ferrite clamp filters (supplied with the

OmniScan SX) to the peripheral cables that will be connected to the OmniScan SX

unit. The optional peripherals are as follows:

Basic Operation 43

Page 52

DMTA-20043-01EN [U8778624], Rev. B, May 2013

•Olympus UT probes

•Olympus PA probe

• Devices connected to the VGA out connector

• USB devices connected with a USB cable (printers, etc.)

•Scanner interface

If the ferrite clamp filters are not attached, the OmniScan SX unit may fail to comply

with the international and European electromagnetic emission specifications.

To attach the clamp filters

• Make sure that the cable is not clamped in between the pawls of the ferrite clamp

filter.

• Attach the ferrite clamp filters as closely as possible to the cable ends. The ferrite

clamp filters are not effective unless they are immediately adjacent to the cable

end connected to the OmniScan SX.

• Use the ferrite clamp filter with the corresponding cable diameter. The filter must

not slip easily or be difficult to clip onto the cable.

• Make sure that the two ferrite clamp-filter parts are closed tight until the clamp

clicks.

1. Attach the ferrite clamp filter on the cable of the Olympus UT probes, in close

proximity to the connector for the OmniScan SX.

2. Attach the ferrite clamp filter on the cable of the Olympus PA probe, in close

proximity to the connector for the OmniScan SX.

3. Attach the ferrite clamp filter to the VGA cable, in close proximity to the

connector for the OmniScan SX.

4. Attach the ferrite clamp filter to the USB cable, in close proximity to the connector

for the OmniScan SX.

5. Attach the ferrite clamp filter to the scanner interface cable, in close proximity to

the connector (LEMO) for the OmniScan SX.

Figure 3-7 on page 45 and Figure 3-8 on page 45 show the applicable connection for

various cables on the OmniScan SX, and the locations where the ferrite clamp filters

must be attached.

44 Chapter 3

Page 53

DMTA-20043-01EN [U8778624], Rev. B, May 2013

UT probe

connections

SVGA output

USB

connection

Scanner interface

PA probe connection

Figure 3-7 Attaching a ferrite clamp filter to a cable (example shown with the

scanner interface cable)

Figure 3-8 OmniScan SX connection diagram — ferrite clamp filters

3.6 OmniScan SX Software Installation

The OmniScan SX software installation is designed to be as trouble-free as possible.

The software is stored on an SDHC card.

Basic Operation 45

Page 54

DMTA-20043-01EN [U8778624], Rev. B, May 2013

During upgrades to new versions, a message appears on the screen to inform you that

the upgrade is taking place. However, no action is required on your part.

Refer to the Olympus website for software updates and all related, applicable

procedures.

46 Chapter 3

Page 55

DMTA-20043-01EN [U8778624], Rev. B, May 2013

4. Maintenance

This chapter describes the basic maintenance that must be performed on the

OmniScan SX unit by operators. The maintenance operations explained below enable

you to keep your instrument in good physical and working condition. By virtue of its

design, the OmniScan SX only requires minimal maintenance. The chapter covers

preventative maintenance and instrument cleaning.

4.1 Preventative Maintenance

The OmniScan SX does not have many moving parts, and therefore only requires

minimal preventative maintenance. Simply perform regular inspections to keep the

OmniScan SX in proper working order.

4.2 Instrument Cleaning

The OmniScan SX external surfaces may be cleaned as needed. This section provides

the appropriate procedure for cleaning the instrument.

4.2.1 Casing Cleaning

To clean the casing

1. Make sure that the instrument is turned off, and that the power cord is

disconnected.

2. Disconnect all cables and connectors, and make sure that all external ports on the

OmniScan SX have been covered with their rubber protectors.

3. Place the cap on the scanner interface connector.

Maintenance 47

Page 56

DMTA-20043-01EN [U8778624], Rev. B, May 2013

4. Make sure that the battery compartment door is closed correctly.

5. To restore the instrument’s original finish, clean the casing with a soft cloth.

6. To remove persistent stains, use a damp cloth with a mild, soapy solution. Do not

use abrasive products or powerful solvents, which could damage the finish.

7. Once the connector protectors are removed, make sure the connectors are dry

before connecting anything to them. If they are wet, dry them with a soft, dry

cloth, or let them air dry.

4.2.2 Screen and Screen Protector Cleaning

Never use abrasive products or powerful solvents to clean the OmniScan SX touch

screen and screen protector. Clean the touch screen and screen protector using a

damp cloth moistened with a standard, evaporating glass cleaner. If necessary,

remove any paper-towel residue with a soft-bristle brush.

4.3 Replacing the Touch-Screen Protector

This section explains how to replace the touch-screen protector.

To replace the touch-screen protector

1. Remove any dust or dirt on the touch screen (dust and dirt cause bubbles to

appear on the protective film). See section 4.2.2 on page 48.

2. Simply remove the label marked No. 1, and peel away the protective film on the

back.

Avoid touching the back of the screen protector after the protective film on the back is

peeled away. Doing so will leave a trace of your finger prints.

3. Align the protector into the correct position on the screen, and slowly install the

screen protector.

4. Remove the label marked No. 2, and peel away the film on the front. Provided

that there is no dust trapped underneath, all small bubbles will dissipate within

48 hours.

48 Chapter 4

Page 57

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Dust particles can be blown away prior to installation using a can of compressed air.

Maintenance 49

Page 58

DMTA-20043-01EN [U8778624], Rev. B, May 2013

50 Chapter 4

Page 59

DMTA-20043-01EN [U8778624], Rev. B, May 2013

5. Troubleshooting

This chapter will help you resolve minor problems that could occur during operation

of your OmniScan SX unit. This troubleshooting guide has been prepared based on

the assumption that the instrument has not been modified, and that all cables and

connectors used are those provided and documented by Olympus.

5.1 Start-Up Problems

The OmniScan SX does not start.

Possible solutions:

• Check that the DC power adaptor is connected to both the OmniScan SX and a

power outlet with the proper voltage. Use only the adaptor supplied with the

OmniScan SX.

• Make sure that the battery is charged to at least 10 % capacity and correctly

inserted into the battery compartment.

• Press and hold the Power key for three seconds or longer.

5.2 Battery Charging Problems

The battery does not charge when placed in the OmniScan SX.

Possible solutions:

• Make sure that the battery model used in the OmniScan SX is compatible with the

model suggested by Olympus. An incompatible battery may be able to power the

unit, but the recharge protocol may not recognize it.

Troubleshooting 51

Page 60

DMTA-20043-01EN [U8778624], Rev. B, May 2013

• Make sure that the DC power adaptor is connected correctly.

• Charge the battery using an external charger. The battery charges much quicker

when the OmniScan SX is not in use. However, the battery will charge very

slowly, if at all, if the power consumption is too high.

• Shut down the OmniScan SX and wait for it to cool. Battery charging is disabled

when the battery temperature or the system’s internal temperature is too high.

This status will be indicated on the battery status indicator (see Table 5 on page 39

for battery status indicator descriptions).

5.3 Battery Life Problems

The battery charge does not last as long as it used to.

Possible solutions

• Drain the battery completely before recharging it to extend its life.

• Recondition the battery once a month using an external battery charger. Although

the OmniScan SX lithium-ion battery does not suffer from the “memory effect”

commonly affecting other battery types, it should be reconditioned for optimum

efficiency (for details, see section 3.4.2.5 on page 41).

• Verify your current configuration. There may be an option or combination of

options that are causing the battery to drain too quickly. Such options could

include the brightness, voltage level, and acquisition rate.

52 Chapter 5

Page 61

DMTA-20043-01EN [U8778624], Rev. B, May 2013

6. Specifications

This chapter covers the OmniScan SX unit specifications (see Table 6 on page 53 to

Table 11 on page 58).

Table 6 OmniScan SX general specifications

Housing

Size 267 mm × 206 mm × 91 mm

(10.5 in. × 8.1 in. × 3.6 in.)

Weight 3.4 kg (7.5 lb) [with battery inside]

Environmental conditions

Operating

temperature

Storage temperature –20 °C to 60 °C (with battery inside)

Relative humidity

(RH)

Altitude Up to 2000 m

Outdoor use To be used with the battery only

IP rating Designed to meet requirements of IP66

Pollution level 2

Installation category II

Battery model OMNI-A-BATT2 (U8760059)

Battery type Smart lithium-ion battery

Number of batteries 1

–10 °C to 45 °C

–20 °C to 70 °C (with no battery inside)

Max. 70 % RH at 45 °C noncondensing

Battery

Specifications 53

Page 62

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 6 OmniScan SX general specifications (continued)

Battery storage

temperature

Battery charge time 3 hours using the internal charger or an

Battery life Minimum 6 hours under normal

Size Approximately

DC-IN voltage 15 VDC to 18 VDC (min. 50 W)

Connector Circular, 2.5 mm pin diameter, center-

Suggested model OMNI-A-AC (U8767093)

Display size (diagonal) 213 mm (8.4 in.)

Resolution 800 × 600 pixels

Number of colors 16 million

Type TFT LCD

Viewing angles Horizontal: –80° to 80°

Storage devices SDHC card or most standard USB

Maximum data file

size

USB port 2 USB ports compliant with USB 2.0

Video output Video out (SVGA)

Encoder 2-axis encoder line (quadrature or

–20 °C to 60 °C at 80 % relative

humidity

optional battery charger

operating conditions

214 mm × 58.7 mm × 21.9 mm

(8.4 in. × 2.3 in. × 0.9 in.)

External DC Supply

positive

Display

Vertical: –60° to 80°

Data storage

storage devices

300 MB

I/O ports

specifications

I/O lines

clock/direction)

54 Chapter 6

Page 63

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 6 OmniScan SX general specifications (continued)

Digital input 4 digital inputs TTL, 5 V

Digital output 3 digital outputs TTL, 5 V, 15 mA

maximum per output

Remote

communication

Acquisition on/off

switch

Power output line 5 V nominal, 500 mA (short-circuit

Pace input 5 V, TTL pace input

Table 7 OmniScan SX alarms

Number of alarm

zones

Conditions Any logical combination of gates

Remote communication RS-232: 2 serial

ports using 3-wire RS-232

Through configuration of a digital

input

protected)

Alarms

3

• To reduce the risk of electric shock, avoid touching the inner conductor of the

probe connectors. Up to 340 V can be present on the inner conductor of the UT

connectors, and up to 115 V can be present on the PA connector. The warning

symbol near the probe connectors signals this electric shock risk.

• Reinforced insulation must be provided for the probes connected to the

OmniScan SX instrument.

Use only compatible Olympus probes.

Specifications 55

Page 64

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 8 on page 56 and Table 9 on page 56 detail the acoustic specifications of the

pulser, receiver, and beam formation, for both UT and PA modes.

Table 8 Acoustic specifications — UT channel using UT connector

Pulser

Voltage 95 V, 175 V, and 340 V

Pulse width Adjustable from 30 ns to 1000 ns;

resolution of 2.5 ns

Fall time < 10 ns

Pulse shape Negative square pulse

Output impedance < 30 Ω

Receiver

Gain range 0 dB to 120 dB maximum input signal

34.5 Vp-p (full-screen height)

Input impedance 60 Ω in pulse-echo mode

50 Ω in pulse-receive mode

System bandwidth 0.25 MHz to 28 MHz (–3 dB)

When the UT channel is used in pulse-echo mode, pulses occur on both the P1 and R1

connectors. When pulse-echo mode is selected, Olympus recommends using only the

P1 connector to connect the probe.

Table 9 Acoustic specifications — PA channel

Pulser

Voltage 40 V, 80 V, and 115 V

Pulse width Adjustable from 30 ns to 500 ns;

resolution of 2.5 ns

Fall time < 10 ns

Pulse shape Negative square pulse

56 Chapter 6

Page 65

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 9 Acoustic specifications — PA channel (continued)

Output impedance 35 Ω (pulse-echo mode); 30 Ω (pitch-

catch mode)

Receiver

Gain range 0 dB to 80 dB maximum input signal

550 mVp-p (full-screen height)

Input impedance 60 Ω (pulse-echo mode); 150 Ω (pitch-

catch mode)

System bandwidth 0.6 MHz to 18 MHz (–3 dB)

Beam formation

Scan type Sectorial and linear

Aperture OMNISX-PA1664PR = 16 elements

OMNISX-UT = N/A

Number of focal laws 256

Delay range

0 µs to 10 µs in 2.5 ns increments

transmission

Delay range reception 0µs to 6.4µs in 2.5ns increments

Table 10 on page 57 lists the acquisition specifications for frequency, data display, and

synchronization.

.

Table 10 Acquisition specifications

Frequency

Digitizing frequency 400 MHz (12 bits) after interpolation

per 4 (UT channel) and 5/4 (PA

a

A-scan (acquisition

mode)

channel)

Up to 6000 A-scans per second

(512-point, 8-bit A-scan)

Maximum pulsing rate Up to 6 kHz (C-scan)

Depth in material 59.8 meters in steel (longitudinal

wave), 10 ms with compression

0.49 meter in steel (longitudinal wave),

81.9 µs without compression

Specifications 57

Page 66

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 10 Acquisition specifications (continued)

Display

Refresh rate A-scan: 60 Hz; S-scan: 60 Hz

Envelope (echodynamic mode)

On internal clock 1Hz to 6kHz

External pace Yes

On encoder On two axes: from 1 to 65536 steps

a. The interpolation is disabled for the TOFD channel, and when FFT

is enabled.

Table 11 on page 58 details the data specifications of processing, TCG, and storage.

Table 11 Data specifications

Number of data points Up to 8192

Real-time averaging PA: 2, 4, 8, 16

Rectification RF, full wave, half wave+, half wave–

Filtering PA channel: 3 low-pass, 3 band-pass,

Video filtering Smoothing (adjusted to the probe

Number of points 16: One TCG (time-corrected gain)

Range PA: 40 dB per step of 0.1 dB

Maximum slope 40 dB/10 ns

Yes: Volume-corrected S-scan (30 Hz)

Synchronization

Processing

UT: 2, 4, 8, 16, 32, 64

and 5 high-pass filters

UT channel: 3 low-pass, 6 band-pass,

and 3 high-pass filters (8 low-pass

filters when configured in TOFD)

frequency range)

Programmable TCG

curve per focal law

UT: 100 dB per step of 0.1 dB

58 Chapter 6

Page 67

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 11 Data specifications (continued)

Storage

A-scan recording 6000 A-scans per second (512-point,

8-bit A-scan)

C-scan recording I, A, B, up to 6 kHz

Maximum file size Limited to available internal flash

memory: 300 MB

Specifications 59

Page 68

DMTA-20043-01EN [U8778624], Rev. B, May 2013

60 Chapter 6

Page 69

DMTA-20043-01EN [U8778624], Rev. B, May 2013

7. Connector References

Always use equipment and accessories that meet Olympus specifications. Using

incompatible equipment can result in a malfunction, equipment damage, or injury.

This chapter provides a technical description of the OmniScan SX unit connectors and

adaptor.

The following information is provided for each of the connectors: a brief description,

the manufacturer’s number, the number of the corresponding cable connector, an

illustration, and a table with the signal pinout for the connector.

The following OmniScan SX connectors comply with their respective standards:

• Scanner interface connector

• SDHC (memory card slot)

• Circular DC power jack, 2.5 mm pin diameter, 15 VDC to 18 VDC (see Figure 7-1

on page 61).

Figure 7-1 Circular DC power jack polarity

•USB

•VGA

•

R1

Connector References 61

Page 70

DMTA-20043-01EN [U8778624], Rev. B, May 2013

• P1

•PA

7.1 Scanner Interface Connector

Description

LEMO, 16-pin female circular connector

Manufacturer, number

LEMO, EEG.1K.316.CLL

Suggested cable connector

LEMO, FGG.1K.316.CLAC65Z

Pin I/O Signal Description Current Level

1 N/A N/A N/A N/A N/A

2 Out +5 V External power supply. 500 mA N/A

62 Chapter 7

Figure 7-2 The scanner interface LEMO connector (pin side)

Table 12 Pinout for the scanner interface LEMO connector

Page 71

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 12 Pinout for the scanner interface LEMO connector (continued)

Pin I/O Signal Description Current Level

3In DIN1/

Preset1

4In DIN2/

Preset2

Digital input 1/preset

axis 1.

Programmable input.

Can be configured as

generic input 1, or as

the preset of encoder 1.

Refer to the

OmniScan MXU

Software User’s Manual

(“Configuring the

Digital Input” section)

for information on

programming this

input.

To preset, you must use

a high-level signal with

a minimum signal

length of 50 ms.

Digital input 2/preset

axis 2.

Programmable input.

Can be configured as

generic input 2, or as

the preset of encoder 2.

Refer to the

OmniScan MXU

Software User’s Manual

(“Configuring the

Digital Input” section)

for information on

programming this

input.

To preset, you must use

a high-level signal with

a minimum signal

length of 50 ms.

N/A TTL

N/A TTL

Connector References 63

Page 72

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 12 Pinout for the scanner interface LEMO connector (continued)

Pin I/O Signal Description Current Level

5InDIN3/

AcqEn

Digital

input 3/acquisition

enable.

Programmable input.

Can be configured as

generic input 3, or as

an acquisition-enabled

signal (enabled at a

high level with a

minimum signal length

of 50 ms). By default,

configured as generic

input 3. Refer to the

OmniScan MXU

Software User’s Manual

(“Configuring the

Digital Input” section)

for information on

programming this

input.

N/A TTL

64 Chapter 7

Page 73

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 12 Pinout for the scanner interface LEMO connector (continued)

Pin I/O Signal Description Current Level

6 In DIN4 Digital input 4/external

N/A TTL

pace input.

Programmable input.

Can be configured as

generic input 4, or as

an external pace input

(high level with a

minimum signal length

of 50 ms when used as

DIN4, or 21 µs as

ExtPace).

Refer to the

OmniScan MXU

Software User’s Manual

(“Configuring the

Digital Input” section)

for information on

programming this

input.

7OutDOUT1/

PaceOut

Digital out 1/pace

output.

±15 mA TTL

8 Out DOUT2 Digital output 2 ±15 mA TTL

9 In PhA axis 1 Encoder 1:

phase A/clock/up/

down.

10 In PhB axis 1 Encoder 1:

phase B/direction/

N.U./N.U.

11 In PhB axis 2 Encoder 2:

phase B/direction/

N.U./N.U.

N/A TTL

N/A TTL

a

N/A TTL

Connector References 65

Page 74

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 12 Pinout for the scanner interface LEMO connector (continued)

Pin I/O Signal Description Current Level

12 In PhA axis 2 Encoder 2:

phase A/clock/up/

down.

13 Out DOUT3 Digital output 3 ±25 mA TTL

14 In RRx Rx N/A RS-232

15 Out RTx Tx N/A RS-232

16 – Gnd Ground N/A N/A

a. N.U. = Not used

N/A TTL

7.2 Scanner Interface Adaptor

The scanner interface adaptor cable, which is used to connect scanners equipped with

a DE-15 connector to the new LEMO scanner interface, is an optional accessory.

Description

LEMO connector

Manufacturer, number

LEMO, FGG.1K.316.CLA.C65Z

Figure 7-3 The scanner interface adaptor LEMO connector (weld side)

66 Chapter 7

Page 75

Description

DE-15 connector

Manufacturer, number

Amphenol, 17EHD-015-SAA-000

Figure 7-4 The scanner interface adaptor DE-15 connector (weld side)

Table 13 Scanner interface adaptor pinout [DE-15 to LEMO]

LEMO Signal DE-15

1Analog In 4

2+5V 3

DMTA-20043-01EN [U8778624], Rev. B, May 2013

3DIN1 1

4DIN2 2

5DIN3 5

6

N.U.

a

7DOUT1 6

8DOUT2 14

9 PHA-1 9

10 PHB-1 10

11 PHB-2 12

12 PHA-2 11

Connector References 67

Page 76

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Table 13 Scanner interface adaptor pinout [DE-15 to LEMO] (continued)

LEMO Signal DE-15

13 Connector keying

(index)

14 RX 7

15 TX 8

16 GND 15

Casing Shield Casing

a. N.U. = Not used

13 (removed)

68 Chapter 7

Page 77

DMTA-20043-01EN [U8778624], Rev. B, May 2013

Appendix: Compatibility Tables

Always use equipment and accessories that meet Olympus specifications. Using

incompatible equipment can result in a malfunction, equipment damage, or injury.

This appendix presents the software and accessories that are compatible with the

OmniScan SX (see Table 14 on page 69 and Table 15 on page 70).

The software versions mentioned in Table 14 on page 69 were the versions available at

the time of the publication. Subsequent qualified versions will also be compatible.

Table 14 OmniScan SX software compatibility