Page 1

LPC-E2468 development board

Users Manual

Rev.B, February 2008

Copyright(c) 2008, OLIMEX Ltd, All rights reserved

Page 2

INTRODUCTION:

LPC-E2468 uC Linux development prototype board with LPC2468 USB,

Ethernet, SD/MMC in credit card format.

BOARD FEATURES:

- MCU: LPC2468;

- 16MB SDRAM;

- 128 MB NAN Flash;

- standard JTAG connector with ARM 2x10 pin layout for

programming/debugging with ARM-JTAG;

- Ethernet 100MBit;

- 2x USB hosts;

- USB-to-RS232 converter device connected to LPC2468 UART;

- SD/MMC card connector;

- UEXT connector with I2C, SPI, RS232 and power supply for

connecting add-on modules like RF link, MP3, etc available from

Olimex;

- trimpot connected to ADC;

- RESET circuit with external control of Philips ISP utility via RS232

port;

- two USER button;

- RESET Button;

- two on board voltage regulators 3V and 5V with up to 800mA

current;

- Extension port connector for many of microcontrollers pins;

- single power supply: External power supply, USB or JTAG connector;

- Battery holder and connector for the RTC;

- power supply led;

- FR-4, 1.5 mm, red soldermask, component print;

- Dimensions: 90x60mm (3.54 x 2.36").

ELECTROSTATIC WARNING:

The LPC-E2468 development board is shipped in protective anti-static

packaging. The board must not be subject to high electrostatic potentials.

General practice for working with static sensitive devices should be applied

when working with this board.

Page 3

BOARD USE REQUIREMENTS:

Cables: USB A-B cable to connect to virtual serial port on the board.

You will need LPT cable if you want to program the MCU with

AVR-JTAG. You might need other cables in case of other

programmers/debuggers.

Hardware: Programmer/debugger AVR-JTAG or any compatible tool.

Software: The board is delivered with uC Linux pre-loaded. You could

develop projects for the board with Eclipse, IAR, etc. Please,

refer to the LPC-E2468 Quickstart Guide which is on the CD

for more details on the software requirements.

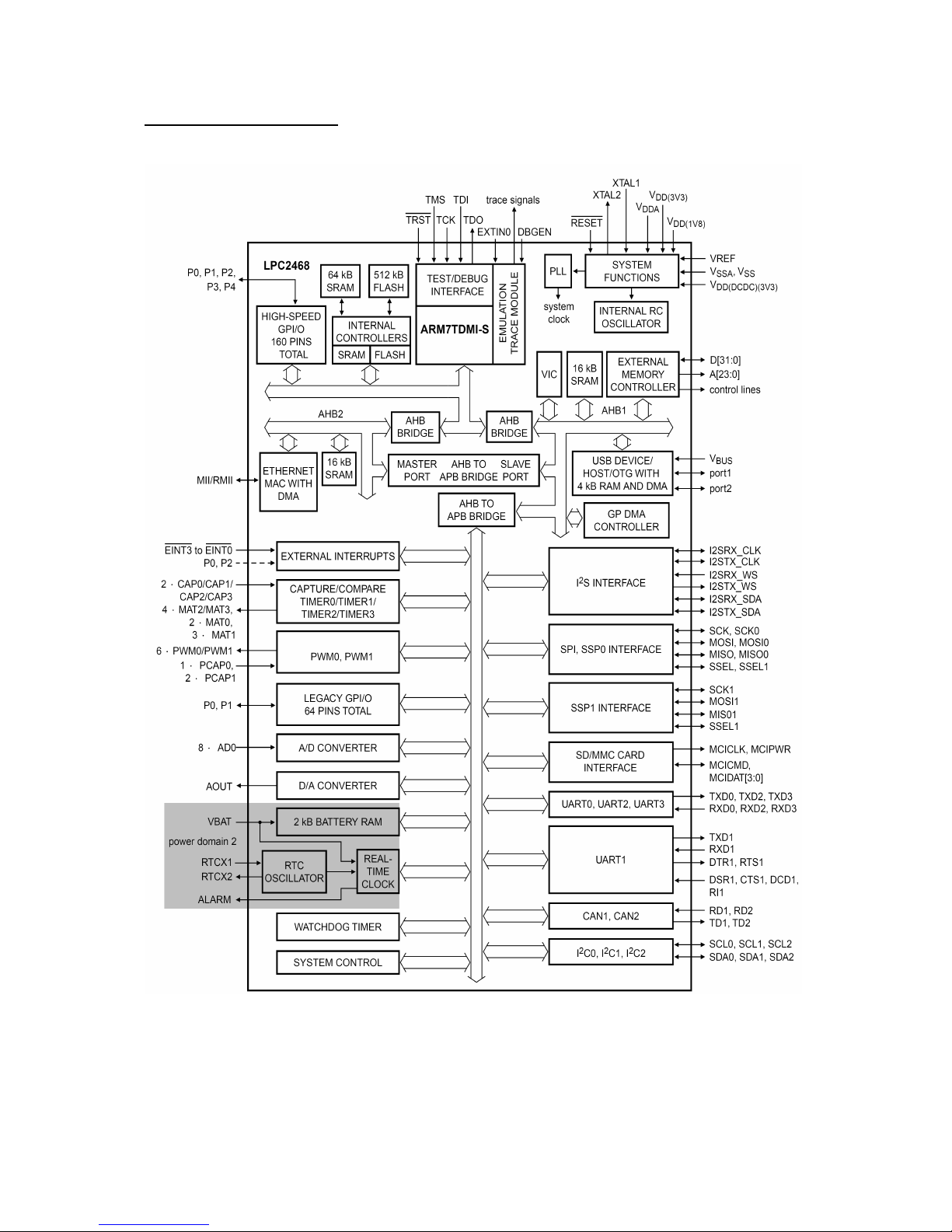

PROCESSOR FEATURES:

The LPC2468 processor has the following features:

● ARM7TDMI-S processor, running at up to 72 MHz.

● 512 kB on-chip flash program memory with In-System Programming

(ISP) and In-Application Programming (IAP) capabilities. Flash

program memory is on the ARM local bus for high performance CPU

access.

● 98 kB on-chip SRAM includes:

▬ 64 kB of SRAM on the ARM local bus for high performance CPU

access.

▬ 16 kB SRAM for Ethernet interface. Can also be used as

general purpose SRAM.

▬ 16 kB SRAM for general purpose DMA use also accessible by

the USB.

▬ 2 kB SRAM data storage powered from the Real-Time Clock

(RTC) power domain.

● Dual Advanced High-performance Bus (AHB) system allows

simultaneous Ethernet DMA, USB DMA, and program execution

from on-chip flash with no contention.

● EMC provides support for asynchronous static memory devices such

as RAM, ROM and flash, as well as dynamic memories such as

Single Data Rate SDRAM.

● Advanced Vectored Interrupt Controller (VIC), supporting up to 32

vectored interrupts.

● General Purpose AHB DMA controller (GPDMA) that can be used

with the SSP,

● I2S-bus, and SD/MMC interface as well as for memory-to-memory

transfers.

● Serial Interfaces:

▬ Ethernet MAC with MII/RMII interface and associated DMA

controller. These functions reside on an independent AHB bus.

▬ USB 2.0 full-speed dual port Device/Host/OTG Controller with

on-chip PHY and associated DMA controller.

Page 4

▬ Four UARTs with fractional baud rate generation, one with

modem control I/O, one with IrDA support, all with FIFO.

▬ CAN controller with two channels.

▬ SPI controller.

▬ Two SSP controllers, with FIFO and multi-protocol capabilities.

One is an alternate for the SPI port, sharing its interrupt. SSPs

can be used with the GPDMA controller.

▬ Three I2C-bus interfaces (one with open-drain and two with

standard port pins).

▬ I2S (Inter-IC Sound) interface for digital audio input or output.

It can be used with the GPDMA.

● Other peripherals:

▬ SD/MMC memory card interface.

▬ 160 General purpose I/O pins with configurable pull-up/down

resistors.

▬ 10-bit ADC with input multiplexing among 8 pins.

▬ 10-bit DAC.

▬ Four general purpose timers/counters with 8 capture inputs

and 10 compare outputs. Each timer block has an external

count input.

▬ Two PWM/timer blocks with support for three-phase motor

control. Each PWM has an external count inputs.

▬ RTC with separate power domain, clock source can be the RTC

oscillator or the APB clock.

▬ 2 kB SRAM powered from the RTC power pin, allowing data to

be stored when the rest of the chip is powered off.

▬ WatchDog Timer (WDT). The WDT can be clocked from the

internal RC oscillator, the RTC oscillator, or the APB clock.

● Standard ARM test/debug interface for compatibility with existing

tools.

● Emulation trace module supports real-time trace.

● Single 3.3 V power supply (3.0 V to 3.6 V).

● Three reduced power modes: idle, sleep, and power-down.

● Four external interrupt inputs configurable as edge/level sensitive.

All pins on PORT0 and PORT2 can be used as edge sensitive

interrupt sources.

● Processor wake-up from Power-down mode via any interrupt able to

operate during Power-down mode (includes external interrupts, RTC

interrupt, USB activity, Ethernet wake-up interrupt, CAN bus

activity, PORT0/2 pin interrupt).

● Two independent power domains allow fine tuning of power

consumption based on needed features.

● Each peripheral has its own clock divider for further power saving.

These dividers help reducing active power by 20 - 30 %.

● Brownout detect with separate thresholds for interrupt and forced

reset.

Page 5

● On-chip power-on reset.

On-chip crystal oscillator with an operating range of 1 MHz to 24 MHz.

● 4 MHz internal RC oscillator trimmed to 1 % accuracy that can

optionally be used as the system clock. When used as the CPU clock,

does not allow CAN and USB to run.

● On-chip PLL allows CPU operation up to the maximum CPU rate

without the need for a high frequency crystal. May be run from the

main oscillator, the internal RC oscillator, or the RTC oscillator.

● Boundary scan for simplified board testing.

● Versatile pin function selections allow more possibilities for using

on-chip peripheral functions.

Page 6

BLOCK DIAGRAM:

Page 7

MEMORY MAP:

LPC2468 memory map

Page 8

SCHEMATIC:

Page 9

BOARD LAYOUT:

POWER SUPPLY CIRCUIT:

LPC-E2468 can take power from power connector PWR, where +(9-12) VDC

or (6-9) VAC external voltage source has to be applied. The board could also

take power from USB_D or from battery. Note: the battery only supplies the

internal 2MB SRAM and the RTC.

The board power consumption is: about 150 mA at 9VDC.

RESET CIRCUIT:

LPC-E2468 reset circuit is made with RC group R4 – 47K, C20 – 100nF

and RESET button.

CLOCK CIRCUIT:

Quartz crystal 12MHz is connected to LPC2468 pin 44 (XTAL1) and pin 46

(XTAL2).

32.768 KHz quartz crystal is connected to LPC2468 pin 34 (RTCX1) and

pin 36 (RTCX2) for its internal Real Time Clock.

Page 10

JUMPER DESCRIPTION:

3.3V_E

This jumper, when closed, supplies 3.3 V voltage to the

VDD1-10 pins of the MCU.

Default state is closed.

3.3VA_E

This jumper, when closed, supplies 3.3 V voltage to the VDDA

pin of the MCU.

Default state is closed.

VREF_E

This jumper, when closed, supplies 3.3 V reference voltage to

the VREF pin of the MCU.

Default state is closed.

PHY_PD

This jumper controls the PHY signal of the Ethernet controller.

If the jumper is pen the PHY is always enabled, if the pin is closed the MCU

controls the PHY.

Default state is open .

WP_E

This jumper, when closed, inputs the Write protect signal from

the SD/MMC card to the MCU.

Default state is closed .

NF_WPE

This jumper, when closed, write-protects the flash and when

open, disables the write protection.

Default state is open .

N_CE/CS1

When 1-2 is shorted, you could select the flash memory for

work through the Chip Select 1 signal. If 2-3 is shorted, the #CE

pin of the NAND flash memory is connected to the N_CE pin of the

MCU.

Default position is 1-2 shorted.

ISP_E

If you put this jumper, you enable the ISP (In-System

Programming). This is used when you want external software to program the

LCP2478. This jumper is used in combination with the RST_E jumper.

Default state is open.

RST_E

If you put this jumper, you enable external software to control

the Reset signal to the processor. This is used when you want external

software to program the LCP2478. This jumper is used in combination with the ISP_E

jumper.

Default state is open.

Page 11

BDS_E

Boundary scan enable.

Default state is open.

BAT/EXT This jumper controls the input power supply for the VBAT

pin.

If 1-2 are shorted, the external battery is connected to

the VBAT pin.

If 2-3 are shorted, the VBAT pin is supplied by the

on- board +3.3V supply.

Default state is 2-3 shorted.

EXT/USB_D This jumper controls 3.3V power supply for the board.

If 1-2 are shorted, the external power (from the PWR

jack and after the +5V voltage regulator) is input to

the +3.3V voltage regulator and supplies the board.

If 2-3 are shorted, the USB device provides +5V to the

+3.3V voltage regulator and supplies the board.

Default state is 1-2 shorted.

Page 12

INPUT/OUTPUT:

One reset button with name RESET – connected to LPC2468 pin 35

(#RESET).

Two user buttons with names BUT1 – connected to LPC2468 pin 102

(P2[13]/#EINT3/MCIDAT3/I2STX_SDA) and BUT2 – connected to LPC2468

pin 81 (P2[21]/#DYCS1);

Two LEDs named STAT1(green) and STAT2(red) – connected to LPC2468

pin 104 (P4[17]/A17) and LPC2468 pin101 (P4[16]/A16);

Two yellow LEDs named USB_1 and USB_2 – connected to LPC2468 pin 66

(P1[18]/USB_UP_LED1/PWM1[1]/CAP1[0]) and LPC2468 pin 45

(P0[13]/USB_UP_LED2/MOSI1/AD0[7]);

One red LED named SD indicating that SD/MMC card is powered up;

Power supply red LED with name PWR – indicates that 3.3V is present.

Page 13

EXTERNAL CONNECTOR DESCRIPTION:

PWR:

Pin #

Signal Name

1 PWR

2 GND

You should apply voltage +(9-12)VDC or (6-9) VAC at the PWR pin.

USB_D:

Pin #

Signal Name

1 VCC

2 USBDM

3 USBDP

4 GND

USBDM, USBDP These signals form the differential input/output for the USB device

depending on the direction of the data flow.

USB_H:

Pin #

Signal Name

Pin #

Signal Name

1 USB_PWRD1 5 USB_PWRD2

2 U1D- 6 U2D-

3 U1D+ 7 U2D+

4 GND 8 GND

USB_PWRD1 Output USB Power 1. This signal is output from the processor and

input for the USB host 1.

U1D-, U1D+ I/O This signals form the differential input/output for USB host 1

depending on the direction of the data transfer.

Page 14

USB_PWRD2 Output USB Power 2. This signal is output from the processor and

input for the USB host 2.

U2D-, U2D+ I/O This signals form the differential input/output for USB host 2

depending on the direction of the data transfer.

JTAG:

Pin #

Signal Name

Pin #

Signal Name

1 3.3V 2 3.3V

3 TRSTN 4 GND

5 TDI 6 GND

7 TMS 8 GND

9 TCK 10 GND

11 RTCK 12 GND

13 TDO 14 GND

15 RSTN 16 GND

17 10K to GND 18 GND

19 10K to GND 20 GND

TDI Input Test Data In. This is the serial data input for the shift register.

TDO Output Test Data Out. This is the serial data output for the shift register. Data is

shifted out of the device on the negative edge of the TCK signal.

TMS Input Test Mode Select. The TMS pin selects the next state in the TAP state

machine.

TCK Input Test Clock. This allows shifting of the data in, on the TMS and TDI pins. It is

a positive edge triggered clock with the TMS and TCK signals that define the internal state of

the device.

TRSTNInput Test Reset N. This signal resets the JTAG controller.

RTCK OutputReturn Clock. This is a synchronization signal which the JTAG connector

uses to acknowledge it is ready to receive/transmit.

RSTN Input Reset. This signal resets the MSU.

JTAG is used to to program and debug the MCU.

UEXT:

Pin #

Signal Name

Pin #

Signal Name

1 3.3V 2 GND

3 TXD1 4 RXD1

5 SCL0 6 SDA0

7 MISO 8 MOSI

9 SCK 10 SSEL

Page 15

TXD1 OutputTransmit Data. This is the asynchronous serial data output (RS232) for the

RS232 interface.

RXD1 Input Receive Data. This is the asynchronous serial data input (RS232) for the

RS232 interface.

SCL0 I/O Serial (Synchronization) Clock. This is the synchronization clock for

the data transfer through I2C interface. This could be either input or output depending on

whether the MCU is master or slave.

SDA0 I/O Serial Data. This pin is data input or output (depending on the data

flow direction) for the I2C interface.

MISO I/O Master In Slave Out. This pin could be either data input (MCU is

master) or data output(MCU is slave). The signal is pat of the SPI interface.

MOSI I/O Master Out Slave In. This pin is be used for communication through

SPI interface and it is either data output from the MCU (when it is master) or data input for

the MCU (when it is slave).

SCK I/O Serial (Synchronization) Clock . This is the synchronization clock

for the data transfer through the SPI interface. It could be either input or output depending

on whether the MCU is master or slave.

SSEL I/O Slave Select. This is the slave select signal for the SPI interface. If the

MCU is master, this is output. If the MCU is slave, this signal is input.

LAN:

Pin # Signal Name Chip Side Pin # Signal Name Chip Side

1 TD+ 5 Not Connected (NC)

2 TD- 6 Not Connected (NC)

3 3.3V 7 RD+

4 Not Connected (NC) 8 RD-

LED Color Usage

Right Yellow Activity

Left Green 100MBits/s (Half/Full duplex)

TD- Output Differential signal output. This signal is output from the MCU.

TD+ OutputDifferential signal output. This signal is output from the MCU.

RD- Input Differential signal input. This signal is input for the MCU.

RD+ InputDifferential signal input. This signal is input for the MCU.

Page 16

SD/MMC card slot:

Pin # Signal Name Pin # Signal Name

1 MCIDAT3 2 MCICMD

3 GND (VSS1) 4 VDD

5 MCICLK 6 GND (VSS2)

7 MCIDAT0 8 MCIDAT1

9 MCIDAT2 10 WP

11 - 12 -

13 CP 14 GND

15 GND

MCIDAT0-3 I/O Memory Card Interface Data 0-4. These are the data lines for the

SD/MMC connector. They could be both input and output for the MCU depending on the

data flow direction.

MCICMD Output Memory Card Interface Command. This is a command sent form the

processor to the memory card and as such it is output from the processor.

MCICLK Output Memory Card Interface Clock. This signal is output from the MCU

and synchronizes the data transfer between the memory card and the MCU.

WP Input Write Protect. This signal is input for the MCU.

CP Input Card Present. This signal is input for the MCU.

Page 17

EXT1&EXT2:

Pin #

Signal

Name

Pin # Signal

Name

Pin # Signal

Name

Pin # Signal

Name

EXT1-1 3.3V EXT1-2 GND EXT2-1 3.3V EXT2-2 GND

EXT1-3 +5V EXT1-4 RSTN EXT2-3 +5V EXT2-4 P4[23]

EXT1-5 ALARM EXT1-6 P1[29] EXT2-5 P4[22] EXT2-6 P4[21]

EXT1-7 P1[28] EXT1-8 P1[26] EXT2-7 P4[20] EXT2-8 P3[31]

EXT1-9 P1[25] EXT1-10 P1[24] EXT2-9 P3[30] EXT2-10 P3[29]

EXT1-11 P1[23] EXT1-12 P1[21] EXT2-11 P3[28] EXT2-12 P3[27]

EXT1-13 P1[20] EXT1-14 WP EXT2-13 P3[26] EXT2-14 P3[25]

EXT1-15 P0[26] EXT1-16 P0[25] EXT2-15 P3[24] EXT2-16 P3[23]

EXT1-17 VREF EXT1-18 P0[24] EXT2-17 P3[22] EXT2-18 P3[21]

EXT1-19 P0[23] EXT1-20 P0[22] EXT2-19 P3[20] EXT2-20 P3[19]

EXT1-21 P0[21] EXT1-22 PHY_PD EXT2-21 P3[18] EXT2-22 P3[17]

EXT1-23 P0[19] EXT1-24 P0[14] EXT2-23 P3[16] EXT2-24 P2[31]

EXT1-25 P0[11] EXT1-26 P0[10] EXT2-25 P2[30] EXT2-26 P2[27]

EXT1-27 P0[9] EXT1-28 P0[8] EXT2-27 P2[26] EXT2-28 P2[25]

EXT1-29 P0[7] EXT1-30 P0[6] EXT2-29 P2[23] EXT2-30 P2[22]

EXT1-31 P0[5] EXT1-32 P0[4] EXT2-31 P2[15] EXT2-32 P2[14]

EXT1-33 P0[1] EXT1-34 P0[0] EXT2-33 P2[9] EXT2-34 P2[8]

EXT1-35 P4[30] EXT1-36 P4[29] EXT2-35 P2[7] EXT2-36 P2[6]

EXT1-37 P4[28] EXT1-38 P4[27] EXT2-37 P2[5] EXT2-38 P2[4]

EXT1-39 P3[26] EXT1-40 P4[15] EXT2-39 P2[3] EXT2-40 P2[2]

Page 18

MECHANICAL DIMENSIONS:

All measures are in mm.

AVAILABLE DEMO SOFTWARE:

LPC-E2468 is delivered pre-loaded with C Linux and the sources and binaries are on the

accompanying CD.

Page 19

ORDER CODE:

LPC-E2468 – assembled and tested (no kit, no soldering required)

How to order?

You can order to us directly or by any of our distributors.

Check our web www.olimex.com/dev for more info.

All boards produced by Olimex are RoHS compliant

Revision history:

REV.A - created February 2008

Disclaimer:

© 2008 Olimex Ltd. All rights reserved. Olimex®, logo and combinations thereof, are registered trademarks of

Olimex Ltd. Other terms and product names may be trademarks of others.

The information in this document is provided in connection with Olimex products. No license, express or implied

or otherwise, to any intellectual property right is granted by this document or in connection with the sale of Olimex

products.

Neither the whole nor any part of the information contained in or the product described in this document may be

adapted or reproduced in any material from except with the prior written permission of the copyright holder.

The product described in this document is subject to continuous development and improvements. All particulars of

the product and its use contained in this document are given by OLIMEX in good faith. However all warranties

implied or expressed including but not limited to implied warranties of merchantability or fitness for purpose are

excluded.

This document is intended only to assist the reader in the use of the product. OLIMEX Ltd. shall not be liable for

any loss or damage arising from the use of any information in this document or any error or omission in such

information or any incorrect use of the product.

Loading...

Loading...