Page 1

OLYMPUS

1

RESEARCH

MlCROSCOPES

SERIES

BH2

REPAIR

(BHS)

MANUAL

Page 2

TO

OLYMPUS MICROSCOPE SERVICING PERSONNEL

This manual has been published chiefly for proviciing repair procedures for the OLYMPUS System Microscope BHS, but

internal construction of the main body. However, light sources of these models are different and specifically described in "Troubleshooting" contained in the

The Series BH2 models feature

of the Series BH, except for

BH2-BIITR tubes are of the constant tube length design and are different in the internal mechanism from

BH-BIITR, though optical alignment procedures for the prisms are nearly the same. Further, adoption

of the constant tube length design has made it possible

inserted into the right side eyepiece sleeve of the

adjust parfocality of observation tube and phototube.

In order to prevent trouble from occurring during

parts are fixed with cement and are particularly

Removing procedures are given for parts which are

ing force.

Prisms are glued with Araldite

cement with

be disassembled even after removing excessive cement, heat the entire area of the cemented surface with

a soldering iron or a similar tool.

In the descriptions contained in this manual, "right" and "left" are defined in the direction as seen by the

microscopist sitting in the observing position through the microscope.

For cleaning lenses, a liquid mixture of alcohol

should be made to "How to Clean the Microscope" which

is

applicable also to the Models BHT and BHTU which are similar to the Model BHS in the

last

part of this manual.

a

fine & coarse adjustment assembly of essentially the same design as that

a

reduction gear unit which

OT1028. When

a

razor blade (one-side edge) or knife edge before attempting disassembly. If the prisms cannot

it

is

attached to the rear of the arm in Series BH2.

lo

take lnicrographs with the focusing eyepiece

observatio~i lube, illereby introducing the necessity to

shipmelit or long-term use, importants immovable

descrit~ed at the steps of disassembly in this manual.

glued with adhesive agents of exceptionally high bond-

is

necessary to disassemble these prisms, cut off excessive

(3)

and ether

is

(7)

should be used. For details, reference

available upon separate request.

Requisites for repairs:

1.

First of all, ascertain what parts of the microscope the user or owner of which wishes you to repair.

2. Never fail to check the entire function of the microscope before you commence

a) Find out what parts are defective and how much they are

b) Prior to

efficient way.

3.

After completing the repair, check the functions of not only the re-assembled parts but also the entire

microscope to make sure no defect should be left unremedied.

4.

Be careful not to deform repair parts during the assembly, make

fied for purpose.

5.

Make repairs promptly and accurately.

repair, think of the best possible order to disassembling the defective parts in

damaged.

it

practice to use tools and jigs speci-

its

repair.

a

most

Page 3

CONTENTS

1 . REPAIR TOOLS AND JIGS

.

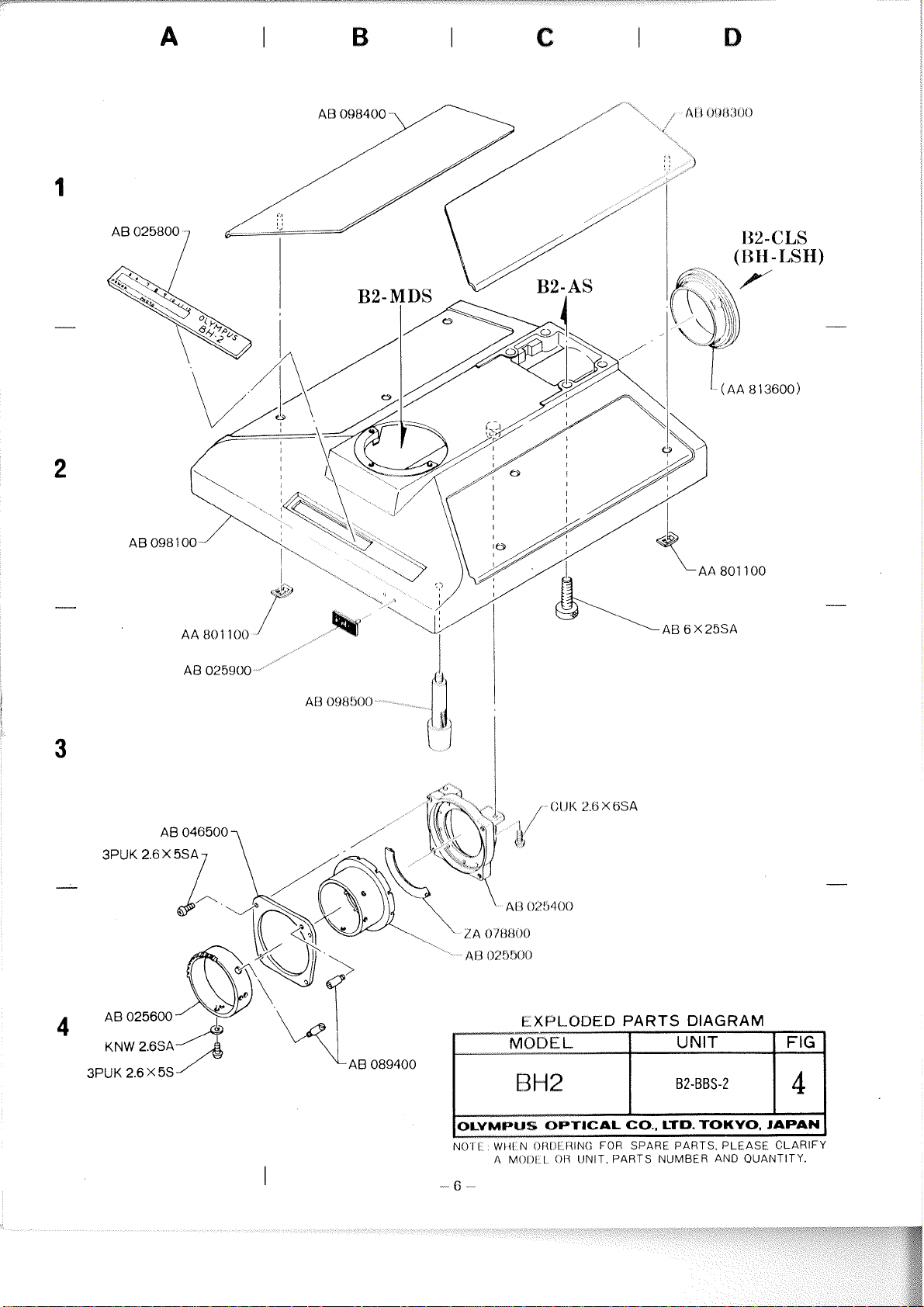

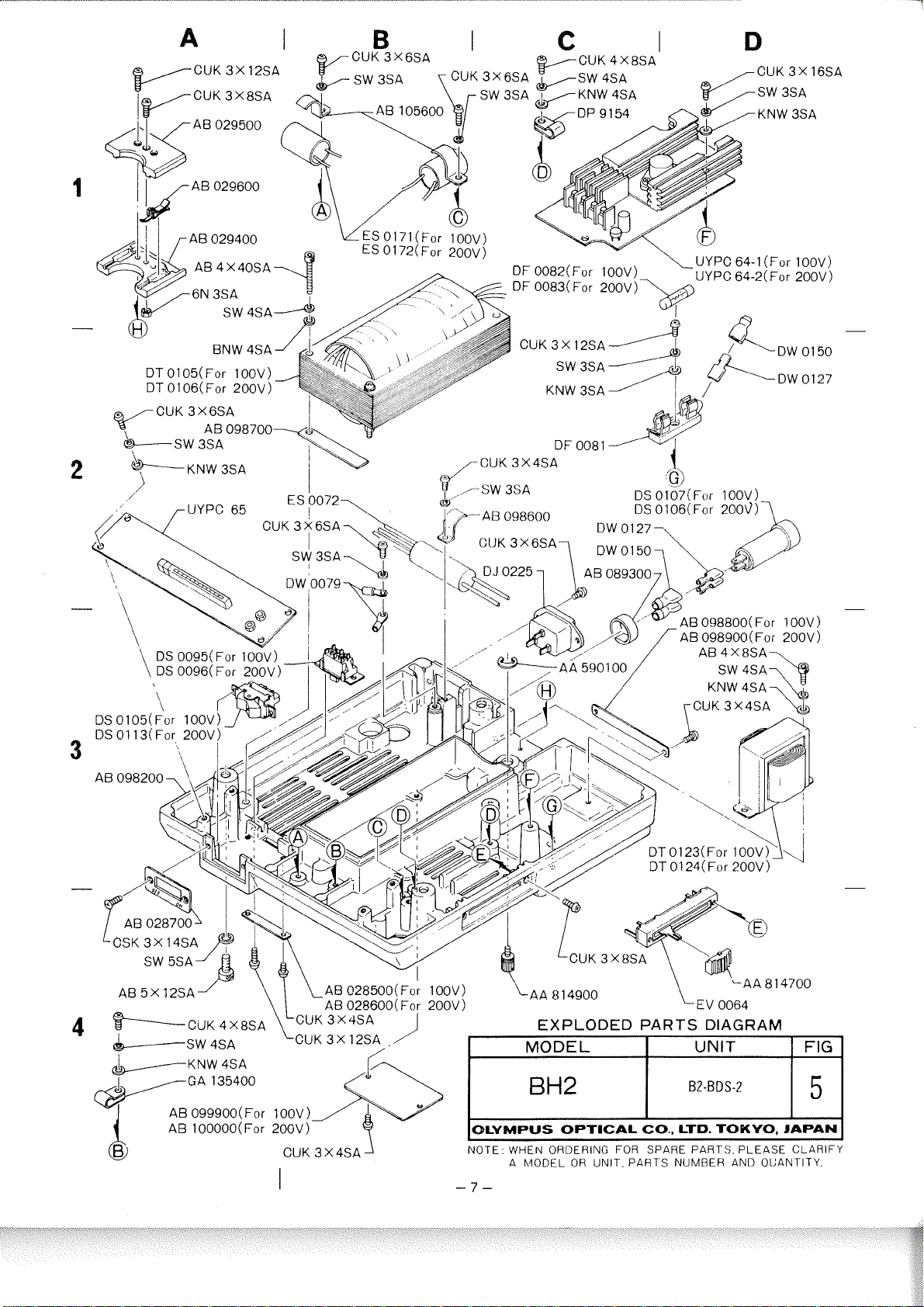

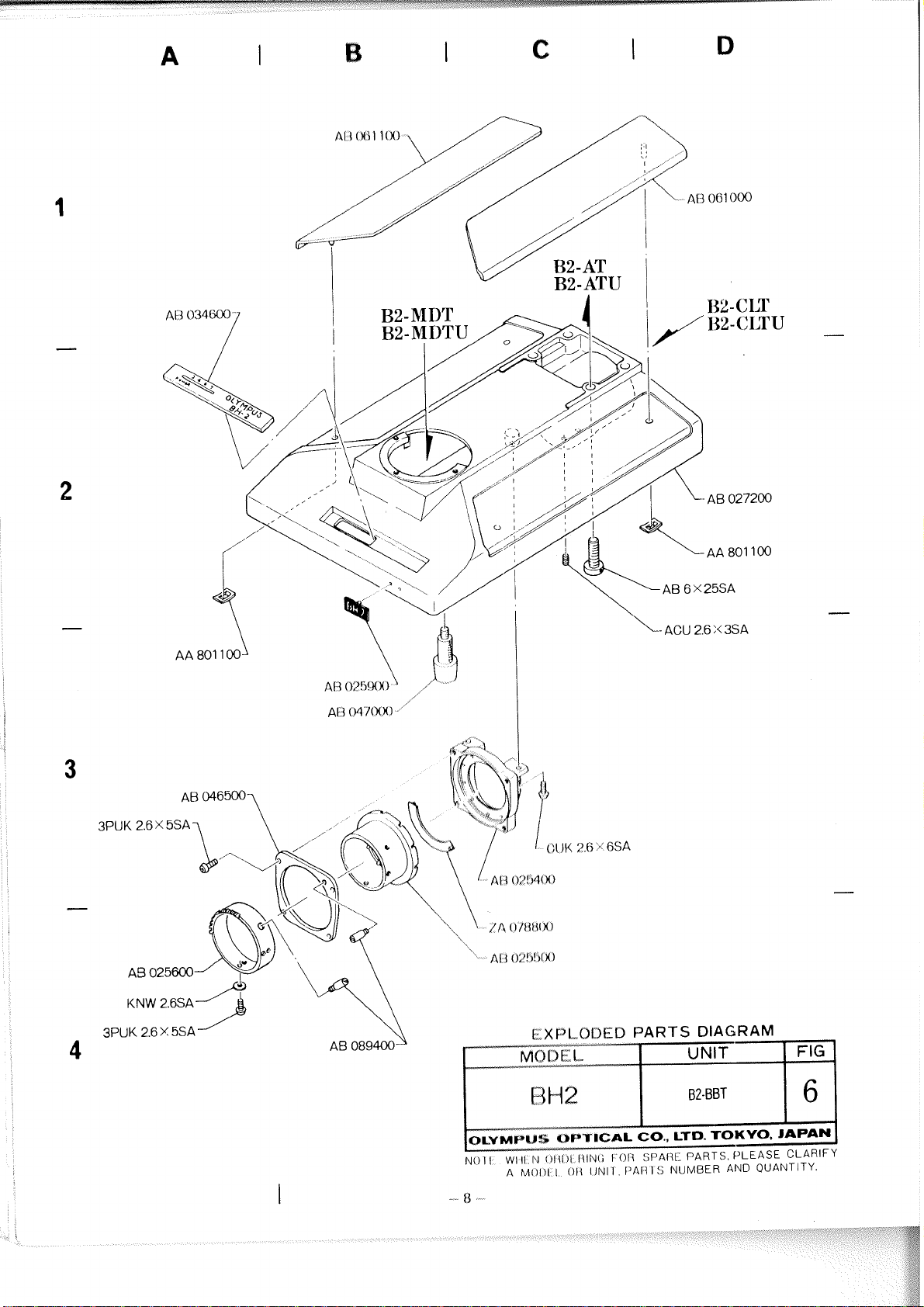

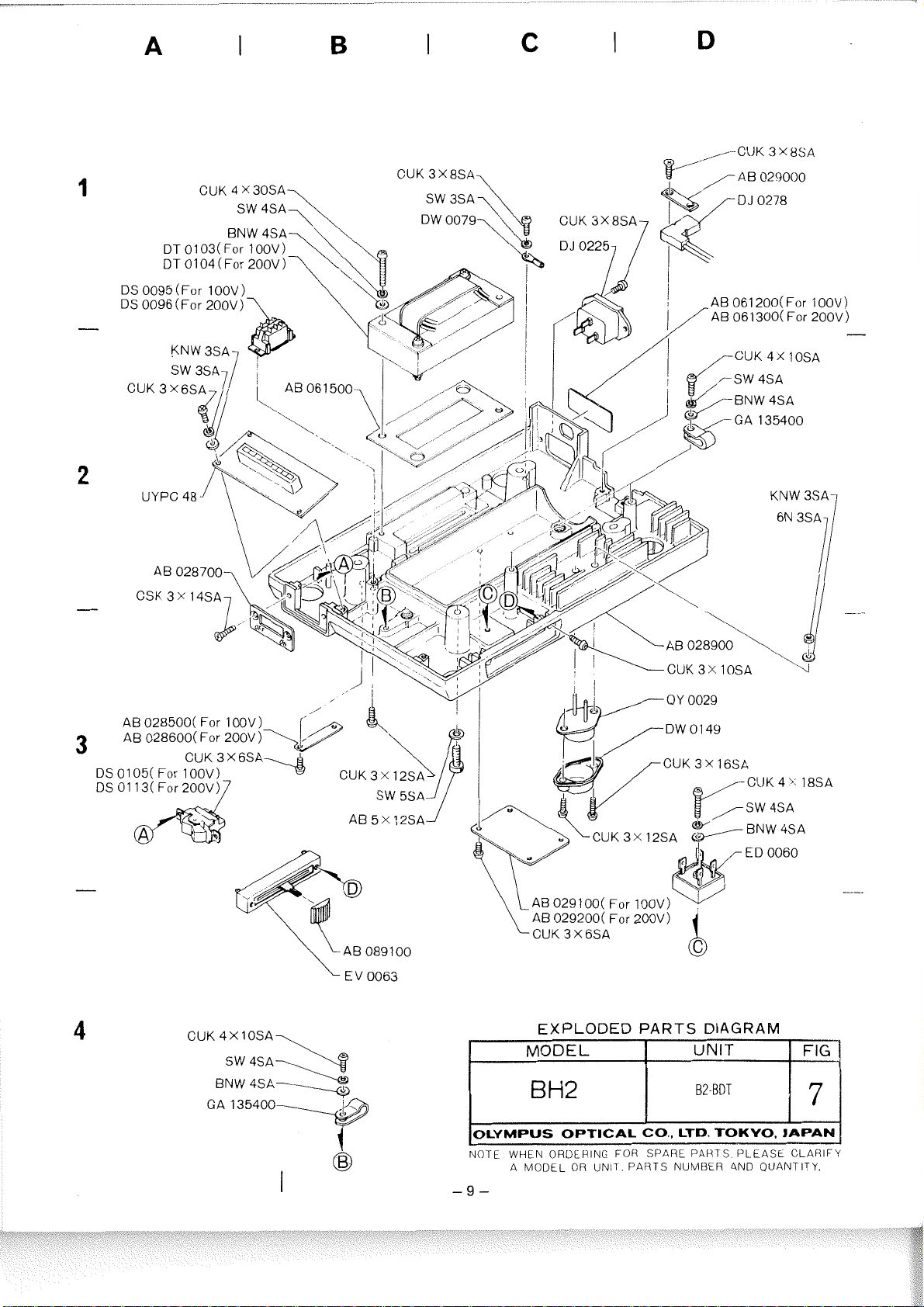

EXPLODED PARTS DIAGRAMS

2

.

DISASSEMBLY PROCEDURE FOR FlNE

3

COARSE ADJUSTMENT UNIT OF BHS

4

.

ASSEMBLY PROCEDURE FOR FlNE

COARSE ADJUSTMENT UNIT OF BHS

.

DISASSEMBLY PROCEDURE FOR BASE UNIT

5

.

6 ASSEMBLY PROCEDURE FOR BASE UNIT 42

.

7 DISASSEMBLY PROCEDURE FOR BIi2.CH 44

.

8 ASSEMBLY PROCEDURE FOR BH2 ..CH.. 46

.

OVERALL ASSEMBLY AND ADJUSTMENT FOR BHS-F

9

.

10 DISASSEMBLY PROCEDURE FOR BH2.BI

.

11 ASSEMBLY PROCEDURE FOR BH2.BI 57

12

.

DISASSEMBLY PROCEDURE FOR BH2.TR

.

ASSEMBLY PROCEDURE FOR BH2.TR

13

14

.

DISASSEMBLY PROCEDURE FOR BH2.SV

............................................

........................................

&

..................................

&

..................................

...........................

1

3

21

29

40

..............................

...............................

................................

...................

................................

48

52

...................................

...............................

..................................

...............................

67

69

75

.

ASSEMBLY PROCEDURE FOR BH2.SV

15

16 . DISASSEMBLY AND ASSEMBLY PROCEDURE FOR BH2.HRIHL 89

17

.

DISASSEMBLY PROCEDURE FOR BH2.AAC

.

ASSEMBLY PROCEDURE FOR BH2.AAC

18

.

DISASSEMBLY AND ASSEMBLY PROCEDURE FOR BH2.CD..

19

.

TROUBLESHOOTING OF ELECTRICAL SYSTEM

20

.

ELECTRIC CIRCUIT DIAGRAM

21

........................................

..................................

81

............

..............................

.................................

.............

..........................

90

92

94

95

97

Page 4

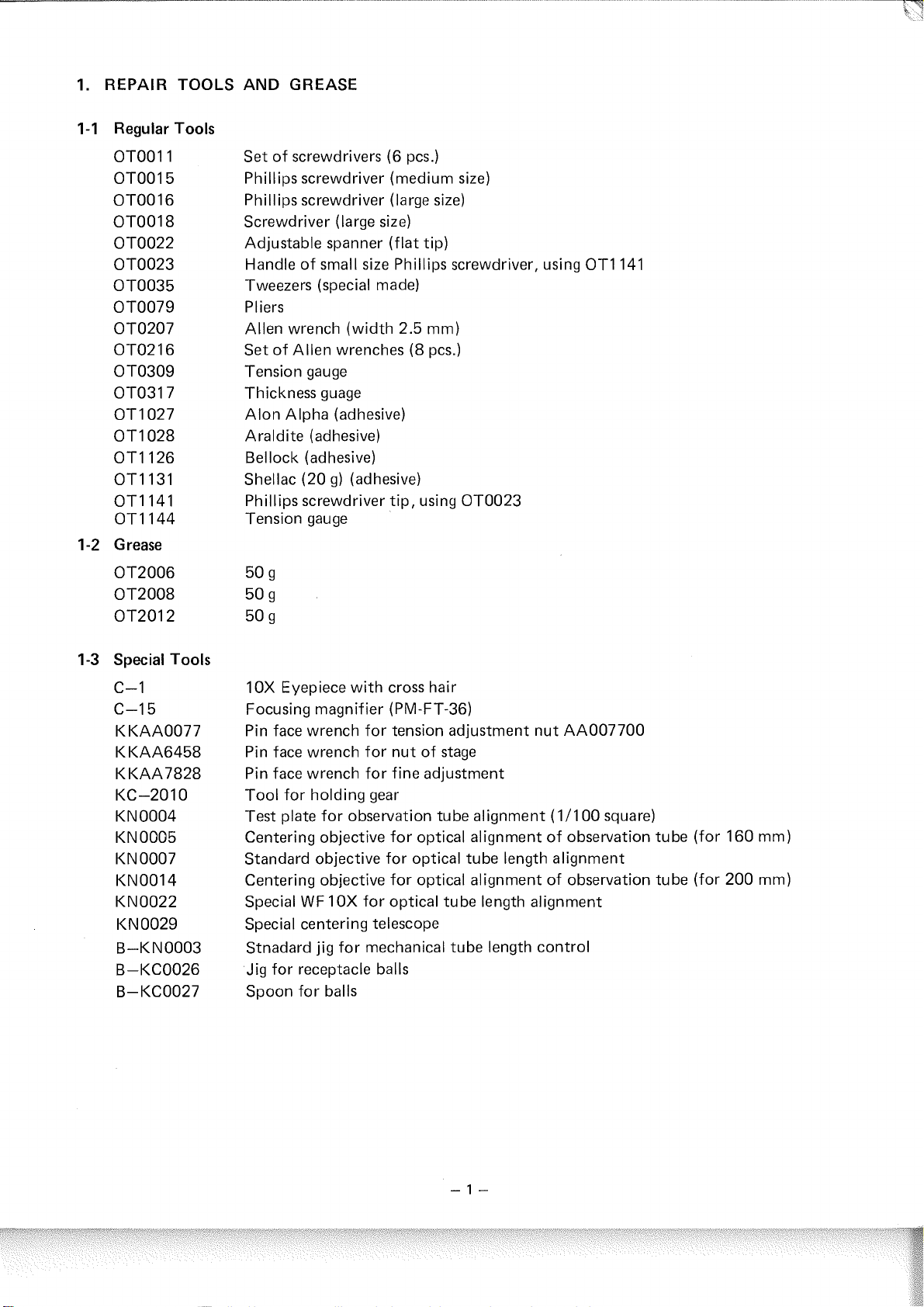

1.

REPAIR TOOLS AND GREASE

1-1

Regular Tools

1-2

OTOOl

I

OT0015

OT0016

OT0018

OT0022

OT0023

OT0035

OT0079

OT0207

OT02 16

OT0309

OT0317

OT1027

OT1028

OT1126

OT1131

OT1141

OT1144

Grease

OT2006

OT2008

OT2012

Set of screwdrivers (6 pcs.)

Phillips screwdriver (medium size)

Phillips screwdriver (large size)

Screwdriver (large size)

Adjustable spanner (flat tip)

Handle of small size Phillips screwdriver, using

Tweezers (special made)

Pliers

Allen wrench (width 2.5

mm)

Set of Allen wrenches (8 pcs.)

Tension gauge

Thickness guage

Alon Alpha (adhesive)

Araldite (adhesive)

Bellock (adhesive)

Shellac (20

Phillips screwdriver tip, using

g) (adhesive)

OT0023

Tension gauge

OT1 141

1-3

Special Tools

OX Eyepiece with cross hair

1

Focusing magnifier (PM-FT-36)

Pin face wrench for tension adjustment nut

AA007700

Pin face wrench for nut of stage

Pin face wrench for fine adjustment

Tool for holding gear

Test plate for observation tube alignment

(1/100 square)

Centering objective for optical alignment of observation tube (for 160

Standard objective for optical tube length alignment

Centering objective for optical alignment of observation tube (for 200

Special WF 10X for optical tube length alignment

Special centering telescope

Stnadard jig for mechanical tube length control

Jig for receptacle balls

Spoon for balls

mm)

mm)

Page 5

Pin tiole tube for aligning optical axis of mirror

Centering adapter

Positionitiy jig for rack AB024100

Block for cliccl<iny sensitivity of fine adjustment

Block for cliccking sensitivity of fine adjustment

Jig for

UIITR tulle prism alignment of BH2 series

Alignment jig

IJosilionilig jig for prism ZA071000 of BH2-TR

.Jig fol intcrljupillary distance

at

62 mm of BH2-BIITR

Aligri~r~etit jig for photo tube of BH2-TR

Finder

eyepiccc

Page 6

I

A MODEL OR UNIT. PARTS NUMBER AND QUANTITY.

-3-

Page 7

L7:::8500/ KNW 3SA

/

AB

0866007,

3

X

AB 034700

AB 023400

AB 024800

105A

Al

j

0:3?

AA 001

PI

100

A13

033800

II<

-

t100

3X/l(;,

/

-

I

"

Uv

/

\

V'

AA 782900

PUK 2x6s.

AB 034800

--

A13

AB 4 X

6SA

PUK 2 X 4SA

AU 0!19000

AB 059200

AB

3X6SA

3PUK 2 6 X 4SA7 TAB 060700

'$w@~

russuu-

CA 035600

EXPLODED PARTS

OLVMPUS OPTICAL

WtfL

N

01~1)~

A

MOIH

I

lilbi(i

011

O~JI

,

----

1

014

I

C,Ul,

'~I'AfiI

IIAII

,,r

11

1%

1~~it4

I

ct

rd11t

t1i1

CSK 2 6 X 6%

DIAGIIAM

Pl%i&'lTC'r.

.-

*&

I

lsl

I

A'JI

ti

~trit)

OlJAN I I1

JAP

(:I

ARIF

Y.

Y

Page 8

CSK

2.6

X

6SA

EXPLODED PARTS DIAGRAM

I

NOTE: WHEN ORDERING FOR SPARE PARTS. PLEASE CLARIFY

-5-

MODEL

A MODEL OR UNIT. PARTS NUMBER AND QUANTITY.

I

UNIT

1

FIG

I

Page 9

A

M0I)I I OIi UNIT. PARTS NUMBER AND OUANTITY.

Page 10

DT 0105(For 100V)

DT 01 06(For 200V)

UYPC 64-1 (For 100V)

UYPC 64-2(For 200V)

-CUK 3X4SA

AB 099900( For 100V)

CUK 3 X 4SA

I

'AA 8 14700

EXPLODED PARTS DIAGRAM

MODEL

B2-BDS-2

OLYMPUS OPTICAL CO., LTD. TOKYO, JAPAN

I"

NOTE. WHEN ORDERING FOR SPARE PARTS. PLEASE CLARIFY

- 7 -

h40DEL OR UNIT. PARTS NUMBER AND QUANTITY.

A

Page 11

AB

A9 025600

KNW 2.6SA

3PUK 2.6 Y 5SA

046500

,*

\

A[

1

O;'!?!)lH)

Page 12

CUK 4 x 30SA

DT

0103(For 100V)

DT 01 04 (For 200V

)

DS 0095 (For 100V

DS 0096 (For 200V)

AB 028500( For 100V)

AB 028600( For 200V)

)

'

AB 061 200(For IOOV)

AB 061 300( For 200V)

-

4

CUK 4X lOSA,,,

BNW 4SA

GA 135400

CLJK 4' 18SA

EXPLODED PARTS DIAGRAM

NOTE WHEN ORDERING FOR SPARE PARTS PLEASE CLARIFY

A MODEL OR UNIT. PARTS NUMBER 4ND QUANTITY.

Page 13

Page 14

Page 15

LA 459400.1

CUK

2.6 X 25SA

I

'

-

----

LA 459600

AB 058500

O&---

2;

7;;:;;

AA 726300

1

fY3\

A% 022400

1

NO1 I WIII N OI\I)I IIING FOR SPARE PARTS. PLEASE CLARIFY

A

MOIII-

I.

ON

UNIT, PARTS NUMBER AND QUANTITY.

--

1

2

-

-

Page 16

A

I

CUK

2.6 X 30SA

B

I

C

096200 AB 060200-

I

D

CUK

3 X 8SA

-

EXPLODED PARTS DIAGRAM

MODEL

I

OLYMPUS OPTICAL CO.. LTD. TOKYO, JAPAN

NOTE. WHEN ORDERING FOR SPARE PARTS. PLEASE CLARIFY

A MODEL OR UNIT. PARTS NUMBER AND QUANTITY.

1

I

UNIT

I

1

I

FIG

Page 17

AB 021 000

AB 021200---.

.--

-

I

---

---SP

1.6X4U0

---

AB 0 1 8400

-

..

ACU 2.6

-

X

1

OSA

Page 18

PSK

2

x

~SA'

-

"%M*d4d--

L

XPL

061LAX3

PSK

2

TS

DIAGRAM

x

4~~1

I

0I.VMPIJS

NO]

I

-

15

-

OfJTICAL

WI{L

N

OITIII

A MOl)l 1 01i ON11 PARTS NUMBER AND OUANTITY.

I~ING

I

o1i

CQ.,

SPARE

LTD. TOKYO,

P'ARTS

PLEASE

JAPAN

CLARIFY

Page 19

Page 20

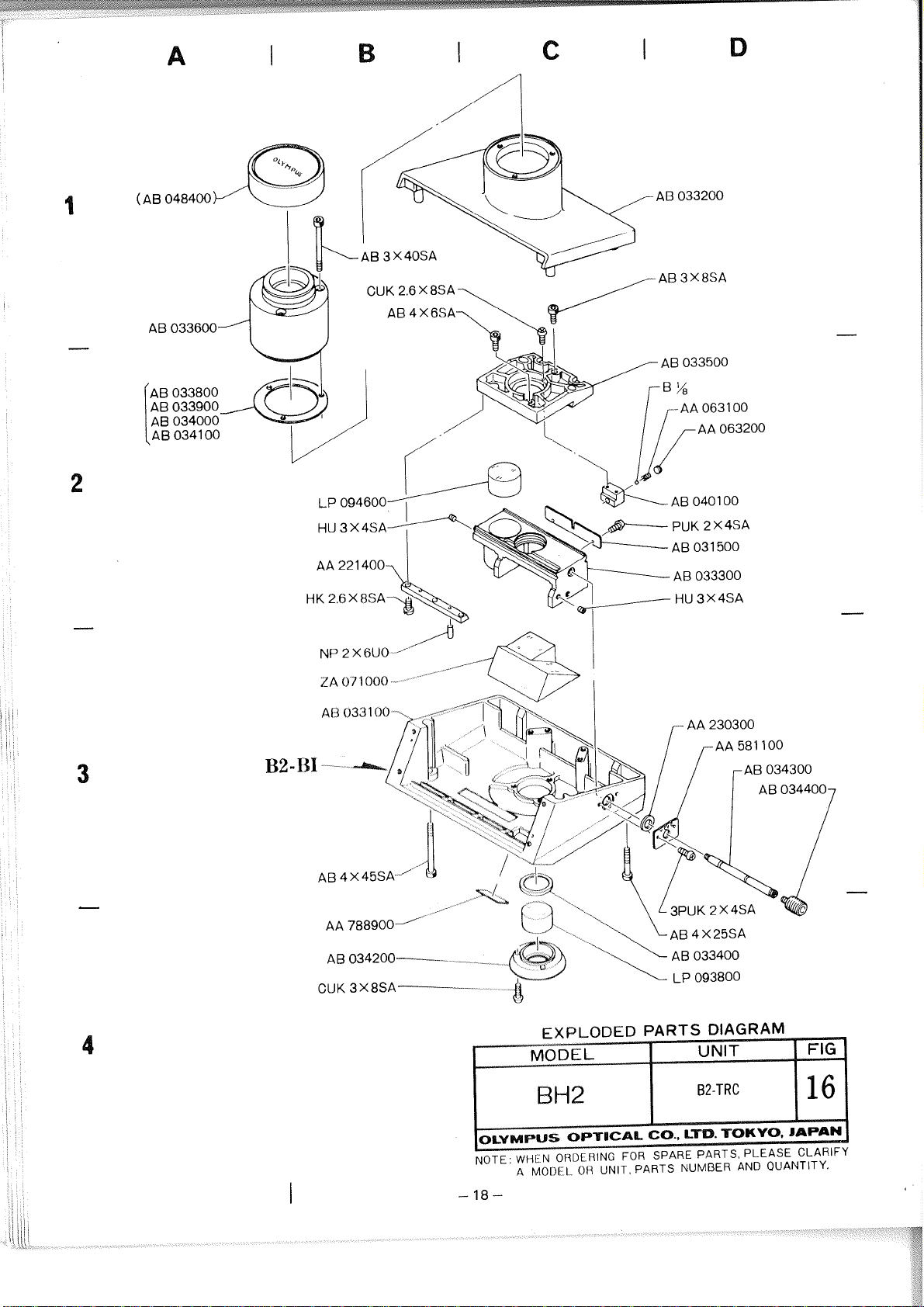

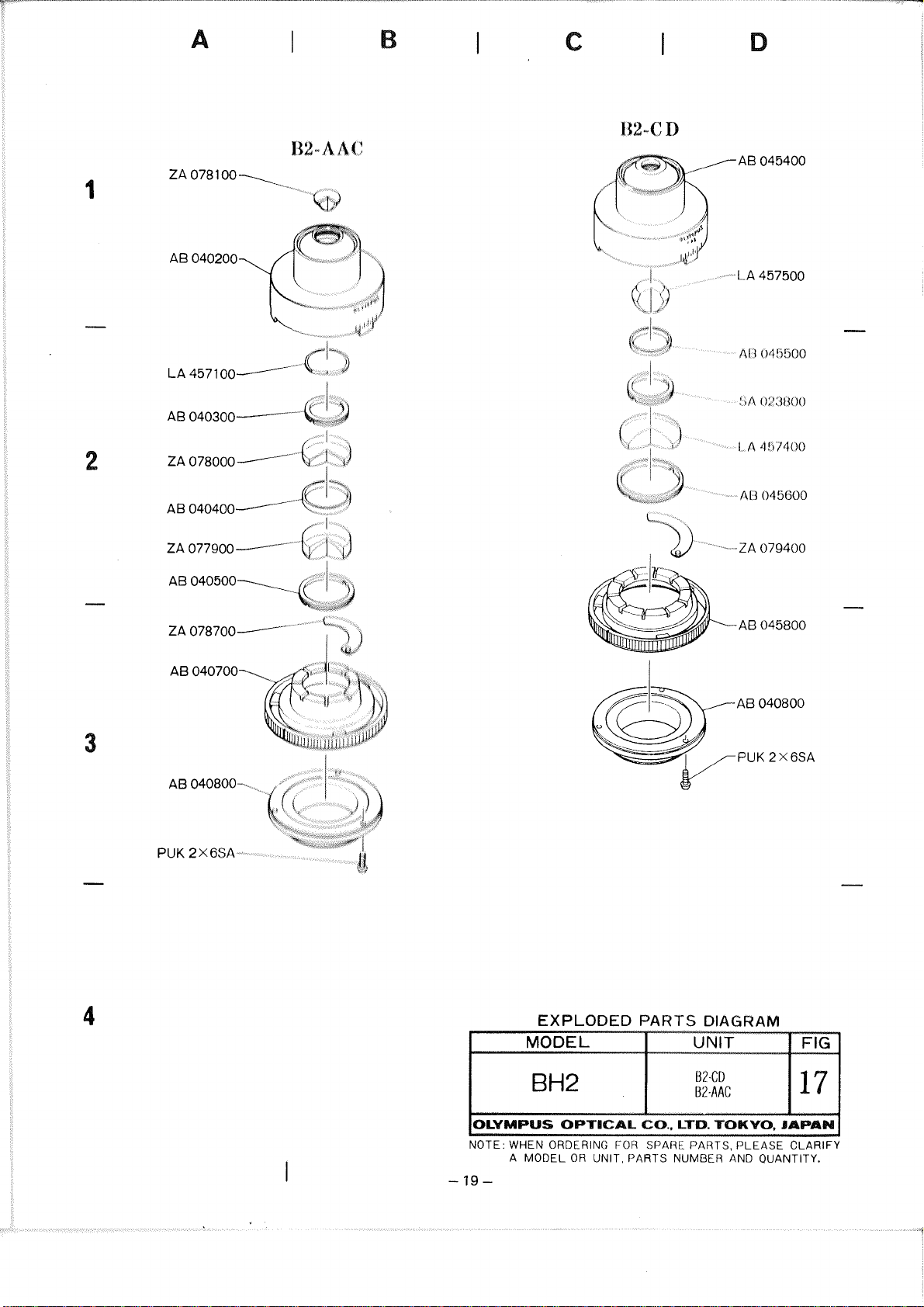

EXPLODED PARTS DIAGRAM

NO1

E:

WHEN ORDERING FOR SPARE PARTS. PLEASE CLARIFY

A MODEL OR UNIT. PARTS NUMBER AND

OiJANTITY.

Page 21

AA 788900~

AB 034200---

CUK

3X8SA

__

ER

AND

QUANTITY.

Page 22

AB 040800

PUK

2

X

EXPLODED PARTS DIAGRAM

6SA

OLVMPUS OPTICAL CO., LTD. TOKVO

NOTE WHEN ORDERING

A MODEL OR UNIT. PARTS NUMBER AND QUANTITY.

FOH

SPARE PARTS. PLEASE CLARIFY

JAPAN

Page 23

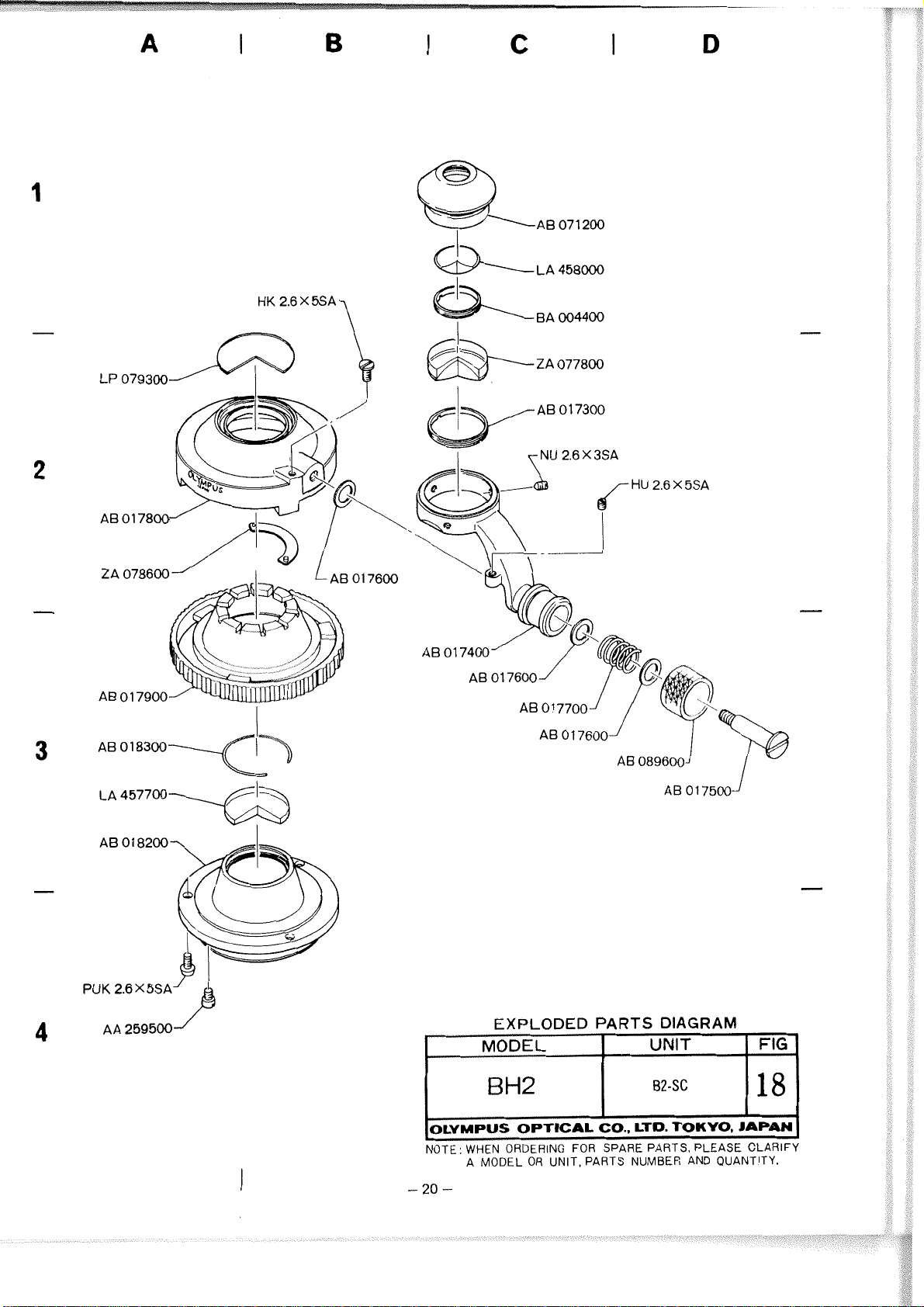

[

EXPLODED

MODEL

PARTS

I

DIAGRAM

UNIT

I

I

FIG

I

OLVMPUS OPTICAL CO.. LTD. TOKYO. JAPAN

NnTF

WHFN

..".

-,

ORDERING FOR SPARE PARTS. PLEASE CLARIFY

.. .-

.

-

A MODEL

OR

UNIT, PARTS NUMBER AND QUANTITY.

I

Page 24

D

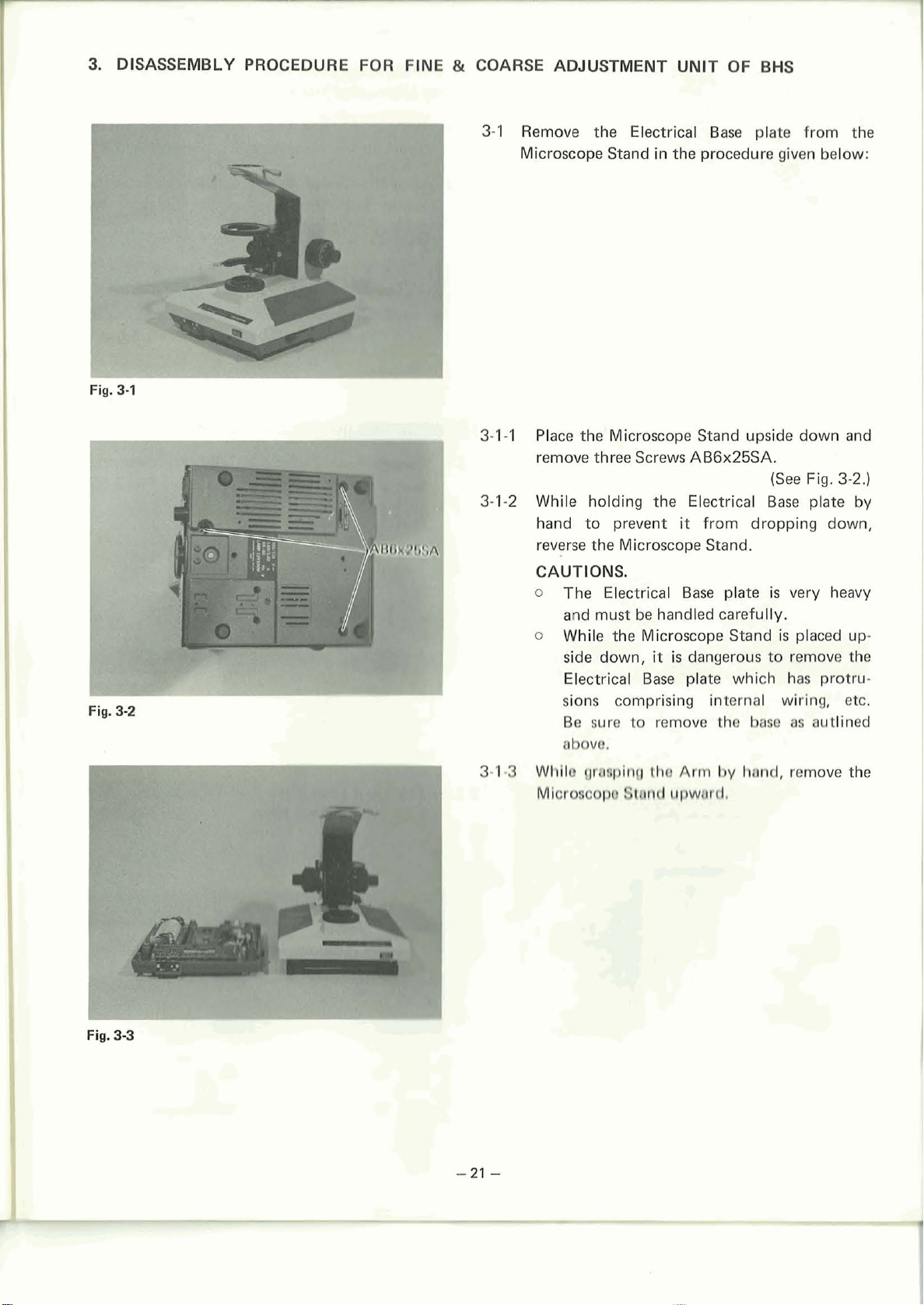

3.

DISASSEMBLY PROCEDURE FOR FINE & COARSE ADJUST3MQ&T OF

BHS

-

3-1 Remove the Electrical Base plate from the

Microscope Stand in the procedure given below:

Fig.

3-1

3-1-1 Place the Microscope Stand upside down and

remove three Screws

3-1-2 While holding the Electrical Base plate

hand to prevent

AB6x25SA.

(See Fig.

it

from dropping down,

3-2.)

by

reverse the Microscope Stand.

Fig.

3-2

I

3-19

CAUTIONS.

o

The Electrical Base plate

is

very heavy

and must be handled carefully.

o

While the Microscope Stand is placed up-

it

is

side down,

dangerous to remove the

Electrical Base plate which has protru-

sions comprising internal wiring, etc.

Be sure to remove the base as autlined

abova.

Whllr

Mlcro8cop~

grr~plng tha

Bund

upward.

Arm

by

hand, remove the

Fig.

3-3

-21

-

Page 25

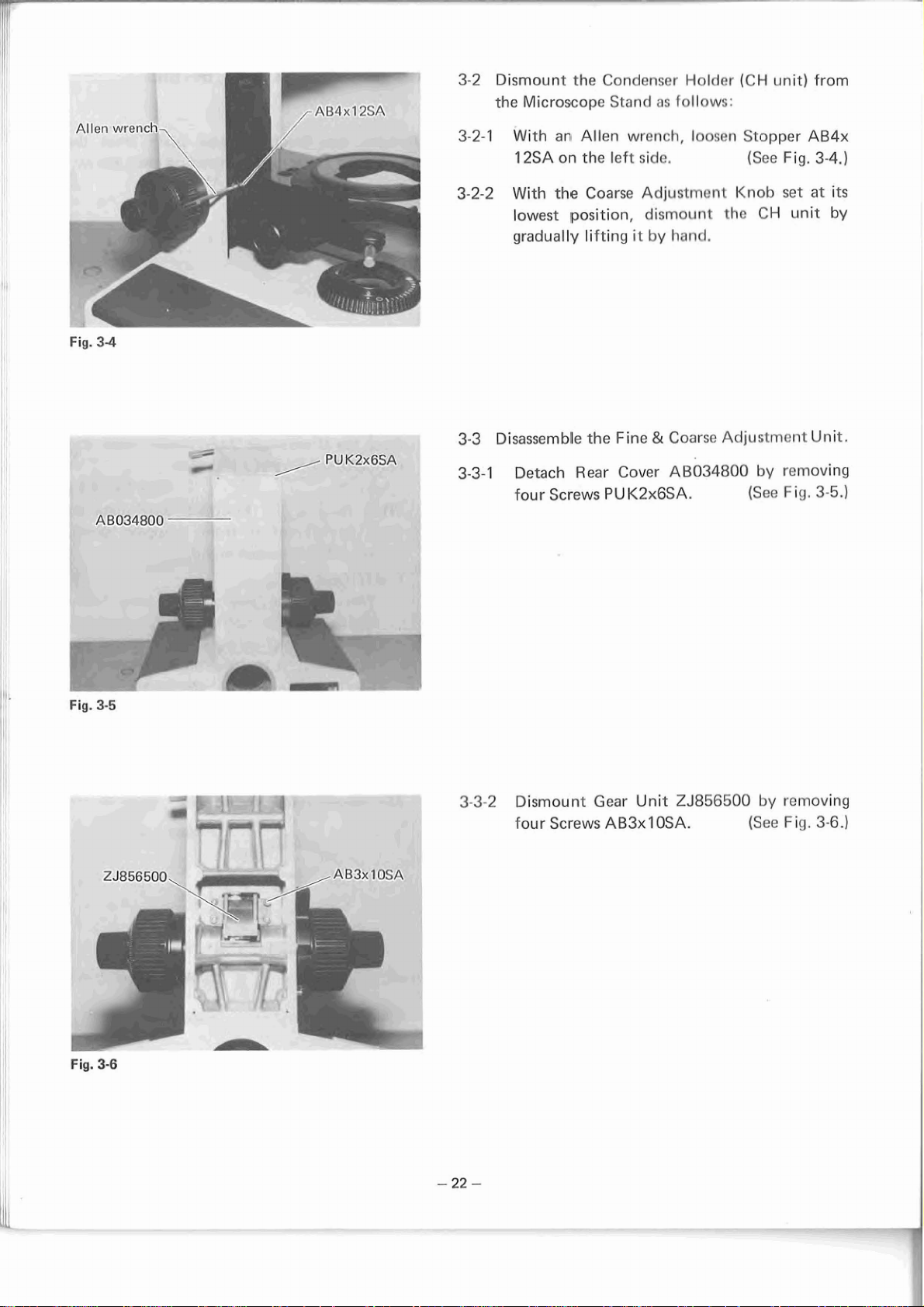

3-2

Dismount

the

Microscope

the

Condenser

Stand

Holder

as

follows:

{CH

unit)

from

Fig.

34

4

/

-

PU

K2x6SA

3-2-1

3-2-2

3-3

Disassemble

3-3-1

With

an,

Allen

12SA

on

the

left

With

the

Coarse

lowest

gradually lifting

Detach

four

position,

the

Rear

Screws

fine

Cover

PUK2x6SA.

wrench,

side.

Adjustrncnt

dismount

it

by

hand.

&

Coarse

loosen

~~034800

Stopper

(See

Knob

the

CH

Adjustment Unit.

by

(See

AB4x

Fig.

3-4.)

set

at

its

unit

by

removing

Fig.

3-5.)

Fig.

Fig,

3-5

3-6

h-

c.

3.3-2

~C.7

YE-

',-+:

-

4

7

,

>-'

"~1.-

w

Dismount

four

Screws

Gear

AB3xl

Unit

OSA.

ZJ856500

by

(See

removing

Fig.

3-6.)

Page 26

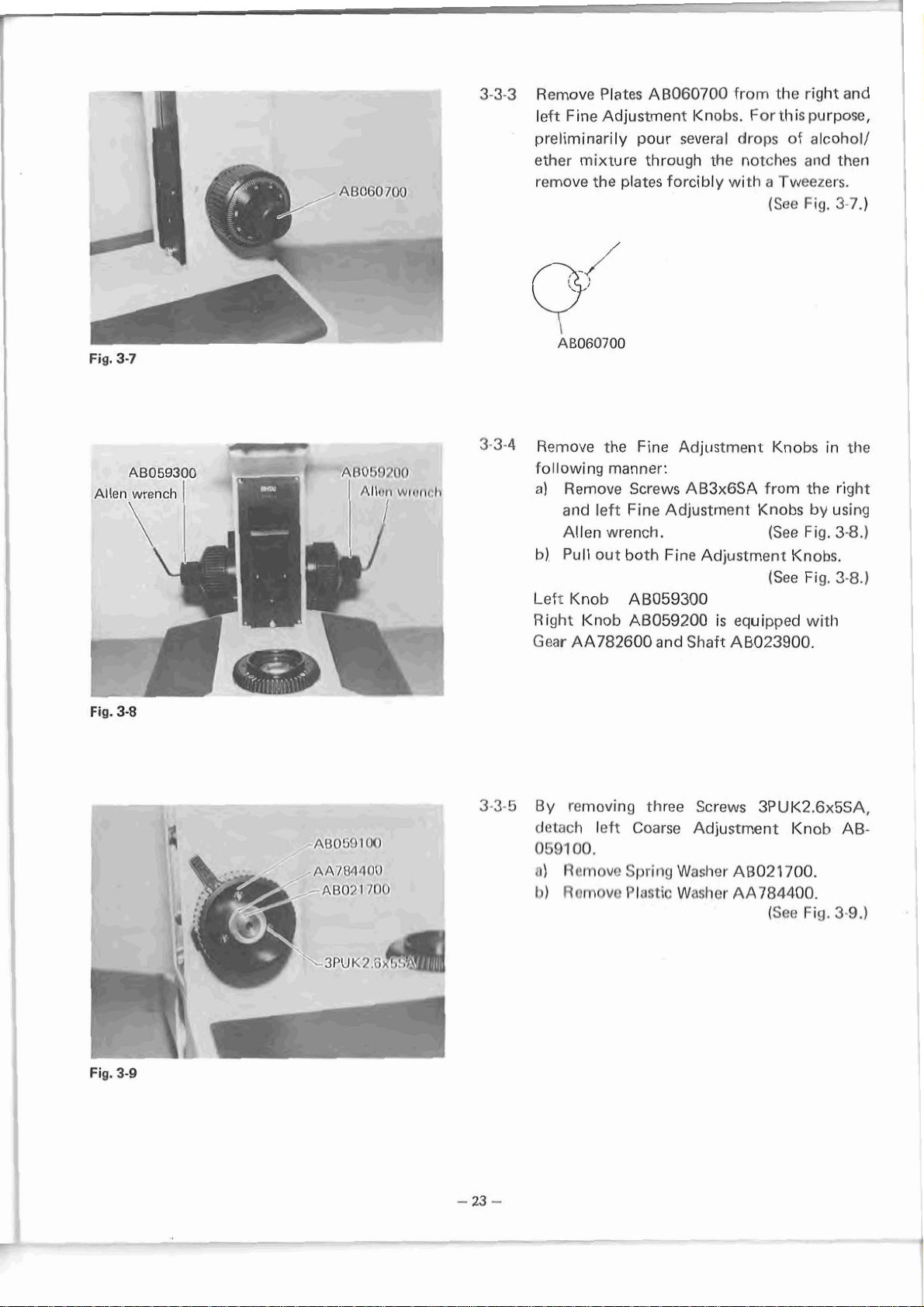

Fig.

3-7

3-3-3

preliminarily

ether

remove

a,,

.-.

'#

~not;n/oo

I

_.

Remove

left Fine Adjustment

Plates

mixture

the

plates forcibly

AB060700

pour

through

Knobs.

several

the

from

For

drops

notches

with

a

(See

the

right

this

purpose,

of

alcohol/

and

Tweezers.

Fig.

and

then

3.7.)

Allen

It

I

Fig.

AB059300

wrench

\

3-8

I

n

4

-

[)n1~o1o~~

4rl11!1

7

1

/[lo

3-34

3-3-5

Remove

following

a)

Remove

and

Allen

bJ

Pull

Left

Knob

Right

Gear

By

detach

0591

n)

1))

Knob

AA782600

removing

00.

Rt!movo

nnrnovr!

the

Fine

manner:

Screws

lef~

Fine

wrench.

out

both

AB059300

A8059200

left

Coarse

Spring

Plastic

Adjustment

AB3xGSA

Adjustment

Fine Adjustment

is

equipped

and

Shaft

A8023900.

three

Screws

Adjustment

Washer

Washer

AB021700.

AA784400.

Knobs

from

Knobs

(See

(See

3PUK2.6x5SA.

(See

in

the

by

using

Fig

.3-8

Knobs.

Fig.

with

Knob

Fig.

the

right

,)

3-8.)

AB-

3-9.)

I

I

3l

>L

Page 27

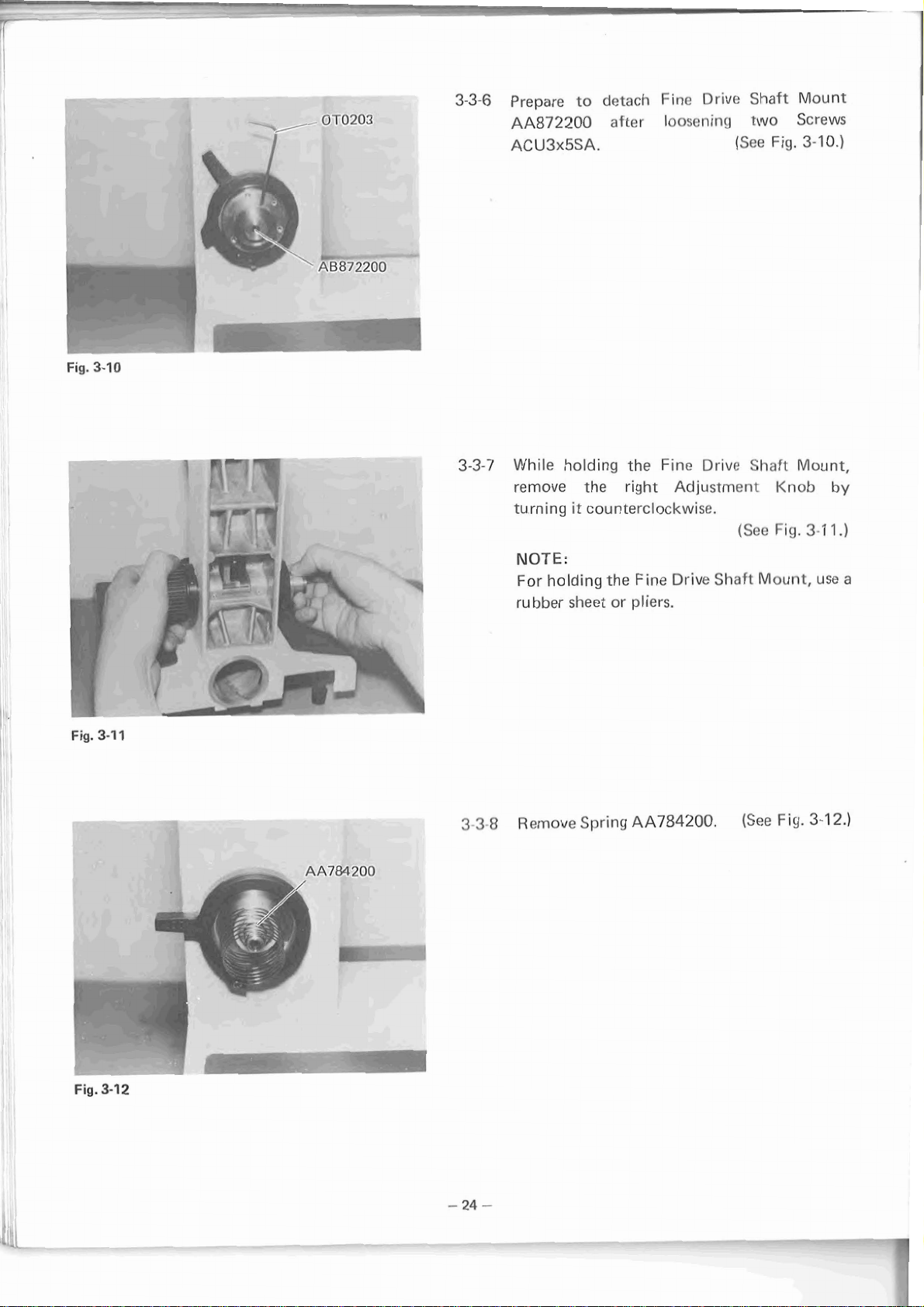

Fig.

3-1

3-36

./---

-

1

0

0T02Q3

Prepare

to

AA872200

ACU3x5SA.

detach

after

Fine

Drive

loosening

Shaft

two

(See

Fig.

Mount

Screws

3-1

0.)

Fig.

3-1

3-3-7

While holding

remove

tu.rning

it

the

Fine

the

right

Adjustment Knob

counterclockwise.

Drive

Shaft

(See

Fig.

Mount,

by

3-1

1

.)

NOTE:

For

I

holding

rubber sheet

1

3-3-8

Remove

the

or

Spring

Fine

Drive

pliers.

AA784200.

Shaft

(See

Mount,

Fig.

use

3-1

a

2.)

Fig.

3-1

!

2

Page 28

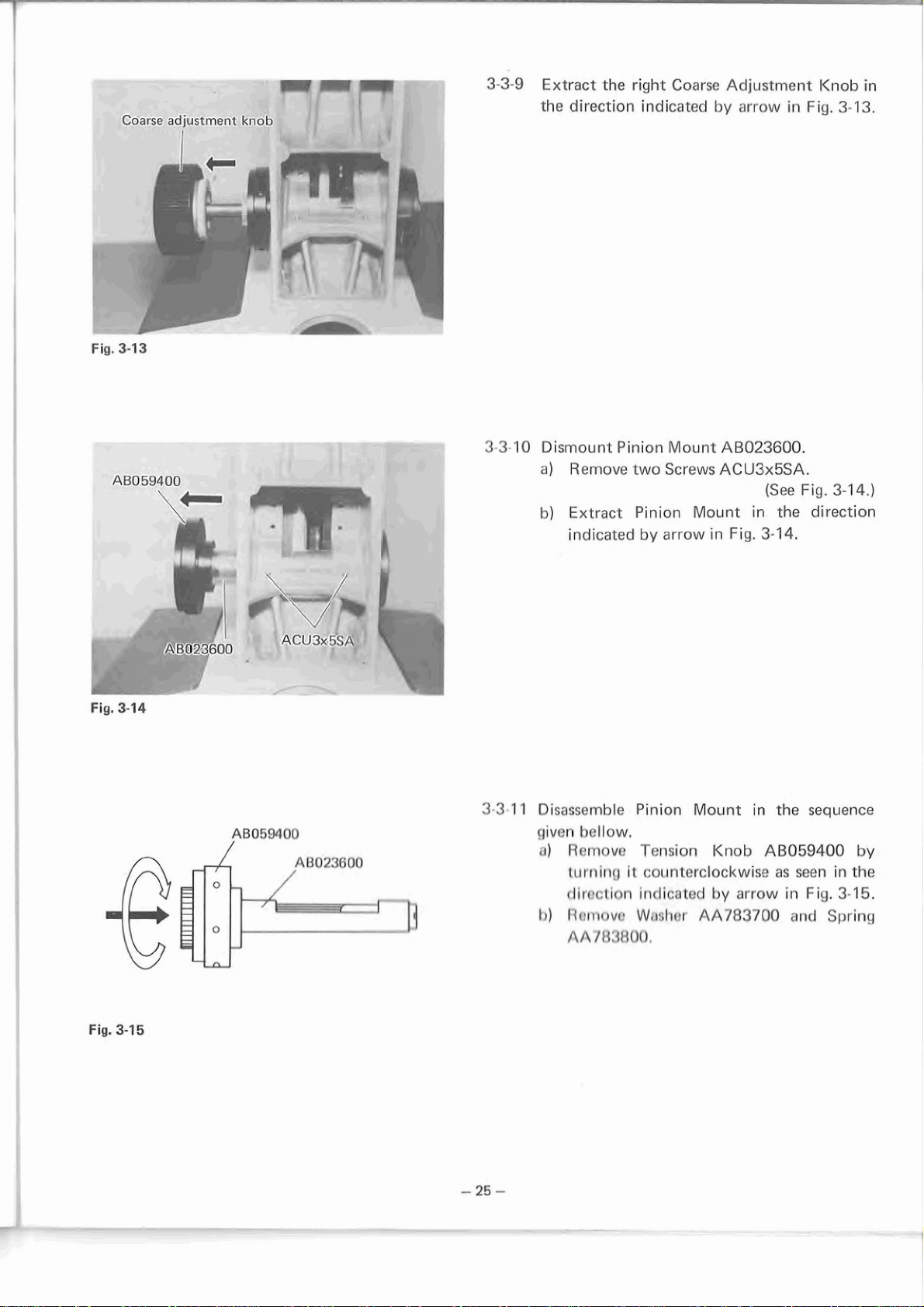

Fig.

Coarse

3-13

adjustment

I

'.-

-'

-

-

-

3-3-9

3-3-1

Extract

the

0

Dismount

a)

b)

the

direction

Pinion

Remove

Extract

indicated

right

Coarse

indicated

Mount

two

Screws

Pinion

by

arrow

Adjustment

by

arrow

AB023600.

ACU3x5SA.

Mount

in

in

Fig.

in

(See

the

3-14.

Knob

Fig.

3-1

Fig.

3-1

direction

in

3.

4.1

Fig.

Fig.

3-14

3-15

AB0591.00

1

3.3

11

Disassemble

given

n)

1))

Pinion

bellow.

Remove

turning

rlirrr:tion

Rcqrnnvr

AA7tt3ftO0,

Tension

it

counterclockwise

indicated

Wlrnhrr

Mount

AA783700

Knob

hy

arrow

in

AB059400

the

as

in

and

seen

Fig.

sequence

by

in

the

3-15.

Spring

Page 29

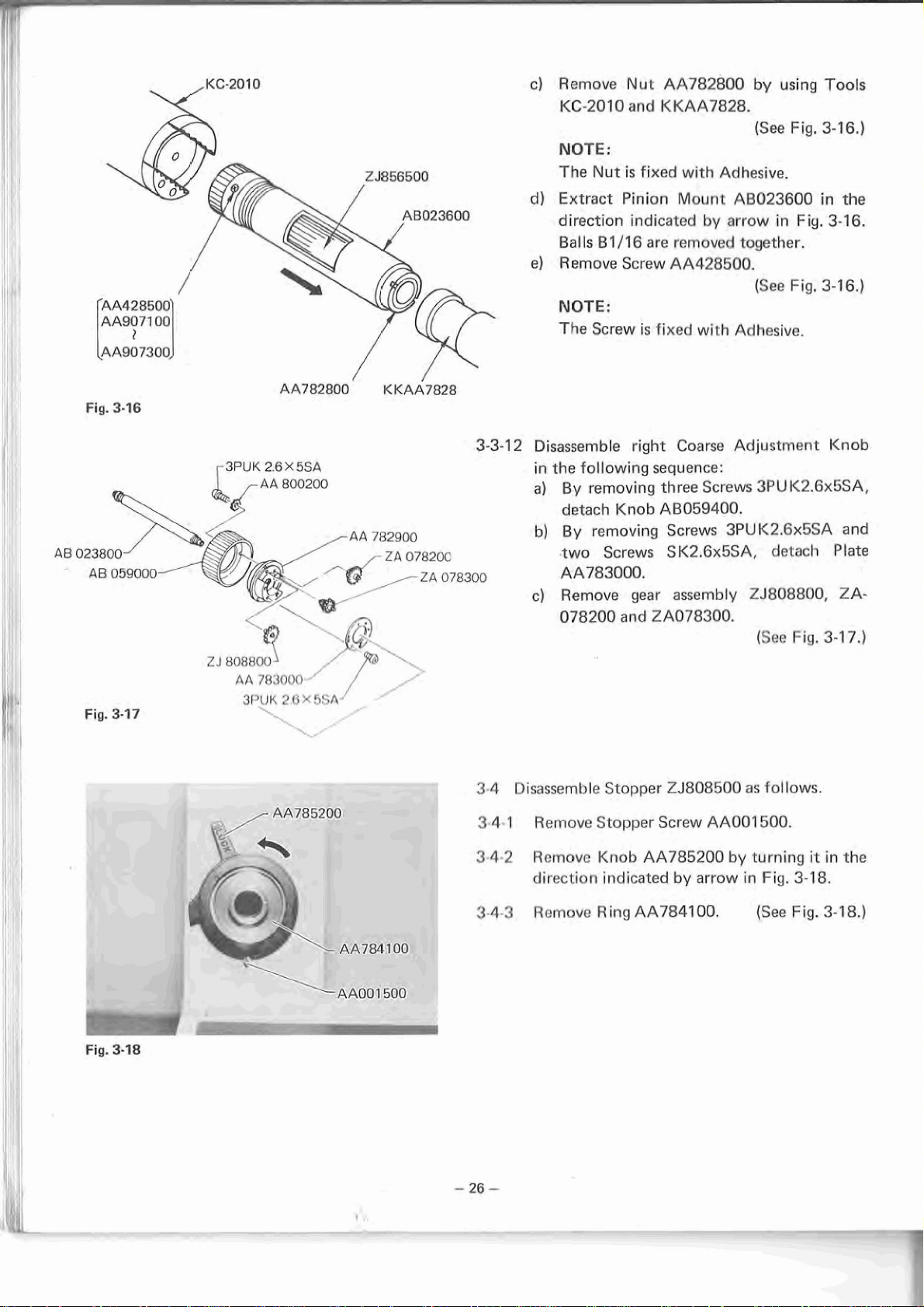

c)

Remove

NOTE:

The

d)

Extract

direction

Balls

el

NOTE:

Tbe

KC-2010

Nut

B1/16

R

ernove

Screw

Screw

Nut

AA782800

and

KKAA7828.

is

fixed

with

Pinion

Mount

indicated

are

removed

AA428500.

is

fixed

Adhesive.

AB023600

by

arrow

together.

with

Adhesive.

by

{See

in

(See

using

Fig.

Fig.

Fig.

Tools

3-

f

6.)

in

the

3-16.

3-16.)

Fig.

3-76

3PUK

~~782800'

2.6

X

5SA

K

~~~7828

3-3-1

2

Disassemble

in

the

following

a)

By

removing

detach

b)

By

removing Screws

two

Screws

right

Coarse

sequence:

three

Screws

Knob AB059400.

3PUK2.6x5SA

S

K2.6x5SA,

Adjustment

3PU

K2.6x5SA,

detach

Knob

and

Plate

AA783000.

c)

Remove

078200

I

!

Fig.

3-17

3.4

Disassemble

3m4.1

Remove

gear

and

2

Stopper

Stopper

assembly

A078300.

ZJ808500

Screw

AAOOl

23808800,

(See

Fig,

as

follows.

500.

3-1

ZA-

7.)

Fig.

3-18

fr

$rn

---\

-'-/

\;

!

AA784100

3-4-2

3-43

Remove

direction

Remove

Knob

AA785200

indicated

R

ing

AA784100.

by

arrow

by

turning

in

(See

Fig.

it

3-18,

Fig.

in

3-1

the

8.)

Page 30

-

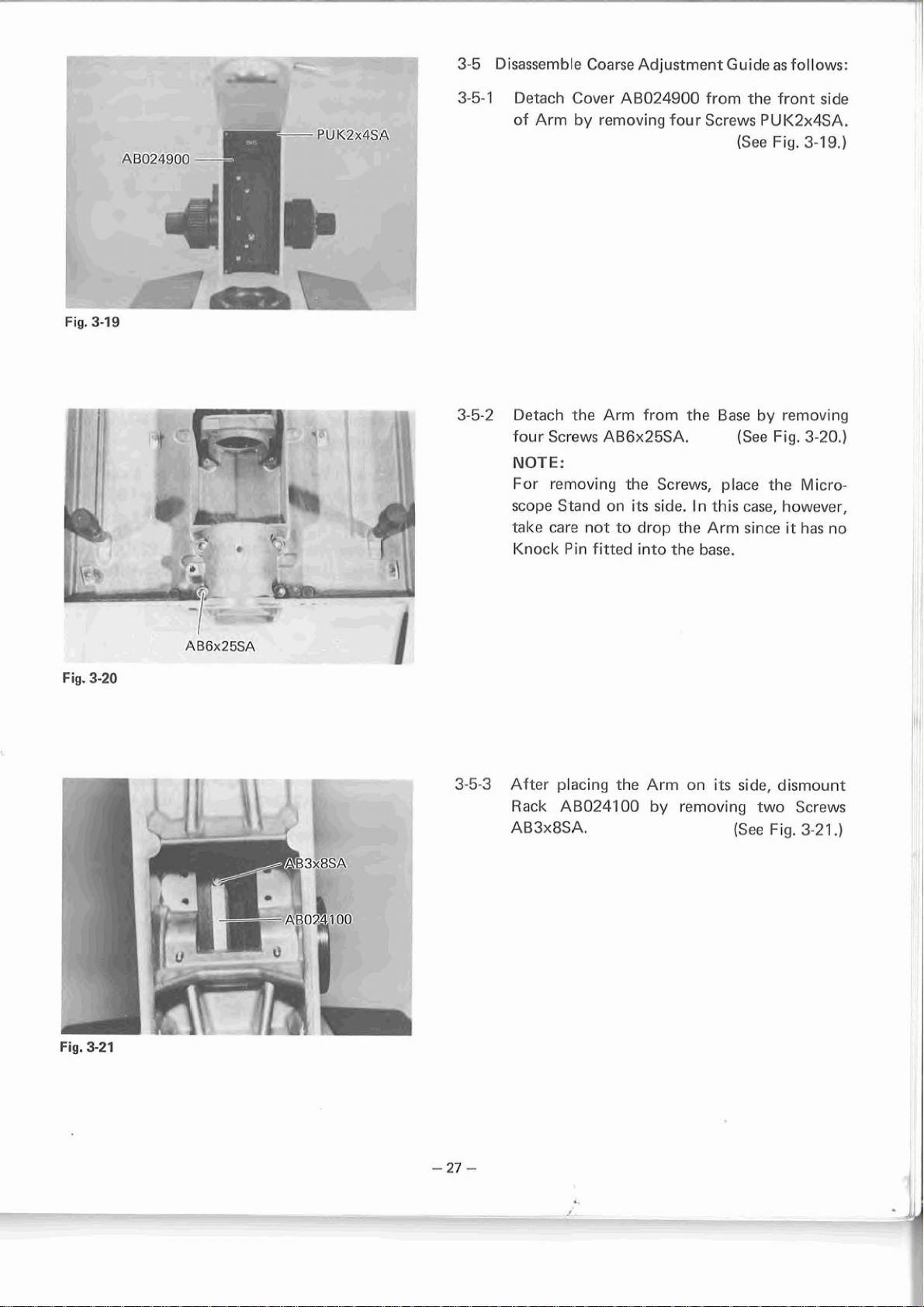

3-5

Disassemble

Coarse

Adjustment

Guide

as

follows:

Fig.

AB024900

3-19

--

p-r

PU

K2x4bu

.-

3-5-1

3-5-2

Detach

of

Detach the

four

NOTE:

For

scope

take

Knock

Cover

Arm

Screws

removing the Screws,

Stand

care

Pin

AB024900

by

removing

Arm from

AB6x25SA.

on

not

to

fitted

its

drop

into

four

side.

the

the

In

the

from

Screws

(See

Base

(See

place

this

Arm

base.

the

P

U

Fig.

by

Fig,

the

case,

since

front

side

K2x4SA.

3-79,)

removing

3-20.)

Micro-

however,

it

has

no

Fig,

3-20

1

Lc5ESY

Fig.

3-21

-

L

ie

TT

rl

7

F-

1

3-5-3

After

Rack

placing

AB024100

AB3xBSA.

the

Arm

by

on

its

removing

(See

side, dismount

two

Screws

Fig.

3-21

.)

Page 31

I--

Fig.

3-22

3-5-4

<<<

.\>

1

3-5-5

Sufficiently

which

Loosen

are

four

used

loosen

to

Screws

two

Screws

attach

Guide

AB3x12SA

AB3x

Fixing

(See

Fig.

sufficiently.

(See

Fig.

16SA

Piece

3-22.)

3-22.)

t

Fig.

3-23

---

r

..

. - -.

L

---

.-

-c

-

--

3

3-6

'Disassemble

the

3-6-1

3-6-2

3-6-3

3-6-4

sequence

Extract

Guide

in

Remove

Spacers

and

Remove

Ball

Wash

After

completely

Fig.

four

Guide

each

the

unit

3-23.

sixteen

AB023300,

Wires

Guide

washing,

Inner

Ball

given

below:

entire

in

the

direction

Rollers

AB023500.

Fixing

AB024800.

part

with

wipe

with

a

piece

Guide

assembly

Unit

indicated

AB022700,

four

Wires

Piece

gasoline

off

gasoline

of

dry

ABOT4700

of

Inner

by

(See

Fig.

A8023400

(See

Fig.

AB009700

(See

Fig.

or

xylol.

or

cloth.

in

Ball

arrow

3-23.)

two

3-23,)

and

3-24.)

xylol

Fig.

3-24

Page 32

4.

ASSEMBLY

Fig.

4-1

PROCEDURE

AB024

JOO

AB009700

FOR

FINE & COARSE

AB3x 1 6SA

ADJUSTMENT

4-1

Assembly

Unit.

4-1

-1

Assemble

lnner Ball

two

NOTE:

The

to

the

of

Coarse

Guide

Guide

Screws

Screws

such

Gu

AB3xl6SA.

should

a

degree

ide Fixing Piece.

UNIT

&

Fixing

ABO24700

be

that

OF

BHS

Fine

Adjustment

Piece

tightened

they will

Guide

ABO09700

by

tightening

(See

Fig.

temporarily

not

drop

with

4-3.)

from

Fig.

I

Fig.

4-2

4-3

'~80243

A8023500

00

4

4-1-3

Assemble

Guide

For

B2KC1006

shown

from

tightening

Assemble

the

guide

Rack

AB024700.

this

purpose,

to

in

Fig.

the

right

two

four

groove

NOTE:

After

surface

them

guides

in

this

applying

of

the

into

the

should

manner.)

CAUTION:

Make

sure

that the Wire

scratched

malfunction.

or

AB024100

attach

l

nner

Ball

4-2,

press

side

to

Screws

Wire

Guides

of

Arm

Grease

Wire

Guides,

guide

be

coated

nicked,

wi.th

positioning

Guide

the

AB024700

Rack

Jig

and

AB3x8SA.

(See

AB023500

AB022900.

OT2008

strech

groove.

with

{All

Grease

{See

Guides

which

are

lnner Ball

AB024100

fix

it

Fig.

4-2.1

into

onto

each

and

clamp

the

wire

and

Fig.

4-3.)

not

bent,

may

cause

Jig

as

by

set

Page 33

Fig.

id-

4-4

4-1-4

Assemble

AB022700

Spacer

(lower

AB023300

side

only).

and

Rollers

NOTES:

1.

..

.-

----

-

-

,

5-2

:<g

'

Apply

the

2,

Arrange

as

at

a

Rollers

shown

the

center,

thin

and

the

in

layers

Spacer

Rollers

Fig.

4-4

of

Grease

respectively.

in

alternate

and

place

(See

QT2008

directions

the

Spacer

Fig.

4-4.)

to

Fig.

p--

4-5

-

AB02330Q

4-1-5

Assemble

Inner Ball

Wire

Guide.

guides

A8023400

with

the

NOTE:

The

Wires

procedure

Arm.

the

1

4-1-6

Mount

Rollers

Ball

Guide

should

as

that

two

Wire

AB022700

A6024800.

be

assembled

for

assembling

Guides

and

Spacer

by

the

them

(See

Fig.

ABQ23400,

A6023300

(See

Fig.

same

with

4-5.)

eight

on

4-6.)

NOTE:

Assembling

for

assembly

procedure

with

the

is

Arm.

the

same

as

that

Fig.

46

Page 34

t-

'

Fig.

4-7

[&

--<,

.

.

4-3

-7

Mount

(Fig.

4-4).

the

Inner

Guide

(Fig.

4-5)

(See

on

the

Fig.

Arm

4-7.)

Fig.

wf

4-8

vLb-:

-

-------=

;

9

/AB024800

.-

,

'

+

.

L:~

-

-

AB3x12SA

:f,

".dl'=

4.

.-

.+--

,.-p

-,:d

-I_

-

-

>'

<.

.

-

-&

-T-

-

.

4-1

4-1-9

Assemble

-8

Ing

manner:

a)

Push

position.

b)

AB3xl6SA

c)

By

clamp

degree

play

Fix

Guide

AB3x12SA.

Ball

in

If

the

Ball

Fixing

tightening

Ball

Guide

Piece.

the

that

A8024700

Guide

the

Guide is

Guide

Ball

which

the

(Fig.

4-6)

Guide

too

is

used

two

Screws

Fixing

Ball

Guide

AB024800

by

tightening

and

tight

for

Piece

and

(See

in

assemble

(See

loosen

the

follow-

it

in

Fig.

4-8.)

Screw

the

Guide

AB3xlGSA,

to

such

a

is

free

from

Inner Ball

four

Screws

Fig.

4-9.)

Fig.

*

4-9

Page 35

I

Fig.

4-10

STANDARD

OT0309

I

I

for

sliding

-

-

-

-

#.

1.-

force:

-

80

--

--

-

--

-

120

4-1

-1

0

Check

operation

a)

-

-

-

1

g

b)

c)

d)

and

adjust

in

the

By

using Tension

the

Ball

Guide

it

casily.

If

the

force

as

follows:

(1)

After

I

2SA,

to

clamp

(2)

Tighten

(3)

Measure

the Ball

If

the

force

reduce

ing

Check

clamping

Piece

the

referring

the

Ball

sequence

Gauge

for

force

is

weaker

loosening

tighten

four

guide

Ball Guide

the

Screws

force

is

two

Guidc

once

stronger

force

to

Guide

given

khan

four

for

below:

OT0309,

required

(See

specified

Screws

Screws

Fixing

AB3x12SA.

required

ai~air~.

tllnn specified,

for

the

b)

ahove,

for

its

proper

its

proper

check

to

Fig.

4-1

adjust

AB3x

Piece.

(or

sliding

Guide!

opera-

side

0.)

AB3x

f

6SA

Fix-

1

1

i

i

Fig.

4-71

Desk

B-KC0027

4-2-1

Assemble

Mount

dure.

a)

Place Pinion

b)

lnsert30BallsBl/lGinjiqA-KC0027(30

balls

grooves.)

NOTE:

Apply

before

c)

Drop

by

a

around

d)

While

arrangement,

direction

Pinion

AB023600

can

be

Grease

insrtion.

the

Balls

arrow

Tweezers

{A)

the

Pinion.

taking

indicated

ZJ856400

in

the

ZJ856400

arranged

by

and

care

remove

with no

OT2012

in

the

pushing

arrange them

not

Jig

by

with Pinion

followinq

on

Jly

(SRC!

(SOH

to

direction

them

(See

to

disturb

B-KC0026

arrow

(B).

(See

R-KC0026.

F

in.

.tl;~ps

F

iq.

flails

indicated

with

Fig.

the

Fig.

proce-

4-

1 1

.)

in

the

4-1

1

.)

Bll16

tip

of

reatly

4-1

1

.)

Ball

in

the

4-1

1

.)

Page 36

e) Assemble Pinion Holder AB023600 in

position. (See Fig. 4-12.)

NOTE:

Take care not to disturb the Ball arrangement.

Fig. 4-12

I

1

,25856400

Drop the Balls in the direction

f)

to steps

g) Tighten Nut AA782800 to Pinion

856400 to eliminate thrust play

b) and c) above. (See Fig. 4-1 2.)

(C),

similar

ZJ-

Fig. 4-13

A5059400

\

4-2-2

Assemble Tension Adjusting Knob

with Pinion Mount AB023600.

NOTE:

Apply Grease OT2006 to the thread surface.

Assemble Spring

AA783700 in position. (See Fig. 4-1 3.)

NOTE:

Apply Grease OT2006 to contact surfaces.

AA783800 and Washer

AB059400

(See Fig. 4-1 3.)

Page 37

Fig.

4-74

I

A(:!

r:{x!,sn

4-2-4

Assemble the Pinion

Arm

by

tightening

two

NOTE:

Cement the

Screws

with

Mount

Screws

(See

Adhesive

Unit with the

ACU3xSSA.

Fig.

4-1

4.)

OT113T.

Fig.

4-15

~~02360d

Fig.

-

4-16

782800

4-2-5

Adjust Pinion

a)

While

ZJ856400

turning Pinion

adjust tightness condition

782800

uneven

until

rotation

the

or

thrust

NOTE:

Torque required to turn

Approx.

b)

For

loosening,

three points

AA782800

5

g

(rotatable very lightly)

preventing

apply

on

and

Pinion

Nut

Adhesiua

the

as

follows:

ZS8.56400

Pinion

is

play.

(See

AA7.82.800

threads

ZJ856400.

(See

by

of

Nut

frt?c!

Fig.

the

Pinion;

OT1027

of

the

Fig.

hand

AA-

from

4-1

from

Nut

4-

t

6.)

5.1

at

Fig.

4-17

4-2-6

Fit

Ring

AA784100

ZJ808500

into Outer

following manner:

a)

Carefully

free

6)

Also clean the inside

AA784000

is

to

wipe

from grease or contaminant.

into

be

fitted.

attached

Ring

Ring

AA784100

which

to

Cock

AA784000

until

of

Outer Ring

Ring

AA784100

(See

Fig.

Knob

in

the

it

4-1

7.)

is

Page 38

b

AB

785200

I

----*

4-2-7

4-2-8

Assemble

For

this

purpose,

0162D06

Knob

to the

clockwise

Assemble

Lock

Knob

as

Stopper

AA785200

apply

thread

far

as

a

and

it

AA001500

thin

will

in

coat

turn

go.

[See

in

(See

position.

of

Grease

the

Lock

Fig.

4-18,)

position,

Fig.

4-18.)

Fig.

Fig,

4-1

4-19

-

8

AAOll

I

'>llt~

4-2-9

4-2-10

Assemble

a)

the

b)

Assemble

078300,

by

two

Apply

each

Assemble

together

tightening three

Gear

Assemble

Mount

into

NOTE

Apply

AA782900

mount.

:

Adhesive

thread.

25808800

tightening

Screws

NOTE:

Grease

gear

unit.

Coarse

with

Mount

Shaft

AA782900

AB0238QO

OT1028

Gear

Units

Screw

S

K2.6x5SA.

OT2012

Adjustment

three

Washers

Screws

3PU

as

follows:

with

by

threading

IAraFdite)

ZA078200,

and

Plate

AA783000

3PVK2.6x5SA

(See

Fig.

to

the

shaft

KnobAB059000

AA800200

K2.6x5SA.

Gear

shaft

ZJ-

and

4-1

9.)

by

to

of

I

I

I-

-

bU

I

I,

rf

1

u

4-2-1 1 l

4-2-12

nsert

Shaft

ment

into

the

Hook

Knob (Fig.

Pinion

Microscope

Screw

AA784100

of

Spring

AA784200.

A6023800

4-19)

25856400

Stand.

AA146300

into

the

circular

of

the

from

which

located

portion

Coarse

the

is

attached

(See

Fig.

{See

Fig.

Adjust-

right

4-20.)

on

at

theend

4-20.)

side

to

Ring

Page 39

Fig.

4-21

4-2-1

3

Assemble

as

follows:

a)

Apply

Screw

b)

After

AA872300,

c)

Temporarily

6SA

AA872200.

Fine Drive

Adhesive

AA146300

Drive

Shaft

applying

to

protrude

Mount.

it

assemble

such

inside

Shaft

OTl

and screw

Grease

in

position,

a

degree

Fine

Mount

126

to

the

it

OT2008

twoscrews

that they

Drive

Shaft

{See

Fig.

AA872250

thread

into

to

of

Fine

Washer

ACU3x

do

not

Mount

14-21,)

I

Fig.

4-22

Screw

--

4

AA146300

I

on

AA784100

"-2-14

I

Place

Fine

position

a)

Fit

Drive

circular

AA784200

While

Mount

Stand,

Then

brought

While

872200

Stand,

other

as

A

After

depress

lightly

again.

Drive

as

follows:

Screw

AA146300 located

Shaft

portion

(as

depressing

lightly

turn

it

the

two

into contact

:keeping

a

little

move

screws.

+

B

+

C

one

screw

the

anto

Shaft

Mount

Mount

AA782200

at

the

shown

the

in

toward

one

rotation

Screws

Fine Drive

apart

from

Screw

(These

in

Fine

the

AA'146300

steps

Fig,

4-23.)

rotated

Drive

Microscope

AA872200

other

end

Fig,

4-20).

Fine

Drive

the

clockwise.

(See

AA146300

with

Shaft

the

are

over

Shaft

(See

in

on

Fine

into the

of

Spring

Shaft

Microscope

Fig.

4-22.)

are

each

other.

Mount

M

AA-

icroscape

over

the

illustrated

the

other,

Mount

Stand

Fig.

once

4-23.)

Fig.

4-23

Screw

AA146300

on

AA872200

Page 40

Fig.

4-24

b)

While depressing Fine

AA872200

Stand,

ment

Knob

For

final clamping

Mount, tighten

holding

pliers.

CAUTION:

Be

sure

with

Pinion

Adjustment

malfunction

c)

Firmly tighten

which

Drive

Shaft

d)

Make

Knob

ZJ808500

NOTE:

To

check

operation,

the

Set

tion.

Turn

Knob

clockwise

should normally

upon

releasing

in its locking condition.

Coarse

right

make

steps

sure that

Knob

4-2-6

lightly onto the Microscope

clamp

it

by

AB05900

the

Fine

to

keep

ZJ856400

Knob

may

are

temperarily

Mount AA872200.

sure

that

turn smoothly

is

normally

the

Lock

proceed

Lock

Knob

the

half a rotation

direction.

it.

Adjustment Knob clockwise;

it

is

not

operating normally,

and

4-2-1

Drive

Shaft Mount

turning

Coarse

clockwise.

of the

the

Drive

Gear

A

be

two

the

as

right

Fine Drive

knob firmly

Shaft

(See

ZAO78300

in

turning

B059000,

caused.

Screws

assem

bled

Coarse

and

operative.

Knob

in

for

follows:

its

locking

Coarse

in

The

the

Lock

Mount with

ACU3x5SA

Adjustment

Lock

Adjustment

make a clicking

Then,

set

is

locked. If

4

above

the

Lock

By

turning the

once

Adjust-

Shaft

while

Fig.

4-24.)

engaged

Coarse

otherwise

on

Fine

Knob

its

normal

condi-

counter-

Knob

sound

Knob

the

Lock

repeat

again.

Il'

I!.-

Fig.

-

-

4-25

4-2-1

5

4-2-16

Assemble

AB059100

AA800200

left

together with

by

tightening

2,6x5SAb

After applying

AA784400, place

Coarse Adjushtment

three

three

Screws

(See

Fig.

Grease

i-2:

in

position.

OT2008

(See

to

Fig.

Knob

Washers

3PU

K

4-25.)

~ahser

4-25.)

Page 41

Fig.

fig.

426

-

4-25

-

fl

Fine

adjustment

1

knob

assembly

'b

ac

-

-

C

I

-

1

L

.

2,-

4-2-1

4-2-18

4-2-19

7

Plncs

aftcr

npplylriq

Assemble

AB069200

parts:

Gear

Shaft

Screw

Insert

Assemble

059300

Fine

Adjustment

A

B3xGSA.

NOTE:

Apply

AB3x6SA

Sprincl

the

together

AA782600

A

0023900

AB3xBSA

Shaft

A0023900

left

in

position.

Adhesive

beforehand.

Wnnllnr

Grnn~n

right

Fine

Adjustment

Knobs

OT1026

AR0713130

01

700n,

(Srrr*

Fine

Adjustment

with

into

Fix

the

Shaft

(See

the

by

tightening

to

threads

right

In

position

Fiq,

following

A6023800.

Fig.

4-27.)

Knob

and

Screws

(See

Fig.

of

Screws

I

4-26.)

Knob

AB-

left

3-3.)

4-2-20

Check

normal

a)

If

rotate

related

for

b)

If

tho

on

AB031700

of

Sprinq

the

Fine

rotation.

the

Fine

smoothly,

pnrts,

injury

Finn

tho

or

~hr~rst

Wnnhnr.

Adjustment

Adjustment Knobs

check

shafts,

contamination.

Arliustrnnnt

sirln,

is

irit~lfncfivr!,

Knobs

the pnrts

bearings

Knolls

Sprinq

Atllrrst

for

do

(qears

nnrl

washers)

hnve

Wnsher

curvature

their

not

and

play

of

Page 42

b

Fig.

--

AU~X

IOSA-

4-28

-

4-2-21

Assemble

a)

Temporarily

856500

Gear

with

Unit

ZJ856500

assemble

four

Screws

as

follows:

Gear

AB3x1

(See

Unit

OSA.

Fig.

ZJ-

4-28.)

NOTE:

Washers

before

7-

-

assembly.

b)

Loosen

Unit

Gear

by

four

necessary

between

Rack,

KNW3SA

disassembly

four

ZJ856500

Unit

ZJ856500,

approx.

Screws

to

the

Pinion.)

and

should

Screws

0.5mm

AB3xlOSA

slightly

then

and

AB3xlOSA.

compensate

teeth

of

AB086600

be

reused

of

and

press

raise

it

upward

finally

(This raise

for

Gear

the

Unit

tighten

backlash

used

for

Gear

down

is

and

42-22

4-2-23

NQTE:

Be

careful

oblique

c)

Check

Knobs

Knobs

repeat

d)

After

properly,

Screws

Assemble

ing

four

Screws

Assemble

left

Fine

not

to

position

the

for

do

step

the

apply

AB3xl

Rear

Fine

their

not

b)

above

Knobs

OSA.

Cover

to

normal

rotate

Adhesive

PUK2x6SA.

Plates

At3060700

Adjustment

assemble

Arm.

&

Coarse

operations.

smoothly

once

again.

have

OT3

AB034800

to

Knobs.

Gear

Unit

Adjustment

or

evenly,

been

131

by

(See

the

adjusted

to

tighten-

Fig.

right

in

If

the

four

3-5.)

and

Page 43

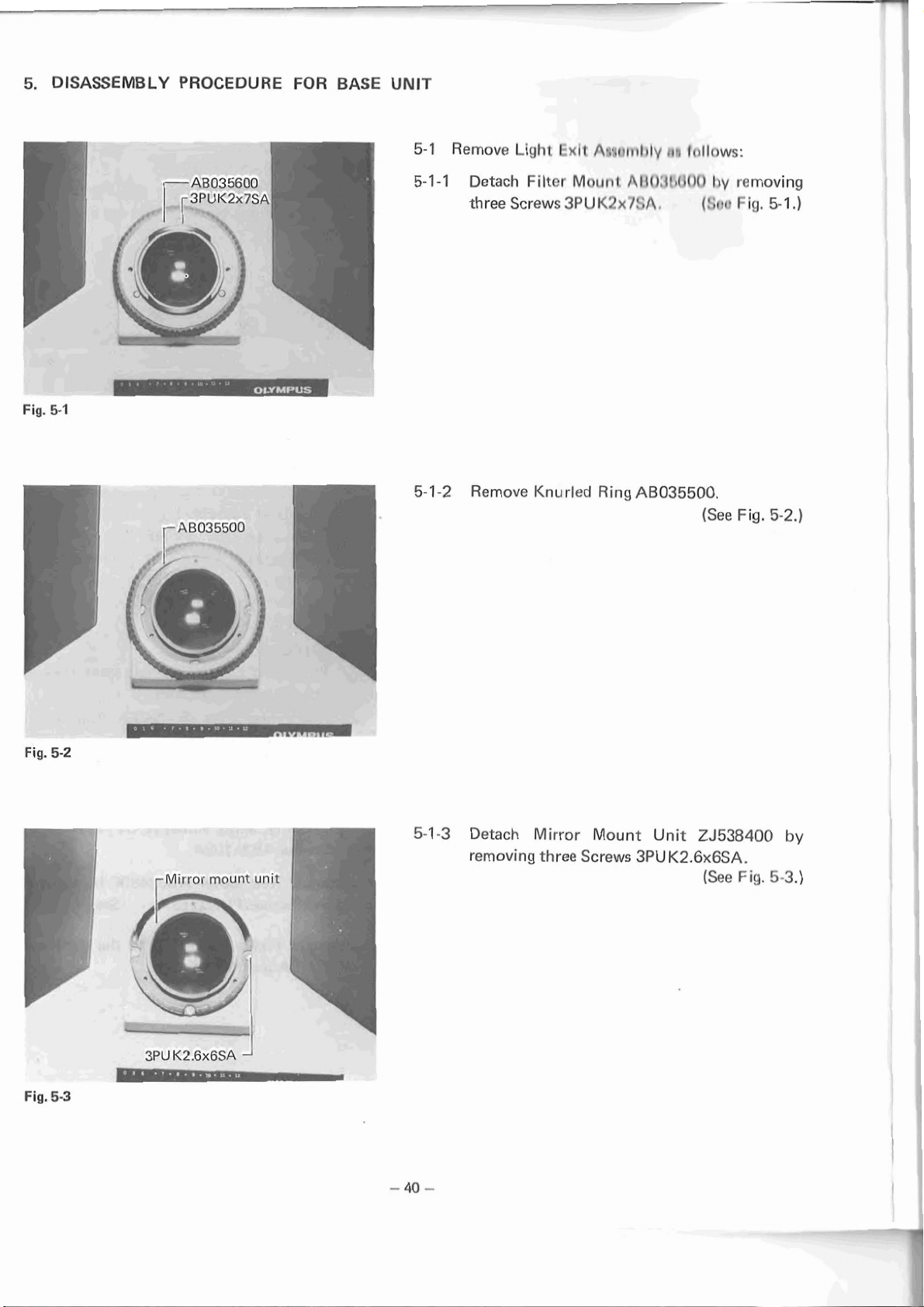

5.

DISASSEMBLY

PROCEDURE

FOR

BASE

UNIT

5-1

Remove

Light

Fxlt

Awrlr~il~ly

rirl

Ir~IInws:

Fig.

5-1

5-1

3PU

K2x

JSA

a

*

-

5-1-2

Detach

-1

threeScrews3PUK2xJt;A,

Remove

Filter

Mount

Knurled

Allfl:4tlf100

Ring

AB035500.

try

removing

(!;tloFig.5-1,)

(See

Fig.

5-2.)

Fig.

Fig.

5.2

5-3

rMirror

mount

unit

.

.

l"-l

--

Detach

removing

Mirror

three

Mount

Screws

Unit

ZJ538400

3PUK2.6x6SA.

(See

Fig.

by

5-3.1

Page 44

Fig.

5-4

5-1-4

Disassemble

a)

Remove

using

Adjustable

b)

Remove

the

Lens

Lens

Light

Exit

Unit:

Retainer

Spanner

ZA077700.

AB035800

OT0022.

(See

Fig.

by

5-4.)

7~-

Fig.

5-5

?Id diaphr

agm

"

1

unit

*

11,

1'1

I

1

'

5-2

Disassemble

5-2-1

By

removing

detach

Detach

Screw

Detach

Screws

the

the

Field

Circular

3PU

K2.6x5SA.

Plate

3PU

K2.6x5SAm

Field

Diaphragm

two

Screws

Diaphragm

Rack

A8025600

AB046500

Unit

as

CUK2.6x6SA,

from

the

(See

by

(See

by

removing

(See

follows:

Base.

Fig.

5-5.)

removing

Fig,

5-6.)

four

Fig.

5-6.)

KNw2*6$ 3PUK

2.0X

Fig.

5-6

5S

Remove

Remove

'-?4ABm,,

Rotary

Diaphragm

Frame

AB025500.

Blades

ZA078800.

[See

[See

Fig.

Fig.

5-6.)

5-6.)

Page 45

6.

ASSEMBLY

Fig.

6-1

PROCEDURE

Base

Arm

FOR

BASE

UNIT

6-1

Assamble

thr'

Anri

wlth

thn

Onse

Unit,

NOTES:

1.

The

Arm

should

not

to dcgrarle

Screws

2.

Arm

6-2

Assemble

6-2-1

6-2-2

cordance

Assemble

Diaphragm

Assemble

j

must

will

not

the

with

the

Diaphragm

Frame

Rotary

tion.

t1e

mor

flpp0rlrimt:e.

bc

t~ql~tr?~\rtl

camp

loose,

Field

Diaphmgm

proceclurr!

Blocl~ts

AB025400.

Frame

rnlsd

precisely

/See

Cirrnly

so

Unit

(rivan

helowr

ZA07R80Q

(Sec

AB025500

(Sol!

Fig.

that

Fig.

in

Fig.

so

6-1

the

in

ac-

with

5-6.)

posi-

5-6,)

as

.)

Fig.

6-2

7-

Cross

hair

Image

should

within

of

KN0029

of

fieEd

be

contained

this

circle.

diaphragm

6-2-3

6-2-4

6-3

Mount

by

rarily.

6-3-1

Position

Screws

Plate

3PUK2.6x5SA.

NOTE:

Check

operation.

Assemble

tian

Bring

shown

by

the

using

down

the

Diaphragm

Circular

tightening

Ficld

twn

Microscope

in

Fin.

NOTE:

Recommended

other

and

a)

b)

C)

d)

packing

deslc

surface.

Insert

the

of

Looking

scope

portion

Centering

illuminator

Microscope

through

KN0029,

(helicoid)

hairs.

Insert

down

Slide

back

KN0029

the

the

and

Field Diaphragm

AB046500

Rack

Screw

Diapl~raqm

Scr~ws

CUK3.6x6SA,

6-2.

to

apply

material

Adapter

insenion

Base.

Special

rotate

to

into

Field

Diaphragm

front

forth

lens

until

is

brought

by

tightening

(Soa

Blades

far

A6025600

3PUK2.6x5SAm

(SRF!

Unit

ante

Stand

on

soft

cloth

between

its

Nosepiece

B2KCf

port

at

Centering

its

front

focus

on

B2KCl003

all

the

portion

the

of

image

into

four

Fig.

5-6.)

normal

in

pasi-

Fig.

5-6.)

the

Base

tempo-

front

or

same

003

into

the

back

Tele-

lens

the

crass

and

stop

way

KNOD29

of

focus.

as

the

Page 46

E

-

e)

Loosen

Unit

the image

correctly

cross

STANDARD:

f)

Tighten

-

-

-

64

Assemble

given

below:

two

Screws

slightly and

of

centered

hairs

of

KN0029.

two

Screws

the

Light

of

Field

Diaphragm

move

the Field Diaphragm

Within

scale

of

it

leterally

concentric

1.5

divisions

K

N0029.

with

CUK2.6x6SA.

Exit

Unit

in

the

procedure

until

on

is

the

the

Fig.

6-3

6-4-1

Assemble

Unit

6-4-2

Clamp

OT0022.

6-5

Mount

three

the

Screws

NOTE:

It

is

recommended

ment

in

6-5

Assemble Knurled

Lens

ZA077700

23538400,

the

Lens

Light Exit Unit on

3PU

K2.6x6SA.

to

this

condition.

Ring

Retainer

perform

AB035500

in

Mirror

(See

Fig.

AB035800

(See

Fig.

the

Base

by

(See

Fig.

overall

(refer

in

position,

{See

Fig.

Mount

602.)

with

6-3.)

using

6-4.)

adjust-

to

9-3

1

6-5.)

Fig.

Fig.

64

6-5

6-6

Assemble

with

6-6-1

66-2

L---

Check

ing

If

engagement

and

Filter

Screw

the

range

the

graduations

teeth

Mount

AB03560D

3PUK2x7SA.

Field

Diaphragm

and

graduations.

are

between

of

Circular

Rotary

Rack

in

position

(See

Fig.

Unit

for

its

rniscalibrated,

Ring

A8035500

AB025600.

6-5.)

work-

adjust

Page 47

7.

DISASSEMBLY

PROCEDURE

FOR

BH2-CH

Fig.

7-1

Disassemble

I-?

manner:

7-1 - 1

7-1-2

the

Remove

Stopper

by

Remove

Detach

Stopper

H

lowering

the

Knob

K2.6x4SA

the

Condenser

ACUT.Gx4SA.

Stage

Mount

H

K2.6x4SA.

Condenser

Holder

A8059800

in

can

Mo'lder.

by

the

following

he

uncovered

(See

Fig.

by

loweriny

removing

(See

Fig.

7-1

.)

it.

Screw

7-2.)

I

I

I

Fig.

Fig.

7-2

7-3

-4

Remove

7-1

0077,

-5

Remove

Remove

Washer

7-1

7-1-6

/

Nut

AA007700

Tension

Ball

Screw

B3J32,

AA272600.

by

using

AB026900.

Pinion

AB026800

Tool

KKAA-

(See Fig.

(See

Fig.

7-3.)

7-3.)

and

Page 48

AA061400

7-2

Disassemble

ing

7-2-1

7-2-2

the

procedures:

Remove

Condenser

059600.

Remove two

Condenser

Centering

Holder

Clamping

Knobs

AB026000.

in

the

Knob

follow-

AB-

AB059600

Fig.

7-4

1

I

7-2-3

7-2-4

Detach

six

Screws

Remove

three

Plates

3PU

Condenser Mount

AB06'1400

K2x4SA.

by

removing

(See

Fig.

AB059000.

(See

Fig.

7-4.)

7-5.)

'Fig.

7-5

7-2-5

Dismount

Screws

Two

Rack

CU

K2.6x6SA.

Washers

NW2.9-450BN

the

Rack.

AB026700

SW2.6SA

are

removed

by

and

removing

(See

Fig.

two

Washers

together

two

7-6.)

with

Page 49

%

7-2-6

*

7-2-7

Remove

Remove

Screw

Spring

AA253000.

AA097400.

Fig.

7-7

8.

ASSEMBLY

PROCEDURE

FOR

BH2-CH

7-2-8

7-2-9

8-1

RemoveShaftAB026200.

NOTE:

The

Spring

Screw

CAUTION

Do

not

and

Shaft

AA253000

:

remove

Height

is

removed.

12WO.

After

or

xyloi

drv

Assemble

procedure

gasoline

cloth.

After

Shaft

or

AB026300

disassembly,

to

rernovt!

gasoline

the

Condnnsnr

below:

appl

yinq

cornplotcly

G

In

Wash

rcnse

pasi

can

ba

rlismotr

Adjustment

tlir:

parts

qreasc?.

Hnlder

Thcn,

with

Unit

OT2008,

tian.

(See

nted

Pin

(Scc

with

a

as

(See

Fig.

7-7.)

after

NP5x

Fig.

7-7.)

xylol

wipe

off

piece

of

per

the

assemble

Fig.

8-1

.)

Fig.

8-1

8-1

-5

8-1-6

8.1-7

8-1

-8

After

Spring

ilpplyinrl

AB076300

Tighten

After

surface,

applyirlq

059500

Attach

six

Aftcr

OT2006

Knoh

Aftet

OT7006

Knob

Check

ing

thrc!e

Scrcws

applying a small

AB026000

applying

AR059600

operation

Knob.

Grcasr:

in

Scr~w

AA3530OO

Grease

assemble

in

position.

Plates

3PUK3x4SA.

to

the

thread,

in

a

to

the

thread,

in

by

OT2008,

position.

{See

in

position.

(See

OT2008

Condenser

A6061400

Mount

(See

by

(See

amount

assemble Centering

position.

small

position.

manipulating

(See

amount

assemble

(See

assemble

Fig.

Fig,

to

the

Fig.

tightening

Fig.

of

Grease

Fig.

of

Grease

Clamping

Fig.

the

Center-

8-1

.)

8-1.)

slide

AB-

7-5.)

7-4.)

7-4.)

7-4,)

8-1-9

Assemble

tightening

Rack

two

AB026700

Screws

CU

K2.6x6SA.

in

position

{See

Fig.

by

7-6.)

Page 50

AB

026400

8-2

8-2-1

Assemble

With

Washers

Balls

83/32

assemble

NOT€

Apply

by

arrows.

the

Stage

it in

Grease

Mount Unit

AA272600,

placed

Stage

OT2008

on

Mount

to

as

follows:

NW4.6-26580

Pinion

Unit

the

AB026800,

AB026400.

parts

indicated

(See

Fig.

and

8-2.)

Fig.

8-2

/-

AA

s

y-'

272800

NW

4.6-3858n

8-2-2

8-3.3

!I-2-4

8.2-5

Asscrnbic?

tion.

Assernl>lr!

Tool

Assemhl~

this

tit~le

Screws

Check

Nut

K

KAA0077,

purpose,

lormarl

ACU3x4SA

Pinion

required.

a)

When

has

thrust

Loosen

Tighten

Tighten

b)

When

the

Loosen

Loosen

Tighten

Tcr~sion

Scr~w

AA007700

I(nat~

AB059800

fit

the

in

the

firmly.

for

its

the Pinion

play:

AA007700.

4

A8026900.

4

AA007700.

Pinion

rotates

AA007700.

-1

ABQ26900.

5.

AA007700.

A0026900

in

pas1

in

Pinion

Knob

operation and adjust

rotates

Shaft

and

too

too

in

tion

by

position.

into

tighten

(See

Fig.

lightly

heavily:

posi-

using

For

the

two

8-2.)

it

if

or

Page 51

8-3 Assemble Stage Moi~nl UtliZ with Condenser

Holder Unit as follows:

8-3-1

8-3-2 Check Condensctt Iloldt~t IJ~iil for its verti-

CU

K2.6x6SA

/

To be selected from among

AB059900 through AB060000.

Fig.

8-3

9.

OVERALL ASSEMBLY AND ADJUSTMENT OF BHS-F

Assemble

Condenser

Stagc

Mount

Holder Utlil

I111il

AB026400

Af31326500.

(See Fig. 7-1

cal motion and adjr1l;l

li

t

t?clrlir

c?d.

a) When the rack llils 11loy:

Place Wasll(,t

s

A130!1l)flO0 AB060000

under Ihc Hnclt, (Scc Fig. 8-3.)

b) When Waclt

Remove

or replacc!

c:tc?;rl.af;

Wusllrvs

tlrc!tri

wllli

(11

rllovtjs

A1113!~8%(3(3

IIiilltit?~ ones.

loo

heavily:

-

AB060000

(See Fig.

with

.)

8-3.)

STANDARD:

1

division on the

scale

9-1 Check

system

9-1-1 Place

scope

B21<C0002:

82KC10013: Cc!lituritiy adapter

K NO029

and

ulbtic~rl crli!lntrlcnl of illumination

lhc lollow~r~cj

Slarid

as

:

J~!js

oti 1Jie Micro-

sllc~w~r

i~r

Fig.

I'it\llc)l~'

9

1:.

lube

Sl)c.?cial cenlering telescope

Page 52

Pin hole image slioi~l(l

be contained

this circle.

within

9-1-2

9-1-3

9-1-4

Bring down Microscope Stand on

shown in Fig. 9-1. Recommended to apply

soft cloth or some other packing material

between Nosepiece and desk surface.

Looking through Special Centering Telescope

KN0029, rotate

to focus on the cross hairs.

Slide the front lens portion of

and forth to

I<C0002.

STANDARD: 1 division of cross hairs of

;I)

I1 tile S1-ANDAR D is not met (deviation

c?xct:eds 1 tlivisiotis), adjust position of

1I1(2 Ligllt Exit Utiil.

I,)

Alie~ loosening Screws 3PUK2.6x6SA on

Mirror

pillhole Image within 1 division on the

cross hair of

Tighten Screws 3PUK2.6x6SA.

its

front lens portion (helicoid)

focus on the Pin Hole of B2-

I<N0029.

Mourlt Unit ZJ538400, adjust the

KN0029.

its

front

as

KN0029 back

Fig.

9-1

B-KN0003

LB

Specimen

objective

--

Condenser

Cross hair of

*

WHKIOX

f

l

w

rn

I

I

KNOI)?Y

9-2 Assemble the Electrical Base with Microscope

Stand by tightening three Srews

9-3 Check and adjustment of Fine Adjustment

sensitivity

9-3-1 Use the following jigs on the Microscope

Standard as shown in Fig. 9-2:

B-KN0003:

LB40x objective

WHKIOX or

Condenser

Ordinary specimen

Fine adjustment sensitivity

STANDARD: Within

NOTE:

If no B-KN0003

observation tube instead.

Standard jig for tube length

WKlOx

visions on knob scale)

AB6x25SA.

4p (within 2 di-

is

available use any

Fig.

9-2

-49-

Page 53

9-3-2 Checki~~!l

a)

111

81 in:! tl~c

s~)ccir~~l:tl,

ttic Fill(: A(JJ~~!,IIII(*II~ l<1lol3.

b) Turri

Zl,ct

divisiol'ls)

retirrn

focus

it

an

read indication

Adjustmet11 I<tiol). 1 l~a? ciiffer(:nce of the

readings

be within

c) Check fine acij~~sftrl(!rit ~c:tlsitivity by

turning the

to those selected

occrdrrro

i~rslr\i~nc!~~l

rI(:iici

ili(i~(:~jf

I

in(:

Atlj~rstrno~ll 1<1iob 20p (10

ill

oilllihr tiit

tr~llil

111~

tlio

spncirrii?~i.

o~i ill(?

oblailiecl ill slc(3s

2

divisio~ls.

Itno11

io11

ill~31~t~~~~('tit is

iri

tlio

ill

slol)s

in focus on the

on

the scale of

(:(:I

ion, and then

brought in

111

this condition,

sc:alc?

of the Fine

ii)

i~tid b) must

cfilt?ctio~is reverse

;I)

;11,c1

b)

above.

A

Point

Block B2KC0009

Point B Stage

B2KCOOlO

Block

Point C Stage

Fig.

9-3

Stage

Specimen

1

Specimen

9-3-3 Check fine adjustment sensitivity

steps a),

b) and

c)

above

at

thrce points A,

and C specified in Fig. 9-3. (At poi~lls B and

C,

a

block

is

placed between the spccinlcri and

stage to change height of stage.)

UAR

D

is

9-3-4

9-3

5

If the STAN

UniL

of Gear

thc STAN DAR W cannot be rnet by adjust-

If

ing

Gear Unit ZJ856500, proceed

a)

Cliccl< the Gear and Shaft for engagement

arid

ZJ856500.

play in the Coarse Adjustment Knob.

trot Irrc?l, change setting

b) Cl~eclt the Ball Guide assembly

ings of

tlie

Wires and Rollers as well as

operation.

by repeating

B

(Sce Fig. 9-3)

(Sce Fig. 4-28)

as

follows:

(See 4-2-9)

for

sett-

its

Page 54

OPTICAL PATH DIAGRAMS

OF

BH2-BI AND BH2-TR

BH2-BI

BH2-TR

designates the combination of

designates the combination of

B2-BI

B2-BI

unit and

unit and

B2-BIC

B2-TRC

unit

unit

Page 55

10.

DISASSEMBLY

PROCEDURE

FOR BH2-&I

10-1

Disassemble

B2-BI

Unit

BH2-BI

as

per

the

procrdum

into

R2-81C

given

Unit

below:

and

Fig.

-

10-1

10-1-1

. .

.

-

10-1-2

Detach

three

Diopter

Screws

Disassemble

Finger

Rest

R

PUK2xlOSA

two

Screws

rest).

CUK7.llixSSA

Ring

AR033700

ACU2.Gx4SA.

Finqnr

Ali037700

{frorn

Rnst

L

by removing

nnch

(from

by

removing

(See

Fig.

AB032100

finger rest)

each

(See

Fig.

10-1)

and

Screw

and

finger

10-2)

Fig.

Fig.

10-2

10-3

10-1-3

Detach Graduated

ing

four

Screws

PUKZx4SA.

PFateAB031900

(See

by

rernov-

Fig.

10-3)

Page 56

Fig.

10-4

10-1-4

10-2

Disassemble

Disassemble

by

removing

B2-BIC

'B2-BI

four

Unit

from B2-BIC Unit

Screws CUK3x6SA.

Unit

as

follows:

(See

Fig.

10-4)

Fig.

-

10-5

---

-

- - - - - - - -

CP093900

1

10-2-1

-

-.

---

--

-

-,

10-2-2

Disassemble

Body

AB033000

CUK3x8SA.

Remove

P2

Prism

Mount

by

LP093900

AB032900

removing

from

three

(See

Prism

Screws

Fig.

Mount

from

10-5)

AB032900:

a)

After

remove

loosening

the

Adhesive

two

Screws

OT1028

(See

HU3x4SA,

(Araldite).

Fig.

10-6)

Fig.

106

Page 57

--

.I

---

-

10-3

Disassemble

B2-BI

Unit

as

follows:

Fig.

1

30-7

10-3-1

10-3-2

Remove

tube

length

a)

Remove

b)

Remove

AB031800,

Remove

Spring

device:

Spring

Spring

two

Keys

AB031200

Hanger

from

AB032800.

AB031200from

AB031800.

the

(See

(See

constant

each

Fig.

10-7)

Fig.

10-8)

Key

Fig.

I

I

Fig.

10-8

10-9

H

K3x5SA

/

10-3-3

Rernovn

a)

Prism

crrn

Screws

Do

b)

mount.

Prisms

ho

not

P3

Mount

and

disassembled by

H

K3x5SA.

remove

and

Prisms

Prism

P4:

R3,

removing

(See

P3,

P4

P4

23538700

Fig.

from

two

10-9)

Prism

Page 58

7---

Fig.

10-1

-

-

'-

0

10-3-4

Dismount

AB031100

5SA.

a)

Now,

Dovetail

by

removing two

Prisms

P5

(left)

and

and

P6

Dovetail

Screws

(See

Fig.

can

be

(right)

CUK2x

10-10)

disas-

sembled.

PS

(ZJ856700,Z3538800)

P6

(ZS856600,ZJ53$900)

(See

Fig.

10-1

1)

Fig.

Fig.

f

0-1

10-72

1

I

ZJ538800

10-3-5

Remove

side

Screws

10-3-6

Remove

side

Screws

I

Prism

Dovetail

H

K3x 1 OSA.

Prism

Dovetail

H

K3x 1 OSA.

Mount

ZJ538800

ZJ856700

Mount

ZJ538900

ZJ856600

by

removing

(See

by

removing

(See

from

Fig.

from

Fig.

right

two

10-1

2)

left

two

70-12)

Page 59

10-3-7

10-3-8

Detach

ride

Dovetail

by

placing

the

notch

with

a

tweezers

Extract

Circular

ZJ856700.

small

and

or

Inner

Tube

Cover

then

AB030700

amount

forcibly

a

similar

AB032600.

It

of

tool.

can

from

be

dislodged

solvent

extracting

(See

Fig.

right

through

it

10-13)

10-3-9

Remove

Sleeve

AB032600

a)

Remove

b)

Remove

in

Fig,

R

A8032300

as

follows:

Screw

Adhesive

t

0-1

3.

NU2x3SB.

by

heating

from

Inner

it

as

Tube

shown

Fig.

10-13

Page 60

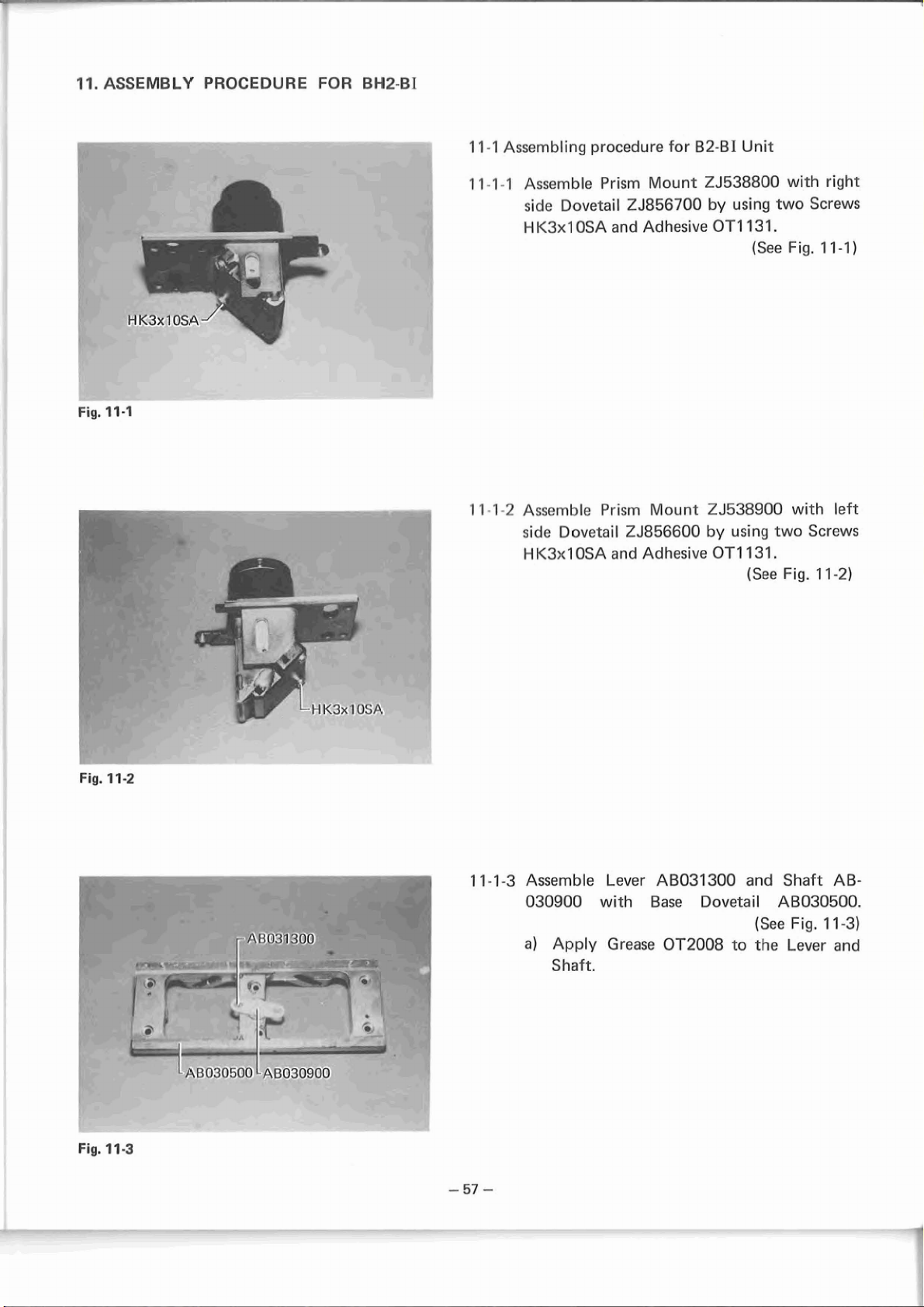

11.

ASSEMBLY

PROCEDURE FOR

-

-

<

- - -

.

BM2-BI

11-1

Assembling

procedure

for

82-BI

Unit

Fig.

11-1

Il-1-1

t8-

11-1-2AssernblePrismM~lountZJ538900with

Assemble

side

Dovetail

1-I

K3x1

OSA

side

Dovetail

H

K3xl

OSA

Prism

ZJ856700

and

Adhesive

ZJ856600

and

Adhesive

Mount

ZJ538800

by

using

OT113 1.

(See

by

using

OT1131.

(See

with

two

Fig.

two

Fig.

right

Screws

1

1-11

left

Screws

1

1-21

Fig.

P

Fig.

11-2

11-3

--

fi1r031300

11-1-3

I

1

I

Assemble

030900

a)

Apply

Shaft.

Lever

with

Grease

AB031300

Base

Dovetai

OT2008

to

and

I

(See

the

Shaft

AB-

AB030500.

Fig.

11-3)

Lever

and

Page 61

r---

Fig.

11-4

-

-

-

.

.

-

-

- - -

1

T

1-7-4

Assemble

tion

respectively.

Apply

a)

surfaces

left

and

Grease

of

the

right

side

OT2008

Dovetai

Dovetails

(See

to

Is.

Fig.

the

in

posi-

11-41

sliding

Fig.

11-5

11-1-5

1 1-1

-6

11-1-7

Assemble

two

Move

two

Screws

the

two

operntion.

Temporarily

P3

and

P4

5SA.

Douctnils

CUK2.Gx5SA

dovetails

clamp

Z,!538700

and

the

with

AB031100

for

each.

(See

Fig.

check

far

Prism

two

assembly

Screws

(See

by

using

1

smooth

HK3x

Fig.

1-51

of

17-61

Fig.

1

1-6

Page 62

Fig.

11-7

-

-

-

.

.

--

-.

-.

11-1-8

1

1-1

-9

1

1-1

-1

Assemble

position.

Check

play or

diameter

0

Assr?mblc

Key

AB047500

movement

of

friction. Select

keys

to

achieve

Spring

or

keys

in

smaller

smooth

AB031200

AB033800

(See

Fig.

their

slots for

or

larger

operation.

(See

Fig.

in

position.

(See

Fig.

in

3

1-7)

T

1-7)

11-8)

Fig.

--

Fig.

1

1-8

-

11-9

- - -

-

-

--

11-1-1

I

Hold

the Spring

Hangers

AB0328000.

(See

Fig.

11-9)

Page 63

r.1

11-2 Optical alignment of B2-BI unit

Jigs

11-2-1

Use the following

the Microscope

StantJ.

B2KC0402: Ji!j

i111~1

lor

111

ism alignment

KN0014: Conl(:~ ill!] ol~jective (200mm)

C-1

:

10x c.ycl)ioce with cross hair

B2-BI unit on

(See Fig. 11-10)

Fig. 11-10

11-2-2

Adjust

posilion

taking Prism ,~ssc:~r~ljly ol

standard.

1 1-2-3

If B2-Bl unit

fit

ti11 foil I~ulwt~c~~~

Prism MOUIII.

11-3 Assembl~~i(~

11-3-1

Assen~l~lc I9

111

or;cvfrrtt* lot 132 BIC Unit

Mounl A130:3>~/300

Aftcr i11sc:t Iirlrj

mal<c

!;1lrc3

colrlljlc!lr!ly, 1 l1111r

wil

li

Acilic?s~vr:

01

I:OI~IIOI

I~III

1'1

1'1

I*,III 1'1 illlo

111,11

111

(:(4~1i~?~i1

0

I

107t3.

IJ~~srll

Mount ZJ538700

P5

and P6

IN:

c:i?~>te~ed properly,

flit-

Ii1islrl assembly and

l..P093800 with Prism

Ifle

Prism Mount,

14111

has

bcen inserted

it

at

three points

as

Fig. 11-1 1

Fig. 11-12

LP093800

1

1

3

2

Asc;c:lnl)l($

fS1

:

I31e!;\

celrir!lll

OT

1

0313.