Warranty

Procedure IMPORTANT

Please Read

Should there be a mechanical problem with your warrantied unit(s) Monday through Friday, follow

the procedure below.

1. Call our Service Manager, Kevin Kessel, at 1-800-223-9667 between the hours of 8:00

am - 5:00 pm, Monday thru Friday CST. Give Kevin your Model and Serial Number of

your unit.

2. Explain the problem. Most often the problem can be handled by the Service Manager.

If the problem requires a service company, OHP Service Manager will contact the

service company, ascertain the work needed, issue an authorization number to the

service company and contact you with date, time and service work that has been preapproved.

3. After pre-assigned service has been completed, call the OHP Service Manager to make

sure defective parts are returned and all work has been completed.

Should there be a mechanical problem with your warrantied unit(s) during the weekend or any

holidays that OLE HICKORY PITS home office is not opened, follow the procedure below.

1. Call our office at 1-800-223-9667 and leave message containing Name, Address, Business

Name, Model, Serial # and mechanical problem. Also leave the name and phone number

of the pre-approved service company you will be using.

2. Contact your pre-approved service company.

3. Contact OLE HICKORY PITS, during the next regular business day that the required work

has been completed and defective parts have been returned.

Failure to follow the above may result in warranty claim being denied.

* Also read and follow the LIMITED WARRANTY Page in this manual.

REV110928

Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other

appliances.

OLE HICKORY PITS

333 North Main Street

Cape Girardeau, MO 63701

Owner’s Manual for Model SSG

Installation & Operating Instructions

Notice: These instructions should be affixed to the unit or adjacent to your Ole Hickory Pit

Please retain this manual for future reference

Notice: Installation must conform with local codes, or in the absence of local codes, with the

National Fuel Gas Code, ANSI Z223.1-1992, including

1) The unit and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of that system at test pressures in excess of

one half psig.

2) The unit must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at

test pressures equal to or less than one half psig.

Notice: This unit must be electrically grounded in accordance with local codes, or in the

absence of local codes, with the National Electrical Code, ANSI/NFPA 70-1990.

FOR YOUR SAFETY

Keep the unit free of combustible material. Allow 18" clear space around access panels.

If you smell gas: 1) Open Windows

2) Don’t Touch Electrical Switches

3) Extinguish Any Open Flame

4) Immediately Call Your Gas Supplier

Electrical Instructions: This appliance is equipped with a three-prong (grounding) plug for your

protection against shock hazard and should be plugged directly into a properly grounded three-prong

receptacle. DO NOT CUT OR REMOVE THE GROUNDING PRONG FROM THIS PLUG.

Warning - Exterior Surfaces May Be Hot

WARNING: This unit must be properly vented and used in an area where there is sufficient

dilution air to prevent concentration of CO from occurring.

Do Not Obstruct The Flow of Combustion and Ventilation Air Around Unit

Allow Adequate Clearances For Servicing and Proper Operation

WARNING; Improper installation, adjustment, alteration, service or maintenance can

cause property damage, injury or death. Read the installation, operating and maintenance

instructions thoroughly before installing or servicing this equipment.

Model SSG

Please Read All Instructions Thoroughly

Installation Instructions:

These instructions were prepared for the guidance of those installing this particular

gas and wood burning barbecue pit. While they apply in principle to most installations, they

should not be interpreted as meaning the only safe and economical way to install the unit. It

may be necessary to deviate from these instructions in some instances in order to comply

with local codes in effect in your area. We recommend the installer confer with the proper

local municipal officials regarding any specific code regulations. Installation should be

performed by a qualified installer.

VISUALLY INSPECT THE INSTALLATION LOCATION: An Ole Hickory Pit shall not be

installed in any location where facilities for normal air circulation or infiltration are so

limited so as to interfere with ready obtainment of all air necessary for proper ventilation

and draw.

Ole Hickory Pits must be secured for stationary installation on a level; impervious

floor (concrete or comparable). Floor has to support 2100 to 2600 pounds at all times. The

unit is suitable for installation on a combustible floor.

‘NOTICE; If your Ole Hickory Pit is to be installed with casters, it must be installed

with the casters supplied, a connector complying with either ANSI Z21.69 or CAN/CGA-6.16

and a quick-disconnect device complying with either ANSI Z21.41 or CAN1-6.9. It must also

be installed with restraining means to guard against transmission of strain to the connector,

as specified in the appliance manufacturer’s instructions.” Adequate means has been

provided to limit the movement of the unit without depending on the connector and the

quick disconnect device or its associated piping to limit oven movement. PLEASE LOCK

CASTERS ONCE UNIT IS IN PLACE.

A manual shutoff valve MUST be supplied in the gas line between the unit and the

meter in an easily accessible location. A regulator is required to maintain correct gas

pressure to burner. Please include a drip leg or sediment trap in the gas supply line.

INSPECTION AND PREPARATION OF UNIT. Visually inspect the Ole Hickory Pit by

removing the service access panels and ensure that motors and burner have not been

loosened during shipment of unit. Replace the service panels after inspection. The racks in

the cooking chamber should be properly set in position.

Before proceeding with installation, read all instructions carefully and make sure all

switches are set to the “OFF” position.

SAFETY TIPS

Please Read & Follow All Safety Instructions!

1. The area surrounding the Ole Hickory Pit MUST be kept clear of combustible materials. DO NOT

STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS OR LIQUIDS IN THE VICINITY OF THIS

OR ANY OTHER APPLIANCE.

2. Ventilating air MUST NOT be obstructed from reaching the pit. Adequate makeup air and

ventilation are required to keep motors cool and allow proper operation of the burner.

3. At time of installation, the unit must be electrically grounded in accordance with local codes. In

the absence of local codes, please refer to the National Electrical Code, ANSI/NFPA 70-1996.

4. The service access panels should be properly installed and maintained in place during operation

of the unit. Should servicing be required, make sure the gas supply to the unit is turned off and

that the unit is unplugged before removing service panels.

5. NO ADJUSTMENTS TO THE POWER BURNER SHOULD BE MADE BY USER. If the burner does not

appear to be operating properly, turn gas supply off and contact Ole Hickory Pits or a qualified

serviceman for repairs.

6. Service work performed by unqualified personnel may void the warranty. Please do not allow

adjustments to be made to the unit that would alter the operation or disable the built in safety

features. Such alterations may result in a hazardous condition.

7. Flues are required on ALL Ole Hickory Pits. Failure to do so will result in unit malfunction and

substandard performance. (See the Gas Piping and Venting Instructions page)

8. This unit is suitable for installation on combustible floors.

9. Failure to follow recommended cleaning and maintenance procedures might also result in

hazardous conditions and void equipment warranty.

10. Please note on Fire Box: “Warning-Hot Surface Do Not Touch”

11. Please instruct all persons using this equipment on the proper use and maintenance.

12. Please maintain a minimum safety clearance from surrounding materials as follows:

Combustible Construction Noncombustible construction

Back: * 2" 2"

Right Side: * 18" 18"

Left Side: 18" 18"

Top: 2” 2”

Bottom: 6” 6”

*Indicates clearance needed for servicing and maintenance of smoker.

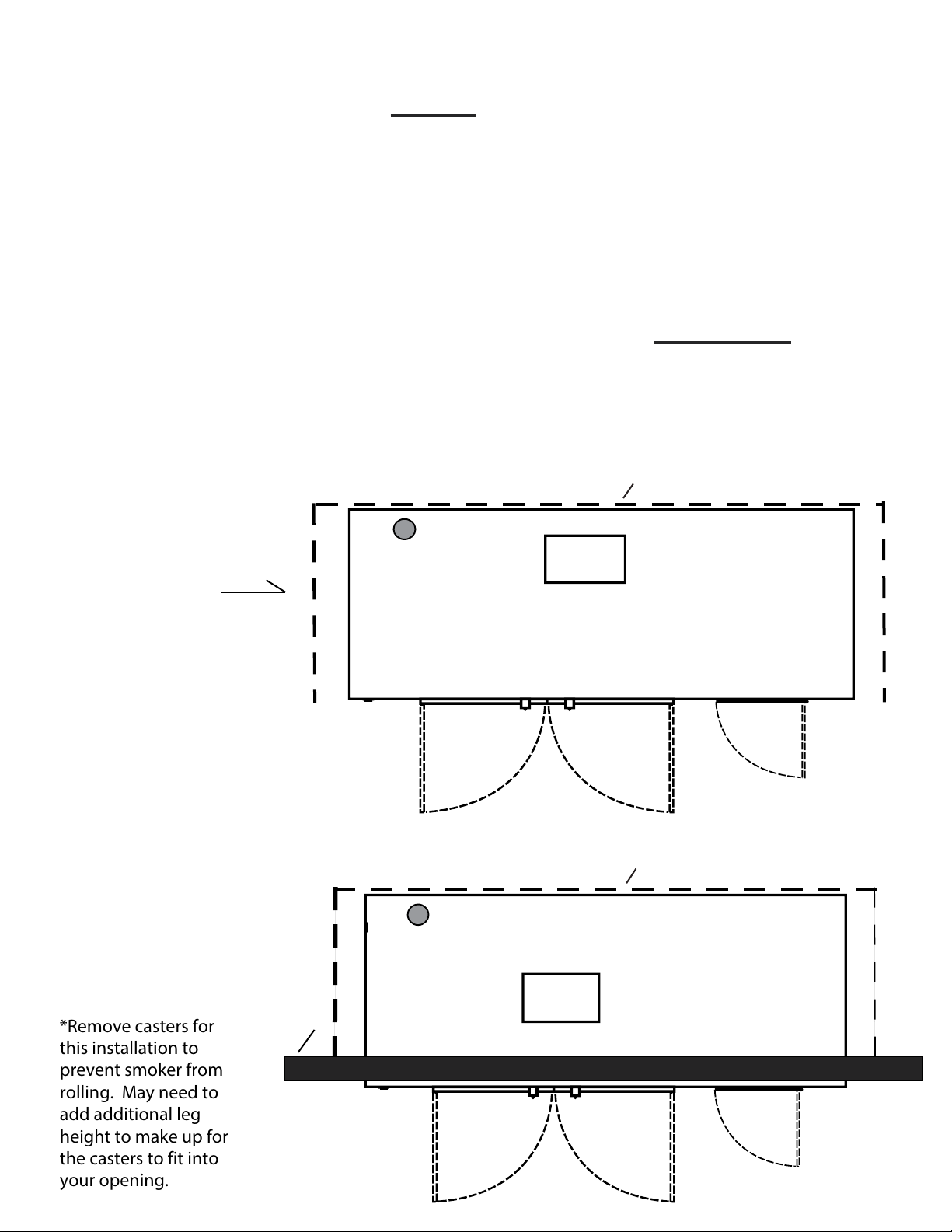

Models SSM, SSG, SSL & SSE Top View

Showing Clearance, Page 3 of Owners Manual, Titled Safety Tips:

#12. Please maintain a MINIMUM safety or mechanical clearance

from surrounding materials as follows:

Combustible Construction: Back 2"

Right S

Left S

Noncombustible Construction: Back: 2"

Right S

Left S

Any Installation that does not allow for the proper MINIMUM

Safety or Mechanical Clearance, as per ETL, may be considered a

Non-Approved Installation by Ole Hickory Pits. A Non-Approved

ide: 18"

ide: 18"

ide: 18"

ide: 18"

Installation ma

Example 1:

Free Standing

Inside or Outside

Bu

liding.

y void your warranty.

18"

2"

Smoke Evac.

Opening

18"

2"

Example 2:

Faced Thru Wall

Installation

*Remove casters for

this installation to

prevent smoker from

rolling. May need to

add additional leg

height to make up for

the casters to fit into

your opening.

Outside

Wall

18"

18"

Smoke Evac.

Opening

Operating Instructions

1. Preheat the Ole Hickory Pit to desired temperature by turning on all switches found on

the control panel. Recommended cooking temperature is 225 degrees F. and CANNOT

exceed 350 degrees F.

WARNING: Unit is equipped with an upper limit switch

that will shut down all operations until the

reset button, located under the service panel,

is manually reset.

Disconnect Power Before Removing Panel.

2. During the heating process, prepare the product to be cooked.

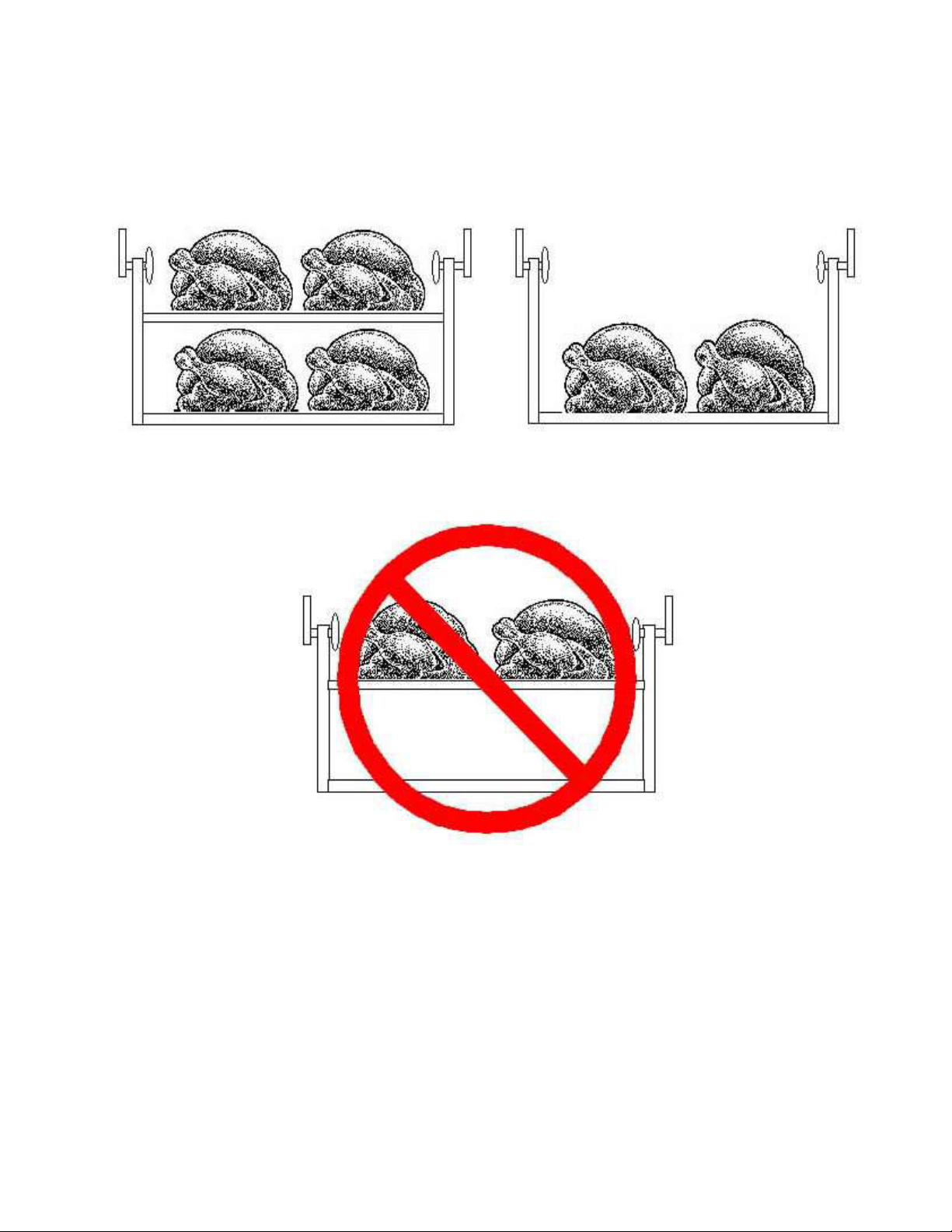

3. Begin loading the unit on the bottom racks first and evenly distribute the weight of the

product on all racks. DO NOT allow any of the product to hang over the front or back

edges or the racks. This may cause racks to tip and jam the rotisserie. If the product is

too large for the bottom rack, remove the top rack and load the product on the bottom

rack.

4. To advance the racks with the cooking chamber doors open, depress the Rotisserie Foot

Advance until the racks are advanced to the next position.

5. After, loading, allow the rotisserie to complete two revolutions to check for adequate

clearance of the product to the walls of the cooking chamber and racks. Reposition

product if necessary.

6. Wood used should be 4" to 10" in diameter and 16" to 24" in length. DO NOT ALLOW

ASHES OR LOGS TO OBSTRUCT THE BURNER TUBE OPENING. It is recommended to use

no more than 2 or 3 sticks of wood for a complete cooking cycle. Excessive amounts of

wood usage will overheat the cooking chamber and may trip the Upper Limit Switch.

7. When checking the meat, upon opening of the cooking chamber doors, the burner, and

convection systems are disabled. When the doors are closed, all systems are reactivated.

8. IN CASE OF POWER FAILURE: Turn off gas supply to unit. To prevent product spoilage if

cooking, the inside temperature of the unit can be maintained by manually keeping wood

in the firebox.

9. Contact factory, the factory representative or a local service company to perform

maintenance and repairs.

ROTISSERIE

YES YES

NO

To Avoid “Dumping” Racks, Load the Racks Vertically

as well as Horizontally. NEVER put heavy product on

the top rack with empty or lightly loaded bottom rack.

Gas Piping and Venting Instructions

Gas Requirements

Flexible hose must be used for the installation of all Ole Hickory Pits. A manual shutoff valve MUST be supplied in the gas line between the unit and the meter in an easily

accessible location. A low-pressure regulator is required to maintain correct gas

pressure to the burner. Please include a drip leg or sediment trap in the gas supply

line. Installation shall be made with a connector that complies with the Standard for

Connectors for Moveable Gas Appliances, ANSI Z21.41-1987, and a quick disconnect

device that complies with the Standard for Quick Disconnect Devices for Use With Gas

Fuel, ANSI Z21.41-1978, and Addenda Z21.41a-1981 and Z21.41b-1983. Once unit is

installed, PLEASE BE SURE TO LOCK CASTERS IN PLACE to prevent movement of the

unit. Casters may be removed for stationary installation.

Natural Gas: minimum supply pressure is 4.5 “W.C.”

maximum supply pressure is 10.5 “W.C.”

L.P. Gas: minimum supply pressure is 11.0 “W.C.”

maximum supply pressure is 13.0 “W.C.”

All piping must comply with local codes and ordinances or the National Fuel Gas Code

ANSI 23.1-1984 and NFPA No. 54.

A union shall be installed in the gas line adjacent to and upstream from the control

manifold and downstream from the manual main shutoff valve.

A 1/8" N.P.T. plugged tapping accessible for test gauge connection shall be installed

immediately upstream of the gas supply connection for the purpose of determining

the gas supply pressure to the burner.

The unit and its individual shutoff valve must be disconnected from the gas supply

piping system during any pressure testing of the system at test pressures in excess of

one half psig.

The unit must be isolated from the gas supply piping system by closing its in piping

system individual manual shutoff valve during any pressure testing of the gas supply

at test pressures equal to or less than one half psig.

Venting

Flues are required to extend 3 feet above the highest point where they pass through

the roof and at least 2 feet higher than any portion of a building within 10 feet. Flues

should be installed in an upward direction. Care should be given to avoid right angle,

elbow turns and the like that may restrict proper ventilation. A rain cap must be

utilized on a flue exhaust. A 4 foot flue extension is required for all units used

outdoors. Your flue extension rests inside the flue collar.

Electrical Specifications

Specifications:

120 Volts, 60 HZ, 1 Phase

AVOID NON-GROUNDED EXTENSION CORDS

15 amp Wiring

Instructions:

1. Electrical receptacles must be wired in accordance with local codes and

supplied by a qualified electrician.

2. All switches should be in the “OFF” position prior to power cord plug

insertion into receptacle.

Equipment:

1. One standard 1/4 horse motor drives the gear reducer (96 tooth sprocket)

for rotisserie operation.

2. One 1/4 horse 1,625 RPM motor for convection fan.

3. Gas burner is equipped with an electrical igniter system. (See complete

burner instructions)

Caution:

Burner electrical system is wired through an upper limit switch, which is preset at

350 degrees F. If the temperature inside the cooking chamber exceeds 350 degrees

F., the upper limit switch will not allow the burner to fire again until the upper limit

button, located under the service access panel, is manually reset. THE THERMOSTAT

IS NOT DESIGNED TO REDUCE TEMPERATURE IF FIRE GETS TOO HOT FROM

EXCESSIVE WOOD USAGE.

General Specifications

Dimensions:

Over-all Length: 8' 7"

Depth: 4' 7" Plus door handle clearance (with cooking chamber

Height: 6' 6-1/2" (with flue coupling; includes 6-1/2" casters)

Weight: 2100 pounds

Materials:

Basic Frame: 12 gauge steel, welded to 2" tubular steel 1/8" thick

Front: 22 gauge stainless steel, type 304 # 4 finish

Sides, Top & Front: 22 gauge stainless steel

Firebox Door: 1/4" steel plate, 21" h., 21"w.

door open: 6' 10")

square steel legs

Rack Levels:

Chrome wire (Stainless steel available at extra charge)

(15) each rack is 12" x 42"

Total Cooking Surface Area: 52.5 Sq. Ft.

Insulation:

Mineral Wool Rated to 1500 degrees F.

(Contains NO Asbestos)

Top & Side: 1" thick

Back: 1-1/2" thick

Front & Doors: 2" thick

Rotisserie:

Chain driven from 1/4 horse motor and reduction gear.

Maintenance & Cleaning

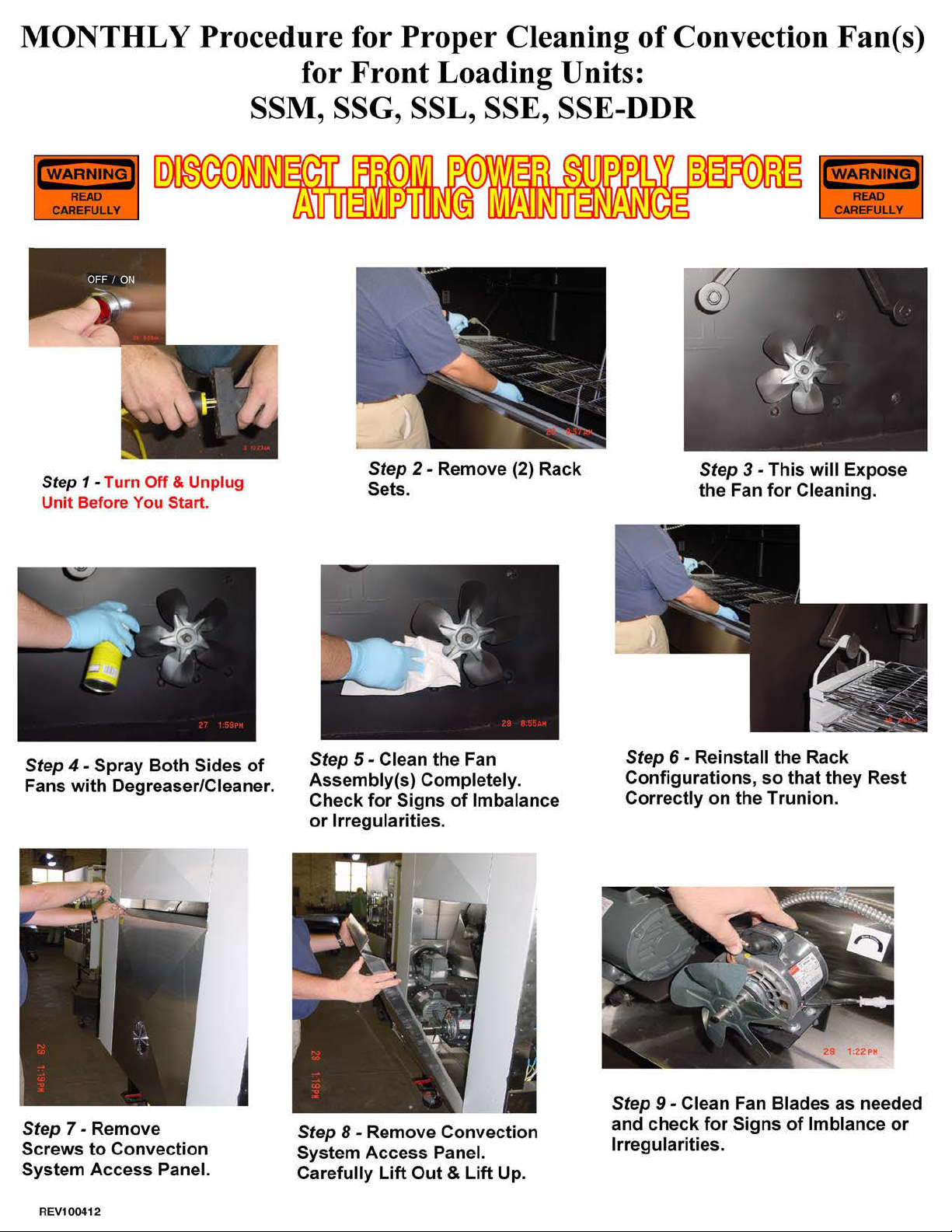

BEFORE PERFORMING ANY MAINTENANCE OR CLEANING

MAKE SURE UNIT IS DISCONNECTED FROM POWER SUPPLY

AND GAS IS TURNED OFF !

REFER SERVICING TO QUALIFIED PERSONNEL

1. a: Remove ashes and coals from firebox after each cooking. Ashes should be placed in a

non-combustible container and placed away from all combustible material. Make sure

there are in obstructions in the burner tube. USE EXTREME CAUTION WHEN CLEANING

THE BURNER TUBE TO NOT DAMAGE THE ELECTRODES OR OTHER PARTS INSIDE

BURNER TUBE.

b: Creosote-Formation and Need for Removable When wood is burned slowly, it

produces tar and other organic vapors, which combine with expelled moisture to form

creosote. The creosote vapors condense in the relatively cool chimney flue of a slowburning fire. As a result, creosote residue accumulates on the flue lining. When ignored,

this creosote makes an extremely hot fire. The chimney connector and chimney should

be inspected at least twice monthly to determine if a creosote buildup has occurred. If

creosote has accumulated. It should be removed to reduce the risk of a chimney fire.

2. Grease should be drained from the unit DAILY. Please dispose of grease in an approved

disposal container. Caution: Grease may be Hot !

3. Remove and clean cooking racks. To remove racks lift up on the right side of rack and

slide as far left as possible. Pull rack forward till it is free of pivot arm. Lift off left side of

rack and remove from unit.

4. Thoroughly clean complete interior and racks with a food service non-flammable

degreaser. Rinse with water and drain through drain valve on unit. Dispose of waste

properly. Make sure the drain is closed after cleaning.

5. Bi-weekly greasing of the bearings is necessary for proper operation of the unit.

Rotisserie shaft bearings are easily accessible and can be greased with a hand grease

gun.

6. Remove service access panels and inspect burner for accumulation of creosote or ashes.

Clean if needed. Check sprocket for broken or worn teeth. Check alignment of sprockets.

Replace service access panels when complete.

7. Check gasket material around cooking chamber doors and firebox for damage. Replace if

needed.

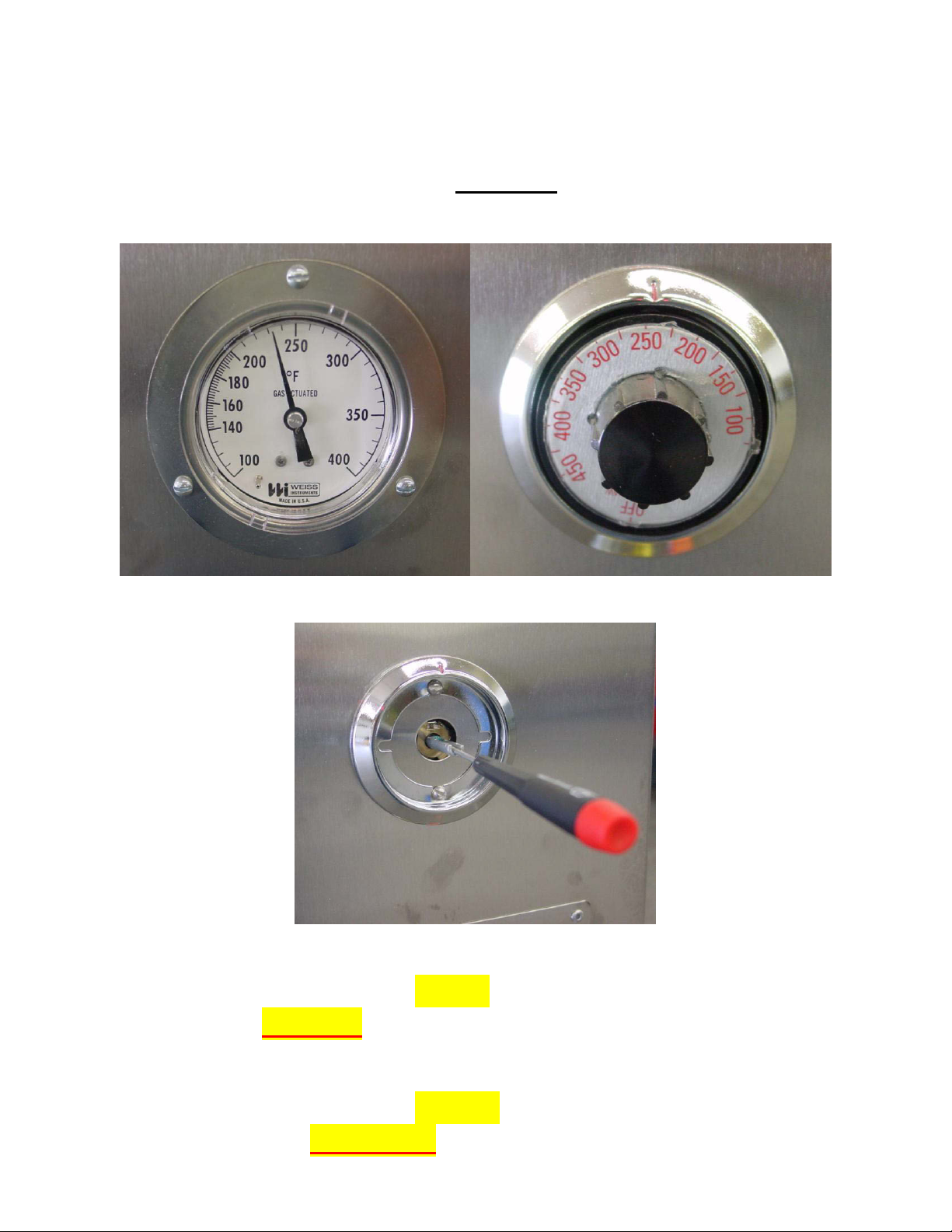

How To Calibrate The Thermostat

After the smoker has heated for about an hour, if the

Thermometer & Thermostat DO NOT agree…

Follow This Procedure:

Thermometer Thermostat

After removing knob, locate the screw inside the shaft.

If the thermometer reads lower than the thermostat, turn

slotted screw counter clockwise, no more than 1/8 turn at a

time.

If the thermometer reads higher than the thermostat, turn

the slotted screw clockwise, no more than 1/8 turn at a time.

Limited Warranty

Ole Hickory Pits warrants its product and components to be free from defects due to

faulty workmanship or defective materials at time of shipment and under normal use and

service for twelve (12) months from the date of delivery. This LIMITED WARRANTY does not

extend or apply to Ole Hickory Pits, or any component thereof, which has been misused,

neglected, improperly installed or otherwise abused. IT IS THE CUSTOMER’S RESPONSIBILITY

TO MAINTAIN ADEQUATE MAKE UP AIR. FAILURE TO DO SO CAN RESULT IN A HAZARDOUS

SITUATION AS WELL AS VOIDING THE WARRANTY. Equipment which is defective in material

or workmanship and which is removed within the specific time period will be repaired or

replaced as follows:

____________ (1) All service work to be performed is to be pre-approved by Ole Hickory Pits

PRIOR to the service call.

____________ (2) Only ORIGINAL equipment parts should be used in the repair of the unit. Other

parts used as replacement parts will void warranty.

____________ (3) Controls, motors, or other components which are so repaired or replaced will

carry this LIMITED WARRANTY equal to the unexpired portion of the original

product LIMITED WARRANTY.

____________ (4) Ole Hickory Pits is NOT responsible for any labor beyond the PRE-APPROVED

limit. Overtime rates and excessive labor will be the responsibility of the

customer.

____________ (5) Upon return of malfunctioning product, if inspection by Ole Hickory Pits does

not disclose any defect covered by this LIMITED WARRANTY, the product will

be repaired or replaced at the expense of the customer and Ole Hickory Pits

regular charges will apply.

____________ (6) Replacement parts covered under warranty will be shipped from our factory,

located in Cape Girardeau, MO, by REGULAR ground service at no cost to the

customer. Any request for overnight shipping to the customer’s location will be

billed to the CUSTOMER in the amount of the additional charges to comply with

the customer’s special request.

____________ (7) All parts replaced under this LIMITED WARRANTY must be returned to Ole

Hickory Pits within 30 days of service work or Ole Hickory Pits reserves the

right to deny warranty coverage.

THE FOREGOING STATES THE SOLE AND EXCLUSIVE REMEDY FOR ANY BREACH OF

WARRANTY OR FOR ANY OTHER CLAIM BASED ON ANY DEFECT IN, OR NON-PERFORMANCE

OF, THE PRODUCTS, WHETHER IN CONTACT, WARRANTY OR NEGLIGENCE. NO OTHER

WARRANTY, WHETHER EXPRESSED OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE, SHALL EXIST IN CONNECTION

WITH THE SALE OR USE OF SUCH PRODUCTS AND IN NO EVENT WILL OLE HICKORY PITS BE

LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF FUTURE NATURE. Ole

Hickory Pits neither assumes nor authorizes any person to assume for Ole Hickory Pits any

other liability or obligation in connection with the sale of these products.

Customer Signature:______________________________________________________Date:______________________________

Your signature constitutes understanding and acceptance of the above terms of the Warranty Agreement.

***IMPORTANT***

READ CAREFULLY

POSITIVE AIR FLOW through the air

shutter on the burner MUST be maintained

for safe and proper operation of the unit(s).

Burner air flow may be affected by one or

a combination of the following.

1. Improper flue installation.

2. Inadequate makeup air for hood

systems or exhaust fans.

3. Competing hood systems or

ventilation in the building.

4. Extreme drafts or inadequate

clearance.

If there are questions, consult your

owners manual or call 1-800-223-9667 for

support.

BURNER INSTRUCTIONS

ALLOW A FIVE (5) MINUTE COMPLETE SHUTOFF

PERIOD BEFORE APPLIANCE IS RE-LIGHTED.

Initial Start of Burner:

1. Remove service access panel.

2. Check burner for proper connection to gas lines.

3. Turn gas supply to burner on.

4. Depress the gas valve control knob on the combination

gas valve and turn to on position.

5. Replace service access panel.

6. Turn on burner switch located on front control panel.

7. Set thermostat to desired temperature.

To Put Burner Out of Operation for an Extended

Period:

1. Set all switches located on front of unit to “OFF” position.

2. Unplug unit from electrical source.

3. Turn gas supply off.

4. Depress the gas valve control knob on the combination

gas valve and turn to off position.

5. Replace service access panel.

PURPOSE

The purpose of the Smoke Evacuator System is to remove smoke from the front-loading

area of the unit once the doors are opened and prevent excess smoke from escaping

into the kitchen or food processing area. This enables the operator to work

unobstructed by interference from escaping smoke and heat. The smoke will be drawn

from the inside of the unit as opposed to an externally mounted hood system.

OPERATION

The procedure for operating the Smoke Evacuator System is quite simple. First,

activate the smoke evacuator by pressing in on the Black “ON” button and continue to

hold for 5 seconds. Second, while holding the Black “ON” button in for 5 seconds, grasp

door handle to cooking chamber. After the initial 5 seconds, slowly open the cooking

chamber door; operator may now release push button. The smoke evacuator will

remain on while the cooking chamber door is open. The smoke evacuator will

automatically turn off when the operator closes the door to the cooking chamber and

the unit will return to normal operating.

SMOKE EVACUATOR

(Push Button)

(Optional Equipment)

COMPONENTS

The Evacuator System is made up of four (4) basic components: (1) the switch, (2) the

Evacuator (power damper), (3) the 10” diameter duct and (4) the ventilator fan. Items

(1) and (2) are sold by Ole Hickory Pits as optional equipment. Items (3) and (4) are

purchased by you and are of your installation responsibility. ADEQUATE MAKEUP

AIR IS REQUIRED FOR SAFE OPERATION. Consult manual for more information.

It is your responsibility to maintain essential combustion air at all times during

operation of the unit.

INSTALLATION

Attach the 10” diameter duct to the 10” diameter duct collar located on the top of the

Evacuator. Check with your local inspector to make sure the duct complies with local

codes. The duct will go through your roof and will attach to the ventilator fan above

the roof. The ventilator fan can then be wired into your units relay system, thus

allowing your switch to activate the Evacuator and the ventilator fan at the same time.

As always, use a qualified local contractor for your installation.

AUTHORIZATION TO MARK

y

This authorizes the application of the Certification Mark(s) shown below to the models described in the Product(s)

Covered section when made in accordance with the conditions set forth in the Certification Agreement and Listing

Report. This authorization also applies to multiple listee model(s) identified on the correlation page of the Listing

Report.

This document is the property of Intertek Testing Services and is not transferable. The certification mark(s) may be

applied only at the location of the Party Authorized To Apply Mark.

Applicant: Manufacturer:

Address: Address:

Countr

Contact: Contact:

Phone: Phone:

FAX: FAX:

Email: Email:

Party Authorized To Apply Mark:

Report Issuing Office:

Control Number:

Ole Hickory Pits

333 North Main St

Cape Girardeau, MO 63701

USA USA

: Country:

Mr. David Scherer

(800) 223-9667 (573) 334-3377

(573) 334-2507 NA

NA

Same as Manufacturer

Arlington Heights

5006430

Authorized by:

for Dean Davidson, Certification Manager

David B. Knight & Associates, Inc, DBA

Ole Hickory Pits

4077 Nash Road

Cape Girardeau, MO 63701

Mr. David Scherer

Mr. Kevin Kessel

kdscherer@olehickorypits.com

kevin@olehickorypitss.com

This document supersedes all previous Authorizations to Mark for the noted Report Number.

This Authorization to Mark is for the exclusive use of Intertek's Client and is provided pursuant to the Certification agreement between Intertek and its Client. Intertek's responsibility and liability are

limited to the terms and conditions of the agreement. Intertek assumes no liability to any party, other than to the Client in accordance with the agreement, for any loss, expense or damage occasioned

by the use of this Authorization to Mark. Only the Client is authorized to permit copying or distribution of this Authorization to Mark and then only in its entirety. Use of Intertek’s Certification mark is

restricted to the conditions laid out in the agreement and in this Authorization to Mark. Any further use of the Intertek name for the sale or advertisement of the tested material, product or service must

first be approved in writing by Intertek. Initial Factory Assessments and Follow up Services are for the purpose of assuring appropriate usage of the Certification mark in accordance with the

agreement, they are not for the purposes of production quality control and do not relieve the Client of their obli gations in this respect.

Intertek Testing Services NA Inc.

545 East Algonquin Road, Arlington Heights, IL 60005

Telephone 800-345-3851 or 847-439-5667 Fax 312-283-1672

Gas Food Service Equipment [ANSI Z83.11:2016 Ed.4]

Standard(s):

Gas Food Service Equipment [CSA 1.8:2016 Ed.4]

Product:

Models:

Indoor/Outdoor Gas Bar-Be-Que pits

EL, EL-ED, EL-ED/X, ELIB, EL-EW, ELEX, ELEC, ELES, ELVS, SDL, SDLX, SSE, SSG, SSI, SSJ, SSJAE, SSJ-EW, SSL, SSM, SRO, SSO, SSRD, VS3 and VS4

Page 2 of 2 ATM for Report 550536CHI-001

ATM Issued: 24-May-2018

ED 16.3.15 (20-Apr-17) Mandatory

AUTHORIZATION TO MARK

y

0

This authorizes the application of the Certification Mark(s) shown below to the models described in the Product(s)

Covered section when made in accordance with the conditions set forth in the Certification Agreement and Listing

Report. This authorization also applies to multiple listee model(s) identified on the correlation page of the Listing

Report.

This document is the property of Intertek Testing Services and is not transferable. The certification mark(s) may be

applied only at the location of the Party Authorized To Apply Mark.

Applicant: Manufacturer:

Address: Address:

Countr

Contact: Contact:

Phone: Phone:

FAX: FAX:

Email: Email:

Party Authorized To Apply Mark:

Report Issuing Office:

Control Number:

Ole Hickory Pits

333 North Main

Cape Girardeau, MO 63701

USA USA

: Country:

Mr. David Scherer

(573) 334-3377 (573) 334-3377

(573) 334-6512 NA

dscherer@olehickorypits.com

Same as Manufacturer

Chicago, IL

500643

Authorized by:

for Dean Davidson, Certification Manager

David B Knight & Associates, Inc.,

DBA Ole Hickory Pits

4077 Nash Road

Cape Girardeau, MO 63701

Mr. David Scherer

Kevin Kessel

dscherer@olehickorypits.com

kevin@olehickorypitss.com

This document supersedes all previous Authorizations to Mark for the noted Report Number.

This Authorization to Mark is for the exclusive use of Intertek's Client and is provided pursuant to the Certification agreement between Intertek and its Client. Intertek's responsibility and liability are

limited to the terms and conditions of the agreement. Intertek assumes no liability to any party, other than to the Client in accordance with the agreement, for any loss, expense or damage occasi oned

by the use of this Authorization to Mark. Only the Client is authorized to permit copying or distribution of this Authorization to Mark and then only in its entirety. Use of Intertek’s Certification mark is

restricted to the conditions laid out in the agreement and in this Authorization to Mark. Any further use of the Intertek name for the sale or advertisement of the tested material, product or service must

first be approved in writing by Intertek. Initial Factory Assessments and Follow up Services are for the purpose of assuring appropriate usage of the Certification mark in accordance with the

agreement, they are not for the purposes of production quality control and do not relieve the Client of their obli gations in this respect.

Intertek Testing Services NA Inc.

545 East Algonquin Road, Arlington Heights, IL 60005

Telephone 800-345-3851 or 847-439-5667 Fax 312-283-1672

Standard(s):

Product:

Models:

Commercial Cooking, Rethermalization, And Powered Hot Food Holding And Transportation Equipment

[NSF 4:2016 ]

Indoor/ Outdoor Gas Bar-Be-Que Pits

EL, EL-ED, EL-ED/X, ELIB, EL-EW, ELEX, ELEC, ELES, ELVS, SDL, SDLX, SSE, SSG, SSI, SSJ, SSJAE, SSJ-EW, SSL, SSM, SRO, SSO, SSRD, VS3 and VS4.

Page 2 of 2 ATM for Report 3098759CHI-001

ATM Issued: 18-Jan-2018

ED 16.3.14 (20-Apr-17) Mandatory

Report No. 550536CHI-001 Page 17 Issued: 06/13/95

David B. Knight & Associates, Inc, DBA Ole Hickory Pits Revised: 10/11/11

J) Minimum lettering height of 0.10 inch with a minimum vertical spacing between lines of 0.066 inch:

Minimum clearance from combustible construction minimum 2 inches from sides and back. Minimum

6” from floor.

K) Instructions for lighting and shutdown the appliance. Lighting instructions specify a 5-minute

complete shutoff period before the appliance is re-lighted.

L) "This equipment is to be installed to comply with the applicable Federal, state or local plumbing codes

having jurisdiction." and Cet équipement doit être installé pour se conformer aux codes de plomberie

applicable fédérale , provinciales ou locales ayant compétence"

M) The word "NOTICE" and "Avis" in letters having a minimum lettering height of .36 inches. The

remainder of the marking has a minimum lettering height of 0.180 inch with a minimum vertical

spacing between lines of 0.069 inch, the lettering is in black, on a yellow background, where visible

after installation:

"NOTICE: When this appliance is installed with casters, it must be installed with the casters supplied,

a connector complying with either ANSI Z21.69 or CAN/CGA-6.16 and a quick disconnect device

complying with either ANSI Z21.41 or CANI-69. It must also be installed with a restraining means to

guard against transmission of strain to the connector, as specified in the appliance manufacturer's

instructions." And “AVIS: Les appareils sur roulettes doivent être pourvus des roulettes fournies, d’un

tuyau de raccordement conforme à la norme ANSI Z21.69 ou CAN/CGA 6.16 et d’une raccord à

débrancement rapide satisfaisant les exigencies de la norme ANSI Z21.41 ou CAN1-6.9. lls doivent

aussi être minis d’un dispositif de retenue pour empêcher toute transmission de tension au tuyau de

raccordement confromément aux instructions du fabricant.” Provided only on units shipped with

casters.

N) "Warning" followed by "Electrical Grounding Instructions" followed by "This appliance is equipped

with a three-prong (grounding) plug for your protection against shock hazard and should be plugged

directly into a properly grounded three-prong receptacle. Do not cut or remove the grounding prong

from this plug." And “Cet appareil est pourva d’une fiche à trios broches dont une mise à la terre

assurant une protection contre les chocs électriques. La prise dans laquelle elle est branchée doit être

correctement mise à la terre. Ne pas couper ni enlever la broche de mise à la terre de la fiche.”

Provided only on units, which are cord connected to the supply source.

O) Wiring Diagram provided on the unit, where accessible during servicing of electrical components.

Provided only on units with electrical components.

P) Instructions for lubrication of the fan motor, or a statement that the bearings are permanently

lubricated, located on the fan housing

The minimum dimension for all letters of the word Caution or similar words conveying a warning are

3/32 inch (2.4 mm) high. "WARNING" and "Attention" in contrasting color from background.

Q) "EVAC Off/On" by EVAC motor switch when EVAC motors are used.

R) "CAUTION, Use Only Dry Seasoned Wood!" and “Attention N’utiliser que du bois sec” marked on

fire box door.

S) "Suitable for outdoor use" and "Convient pour une utilisation en extérieur"

Report No. 3098759CHI-001

Ole Hickory Pits

4.0 Critical Components

Photo #

Item

Name and

no.

1

location

2

Manufacturer/

trademark

3

Page 6 of 28

Material type /

4

model

Issued: 29-Jun-2006

Revised: 20-Dec-2017

Technical data and Acceptance

Mark(s) of

5

conformity

6

21

22

23

24

Food Rack, HFZ,

FC

Rack Support,

HFZ, NFC

Interior Top, HFZ,

NFC

Upper Interior

Sides (Above

lowest rack), HFZ,

NFC

Various

Various steel with

US Coatings Paint

Various steel with

PPG Industries

Powder Coating

Various steel with

US Coatings Paint

Various steel with

PPG Industries

Powder Coating

Various steel with

US Coatings Paint

Various steel with

PPG Industries

Powder Coating

Nickel Chrome

plated steel

Steel painted

black with

HeatGrip 4950

Steel painted

black with

Ebony

PCTT90119

Steel painted

black with

HeatGrip 4950

Steel painted

black with

Ebony

PCTT90119

Steel painted

black with

HeatGrip 4950

Steel painted

black with

Ebony

PCTT90119

Stainless steel

type 200 series

Stainless steel

type 300 series

Stainless steel

type 400 series

NSF/ANSI 51 - Section 6.1.1

ASTM B456-95

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11 Verify

NSF Listing

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11 Verify

NSF Listing

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11 Verify

NSF Listing

NSF/ANSI 51- Section 4.2.1.1 NRVariousDoor Interior, SZ52

NR

NR

NSF

NR

NSF

NR

NSF

26

Interior Bottom,

SZ

Various steel with

US Coatings Paint

Various steel with

PPG Industries

Powder Coating

Steel painted

black with

HeatGrip 4950

Steel painted

black with

Ebony

PCTT90119

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11 Verify

NSF Listing

ED 16.3.14 (20-Apr-17) Mandatory

NR

NSF

Report No. 3098759CHI-001

Ole Hickory Pits

4.0 Critical Components

Photo #

Item

Name and

no.

1

location

2

Manufacturer/

trademark

3

Page 7 of 28

Material type /

4

model

Issued: 29-Jun-2006

Revised: 20-Dec-2017

Technical data and Acceptance

Mark(s) of

5

conformity

6

Various steel with

US Coatings Paint

Interior Side

27

(Below lowest

rack), SZ

Various steel with

PPG Industries

Powder Coating

18

2,3 9 Door Gasket, SZ

Ball Valve - 2"

SZ

Various

MTI Specialty

Silicones

Outer Shelf,

(Optional not

101

Various NSF/ANSI 51- Section 4.2.1.1 NR

shown), SZ

1 11 Casters, NFZ Various

Steel, painted

black with

HeatGrip 4950

Steel, painted

black with

Ebony

PCTT90119

Cast brass w/

chrome plated

brass ball

99-8612T

Stainless steel

type 200 series

Stainless steel

type 300 series

Stainless steel

type 400 series

Stainless plated

steel

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51-

NR

Section 4.4.1, 9.2, 10.1, 11

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11 Verify

NSF

NSF Listing

NSF/ANSI 51 - Section 4.2.3.2

NSF/ANSI 51 - Section 6.1.1

NR

ASTM B650-95

Silicone Rubber, 55-65

Durometer, 325°F

NR

NSF/ANSI 2 NSF

1 12 Stand, NFZ

113

114

External Panels,

NFZ

Door Exterior,

NFZ

Various steel with

US Coatings Paint

Various steel with

PPG Industries

Powder Coating

Various

Various

Steel painted

black with

HeatGrip 4950

Steel painted

black with

Ebony

PCTT90119

Stainless steel

sheet metal

Stainless steel

sheet metal

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11 Verify

NSF Listing

Stainless steel, type 200, 300,

400 series

Stainless steel, type 200, 300,

400 series

NR

NSF

NR

NR

ED 16.3.14 (20-Apr-17) Mandatory

Report No. 3098759CHI-001

Ole Hickory Pits

4.0 Critical Components

Photo #

Item

Name and

no.

1

location

2

Manufacturer/

trademark

3

Page 8 of 28

Material type /

4

model

Issued: 29-Jun-2006

Revised: 20-Dec-2017

Technical data and Acceptance

Mark(s) of

5

conformity

6

115

Door Closer/

Latch, NFZ

Kason Industries

P/N 1092 Plated

steel

Polished zinc plated steel NR

Impact , Abrasion and Heat

116

Black Paint, HFZ,

NFC, SZ, NFZ

US Coatings HeatGrip 4950

PPG Industrial

Coatings

Ebony

PCTT90119

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11

Impact , Abrasion and Heat

Resistance, NSF/ANSI 51Section 4.4.1, 9.2, 10.1, 11 Verify

NR

NSF

NSF Listing

NOTES:

1) Not all item numbers are indicated (called out) in the photos, as their location is obvious.

2) Identifies where on the equipment the part is used by Zone - Food Zone (FZ), Heated Food Zone (HFZ), Splash Zone (SZ), Non-Food

Zone (NFZ), Exterior Zone (EZ), Refuse Contact Zone (RCZ), or Power Zone (PZ). FZ items also indicate either Food Contact (FC) or NonFood Contact (NFC).

3) “Various“ means any type, from any manufacturer that complies with the "Technical Data and Acceptance" and meets the "Mark(s) of

conformity" can be used.

4) Model or part number of the component, or type of material such as: Stainless Steel, Galvanized (or Zinc-Coated) Steel, Aluminum,

Nylon, ABS, Silicone Rubber, etc.

5) Food Contact (FC) items indicate one of the following: the NSF standard (used to obtain the Mark of conformity indicated in next column);

MFCR number preceded by FD; or MAF number preceded by FS with a reference to the illustration. Food Zone, Non-Food Contact (FZ,

NFC) items indicate either the relevant 21 CFR number or the information as indicated for Food Contact (FC) items. Additionally Food Zone

metallic materials indicate both the NSF standard and the clause number.

6) Indicates specific marks to be verified, which assures the agreed level of surveillance for the component. "NR" - indicates Unlisted and

only visual examination is necessary. "See 5.0" indicates Unlisted components or assemblies to be evaluated periodically refer to section

5.0 for details.

ED 16.3.14 (20-Apr-17) Mandatory

Report No. 550536CHI-001

David B. Knight & Associates, Inc, DBA Ole Hickory Pits Revised: 10/11/11

WIRING BOX PHOTO NO. 1

General - Photo No. 1 shows an interior view of the wiring box, model SSJ, which also represents the models

SSO, SSJ-AE, SSJ-EW, SRO, SSE, SSI, SSM, SSG and SSL.

Page 27 Issued: 06/13/95

1. Wiring Box Enclosure - Constructed from 22 gauge stainless steel or galvanized and painted steel, type 304, #4

2. Power Supply Cord - Listed, Type SJOOW, 3 feet to 10 feet long flexible cord, 14/3 AWG, 105°C, 120 VAC,

3. Thermostat - Component, Robert Shaw, model 5300-17E, rated 277 VAC, 30 A, maximum adjustment 325°F,

4. Circuit Breaker - Deleted.

5. Circuit Breaker - Component, any brand, rated minimum 125 VAC, maximum 6 A, single pole, mounted in

6. High Limit Switch - Component, Stemco manufactured for Watlow, model 103K, 30 A, 120 V, rated to cutout

7. Indicator Light Assembly: (1 or 2 provided) One provided for main power and one provided for EVAC motor

8. Power Switch -(4 provided) Component, any brand, DPST, rated minimum 20 A, 120 VAC, pilot light,

finish, 0.70 mm thick, 12 inches by 14 inches by 25 inches.

water resistant, attached with strain relief.

mounted in wiring box.

wiring box.

at 350°, 5°F, mounted in wiring box.

power when used.

Indicator - Component, Dialight, model 50F6198 rated 110-125 V, 75 W.

Lens - Dialight, model 50F6221, red lens cover.

Lamp - Sylvania, model 96F6554, rated 105-125 V, 1.2 A, 1/7 W, mounted in wiring box.

mounted to receptacle enclosure.

Alternate – (Optional) Listed, rated 400 V, 10 A, two position rotary type.

9.

10. Sealing Compound - Sealing compound rated –40°C to 204°C, used to seal wiring box to main enclosure.

11. Foot Control Switch - (Not shown) Component, Linemaster, No. 571-DWH, 20A, 125-250VAC, attached with

12. EVAC Motor Switch - (Optional) Listed, Cutler-Hammer, model 10250T4011 on switch, model 10250T53 on

13. EVAC Motor - (Optional) (Not shown) Listed Motor, rated 0.9 A, 120 V, 60 Hz, when motor is energized, it

14. Industrial Relay - Component, any brand meeting UL508; minimum contact rated 120 V, 10 A, with 120 VAC

15. Safety Interlock Switch - (Not Shown) Component, SPST, Omron Electronics, model A-20GQ-B7-K, contacts

Terminal Block - Component, Buchannan, Model 715, rated 15 A, 600 V, 200°C, mounted in wiring box.

type SJOOW cord, 3 feet to 10 feet long.

Alternate – Listed, Linemaster, No. 531-SWH, 20A, 125-250VAC, attached with type SJOOW cord.

Alternate – (Optional) Listed, rated 400 V, 10 A, momentary push button type, mounted in control panel.

contact block, SPST, rated 4 A, 240 V.

winds up an internal coil and opens louvers, when de-energized, coil then unwinds and closes louvers, mounted

on top of unit.

coil. Typical as Omron, model MGNIC-AC120.

cycle rated 20 amps, 125 volts. Stops rotation of rotisserie motor, located on front door.

(Not supplied

by Ole Hickory Pits)

4" Dia. Flue

See local inspector

for type.

See local inspector

for type.

Cook & Hold Feature

(Optional Feature)

The purpose of the Cook & Hold feature is to allow the operator to set the

cooking time so that when the programmed time has elapsed, the unit will hold at

147 degrees until the operator turns the switch off and removes the meat.

To operate this feature, make sure all the switches for the MAIN, BURNER,

RACK and FAN are turned on. Set the unit primary thermostat to the desired

cooking temperature. Set the timer on the Cook & Hold control to the number of

hours you want the smoker to cook. (Hours from 0 to 30 hrs.)

Turn on the cook and hold switch. The Green “POWER” light will flash and the Red

“OUT” light will be on. This means the unit is operating off the Cook & Hold

thermostat mode.

When the preset time has elapsed, the Green “POWER” light will stay on, but

it will stop flashing. The Red “OUT” light will go off. This puts the unit into Hold

cycle, which is preset at the factory to 150 degrees. (Since this is on a separate

thermostat, you can adjust the hold temperature.) The unit will continue to hold

this temperature unit the Cook and Hold switch is turned off.

Please note that if the Cook & Hold switch is turned off, the unit will operate in the

Normal cook mode.

To Hold & Cook, set the units primary thermostat to the hold temperature.

Adjust the separate Cook & Hold thermostat to the desired cooking temperature.

Set the timer for the number of hours you want to elapse before you want the meat

to start cooking. When the timer reaches the number of hours set, the unit will

begin to cook at the temperature set on the Cook & Hold thermostat. Please note

that the unit will continue to cook at this setting until the Cook and Hold Switch is

turned off.

Date Date Date Date Date

Clean Ashes From Firebox

Drain Grease

Grease Bearings

Clean Fan Blades

Clean Flue Pipe (Internal & External) &

Rain Cap

Clean Racks & Pit Interior

Check Chain Tension & Check Belt

Tension

Check Set Screws On Sprockets,

Pulleys & Fan Blades

Clean Ashes From Burner Tube

(Shut Off Gas Supply)

Clean around door gaskets

Rev100312

After First Month Of Use - (It Should Be Tight)

Then Every 6 Months Or If Rotisserie Is

Jumping

Daily - Dispose Of Safely In A Sealed Metal

Container

Daily

At Least Once A Month

BURNER: Visual inspection daily during the first week of operation, then monthly thereafter. Look for smoke backing out through the air shutter of the

burner blower motor when the burner is not burning. Also, look for signs of any black tar-like substance forming around the air shutter or anywhere

above or below the burner assembly. Positive air pressure must be maintained in the room where the smoker is operated. If inspection indicates any of

the above described conditions, immediate attention is required to avoid potential hazard. Contact OLE HICKORY PITS immediately and review your

owners/operators manual for further instructions. NOTE: Seasonal changes in building ventilation, adding exhaust fans or turning off make-up air fans

may result in the above described conditions.

MAINTENANCE SCHEDULE

*** Disconnect From The Power Supply Before Performing Any Maintenance***

2-3 Squirts Every 2-3 Weeks

After First Month Of Use - Then Every 6

Months

Daily - With hot soapy water or degreaser,

also clean inside surface of doors.

Once a Month - First, Shut Off Gas Supply.

Allow Unit To Cool. Remove Ashes From

Inside Burner Tube Near The Pilot Igniter By

Carefully Blowing With Compressed Air Or

Vacuuming With A Shop Vac. Inspect With A

Mirror When Finished.

At Least Every 6 Months

As Needed (Based On Usage) With Oven

Degreaser & Hi-Pressure Washer

REV080111

SUPPLY BEFORE PERFORMING ANY

MAINTENANCE!

OLE HICKORY

PITS

Tension, Set Screws on Sprockets,

Pulleys, Fan Blades & Grease Bearings

(After 1st Month of Use). Then Place

Them on Their Regular Maintenance

*** Check Chain Tension, Belt

Maintenance Schedule

DISCONNECT FROM POWER

Schedule.

Clean Ashes from Firebox and Drain Grease from Cooking Chamber

DAILY - Maintenance Schedule

Monday

Tuesday

Wednesday

Sunday

Thursday

Insert Date for Daily Cleaning Schedule

Friday

Saturday

Friday

Saturday

Insert Date for Daily Cleaning Schedule

DAILY - Maintenance Schedule

Monday

Tuesday

Wednesday

Sunday

Thursday

Clean Ashes from Firebox and Drain Grease from Cooking Chamber

WEEK12

3456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051

52

Insert Date for Weekly Cleaning

Sunday

Monday

Tuesday

Wednesday

Thursday

Friday

WEEKLY - Maintenance Schedule for Cleaning Racks & Units

Saturday

WEEK12345678910111213141516171819202122232425262728293031323334353637383940414243444546474849505152

Tuesday

Wednesday

Thursday

Friday

WEEKLY - Maintenance Schedule for Cleaning Racks & Units

Saturday

Insert Date for Weekly Cleaning

Sunday

Monday

1.

2.

Clean Fans Blades (SHUT OFF POWER SUPPLY)

ONCE A MONTH - Maintenance Schedule

August

September

October

July

Clean Burner Tube (SHUT OFF GAS SUPPLY)

Once a month with gloved hand. DO NOT use hard objects

Burner Tube

April

May

June

Fan Blade

January

February

March

November

December

Insert Date for Monthly Cleaning

1.

2.

Clean Fans Blades (SHUT OFF POWER SUPPLY)

ONCE A MONTH - Maintenance Schedule

August

September

October

July

Clean Burner Tube (SHUT OFF GAS SUPPLY)

Once a month with gloved hand. DO NOT use hard objects

Burner Tube

April

May

June

Fan Blade

January

February

March

November

December

Insert Date for Monthly Cleaning

May

June

July

October

November

December

September

TWICE MONTHLY - Maintenance Schedule

Grease Bearings - 2 to 3 Squirts Bi-Monthly

March

April

January

February

Insert Date for Twice Monthly Cleaning

August

EVERY SIX MONTHS - Maintenance Schedule

Insert Date for Bi-Yearly Cleaning

PULLEY & FAN BLADES

Check every 6 months

CHECK SET SCREWS ON SPROCKETS,

First 6 Months

Second 6 Months

CLEAN FLUE PIPE

at least every 6 months

CHECK CHAIN TENSION & BELT TENSION

It should be tight, Check every 6 months

Every Six Months - Visual Inspection of Burner

DATE

DATE

DATE

DATE

DATE

DATE

DATE

DATE

DATE

Visual inspection daily during the first week of operation, then every six months thereafter. Look for

may result in the discribed conditions.

SHUT OFF BURNER

After Visual Inspection with a mirror - if ashes are built up inside burner - Remove burner and clean.

smoke backing out through the AIR SHUTTER on the BURNER FAN MOTOR or accumulation of a

BLACK TAR-LIKE substance around or above burner. A POSTIVE flow of air should be maintained

through the air shutter. If inspection indicates any of the above described conditions, IMMEDIATE

attention is required, to avoid a potential hazard. Contact the manufacturer immediately and

REVIEW your OWNERS/OPERATORS MANUAL for further instructions. NOTE: CHANGES in

building VENTILATION such as adding EXHAUST fans or DISCOUNTINUED use of MAKE-UP AIR

r

f

Cooking Capacity Chart

d

Model EL-IB & SSG

Rack Size: (15) 12" X 42" Cooking Surface: 52.5 Sq. Ft.

Item

Ribs (3 & Down) 15 4 45

Baby Back Ribs 15 6 75

Boston Butts (4-6 lbs) 10 5 40

Turkey (8 lbs) 10 3 30

Chicken (Whole) 10 5 50

(Half)

Brisket (12 lb.) 10 4 30

All item counts are estimate

15 9 120

Est. CapacityItem # Per Rack Rack Count

Cooking Time Chart

(Estimated at 225 degrees F)

Ribs (3 & Down)

Baby Back Ribs

Boston Butt

Pork Shoulder

Turkey

Chicken (Whole)

(Half)

Brisket

4 - 5

3 - 4

8 - 12

10 - 14

7 - 10

5 - 6

4 - 5 Hours

8 - 12 Hours

Hours

Hours

Hours

Hours

Hours

Hours

Above cooking times are approximate. Cooking time will vary depending on

product size, weight & beginning internal temperature. Refer to Internal

Temperature Chart below for doneness.

Meat Internal Temperature Chart

(Degrees Fahrenheit)

Pork Butt

Pork Shoulde

Beef Brisket

Bee

Poultry

Internal meat temperature should be taken with a meat thermometer, inserted

into the thickest portion of meat. Avoid touching bone or racks with probe as it

will affect correct temperature reading.

Rare

Medium Rare

Medium

Medium Well Done

Well Done

170 - 180

170 - 180

170 - 180

140

150

160

170

180

170 - 180

Notes:_______________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

_____________________________________________

Loading...

Loading...