OperatingManual

PELLETRONIC

TOUCH

TOUCHV2.00

ENGLISH

Europe’sspecialistinpelletheating

E1389EN2.0

Title:

OperatingmanualPelletronicTouch

Articlenumber:E1389EN2.0

Version:2.0

Versionvalidfrom:05/2013

Approved:

HumbergerStephan

Author:

ÖkoFENForschungs-undEntwicklungsgesmbH

Technicaleditorialdepartment

Gewerbepark1

A-4133Niederkappel

AUSTRIA

Tel.:0043(0)7286/7450

Fax:0043(0)7286/7450/10

oekofen@pelletsheizung.at

www.oekofen.com

©byÖkoFENForschungs-undEntwicklungsgesmbH

Subjecttomodications

Contents

1DearCustomer.................................................................................................................................................5

2Useonlyforthepurposeintended...................................................................................................................6

3Typesofsafetywarningsign............................................................................................................................7

4Pelletronicheatingcontrollerandoperatingdevicewithtouchscreen............................................................8

4.1OperatingDevicewithT ouchscreen.................................................................................................................8

4.2Openingwindow............................................................................................................................................8

4.3Chimneysweep...............................................................................................................................................9

4.4Usercontrolsandtheirfunction..................................................................................................................10

4.5MainMenu....................................................................................................................................................12

5Mode...............................................................................................................................................................13

6MeasuringValues...........................................................................................................................................14

7HeatingCircuit................................................................................................................................................16

7.1MeasuringvaluesHeatingcircuit....................................................................................................................17

7.2TimeprogrammeHeatingcircuit.....................................................................................................................17

7.3Party.............................................................................................................................................................19

7.4Vacation........................................................................................................................................................19

7.5HeatingcurveandHeatinglimits.....................................................................................................................20

7.6Screedprogramme........................................................................................................................................24

8Domestichotwater(DHW).............................................................................................................................25

8.1MeasuringvaluesDomestichotwater.............................................................................................................26

8.2TimeprogrammeDHW..................................................................................................................................26

9DHWReturnpump..........................................................................................................................................27

9.1MeasuringvaluesDHWReturnpump.............................................................................................................27

9.2TimeprogrammeDHWreturnpump...............................................................................................................28

10Solar.............................................................................................................................................................29

10.1MeasuringvaluesSolar................................................................................................................................29

10.2Solarcircuit.................................................................................................................................................30

10.3Yield-SolarEnergy....................................................................................................................................31

11Pellematic.....................................................................................................................................................32

11.1Permanentoperation....................................................................................................................................32

11.2MeasuringvaluesPellematic.........................................................................................................................33

11.3FullPower...................................................................................................................................................34

11.4De-ashingsystem........................................................................................................................................34

11.5FreshWaterModule.....................................................................................................................................35

11.6BoilerCleaning............................................................................................................................................35

11.7SuctionSystem............................................................................................................................................36

11.8Leveldetectionsystem.................................................................................................................................37

12HeatMainPump............................................................................................................................................38

13General.........................................................................................................................................................39

13.1Favorite1and2...........................................................................................................................................39

13.2LocalSettings..............................................................................................................................................40

13.3Malfunction..................................................................................................................................................41

13.4Information..................................................................................................................................................41

14Software.......................................................................................................................................................42

15CodeInput....................................................................................................................................................43

16Startup.........................................................................................................................................................44

17Descriptionoftheheatingcontrollermodule...............................................................................................45

17.1Settingtheaddressattheheatingcontroller..................................................................................................46

17.2Settingtheaddressattheburnercontroller....................................................................................................47

17.3SettingtheaddressattheboilercontrollerCMP.............................................................................................48

17.4Assemblyordisassemblyofthepowersupply...............................................................................................49

17.5Assemblyanddisassemblyoftheheatingcontrollerboard.............................................................................50

18DescriptionoftheOperatingdevicemodule................................................................................................51

18.1ReplacingaTouchoperatingdevice..............................................................................................................51

19Software.......................................................................................................................................................52

E1389EN2.0

OperatingmanualPelletronicT ouch

Contents

19.1Conguration...............................................................................................................................................52

19.2ActivatingthefunctionRoomthermostat........................................................................................................52

19.3UpdateHeatingController,TouchOperatingdeviceandRemoteControl.........................................................53

19.4SoftwareUpdate..........................................................................................................................................53

20PeripheryLearning.......................................................................................................................................54

21Heatingcircuitssettings...............................................................................................................................55

22DHWsettings................................................................................................................................................57

23DHWReturnPumpsettings..........................................................................................................................59

24Solarsettings...............................................................................................................................................60

24.1SolarEnergysettings...................................................................................................................................63

25Accumulatorsettings...................................................................................................................................64

26SystemControlling.......................................................................................................................................66

26.1Cascadesettings.........................................................................................................................................68

26.2ExistingBoiler..............................................................................................................................................71

27Pellematicsettings.......................................................................................................................................73

27.1Measuringvalues.........................................................................................................................................73

27.2Ignitionsettings............................................................................................................................................73

27.3Fullpowersettings.......................................................................................................................................74

27.4RunOnTimesettings...................................................................................................................................75

27.5OutputSettings............................................................................................................................................76

27.6De-ashingsystemsettings............................................................................................................................76

27.7Boilercleaning.............................................................................................................................................77

27.8Washing......................................................................................................................................................78

27.9Settings.......................................................................................................................................................79

27.10BoilerControlledPump...............................................................................................................................80

27.11FRTController...........................................................................................................................................81

27.12NegativeDraft............................................................................................................................................82

28HeatingMainPump.......................................................................................................................................83

29Generalsettings...........................................................................................................................................84

29.1SensorAdjust..............................................................................................................................................84

29.2OutputT est..................................................................................................................................................85

29.3Factorysetting.............................................................................................................................................85

29.4USB............................................................................................................................................................86

30Appendix......................................................................................................................................................87

30.1Calibration...................................................................................................................................................87

30.2Connectionplan...........................................................................................................................................89

30.3Wiringdiagrams...........................................................................................................................................93

30.4CablespecicationPelletronicT ouch............................................................................................................95

30.5Hydraulicconnectingdiagrams.....................................................................................................................96

30.6Defaultvaluesandsettings.........................................................................................................................103

OperatingmanualPelletronicTouch

E1389EN2.0

DearCustomer

5

1DearCustomer

ÖkoFENisEurope’sleadingspecialistinpelletheating.

Prociency,innovationandqualitycombined.ThisisthetraditiononwhichÖkoFENshapesthefuture.

WeareverypleasedthatyoutoohavedecidedtopurchaseaproductfromÖkoFEN.

•Thisinstructionmanualisintendedtohelpyouoperatetheproductsafely,properlyandeconomically.

•Pleasereadthisinstructionmanualrightthroughandtakenoteofthesafetywarnings.

•Keepalldocumentationsuppliedwiththisunitinasafeplaceforfuturereference.

Pleasepassonthedocumentationtothenewuserifyoudecidetopartwiththeunitatalaterdate.

•Pleasecontactyourauthoriseddealerifyouhaveanyquestions.

ÖkoFENattachesgreatimportancetothedevelopmentofnewproducts.OurR&DDepartmentrepeatedlychallenges

theeffectivenessoftried-and-testedsystemsandworkscontinuouslyonimprovements.Inthisway ,wesecureour

technologicaladvantage.Wehavealreadyreceivedmanynationalandinternationalawardsforourproducts.

AllourproductscomplywithEuropeanstandardsinrespectofquality,efciencyandemissions.

E1389EN2.0

OperatingmanualPelletronicT ouch

Useonlyforthepurposeintended

6

2Useonlyforthepurposeintended

ThePellematicpelletheatingsystemisdesignedtoheatwaterforcentralorotherindirectheatingsystemsandhotwater

supplyforbuildings.ItisnotpermissibletousethePellematicpelletheatingsystemforanyotherpurpose.Reasonable

foreseeableinadvertentusesforthePellematicheatingsystemarenotknown.

ThePellematiccomplieswithallrelevantdirectives,guidelines,regulationsandstandardsaspartofthedeclarationof

conformitythatappliestothistypeofequipment.

EUguidelinesDesignation

2006/42/EGGuidelinesformachines

2006/95/EG

Lowvoltageguidelines

2001/95/EGProductsafetyguideline

2004/108/EGGuidelineforelectromagneticcompatibilityofcomponents(EMVG)

Thefollowingharmonisedstandardshavebeenapplied:

Standards

Designation

EN303–5BoilersPart5

EN14961–2

Pelletsfornon-industrialuse

ThefollowingAustrianstandards,guidelinesandspecicationshavebeenapplied:

Standards

Designation

TRVBH118

Technicaldirectiveonreprevention

OperatingmanualPelletronicTouch

E1389EN2.0

Typesofsafetywarningsign

7

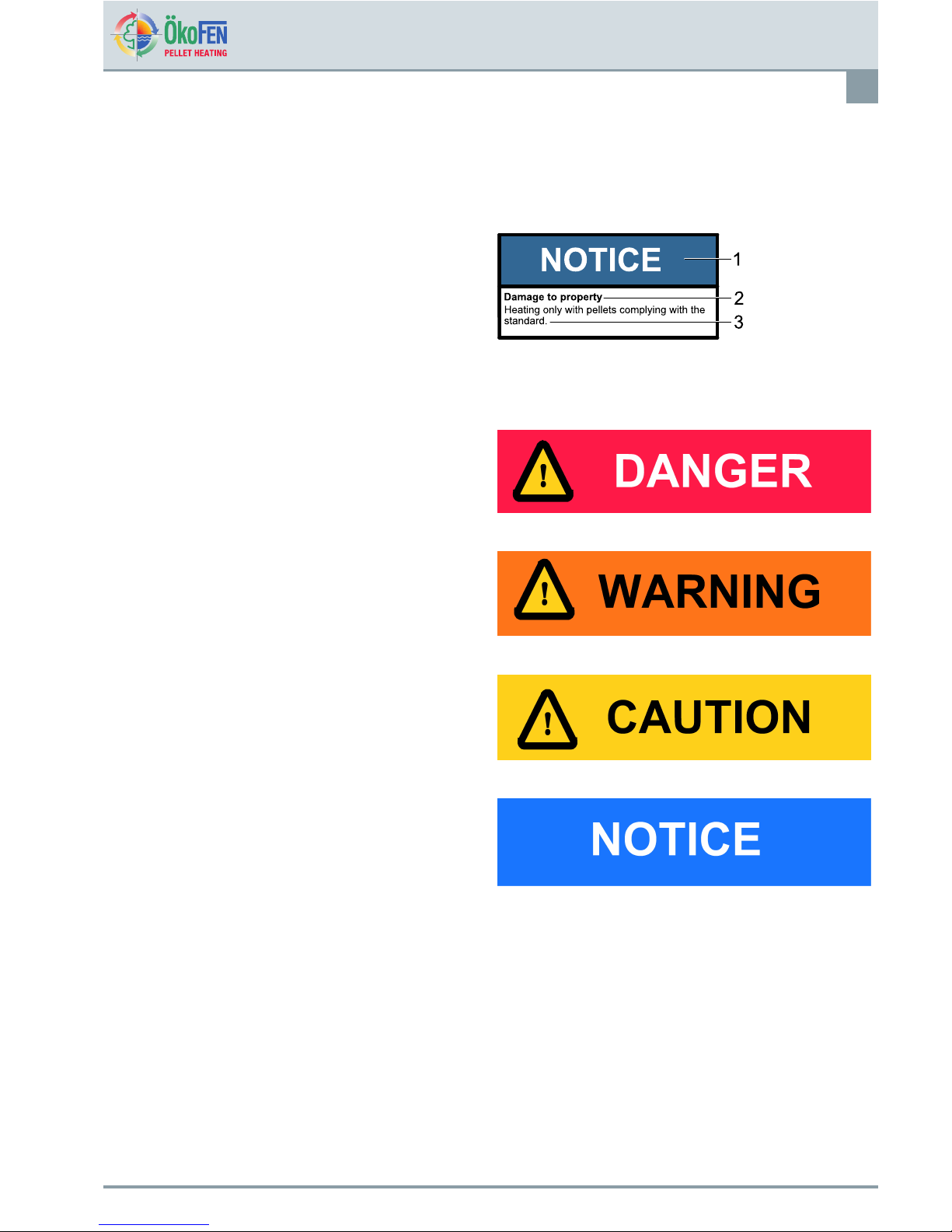

3Typesofsafetywarningsign

Thewarningsignsusethefollowingsymbolsandtext.

Typesofsafetywarningsign

1.Riskofinjury

2.Consequencesofrisk

3.Avoidingrisk

1.Riskofinjury:

Danger-indicatesasituationthatcouldleadtodeathor

life-threateninginjury.

Warning-indicatesasituationthatcouldlead

life-threateningorseriousinjury.

Caution-indicatesasituationthatcouldleadtoinjury.

Note-indicatesasituationthatcouldleadtoproperty

damage.

2.Consequencesofrisk

Effectsandconsequencesresultingfromincorrect

operation.

3.Avoidingrisk

Observingsafetyinstructionsensuresthattheheating

systemisoperatedsafely

E1389EN2.0

OperatingmanualPelletronicT ouch

Pelletronicheatingcontrollerandoperating

devicewithtouchscreen.

8

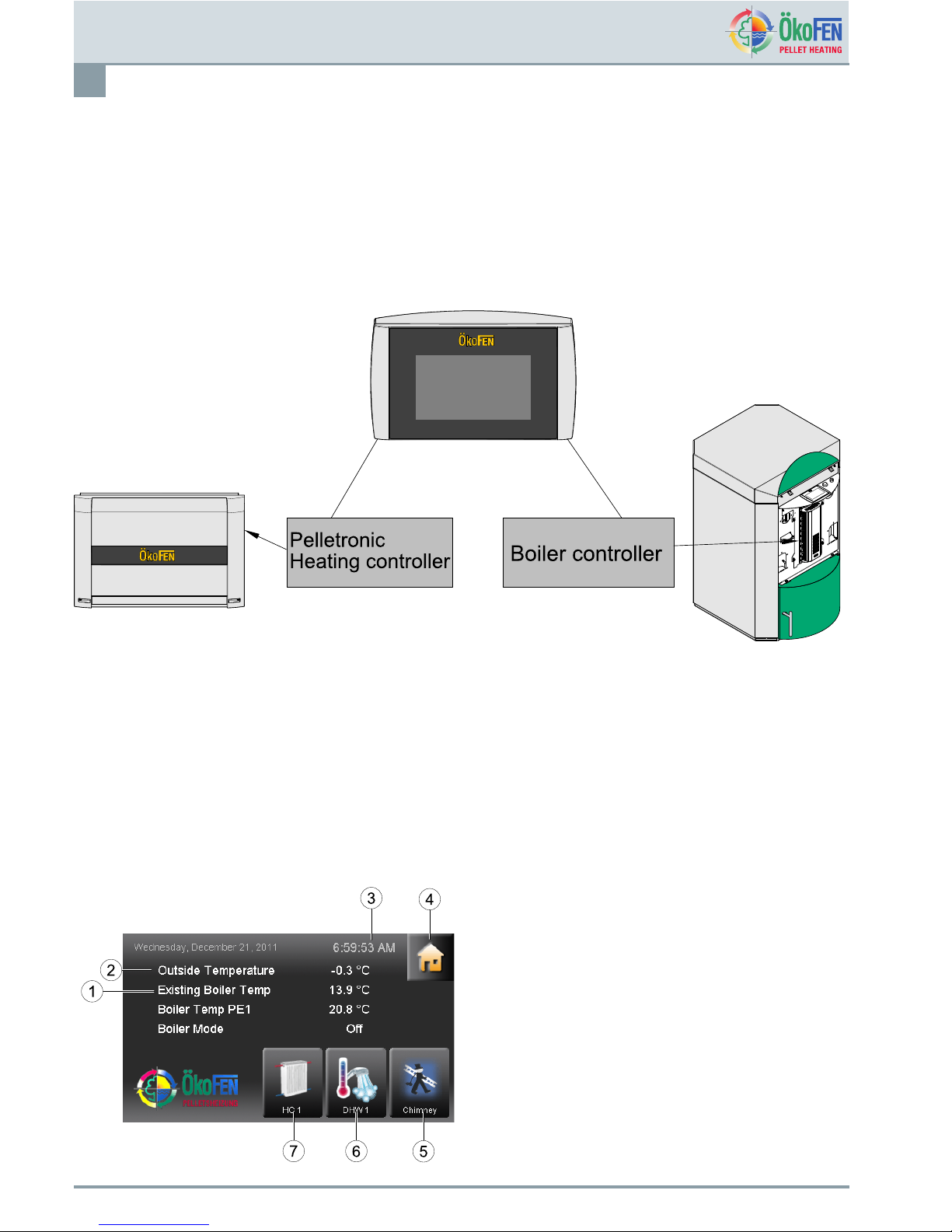

4Pelletronicheatingcontrollerandoperatingdevicewithtouch

screen.

Theheatingcontrollercontrolstheheatingsystemandregulatestheoperatingmodes,heatingcircuits,domestichot

water,accumulator,existingboilerandthesolarthermalsystem.Allinputsandoutputsareconnectedwiththeheating

controller.Visualisationandoperationoftheheatingcontrollerisdonewiththeoperatingdevicewithtouchscreen.It

displaysallmenuoptionsandmeasuringvaluesoftheheatingcontroller.Allspecicsettingsoftheheatingsystemis

donewiththeTouchoperatingdevice.

4.1OperatingDevicewithTouchscreen

TheTouchoperatingdeviceismountedonthecontrolboardofPellematic.The4.7"colordisplayissurroundedby

adesignfoilwithlogo.ApplyngerpressuretooperatetheT ouchscreen.

4.2Openingwindow

Thetouchpanelisdarkwheninstandbymode.Assoonasthesurfaceofthescreenistouched,itlightsupand

displaystheopeningwindow.

1Boilertemperature

2

Outsidetemperature

3Hour

4Theiconhousetakestothemainmenu.

5

Chimneysweep

6Favorite2

7

Favorite1

OperatingmanualPelletronicTouch

E1389EN2.0

Pelletronicheatingcontrollerandoperating

devicewithtouchscreen.

9

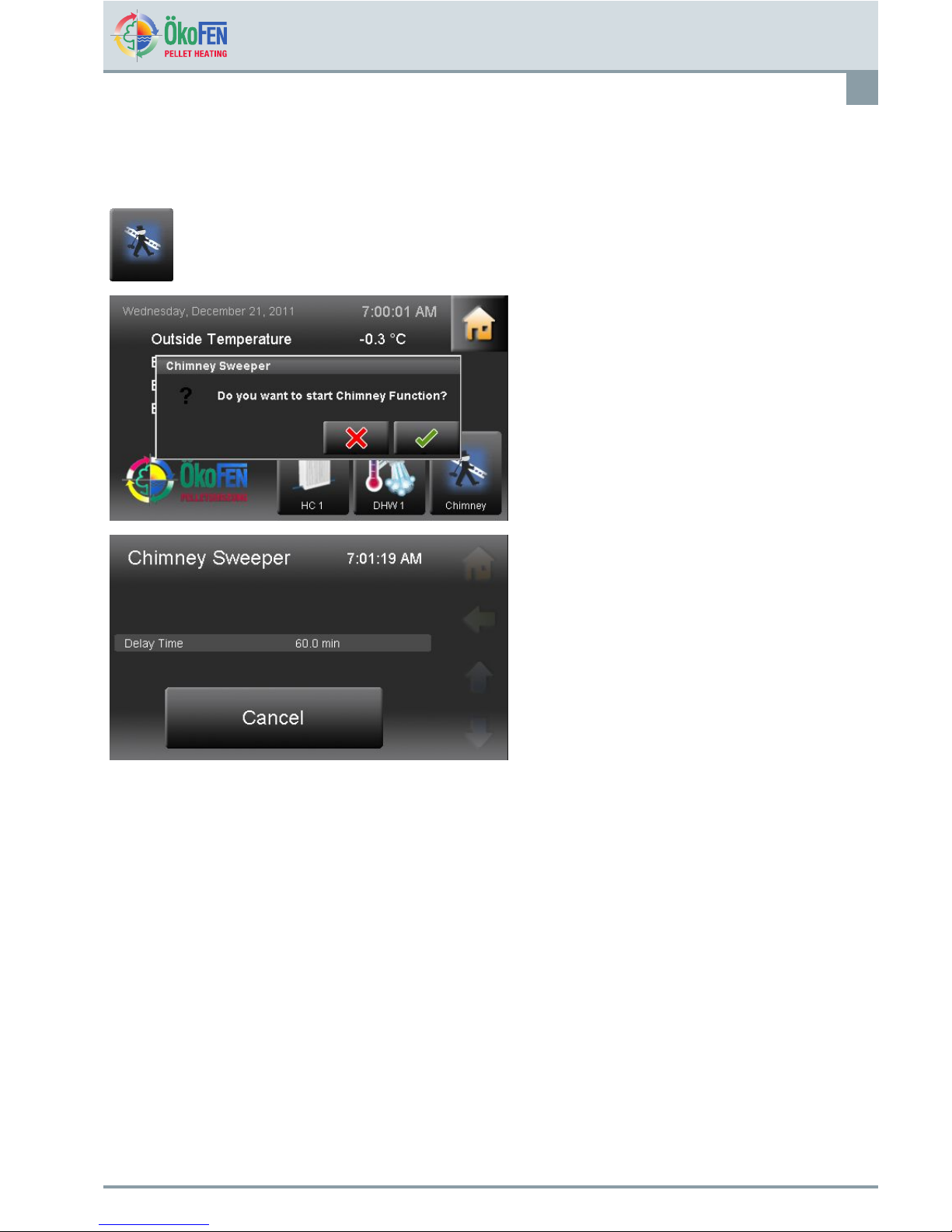

4.3Chimneysweep

ThefunctionChimneysweepisonlyforchimneysweeperorauthorisedservicetecnicians.Itisusedforexhaust

gasmeasurement.

MenuChimneysweepisintheopeningwindow.

Afterselectingthechimneysweepfunctionitwill

querywhethertoexecute.Ifyesthenpressthetick

box.

•Boilertemperaturesetis60°Cforthetotalrunning

timeof30minutes.

•Itdisplaystheactualboilertemperatureanddelay

time.

•ChimneysweepisstoppedwithCancel.

E1389EN2.0

OperatingmanualPelletronicT ouch

Pelletronicheatingcontrollerandoperating

devicewithtouchscreen.

10

4.4Usercontrolsandtheirfunction

1.Howtonavigatetotherightmenu

Navigation-icons

Iconview

chosen

Iconview

Ifyoutouchanicon,thaticonturnsgreen.Thisindicatesthattheitemisselectedand

enablesthatfunction.

Theyellowhomesymboltakesyoudirectlytothemainmenu.

Thehorizontalarrowtakesyouonestepback.

Withthebluedownarrowyougettoadditionallinesofinformationonthisitem.(Down

-scrolldown).

Withtheblueuparrowyougettoadditionallinesofinformationonthisitem.(Topof

page-scrollup)

Navigatetotherespectivemenuitem.

Oncetherespectiveitemhasbeenselectedthenparametersmaybeset.Itwilldisplay

eitheranumericortextkeypad.

2.Numerickeyboard

a.Nameofparameter

b.Valueofparameterwithunit

c.Min/maxvalue–Valuesoutsidethisrange

arenotaccepted.

d.Deleteinputofnumbers–touchonceto

deleteoneplace.

e.Cancel–Youreturntothemenuitem.Input

ofanewvaluewasnotaccepted.Theoriginal

valueisthenrestored.

f.Helpfunction–inactive

g.Conrm

h.Numerickeyboard–usedtoentervalues

withintheMin-Maxrange.

OperatingmanualPelletronicTouch

E1389EN2.0

Pelletronicheatingcontrollerandoperating

devicewithtouchscreen.

11

3.Timeanddateblock

a.Nameofparameter

b.Adjustabletimeordate

c.Cancel

d.Helpfunction–inactive

e.Conrm

WiththePlusMinusblockyouchangenumbers.

4.Textselection

a.Nameofparameter

b.Statustexts

Thenumberofstatustextsdependsonthe

parameter.

Chooseastatustext.Thesetupmenucloses

automaticallyandthechosenstatustextis

displayedinthemenu.

Note

Althoughascrolldownmenuisopen,thenavigation/parametericonsbehindarestillactiveandcanbeused.

E1389EN2.0

OperatingmanualPelletronicT ouch

Pelletronicheatingcontrollerandoperating

devicewithtouchscreen.

12

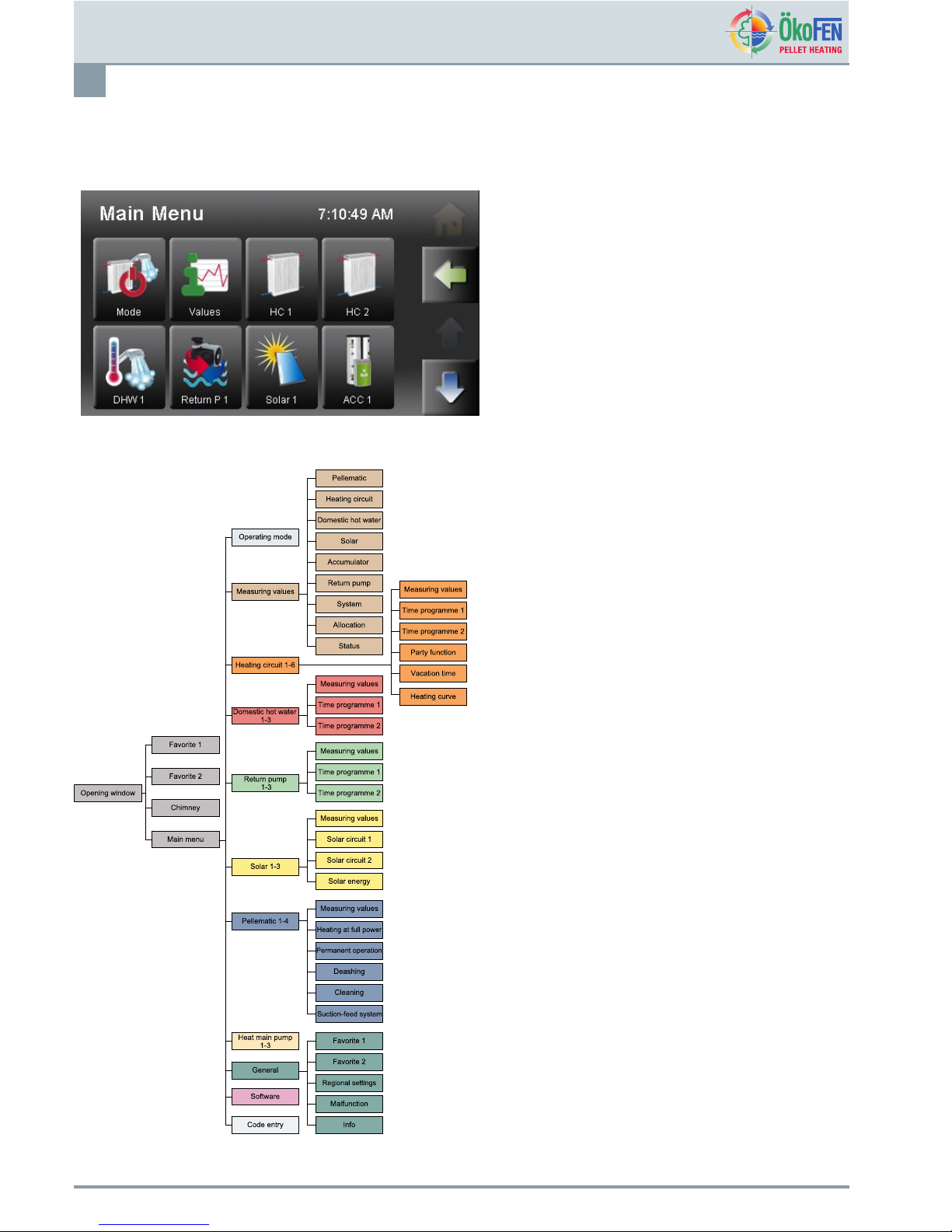

4.5MainMenu

Inthemainmenuallsubmenusaredisplayed.Presstheiconrequiredtoaccessthatprogramme.

MenunavigationofPelletronicTouch

OperatingmanualPelletronicTouch

E1389EN2.0

Mode

13

5Mode

InthemenuitemModesyoucanseetheoperatingmodeoftheheatingsystem,heatingcircuits,domestichotwater

andsolar.

ThemenuitemModeisintheMainmenu.

Overviewoftheoperatingmodes

•HeatingPlant

•Heatingsystem1-6.

•Domestichotwater1-3

•Solar1–3

Choosetheoperatingmodeandsetaccordingly.

OPERATINGMODESSYSTEM

OffTheadjustedoperatingmodeoftheheatingcircuitsandDHWisinactive.

Thefrostprotectionfunctionisactive.

Auto

TheadjustedoperatingmodeoftheheatingcircuitsandDHWisactive.

Thefrostprotectionfunctionisactive.

Domestichotwater

TheadjustedoperatingmodeoftheDHWisactive.

Theadjustedoperatingmodeoftheheatingcircuitsisactive.

Thefrostprotectionfunctionisactive.

Theoperatingmodeheatingcircuits,domestichotwaterandsolararedescribedintherespectivechapters.

E1389EN2.0

OperatingmanualPelletronicT ouch

MeasuringValues

14

6MeasuringValues

InthemenuitemV aluesyoucanviewcurrentsettingsorsetnewvaluesfortheheatingcircuit,domestichotwater,

accumulatororsolar.

ThemenuitemMeasuringValuesisintheMain

menu.

Selecttheappropriatesubmenu.

InthemenuitemHeatingcircuityouseeallactual

andsetvaluesoftheheatingcircuitsinyourheating

system.

InthemenuitemDomestichotwateryouseeall

actualandsetvaluesoftheDHWproduction.

InthemenuitemSolaryouseeallactualandset

valuesofthesolarthermalsystem.

InthemenuitemAccumulatoryouseeallactualand

setvaluesoftheaccumulator.

InthemenuitemSystemyouseeallactualandset

valuesoftheoverallheatingsystem.

InthemenuitemAllocationyouseewhich

heatingcircuitsareallocatedtotheboilerortothe

accumulatores.

OperatingmanualPelletronicTouch

E1389EN2.0

MeasuringValues

15

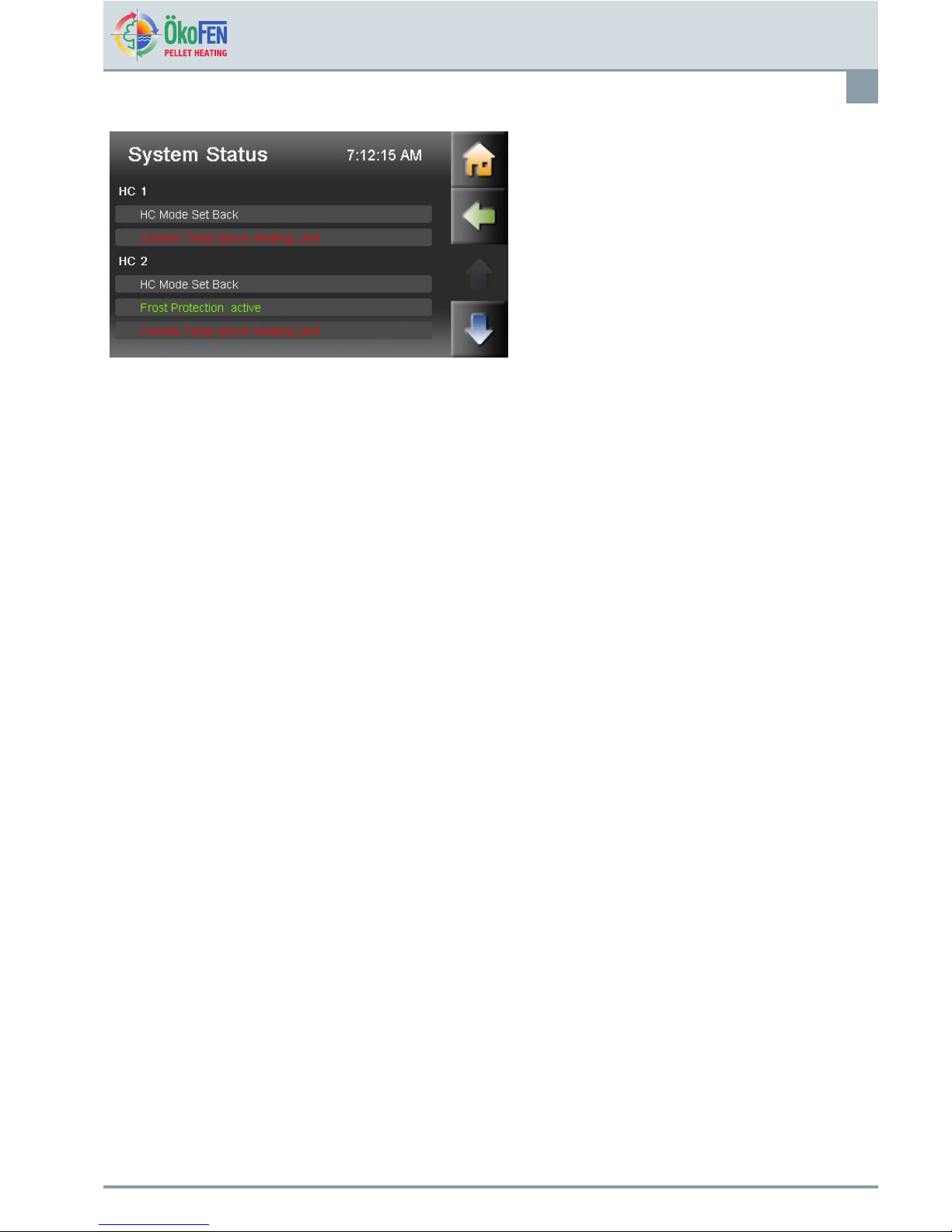

SystemStatusisanoverviewofthewholeheating

system.

E1389EN2.0

OperatingmanualPelletronicT ouch

HeatingCircuit

16

7HeatingCircuit

HeatingCircuitcontainsallrelevantparametersandsettings.Itcanoperateupto6heatingcircuits.

HeatingCircuitisintheMainmenu.

HeatingCircuithasfollowingmenuitems:

•Mode

•RoomTempHeating

•RoomTempSetback

•TimeAllocation

•Values

•Time1

•Time2

•Party

•Vacation

•HeatingCurve

Mode

OffOnlythefrostprotectionfunctionisactive.

AutoTheboilerstartsheatingautomaticallyaccordingtothesetroom

temperature.

Heating

TheboilerheatsconstantlyaccordinglytotheSetroomtemperature.

SetbackTheboilerheatsconstantlyaccordinglytotheSetbackroom

temperature.

Theoperatingmodeoftheheatingcircuitscanonlybechangediftheplantoperatingmode

issettoAUTO.

Theadjustedheatinglimitsandmaximumowtemperaturesareusedinalloperating

modes.

RoomTempHeating

Chooseyourroomtemperature(Temperaturewithintheheatingtimes).

RoomTempSetbackChooseRoomT empSetback(=Minimumtemperaturebeyondtheheatingtimes).

TimeAllocation

ActivateTime1(=Timeprogramme1)andTime2.

OperatingmanualPelletronicTouch

E1389EN2.0

HeatingCircuit

17

7.1MeasuringvaluesHeatingcircuit

MeasuringvaluesHCisintheMainmenu.

Thisdisplaysallcorrespondingheatingcircuitvalues:

•Actualvalue

•Setvalue

•Inputs(sensores)

•Outputs(pumps,mixerandmotors)

7.2TimeprogrammeHeatingcircuit

Theheatingcircuitprogrammeisusedtosettheheatingtimes.

Time1(=Timeprogramme1)andTime2areinthemenuHeatingcircuit.

1

SelectTime

programme1

6

Mo-Frwereassigned

heatingtimes

Withyougettothe

remainingdaysSa-Su.

2

Selecttheheating

days.

Theactivateddaysare

displayedingreen.

7

Sa-Suwereassigned

toheatingtimes.

3

Entertheheatingtimes

fortheseheatingdays

(Mo-Th).

8

Withand

youswitchbetween

theheatingblocks.

Youcanactivateor

deactivateheating

daysintheheating

block.

E1389EN2.0

OperatingmanualPelletronicT ouch

HeatingCircuit

18

4

Theheatingtimesfor

Mo-Thareassigned.

Withyouassign

thedaysheatingtimes

further.

9

Withyousetallthe

heatingtimesintheline

andbelowto0.

5

Fridayisactivated

andheatingtimes

assigned.

10

Gobackwith.

SelectTime2.

Foreachcircuitaretwo

timeprogrammes.You

canselecttwo-time

programs.Inthemenu

itemTimeAllocation

youcanactivateTime

programme1or2.

OperatingmanualPelletronicTouch

E1389EN2.0

HeatingCircuit

19

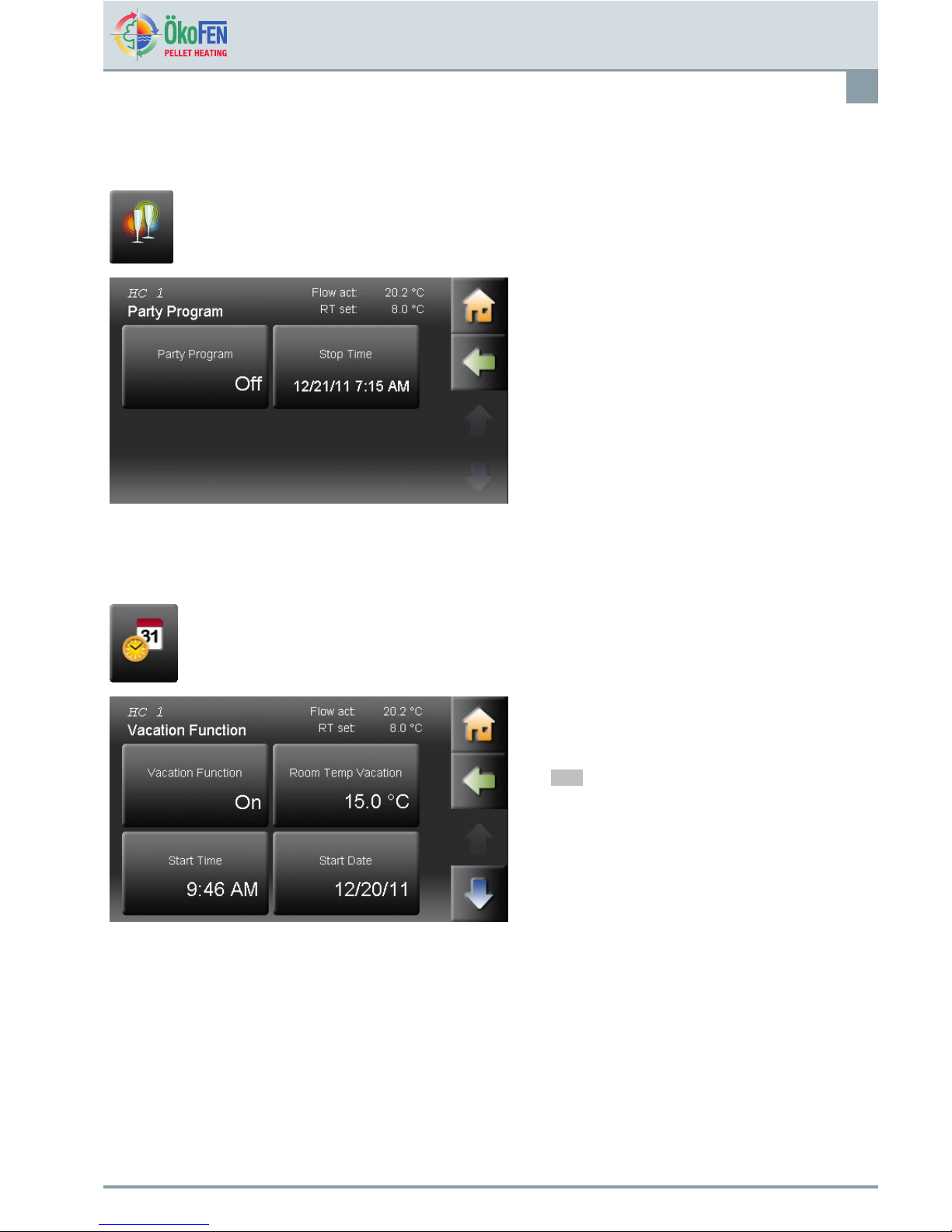

7.3Party

Thepartyfunctionextendstheheatingtimeonce,withoutchangingtheheatingtimes.

PartyisintheMainmenu.

Thepartyfunctionisbasicallyinactive.Enterthe

requiredstoptimethattheroomshouldbeheated

until.ActivatethePartyfunction.

Theheatingtimeisextendeduptotheindicated

time.Thenthepartyfunctiondeactivatesitself

automatically.

7.4Vacation

Theholidayprogrammecancelstheheatingtimesandheatsfortheenteredperiodonthesettemperaturelevel.

VacationisintheMainmenu.

Entertheroomtemperatureonwhichinyourabsence

thebuildingshouldbeheated.Enterthedeparture

(starttime)andreturn(nishdate)andactivatethe

vacationprogramme.

Note

Toreturntoanalreadytemperatebuilding

youshouldenterthedaybeforeyourreturn

asthenishdate.

E1389EN2.0

OperatingmanualPelletronicT ouch

HeatingCircuit

20

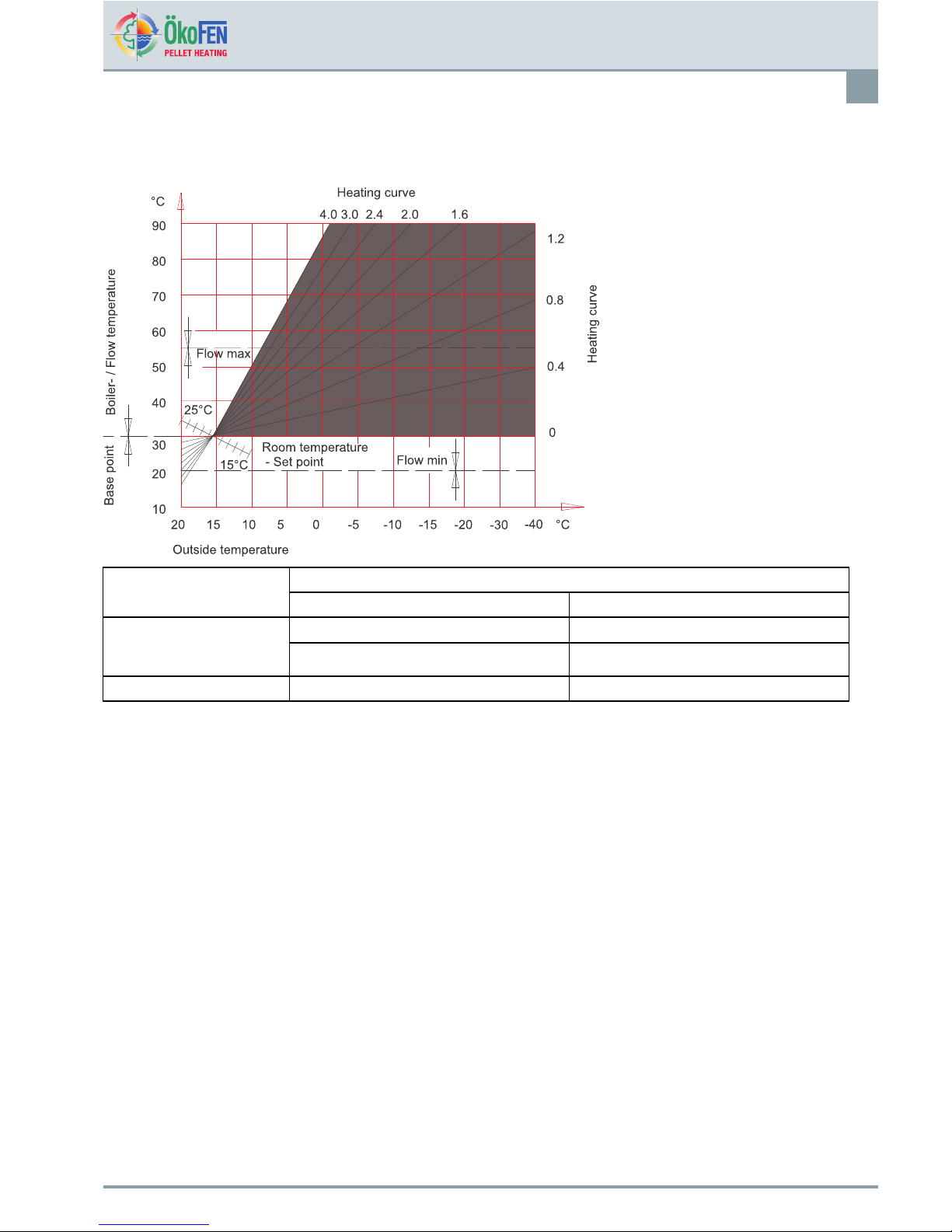

7.5HeatingcurveandHeatinglimits

Startingupforthersttime,theauthorisedtechnicaladviseradjuststheheatingcurve,thebasepointandtheheating

limitsonthebuildingsituationandthehydraulics.IftheSetroomtemperatureisnotreachedorexceeded,adjustthe

heatcurvewiththeowtemperaturesaccordingtooutsidetemperatures.

HeatingcurveisinthemenuHeatingcircuit.

Heatingcurve0.0–4,0

Theheatingcurvedescribesthecombination

betweenoutdoortemperatureandtheassociatedow

temperatureforaheatingcircuit.

Basepointadjustablefrom20-45

Withthechangetheofbasepoint,youprovidea

parallelshiftoftheheatingcurve.

Hlimitheating

Iftheaverageoutsidetemperatureishigherthanthe

settemperature,theheatingcircuitswitchesoffinthe

heatingmode.

Hlimitsettemperature

Iftheaverageoutsidetemperatureishigherthanthe

settemperature,theheatingcircuitswitchesoffinthe

Setbackmode.

OperatingmanualPelletronicTouch

E1389EN2.0

HeatingCircuit

21

Adjustmentofheatingcurveandthebasepointtothebuilding

Becauseofthebuilding´sthermalinertia,itisrecommendedtoperformnomorethanoneadjustmentstepperday.

Roomtemperature Daytime

outsidetemp

toowarm

toocold

Decreaseheatingcurvingvalueby0.2Increaseheatingcurvingvalueby0.2

+5to+15°C

Decreasebasepointvalueby5°Increasebasepointvalueby5°

-20to+5°C

Decreaseheatingcurvevalueby0.2Increaseheatingcurvevalueby0.2

E1389EN2.0

OperatingmanualPelletronicT ouch

HeatingCircuit

22

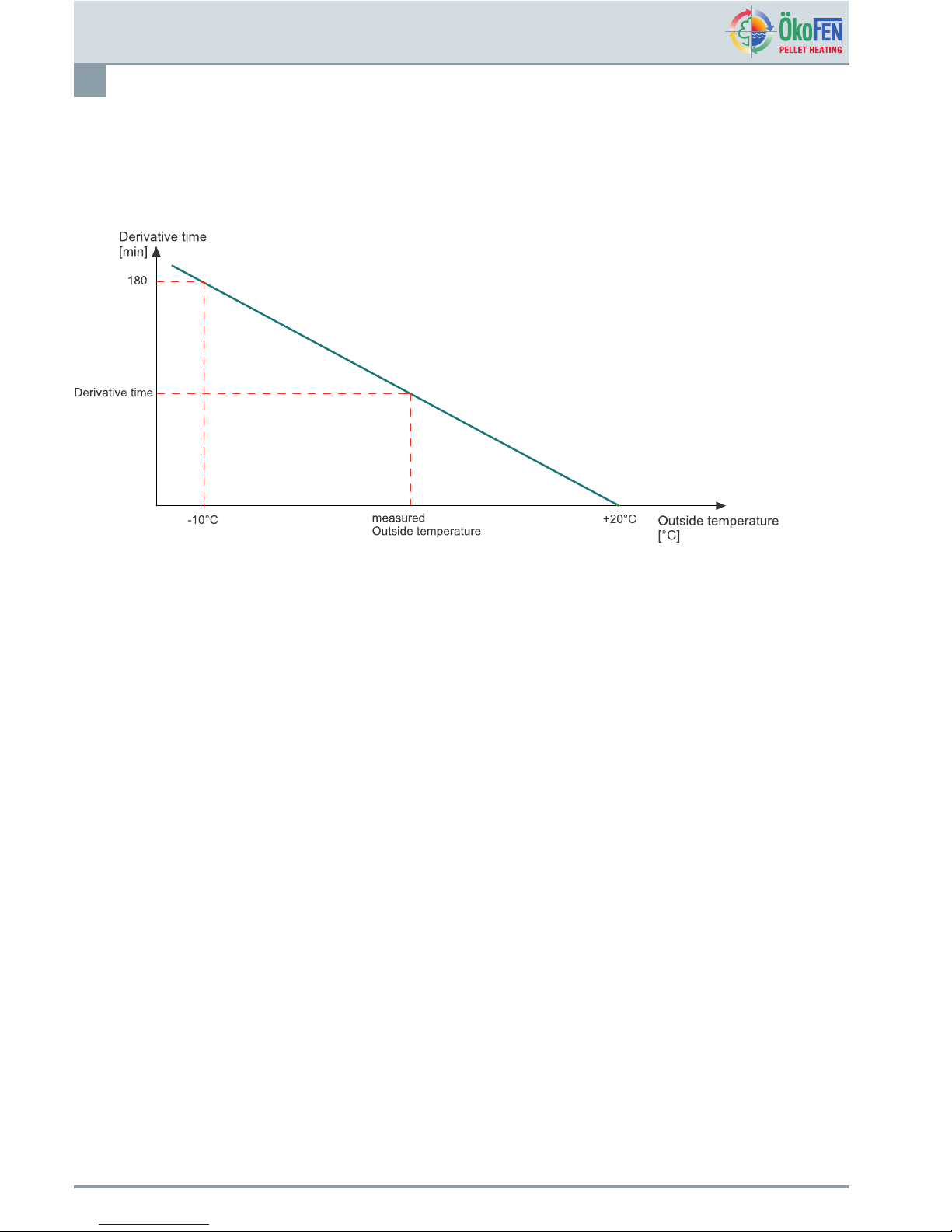

Advancedrunup:

Thisfunctionensuresthatthesetroomtemperatureisreachedbytheprogrammedheatingtimebystartingtheboiler

early.Thegureyousetisamaximumandwillbereducedbythecontrollerdependingontheoutsidetemperature

asshowninthegraphbelow.Wesuggest180minsforunderoorheatinginscreedand60-80minsformostradiator

systems.[useradjustable]

Roomthermostatinuence

Ifthemeasuredroomtemperaturedeviatesfromthesetroomtemperatureitcorrectstheheatingcontrollerandtheow

temperaturewiththeroomthermostatinuence.

TheRoomthermostatinuenceindicateshowmuchtheowtemperatureisraisedorloweredsothattheSetroom

temperatureisreached.

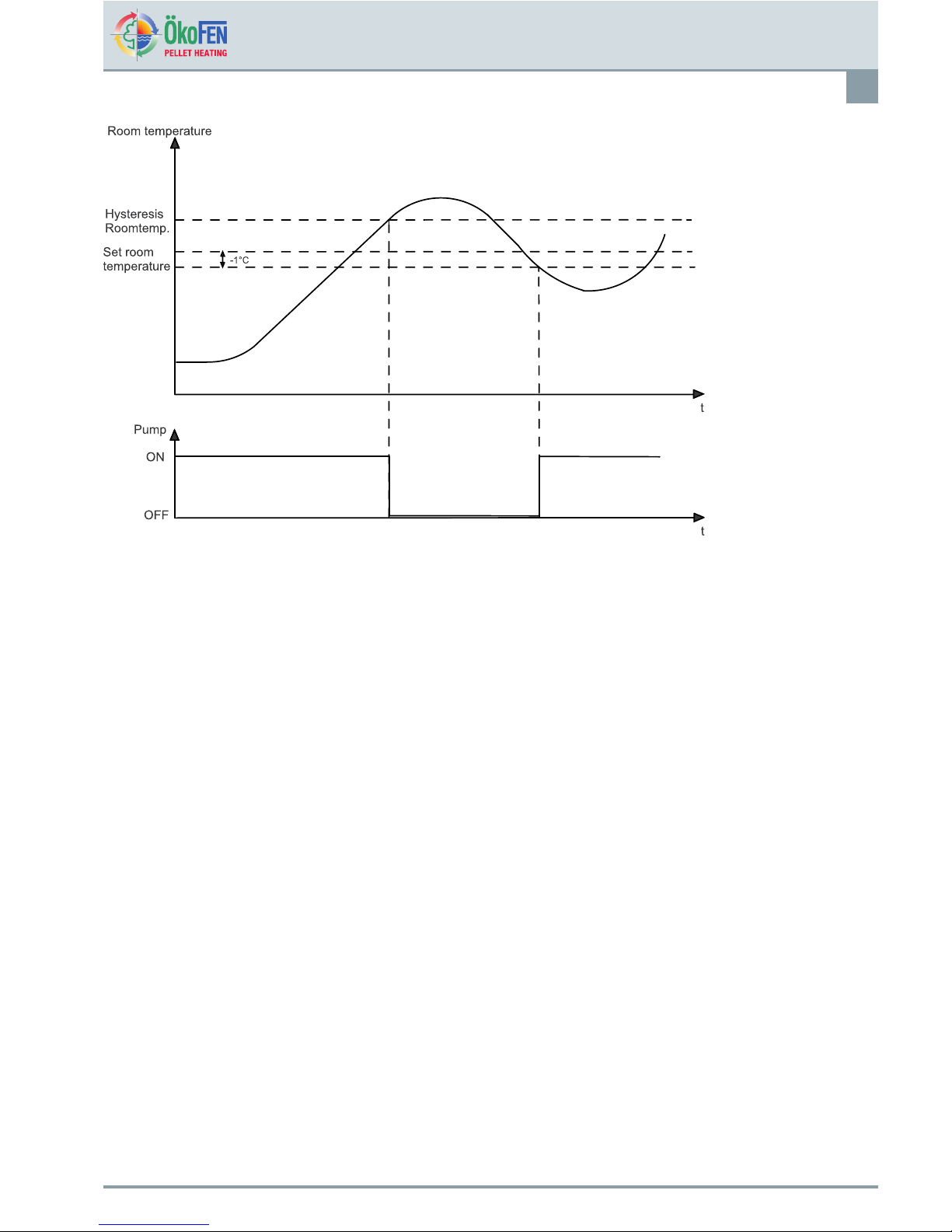

Roomtemperaturehysteresis

Theroomtemperaturehysteresispreventsthecycling(OnOffOnOff...)oftheheatingcircuitpump:IftheSetroom

temperature+roomtemperaturehysteresisisreached,theassociatedpumpstops.IftheSetroomtemperatureis–

1°C,thepumpswitchesonagain.

OperatingmanualPelletronicTouch

E1389EN2.0

HeatingCircuit

23

E1389EN2.0

OperatingmanualPelletronicT ouch

HeatingCircuit

24

7.6Screedprogramme

Thescreedprogrammemaybeoperatedupto31days.

Adesiredowtemperaturemustbeadjustedforeachindividualday.Thesetemperaturesareconstantandnot

dependentonoutsidetemperatureorroomthermostatsettings.Thefunctionisswitchedoffautomaticallyattheendof

theprogrammeandtheheatingcircuitrevertstothepreviousoperatingmode.

Damagestothescreedbytoohightemperatures.

Onlyusethisprogrammeinconjunctionwithapump

interlockswitchpositionedontheowfrompump

tounderoorcentralheating–thismustbesettothemax.

safetemperaturefortheconditionsoftheoor.No

libilityisacceptedbythePelletronicsupplierfordamage

tooorsorsuboors.

Continuouspowersupplyisrequiredtothecontrollerto

maintainthesettingsforthisprogramme.

OnlyuseprogrammetemperaturesapprovedbytheUFCH

andooringsuppliers.

ScreedprogrammeisinthemenuHeatingcircuit.

Attheendofthescreedprogrammeitwillswitchitself

offautomaticallyandreturntothepreviousmode.

Enterthenumberofheatingdays.Thereare0-31

heatingdayspossible.Accordingtothenumberof

heatingdaysaFlowtemperaturesetappearsfor

everyheatingday.

SelecteverysingledayandadjusttheFlow

temperatureset.Thepre-setFlowtemperatureset

perdayis20°C.

With

yougettoallotherdays.

OperatingmanualPelletronicTouch

E1389EN2.0

Domestichotwater(DHW)

25

8Domestichotwater(DHW)

ItcanoperateuptothreemenuitemsinDHW.Domestichotwaterincludesallparametersandsettingsforhotwater

production.

DHWisintheMainmenu.

DHWhasfollowingmenuitems:

•Mode

•DHWBoost

•WaterT empSet

•WaterT empMin

•Values

•Timeprogramme

•Time1

•Time2

Mode

OffSetwatertemperatureisreducedto8°forfrostprotection.

AutoDomestichotwaterwillbeheatedtothesettemperatureduringtimeperiods.

OnThesystemheatsupthedomestichotwatercontinuouslyontheWatertempset.

YoucanchangethemodedomestichotwateronlywhentheOperationmodeison

AUTO.

DHWBoostHeatsthehotwateronceontheWatertempset.

WaterTempSetSetthewatertemperature.

WaterTempMin

Settheminimumwatertemperature.Thewatertemperatureneverfallsbelowthisvalue,

unlessthedomestichotwatermodeisOFF.

ValuesYouseealltheDHWcorrespondingmeasuringvalues.

Timeprogramme

ActivateTime1(=Timeprogramme1)andTime2.

Time1andTime2

IntheDHWtimeprogrammeyousetthetimesofthehot-waterprocessing.TheDHW

timeprogrammeworksthesamewayastheheatingcircuitprogramme.Seechapter7.2

TimeprogrammeHeatingcircuit,page17

E1389EN2.0

OperatingmanualPelletronicT ouch

Domestichotwater(DHW)

26

8.1MeasuringvaluesDomestichotwater

MeasuringvaluesDHWisintheMainmenu.

Displayedareallthecorrespondingmeasuring

values:

•Actualvalue

•Setvalue

•Inputs(sensores)

•Outputs(pumps,mixerandmotors)

8.2TimeprogrammeDHW

IntheTimeProgrammeDHWreturnpumpyousettheDHWusagetimes.

Time1(=Timeprogramme1)andTime2areinthemenuDomestichotwater.

Thedomestichotwatertimeprogrammeworksthe

samewayastheheatingcircuittimeprogramme.

Seechapter7.2TimeprogrammeHeatingcircuit,

page17

OperatingmanualPelletronicTouch

E1389EN2.0

DHWReturnpump

27

9DHWReturnpump

DHWReturnpumpisintheMainMenu.

TheReturnpumpenablestheimmediateuseofhot

water.DHWReturnpumphasfollowingmenuitems:

•Mode

•Switchofftemperature

•Switchonhysteresis

•Timeallocation

•Values

•Time1

•Time2

Mode

Off…DHWReturnpumpinactive

Auto…Temperatureregulationwithinthetimeprogramme

SwitchofftemperatureIfthereturntemperaturesensoroftheDHWReturnpumpreachestheSwitchoff

temperature,thepumpswitchesoff.

SwitchonHysteresisIfthereturntemperaturefallsbelowtheswitchofftemperature–theDHWReturn

pumpswitchesonagain!

TimeAllocation

Choosethetimeprogramme1or2.

ValuesYouseealltheDHWpumpcorrespondingmeasuringvalues.

Time1,Time2

IntheReturnpumptimeprogrammeyousettheruntimesoftheReturnpump.The

Returnpump–timeprogrammeworksthesamewayliketheheatingcircuittime

programme.

Seechapter7.2TimeprogrammeHeatingcircuit,page17

9.1MeasuringvaluesDHWReturnpump

MeasuringvaluesDHWReturnpumpisinmenuDHWReturnpump.

YouseealltheHeatingcircuitcorresponding

measuringvalues:

•Actualvalue

•Setvalue

•Inputs(sensores)

•Outputs(pumps,mixerundmotors)

E1389EN2.0

OperatingmanualPelletronicT ouch

DHWReturnpump

28

9.2TimeprogrammeDHWreturnpump

IntheTimeProgrammeDHWreturnpumpyousettheDHWusagetimes.

Time1(=Timeprogramme1)andTime2areinthemenuDHWreturnpump.

TheDHWreturnpumptimeprogrammeworksthe

samewayastheheatingcircuittimeprogramme.

Seechapter7.2TimeprogrammeHeatingcircuit,

page17

OperatingmanualPelletronicTouch

E1389EN2.0

Solar

29

10Solar

Solarincludesallrelevantparametersandsettingsforthesolarthermalsystem.Youcancontrolupto6solarcircuits.

SolarisintheMainmenu.

Solarhasfollowingmenuitems:

•MeasuringvaluesSolar

•Solarcircuit1–2

•Solarenergy-Yield

10.1MeasuringvaluesSolar

MeasuringvaluesSolarisinthemenuSolar.

ItdisplaysallmeasuringvaluesofSolar:

•Actualvalues

•Setvalues

•Inputs(sensors)

•Outputs(pumps,mixerandmotors)

E1389EN2.0

OperatingmanualPelletronicT ouch

Solar

30

10.2Solarcircuit

Solarciruit1and2areinmenuSolar.

Solarcircuithastwooperatingmodes:

•ONCharge,aslongastheCollectortemperature+

hysteresisishigherthanthetemperatureoftheAC

lowersensororACtemperatureisreached.

•OFFNocharge

AslimitsensorchooseTPU,TPM,TPO,orDHW

sensor.

Note

Thesolarthermalsystemcanbeswitchedon/offirrespectiveoftheplantmode.

TheoperationmodeSOLARcanalsobechanged,iftheOPERATINGMODEPLANTissettoOFF!

VERYHIGHDOMESTICHOTWATERstorage

temperaturesarepossible!

Werecommendconsultingyourspecialistinstallerbefore

changingthesesettings.

ACCtempMaxIfthetemperatureintheACCishigherthantheACCtempMax,thesolarpump

switchesoff.ThelimitsensormeasuresthetemperatureintheACC.

ACCHysteresisThesolarcircuitpumpisswitchedoffduetotheACCtempMaxisreached.The

temperaturemustfallunderACCtempMaxminushysteresis,thenthesolarcircuit

pumpswitchesonagain.Thehysteresispreventsasolarpumpcycling(OnOff

OnOff).

CollectorHystOnIfbetweenthecollectorsensorandTPU,ACClowersensorthetemperature

differenceisgreaterthantheCollHystA,switchesthesolarpumpOn.

CollectorHystOffIfbetweenthecollectorsensorandTPU,ACClowersensorthetemperature

differenceissmallerthantheCollHystA,switchesthesolarpumpOff.

Collectorsmoothing

mode

Itonlyfunctionsonsolarcircuitone,itcanbeswitchedonandoffanditensuresan

efcientdeliveryofenergyfromthecollectors.

Note

Thiscanonlybeset,whenthespeedcontrolfunctionison.Settinginthe

codeprotectedparameter.

Collectorsmoothing

MinTemp

Atthistemperaturethesolarpumpstartstorunatminimumspeed.

Collectorsmoothing

Controlrange

Thepumpspeedincreaseswithinthesetrangeasthecollectortemperature

increases.

OperatingmanualPelletronicTouch

E1389EN2.0

Solar

31

10.3Yield-SolarEnergy

Thisfunctionmeasurestheyieldofthesolarthermalsystemanddisplayscurrentenergyandlogspreviousdays.

Note

Forthefunctionsolarenergyitisnecessarytoinstall:

•Pulsevolumemeter(mustbeconnectedto24VOLTandZ_IN)

•Flowtemperaturesensor

•Returntemperaturesensor

Yield-SolarEnergyisinthemenuSolar.

Yieldmeasuringofsolarenergyhasfollowingmenu

items:

•Actual

Displayofthecurrentsolarenergy,refreshesevery

60sec.

•Yield-Day

Displayoftodayssolarenergysince00:00.

•Yield-Daybefore

Displayoftheofyesterdayssolarenergy .

•Yieldsince

Displayofthesolarenergysincethelastsetdate.

•Flowrate

Displayofthecurrentowrate,refreshesevery

60sec.

•Flowtemperature

Displayofthecurrentowtemperature

•Returntemperature

Displayofthecurrentreturntemperature

E1389EN2.0

OperatingmanualPelletronicT ouch

Pellematic

32

11Pellematic

Pellematicincludesalltherelevantparametersandsettingsforthecontrolofthepelletboiler.

Thereareupto4Pellematicboilerspossible.

PellematicisintheMainmenu.

Pellematichasfollowingitems:

•MeasuringvaluesPellematic

•Permanentoperation

•Fullpower

•Burnerplatecleaning

•Boilercleaning

•Pelletlevel

11.1Permanentoperation

PermanentoperationisinthemenuPellematic.

Ifyouconrmthequery,youacitvatethefunction

Permanentoperation.

Firstofall,thespring-drivenmotoropensthere

protectionsystemattheburner-theprocesstakes

about2minutes.Afterthattheburnermotorrunsin

permanentoperationandtransportspelletstothe

burnerplate.Inheatingsystemswithaugerdelivery

itwillalsooperatetheextractionaugerinpermanent

operation.

OperatingmanualPelletronicTouch

E1389EN2.0

Pellematic

33

11.2MeasuringvaluesPellematic

MeasuringvaluesPellematicisinthemenu

Pellematic.

ItdisplaysallmeasuringvaluesofPellematic:

•Actualvalues

•Setvalues

•Inputs(sensors)

•Outputs(pumps,mixerandmotors)

BoilerTemperatureActualBoilerTemperature

Combustionchamber

sensor

ActualCombustionchambersensor.(Displayedonly,ifaNiCrNicombustion

chambersensorisconnected)

Boilerstatus

Displaystheactualstatusoftheboiler.

BurnerRunTimeS

Burnerruntimeintenthseconds.

BurnerRestTime

Resttimeoftheburnerintenthseconds.

BurnerFanSpeedBurnerFanSpeedinpercent.

FlueGasFanSpeedFlueGasFanspeedinpercent.

UWSpeedPowerofthepumpwithactivatedspeedcontrol.

BurnerContactStatus(On/Off)

KapRA

Capacitivesensoroftheburner

Status(On/Off)

KapZW

Capacitivesensoratthehopper

Status(On/Off)

Note

Defaultdisplayalwayswithsuctionsystem.

Displayalternativewithaugersystem.

FlameReturnGateStatus(On/Off)FlameReturnGate

ExistingBoiler

Status(On/Off)ExistingBoiler

IgnitionTemperature

Mintemperatureandconnectedcombustionchamberascriteriaforignition.

BurnerStartsNumberofBurnerStartsofthesystem

BurnerRunTimeHBurnerRunTimeinhours

AverageRunTime

AverageRunTimeaccordingtothenumberofignitions

NumberIgnition

NumberofIgnitionswithelectricalignition

IgnitionStickStatus(OnOff)IgnitionStick

MotorBCleaningStatus(OnOff)MotorBCleaning

E1389EN2.0

OperatingmanualPelletronicT ouch

Pellematic

34

RelayFaultSignalStatus(OnOff)RelayFaultSignal

MotorRA1

Status(OnOff)MotorRA1

MotorRES1Status(OnOff)MotorRES1

MotorBurnerAuger

Status(OnOff)MotorBurnerAuger

11.3FullPower

FullPowerisinthemenuPellematic

InthemenuitemFullPoweryoucanadjustthefuel

feed.

Fuelcorrection:

Theburneraugerruntimeiscalculatedautomatically

bythePLCdependingontheratedpowerandthe

boilersetpointtemperature.Theburnermotoris

controlledaccordingly.Y oucanreduceorincrease

thevaluecalculatedbythePLC10stepsupordown.

11.4De-ashingsystem

De-ashingsystemisinthemenuPellematic.

ThemenuitemDe-ashingsystemisavailableonly

whenDe-ashingsystemisconnected.Theactivation

isonlypossilbeafterenteringtheCodeforservice

tecnicians.Thede-ashingsystemandtheburner

platecleaningworkparallel.

•Minruntimeoftheboileruntilnextde-ashing

procedure.Valueadjustable

•AshdeliverytimeIstheruntimeoftheashauger.

Valueadjustable.

OperatingmanualPelletronicTouch

E1389EN2.0

Pellematic

35

11.5FreshWaterModule

FreshWaterModuleisinthemenuPellematic.

11.6BoilerCleaning

BoilerCleaningisinthePellematicmenu.

BoilerCleaninghasthefollowingmenuitems.

•Cleaning/Filling

•Cleaning2

•MinRunTime

•CleaningTime

Adjustthesuctionsystemaccordingtothedemandsofyourheatingsystem.

Cleaning/FillingThevaluetobesetisthetime(fullhour)atwhichtheboilercleaningsequenceis

performed.Onvacuumsystemsthehopperisalsolledatthesametime,regardless

ofwhetheritisemptyornot.

Cleaning2YoucansetinCleaning/Fillingasecondcleaningsequence.Thevaluetobeset

isthetime(fullhour)atwhichtheadditonalboilercleaningsequenceisperformed.

Example:20h=additionalboilercleaningsequenceperformedat20:00.Onvacuum

systemsthehopperisalsolledatthesametime,regardlessofwhetheritisempty

ornot.

Defaultvalue-1h:Itisnotperformedasecondcleaningsequence.

MinRunTime

MinRunTimeoftheboileruntilnextcleaningsequence.Valueadjustable.

CleaningTimeDurationoftheboilercleaningsequenceinseconds.Valueadjustable.

E1389EN2.0

OperatingmanualPelletronicT ouch

Pellematic

36

11.7SuctionSystem

SuctionSystemisinthePellematicmenu.

SuctionSystemhasthefollowingmenuitems:

•Cleaning/Filling

•FrequenceRAMotor

•PauseRAMotor

•Suctioninterval

Adjustthesuctionsystemaccordingtothedemandsofyourheatingsystem.

Cleaning/FillingThevaluetobesetisthetime(fullhour)atwhichtheboilercleaningsequenceisto

beperformed.

Thecleaningoftheboilerisperformedatthesametime.

InCleaning2asecondcleaning/llingsequencecanbeset.Thevaluetobeset

isthetime(fullhour)atwhichtheadditonalboilercleaningsequenceisperformed.

Example:20h=additionalboilercleaningsequenceperformedat20:00.Onvacuum

systemsthehopperisalsolledatthesametime,regardlessofwhetheritisempty

ornot.

FrequRAMotor

Frequencyforstorageroomsuctionsystemsinpulsemode,onlyforvacuum

systems.

PauseRAMotor

Pausetimeforstorageroomextractormotor-suctionsysteminpulsemode.If

pausetime=0thennopulsemode.

SuctionIntervalRuntimeofburneraugeruntilnextSuctionInterval.

Thehopperislledatthistimeregardlessofwhetheritisemptyornot.

OperatingmanualPelletronicTouch

E1389EN2.0

Pellematic

37

11.8Leveldetectionsystem

LeveldetectionsystemisinthePellematicmenu.

Leveldetectionsystemhasthefollowingmenuitems:

•Mode

TextileT ank

StorageRoom

CapacitiveSensor

•LimitValue

•CorrectionValue

Adjustthesuctionsystemaccordingtothedemandsofyourheatingsystem.

TextileTank

LeveldetectionsystemusingweighingcellsforFleXILOtextiletanks.

StorageRoom

Leveldetectionsystemusingweighingcellsatthehopperforstoragerooms.(only

forPellematicTypePES36–56)

CapacitiveSensor...Leveldetectionsystemusingacapacitivesensorforstorage

roomsandTextiletanks.

LimitValue

istheminimumweightforawarningmessage.V alueadjustable.Thewarning

messageappearsontheoperatingdeviceanddisappearswhenthellingweightis

abovethesetminimumweight.

ModeChoose:

CorrectionValue

OnlyifmodeFlexiTankorStorageroomischosen.Setthedisplayofthecurrent

weightto0byputtinginthenegativeofthecurrentweightshown

E1389EN2.0

OperatingmanualPelletronicT ouch

HeatMainPump

38

12HeatMainPump

HeatMainPumpisintheMainmenu.

TheHeatMainPumpisanadditionalpump,when

theboileroraccumulatorisseparatedfarfromthe

pumpstation.InthemenuitemComponent,youcan

assignanyorallcircuitstooperatewiththeHeatMain

Pump.TheHeatMainPumprunswithanyassigned

pump.

SwitchtheHeatMainPumpOnorOff.

Note

ForeachheatingcontrolleronlyoneHeat

MainPumporcirculationpumpcanbeused.

TheHeatMainPumpandthecirculation

pumpareclosedfromeachother.

OperatingmanualPelletronicTouch

E1389EN2.0

General

39

13General

Generalincludesthecompleteheatingcontrolrelatedsettingsandindividualoperatingoptionsforthecustomer.

GeneralisintheMainmenu.

ThemenuGeneralincludes::

•Favorite1

•Favorite2

•Localsetting

•Malfunction

•Info

13.1Favorite1and2

FavoriteisintheGeneralmenu.

Withthisfunctionyoucandisplaymostcommonly

usedmenuitemsinthestartmenu.Thisthenenables

directaccess.

Selectthemenuitemyouwishtobedisplayedas

Favorite1intheStartmenu.

Theselecteditemisnowgreen,thisiconisnow

displayedinthestartmenuandactive.

E1389EN2.0

OperatingmanualPelletronicT ouch

General

40

13.2LocalSettings

LocalSettingsisintheGeneralmenu.

LocalSettingshasthefollowingmenuitems:

•Language

•Unit

•Date

•Time

Language

ChoosebetweenthelanguagesGerman,EnglishUK,EnglishU.S.French,Spanish,

Italian,Dutch,DanishandRussian.

UnitYoucanchoosebetweenmetricandimperialmeasuringsystems.

Date

Setthecurrentdate.

Time

Setthecurrenttime.

OperatingmanualPelletronicTouch

E1389EN2.0

General

41

13.3Malfunction

MalfunctionisintheGeneralmenu.

Faultmessagesappearimmediately,theywilloverlay

allscreenmenuitems.Everyfaultmessagewill

displaythedate,timeandthetypeoffault.Itwill

remainuntilacknowledged.

Thefaultremainsintheincidentreportsloguntil

corrected.

13.4Information

InformationisintheGeneralmenu.

InthemenuitemInformationallfaultsarelisted

chronologically.

Thefaulttextshave3status

•C.....CURRENT—whenthefaultoccurs

•Q.....QUIT—whenthefaulthasbeenrectied

•G.....GONE—whenthefaulthasbeenresetby

pressingENTER

E1389EN2.0

OperatingmanualPelletronicT ouch

Software

42

14Software

SoftwareisintheMainmenu.

Softwareshowsthecurrentversionofsoftwarein

use.

OperatingmanualPelletronicTouch

E1389EN2.0

CodeInput

43

15CodeInput

Theheatingcontrolleriscomposedof2levels,oneforcustomerandoneforOkoFENservicetechnicians.Atthe

customerleveltheoperatorcanadjusttheheatingsystemtotheirneeds.AttheOkoFENservicetechnicianlevel

advancedsettingsforstartupandcustomisationoftheheatingsystemsarepossible.Theservicetechnicianlevelis

protectedwithapassword/codetopreventunauthorisedchanges.Thepassword/codeentryappearsinthemainmenu.

CodeInputisintheMainmenu.

TouchtheiconCodeinput.

Enterthecodeinthenumericblock.

YouhavereachedthelevelofÖkoFENservice

technicians.Alladditionalmenuitemsarevisible.

E1389EN2.0

OperatingmanualPelletronicT ouch

Startup

44

16Startup

Startupoftheheatingsystemisbasedonthecompleteinstallationoftheheatingsystemandaftercompletionand

inspectionofthehydraulicinstallation.StartupandSettingsinthecode-protectedparametersmayonlybeadjustedby

ÖkoFENServicetecniciansandqualiedandauthorisedpersonnel.

Beforeperformingstartupontheinstallation,youmustconsiderusingthechecklistfortheentireheatingsystem(see

Pellematicinstallationinstructions).

Toperformtheinstallation-specicsettings,youmustenterviacodeinputintotheservicetechnicianlevel.SeeChapter

15CodeInput,page43

MenuguideshowsthemenulevelsandmenuitemsofthePelletronicheatingcontrollerwiththeadditional

menuitemsforÖkoFENServicetechnicians

OperatingmanualPelletronicTouch

E1389EN2.0

Descriptionoftheheatingcontrollermodule

45

17Descriptionoftheheatingcontrollermodule

Theheatingcontrollerisdesignedtocontroltheheatdistributioninaheatingsystem.Itconsistsofacasingwithan

internalcircuitboardandterminals.Thecoverplateofthecasingisremovable.

Electricshockdanger

Makesurebeforeopening,thatthewholeheatingsystemis

powereddown.

Note

Theheatingcontrollerisprotectedupto8Atotalcurrentconsumption.Eachoutputmaybeoccupiedwith2A.

Makesurethatthesevaluesarenotexceededbytheconnecteddevices.

1

BusconnectingterminalRS485AandB

5

Fuse8A(slow-acting)limitsthecurrent

consumptionoftheheatingcontroller.

2Addressswitch6

Lowvoltage–area(dangerousvoltage)

3

Slotforanoptionalpowersupply

(Thepowersupplyisneededwhentheburner

controlCMP06.2isused.Thepowersupply

takesoverthebussupply.)

7

Extralowvoltage(PELV)

4

Fuse6,3A(fast)forX31andX33

E1389EN2.0

OperatingmanualPelletronicT ouch

Descriptionoftheheatingcontrollermodule

46

17.1Settingtheaddressattheheatingcontroller

Adjustthenumberofheatingcontrollersusingtheaddressswitch.Aheatingsystemcanuseupto3controllers.

Basesetting=0

Withseveralheatingcontrollersyouassigneachheatingcircuitstartingwith0forthecorrespondingnumber.(0–2)

0

=

Heatingcontroller1

1

=

Heatingcontroller2

2

=

Heatingcontroller3

Propertydamage

Adjusttheorderbyusingtheaddressswitch,thisisonly

possibleiftheheatingsystemispowereddown.

Note

ThesettingsintheremotecontrolaredescribedintheOperationinstructionRemotecontroller.

OperatingmanualPelletronicTouch

E1389EN2.0

Descriptionoftheheatingcontrollermodule

47

17.2Settingtheaddressattheburnercontroller

Adjustthetheburnercontrollerusingtheaddressswitch.Ifoperatingasacascadesystemsettheswitchaccordingly.

Basesetting=0

Attheoperatingwithcascadesystemsyouassigntoeveryboilerwith0beginningthesuitablenumber.

Propertydamage

Adjusttheorderusingtheaddressswitchthisisonly

possiblewhenthesystemispowereddown.

E1389EN2.0

OperatingmanualPelletronicT ouch

Descriptionoftheheatingcontrollermodule

48

17.3SettingtheaddressattheboilercontrollerCMP

Insystemswith2,3or4CMP'sthePellematicplugs1to4mustbeinsertedattheinputRGF1011terminalofeach

boilercontrollerbeforeusingLearnPeriphery.ThedifferentPellematicplugs1to4mustbenumberedaccordingto

theboilernumbers.

Propertydamage

Adjusttheorderusingtheaddressswitchthisisonly

possiblewhenthesystemispowereddown.

OperatingmanualPelletronicTouch

E1389EN2.0

Descriptionoftheheatingcontrollermodule

49

17.4Assemblyordisassemblyofthepowersupply

E1389EN2.0

OperatingmanualPelletronicT ouch

Descriptionoftheheatingcontrollermodule

50

17.5Assemblyanddisassemblyoftheheatingcontrollerboard

Itispossibletotakeofftheheatingcontrollerboardfromthecontrollercasingwithoutdisconnectingtheinputsand

outputs.

1.Makesuretheheatingsystemispowereddown.

Electrostaticdischargedamage

Beforestartingwork,touchagroundedobjecttoavoid

damagetotheinsulationboardbyelectrostaticcharging.

2.Openthecoverplateoftheheatingcontroller.

Seepreviouschapter17.4Assemblyordisassemblyofthepowersupply,page49

3.Pullalltheplugsinfromthecircuitboard.Leavetheplugswiththewiringinthecasing.

4.Disassembleofthepowersupply(optional)

Seepreviouschapter17.4Assemblyordisassemblyofthepowersupply,page49

5.Disassemblethecircuitboardfromtheheatingcontroller.

6.Theinstallationofanewcircuitboardshouldbeinreverseorder.

OperatingmanualPelletronicTouch

E1389EN2.0

DescriptionoftheOperatingdevicemodule

51

18DescriptionoftheOperatingdevicemodule

18.1ReplacingaTouchoperatingdevice

Youexchangetheintegratedoperatingdevice(inthecontrolpanel)asfollows.

Electricshock

Switchoffthesystembeforeworkcommencesontheboiler.

BreakdownTouchoperatingdevice

BeforeyoupressouttheTouchoperatingdevice,youmust

unplugallcablesfromtheoperatingdevice.

Whilepressingouttheoperatingdeviceyouhavetocounter

thetopwiththepalm,sothattheoperatingdevicedoesnot

popoutandfalltoground.

E1389EN2.0

OperatingmanualPelletronicT ouch

Software

52

19Software

SoftwareisintheMainmenu.

ContainsthesoftwareupdateoftheT ouchheating

controller,theremotecontrolandtheboilercontroller,

aswellasthecongurationfromtheTouchasMaster

(Operatingdevice),andSlave(Remotecontrol)and

activationoftheroomthermostat.(Master)

19.1Conguration

TheT ouchControlleriseitherMASTER(=Operatingdevice)orSLAVE(=Remotecontrol).

TheT ouchcontrollerisstandardasMastercongured.Itmustthereforebeconguredlocallyinaccordancewiththeuse.

Note

OnlyoneT ouchtobeconguredasMasterandoneasSlaveperheatingsystem

Procedure:

1.ChoosemenuitemSoftware

TouchConguration.

2.ChooseforeachRemotecontroltheCongurationSlaveandassignittoaheatingcircuit.

3.Waituntilallcomponentsarebootedupandoperational.

4.LearnPeriphery

Seecapitel20PeripheryLearning,page54

5.TheOperatingdeviceandtheassociatedRemotecontrollerarefunctionalnow.

19.2ActivatingthefunctionRoomthermostat

ThefunctionRoomthermostatMastercanbeactivatedonlyif:

•TheTouchOperatingdeviceisconguredasMASTER.

•TheTouchOperatingdeviceissituatedinthelivingspace.

ActivatetheintegratedroomthermostatMASTERbyassigningtheappropriatecircuit(HC1–6).

OperatingmanualPelletronicTouch

E1389EN2.0

Software

53

19.3UpdateHeatingController,TouchOperatingdeviceandRemoteControl

Theupdateisfortheheatingcontroller,theT ouchoperatingdeviceandtheTouchremotecontrol

FirmwareUpdate—Approach:

1.Switchoffcompleteheatingsystem.

2.T akethetouchoperatingdeviceoutofthe

controlpanel.

3.PlugintheUSBashdrivewiththenew

softwareinthebackoftheslot:USB0ofthe

heatingcontroller.

4.Placethetouchoperatingdeviceinthecontrol

panel.

5.Switchontheheatingcontroller.

6.GototheCODEbutton,enterthecodeto

reachthelevelsettings.

7.GotothebuttonSoftware

8.ChooseUpdate

Note

IfyouhaveforgottentoinserttheUSBstick

-PresstheRefreshbutton(waitabout

1min)

9.Selecttheappropriatesoftware.

10.PresstheButtonUpdateandreplytothequery

withYES.

19.4SoftwareUpdate

Firstperformasoftwaredownload.IntheÖkoFENdownloadareaisalwaysthecurrentsoftwareavailablefor

downloading.

Link:http://ftp.pelletsheizung.at

Foraccessinformation,pleasecontactyourÖkoFENrepresentative.

E1389EN2.0

OperatingmanualPelletronicT ouch

PeripheryLearning

54

20PeripheryLearning

InthemenuitemPeripheryLearningtheheatingcircuitregulatorrecogniseswhichcomponents(devices,pumps,

mixersandsensors)existintheheatingsystem.AfterPeripheryLearningtheT ouchoperatingdeviceindicates,ifall

componentsarepresent.

Note

Allheatingcontrollers,burnercontroller,touchoperatingdevicesandremotecontrolsmustbeaddressedand

turnedon.

PeripheryLearningisintheMainmenu.

PeripheryLearningappearsonlyinthelevelforthe

ÖkoFENservicetechnician.

Conrmthequery.

Note

Afterthisqueryitisnotpossibletogetback.

•Cascade-numberofboilers

Enterthenumberofexistingboilers.

Note

Ifthenumberofboilersishigherthan1,

additionalsettingsarenecessary.See26.1

Cascadesettings,page68

•DHW-SwitchOn/Off-sensor

ChooseaSwitchOnandaSwitchOffsensor.

Note

Appearsonlyifaaccumulatorexistsinthe

system.

•Allocation

AssignHeatingcircuit1-6andDHW1-3tothe

respectiveboileroraccumulator.

•TouchtheButtonPeripheryLearning.

Theheatingcircuitcontrollerexaminesand

recognisestheexistingcomponents.

OperatingmanualPelletronicTouch

E1389EN2.0

Heatingcircuitssettings

55

21Heatingcircuitssettings

HeatingcircuitssettingsisintheMainmenu.

Heatingcircuitssettingshasfollowingmenuitems:

•Mode

•RoomTempHeating

•RoomTempSetback

•TimeAllocation

•Values

•Time1

•Time2

•Party

•Vacation

•HeatingCurve

•Screedprogramme

Seecustomermenu7HeatingCircuit,page16

TheadditionalmenuitemsHeatingcircuitssettingsarefortheÖkoFENService

technician.TheiconsettingappearsinthemenuHeatingcircuitsonlyafterthecode

input.TouchtheIconSettingtoreachallotheradjustableparameters.

MaxFlowtemperature

Setthemaximumowtemperaturetothechosenheatingcircuit.

MinFlowtemperature

Settheminimumowtemperaturetothechosenheatingcircuit.

Temperatureincrease

(Systemheatloss

adjustment)

Settheboileroraccumulatortemperatureabovethesetowtemperatureofthe

circuitcallingforthehighesttemperature.

E.g.Setat5°Cwithaheating/DHWcircuitwithasettemperatureof60°Cthe

minimumboiler/accumulatortemperaturewillbesetto65°C.

Theboilerdoesnotstartwhenboiler/accumulatorisabovetheminimumtemperature.

MixerYes/NoChoosetypeofvalveusedtocontrolheatingcircuits.

Heatingcircuitwithmixermotorordirectheatingcircuit

Mixeropen–rest–close

Istheopening/rest/closingtimeofthemixer.

BoilerloadrangeThemixeropeningspeedincreaseswithboilertemperatureinthesetrange.

E1389EN2.0

OperatingmanualPelletronicT ouch

Heatingcircuitssettings

56

Flowrange

Thisfunctiondynamicallyreducestherateatwhichthemixeroperatestoreduce

boilercycling,particularlyusefulwhenstartingsystemswithhighload.

Boilertemperature

smoothing

Theboilertemperaturesmoothingcontrolstheboilerloadbysmoothingtheoperation

ofthemixer.

Note

Theboilertemperaturesmoothingoperatesonlyonsystemswithout

accumulatorandexistingboiler.

Temperaturerise

Theminimumvalueofthetemperatureriseattheboilersensor.

BoilerloadcontrolrangeIsthetemperaturerangewithinthePelletronicmeasures.

MinimumTemp/Risetime

Thisistheminimumtemperatureriserequiredovertherisetime.

1Theboilertemperaturerisesorexceedstheminimumtemperaturewithintheset

risetime.

TheMixeropeningtimeisnotinuenced.

2Theboilertemperatureremainssteadywithinthesetrisetime.

Themixerstaysinthesameposition.

3Theboilertemperaturefallswithinthesetrisetime.

Themixerstartstoclose.

4Theboilertemperaturerisesorexceedstheminimumtemperaturewithintheset

risetime.

TheMixeropeningtimeisnotinuenced.

OperatingmanualPelletronicTouch

E1389EN2.0

DHWsettings

57

22DHWsettings

DHWsettingsisintheMainmenu.

DHWsettingshasfollowingmenuitems:

•Mode

•DHWBoost

•WaterT empSet

•WaterT empMin

•Values

•Timeprogramme

•Time1

•Time2

Seecustomermenu8Domestichotwater(DHW),

page25

TheadditionalmenuitemsDHWsettingsarefortheÖkoFENServicetechnician.

TheiconsettingappearsinthemenuDHWonlyafterthecodeinput.T ouchtheIcon

settingreachallotheradjustableparameters.

DHWpriority

Switchthehotwaterpriorityonoroff.DEFAULTsettingON.

Usefulforcombinationtankswithradiatorsystems.

IfONtheheatingcircuitswillnotrununtiltheDHWreachesthesetpoint.

IfOFFtheDHWandheatingwilloperateinparallel.

TemperatureincreaseThisincreasestheDHWsettemperature.

E.g.Usethisfunctiontoovercomeheatlossesinconnectingpipework.

Pumprunon

ThisfunctionissetinminutesanddeterminestherunontimeoftheDHWpump.

ThisallowsresidualenergyintheboileroraccumulatortobetransferredtotheDHW

cylinder.

E.g.10minoriftheboilertempislowerthanDHWcylinder,whateveroccursrst.

Hysteresis

MaintainsthetemperatureoftheDHWwithinthisrangeduringatimedormanual

ONperiod.

OnlyfunctionswhentheoperatingmodeoftheDHWhastobeONorAUTO.

IftheoperatingmodeissetAUTO,therehastobeademandfortheburner.

Legionellaprotection

RaisesDHWcylindertemperaturetoLegionellapasteurisationtemperature65°ona

chosendayeachweek.Youcandeactivatethisfunction.

E1389EN2.0

OperatingmanualPelletronicT ouch

DHWsettings

58

Note

Fullpasteurisationmaynotbepossibleinsometypesofcylinderdueto

positionofboilercoilorotherconsiderations,consultrelevantcylinder

manufacturesfordetails.

RiskofScoldingfromveryhotwater!

OperatingmanualPelletronicTouch

E1389EN2.0

DHWReturnPumpsettings

59

23DHWReturnPumpsettings

DHWReturnPumpsettingsisintheMainmenu.

DHWReturnpumpsettingshasfollowingmenuitems:

•Mode

•SwitchoffTemperature

•SwitchonHysteresis

•TimeAllocation

•Values

•Time1

•Time2

Seecustomermenu9DHWReturnpump,page27

TheadditionalmenuitemsDHWReturnPumpsettingsarefortheÖkoFENservicetechnician.Theyarepresent

afterenteringthecode:

PumpreleasetemperatureTheDHWtemperaturemustbehigherthanthePumpreleasetemperature,

otherwisetheDHWreturnpumpdoesnotswitchon.

Flushinginterval

IftheDHWReturnPumpisnotactivealthoughitisintheONmode,thepumpruns

accordingtotheFlushingintervalforrefreshingthereturn-owsensor.

Purgingtime

EntertheFlushingtimemin,whichtheDHWReturnPumpmustruntilltheendof

theushingintervalforgettingcorrectvaluesfromthereturn-owsensor.

E1389EN2.0

OperatingmanualPelletronicT ouch

Solarsettings

60

24Solarsettings

SolarsettingsisintheMainmenu

Solarsettingshasfollowingmenuitems.

•Mode

•ACCTempMax

•ACCHysteresis

•CollectorHystOn

•CollectorHystOff

•CollectorregulationMode

•CollectorregulationTempMin

•Collectorregulationcontrolrange

Seecustomermenu10Solar,page29

TheadditionalmenuitemsSolarsettingsarefortheÖkoFENServicetechnician.Theyarepresentafterentering

thecode:

LimitSensorTheLimitSensormeasuresthetemperatureintheaccumulator.Youcanchooseas

limitsensor:TPO,TPM,TPUlowersensorandDHWsensor.

SolarSwitchOff

CollOverheating

Ifthecollectorreachesthecollectoroverheatingtemperature,thesolarpumpturns

off.

SolarSwitchOff

CollOverheatingHyst

Thesolarcircuitpumpswitchesonagainwhenthecollectortemperaturefallsbelow

theCollOverheatingminusCollOverheatingHysttemperature.

Pump/DiverterValveYoucanchooseforeverysolarcircuitbetweensolarpumpanddivertervalve.

PumpType

ChoosebetweenAcategorypumpandstandardpump.

Pump

SpeedController

Thespeedregulationofthesolarpumpcanbeswitchedonand/oroff.

Onlyfunctionswithsuitablepumps.

Ifthepumpspeedcontrolison,standardpumpscan

bedamaged.

D2differenttypesofAratedpumps:Analogpumpswith0-10VcontrolandPWM

pumpswith24V .Foreachtypeofpumpyouhavetoadjustthesignalattheheating

controller.

TheplugconnectorX34isfortheJumper-settings.Useajumperwithagrid

dimensionof2.54mm.TheterminalsX11andX21canreceiveorexportadifferent

signalstrengthdependingonthejumperposition.

TerminalDesignationFunctionPlug

connector

Position

X11

Out1PWMOut

AnalogOut0-10V

A-BandC-D

A-BandC-D

0

X

X21

Out2PWMOut

AnalogOut0-10V

E-FandG-H

E-FandG-H

0

X

0....Jumperisnotset,pinsopen.

X....Jumperisset,pinsclosed.

OperatingmanualPelletronicTouch

E1389EN2.0

Solarsettings

61

Collector

Protection

ThecollectorprotectionfunctioncanbeswitchedONorOFF.

Note

EveniftheoperationmodeofthesolarthermalsystemisOFF,thecollector

protectionisactive,providedthatitisturnedon.Thisservestoprotectthe

solarthermalsystem.

CollectorProtection

ProtectionTemp

Ifthecollectorprotectionfunctionisactivatedandthecollectorsensorreaches

theprotectiontemperature,theDHWpumpsandheatingcircuitpumpsswitches

on.Furtherthemixeropentillthemaximumowtemperatureisreached.This

processstopsifthecollectortemperaturerisesuntiltheSolarSwitchoff/Collector

Overheating.

Note

ThecollectorprotectionmustbesetlowerthantheSolarSwitchoff/

CollectorOverheating.

CollectorProtection

ProtectionTempHyst

Thisprocessalsostopswhenthecollectortemperaturefallsbelowthecollector

protectiontemperatureminusprotectiontemperaturehysteresisfalls.

Scavenging

Mode

YoucanswitchScavengingONandOFF .Thescavengingprocesscompensates

differenttemperaturesinthesolarcircuit.

Scavenging

RestTime

Scavenging

WithRestTimeandRunTimeyousetthescavenginginterval.

Scavenging

CollectorTempMin

Ifthecollectortemperatureisbelowthecollectortemperatureminimum,the

scavengingprocessisnotperformed.

Scavenging

StartTime

Scavenging

StopTime

WiththeStartTimeyousetthebeginningofthescavengingprocess.

StartandStoptimeareavoidinganunnecessaryoperationofthesolarcircuitpump.

Prio

Mode

Systemswithmorethanonesolarhotwatercylinder/combinationcylinder.

Selectpriorityofsolarcylinders.Allowscascadefunctionloadingofcylinders.

Cylinderscanbeloadedinseriescascadeorinparallel.

Prio

RunTime

Prio

RestTime

Prio

ScavengingTime

SetthesolarpumppulseprogrammeforsolarcircuitPRIO2.

OnlyforsolarcircuitPRIO2itisnecessarytosetthesolarpumppulseprogramme.

AfterthescavengingperiodofsolarcircuitPRIO2followsthescavengingintervalof

bothsolarcircuits.

Afterthescavengingintervalfollowsthescavengingtime.

Duringthescavengingtimethesolarcircuitchecks,ifthereisanewdemandfor

PRIO1ornot.

Ifthereisademandforsolarcircuit1,thepumpruns,ifnotthescavengingperiodof

solarcircuit2starts.

Ifduringthescavengingperiodofsolarcircuit2thereisademandfromsolarcircuit

1,itwillbeimmediatelyfullled.

E1389EN2.0

OperatingmanualPelletronicT ouch

Solarsettings

62

ParallelOperation

TempDifference

Thissettingonlyappearswithtwosolarcircuitswithtwopumps.

Theprocedureisthesameaswithonepump.Additionallybothpumpscanrun

inparallel.IfthetemperaturedifferencebetweencollectorandTPUlowersensor

fromthesolarcircuitwithPRIOAishigherthanthetemperaturedifference,both

solarcircuitsrunparallel.TheparametervalueisonlyinsolarcircuitswithPRIOA

visibleandadjustable.

Timingchartfor2solarcircuitswith1pumpand1diverterValveand2solarcircuitswith2pumps(solarcircuit1

...Prio1,solarcircuit2...Prio2):

OperatingmanualPelletronicTouch

E1389EN2.0

Solarsettings

63

24.1SolarEnergysettings

•Litre/Pulse

Adjustthissettingtotheowrate.Thebasic

setting1,0l/mincorrespondstotheowrateof

theÖkoFENprotset.

•Delete

DeletethedateandthegainofGainsince.

Note

Removethedateandtheactualgainduring

thestartupbypressingtheDeletebutton.

E1389EN2.0

OperatingmanualPelletronicT ouch

Accumulatorsettings

64

25Accumulatorsettings

AccumulatorisintheMainmenu.Accumulatorisdisplayed

afterenteringthecodeintheMainmenu.

Accumulatorhasfollowingmenuitems.

•ACCTempMinOn

•PumpOnTemp

•PumpDependsonRequire

•PumpSpeedController

•PumpSwitchOffHyst

•PumpRunOnTime

•PumpControlRange

Eachheatingcircuityoucanregulateoneaccumulator.Youcanoperatemaximumthreeheatingcontrollersina

system.

Thereforethenumberofaccumulatorsislimitedto3.Connectthesensoroftheaccumulatortotheheatingcontroller.

ThenperformPeripheryLearning.InPeripheryLearningyouassigntotheparticipants(heatingcircuitorhot

water)anaccumulator.

MakefurtheradjustmentsinthemenuAccumulator.

ACCTempMinOnIfthetemperatureattheTPO(ACuppersensor)fallsbelowthespeciedvalueof

ACCtempmin,aburnerdemandoccurstoloadtheaccumulatoruntiltheTPM

(ACmiddlesensor)reachesthelimit.

Pump

OnTemp

IfthetemperatureattheTPO(ACuppersensor)risesoverthevalueofthePump

OnTemp,allthepumpsoftheassignedparticipantsareactivated.

Pump

DependsonRequire

ON:Theaccumulatorisloaded,theaccumulatorisnotloadedfurther.

OFF:Theaccumulatorisloaded,buttheaccumulatorischargedfurther,aslongas

theaccumulatortemperaturedoesnotexceedtheaccumulatortemperatureorthe

boilertemperaturedoesnotexceedthePumpOnTemperature.

Pump

SpeedController

Announcementofachievementofthebuffercasepumpatcyclingmode.

OFF:TheACCpumprunsnotspeedregulated.

ON:TheACCpumprunsspeedregulated.

Pump

SwitchOffHyst

TheACCPumpControlRangeatcyclingmode.TheACCpumpstartstorunatthe

pumpreleasetemperaturewith30%ofachievement.Thepowerincreaseslinearly

toPumpOnT emp+controlrangeon100%.

Pump

RunOnTime

ThepumpswitchesoffonlyafterfallingshortofthePumpOnTempminusPump

SwitchOffHyst.

ItpreventstheONOFFONOFFoftheACCpump.

Pump

ControlRange

PumpControlRangeafterswitchingofftheburnerdemand–inminutes.

OperatingmanualPelletronicTouch

E1389EN2.0

Accumulatorsettings

65

E1389EN2.0

OperatingmanualPelletronicT ouch

SystemControlling

66

26SystemControlling

Inthesystemmenuyoucanadjustallheatingsystemrelatedparameters.

SystemControllingisintheMainmenu.

ExisitingBoiler

InthemenuitemExisitingBoilerareallparameters

toregulatethePellematicwithanexistingboiler.

Cascade

InthemenuitemCascadeareallparametersforthe

regulationof2,3or4boilers.

BoilerTempAbove

BoilerPumpOnTemp

IftheBoilertemperaturereachestheBoilerPump

OnTemp,thepumpsareswitchedon.

Note

Inheatingsystemswithnoaccumulator,the

BoilerPumpOnTempmaylienotunder

60°C.

BoilerTemperatureMin

TheBoilerTemperatureMinprotectstheboiler.

Inheatingsystemswithnoaccumulator,theBoiler

TemperatureMinmaybenotunder60°C.

BoilerTemperatureMax

IftheboilerortheaccumulatorreachestheBoiler

TemperatureMax,allheatingcircuitpumpsswitch

ontotransporttheheatenergyoutoftheboiler.This

processstopswhentheboilertemperaturefallsbelow

theBoilerTemperatureMax–BoilerTempAbove.

(e.G.:BTMax95°CminusBoilerT empAbove10°C=

85°C)

FrostProtection–ProtectionT emp

IftheoutsidetemperaturefallsbelowtheFrost

Protection–ProtectionTemptheheatingcircuits

arescavengedperiodically.Defaultis4°C,adjustable

from–20to4°C.

Note

TheFrostProtectionisadditionallyalways

active:i.e.IfthetemperatureoftheFlow

sensorortheACuppersensoris8°C,the

burnerdemandactivated.

FrostProtection–ScavengingTime/PauseTime

IftheoutsidetemperaturefallsbelowtheFrost

Protection–ProtectionTemptheperiodically

ScavengingoccursaccordingtoScavengingTime

andPauseTime.Defaultvalues:ScavengingTime

5minandPauseTime60min.

Note

Ifthepumpotherreasonsisactivated

becauseofthePauseTimestartsagain.

OperatingmanualPelletronicTouch

E1389EN2.0

SystemControlling

67

OutsideTemperature–TimeofAverage

Withthisfunctionyoudenehowlongtheoutside

temperatureshouldbedetermined.

0=nomessage

E1389EN2.0

OperatingmanualPelletronicT ouch

SystemControlling

68

26.1Cascadesettings

Thecascaderegulatesthecommonoperationoftwo,threeandfourpelletboilersor3pelletboilersandapeakload

boiler.Thereforearecascadesystemswithandwithoutaccumulator.

CascadesettingsisintheMainmenu.Cascadesettingsis

displayedafterenteringthecodeintheMainmenu.

Cascadesettingshasfollowingmenuitems:

Actualvalues–notadjustable

•CascadeBase

•SwitchOnTempActual

•SwitchOffTempActual

•DelayTime

•Boiler1

•Boiler2

•Boiler3

•Boiler4

Setvalues–adjustable

•Hysteresis

•DelayTime

•DelayTemp

•CascadeBaseMin

•SequenceChanges

•PeakLoadBoiler

Conditionsforacascade:

•AcascadesystemwithanaccumulatorisonlypossiblewithaccumulatorNo.1.

•IfaccumulatorNo.1isinstalledallboilersmustbeassignedtothisaccumulator(No.1)

•Theaccumulatorpumpmustbeconnectedtotheboiler.

PeripheryLearning

Note

PriortothePeripheryLearning,allcomponentsmustbeconnectedproperly.

Thenumberofboilersandselectionoftheswitchoffsensorinacascadesystemwithanaccumulatormustbetakenin

themenuPeripheryLearning.SeeChapter20PeripheryLearning,page54

NumberofBoilers

Insertthenumberofboilers.Peakloadboilerscount

tothenumberofboilers.Example:3Pellematicand

1Peakloadboilerresultsinanumberof4!

SwitchOffSensor

Ifanaccumulatorispresent,youcanchoosetheTPO

(ACuppersensor)ortheTPM(ACmiddlesensor)for

theSwitchOffSensor.Ifthereexistsnoaccumulator

inthesystem,thenyoudonothavethischoice.

OperatingmanualPelletronicTouch

E1389EN2.0

SystemControlling

69

Notadjustable

CascadeBaseTheCascadeBaseisthecalculatedsourcetemperatureforthefunctionofthe

cascade.Itresultsaccordingtotheamountofsetvalues.TheHysteresisisadded

totheCascadeBase.

SwitchOnTempActualTheSwitchonsensorataaccumulatorisalwaystheTPO(ACuppersensor)

TheSwitchonsensoratahydraulicseperatoristheboilersensor(switchoffsensor).

TheSwitchonsensormaesurestheSwitchOnTempActual.

SwitchOffTempActualTheSwitchoffsensorataaccumulatoristheTPO(ACuppersensor)ortheTPM

(ACmiddlesensor)

Theswitchoffsensoratahydraulicseperatoristheboilersensor(=switchon

sensor).

TheswitchonsensormaesurestheSwitchOffTempActual.

DelayTime

Atrststartsonlyoneboiler.EachfurtherboilersstartaftertheDelayTime.Yousee

theremainingDelayTimeofeachboiler.

Boiler1–4

Theboilersarenumberedfrom1–4.Thenumberingsystemisthesameasthe

actualboilernumbers.Ifthetextofthatboilerisgreen,itsymbolisesaburner

demand.Aswellastheboilernumberingthereisalsosequencenumbering.Itcan

bedifferenttotheboilersnumberingbecauseofthesequencechanges.Thesettings

Hysteresis,DelayTimeandDelayT emperaturerefertothestartingnumberingof

theboiler.

Adjustable

Hysteresis

ThesettingoftheHysteresisreferstotheboilersstartingnumbering.Foreach

startingnumbersthereisanindividuallyadjustableHysteresis.

TheHysteresisenablesagradualONandturn-OFFoftheboilers.Seegraphic.

DelayTime

ThesettingoftheDelayTimereferstothestartingnumbersoftheboilers.Apart

fromthestartingnumber1,eachstartingnumberhasaDelayTime.

Atrstitstartsonlytheboilerwiththestartingnumber1.Everyotherboilerstarts

attheendoftheDelayTimeinwhichischeckediftheboilerortheboilerscan

fulltherequirements.Withthebunerdemandoftheboilerwithstartingnumber1,

allDelayTimesstartsatthesametime.

DelayTemp

ThesettingoftheDelayT empreferstothestartingnumbersoftheboiler.Apart

fromthestartingnumber1,eachstartingnumberhasaDelayTemp.Iftheoutside

temperatureishigherthantheDelayTemp,thereisnoburnerdemand.

CascadeBaseMinIftheCascadeBase(calculatedfromthesetvalues)fallsbelowthisvalueitwill

deactivate.Ifthereisnorequirement,thecascadeonlyactivates,ifthefrost

protectionfunctionisactive(8°C).