Page 1

I

FIlILIt

01

VOL.

10

I

6-28

CI

On

1151

Oldomobile

in"

Hydro-Lectric

employsareversible

only,

used

circuit.

in

the

connected

behind

the

directly

rear

it

located

through

locationofthe

II

HYDRO

-

LECTRIC

CONTROL

TOP

ii

MOTOR&PUMP

II

THE

HYDRO-LECTRIC

OPERATING

OLDSMOBILE

1951

convertible

Style

in

nowinone.

system

the

rear

compartment

"sealed-in"

sew

type

neld-oentering

The

psnp

to

the

aeat

hack

alter

motor

motorbymeaonoftwo

right

Hydro-Lectric

SYSTEM

SWITCH

ASSEMBLY

CON

bodiesinwhich

This

with

5

control

top

nide

underneath

end

the

motor

unit

TOP

REMOVAL

SERVICE

SYSTEM

VERTI9LE

SUPER

the

top

only

Hydro-Lectric

new

spur

gear

assembly,nocircuit

pomp

switch

located

electricsl

the

fabric

pomp

Shieldinremoved.

for

operating

LIFT

CYLINDERS

OPERATIONS

INFORMATION

TOPS

‘88"

is

operated

system,

at

the

lower

leads.

folding

top

compartment

cosVcriible

FOR

ONLY

SERIES

hydreulloally,osee

for

operating

breakerorsolenoid

edgeofthe

The

motor

end

bag andisaccessible

The

illustration

tops

only.

II

OlYtlIUN

CHLVROLW’

I

PONTIACII

BUICK

II

CODILLAC

convertible

lostromsnt

pomp

assembly

below

"seoled

shows

NO.

.

tops

pnsel

the

I

01

VI

is

in

Page 2

FISHER

BODY

SERVICE

NEWS

The

Hydeo-Lectric

reservoIr

aaoembled

whichinm000ted

panel

soder

the

the

shield

has

beec

An

eoploded

of

the

RESERVOIR

PUMP

TUBE

RESERVOIR

PUMP

TUBES

view

000rmbly

parts

A.

B.

C.

D.

motor

vertically

with

robber

fabric

folding

removed.

of

the

motor

maybeIdentified

RETAINING

SEALING

AND

FASTENER

Md’IOR

and

pomp

into

attaching

top

The

and

NUTS

RINGS

AND

aSsembly

a

ntngle

gromsuets

rompartmeot

entire

uaitIscompletely

pemp

aosembly

as

followsi

GROMMETS

PUMP

ennoistsofon

snit.

The

on

hag.

Is

ASSEMBLY

electric

field

reservotr

the

eight

The

iunStratlao

ceaSed

showsisthe

E.

VALVE

F.

SPUR

U.

PUMP

H.

MOTOR

A

now

lbereveenible

ocly

loor

nprtog

pomp

low

battery

tog

pomp.

component

*

from

thr

identified

A.

BALL

SPUR

B.

PORT

C.

PORT

D.

E.

PUMP

motor,

a

in

locatedatth

side

of

the

rear

below

abmas

aod

is

oct

vented

right

ilinstration

BALL

CHECK

GEAR

PUMP

ATTACHING

UNIT

AND

HYDRAULIC

spur

gear

pumpisosediscnnjnncttnn

type

motor.

moving

parts,

valves.

The

is

fluid

proportional

will

therefore

The

opposite

ports

of

the

motor

attaching

us

followsi

AND

SPRING

GEARS

LOWER

CYLINDER

UPPER

CYLINDER

OPENINGS

to

TO

spor

gear

pomp

topofthe

compartment

the

pump

to

the

atmosphere.

above.

SPRINGS

UNIT

SCREWS

END

PLATE

PUMP

This

new

two

spor

gears

presence

developedbythis

the

opeed

of

renultina

tilontratton

pump

scuembly,anviewed

nide.

These

VALVE

END

END

RESERVOIR

oodafluid

osnnwhly,

lower

division

inotailation

The

component

pomp

employs

nod two

the

motor.

"sioggish"

shows

pasta

may

ufter

with

hal

1-

act

the

be

A

2

Dss.sS,esStnsEstDsy

51

Jshsnde8.510518515k

Msdsl

nD

Page 3

I

REMOVAL

1.

Itsine

the

2.

Through

aide,

Disconnect

etoitch

Rrmove

insulating

the

From

ittideofbody,

cutout

unions

at

"B".

Remove

from

Disconnect

preveot

to

rile

bandytoabsorb

of

Loosen

motor

and

fittings

syuler

all

mule

hydraulic

I.

the

remove

wire.

rear

thy

insideofbody.

four

ftttingu

bold

right

four4torrent

3.

totop

4.

bark

5.

throogb

keife"

wires

t.

"0"

"E".

fittings

lines.

7.

lift

8.Totnvtsll,

hydraulic

thread

of

the

page

AND

top

folding

to

rear

compartment

the

po’oer

to

expose

pump

positive

battery

the

seat

cushion

padonright

carefully

"A".-Remove

and

diecooteet

Also

discontent

2

hydeaslic

teen

hydraulic

lealoiogofhydraulic

any

4

rubher

pomp

nnsrmbly

reverse

the

reithusoitable

by

applying

the

prior

to

levelinthe

INSTALLATION

the

toll

"op’

opeoiog

unit

rover

plate

unit.

tableorbattery

sod

bsek,

sideofbody.

pull

wiriug

lneulation

from

red and

green

gr000d

wire

lion

retsinero

Remove

filler

lines

"F"

and

fluid.

dripping

of

from

sealer

pomp

fluid

at

position.

prucedsre.

hydraulIc

to

the

lives.

reservoir

gromoeeis

above

000neoting

BODY

P155DB

position.

00

the

shield

alto

fold

hu.rtesn

"jack

losd

at

"C".

cap

rap

open

Keep

from

"G"

and

Seal

pipe

threads

Cheek

see

NEWS

SERVICE

I

OF

MOTOR

AND

PUMP

ASSEMBLY

at

at

The

operatlos

sew

Is

column

switch

throsgh

the

rnstrol

via

the

top.

the

design.

sad

hush

the

red

The

green

switch

leadtothe

the

convertible

of

The

owitch

is

oossectedtothe

furward,

the

"hot"

knob

illuntratiosu

FOLDING

is

esrrest

lead

rearward,

motor.

below

top

is

meusted

motor

and

pansen

to

motor.

the

the

nuerent

eaueeo

This

showindetail

TOP

nnstrulled

bottom

at

the

ausembly

pump

directly

The

pannes

the

motor

Bela

CONTROL

by

measuofa

of

the

with

from

the

motor

and

directly

and

pumptooperate

operation

SWITCH

seif-castering

Isutromest

two

electrical

battery,

pomp

then

from

of

the

folding

through

operate

Bee

battery,

paneltothe

in

lop

control

top

right

leado.Bypushing

the top

control

Caine

to

the

top.Bybellhop

through

the

the

oppuotte

dienettes

control switoh.

ewlttb

of

the

the

switch,

switch,

which

steering

control

and

and

and

lnwer

Is

Out

ant

Page 4

FISHER

BODY

SERVICE

NEWS

Each

steel

folding

throughoconnection

"B"

ends,

movable

for the

Rested

be

lubricated

top

lift

top

are

connected

which

are

crimp-retained.

anchorage

to

piston

end

at

"F"toformafluid

withanapproved

cylinders

are

at

FOLDING

Top

during

Disconnect

Remove

CAUTIOII:

the

upper

Remove

3.

to

Remove

cylinder

5.

Grasp

6.

RemOve

to

cylinder.

7.

Remove

shouldbeisa

thin

nperutinn.

the

Owitch

rear

seat

additionSnhangers

In

rear

seat

corner.

the

folding

gale

accessinthe

nut

and

piston

rodtotop

piston

end

down

lote

all

retainers

cotter

the

cyltedertofloor

lift

NOTE

ties

1.

batterytotop

2,

tabs,

each

panel

4.

nusembly

travel.

ing

secarisg

FOLDING

lift

cylmder

in

wills

tile

top

to

the

top

and

the

bracketatthe

lower

"0",

tight

hydraulic

Interchangeable

TOP

raisedorfull

battery

positive

wire.

cushion

and

backissecured

top

rear

top

lift

boltat"A"

liekuge.

sad

manusily push

cylindertofull

from

hydraulic

key

aod

steels

bracket.

TOP

fitted

withapintoo

linkageanshows

bottomofthe

The

lower

end

floor

pao

right

lUnotration.

assembly.

Felt

fluid

see

for

right

sad

LIFT

CYLINDER

"up"

pont-

cableorthe

rear

Heat

and

bend-over

screw

with

a

qnsrter

side

cylinder.

connecting

the

piston

bottom

limit

tubing

lead

pinat"C"

lift

bock

trim

lift

forms

at

Service

left

at

of

LIFT

at

cylinder.

"C".

washer

4

CYLINDERS

rod

onnembly

‘A"isthe

left

The

steel

a

yoke

which

The

opper

The

piston

and

at

the

upper

loformathos

side

use.

REMOVAL

8.

Lift

folding

is

folding

top

outisrear

at

"G".

Remove

9.

DIsconnect

cylinder

of

top

lift

of

hydraulic

fluid.

Ienpucloth

fluid.

10.ToInstall,

pistonisat

Installing,

sealertoall

battery

cableorswitch

operationoftop,

check

for

leaks

and

page9.In

a

sew

coupling.

Osesnss.stnssrtsss

which

raises

aud

illustration

below.

lift

cylinderisfitted

together witharlevis

endofthe

cylinder

both

endscfthe

end

of

the

lift

end

AND

compartment

Seat

hydraulic

linestcprevent

bottomoftravel

applyasuitable

threads

check

caseofa

cylinder

Suggeetiene

INSTALLATION

top

cylinderupthrough

and

buck

compartment

filler

cap

from

tubing

and

remove

bandyinabsorb

reverse

this

when

of

mate

wiee,

looped

the

hydraulic

chrusic

51

JeansdsBn.hs51BakIs

lowers

the

folding

Hydraulic

lines

with

die

cant

pin,

provides

providesabearing

cylinder

are

robher

at

"F"

11.

Folding

access

cut

thrsugh

peaRl

indicated

reservoir.

top

and

Cap

loalsing

any

Make

installing.

pipe

fittings.

iostuliatios,

connections

tubing

fluid

level

always

Msdsl

should

bottom

Before

thread

Connect

innt4ll

on

page

then

from

cylinder.

drippingofhydraulic

procedure.

hydraulic

ufter

all

leek,

top

at

bole

cnt

ends

sure

end

see

410

a

of

Page 5

oporatiooofthe

The

dlreotiosal

The

robe

the top-the

through

the

top

theo

operatetoforce

double-ectiog

to

directly

peso

then

operateinthe

pump

cylboders.

flowofthe

000tcol

ooetrol

cylinders.

lift

from

OPERATION

pooh-poll

hydrualto

lmoh

switch,

the

hydraulic

To

the

battery,

opposite

FISHER

kooh

cootrol

to

aed

located

fluidisOosteolledhythe

poobod

forward.

out

throogh

the

uoder

pressure

fluid

top,

lower

tho

the

the

Switch,

through

directioo

to

BODY

OF

green

cootrol

force

SERVICE

THE

FOLDING

at

the

Soetrument

EleetriOol

leadtotho

throogh

knobiupulled

aod

oot

the

hydraulic

NEWS

paocl

revereible

earreot

thec

motor.

the

hydraulic

the

via

red

fluid

TOP

either

aotiOoofthe

paoseo

The

motor

tobingtothe

rearward

ailowbog

leadtothe

prescore

under

raiSesorlowers

spur

gear

from

dlrectty

ond

Spur

lower

electrical

motor.

The

to

the top

pump.

the

gear

eodo

motor

of

the

top.

l’o

battery,

pomp

of

the

correct

sod

the

lift

RAISING

the

ratee

To

lnutrameot

on

the

to

operate

motor

indicated

in

en

fluid

hydrwolio

of

each

bottom

move

pintoou

to

action,

the

name

above

the

piot000

liestothe

pomp

cylindeee.

the

cylinder,

the

lift

from

drawn

illuotratlun.

sssstsny

0005ssssst

FOLDING

THE

top,

the

foldiug

the

from

The

the

top

paeelispushed

the

oppooite

hydraulic

opward,

hydraulic

duetopiston

reservoirsuObowninthe

of

gears10the

pomp

opur

illusteation.

the

pompinthee

cylinder

lift

ralsieg

thus

fluidtoeaok

is

forced

ont

for

aod

reciroulationtothe

fluid

additiooal

rod

JesusdeBratn,’Sl

TOP

eoitoh

control

oaoeieg

"be"

Preoaurised

forcedtothe

ononiag

the

lift

via

hack

bottom

requiredtofill

dieplaeement,

Model

BsiOk

knob

the

direction

the

top.

By

cylinder

soother

of

In

opposite

410

5

Page 6

LOWERING

lower

jootroment

operation

illustration.

the

lift

hydraulic

piuton

the

pomp

due

to

through

oppoOitc

lbs

foldtog

the

pooel

is

of

the

motor

pompistheo

cylinder

thon

lowerlog

fluid

is

forced

where

it

lift

cylicdern.

pisfoo

rod

the

illustration.

To

the

the

gearstorotateisthe

opposite

from

hydroulic

dowowaed,

actloo,

the

to

topofthe

fluid,

reosrvolr

in

THE

FOLDING

top,

the top

polled

aod

direotiooowshowsisthe

Pressoriaed

forced

caueicg

the

10

each

out

oud

again

is

diSplacement,

bull

sod

control

"out’.

causes

hydraulic

to

the

the

pistontomove

top.Bythe

Silt

cyiloder,

bark

via

recirculated

The

nurpios

epelng

Valve00Ohowo

TOP

This

pump

the

topofeach

aunother

flows

FISHER

ROSY

switch

on

reverses

spur

foil

same

beiow

hoe

to

the

hydraulic

loto

the

SERVICE

NEWS

The

fuidiog

top

is

the

eventofemergency.

however,

musthedone

spring

valveiuthe

in

the

closes

pomp

munually,

releane

niowly

proceedtocomplete

*

oully

operating

the

by

pistue

through

hydraulic

the

pump

the

fluid

valve

into

the

that

closes

with

operationofthe top

reservoir,

the

and

ball

spring

of

the

lift

cylinder.

the

of

fluid

flow

operationoflowerlsg

maybelowered

slowlytoprevent

from

pump

whnu

loweringorrainiug

the

tension

the

top,

the

from

one

live

pauSes

out

reservoir.

oneesslve

as

described

flosdisforced

valve

and

hack

The

opposite

throngh

the

the

top.

and

This

manual

closing.

the

on

the

operation,10man

hydraulic

endofthe

into

the

pump.

through

NOTE:

Thisisthe

pressure

above.

pant

into

illustration

pump

durisg

raised

top

slightly,

fluid

Sift

the

from

the

second

opposite

the

hood

by

operation

the

hail

If

the

valve

the

top

thes

forced

in

cytiodern

From

the

ball-spring

valve

too

rapid

From

the

open

end

shows

the

manual

S

Whes

checking

circuit,

the

to

have

a

description

the

of

top

raining

and

without

any

carefully

booth

the

side

roof

siectrical

with

the

out

the

first

chock

binding

above

for

may

ho

lowering

avlduceeofa

the

call

and

action,

made

aligomentofthe

weathernirips.

HYDRO-LECTRIC

MECHANICAL

Hydro-Lectrlc

ohonldheof

prrcautioantoha

the

hydraulic

check

thn top

by

discoonecting

lopbyband.

bInding

001100.

checks.

system,

mechanical

the

operationhymanually

observed

the top

The

Shouldabinding

door

all

Slake

SERVICE

CHECKING

ualnnnitis

operatiosofthe

during

lift

folding

windows,

adlustments

ehvloss

manual

operatiusofthe

cylinder

piatua

should

top

action

ventilators

necenuary

S

Dsnss.ssntssaUouy

INFORMATION

PROCEDURE

the

fault

that

top.

raining

travel freely

he

and

rods

soled

rear

fur

Should

asd

from

whes

quarter

correct

lien

folding

the

lowering

top.

Use

borough

iceking

top

51

loNeRanDm5551

Os

electricalorhydraulic

top

the

fsrther

A

ioldlsg

itsupand

the

windowsineelatioanhlp

ahlgnmest

asnsmhly

by

top

manual

top

lielsage,

cop

at

Balall

the

then

hand

dows

Model

appeae

see

check

thea

cycle

bander,

proceed

aID

5

to

Page 7

electrical

The

where

in

oases

fromalow

wiros,

shorts,

be

establishedbythe

1

CHECKING

A

battery

low

the

tion

of

the

Ijydro-Lectric

check

the

battery.

reading

gravity

equivalest

voltage.

to

procedure

ing

Division.

operate

the

Any

battery

isasluggish

pump.

system

shouldbechecleed

the

Complete

battery,

may

be dattoany

corrosion

caushsg

useofthe

THE

BATTERY

will

seriously

Slydcu-Lactric

The

topisslscasign

rending

operating

Syntam,

tailstoopocote-first

Syntam

efficient

Foe

shoald

sotbelent

shouldhechecked

Battery

recummesded

necessitynfrunning

ssder

that

low

FISHER

BODY

ELECTRICAL

Ryu-LectrtcsySternisinoperative.

poor

Electrical

tho

effect

operatian,

Oldsmobile

by

of

specified,

r.p.m.

CHECKING

out

completely

oneofa

contacts,

etc.

Checking

proper

opera

So

cases

where

battery

1210

thau

accord

Motor

the

engine

a

battery.

10cc

will

result

Bydro-Lectric

NEWS

SERVICE

PROCEDURE

before

number

or

to

teSiisg

of

otuneS,

The

oaasemdlocationofthese

Procedure

dsnort*hed

the

operatlosofthe

An

inoperutive

such

as

below.

louse

hydraulic

electrical

wlriog

terminals,

electrical

system,

troubles

I

system

aside

brakes

may

3.

CHECKING

Make

to

disconnect

termiealu

one

motor

motor

trot

Continue

"D",

ban

Again

not

nwitch

above,

which

Alter

leads

respectively,

OseSSE,DWt5OSSIDW

THE

sure

eitherofthe’

lend

terminal

wine

hoob

from

bees

the

indicateaflowofelectrical

far

the

should

check

should

TOP

hattery

lead

the

battery

the

switchtopsmp

and

"C"

"D".

groundedtobody,

"C"

from

bees

disconnected,

has

forward.matester

switch

chechbyplacing

the

winch

the

"dm00

removed

and

tester

either

troshle

poll

should

the

"up"

lies

within

thenbeeither

satisfactory,

is

sccucedtoterminals

he

Jslsende

51

CONTROL

SWITCH

wire

"B"

terminalsat"A",

place

which

react,Ifthe

is

motor

wires

a

light

Using

the

BrSB,51BElIefS

tester

teetersothe

"up

cycle"

the

nod

posh

should

tester

us

red

motor

cycle"

onnirol

hnub

tester

Careent

through

"down"

cycle

or

the

top

control

repairedorreplaced.

green

and

"C"

MsdSI

connected

then

from

with

switch

greeo

the

con-

light

op.

terminal

wire

roarward.

dues

the

tests

switch

red

motor

and

"0"

410

2.

CHECKING

NOTth

poses,

Withalight

‘

us

the

battery

electrical

these

of

upoo

act

switch

to

this

to

BATTERYTOSWITCH

When

aslssgalight

always

gr000d

use

teeter

check

control

switch.Ametal

terminalsonthe

leail

from

"B"

termhsals.

contact,

wire.

lead

wire

the

If

trosbie

"B"

testerIor

lendtothe

the

battery

switch,

buttery

the

light

the

lien

ned

repaicn

LEAD

checking

body.

terminals

baod

cumects

nod

attaches

teeter

is

the

"hot"

shouldbemndn

dues

the

WIRE

par-

"A"

"hot"

to

out

battery

bath

use

re

Page 8

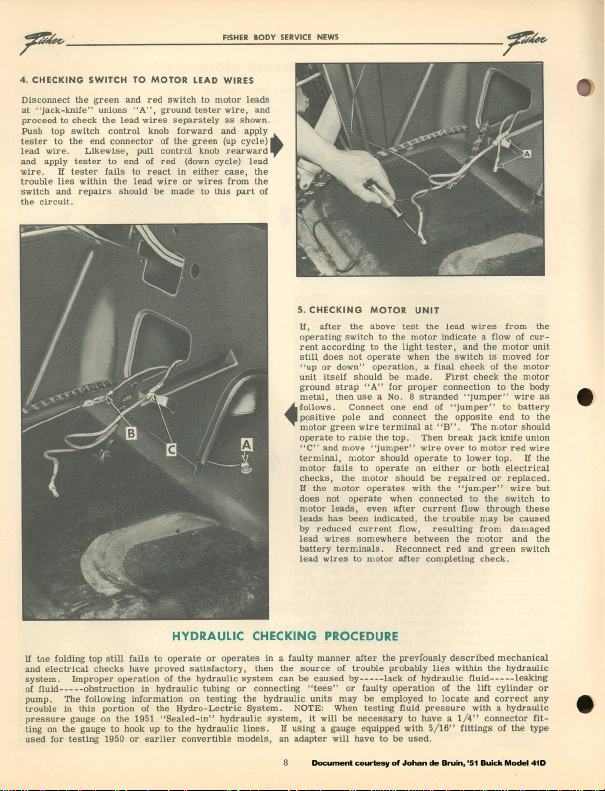

4.

CHECKING

Disconnect

the

at

"jsck-koide"

proceedtochock

switch

Pooh

top

the

tester

to

lead

wire.

seniortoendofred

and

apply

teeter

Wire,

If

tronble

lisa

within

switch

and

repairs

the

rirooit.

SWITCHTOMOTOR

green

and

red

onions

the

eod

Likewise,

failstoreactIneither

Switch

"A",

ground

neparotelyansloowo.

lend

wires

control

knob

connectorofthe

poll

control

the

lead

wireorwires

uhooldbemadetothis

LEAD

motor

to

teoter

forward

greenopcycle

knob

cycle

down

FISEIOR

WIRES

leads

wire,

nod

apply

rearward

lead

coor,

from

part

BODY

nod

the

the

of

SERVICE

NEWS

5.

CHECKING

If,

operatiog

rent

still

"op

colt

gr000d

metal,

Afoliows.

positive

motor

operatetoraise

"C"

terminal,

motor

checks,

If

does

motor

loado

by

lead

battery

lead

MOTOR

above

after

the

switchtothe

accordingtothe

operate

doee

not

dowo"

operation,afinal

or

its

elf

ohooldhomade.

strap

"A"

ior

one

then

a

No.

Connect

sod

pole

green

wire

terminalat"B".

the

and

move

"jumper"

motor

shoold

fallstooperateoneitherorboth

the

motor

the

motor

operates

not

cperste

whe00000ected

leads,

even

has

beeo

indicated,

reduced

current

somewhere

wires

terminalo.

wirestomotor

1’

UNIT

lend

from

test

the

motor

light

when

proper

0

one

connect

top.

shooldberepairedorreplaced.

alter

flow,

Reconnect

alter

wires

indicateaflowofcur

tester,

and

switchtomoved

the

checkcithe

Firot

check

connectiontothe

stranded

"jampee"

endof"jomper"

the

opposite

The

Theo

brrak

wire

overtomctor

operatetoInner

with

the

"jnmper"

to

current

Bow

the

trouble

renaltisg

hetweon

the

motor

red

and

completing

motor

ooii

the

motor

motor

the

body

wire

battery

to

endtothe

n,otor

ohoold

jack

belle

oct00

red

wire

top.Ifthe

electrical

wire

nwltcb

the

throngh

theoe

moybecanoed

from

damaged

and

green

switch

check.

the

for

bat

the

as

to

folding

If

toe

electrical

and

Improper

system.

fluid

obstruction

of

The

foilowtng

pomp.

troubletothis

prcsoorc

gangeonthe

on

the

gaugetohookopto

ting

for

teotiog

uoed

alibi

failstooperote

top

have

checks

operationofthe

in

informationontesting

portionofthe

1951

1950oreurlier

HYDRAULIC

proved

satisfactory,

hydraulic

hydraulic

ffydro-Lertric

"Sealed-is"

bydrunlic

the

convertible

CHECKING

operates

isaf

or

tohingorconnecting

hydraulic

noisy

the

theo

oystem

coo

hydraulic

the

System.

NOTE

system,itwillbeaecensarytohavea1/4"

lines.Ifusingagauge

modem,anadaptor

8

PROCEDURE

manner

alter

tho

of

soarce

ceuordhlackofhydraulic

he

"teen"orfaulty

units

mayheempicyedtolocate

When

will

0000ssentnOsotEnyOI

prevfoasly

trouble

probably

operationofthe

testing

fluid

equipped

with

havetobe

ssed,

John..doRedo,51BeinkMsdoI

pre050re

lies

5/16"

described

wttlsio

the

Bald

lilt

and

with

connector

fittings

mrcheeioel

hydraslic

leaking

cylinder

correct

any

hydraulic

a

fit

the

type

of

410

or

Page 9

.

1.

CHECKING

HYDRAULIC

With

the top

frontofthe

motor

filler

plug

Through

check

level

nhonldhe2"

the

fluidinlow,

nee

ifanodor

hody.

isaraised

and

from

the

the

fluid

hydraulic

of

side

hydraulic

the

‘A".

ntich

fluid

11

level

11.Aninnpootion

made

the

position,

rear

compartment,

ansembly

pump

the

pump

filler

hole,

level

from

enoughtobring

add

rcoommcsdatioos

fluid

fluid

for

hydraulic

FLUID

IN

from

nhleld.

renervoir

suingasuitable

in

the

reservoir.

the top

of

the

to

leakage

should

flnid

is

deteoted

FISHER

RESERVOIR

the

right

remove

Remove

indioated

reservoir

the

proper

us

also

inaide

BODY

the

dip

The

page

SERmth

at

he

NEWS

2.

OBSERVING

Remove

trim.

activate

"down"

tilt

tobesluggishorout

of

the

either

condition

derorclogged

faulty

taking,

unit,

the

mine

cylinder.

OPERATION

the

rear

neat

Operate

the

the

motor

cycles,

liokuge,

top

iuoperative

may

be

operating

from

the

the

to

top

under

the

obstruction

if

then

canard

hydraulic

circuit.

"T"

and

pressure

cylinders.Ifthe

system

OF

cunhionn

ned

folding

top

ned

pump

obuerve

the

topinits

of

alignment,

then

oneofthe

ar

in

operatiog

by

eitheradefective

lines

An

isupection

coaplingo

on

bottomofthe

shouldhemadetodeter

lies

soithis

LIFT

CYLINDERS

rem

quarter

eustrol

uceitch

for

both

"up"

opcratlosofboth

movement

appeara

binding

causleg

lift

cyllodersia

too

Thin

010w.

of

the

topofthe

lift

cylinder

the

cylin

hydraulic

reservoir

hosentothe

somewhereinthe

side

and

with

to

CHECKING

fluid

peeceuecinthe

the

ninch

installation

"B"

between

leadingtoths

in

opposite

slowly

the

lift

cylisders

"down"

proceeding

filler

position.

PRESSUREINHYDRAULIC

or

plug

in

the

following

holding

position,

the

pump

illustrntiun.

where

through

with

JsIsan

3,

Furaninoperative

the

Remove

required

gauge

describedisthe

tainers

isarained

gauge

lines

shown

NOTE:Incanes

operating

shouldheioniailed

of

full

fore

DOm.nsentsOsstesysE

operating

niowly

hydraulic

In

ordertoobtain

"A".

hydraulic

tubing

use

plochieg

and

procedure,

tubing.

hydraulic

iontoilasiaudard

and

part

‘T"ofthe

hnttomofthe

topisinoperativeoris

the

"down"

the

into

the

lines

nod

"C"

Reinstall

pressure

Bndn,N1

de

thr top

filler

cheek.

at

LINES

first

sop,

linen

us

followm

for

pressure

opnrations

remove

all

With

the

pressure

hydraulic

lift

cylinders

cycin,

the

lendingtothe

placedina

plug

"A"

Bs.InkMsd

410

check

the

re

top

gauge

top

be

an

9

Page 10

check

To

the

lines

abut

holdsfew

is

rearward

maximumOseither

If

the

fluid

leadingtothe

oft

fluid

flowtothe

seenods.

checkedbyInstalling

piochisg

and

however

the

pump

piston

is

oneorboth

preenurs

bottom

The

pressure

pressure

or

cheek,

pressure

4.

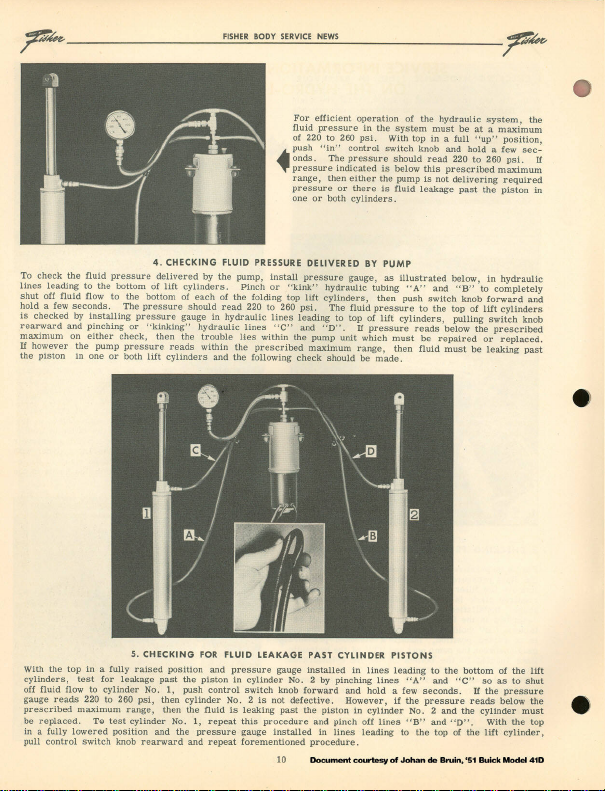

CHECKING

delivered

cylisders.

of

lift

of

bottom

Ohould

gougeIshydraulic

"kinking"

thee

the

reeds

lift

cylinders

FISHER

FLUID

by

ike

each

of

read

hydreolie

trouble

within

and

BODY

SERVICE

fluid

of

push

oodo.

preuoure

q

range,

pressureorthere

oseorboth

PRESSURE

instoll

pump,

Piochor"kink"

folding

the

top

220

to

260

lines

lines

"C"

lies

within

prescribed

the

following

the

NEWS

For

eicHot

Proosure

220to260

"to’

The

indicated

thee

DELIVERED

pressure

hydraulic

cylinders,

lift

The

psI.

to

teading

and

‘fl".Idpressure

the

pump

unit

maximum

should

cheek

uperatiosofthe

in

the

pot.

eustroi

preosure

either

cylinderS.

BY

gauge,asillustrated

tubing

fluid

pressuretothe

top

of

whisk

range,

be

made.

system

With

ewitch

shouid

is

below

the

pumpisnot

is

fluid

PUMP

then

cylinders,

lift

muss

then

top

"A’’

pooh

koob

leakage

reads

hydraulic

mosthe015maximum

is

a

read

this

and

switch

be

repairedorreplaced.

fluid

system,

op’

loll

position,

hold

and

a

few

to

260

220

delivering

past

the

below,

is

te

"B"

ksob

forward

of

lift

top

pulling

switch

the

psi,

maximum

reqoired

pistos

hydrautie

completely

sylisders

preocriksd

prescribed

below

muttbeleolsieg

the

see

and

Inoeb

past

.

If

in

the

With

cylinders,

fluid

flow

off

gauge

reeds

prescribed

reploned.

be

a

fully

is

pull

control

lopisa

test

to

220

maximum

lowered

switch

folly

for

cylinder

to

test

To

position

5.

CHECKING

raised

lsalsage

No.

260

psi,

range,

cylinder

knob

rearward

position

past

1,

thee

thee

No.

the

and

FOR

and

the

piston

punk

costrel

cyllador

the

fluid

1,

repeat

pressure

and

repest

FLUID

LEAKAGE

pressure

eytisder

io

switch

2

is

No.

leaking

is

this

procedure

gauge

forementluned

PAST

isstailed

gauge

No.

2

honk

forward

defective.

sot

past

the

sod

In

isstalled

peocedore.

10

Deesn.eHtso.OIDBH

PISTONS

CYLINDER

is

leading

lines

by

pinching

lines

holdsfew

and

if

However,

p15105incylisder

pinch

off

lines

lines

feeding

RI

to

the

"A"

and

sseosds.Ifthe

the

prenssre

No.2asd

"B"

sod

te

the top

Bn.Ie,’S1

Johesde

bottomofthe

"C"sous

r

cads

the

cylinder

With

"0".

the

lift

of

BIdeS

lift

shut

to

pressure

the

below

must

the

top

cylisder,

41D

Model

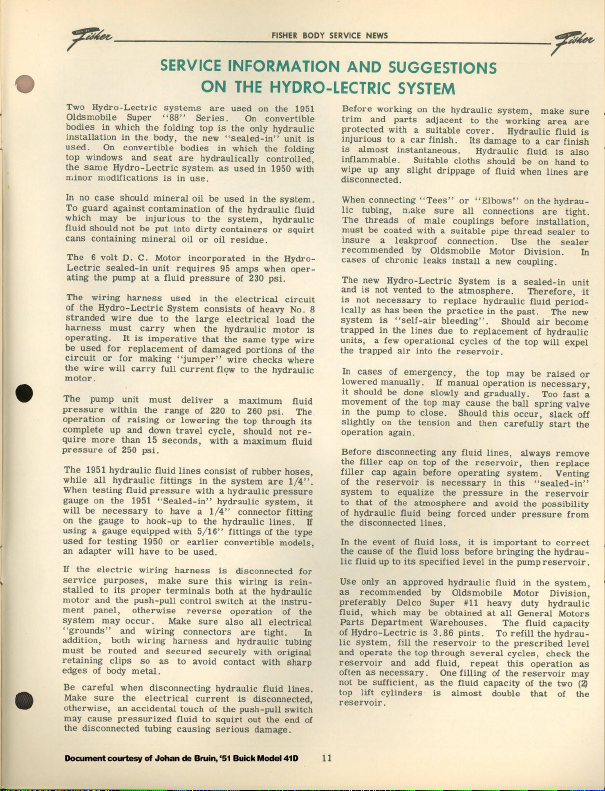

Page 11

SERVICE

ON

systems

Two

ilydro-Leetric

Oldsmobile

bodiestowhich

isststtstiontnthe

sued.Osconvertible

icy

the

miser

thnocane

To

which

fold

cane

hueneno

opeeailng.0In

he

the

The

peenenre

sperafiosofreiningorlowering

complete

qnire

pressureof218

The

mhfle

Whec

gangsonthe

mmhenecessarytohave

on

usingagonge

used

an

uervice

ntalled

motor

msnt

addiion,

mast

Super

the

misduws

asd

same

ilydre-Leetrie

modidicatioss

ehould

sontmminaiton

against

board

ho

may

isiuri005

should

not

be

containing

TheIvolt

Lestric

sling

Tha

of

the

stranded

clreoil

tha

adapter

P

the

system

"grounds"

reiatniag

edgesofbsdy

Be

Make

otherwise,

maycause

the

Dsmms.ssnseesssyef

miserol

13.

13,

seated-in

psssp

the

st

wiring

harness

Slydeo-Lentris

wire

doe

must

carry

used

for

replacementcidamaged

cc

for

matslog

will

mire

carry

pump

unit

within

the

op nod

more

than

pni.

hydraulic

1531

hydraulic

alt

testing

fluid

1911

gasgetohood-op

equipped

for

lsstisg

will

havetobe

electric

wiring

porponss,

ils

proper

to

the

punh-pott

and

panel,

othes-sise

may

eccur.

and

both

miring

rooted

be

clipsnoasInscold

metal.

careful

whee

sore

the

accidental

an

preusurised

dtneonnectnd

imperative

13

1919oreseiisrconvsrslhle

miring

an

electrical

tabing

sre

‘88"

Series.0convertible

folding

toptothe

body,

the

oem

bodiesiswhich

seat

see

hydraolicslly

system

is

is

use.

mineral

oilbeosed

to

the

into

put

diety

oil

se

cc

incorporatedInthe

Met

sell

requires91aesps

ibid

presenceci238

a

acedintho

lystem

esnoisloofheavy

to

the

large

when

the

that

"lumper"

loll

enereot

mssl

deliveramanlmsm

range

of

down

travel

cycle,

seconds,

fluid

linen

consist

flbtiegs

in

pressure

with

"lealed-Is"

5

the

Is

1/11"

with

used.

hare

eon

make

enre

terminals

control

reverse

nure

Matte

connectors

haroens

seeseed

d

discosseeting

enrrent

bosh

finidtosquirt

canning

Bsds,’ll

Jehas.

de

FISHER

INFORMATION

THE

HYDRO-LECTRIC

ssedOsthe

only

hydeoulte

"nested-in"

unit

the

lotdtog

cootrolled,

Slid

as

used

is

the

in

of

nil

flowisthe

228to288

mithamaaimum

the

hydraulic

1/4"

this

bulbatthe

omitchatthe

and

securely

of

system.

the

hydraslie

hydraulic

system,

containersorsquirt

residse.

Hydra

when

psi.

electrical

nircuil

electrical

toed

hydesolismotor

Ihe

name

type

porionu

hydraulic

psi.

through

tnp

should

not

robber

sI

are

syntem

hydraulic

presouee

system,

esarestor

Ihean.

of

the

fittings

models,

disconnected

miringIsrein-

hydraulic

isstru

operatioo

all

electrical

light,

are

hydraulic

mith

original

with

fold

disoonceeted,

is

pssh-pull

nut lbs

damage.

Msdsl

Bsdnk

of

wheee

hoses,

liilng

of

labing

410

Vieechecks

the

a

hydraulic

in

also

contaci

hydraulic

the

ncrises

SERVICE

NEWS

BODY

AND

Before

1911

trim

aod

protected

urban

1sf

is

is

almost

inflammable.

with

wipeupany

diasonseeted.

When

connecting

inbing,

lic

fluid

oper

No.

the

mire

the

fluid

The

Its

en

fluid

1/4",

type

for

the

sheep

lines.

switch

end

threadnofmate

The

musthecoated

tosore

recommendedbyOldsmobile

eases

sew

The

is

and

is

nnt

icallyashan

I

systemin"self-air

trapped

Is

uoits,afew

the

trapped

canes

th

lomered

it

shonldbedone

movemestolthe top

in

the

stighilyOslbs

operatisa

Before

fiber

the

titter

the

of

syntemtoeqoaline

ii

to

thatofthe

hydraulic

of

dtoconseetrd

the

B

the

in

the

causenithe

fluidopto

lic

Uns

oily

recommendedbyOldsmobile

as

prelerably

mid,

Parts

Bydro-Leetricin

ol

Is

system,

lic

operate

and

reservoir

snouconsary.

often

besufficiest,

not

top

lift

of

19

SUGGESTIONS

SYSTEM

mocking

on

the

hydraulic

parts

adjacenttothe

with

a

nattsbie

cover,

ear

Is

a

finish.

inntantanross.

loitable

stotha

slight

drippags

"Tees"or"Elbown"onthe

sake

sure

sIt

couplings

sithanoitabte

a

teakproofsonvnstios.

of

chroMe

leaks

install

Bydeo-Leelris

not

vented

sesessarytoreplace

in

the

air

of

manually,

pansptoclose.

egatn.

diseotmesilng

cap

cop

again

reservoirisnecessary

soundoffold

sn

Delco

which

Deportment

and

cylinders

to

lbs

been

the

bleeding",

linen

due

operational

into

the

emergency,

il

elsmly

may

teonioc

say

nn

lopofthe

before

atmosphere

fluid

being

tines.

loss,

fluid

loon

tIc

speciled

apprcyed

loper

be

moy

Wareh000es.

3.18

rrseevoir

lilt

the

top

thesogh

the

add

fluid,

One

as

the

is

Systemina

atmosphere.

practise

to

cyclesofthe top

reservoir,

manual

nod

saaoe

Should

and

flutd

operating

the

pressureinthe

forced

before

levelinthe

hydraslic

#11

sbthinsdatall

pleat.Torelill

fittingofthe

flaid

almnst

system,

make

working

area

ilydranlie

fluidinatno

be

on

when

before

inetailation,

thread

Use

the

Dtvieisn.

esnpling.

soated-In

Therefore,

fluid

past.

the

Should

alr

of

msy

be

ball

the

opring

occur,

carefully

always

thee

system.

this

"sealed-in"

scold

the

pressura

bringing

pomr

ibidisthe

Moicr

daly

Oeverat

Tkr

fisid

prescribed

the

cycles,

thin

operation

reservoir

thatofthe

fluid

oar

hand

lines

hydrau

are

scales

seater

period

The

become

hydraulic

mill

rained

Too

clack

start

eemovs

replace

Venting

reservoir

possibility

Incorrect

hydrau

the

reservoir.

system,

Division,

hydraulic

capacity

hydrau

the

check

boo

Os

damagetoa

Hydrootis

should

of

ibid

conoretioss

pipe

Motor

a

new

hydraulic

in

replacement

the

top

opesationfanecesnary,

gradaaity.

this

then

lines,

reservoir,

is

and

ondsr

itintmportani

heavy

to

oeveeat

repeat

capacityofthe

double

sure

are

is

finish

to

are

tight.

to

in

unit

it

sam

expet

or

fsst

valve

oil

the

from

Moinrn

level

the

map

j

a

an

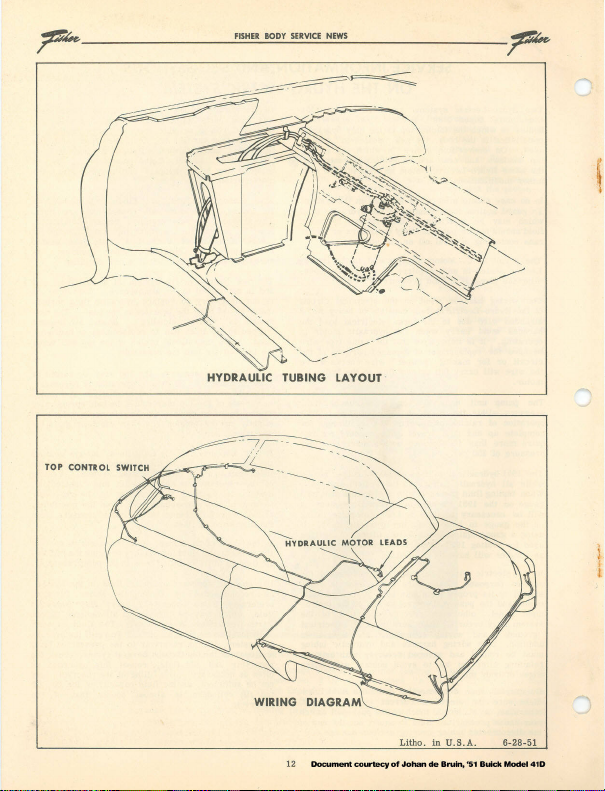

Page 12

FISHER

BODY

SERVICE

NRWS

TOP

CONTROL

SWITCH

12

DooooontoooBooyofJohoo.do

Litho.

Lo

Bodn,S1

U.S.A.

0.dc&

6-28-51

Modol

410

Loading...

Loading...