NO-TOUCH

User manual

Bedienungsanleitung

Инструкция по применению

AC10000879611.6

1 - TARGET AUDIENCE

EN

2 - REQUIRED READING

3 - SECURITY AND SYMBOLS

4 - BEFORE INSTALLATION

5 - ON-SITE ASSEMBLY CONDITIONS

6 - PRODUCT

7 - TECHNICAL SPECIFICATIONS

8 - FIRST USE

9 - PRINCIPLE OF OPERATION

10 - FUNCTIONS AND SETTINGS

11 - ENERGY AND SUSTAINABILITY

12 - TROUBLESHOOT

13 - CARE AND MAINTENANCE

14 - TERMS & CONDITIONS

5

5

5

6

6

7

8

8 - 9

10

11 - 14

14

15 - 17

18 - 22

22

1 - ZIELGRUPPE

DE

2 - PFLICHTLEKTÜRE

3 - SICHERHEIT UND SYMBOLE

4 - VOR DER INSTALLATION

5 - MONTAGEBEDINGUNGEN VOR ORT

6 - PRODUKT

7 - TECHNISCHE SPEZIFIKATION

8 - ERSTE BENUTZUNG

9 - FUNKTIONSPRINZIP

10 - FUNKTIONEN UND EINSTELLUNGEN

11 - ENERGIE UND NACHHALTIGKEIT

12 - FEHLERBEHEBUNG

13 - PFLEGE UND WARTUNG

14 - GESCHÄFTSBEDINGUNGEN

1 - ЦЕЛЕВАЯ АУДИТОРИЯ

RU

2 - ОБЯЗАТЕЛЬНО ДЛЯ ОЗНАКОМЛЕНИЯ

3 - БЕЗОПАСНОСТЬ И СИМВОЛЫ

4 - ПЕРЕД УСТАНОВКОЙ

5 - УСЛОВИЯ СБОРКИ НА МЕСТЕ

6 - ИЗДЕЛИЕ

7 - ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

8 - ПЕРВОЕ ИСПОЛЬЗОВАНИЕ

9 - ПРИНЦИП ДЕЙСТВИЯ

10 - ФУНКЦИИ И НАСТРОЙКИ

11 - ЭНЕРГИЯ И ДОЛГОВЕЧНОСТЬ

12 - ВЫЯВЛЕНИЕ НЕИСПРАВНОСТЕЙ

13 - УХОД И ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ

14 - ОФИЦИАЛЬНОЕ УВЕДОМЛЕНИЕ

23

23

23

24

24

25

26

26 - 27

28

30 - 32

32

33 - 35

36 - 40

40

41

41

41

42

42

43

44

44 - 45

46

47 - 50

50

51 - 53

54 - 58

58

3

4

EN

1-TARGET AUDIENCE

These assembly instructions are intended for installation companies specializing in sanitary systems with

electrical components. The product described in these instructions must only be installed by authorized

installation companies in the area of sanitary systems.

2-REQUIRED READING

The installation company is committed to read, understand and observe the assembly instructions and, in

particular, the chapter on safety regulations. If you have any questions, please contact OLI sta.

3-SECURITY AND SYMBOLS

MEANING OF SAFETY NOTICES AND SAFETY STANDARDS

SAFETY NOTES

The pictograms and signs relating to safety instructions, precautions and warnings in the installation

instructions have the following meaning:

Warning! Possible damaging situation, can damage the product or something around it.

Important! Instructions for use and other useful information to facilitate the use of the product

in accordance with the standards.

DE

RU

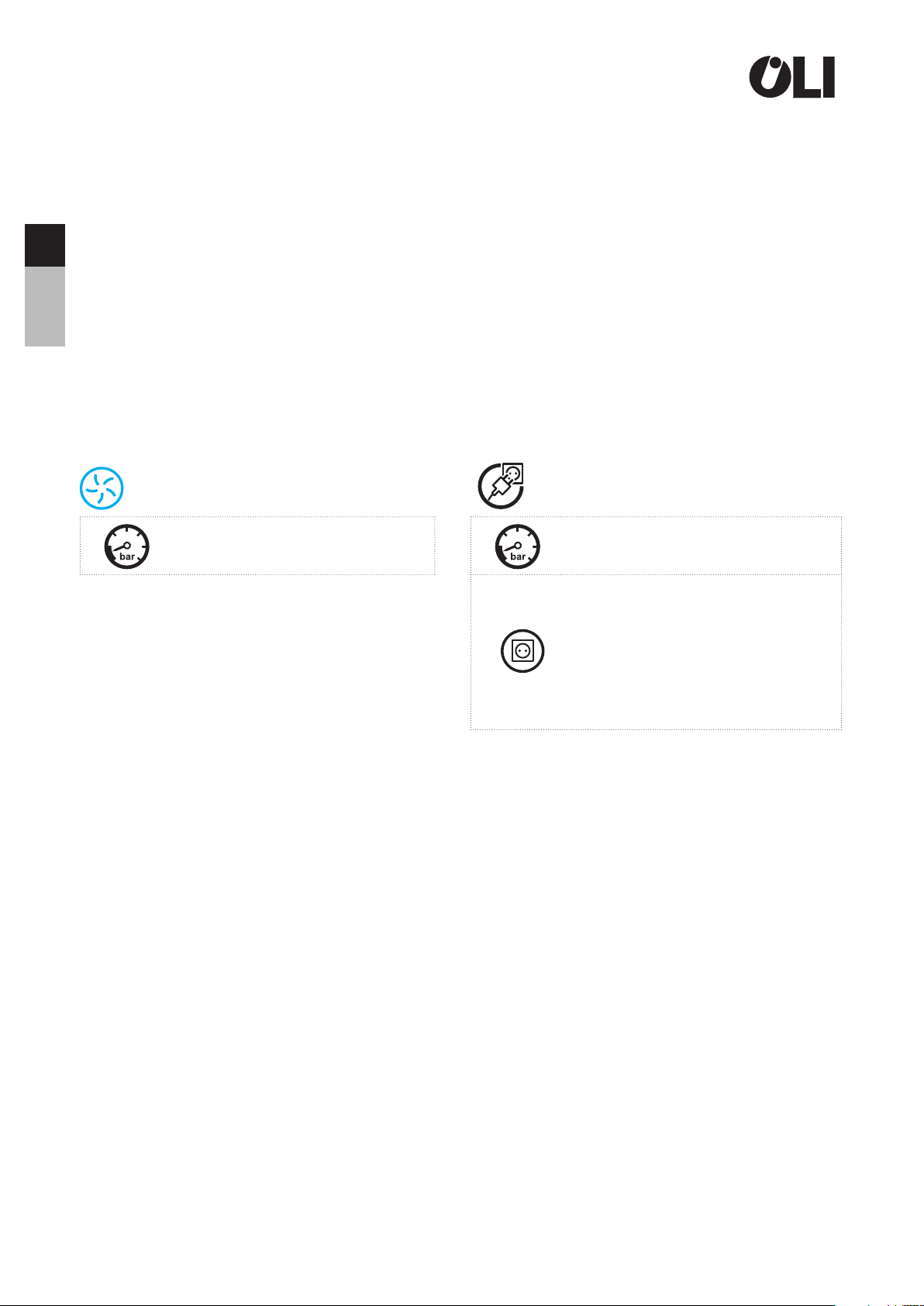

To test / attention to moisture.

Electrical voltage hazard.

System with hydro generator - Hydroboost

Mains power system - AC

5

EN

DE

RU

4-BEFORE INSTALLATION

Before starting the assembly, read thoroughly and understand the assembly instructions.

The product must be assembled, installed and connected only in accordance with these instructions.

Before applying your system confirm the compatibility of your installation at www.oli-world.com.

When planning and installing sanitary equipment, local, national and international regulations and standards

must be observed and respected.

Examine the contents of the product before beginning the assembly to verify that it is complete.

A product that is incomplete or has visible damage or malfunctions should not be installed. No liability can be

assumed for damages caused by improper transport or by temporary storage.

5-ON-SITE ASSEMBLY CONDITIONS

Water grid pressure 0.5 bar at

max. 10 bar

Water grid pressure 0.5 bar at

max. 10 bar

Mains voltage

110 - 240 VAC / 50-60Hz with a

general switch for all poles

connected to mains supply and

contact opening capacity of 3 mm.

6

EN

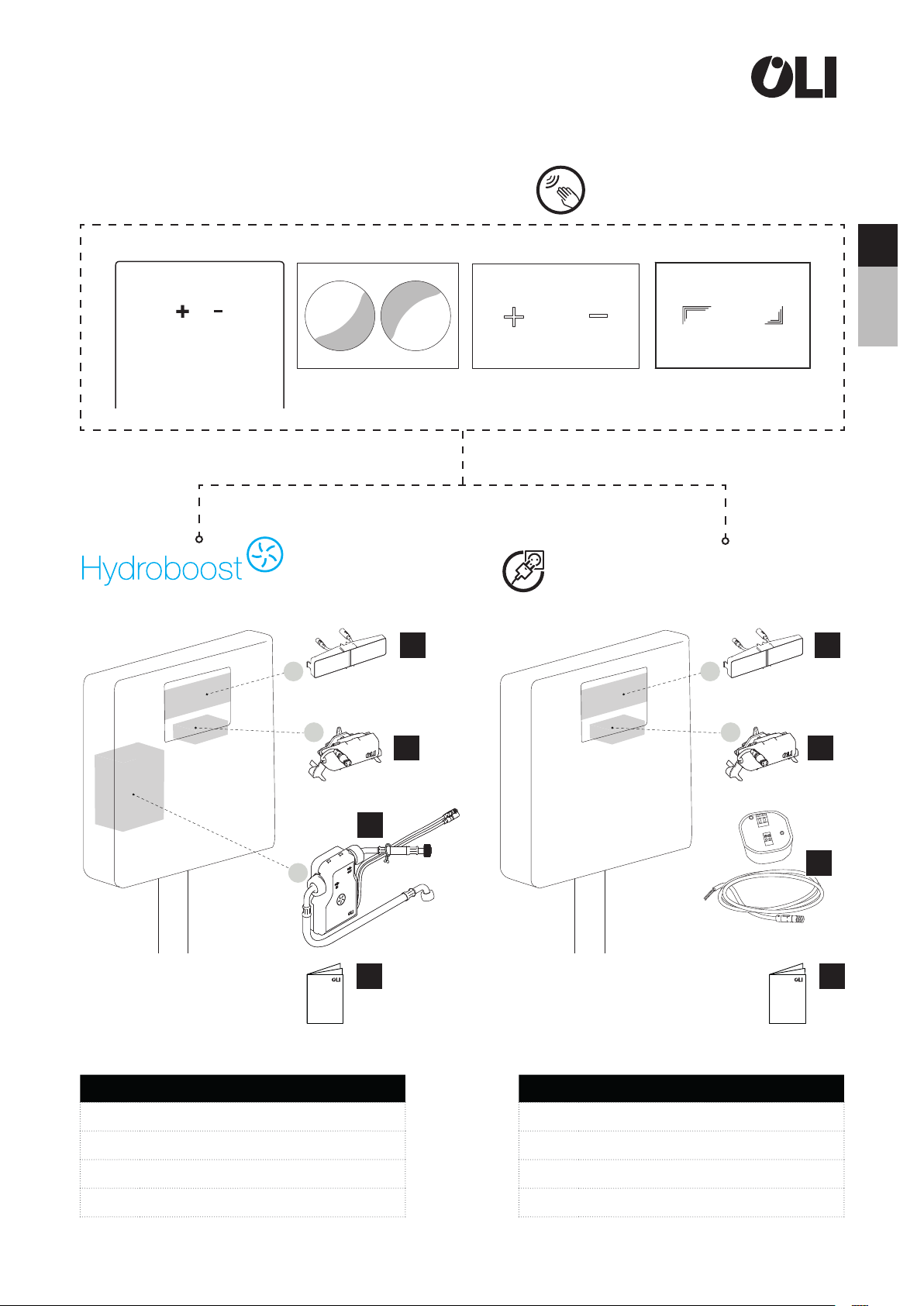

6-PRODUCT

NO TOUCH

QR-INOX

MOON GLASSY TRIBE

AC power-mains

1

DE

RU

1

NR DESCRIPTION

1 CAPACITIVE SENSOR

2 SERVOMOTOR

3 HYDRO GENERATOR

2

2

3

3

4

NR DESCRIPTION

1 CAPACITIVE SENSOR

2 SERVOMOTOR

3 TRANSFORMER

4

4 ASSEMBLY INSTRUCTIONS

4 ASSEMBLY INSTRUCTIONS

7

EN

7-TECHNICAL SPECIFICATIONS

HYDROBOOST

RATED VOLTAGE 6.4V DC

DE

RU

BATTERY TYPE

BATTERY CAPACITY

OPERATION WATER

PRESSURE

LiFePO4

3000

0.5 - 10 BAR

• Non-contact electronic flush system

• Capacitive Sensor Dual Flush

• For front flush plate installation GLASSY /

TRIBE / MOO or QR installation QR-INOX

• IP68 protection rate

• Customizable LED lighting

• Configurable hygienic flush

mAh

REDE ELÉTRICA

OPERATION VOLTAGE 110 - 240 V AC

GRID VOLTAGE 50-60 HZ

TYPE OF GRID CONNECTION

OPERATION WATER

PRESSURE

BORNE KRE

0.5 - 10 BAR

8-FIRST USE

BEFORE ANY USE

For safety and longevity of the system, the battery of the hydro generator is only partially

charged. For optimum use, the full charge of the hydro generator, with the supplied charger, is

advised before any use (see Charging the Battery in the maintenance chapter).

8

EN

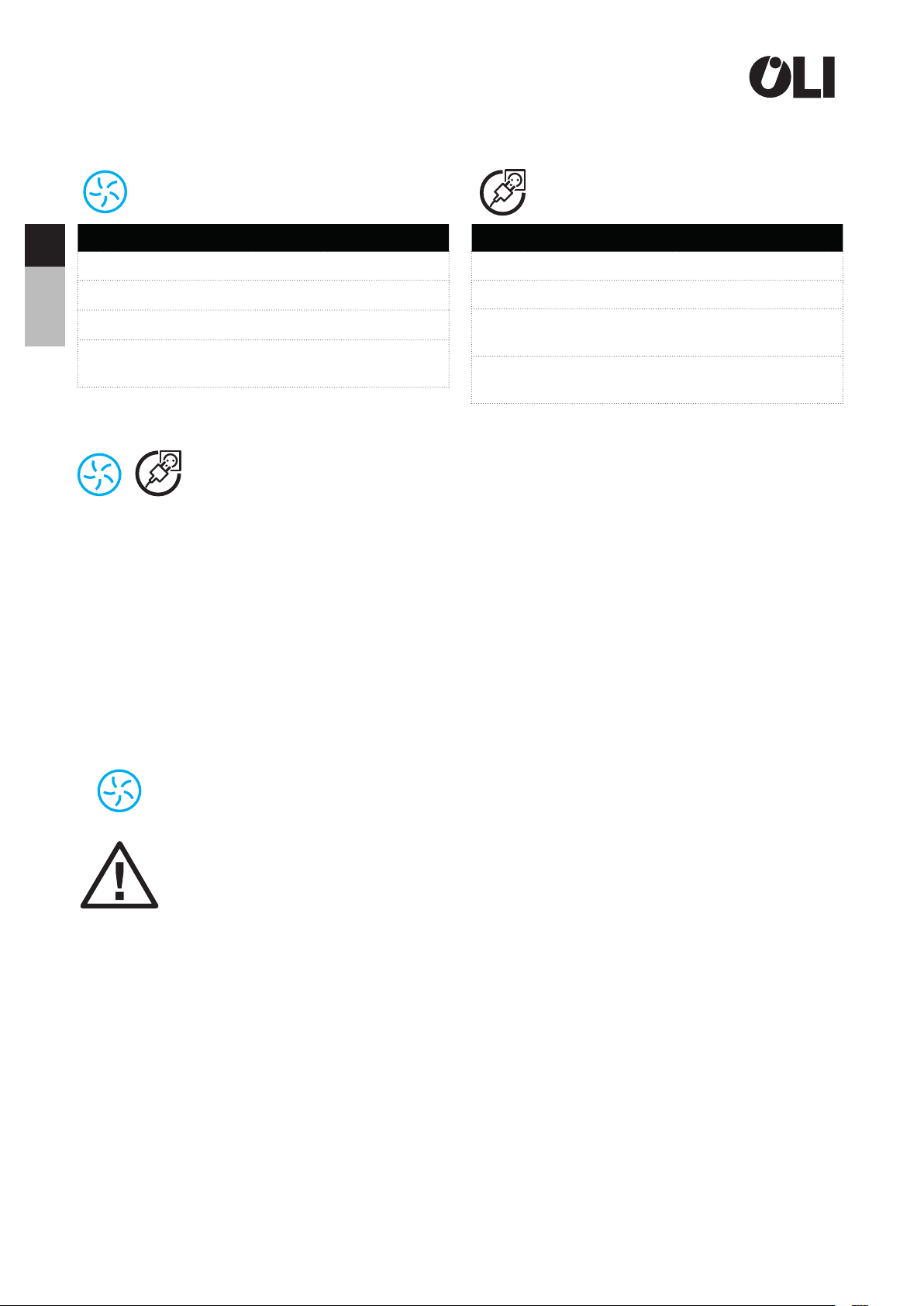

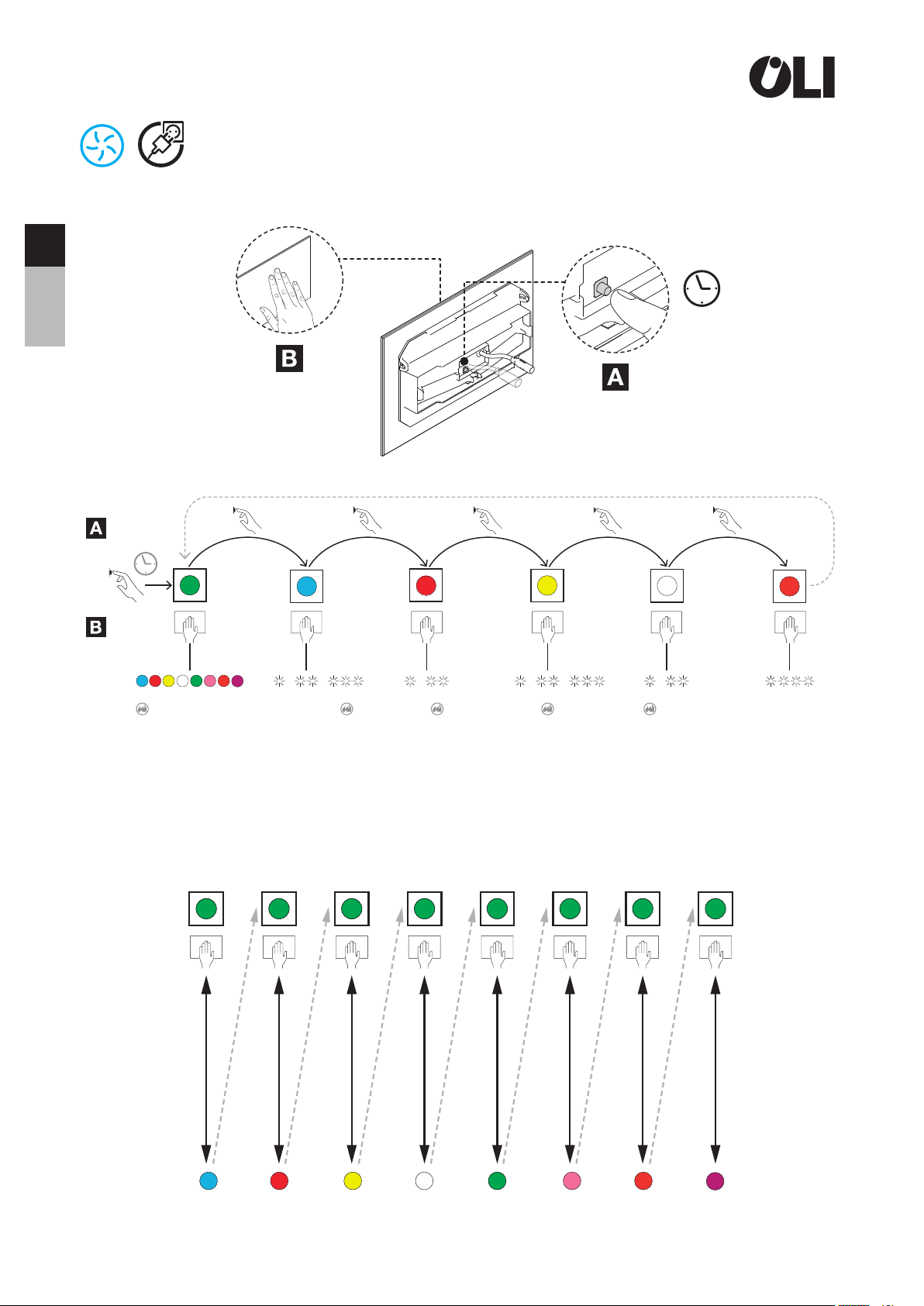

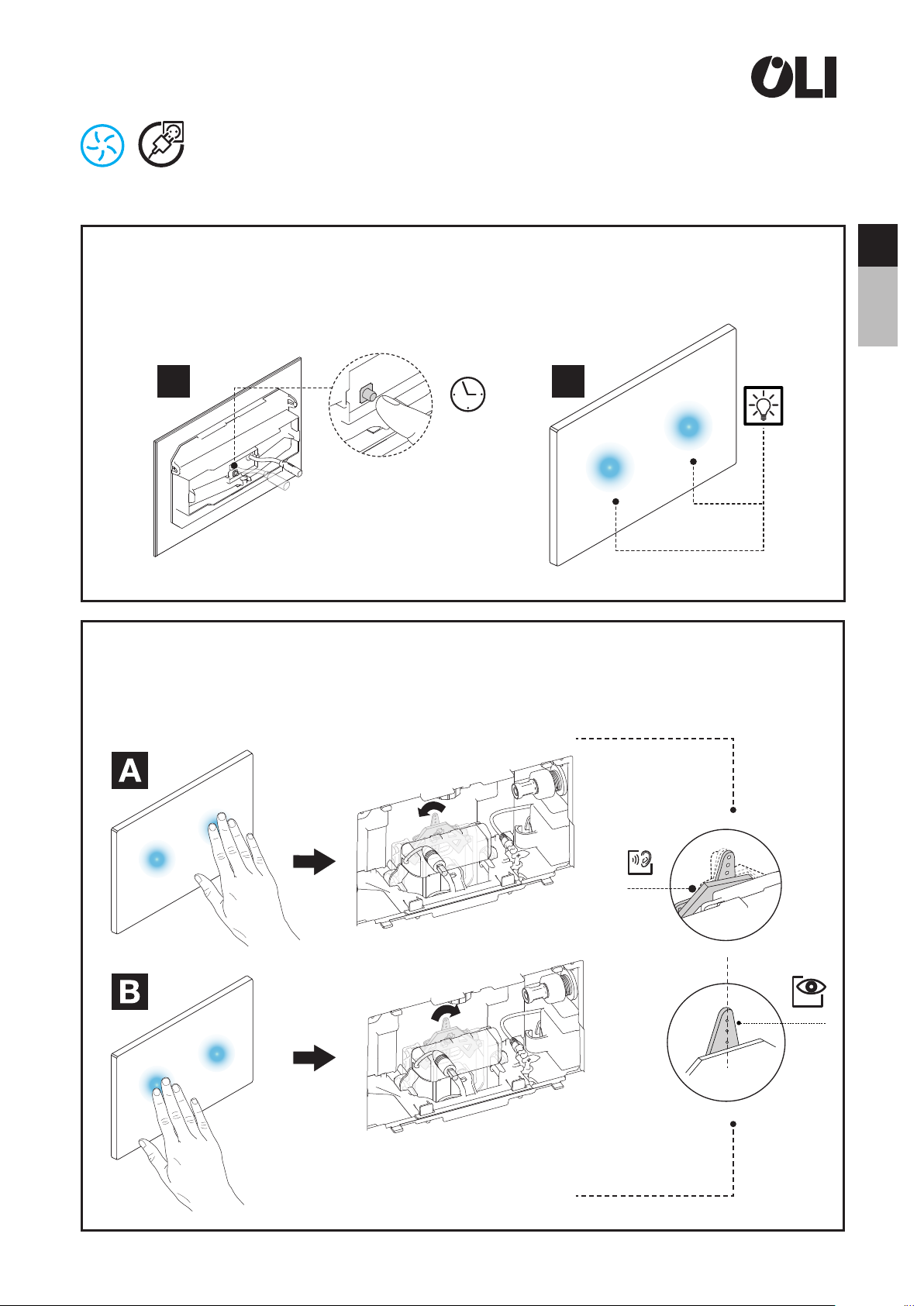

CALIBRATION

To ensure correct operation of the flush plate over a variety of environmental conditions - temperature and

humidity - the sensor is equipped with an automatic calibration function (procedure)

Once the sensor is connected to the power

1

source, it will confirm that it has energy

through 3 consecutive flashes.

X3

In the ceramic flush plate there

is no feedback (the flashes are

not visible in the ceramic flush

plate).

There is a 20-second period in which

2

the user / installer should complete the

installation and place the system in its final

operating position.

00.00

0:00:20.00

1

DE

RU

After the standby period has elapsed, the

3

calibration routine starts automatically and

its completion is communicated again by

3 consecutive flashes. The system is ready

for use.

X3

In the ceramic flush plate there

is no feedback (the flashes are

not visible in the ceramic flush

plate).

Note: For proper operation of the product, calibration must be performed with the sensor /

flush plate in its final operating position. Otherwise, the product may not detect the user or

cause incorrect or unwanted flushes. If any of these symptoms occur, turn o the system and

follow this procedure again.

2

CLICK

9

EN

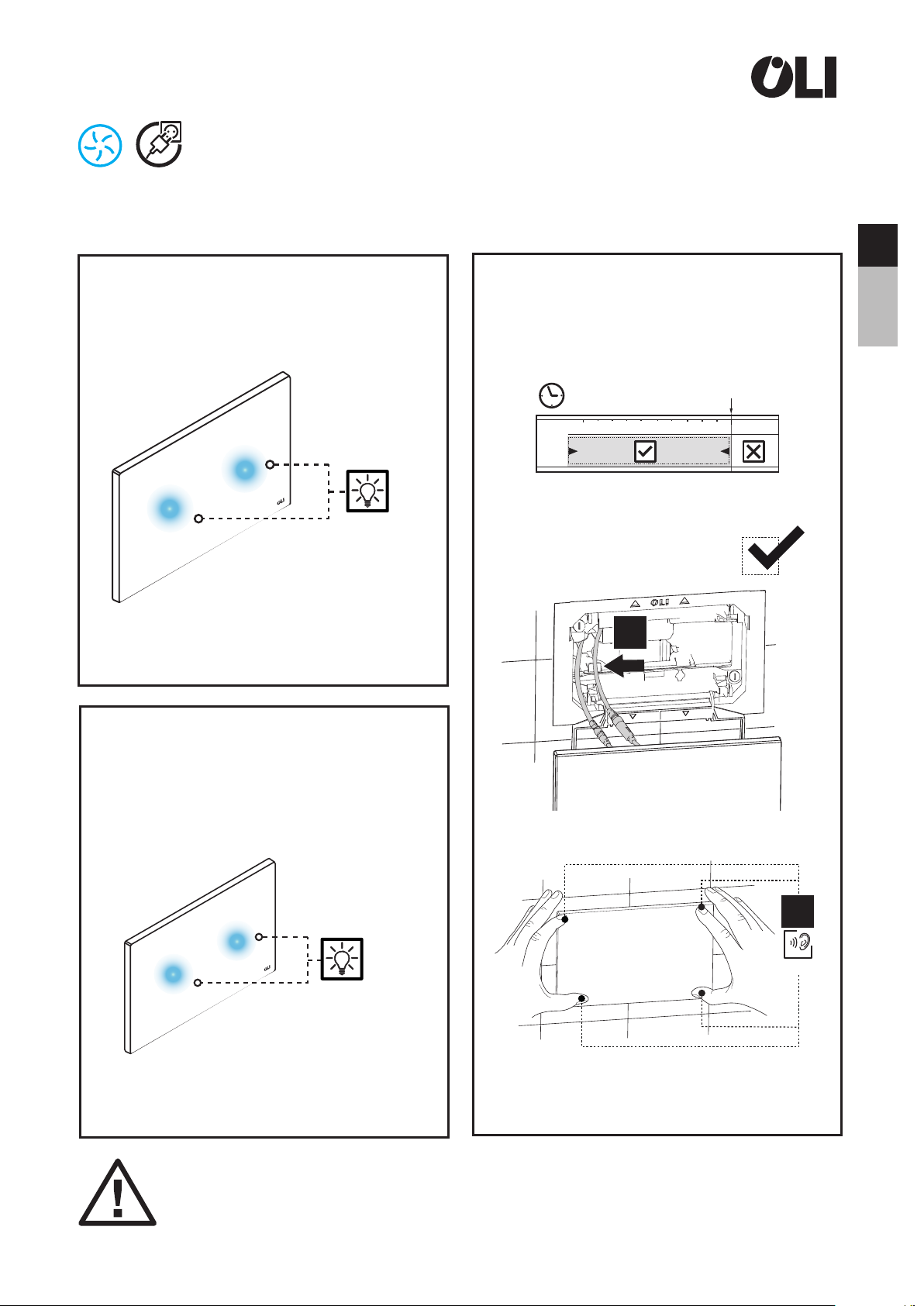

9-PRINCIPLE OF OPERATION

SYSTEM ACTUATION

The realization of no touch flushes is achieved through an electronic system, composed of capacitive

DE

RU

sensors, that senses user inputs. Detection is made up to 30mm from the flush plate.

INTERACTION

Move your hand close to the flush symbol you want to perform

1

Higher volume flush (full flush)

(left capacitive button)

Remain until the LED lights up or the flush

2

is performed

0:00:01.00

Lower volume flush (half-flush)

(right capacitive button)

Remove your hand

3

10

EN

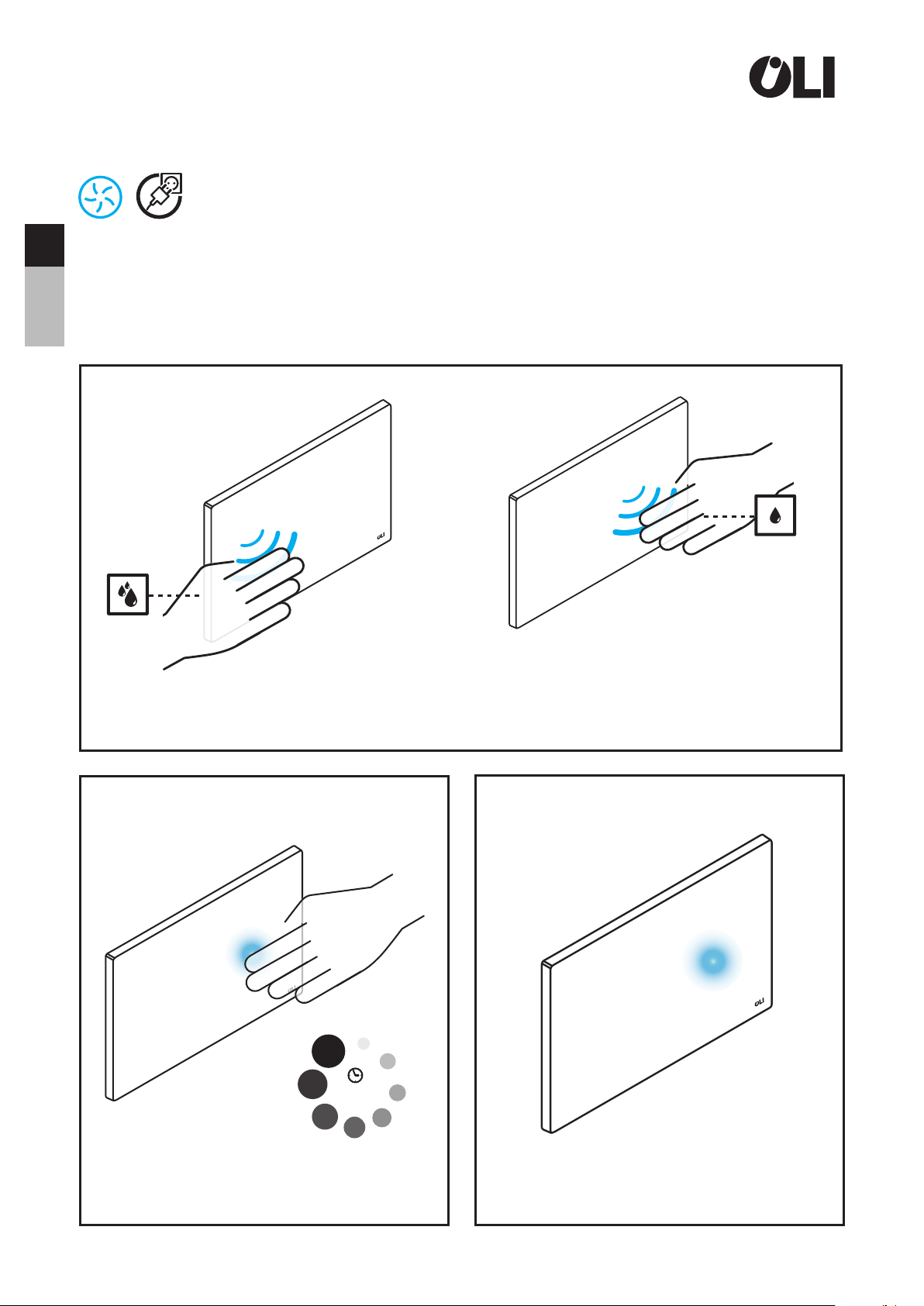

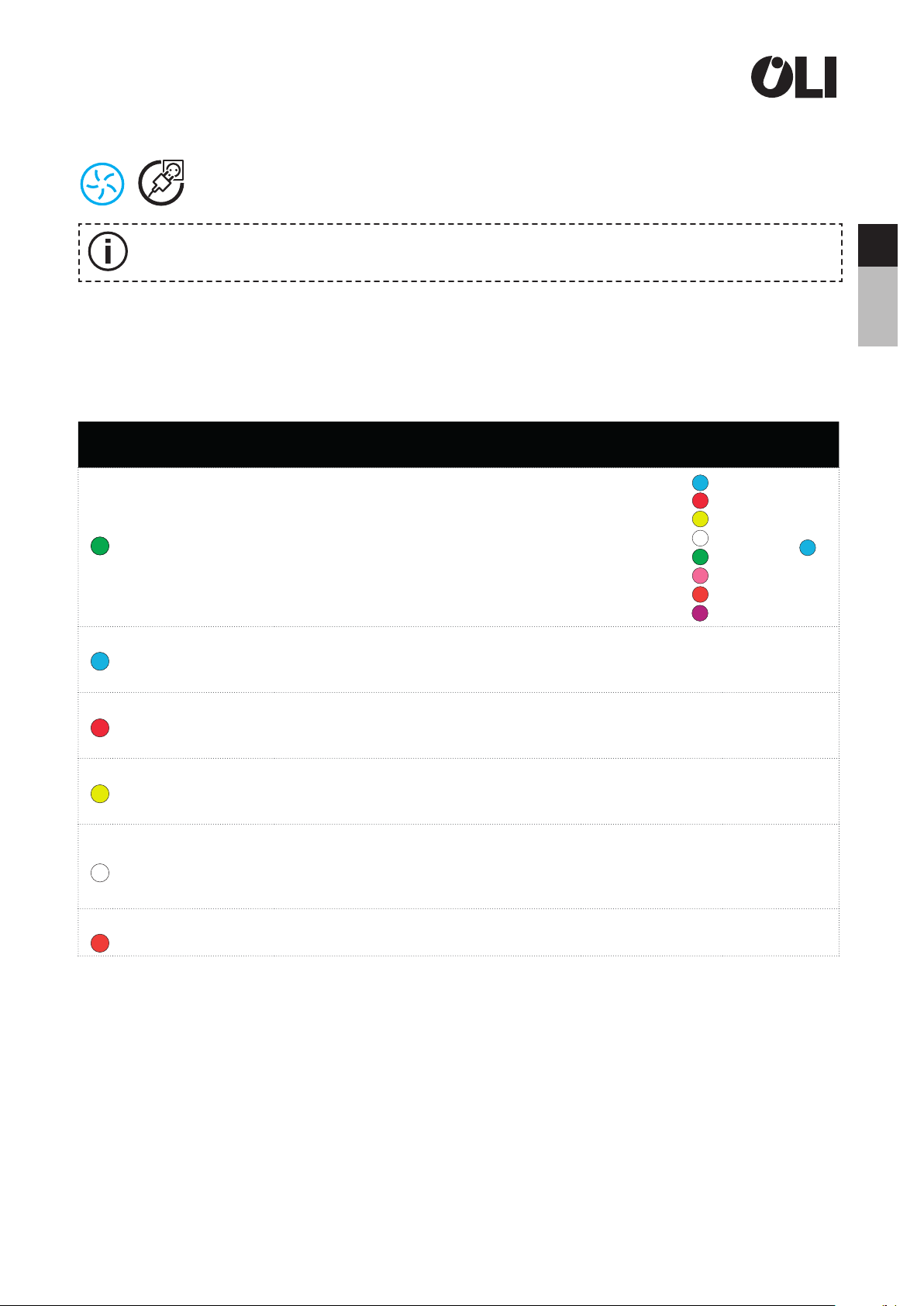

10-FUNCTIONS AND SETTINGS

For functions and settings in the ceramic flush plate, see page 14 to disassemble the flush plate.

DE

MENU NAVIGATION

Navigation through the 6 menus is done using the physical button on the back of the sensor. To activate the

menu, press the button for 5 seconds. The illumination of both sensors will light up and the colour of the LEDs

indicates the active menu.

FUNCTION DESCRIPTION

Colour adjustment

of the LED lights

Sensor sensitivity

adjustment

Enable or disable

duty flush

The following colours can be set: Blue,

Red, Yellow, White, Green, Violet,

Orange, Purple

The sensor allows you to adjust the

detection sensitivity in three levels

The sensor allows automatic flushs to be

performed at regular intervals if there is

no frequent usage

AVAILABLE

SETTINGS

Blue

Red

Yellow

White

Green

Violet

Orange

Purple

Low

Medium

High

ON

OFF

FACTORY

SETTINGS

Blue

High

OFF

RU

Set automatic/

hygienic flush timing

Enable or disable

sensor lighting

Reset factory

settings

It is possible to define three regular time

intervals between automatic flushes

For greater energy savings (or if the

ceramic flush plate is used), it is possible

to deactivate the sensor illumination

The parameters for all functions are reset

to the factory default values

3H

24H

72H

ON

OFF

Reset -

24H

ON

11

EN

DE

NAVIGATION BETWEEN MENUS

RU

0:00:05.00

START

Low Medium High 3H 24H 72HON OFF ON OFF

RESET

SETTINGS AJUSTMENT

The navigation and settings definition of each function is done on the full flush capacitive button.

After choosing the menu you want, to go through each one of the options you have to proceed as follows,

when approaching your hand to the discharge symbol the first menu option will appear. If you want to

change to another menu option, you always have to bring your hand closer to the discharge symbol.

Check the scheme below:

12

EN

After setting the desired menu option, wait, and the system will take your option and return to discharge

mode. As you can verify below:

These procedures are the same for all menus.

DE

RU

With each change made, the flush plate/

1

sensor reports the new setting status

through the number of flashes (e.g. in

menu

sensitivity level has been selected is given

by 3 consecutive blue flashes).

, the indication that the high

X3

To validate your changes and exit the

2

menu, wait 10 seconds without interacting

with the sensor. The flush plate is ready for

use when the lights go o.

0:00:10.00

Note: All settings are stored in the sensor memory even when the sensor is out of power or is

restarted.

13

EN

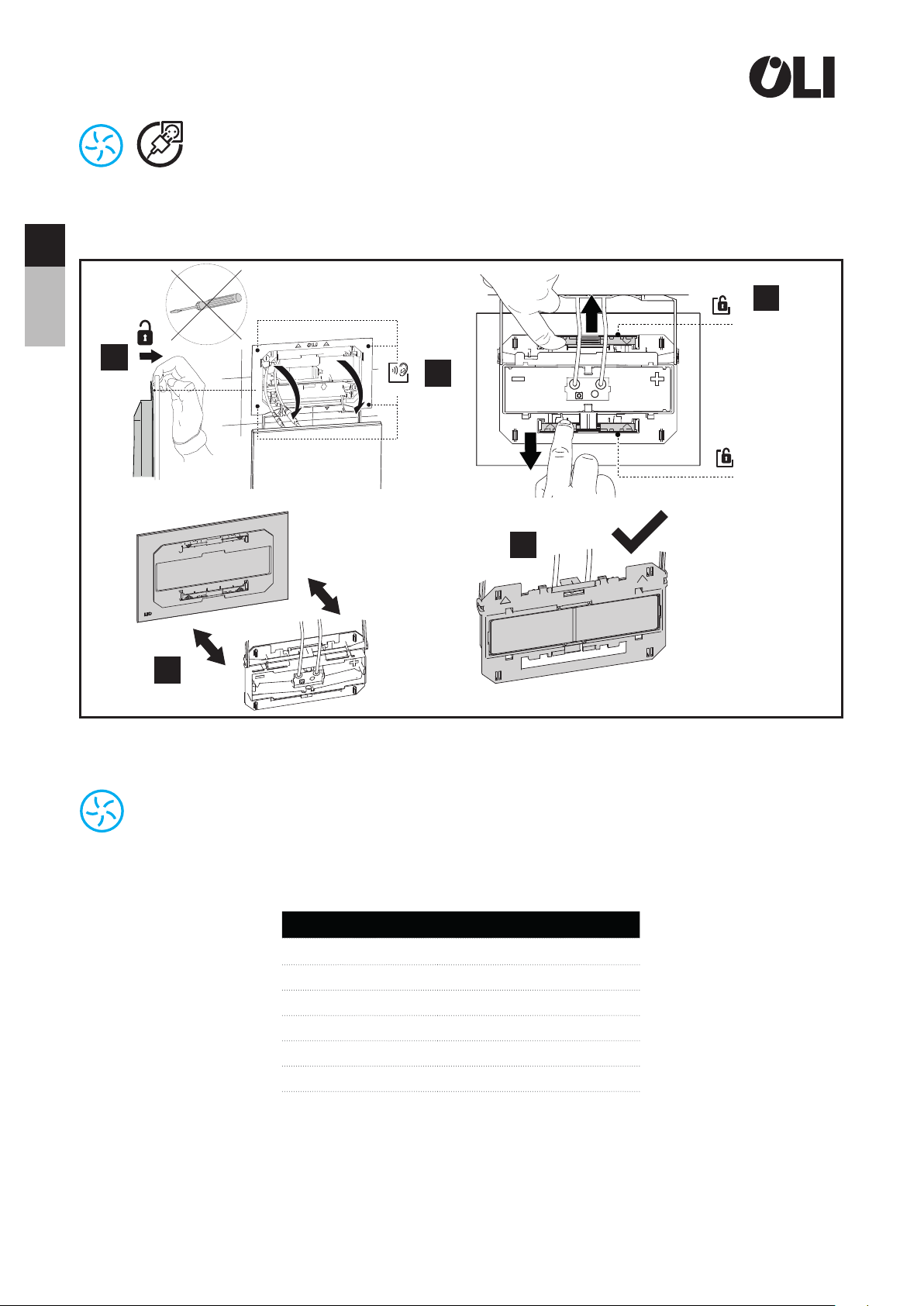

DISASSEMBLY OF CERAMIC FLUSH PLATE

-

+

-

To access the menu settings on the ceramic flush plate it is necessary to disassemble the flush plate as

instructed.

DE

RU

3

UNLOCK

1

2

CRACK

UNLOCK

5

4

11-ENERGY AND SUSTAINABILITY

When the cistern is being filled - when water flows from the angle valve to the filler mechanism - the hydro

generator generates an electric current. This energy is stored in the battery for later use. In turn, this battery

feeds the capacitive sensor for the user interface and actuator mechanism to perform flushes.

FLUSHES PER DAY CHARGES (2 YEARS)

0 5

5 4

10 3

15 2

20 1

25 0

The high-capacity battery pack ensures system operation for several months, even with reduced product

usage.

With more frequent use, their lifetime is extended, thanks to the energy generated by the hydro generator - the

surplus energy generated is accumulated in the batteries.

*It is possible to recharge the batteries through the provided charger.

14

EN

12-TROUBLESHOOT

MALFUNCTION POSSIBLE CAUSE PROCEDURE

Flush plate flashes red after flushing • Low energy level • Recharge battery

• Extremely low energy level • Recharge battery

Flush plate flashes red and doesn’t flush

Frequent low battery (red flashes) indication

When interacting with the flush plate, lighting works

but no flush is performed

When interacting with the flush plate, lighting doesn’t

work but a flush is performed

When interacting with the flush plate, lighting doesn’t

work and no flush is performed

When interacting with the flush plate, two flashes in

both sensors are presented and no flush is performed

Ceramic bowl cleaning is not eective • Flush volumes may be set incorrectly

Water runs continuously in ceramic bowl

Unprovoked flushes

Incorrect flushes

Charger doesn’t show green light

• Faulty mechanism • Replace flush mechanism

• Obstructed servomotor

• Clogged filter • Verify/clean the filter

• Faulty hydro generator • Replace hydro generator

• Faulty software • Reboot system

• Servomotor misconnection • Check connections

• Faulty servomotor • Replace servomotor

• Empty cistern

• Faulty software • Reboot system

• LED function deactivated • Check LED function setting

• Faulty software • Restart system

• Drained battery • Recharge battery

• Misconnections

• Faulty hydro generator • Replace hydrogenate

• Poor calibration • Reboot system

• Faulty sensor • Replace sensor / flush plate

• Cleaning mode activated due to poor

calibration

• Excessive condensation inside the flush plate • Verify / clean flush plate interior

• Faulty software • Reboot system

• Faulty rubber sealing • Replace rubber sealing

• Faulty flush system • Replace flush system

• Faulty filling mechanism (inlet valve) • Replace filling mechanism (inlet valve)

• Hygienic automatic flush activated

• Poor calibration • Reboot system

• Faulty software • Reboot system

• Dirty or wet flush plate • Verify / clean flush plate interior

• Poor calibration • Reboot system

• Faulty wall charger • Replace the wall charger

• Faulty hydro generator • Replace hydro generator

• Check the flush mechanism (outlet

valve) configuration

• Check angle valve

• Check for eventual blocking in the

filling mechanism (inlet valve)

• Check for water in the grid

• Check connection with hydro

generator

• Reboot system

• Check the flush mechanism (outlet

valve) configuration

• Check if the filling mechanism (inlet

valve) is performing correctly

• Verify hygienic automatic flush

function setting

DE

RU

15

EN

DE

RU

12-TROUBLESHOOT

MALFUNCTION POSSIBLE CAUSE PROCEDURE

• Clogged filter • Verify/clear hydro generator filter

Long filling times

• Low water grid pressure (<2 bar/>120s)

• Faulty software • Reboot system

• Servomotor misconnection • Check connections

When interacting with the flush plate, lighting works but no

flush is performed

When interacting with the flush plate, lighting doesn’t work

but a flush is performed

When interacting with the flush plate, lighting doesn’t work

and no flush is per formed

When interacting with the flush plate, two flashes in both

sensors are present and no flush is performed

Ceramic bowl cleaning is not eective • Flush volumes may be set incorrectly

Water runs continuously in ceramic bowl

Unprovoked flushes

Incorrect flushes

• Faulty servomotor • Replace servomotor

• Empty cistern

• Faulty software • Reboot system

• LED function deactivated • Check LED function setting

• Faulty software • Reboot system

• Blackout • Check electrical power

• Faulty software • Reboot system

• Falha de energia • Check connections to the mains adaptor

• Misconnections • Check connections to the mains adaptor

• Faulty mains adaptor • Replace mains adaptor

• Poor calibration • Reboot system

• Faulty sensor • Replace sensor / flush plate

• Cleaning mode activated due to poor calibration • Reboot system

• Excessive condensation inside the flush plate • Verify / clean flush plate interior

• Faulty software • Reboot system

• Faulty rubber seal • Replace rubber seal

• Faulty flush system • Replace flush system

• Faulty filling mechanism (inlet valve) • Replace filling mechanism (inlet valve)

• Hygienic automatic flush activated

• Poor calibration • Reboot system

• Faulty software • Reboot system

• Dirty or wet flush plate • Verify / clean flush plate interior

• Poor calibration • Reboot system

• Remove flow regulator from the filling

mechanism (inlet valve)

• Check angle valve

•Check for eventual blockage in the filling

mechanism (inlet valve)

• Check for water in the grid

• Check the flush mechanism (outlet valve)

configuration

• Check if the filling mechanism (inlet valve)

is performing correctly

• Verify hygienic automatic flush function

setting

16

EN

MANUAL CALIBRATION

To calibrate the servomotor you need to press the button at the back of the sensor.

1

The button should be pressed during 30 seconds or more (1) until the two blue flushes (2) light

up.

DE

RU

1

> 0:00:30.00

After the blue light appears, you can calibrate by placing your hand over one of the capacitive

2

buttons.

When positioning the hand over the half flush capacitive button (A), the servomotor will move to

the left. If you place your hand over the full flush capacitive button (B) the servomotor will move

to the right.

2

ZOOCK!!

0º

CHECK

17

EN

DE

RU

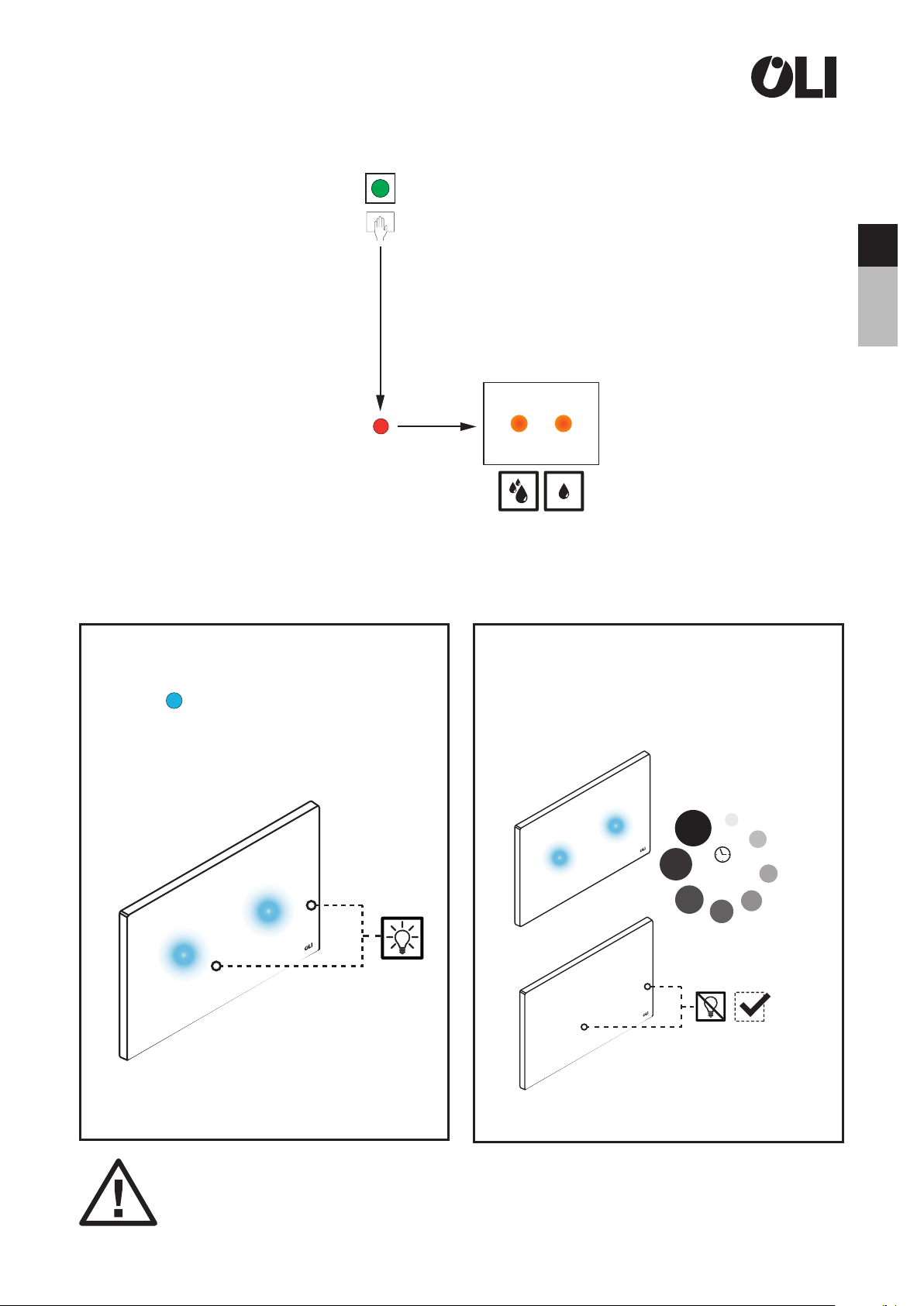

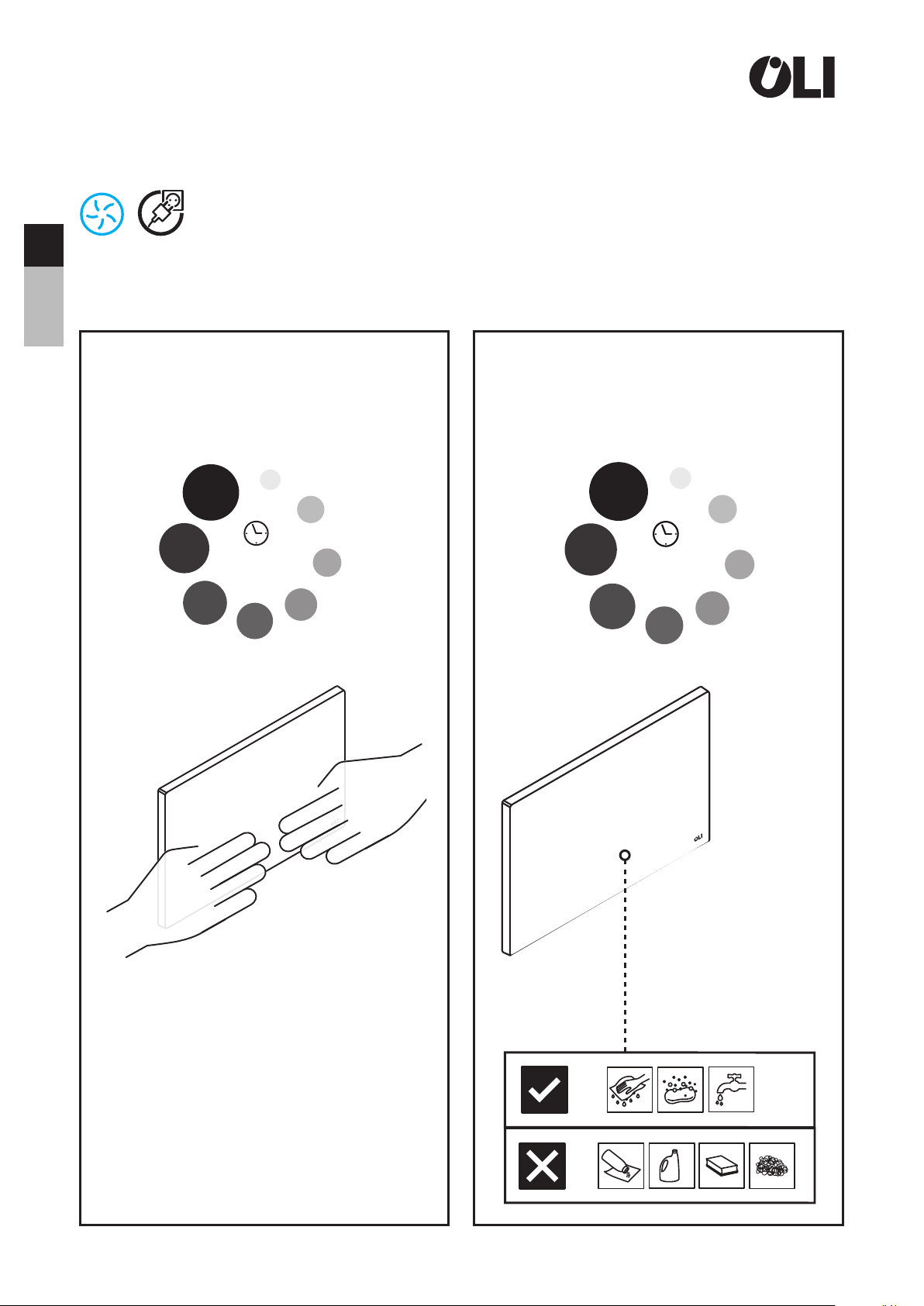

13-CARE AND MAINTENANCE

CLEANING MODE

The flush plate has a cleaning mode that allows the user to clean it without provoking undesired flushes.

Unlike the other functions, this

can be activated directly without

disassembling the flush plate, with

the simultaneous interaction of both

sensors for 10 seconds.

Once the cleaning time has elapsed -

21

60 seconds - the flush plate returns to

the normal operating mode.

0:00:10.00

0:00:60.00

18

EN

CLEANING THE FLUSH PLATE

The surface is simple to clean and care for. Use a soft cloth and soap and water solution for regular care.

Wipe clean with a dry cloth.

Avoid the use of abrasives or solvents, which damage the surface.

Damage caused by improper handling by the user is not covered by our warranty.

DE

RU

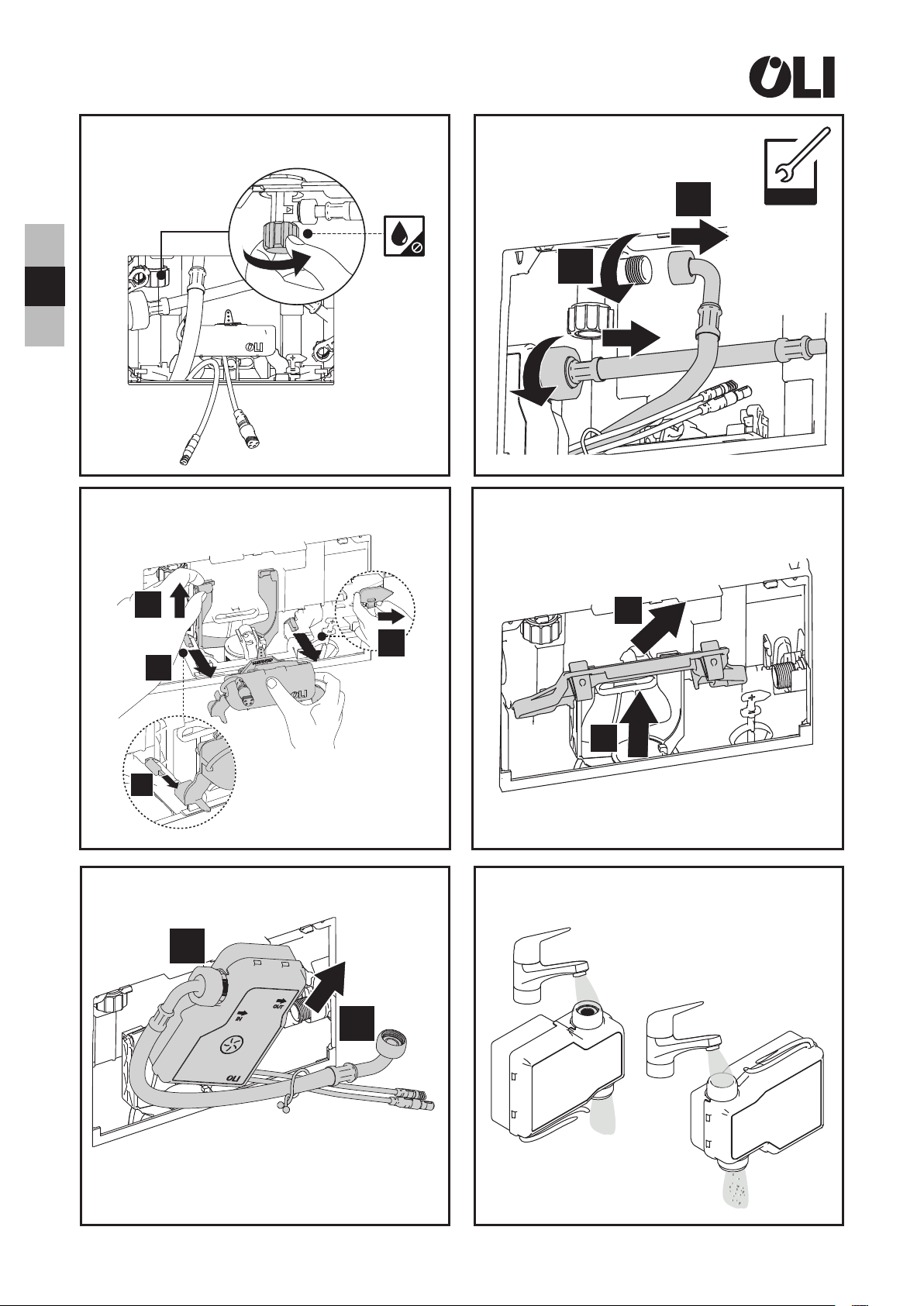

CLEANING THE FILTER

For protection of the hydro generator and filling mechanism (inlet valve), the Hydroboost system incorporates

a small particles filter in the water circuit. In case of installation in areas with polluted water/new buildings,

there is the possibility of debris accumulating over time and loss of circuit eciency

Therefore, periodic maintenance is advised.

Open the flush plate.

1

1

2

CRACK

disconnect all electrical connections and

2

remove counterplate.

19

EN

Close the stop valve

3

Disconnect the flexible hose

4

DE

RU

Retirar servomotor

5

2

3

2

19

1

Remove the central block

6

2

1

3.3

Remove hydro generator

7

1

1

wash thoroughly with water on both sides.

8

2

20

EN

CHARGING THE BATTERY

The Hydroboost system consists of a hydro generator and a battery pack. As such, the energy level in the

batteries might be low with infrequent use (the hydro generator only produces energy and charges the

battery when flushes are performed) and / or by the natural decay of the batteries over time. In both cases,

the system may need to be charged with the charger provided for this purpose.

DE

RU

To do this, follow the procedure:

Remove the flush plate.

1

CRACK

CHECK

Plug the charger into an outlet and confirm

2

the charger light (red) turns on, indicating

that it is charging.

22

1

2

Please insert the charger in an electric

3

socket.

1

Minimum charging time 4h.

The system can be used

normally during charging

2

4:00:00.00

21

EN

Put back the plug safety cover and fit the cable into its housing slot.

4

The flush plate should be placed back into its operating position and the charger

stored for future use.

DE

RU

1

CHECK

2

CLICK

3

14-TERMS & CONDITIONS

DECLARATION OF CONFORMITY

Manufacturer: OLI-Sistemas Sanitários, S.A

Declares that they comply with European standards.

WARRANTY :

You should consult information about the warranty for this product from the manufacturer’s website:

www.oli-world.com

22

EN

1-ZIELGRUPPE

Diese Montageanleitung richtet sich an Sanitär-Installationsfirmen, welche auf Montagen in Verbindung mit

elektrischen Komponenten spezialisiert sind. Das in dieser Anleitung beschriebene Produkt darf nur von

autorisierten Installationsfirmen der Sanitärbranche installiert werden.

2-PFLICHTLEKTÜRE

Das Installationsunternehmen ist verpflichtet, die Montageanleitung und insbesondere das Kapitel über

Sicherheitsvorschriften zu lesen, zu verstehen und zu beachten. Wenn Sie Fragen haben, wenden Sie sich

bitte an die Mitarbeiter von OLI.

3-SICHERHEIT UND SYMBOLE

BEDEUTUNG VON SICHERHEITSHINWEISEN UND SICHERHEITSSTANDARDS

SICHERHEITSHINWEISE

Die Piktogramme und Zeichen in Bezug auf Sicherheitsanweisungen, Vorsichtsmaßnahmen und Warnungen

in die Installationsanleitung haben folgende Bedeutung:

Warnung! Mögliche Schadenssituationen, können das Produkt oder etwas um es herum

beschädigen.

Wichtig! Gebrauchsanweisung und andere nützliche Informationen um die Verwendung des

Produkts in Übereinstimmung mit den Standards zu erleichtern.

DE

RU

Zum Prüfen / Aufmerksamkeit bei Feuchtigkeit

Gefahr durch elektrische Spannung

System mit Hydrogenerator - Hydroboost

Hauptstrom-System - AC

23

EN

DE

RU

4-VOR DER INSTALLATION

Lesen Sie sich vor Beginn der Montage die Montageanleitung durch und verstehen diese.

Das Produkt muss gemäß dieser Anleitung montiert, installiert und angeschlossen werden.

Bevor Sie Ihr System installieren, bestätigen Sie die Kompatibilität Ihrer Installation unter

www.oli-world.com.

Bei der Planung und Installation von Sanitäreinrichtungen müssen lokale, nationale und internationale

Vorschriften und Normen beachtet und eingehalten werden.

Überprüfen Sie den Inhalt des Produkts, bevor Sie mit der Montage beginnen, um sicherzustellen, dass es

vollständig ist.

Ein Produkt, das unvollständig ist oder sichtbare Schäden oder Fehlfunktionen aufweist, sollte nicht installiert

werden. Für Schäden, die durch unsachgemäßen Transport oder durch Zwischenlagerung entstehen, kann

keine Haftung übernommen werden.

5-MONTAGEBEDINGUNGEN VOR ORT

Wassernetzdruck 0,5 bar bei

max. 10 Bar

Wassernetzdruck 0,5 bar bei

max. 10 Bar

Netzspannung

110 - 240 VAC / 50-60Hz mit einem

allgemeinen Schalter für alle an das

Netz angeschlossenen Pole und

Kontaktönungsvermögen von 3 mm.

24

EN

6-PRODUKT

NO TOUCH

QR-INOX

MOON GLASSY TRIBE

AC Hauptstrom-System

1

DE

RU

1

NR BESCHREIBUNG

1 KAPAZITIVER SENSOR

2 SERVOMOTOR

3 HYDROGENERATOR

2

2

3

3

4

NR BESCHREIBUNG

1 KAPAZITIVER SENSOR

2 SERVOMOTOR

3 TRAFO

4

4 MONTAGEBESCHREIBUNG

4 MONTAGEBESCHREIBUNG

25

EN

7-TECHNISCHE SPEZIFIKATION

DE

RU

HYDROBOOST

NENNSPANNUNG 6.4V DC

BATTERIEART

BATTERIEKAPAZITÄT

BETRIEBSWASSERDRUCK

LiFePO4

mAh

3000

0.5 - 10 BAR

• Berührungsloses elektronisches Spülsystem

• Kapazitiver Sensor 2-Mengen Spülung

• Für Front Betätigungsplatten Installation

GLASSY / TRIBE / MOO oder QR Installation

• IP68 Schutzrate

• Anpassbare LED Farbe

• Konfigurierbare Hygiene-Spülung

HAUPTSTROM

SYSTEM

BETRIEBSSPANNUNG 110 - 240 V AC

NETZSPANNUNG 50-60 HZ

ART DER

NETZVERBINDUNG

BETRIEBSWASSERDRUCK 0.5 - 10 BAR

BORNE KRE

8-ERSTE BENUTZUNG

VOR DER ERSTEN NUTZUNG

Zur Sicherheit und Langlebigkeit des Systems wird die Batterie des Hydrogenerators nur

teilweise geladen. Für eine optimale Nutzung wird die volle Ladung des Hydrogenerators mit

dem mitgelieferten Ladegerät vor jeder Verwendung empfohlen (siehe Aufladen der Batterie im

Kapitel Wartung).

26

KALIBRIERUNG

EN

Um den einwandfreien Betrieb der Betätigungsplatte bei verschiedenen Umgebungsbedingungen Temperatur und Feuchtigkeit - zu gewährleisten, ist der Sensor mit einer automatischen Kalibrierfunktion

ausgestattet.

Sobald der Sensor an die Stromquelle

1

angeschlossen ist, wird durch drei

aufeinanderfolgende Blitze bestätigt, dass

er Energie hat.

Bei der KeramikBetätigungsplatte gibt es keine

Rückmeldung (die Blitze sind in

der Keramik-Betätigungsplatte

nicht sichtbar).

X3

Es gibt einen Zeitraum von 20 Sekunden,

2

in dem der Benutzer / Installateur die

Installation abschließen und das System in

seine endgültige Betriebsposition bringen

sollte.

00.00

0:00:20.00

1

DE

RU

Nach Ablauf der Standby-Zeit startet die

3

Kalibrierungsroutine automatisch und

ihre Beendigung wird erneut durch drei

aufeinanderfolgende Blitze bestätigt. Das

System ist betriebsbereit.

X3

Bei der KeramikBetätigungsplatte gibt es keine

Rückmeldung (die Blitze sind in

der Keramik-Betätigungsplatte

nicht sichtbar).

Hinweis: Für einen ordnungsgemäßen Betrieb des Produkts muss die Kalibrierung mit dem Sensor /

der Betätigungsplatte in der endgültigen Betriebsposition durchgeführt werden. Andernfalls erkennt das

Produkt den Benutzer möglicherweise nicht oder verursacht falsche oder unerwünschte Spülungen.

Wenn eines dieser Symptome auftritt, schalten Sie das System aus und befolgen Sie diesen Vorgang

erneut.

2

CLICK

27

9-FUNKTIONSPRINZIP

EN

SYSTEMBETÄTIGUNG

Die Realisierung von “touch flushes” wird durch ein elektronisches System erreicht, das aus kapazitiven

DE

Sensoren besteht und Benutzereingaben erfasst. Die Erkennung erfolgt bis zu 30 mm von der

Betätigungsplatte entfernt.

RU

INTERAKTION

Bewegen Sie Ihre Hand in die Nähe des Symbols, welches Sie ausführen möchten.

1

Große Spülung

(linke kapazitive Taste)

Halten Sie so lange bis die LED leuchtet

2

oder die Spülung ausgeführt wird

0:00:01.00

Kleine Spülung

(rechte kapazitive Taste)

Entferne Deine Hand

3

28

10-FUNKTIONEN UND EINSTELLUNGEN

EN

Für Funktionen und Einstellungen der Keramik-Betätigungsplatte siehe Seite X, um die

Betätigungsplatte zu demontieren.

DE

MENÜ NAVIGATION

Die Navigation durch die 6 Menüs erfolgt über die Taste auf der Rückseite des Sensors. Um das Menü zu

aktivieren, drücken Sie die Taste für 5 Sekunden. Die Beleuchtung beider Sensoren leuchtet auf und die

Farbe der LEDs zeigt das aktive Menü an.

FUNKTION BESCHREIBUNG

Folgende Farben können

Farbeinstellung der

LED Beleuchtung

Sensor –

Sensibilitätseinstellung

Aktivieren oder

Deaktivieren Sie die

Pflichtspülung

eingestellt werden: Blau, Rot,

Gelb, Weiß, Grün, Violett,

Orange, Lila

Mit dem Sensor können Sie die

Erkennungsempfindlichkeit in

drei Stufen einstellen

Der Sensor ermöglicht

automatische Spülungen in

regelmäßigen Intervallen, wenn

keine häufige Nutzung erfolgt

VERFÜGBARE

EINSTELLUNGEN

Blau

Rot

Gelb

Weiß

Grün

Violett

Orange

Lila

Niedrig

Mittel

Hoch

An

Aus

WERKSEINSTELLUNGEN

Blau

Hoch

Aus

RU

Einstellen der

automatischen /

hygienischen Spülzeit

Aktivieren oder

Deaktivieren Sie die

Sensorbeleuchtung

Werkseinstellungen

zurücksetzen

Es ist möglich, drei regelmäßige

Zeitintervalle für automatische

Spülungen zu definieren

Für größere Energieeinsparungen

(oder wenn die KeramikBetätigungsplatte verwendet

wird) ist es möglich, die

Sensorbeleuchtung zu

deaktivieren

Die Parameter für alle

Funktionen werden auf

die Werkseinstellungen

zurückgesetzt.

3H

24H

72H

An

Aus

Reset -

24H

An

29

EN

NAVIGATIONS MENÜ

DE

RU

START

Niedrig Mittel Hoch 3H 24H 72HAn Aus An Aus

0:00:05.00

ANPASSUNG EINSTELLUNGEN

Die Navigation und die Einstellungen für jede Funktion werden auf der kapazitiven Vollspültaste (große

Menge) vorgenommen.

Nachdem Sie das gewünschte Menü ausgewählt haben, gehen Sie wie folgt vor, um jede der Optionen

zu durchlaufen. Wenn Sie sich mit Ihrer Hand dem Auslösungssymbol nähern, wird der erste Menüpunkt

angezeigt. Um zu einem anderen Menüpunkt zu wechseln, muss die Hand idem Auslösungssymbol genähert.

Überprüfen Sie das Schema unten:

RESET

30

EN

Warte nach dem Einstellen der gewünschten Menüoption und das System nimmt die Auswahl an und kehrt

zum Startpunkt zurück Modus. So kannst Du bestätigen:

Diese Verfahren sind für alle Menüs gleich.

DE

RU

Bei jeder durchgeführten Änderung

meldet das die Betätigungsplatte / der

Sensor mit dem neuen Einstellstatus

durch die Anzahl der Blitze (z. B. im

Menü

Empfindlichkeitsstufe ausgewählt wurde,

durch drei aufeinanderfolgende blaue Blitze

angegeben).

, wird angezeigt, dass die hohe

X3

Um Ihre Änderungen zu bestätigen und

21

das Menü zu verlassen, warten Sie 10

Sekunden, ohne mit dem Sensor zu

interagieren. Die Betätigungsplatte

ist betriebsbereit, wenn die Lichter

ausgehen.

0:00:10.00

Hinweis: Alle Einstellungen werden im Sensorspeicher gespeichert, auch wenn der Sensor

nicht mit Strom versorgt wird oder neu gestartet wird.

31

ABNAHME DER KERAMIKPLATTE

EN

-

+

-

Um auf die Menüeinstellungen der Keramik-Betätigungsplatte zugreifen zu können, müssen Sie die

Betätigungsplatte wie vorgeschrieben demontieren.

DE

RU

3

UNLOCK

1

2

CRACK

UNLOCK

5

4

11-ENERGIE UND NACHHALTIGKEIT

Wenn der Spülkasten gefüllt wird - wenn Wasser vom Eckventil zum Füllmechanismus fließt - erzeugt

der Hydrogenerator elektrischen Strom. Diese Energie wird zur späteren Verwendung in der Batterie

gespeichert. Diese Batterie speist wiederum den kapazitiven Sensor für die Benutzerschnittstelle und den

Aktuatormechanismus, und die Spülung durchzuführen.

SPÜLUNGEN/TAG LADUNGEN (2 JAHRE)

0 5

5 4

10 3

15 2

20 1

25 0

Der Hochleistungsakku sorgt für einen mehrmonatigen Systembetrieb auch bei reduziertem Produkteinsatz.

Bei häufigerer Nutzung verlängert sich ihre Lebensdauer dank der vom Generator generierten Energie - die

überschüssige Energie wird in den Batterien gespeichert.

*Es ist möglich die Batterien über ein mitgeliefertes Ladegerät aufzuladen.

32

12-FEHLERBEHEBUNG

EN

MALFUNCTION POSSIBLE CAUSE PROCEDIMENTO

Betätigungsplatte leuchtet rot nach Spülung • Niedriger Energiestand • Aufladen der Batterie

• Sehr nedriger Batteriestand • Aufladen der Batterie

Betätigungsplatte leuctet rot und spült nicht

Häufige schwache Batterie (blinkt rot)

Bei der Interaktion mit der Betätigungsplatte funktioniert die

Beleuchtung, es wird jedoch keine Spülung ausgeführt

Bei der Interaktion mit der Betätigungsplatte funktioniert die

Beleuchtung nicht, sondern es wird gespült

Bei der Interaktion mit der Betätigungsplatte funktioniert die

Beleuchtung nicht und es erfolgt keine Spülung

Bei der Interaktion mit der Betätigungsplatte werden zwei

Blitze in beiden Sensoren angezeigt und keine Spülung

durchgeführtmed

Die Reinigung der WC Keramik ist nicht eektiv • Spül-Volumen sind möglicherweise falsch eingestellt

Wasser läuft kontinuierlich in die WC Keramik

Unprovozierte Spülung

Falsche Spülungen

Ladegerät zeigt kein grünes Licht an

• Füllmechanismus defekt • Entlademechanismus ersetzen

• Verstopfter Servomotor

• Verstopf ter Filter • Überprüfe/Reinige den Filter

• Fehlerhafter Hydrogenerator • Austausch Hydrogenerator

• Software Fehler • Reboot System

• Servomotor falsch verbunden • Prüfe die Verbindung

• Fehlerhafter Servomotor • Tausche den Servomotor

• Leerer Spülkasten

• Software Fehler • Reboot system

• LED Funktion deaktiviert

• Fehlerhafte Software • Restart system

• Entleerte Batterie • Aufladen Batterie

• Fehlverbindungen

• Fehlerhafter Hydrogenerator • Austausch Hydrogenerator

• Schlechte Kalibrierung • Reboot system

• Fehlerhafter Sensor • Austausch Sensor/Betätigungsplatte

• Reinigungsmodus wegen schlechter Kalibrierung

aktiviert

• Übermäßige Kondensation in der Betätigungsplatte

• Fehlerhafte Software • Reboot system

• Fehlerhafte Gummidichtung • Austausch Gummidichtung

• Fehlerhaftes Spülsystem • Austausch Auslaufventil

• Fehlerhaftes Füllventil • Austausch Füllventil

• Automatische Hygiene Spülung aktiviert

• Schlechte Kalibrierung • Reboot system

• Fehlerhafte Software • Reboot system

• Schmutzige oder nasse Betätigungsplatte

• Schlechte Kalibrierung • Reboot system

• Fehlerhaftes Ladegerät • Austausch Hydrogenerator

• Fehlerhafter Hydrogenerator • Austausch Hydrogenerator

• Überprüfen Sie die Konfiguration des

Spülmechanismus

• Prüfe das Eckventil

• Eventuelle Blockierung beim

Füllmechanismus (Einlassventil) prüfen

• Auf Wasser im Gitter prüfen

• Überprüfen Sie die LED Funktionseinstellung

• Prüfe die Verbindung mit dem

Hydrogenerator

• Reboot system

• Prüfen / Reinigen Sie das Innere der

Betätigungsplatte

• Überprüfen Sie die Konfiguration des

Spülmechanismus (Auslassventil)

• Überprüfen Sie, ob der Füllmechanismus

(Einlassventil) korrekt funktioniert

• Überprüfen Sie die automatische

automatische Spülfunktion

•Überprüfe/Reinige das Innere der

Betätigungsplatte

DE

RU

33

EN

DE

RU

12-FEHLERBEHEBUNG

MALFUNCTION POSSIBLE CAUSE PROCEDIMENTO

• Verstopfter Filter

Lange Füllzeiten

• Niedridger Waserdruck

• Software Fehler • Reboot System

• Servomotor falsch verbunden • Prüfe die Verbindung

Bei der Interaktion mit der Betätigungsplatte funktioniert die

Beleuchtung, es wird jedoch keine Spülung ausgeführt

Bei der Interaktion mit der Betätigungsplatte funktioniert die

Beleuchtung nicht, sondern es wird gespült

Bei der Interaktion mit der Betätigungsplatte funktioniert die

Beleuchtung nicht und es erfolgt keine Spülung

Bei der Interaktion mit der Betätigungsplatte werden zwei

Blitze in beiden Sensoren angezeigt und keine Spülung

durchgeführtmed

Die Reinigung der WC Keramik ist nicht eektiv • Spül-Volumen sind möglicherweise falsch eingestellt

Wasser läuft kontinuierlich in die WC Keramik

Unprovozierte Spülung

Falsche Spülungen

• Fehlerhafter Servomotor • Tausche den Servomotor

• Leerer Spülkasten

• Software Fehler • Reboot system

• LED Funktion deaktiviert

• Fehlerhafte Software • Restart system

• Stromausfall • Überprüfen Sie die Stromversorgung

• Fehlverbindungen

• Fehlerhaftes Netzteil • Netzteil ersetzen

• Schlechte Kalibrierung • Reboot system

• Fehlerhafter Sensor • Austausch Sensor/Betätigungsplatte

• Reinigungsmodus wegen schlechter Kalibrierung

aktiviert

• Übermäßige Kondensation in der Betätigungsplatte

• Fehlerhafte Software • Reboot system

• Fehlerhafte Gummidichtung • Austausch Gummidichtung

• Fehlerhaftes Spülsystem • Austausch Auslaufventil

• Fehlerhaftes Füllventil • Austausch Füllventil

• Automatische Hygiene Spülung aktiviert

• Schlechte Kalibrierung • Reboot system

• Fehlerhafte Software • Reboot system

• Schmutzige oder nasse Betätigungsplatte

• Schlechte Kalibrierung • Reboot system

• Überprüfe/Reinige den Hydrogenerator

Filter

• Durchflussregler vom Füllmechanismus

(Einlassventil) entfernen

• Prüfe das Eckventil

• Eventuelle Blockierung beim

Füllmechanismus (Einlassventil) prüfen

• Auf Wasser im Gitter prüfen

• Überprüfen Sie die LED Funktionseinstellung

• Überprüfen Sie die Verbindungen zum

Netzteil

• Reboot system

• Prüfen / Reinigen Sie das Innere der

Betätigungsplatte

• Überprüfen Sie die Konfiguration des

Spülmechanismus (Auslassventil)

• Überprüfen Sie, ob der Füllmechanismus

(Einlassventil) korrekt funktioniert

• Überprüfen Sie die automatische

automatische Spülfunktion

•Überprüfe/Reinige das Innere der

Betätigungsplatte

34

EN

MANUELLE KALIBRIERUNG

Um den Servomotor zu kalibrieren, müssen Sie die Taste an der Rückseite des Sensors drücken.

1

Die Taste sollte 30 Sekunden oder länger (1) gedrückt werden, bis die beiden blauen Spülungen

(2) aufleuchten.

DE

RU

1

> 0:00:30.00

Nachdem das blaue Licht angezeigt wird, können Sie die Kalibrierung durchführen, indem Sie

2

Ihre Hand über eine der kapazitiven Tasten (kleine oder große Spülung) halten.

Wenn Sie die Hand über den halbspülenden kapazitiven Knopf (A) positionieren, bewegt sich

der Servomotor nach links. Wenn Sie Ihre Hand über den kapazitiven Vollspültaster (B) halten,

bewegt sich der Servomotor nach rechts.

2

ZOOCK!!

0º

CHECK

35

EN

DE

RU

13-PFLEGE UND WARTUNG

REINIGUNGSMODUS

Die Betätigungsplatte hat einen Reinigungsmodus, der es dem Benutzer ermöglicht, ihn zu reinigen, ohne

unerwünschte Spülungen zu verursachen.

Im Gegensatz zu den anderen

Funktionen kann diese direkt aktiviert

werden, ohne die Betätigungsplatte zu

demontieren, wobei beide Sensoren

gleichzeitig für 10 Sekunden in

Wechselwirkung stehen.

Nach Ablauf der Reinigungszeit

21

- 60 Sekunden - kehrt die

Betätigungsplatte in den normalen

Betriebsmodus zurück.

0:00:10.00

0:00:60.00

36

REINIGUNG DER BETÄTIGUNGSPLATTE

EN

Die Oberfläche ist einfach zu reinigen und zu pflegen. Verwenden Sie ein weiches Tuch und Seife sowie

Wasserlösung für die regelmäßige Pflege. Mit einem trockenen Tuch abwischen.

Vermeiden Sie die Verwendung von Schleifmitteln oder Lösungsmitteln, die die Oberfläche beschädigen.

Schäden die durch unsachgemäße Behandlung durch den Benutzer entstehen, sind nicht von unserer

Garantie abgedeckt.

DE

RU

FILTERREINIGUNG

Zum Schutz des Hydrogenerators und des Füllmechanismus (Einlassventil) enthält das Hydroboost-System

einen kleinen Partikelfilter im Wasserkreislauf. Bei der Installation in Gebieten mit verschmutztem Wasser

/ neuen Gebäuden besteht die Möglichkeit, dass sich im Laufe der Zeit Ablagerungen ansammeln und die

Ezienz des Kreislaufs beeinträchtigt wird

Daher wird eine regelmäßige Wartung empfohlen.

Öne die Betätigungsplatte.

1

1

2

CRACK

Trennen Sie alle elektrischen Anschlüsse

2

und entfernen Sie die Gegenplatte.

37

Schließe das Eckventil.

EN

3

Trennen Sie den flexiblen

4

Schlauch.

DE

RU

Entferne den Servomotor.

5

2

3

2

19

1

Entfernen Sie den Hebellager

6

2

1

3.3

Entferne den Hydrogenerator

7

1

2

1

Gründlich mit Wasser auf beiden Seiten

8

waschen

38

BATTERIE LADEN

EN

Das Hydroboost-System besteht aus einem Hydrogenerator und einem Batteriepack. Daher kann das

Energieniveau in den Batterien bei seltenem Gebrauch niedrig sein (der Hydrogenerator erzeugt nur Energie

und lädt die Batterie, wenn Spülvorgänge durchgeführt werden) und / oder durch den natürlichen Abfall der

Batterien im Laufe der Zeit. In beiden Fällen muss das System möglicherweise mit dem dafür vorgesehenen

Ladegerät geladen werden.

DE

RU

Befolgen Sie dazu das Prozedere.

Entferne die Betätigungsplatte.

1

CRACK

CHECK

Entfernen Sie das Ladekabel des

2

Hydrogenerators aus dem Gehäuse und

nehmen Sie die Abdeckung ab.

40

1

2

Bitte stecken Sie das Ladegerät in eine

3

elektrische Steckdose.

1

Mindestladezeit = 4 Stunden.

Das System kann während des

Ladevorgangs normal verwendet

werden

2

4:00:00.00

39

Setzen Sie die Steckerschutzkappe wieder auf und schtecken Sie das Kabel in das

EN

4

Gehäuse ein. Die Bedienfeldposition sollte auf die Betriebsposition zurückgesetzt und

das Ladegerät für zukünftige Ladevorgänge aufbewahrt werden.

DE

RU

1

CHECK

2

CLICK

3

14-GESCHÄFTSBEDINGUNGEN

KONFORMITÄTSERKLÄRUNG:

Hersteller: OLI-Sistemas Sanitários, S.A

Erklärt dass sie Europäischen Standards entsprechen.

GEWÄHRLEISTUNG :

Sie sollten Informationen über die Gewährleistung für dieses Produkt in der Website des Herstellers

konsultieren: www.oli-world.com

40

1-ЦЕЛЕВАЯ АУДИТОРИЯ

EN

Данные инструкции по сборке предназначены для монтажных компаний, специализирующихся

на канализационных системах с электрическими деталями. Изделие, описанное в настоящей

инструкции, должно устанавливаться только уполномоченными монтажными компаниями в области

канализационных систем.

2-ОБЯЗАТЕЛЬНО ДЛЯ ОЗНАКОМЛЕНИЯ

Монтажная компания обязана прочитать, понять и соблюдать инструкции по сборке и, в частности,

раздел о правилах безопасности. Если у Вас есть какие-либо вопросы, обратитесь к сотрудникам

компании «OLI».

3-БЕЗОПАСНОСТЬ И СИМВОЛЫ

ЗНАЧЕНИЕ ПАМЯТОК ПО БЕЗОПАСНОМУ ИСПОЛЬЗОВАНИЮ И ПРАВИЛ ТЕХНИКИ

БЕЗОПАСНОСТИ

ПАМЯТКИ ПО БЕЗОПАСНОМУ ИСПОЛЬЗОВАНИЮ

Пиктограммы и знаки, относящиеся к инструкциям по технике безопасности, мерам

предосторожности и предупреждениям в этих инструкциях по установке, имеют следующие значения:

Предупреждение! Возможна ситуация повреждения, в результате которой может

произойти повреждение изделия или что-либо вокруг него.

Важно! Инструкции по применению продукта и другая полезная информация

предназначены для использования последнего в соответствии со стандартами.

DE

RU

Следует проверить/обратить внимание на влажность

Опасность электрического напряжения

Система с гидрогенератором- Hydroboost

Система электропитания - AC

41

EN

DE

RU

4-ПЕРЕД УСТАНОВКОЙ

Перед началом сборки внимательно прочитайте и ознакомьтесь с инструкциями по сборке.

Изделие необходимо собрать, установить и подключить только в соответствии с данными

инструкциями.

Перед использованием системы подтвердите совместимость установки на сайте: www.oli-world.com

При планировании и установке санитарно-технического оборудования необходимо соблюдать

местные, национальные и международные нормы и стандарты.

Проверьте содержимое изделия до начала сборки, чтобы убедиться, что оно полностью

укомплектовано.

Запрещено устанавливать неукомплектованное изделие или изделие с видимыми повреждениями

или неисправностями. ОЛИ не несет ответственность за повреждения, причиненные вследствие

неправильной транспортировки или на складах временного хранения.

5-УСЛОВИЯ СБОРКИ НА МЕСТЕ

Давление водопроводной сети

0,5 бар при макс. 10 бар

Давление водопроводной сети 0,5

бар при макс. 10 бар

Напряжение сети составляет

110-240 В переменного тока/5060 Гц с общим переключателем

для всех полюсов, подключенных

к электропитанию и контактным

отверстием 3 мм.

42

6-ИЗДЕЛИЕ

EN

NO TOUCH

QR-INOX

MOON GLASSY TRIBE

AC - Система электропитания

1

DE

RU

1

Nº ОПИСАНИЕ

1 ЕМКОСТНЫЙ ДАТЧИК

2 СЕРВОПРИВОД

3 ГИДРОГЕНЕРАТОР

2

2

3

3

4

Nº ОПИСАНИЕ

1 ЕМКОСТНЫЙ ДАТЧИК

2 СЕРВОПРИВОД

3 ТРАНСФОРМАТОР

4

4 ИНСТРУКЦИИ ПО СБОРКЕ

4 ИНСТРУКЦИИ ПО СБОРКЕ

43

7-ТЕХНИЧЕСКИЕ ХАРАКТЕРИСТИКИ

EN

DE

RU

HYDROBOOST

РАБОЧЕЕ НАПРЯЖЕНИЕ 6.4V DC

ТИП АККУМУЛЯТОРНОЙ

БАТАРЕИ

МОЩНОСТЬ

АККУМУЛЯТОРНОЙ

БАТАРЕИ

РАБОЧЕЕ ДАВЛЕНИЕ ВОДЫ 0.5 - 10 BAR

LiFePO4

mAh

3000

• Бесконтактная электронная система смыва

• Сенсорный датчик для системы двойного

смыва

• Для установки панелей слива

GLASSY / TRIBE / MOON или для

санитарного модуля QR-INOX

• Степень защищенности IP68

• Настраиваемое светодиодное освещение

• Настраиваемый гигиенический смыв

НОМИНАЛЬНОЕ

НАПРЯЖЕНИЕ

СЕТЕВОЕ

НАПРЯЖЕНИЕ

ТИП ПОДКЛЮЧЕНИЯ К

ЭНЕРГОСЕТИ

РАБОЧЕЕ ДАВЛЕНИЕ

ВОДЫ

СИСТЕМА

ЭЛЕКТРОПИТАНИЯ

110 - 240 V AC

50-60 HZ

BORNE KRE

0.5 - 10 BAR

8-ПЕРВОЕ ИСПОЛЬЗОВАНИЕ

ПЕРЕД ЛЮБЫМ ИСПОЛЬЗОВАНИЕМ

Для безопасности и долговечности системы, батарея гидрогенератора заряжена

только частично. Для оптимальной работы рекомендуется использовать полный заряд

гидрогенератора. Перед использованием его можно зарядить с помощью прилагаемого

зарядного устройства (См. «Зарядка батареи» в разделе технического обслуживания).

44

КАЛИБРОВКА

EN

Для обеспечения правильной работы панели смыва в различных условиях – температуры и влажности

- датчик оснащен функцией (процедурой) автоматической калибровки.

Как только датчик будет подключен

1

к источнику питания, он подтвердит

наличие энергии посредством трех

последовательных вспышек.

В керамической панели

смыва отсутствует обратная

связь (вспышки не видны в

керамической панели смыва).

X3

Пользователь/установщик должен

2

завершить установку и поместить

систему в её конечное рабочее

положение в течение 20 секунд.

00.00

0:00:20.00

1

DE

RU

По истечении периода простоя,

3

процедура калибровки запускается

автоматически, а завершение снова

сообщается тремя последовательными

вспышками. Система готова к

использованию.

X3

В керамической панели

смыва отсутствует обратная

связь (вспышки не видны в

керамической панели смыва).

Примечание: Для правильной работы изделия калибровка должна выполняться с помощью

датчика/панели смыва в его конечном рабочем положении. В противном случае изделие

может не обнаруживать пользователя или вызвать неправильные или лишние смывы. При

возникновении какого-либо из этих признаков выключите систему и повторите данную

процедуру снова.

2

CLICK

Система «Click»

45

EN

DE

RU

9-ПРИНЦИП ДЕЙСТВИЯ

СРАБАТЫВАНИЕ СИСТЕМЫ

Выполнение смывов без прикосновения достигается посредством электронной системы, состоящей

из емкостных датчиков, которые реагируют на команды пользователя. Обнаружение происходит в 30

мм от панели смыва

Поднесите свою руку ближе к символу смыва, который Вы хотите выполнить.

1

Больший объем сливаемой воды

с левой стороны

Оставайтесь в том же положении до тех

2

пор, пока не загорится светодиод или не

будет выполнен смыв.

0:00:01.00

Меньший объем сливаемой воды :

с правой стороны

Уберите руку

3

46

10-ФУНКЦИИ И НАСТРОЙКИ

EN

Для функций и настроек в керамической панели слива, см. страницу X, чтобы разобрать

панель слива.

DE

НАВИГАЦИОННОЕ МЕНЮ

Навигация по меню осуществляется с помощью кнопки на задней части датчика. Чтобы активировать

меню, удерживайте кнопку в течение 5 секунд. Подсветка обоих датчиков загорится, и цвет

светодиодов отобразит активное меню.

ФУНКЦИЯ ОПИСАНИЕ

Настройка цвета

светодиодов

Настройка

чувствительности

датчика

Включение или

отключение функции

смыва

Можно настроить следующие цвета

Датчик позволяет настроить

чувствительность обнаружения на

трех уровнях

Датчик позволяет выполнять

автоматические смывы с равными

интервалами при нечастом

использовании.

ДОСТУПНЫЕ

НАСТРОЙКИ

синий

красный

желтый

белый

зеленый

фиолетовый

оранжевый

пурпурный

Низкий

Средний

Высокий

ВКЛЮЧЕНО

ВЫКЛЮЧЕНО

ЗАВОДСКИЕ

НАСТРОЙКИ

синий

Высокий

ВЫКЛЮЧЕНО

RU

Установка времени

автоматического/

гигиенического смыва

Включение или

отключение

освещения датчика

Восстановление

заводских настроек

Можно задать три равных интервала

времени между автоматическими

смывами:

Для большей экономии энергии (или

при использовании керамической

панели смыва) можно отключить

подсветку датчика.

Параметры все функций

восстанавливаются в соответствие с

заводскими настройками.

47

3 ч.

24 ч.

72 ч.

ВКЛЮЧЕНО

ВЫКЛЮЧЕНО

Перезагрузить

систему

24 ч.

ВКЛЮЧЕНО

-

EN

DE

Перезагрузить

НАВИГАЦИОННЫЙ ПОТОК МЕЖДУ МЕНЮ

RU

0:00:05.00

START

Низкий Средний Высокий 3 ч. 24 ч. 72 ч.ВКЛЮЧЕНО ВЫКЛЮЧЕНО

ВКЛЮЧЕНО ВЫКЛЮЧЕНО

систему

НАСТРОЙКА ПАРАМЕТРОВ

Определение навигации и настроек каждой функции выполняется на кнопке полного смыва.

Выбрав нужное вам меню, чтобы посмотреть каждый вариант этого меню, вам нужно приблизить

руку к символу разряда (слива). Если вы хотите перейти на другой вариант меню, вам всегда нужно

приблизить руку к символу разряда.

Проверьте схему ниже:

48

EN

После установки нужного вам варианта подождите, и система примет ваш вариант и вернется в

режим разгрузки. Как вы можете проверить ниже:

Эти процедуры одинаковы для всех меню.

DE

RU

С каждым изменением панель смыва/

1

датчик сообщает о новом статусе

настройки с помощью ряда вспышек

(например, в синем меню

того, что выбран высокий уровень

чувствительности, является три

последовательные синие вспышки).

указанием

X3

Чтобы подтвердить свои изменения и

2

выйти из меню, подождите 10 секунд, не

взаимодействуя с датчиком.

0:00:10.00

Панель слива готова к

использованию, когда

погаснет свет.

Примечание: Все настройки сохраняются в памяти датчика, даже когда датчик не

работает или перезапускается.

49

EN

DE

-

+

-

RU

РАЗБОРКА КЕРАМИЧЕСКОЙ ПАНЕЛИ СМЫВА

Для доступа к настройкам меню на керамической панели смыва необходимо разобрать панель

смыва в соответствии с инструкциями.

3

UNLOCK

1

2

CRACK

UNLOCK

5

4

11-ЭНЕРГИЯ И ДОЛГОВЕЧНОСТЬ

Когда бачок заполняется, гидрогенератор производит электрический ток. Эта энергия хранится в

батарее для последующего использования. Данная батарея по очереди питает емкостный датчик для

пользовательского интерфейса и механизм привода для осуществления смывов.

КОЛИЧЕСТВО СМЫВОВ В ДЕНЬ ЗАРЯДК А (2 ГОДА)

0 5

5 4

10 3

15 2

20 1

25 0

Комплект батарей с высокой мощностью обеспечивает работу системы в течение нескольких месяцев

даже при уменьшенном использовании изделия.

При более частом использовании их срок службы увеличивается благодаря энергии, производимой

генератором – произведенная избыточная энергия накапливается в батареях.

* Можно перезаряжать батареи с помощью прилагаемого зарядного устройства.

50

11-ВЫЯВЛЕНИЕ НЕИСПРАВНОСТЕЙ

EN

НЕИСПРАВНОСТЬ ВОЗМОЖНАЯ ПРИЧИНА УСТРАНЕНИЕ НЕИСПРАВНОСТИ

Панель смыва мигает красным цветом

после смыва

Панель смыва мигает красным цветом и

не смывает

Частая индикация низкого заряда

батареи (красные вспышки)

При взаимодействии с панелью смыва

освещение работает, но не происходит

смыв

При взаимодействии с панелью смыва

освещение не работает, но выполняется

смыв

При взаимодействии с панелью смыва

освещение не работает и не происходит

смыв

При взаимодействии с панелью смыва в

обоих датчиках мигают две лампочки, и

не выполняется смыв

Очистка керамической чаши не

эффективна

В керамической чаше постоянно течет

вода

Ничем не вызванные смывы

Неправильные смывы

Зарядное устройство не показывает

зеленый свет

• Низкий уровень энергии • Перезарядить батарею

• Неисправный механизм • Перезарядить батарею

• Заменить промывочный механизм • Заменить промывочный механизм

• Чрезвычайно низкий уровень энергии

• Засоренный фильтр • Проверить/очистить фильтр

• Неисправный гидрогенератор • Заменить гидрогенератор

• Неисправное программное обеспечение • Перезагрузить систему

• Неправильное подключение сервопривода • Проверить соединения

• Неисправный сервопривод • Заменить сервопривод

• Пустой бачок

• Неисправное программное обеспечение • Перезагрузить систему

• Функция светодиода отключена • Проверить настройки функции светодиода

• Неисправное программное обеспечение • Перезапустить систему

• Разряженная батарея • Перезарядить батарею

• Неправильное подключение • Проверить соединение с гидрогенератором

• Неисправный гидрогенератор • Заменить гидрогенератор

• Неправильная калибровка • Перезагрузить систему

• Неисправный датчик • Заменить датчик/панель смыва

• Активирован режим очистки из-за

неудовлетворительной калибровки

• Чрезмерная конденсация внутри панели

смыва

• Объемы смыва могут быть установлены

неправильно

• Неисправное программное обеспечение • Перезагрузить систему

• Поврежденное резиновое уплотнение • Заменить резиновое уплотнение

• Неисправная система смыва • Заменить систему смыва

• Неисправный механизм заполнения

(наполнительный клапан)

• Активирован гигиенический автоматический

смыв

• Неправильная калибровка • Перезагрузить систему

• Неисправное программное обеспечение • Перезагрузить систему

• Грязная или мокрая панель смыва

• Неправильная калибровка • Перезагрузить систему

• Неисправное настенное зарядное устройство • Заменить настенное зарядное устройство

• Неисправный гидрогенератор • Заменить гидрогенератор

• Проверьте конфигурацию промывочного

механизма (выпускного клапана)

• Проверить угловой клапан

• Проверить возможную блокировку

механизма заполнения (наполнительный

клапан)

• Проверить наличие воды в сети

• Перезагрузить систему

• Проверить/очистить внутреннюю часть

панели смыва

• Проверить конфигурацию механизма слива

(спускной клапан)

• Проверить, правильно ли работает механизм

заполнения (наполнительный клапан)

• Заменить механизм заполнения

(наполнительный клапан)

• Проверить настройку функции

гигиенического автоматического смыва

• Проверить/очистить внутреннюю часть

панели смыва

DE

RU

51

11-ВЫЯВЛЕНИЕ НЕИСПРАВНОСТЕЙ

EN

DE

RU

НЕИСПРАВНОСТЬ ВОЗМОЖНАЯ ПРИЧИНА

• Засоренный фильтр

Длительное время заполнения

При взаимодействии с панелью смыва освещение

работает, но не происходит смыв

При взаимодействии с панелью смыва освещение

не работает, но выполняется смыв

При взаимодействии с панелью смыва освещение

не работает и не происходит смыв

При взаимодействии с панелью смыва в обоих

датчиках мигают две лампочки, и не выполняется

смыв

Очистка керамической чаши не эффективна

В керамической чаше постоянно течет вода

Ничем не вызванные смывы

Неправильные смывы

• Низкое давление водопроводной сети (<2

бар/ >120 с)

• Неисправное программное обеспечение • Перезагрузить систему

• Неправильно подключение сервопривода • Проверить соединения

• Неисправный сервопривод • Заменить сервопривод

• Пустой бачок

• Неисправное программное обеспечение • Перезагрузить систему

• Функция светодиода отключена

• Неисправное программное обеспечение • Перезагрузить систему

• Выключение света • Проверить электропитание

• Неправильное подключение

• Неисправность сетевого адаптера • Заменить сетевой адаптер

• Неправильная калибровка • Перезагрузить систему

• Неисправный датчик • Заменить датчик/панель смыва

• Активирован режим очистки из-за

неудовлетворительной калибровки

• Чрезмерная конденсация внутри панели

смыва

• Объемы смыва могут быть установлены

неправильно

• Неисправное программное обеспечение • Перезагрузить систему

• Поврежденное резиновое уплотнение • Заменить резиновое уплотнение

• Неисправная система смыва • Заменить систему смыва

• Неисправный механизм заполнения

(наполнительный клапан)

• Активирован гигиенический автоматический

смыв

• Неправильная калибровка • Перезагрузить систему

• Неисправное программное обеспечение • Перезагрузить систему

• Грязная или мокрая панель смыва

• Неправильная калибровка • Перезагрузить систему

УСТРАНЕНИЕ

НЕИСПРАВНОСТИ

• Проверить/очистить фильтр

гидрогенератора

• Снять регулятор потока

с механизма заполнения

(наполнительный клапан)

• Проверить угловые клапаны

• Проверить возможную

блокировку механизма заполнения

(наполнительный клапан)

• Проверить наличие воды в сети

• Проверить настройки функции

светодиода

• Проверить соединения с сетевым

адаптером

• Перезагрузить систему

• Проверить/очистить внутреннюю

сторону панели смыва

• Проверить конфигурацию

механизма слива (выпускной клапан)

• Проверить, правильно ли

работает механизм заполнения

(наполнительный клапан)

• Заменить механизм заполнения

(наполнительный клапан)

• Проверить настройку функции

гигиенического автоматического

смыва

• Проверить/очистить внутреннюю

часть панели смыва

52

EN

РУЧНАЯ КАЛИБРОВКА

Для калибровки сервопривода необходимо нажать на кнопку, которая расположена на

1

задней панели датчика.

Необходимо удерживать кнопку в течение 30 или более секунд (1), пока не загорятся два

индикатора синего цвета (2).

DE

RU

1

> 0:00:30.00

После загорания синего индикатора вы можете выполнить калибровку, приближая руку к

2

определенному датчику.

Приблизив руку к датчику половинного слива (А), сервопривод переместится влево.

Если вы поднесете руку к датчику полного слива (B), сервопривод переместится вправо.

2

ZOOCK!!

0º

CHECK

53

EN

DE

13-УХОД И ТЕХНИЧЕСКОЕ ОБСЛУЖИВАНИЕ

РЕЖИМ ОЧИСТКИ

У панели смыва есть режим очистки, который позволяет пользователю очищать её, не вызывая

нежелательных смывов.

RU

В отличие от других функций, данную

функцию можно активировать

напрямую, не разбирая панель слива

при одновременном взаимодействии

двух датчиков в течение 10 секунд.

0:00:10.00

21

По истечении времени очистки

– 60 секунд – панель смыва

возвращается в обычный режим

работы.

0:00:60.00

54

ОЧИСТКА ПАНЕЛИ СМЫВА

EN

За поверхностью легко ухаживать и очищать. Используйте мягкую ткать и мыльную воду для

регулярного ухода. Протирайте сухой тряпкой.

Избегайте использования абразивных материалов или растворителей, которые повреждают

поверхность.

Повреждение, вызванное неправильным обращением пользователя, не покрывается нашей гарантией.

DE

RU

ОЧИСТКА ФИЛЬТРА

Для защиты гидрогенератора и наполнительного клапана, система «Hydroboost» включает фильтр.

В случае установки в районах с загрязненной водой/новостройками есть вероятность постепенного

накопления мусора и потери эффективности работы.

Поэтому рекомендуется проводить периодическое техническое обслуживание.

Откройте панель слива.

1

1

2

CRACK

Отключите все электрические

2

соединения и снимите опорную пластину.

55

Закройте запорный клапан

EN

3

Отсоедините гибкие шланги

4

DE

RU

Снимите сервопривод

5

2

3

2

19

1

Снимите блок

6

2

1

3.3

Снимите гидрогенератор

7

1

2

1

Тщательно промойте водой с обеих

8

сторон.

56

ЗАРЯДКА БАТАРЕИ

EN

Система «Hydroboost» состоит из гидрогенератора и комплекта батарей. Таким образом, уровень

энергии в батареях может быть низким при редком использовании (генератор производит энергию

и заряжает батарею только при выполнении смывов) и/или при естественном расходе батареи с

течением времени. В обоих случаях системе может потребоваться зарядка с помощью зарядного

устройства.

DE

RU

Для этого выполните процедуру:

Снимите панель слива

1

CRACK

CHECK

Снимите зарядный кабель

2

гидрогенератора с его корпуса.

Снимите защитный колпачок с конца

кабеля.

58

1

2

Вставьте зарядное устройство в

3

электрическую розетку.

1

Минимальное время зарядки батареи – 4 часа.

Во время зарядки система

может использоваться в

обычном режиме

2

4:00:00.00

57

Наденьте обратно защитный колпачок на конец кабеля и поместите кабель в его

EN

EN

4

корпус.

Панель слива следует поместить обратно в рабочее положение, а зарядное

устройство сохранить для дальнейшего использования.

DE

RU

1

CHECK

CLICK

Система «Click»

2

3

DE

ES

14-ОФИЦИАЛЬНОЕ УВЕДОМЛЕНИЕ

ДЕКЛАРАЦИЯ О СООТВЕТСТВИИ:

Производитель: OLI-Sistemas Sanitários, S.A. заявляет, что соответствует европейским стандартам.

ГАРАНТИЯ:

Вам необходимо ознакомится с информацией о гарантии на данное изделие на сайте производителя:

www.oli-world.com

58

SAVE

Inspired by water...

OLI-Sistemas Sanitários,

S.A.

Travessa do Milão, Esgueira

3800-314 Aveiro,

Portugal

T (+351) 234 300 200

F (+351) 234 300 210

www.oli-world.com

geral@oli-world.com

Loading...

Loading...