Operating

Manual

+ Initial start up Pellet

heating system with auger

delivery system or vacuum

suction system for

professionals

PELLEMATIC®

PE(S)(K)(B) 10 — 56

FA_V2.03

Pelletronic TOUCH

ENGLISH

PE 567 EN 1.1 · www.oekofen.com

Title:

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

Article number:

PE 567 EN 1.1

Version valid

from:

06/2015

Approved: Wohlinger Christian

Author

ÖkoFEN Forschungs- &.

EntwicklungsgesmbH

A-4133 Niederkappel, Gewerbepark 1

Tel.: +43 (0) 72 86 / 74 50

Fax.: +43 (0) 72 86 / 74 50 – 10

E-Mail: oekofen@pelletsheizung.at

© by ÖkoFEN Forschungs- und EntwicklungsgesmbH

www.oekofen.com Subject to modifcations

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

11DDeeaarrCCuussttoommeerr .................................................................... .............. .............................................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .................................. 55

22UUsseeoonnllyyffoorrtthheeppuurrppoosseeiinntteennddeedd .............. .............. ........................................................................ .............. .............. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 66

33TTyyppeessooffssaaffeettyywwaarrnniinnggssiiggnn...................................................................... ............................ .............................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 77

44SSyysstteemmoovveerrvviieeww .......................................................... .............. ........................................................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ...... .................. 88

55CCoonnttrrooll ssyys

stteemm ........................ ............................ .............. ............................ .................................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..............................1100

66PPaarraammeetteerrAAddjjuussttmmeennttss ............................................ ............................ .............. ............................ .............. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..1111

77TThheebbooiilleerrccoonnttrroolllleerr .......................... ...................................................................................................... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ............ 1122

7.1 Plugs on the boiler control unit ......................... . . . . . ....................... . . . . . ........................ . . ................................ 13

7.2 Wiring diagrams .... . . .................................................................................................................................... 15

7.3 LED status boiler controller....... . . . . . . ........................ . . .......................... . . ......................... . . . .......................... 19

7.4 Cable Routing.................. . . ........................... . .............................................................................................. 19

88TThheehheeaattiinnggccoonnttrroolllleerr .............................................................................. .............. ............................ ........ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ....2200

8.1 LED status heating controller . . . ................................................................................................................... 21

8.2 Connection plan .................. . . . . . ....................... . . . .......................... . . ......................... . . . .................................22

8.2.1 Jumper X34 for analog voltage outputs X11 (OUT1) and X21 (OUT2) . ....................... . . . . .............25

8.3 Rules of wiring for micronetwork with 1,2 or more heating controllers ... . . . . ...............................................25

8.4 Wiring diagrams. . ....................... . . . . . ........................ . . . ......................... . . ..................................................... 26

8.5 Assembly and disassembly of the heating controller circuit board .......................................................... 28

8.6 Cable specification Pelletronic Touch...... . . ....................... . . . . . ........................ . . . . ........................................ 30

8.7 Sensor values..... . . .......................... . . ....................... . . . . . . ....................... . . . ..................................................... 31

8.8 Hydraulic connecting diagrams ..................................................................................................................32

8.8.1 Hydraulic connecting diagrams Pelletronic Touch ............... . . . ...................................................32

99TThheeTToouucchhooppeerraattiinnggddeevviiccee........ ............................ .............. .............................................................................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 4411

9.1 User controls and their function ........ . . ........................ . . . . ........................ . . . . ........................ . . . .................... 43

9.2 Main Menu .................................................................................................................................................. 45

9.3 Replacing a Touch operating device . . ......................... . . . ....................... . . . . . ............................................... 46

9.4 Backside of the Touch operating device .. . . . . ........................ . . ................................................................... 47

9.5 Calibration .................................................................................................................................................. 48

1100DDeeffaauullttvvaalluueessaannddsseettttiinnggss........................................................................ ............................ ............................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 4499

1111DDeeffaauullttvvaalluueessaannddsseettttiinnggss .......... ............................ .............. ........................................................................ .... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 5533

1122OOnnlliin

neeTToouucchh .......................................... .............. ............................ .............. .............................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ................................ 5577

12.1 Product Description . . . .................................................................................................................................57

12.1.1 Installation Requirements ... . . . . ........................ . . . . ........................ . . . .......................... . ...................57

12.1.2 System Description .................................................................................................................... 58

12.2 Settings on the Touch Operating Device. ........................ . . . .......................... . ........................................... 59

12.3 Opening the Password-Protected Remote Maintenance Website ................... . . . . ...................... . . . . . . ........ 61

12.4 Description of the Pelletronic Online Website.......................................................................................... 62

12.4.1 Making Settings ........... . . . ....................... . . . . . . ....................... . . . .................................................... 63

12.4.2 Adjustment of the power rating . . ............................................................................................. 64

12.4.3 Error Messages by E-mail . . . . . ........................ . . . . ........................ . . .............................................. 65

12.4.4 Quit malfunction ........................ . . . . . . ......................................................................................... 67

12.4.5 Code input................................................................................................................................. 68

1133SSttaarrttiinngguuppffoorrtthheeffiirrssttttiimmee.......................................... .............. ............................ ............................................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 6699

13.1 Performance adjustment ...................... . . . . ........................ . . ....................................................................... 70

13.2 Setting the adresses of the Bus-participants............................................................................................ 70

13.2.1 Setting the address at the burner controller . . ...........................................................................70

13.2.2 Setting the address at the heating controller ......................... . . . . ............................................... 71

13.2.3 Setting the adress for the remote control . . . . ......................... . ........................... . . ......................72

13.2.4 Settings before starting up........................................................................................................72

13.2.5 Setting the adress for remote control Touch ...... . . . ...................................................................73

13.2.6 Setting the adress for remote control ...... . . ......................... . . . .................................................. 74

13.2.7 Code Input. ....................... . . . . . .....................................................................................................75

13.2.8 Periphery Learning.................. . . . .......................... . .....................................................................77

13.2.9 Flowtronic ........................ . . ........................... . ......................... . . . . ....................... . . . . . .................. 84

13.3 Mode.......................................................................................................................................................... 84

13.3.1 Operation mode.. . ........................... . . ....................... . . . . . . ...................... ...................................... 85

13.3.2 Operation mode HC 1 .... . . . . . ....................... . . . . ......................... . ........................... . . ..................... 85

Contents

Contents

13.3.3 Operation mode HC 2–6 ........................................................................................................... 85

13.3.4 Operation Mode DHW .............................................................................................................. 86

13.3.5 Operation mode solar ............................................................................................................... 86

13.3.6 Operation mode Pellematic . . ........................ . . .......................... . . .............................................. 87

13.4 Measuring values....................................................................................................................................... 87

13.5 Weather..................................................................................................................................................... 88

13.6 Eco Mode .................................................................................................................................................. 89

13.7 Heating Circuit.. . . . . . ........................ . . . ......................... . . ........................... . ................................................... 91

13.7.1 Screed programme . . ......................... . . . . ...................... . . . . . . ........................ . . ............................... 94

13.8 Solar Heating.... . . . .......................... . ......................... . . . . ...................... . . . . . . .................................................. 94

13.8.1 Menu Solar Heating...... . . . ....................... . . . . . . ....................... . . . . ......................... . ......................... 95

13.9 DHW settings ........................ . . . . . . ....................... . . . . ......................... . ........................... . . ............................ 96

13.10 DHW Return Pump settings . . ....................... . . . .......................... . . ......................... . . . ................................ 97

13.11 Solar settings .............. . ........................ . . . . . ....................... . . . . . ........................ . . .......................................... 98

13.12 Accumulator settings...................... . . . . ......................... . . .......................... . . .............................................104

13.13 System Regulation ................. . . . . ...................... . . . . . ......................... . . .......................... . . ...........................106

13.13.1 Cascade settings.................. . . . . ........................ . . . .......................... . ......................... . . . . ............. 107

13.13.2 Existing Boiler ...........................................................................................................................111

13.14 Pellematic settings ................................................................................................................................... 113

13.14.1 Outertemperature control... . . ................................................................................................... 114

13.14.2 External Power Ventilator........................................................................................................ 115

13.14.3 Permanent operation. . .......................... . ......................... . . . . ..................................................... 115

13.14.4 Ignition settings .......................................................................................................................116

13.14.5 Full power settings .................................................................................................................. 117

13.14.6 Run Down Time settings.. . . . . ........................ . . . . ........................ . . . .......................... . .................. 118

13.14.7 De-ashing system settings ................. . . . ....................... . . . . . . ....................... . . . . .......................... 119

13.14.8 Boiler cleaning ....................... . . . . . ........................ . . . ......................... . . ....................................... 121

13.14.9 Negative Draft . .......................... . ........................... . . ....................... . . . . . . .................................. 122

13.14.10 FRT Controller . . ........................ . . . . ........................ . . . .......................... . . .................................. 123

13.14.11 Level detection system ....... . . . . ...................... . . . . . . ........................ . . .......................... . . ............. 125

13.14.12 Boiler Controlled Pump . ......................... . . ........................... . ........................ . . . . . .................... 126

13.14.13 Suction turbine ....................... . . . ............................................................................................ 128

13.14.14 Output Settings ................. . . . . . ............................................................................................... 129

13.14.15 Output Test......... . . .................................................................................................................130

13.14.16 Maintenance .. . . . ....................... . . . ........................................................................................... 132

13.14.17 Calibrate........... . ..................................................................................................................... 133

13.14.18 Magnet Valve..................... . ................................................................................................... 134

13.14.19 Settings....................... . .......................................................................................................... 135

13.15 Heating Main Pump...................... . . . ........................................................................................................ 137

13.16 General settings .... . . . . . ......................... . . .................................................................................................. 138

13.16.1 Chimney................... . . . . . . ........................ . . . ................................................................................ 141

13.16.2 Datalog........... . . . . ........................ . . . . ........................ . . ........................... . . .................................. 142

13.16.3 Delete Log............. . . . . . ....................... . . . . .................................................................................. 143

13.16.4 ModBUS . . . ....................... . . . . . ........................ . . .........................................................................144

13.16.5 E-Mail ........ . . . . . ........................ . . . .......................... . ......................... . . . . ...................................... 146

13.16.6 IP Config .................... . . . ........................ . . . . . ....................... . . . . ......................... . ........................ 147

13.16.7 USB ............... . . . .......................... . ......................... . . . . ...................... . . . . . ....................................150

13.17 Software settings ............................ . . ........................ . . . . ........................ . . . . ............................................... 151

13.17.1 Configuration .......................... . . ....................... . . . . . ........................ . . . . .......................

................. 151

13.17.2 Function room sensor ................ . . . . . ....................... . . . . ......................... . . ......................... . . ....... 152

13.17.3 Update Heating Controller, Touch Operating device and Remote Control . . . . . . ..................... 152

13.17.4 Software Update................. . ........................ . . . . . ....................... . . . . . ........................ . . ................ 153

1144AAppppeennddiixx.... .............. ............................ .............. .................................................................... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ................ ..........................115544

14.1 Malfunctions.............................................................................................................................................. 154

14.1.1 Malfunctions - what to do............. . . . ......................... . . ......................... . . . . ...................... . . . . . . ...... 154

14.1.2 Fault texts ........... . . . ................................................................................................................... 154

14.1.3 Malfunction report .................................................................................................................... 155

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

Dear Customer 5

11 Dear Customer

ÖkoFEN is Europe’s leading specialist in pellet heating.

Proficiency, innovation and quality combined. This is the tradition on which ÖkoFEN shapes the future.

We are very pleased that you too have decided to purchase a product from ÖkoFEN.

• This manual is intended to help you operate the product safely, properly and economically.

• Please read this manual right through and take note of the safety warnings.

• Keep all documentation supplied with this unit in a safe place for future reference.

Please pass on the documentation to the new user if you decide to part with the unit at a later date.

• Please contact your authorised dealer if you have any questions.

ÖkoFEN attaches great importance to the development of new products. Our R&D Department repeatedly

challenges the effectiveness of tried-and-tested systems and works continuously on improvements. In this

way, we secure our technological advantage. We have already received many national and international

awards for our products.

All our products comply with European standards in respect of quality, efficiency and emissions.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

6

Use only for the purpose intended

22 Use only for the purpose intended

The pellet heating system is designed to heat water for central or other indirect heating systems and hot

water supply for buildings. It is not permissible to use the pellet heating system for any other purpose.

Reasonable foreseeable inadvertent uses for the heating system are not known.

PE 567 EN 1.1

Types of safety warning sign

7

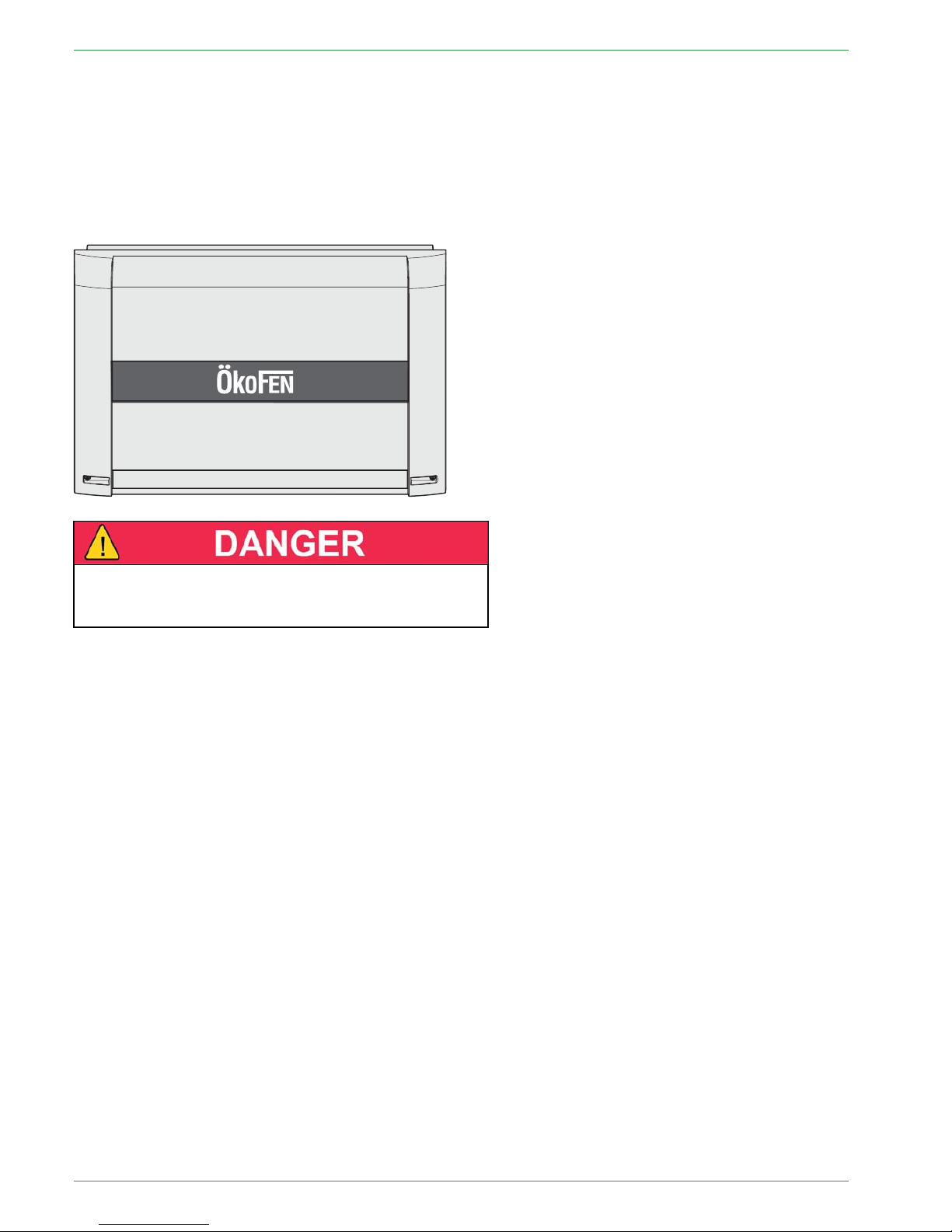

33 Types of safety warning sign

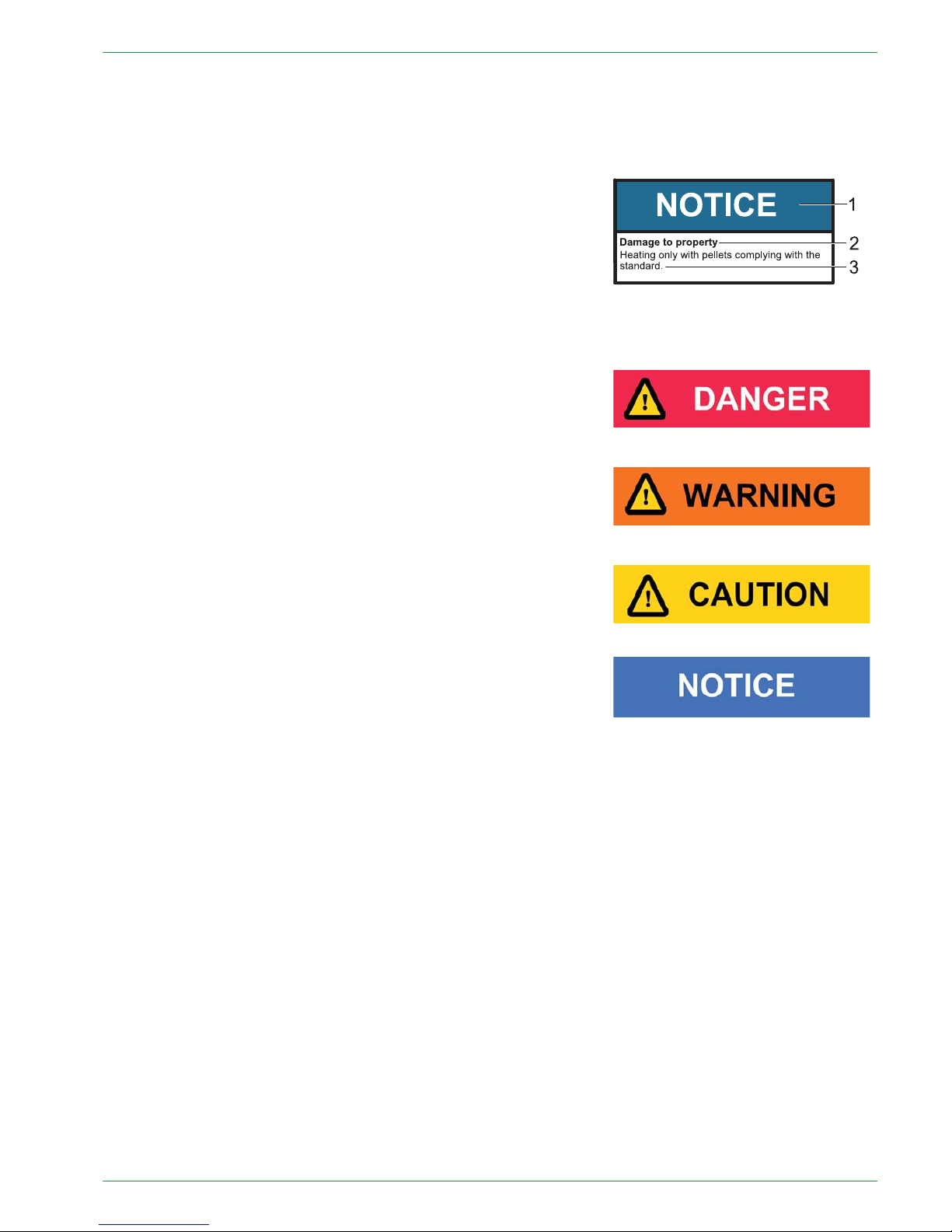

The warning signs use the following symbols and texts.

Types of safety warning sign

1. Risk of injury

2. Consequences of risk

3. Avoiding risk

1. Risk of injury:

Danger - indicates a situation that could lead to death or lifethreatening injury.

Warning - indicates a situation that could lead life-threatening or

serious injury.

Caution - indicates a situation that could lead to injury.

Note - indicates a situation that could lead to property damage.

2. Consequences of risk

Effects and consequences resulting from incorrect operation.

3. Avoiding risk

Observing safety instructions ensures that the heating system is

operated safely

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

8

System overview

44 System overview

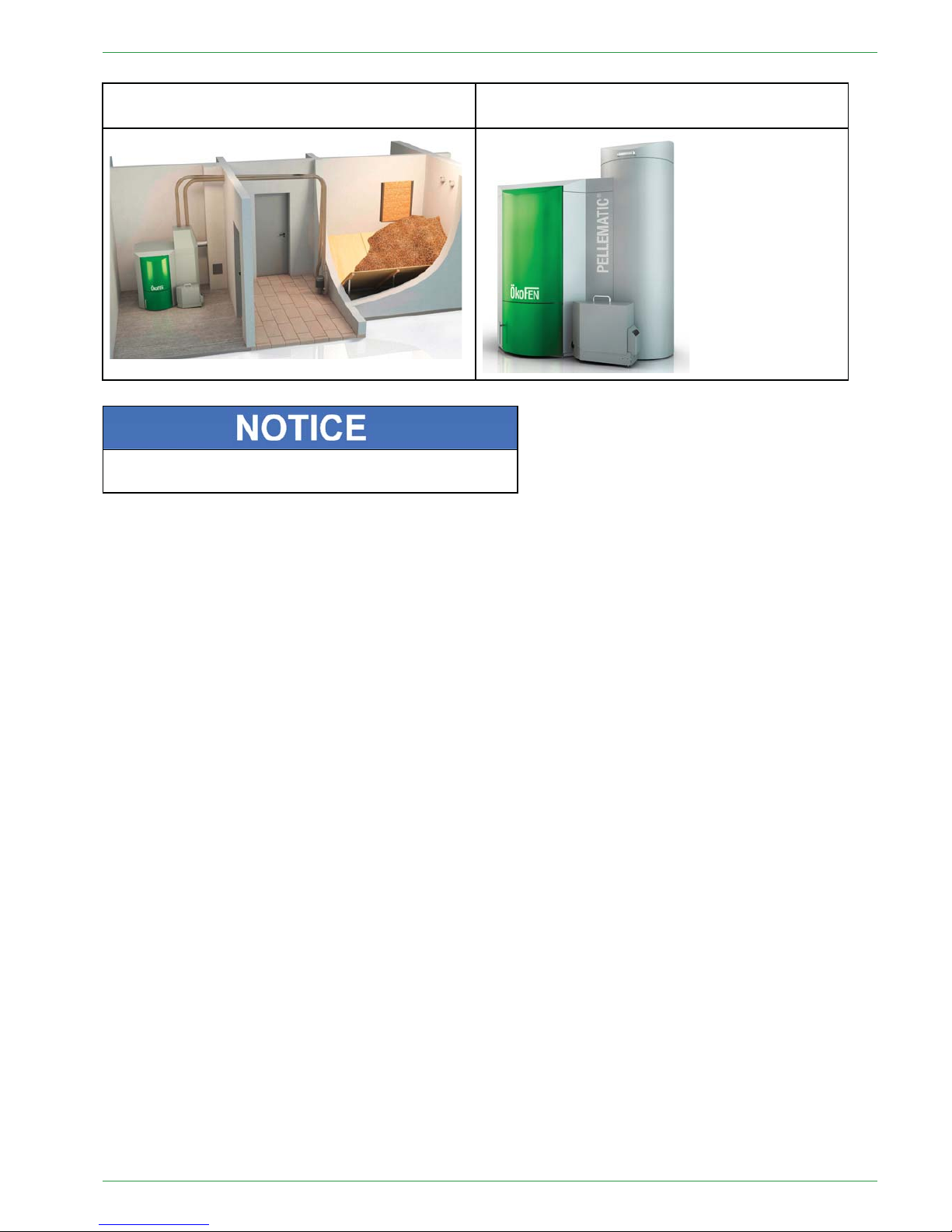

The whole system consists of following components:

ଉ Pellematic boiler:

• PE - Boiler with pellets transport auger as delivery system

• PES - Boiler with vacuum suction system as delivery system

• PEB - Boiler with hopper for hand filling

• PESKA - cascade with up to 4 possible boilers

ଉ Pellet storage room with pellet-delivery system:

• Storage room

• Textile tank

ଉ Possible additional components:

• Domestic hot water

• Accumulator

• Solar thermal panel

• Existing external boiler

Pellematic with storage room and auger delivery Pellematic with textile tank and auger delivery

Pellematic with storage room and vacuum

suction

Pellematic with textile tank and vacuum suction

PE 567 EN 1.1

System overview

9

Pellematic cascade with textile tank and auger

delivery system

Pellematic with hopper for hand filling

There are seperate manuals for all components, which

describe functions and installation in detail.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

10

Control system

55 Control system

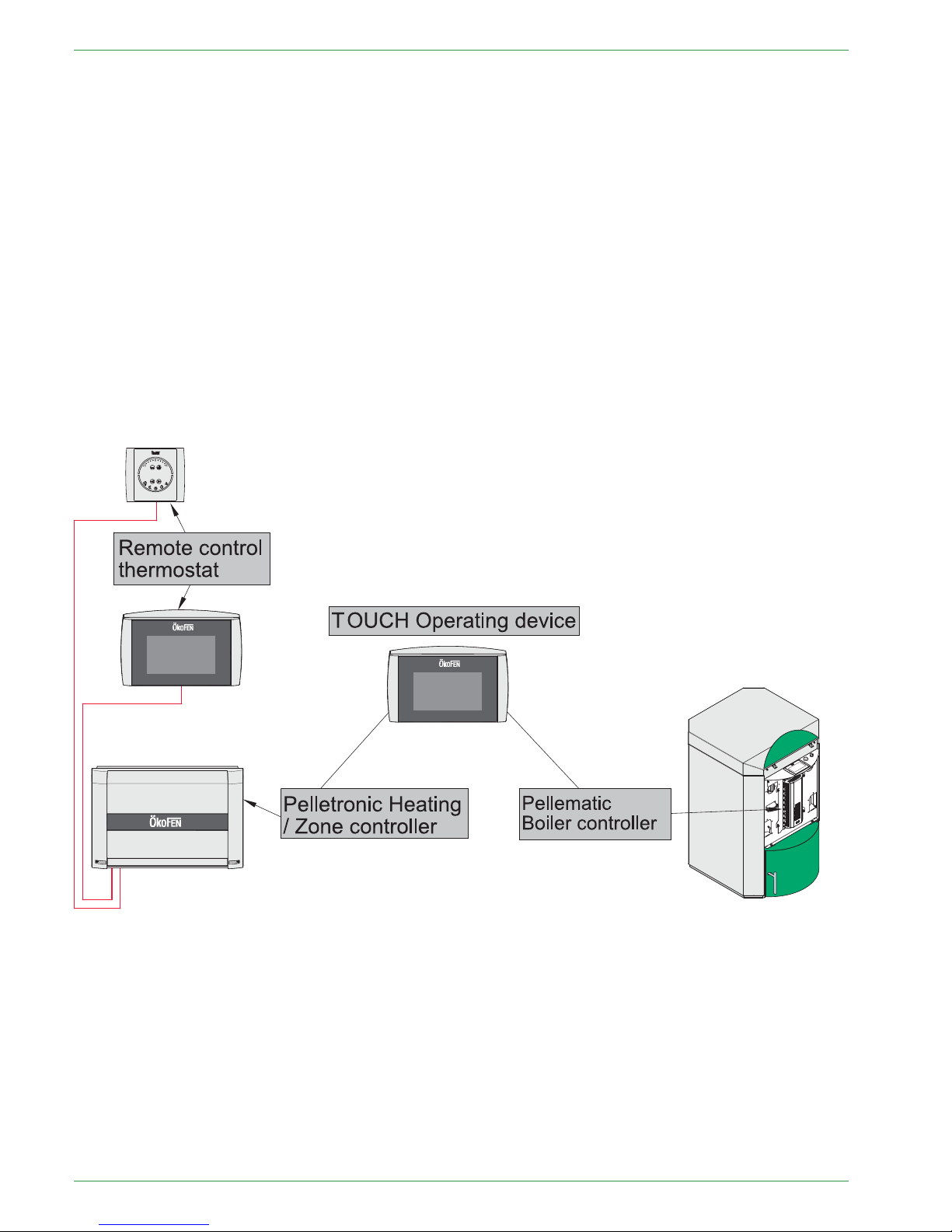

Basically the Controlsystem consists of following components:

• Pellematic boiler controller:

The boiler controller controls all boiler functions (pellet feed system, combustion, deashing, etc.)

• Pelletronic heating controller (max. 3 wall boxes = 6 zones, 3 domestic hot water, 3 accumulators)

The heating controller regulates the whole heat distribution system. (Room temperature, domestic hot

water, time programmes, solar, accumulator management, etc.)

Additionally remote controls can be installed in the system. These can be connected to the heat controller

by a bus-connection.

• Touch Operating Device

The Touch Operating Device is in the boiler. It is connected by a bus-connection with both, heating- and

boiler controller. It serves for:

– visualizing the measuring values

– adjusting the desired values and the time programme on the heating controller.

– adjusting the parameters of the boiler controller

PE 567 EN 1.1

Parameter Adjustments

11

66 Parameter Adjustments

There are two areas in which adjustments can be set:

• User-specific adjustments: e.g. Room temperature, Time program, Domestic hot water temperature,

Domestic hot water time program, Party-function etc.

• System-specific adjustments: e.g. combustion temperature regulation, deashing, ignition parameters,

suction interval, etc.

Ex works, adjustments are basically set, so no further adaption is neccessary.

A detailed description of all important setting options for the end user is to be found in the operating manual

of the End User.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

12

The boiler controller

77 The boiler controller

The boiler controller is directly on the Pellematic boiler behind the half-round front cover of the boiler.

It is used to control the combustion process and the fuel-feeding system.

The boiler controller is connected to the touch operating device by a bus-connection.

The Touch allows the owner / operator to see important measured values and Change to "Provides for

adjustment of desired values and parameters of boiler operation. Only authorized installers should adjust

boiler operating parameters."

1 F1: Fuse T10A

2 F2: Fuse T8A

DDaammaaggeeooffpprrooppeerrttyy

Fuses must be replaced only with fuses having the same

current and voltage ratings.

PE 567 EN 1.1

Plugs on the boiler control unit

13

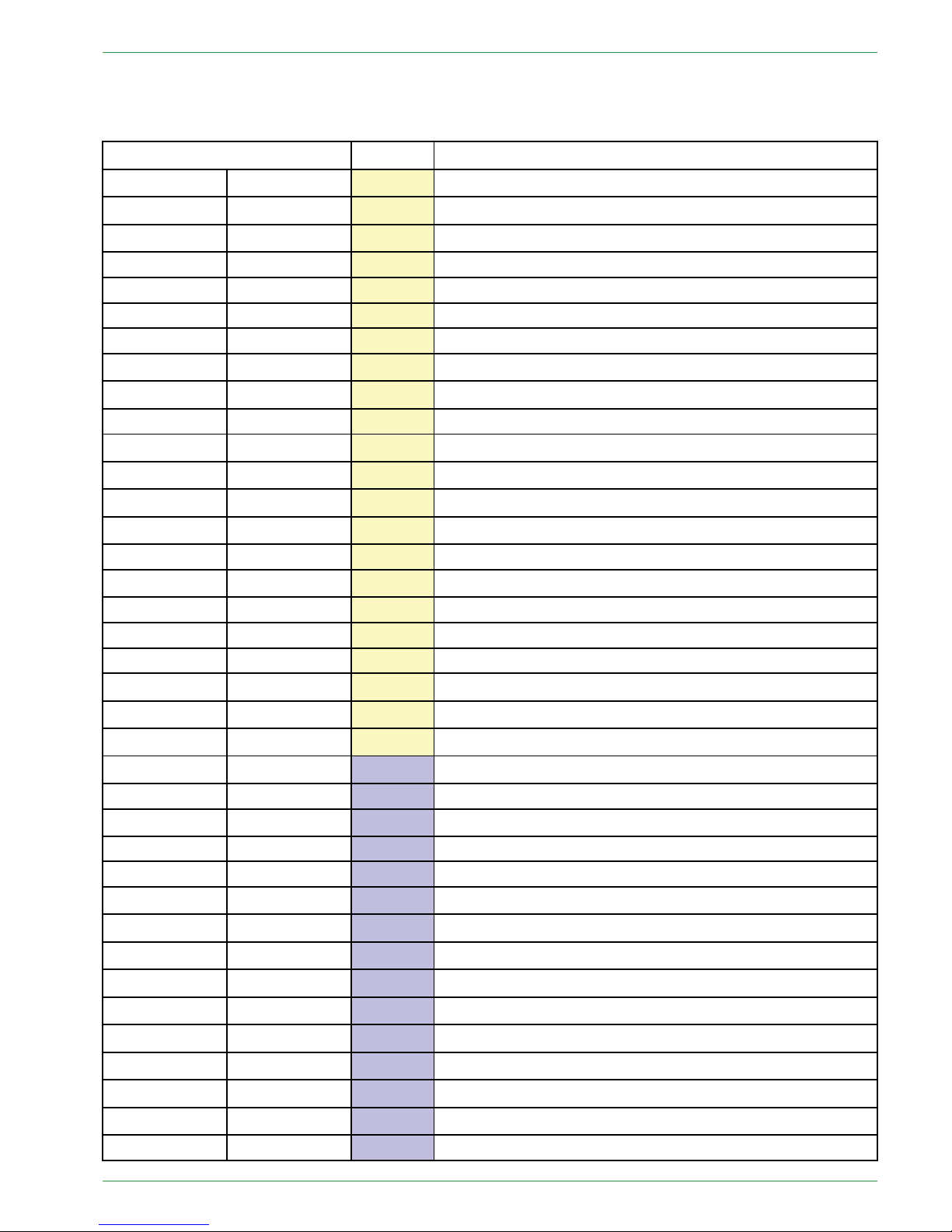

7.1 Plugs on the boiler control unit

The designation of the plugs must correspond with the labeling of plug-in positions.

Designation of plug-in position Voltage Name of sensors, motors and pumps

X1A

3 2 GND 1

24 Volt Operating display

X1B 3 2 GND 1

24 Volt Heating controller (BUS)

X2 5 4

24 Volt Power supply display

R1 46 45

24 Volt Not used

R2 44 43

24 Volt Not used

AF 42 41

24 Volt Not used

KF

89

24 Volt Boiler sensor

UP

234

24 Volt Negative draft measuring

AE2 5 6 7

24 Volt Level detection system

AE1

10 9 8

24 Volt Not used

FRT 12 13

24 Volt Combustion chamber temperature sensor

RGF 14 15

24 Volt Flue gas temperature sensor (optional)

PWM 16 17

24 Volt PWM for speed controlled high-efficiency pump

Analog IN

18 19

24 Volt Not used

BR1 7 8

24 Volt

Burner contact

AK 11 12

24 Volt Existing boiler (optional)

ESAV 32 33 34

24 Volt End switch ash box

DE 1 37 36 35

24 Volt Not used

DE 2 40 39 38

24 Volt Not used

KAPZW 26 25 24

24 Volt Capacitive sensor – hopper

KAPRA 5 4 3

24 Volt Capacitive sensor – burner

BSK 654321

24 Volt Flame return gate

X21 PE L N

230 Volt Power supply

VAK 56 PE 55

230 Volt Vacuum turbine

ZUEND

NPE22

230 Volt

Ignition

AV 52 PE 51

230 Volt Motor ashbox

RES 2 54 PE 53

230 Volt Not used

MA 48 PE 47

230 Volt Magnetic valve (Cleaning nozzle, heat exchanger)

RM 15 PE N

230 Volt Motor boiler cleaning device

SM 19 20

230 Volt Relay fault signal (optional)

SZ 17 PE N

230 Volt Flue gas fan

UW 13 PE N

230 Volt Boiler controlled pump

STB 17 PE 19

230 Volt Safety temperature sensor

NOT 41 43

230 Volt Emergency stop heating

RA1 N PE 14 15 16

230 Volt Fuel transport system

RES1 50 PE 49

230 Volt Motor hopper – PES 36–56 only

ZW

NPE262524

230 Volt Vibration motor

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

14

Plugs on the boiler control unit

ES 1 2 3 N PE 6

230 Volt

Burner motor

LUFT N PE 11

230 Volt Burner fan

PE 567 EN 1.1

Wiring diagrams

15

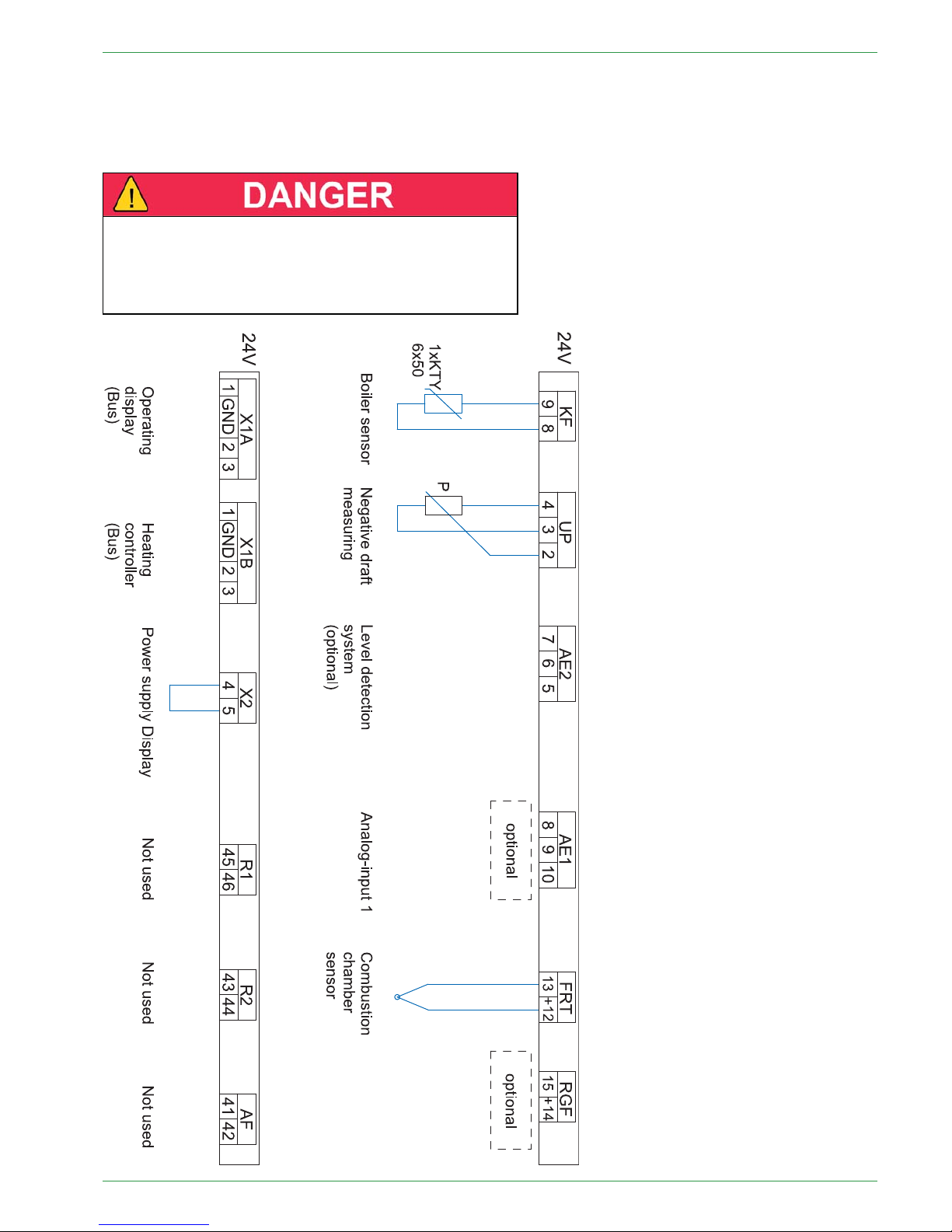

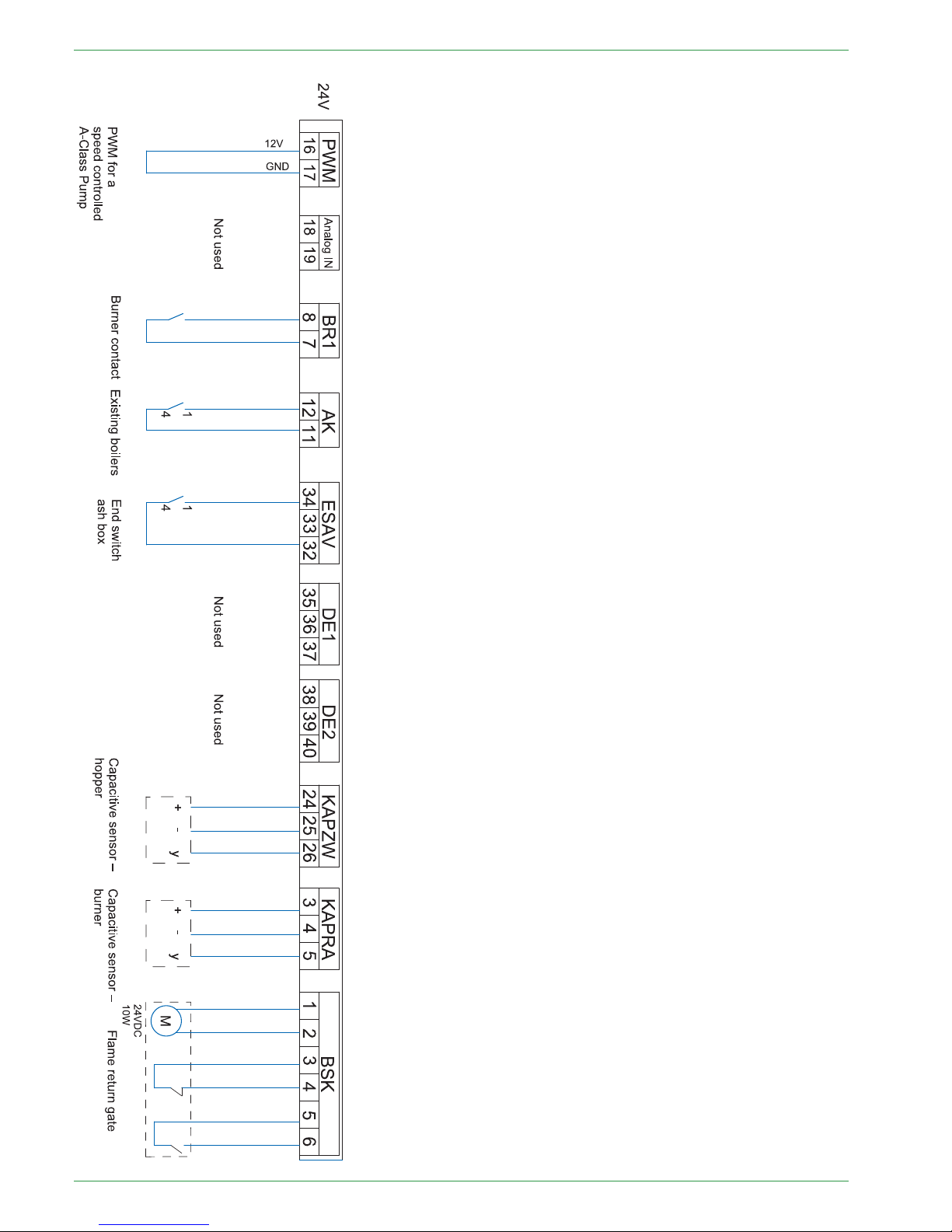

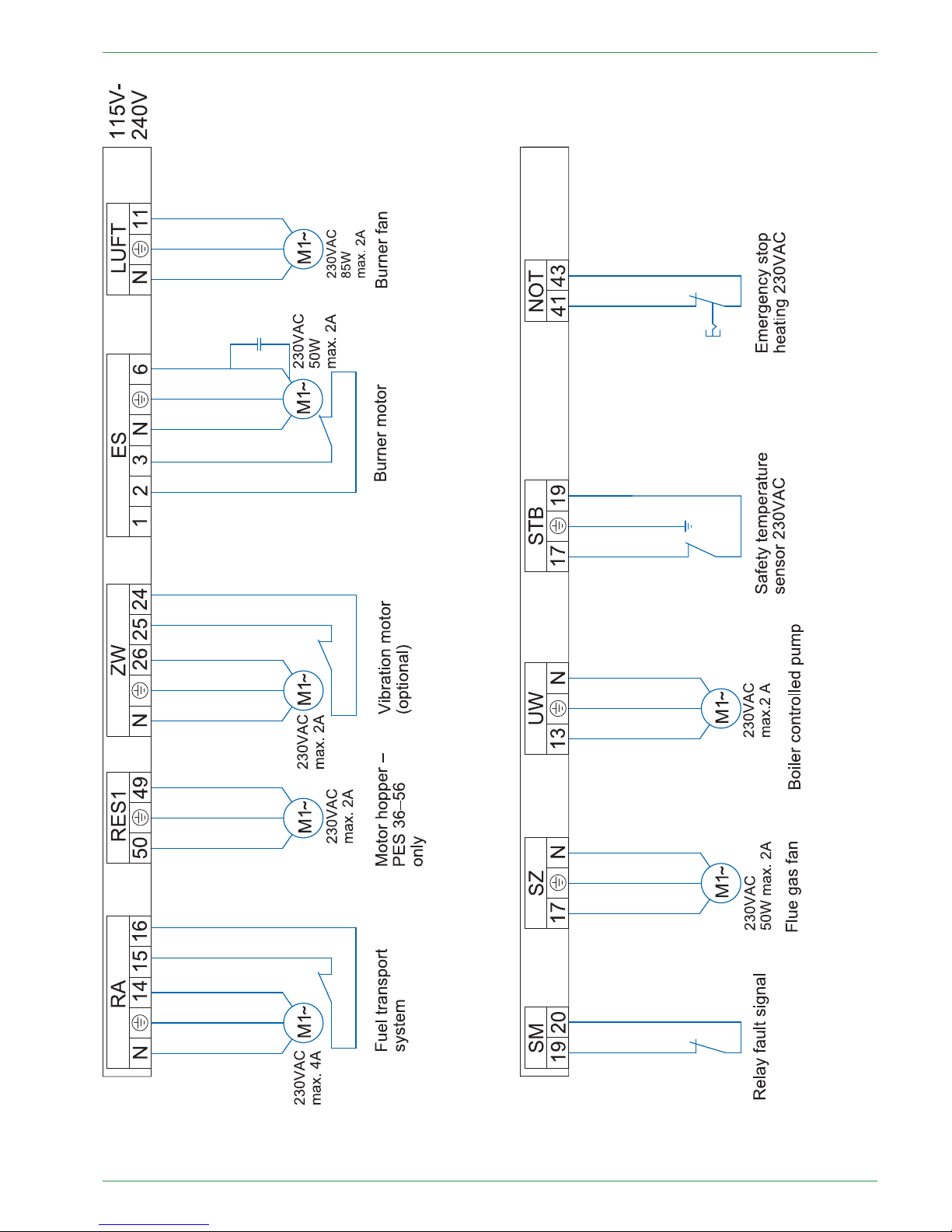

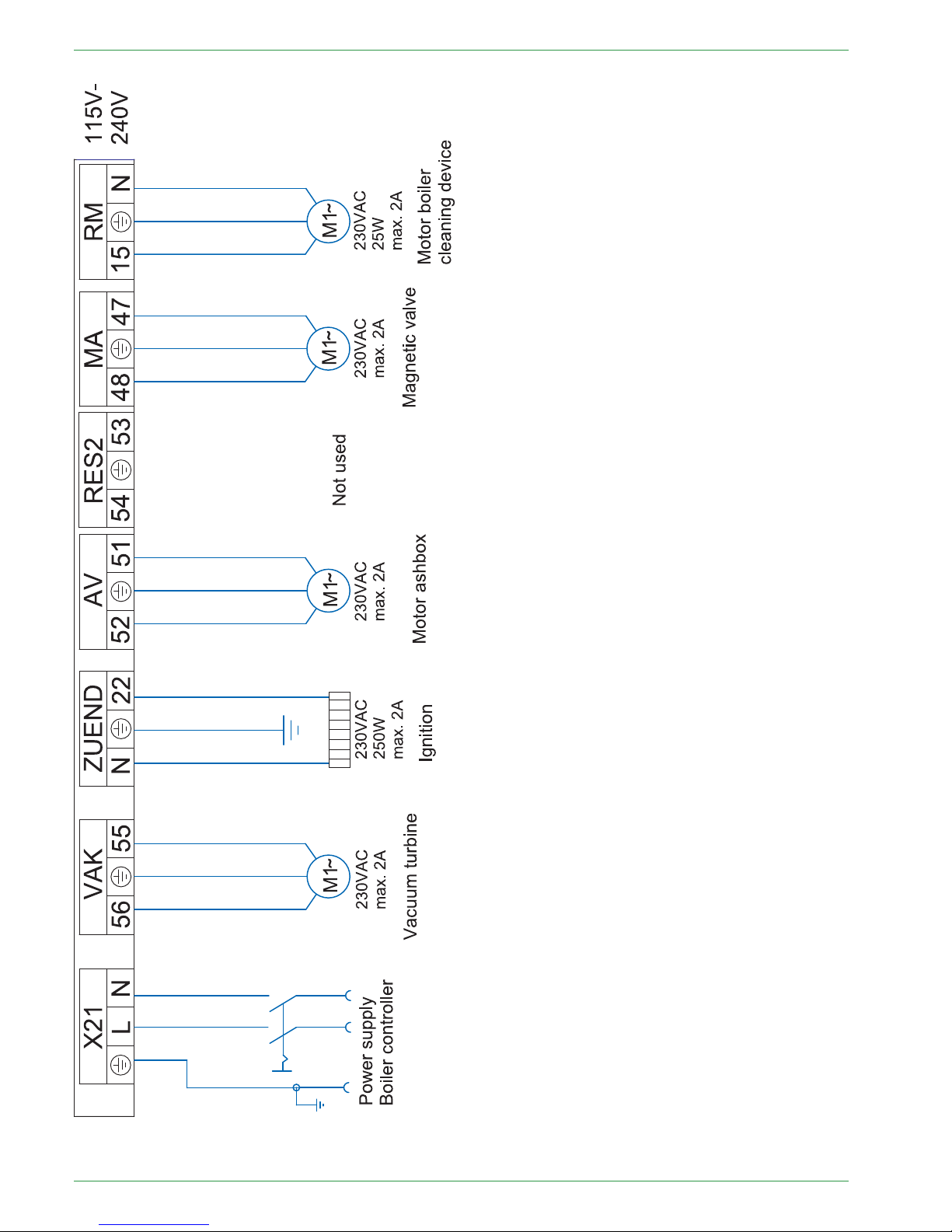

7.2 Wiring diagrams

The wiring diagrams for the boiler control unit provide detailed technical information for certified installers.

Only certified installers or electricians under the direction of a certified installer may connect to the

controller.

RRiisskkooffeelleeccttrriiccsshhoocckk

Only an authorised installer may connect the pellet boiler to the power supply.

Always disconnect / de-energize the power supply before working on the boiler.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

16

Wiring diagrams

PE 567 EN 1.1

Wiring diagrams

17

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

18

Wiring diagrams

PE 567 EN 1.1

LED status boiler controller 19

7.3 LED status boiler controller

Display Description Cause and remedy

red Power supply present

—

red flashing Error condition

no communication possible

Check the software version

Check the bus wiring

Check the address

red / orange flashing

In the bus systems are devices using

the same address

Change the address

orange

Power supply present

Processor runs

No bus communication

Check the software version

Check the bus wiring

Check the address

orange flashing Firmware- update is in progress

—

green flashing Initialization (Firmware boots) If state is unchanged, software must

be checked.

green

Operation

Cyclic communication possible

—

7.4 Cable Routing

Th cable routing and the connection of the motors and sensors is precisely described in the Installation manual .

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

20

The heating controller

88 The heating controller

The heating controller is in a wall box, which is in most cases installed nearby the heating circuit distributor.

It is used to control the whole heat distribution system for example: domestic hot water, room temperature,

solar system, accumulator, etc

It consists of a casing with an internal circuit board and terminals.

The cover plate of the casing is removable.

EElleeccttrriiccsshhoocckkddaannggeerr

Before opening, make sure that the whole heating

system is powerless.

Note:

The heating controller is limited to 8 amps total current draw. Also, each output is rated at 2 amps max.

Make sure that these values are not exceeded to avoid fuse failure.

PE 567 EN 1.1

LED status heating controller

21

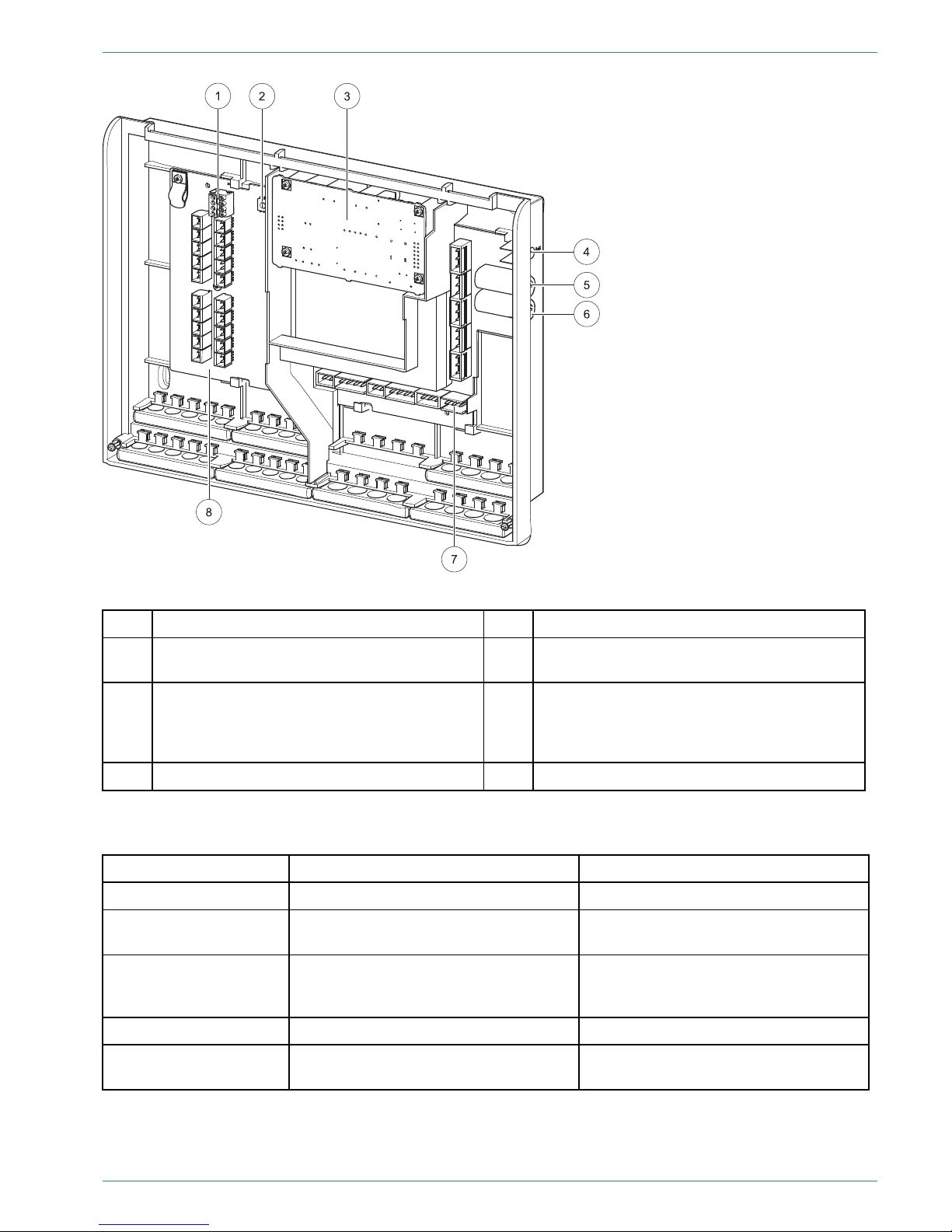

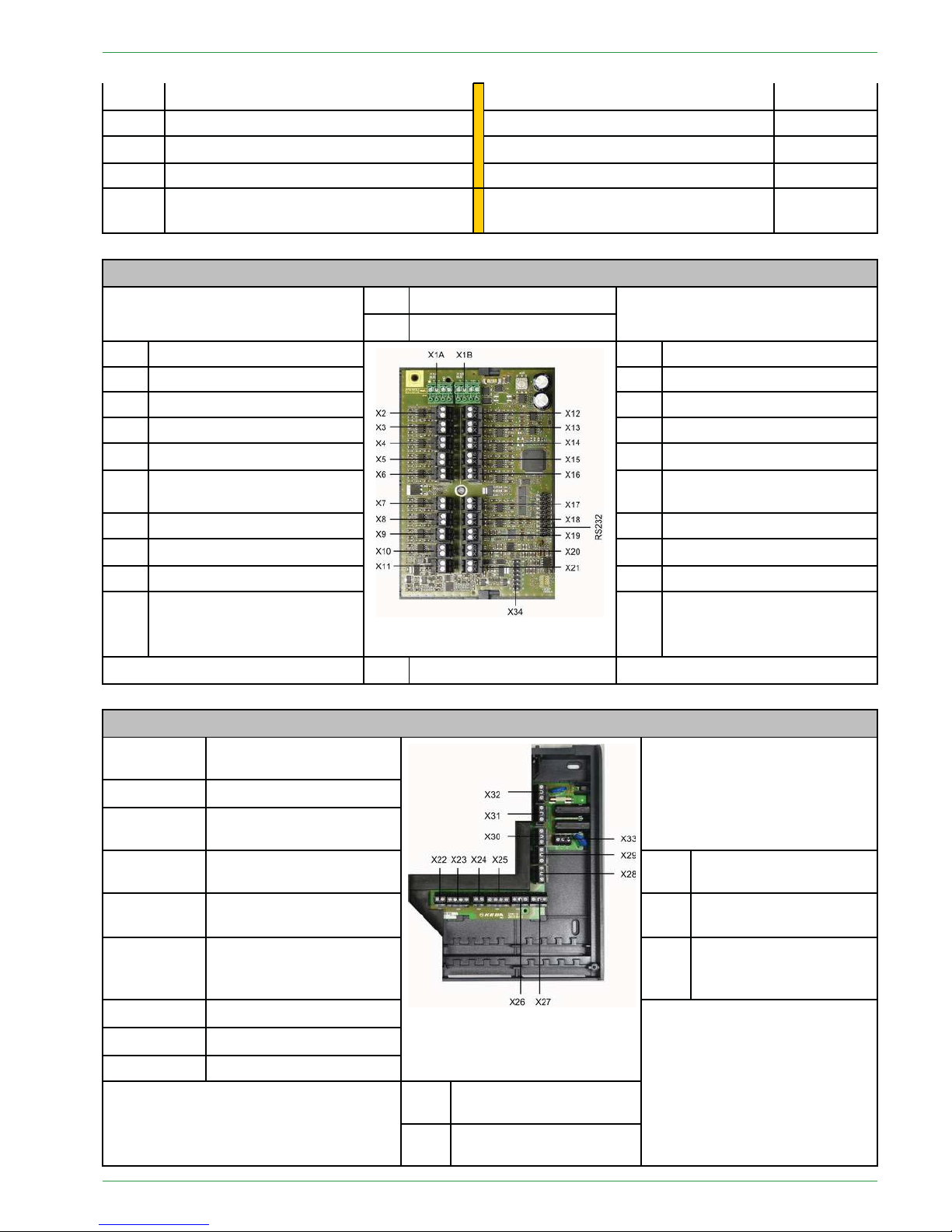

1

Bus connecting terminal RS485 A and B

5

Fuse 6,3 A (fast) for X31 and X33

2

Address switch

6

Fuse 8 A (slow-acting) limits the current

consumption of the heating controller.

3

Slot for an optional power supply

(The power supply is needed when the

burner control CMP 06.2 is used. The power

supply takes over the bus supply.)

7

Low voltage – area (dangerous voltage)

4 Status-LED 8

Extra low voltage (PELV)

8.1 LED status heating controller

Display Description Cause and remedy

red Power supply present

—

red flashing Error condition

no communication possible

Check software version

Check bus wiring

orange

Power supply present

Processor runs

no communication possible

Check bus wiring

green flashing Initialization (Firmware boots)

—

green

Operation

Cyclic communication possible

—

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

22

Connection plan

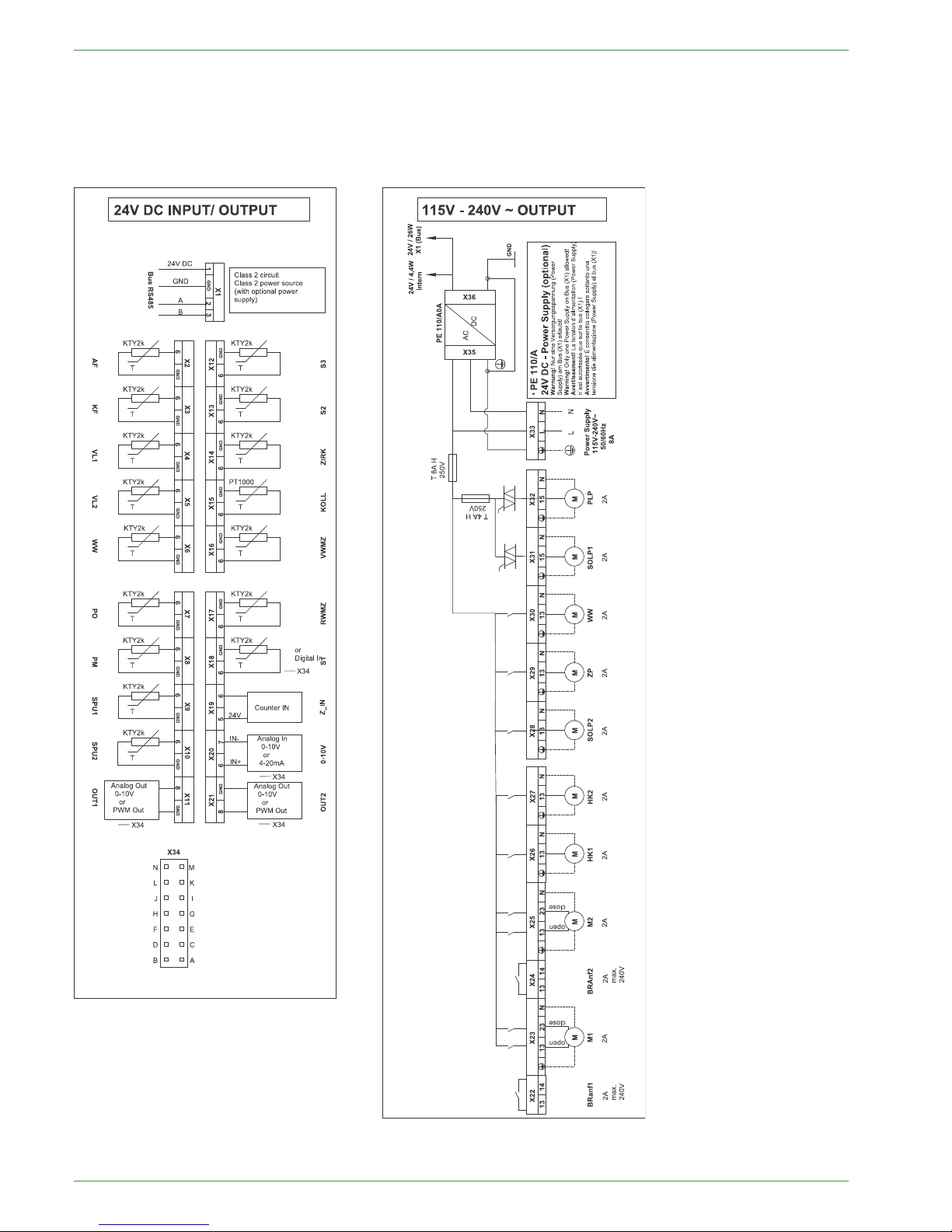

8.2 Connection plan

The Connection plan is a description of all the electrical connections from the Pelletronic heating controller:

Only an authorised installer may install and connect the

heating controller to the power supply.

Isolate the entire heating system from the power supply

before starting work on the heating controller.

Boiler sensor + outside sensor must be connected on

the first heating controller!

Terminals extra-low voltage zone Terminals low voltage zone - 120VAC

X1A Bus wiring – Bus RS485

Burner demand 1 – BRanf 1

X22

X1B Bus wiring – Bus RS485 Mixer HK1 opening – M1

X23 – 13/N

X2

Outdor sensor – AF Mixer HK1 closing – M1

X23 – 23/N

X3

Boiler sensor – KF Burner demand 2 – BRanf 2

(Potencial free contact)

X24

X4

Flow sensor HK1 – VL1

Mixer HK2 opening – M2

X25 – 13/N

X5

Flow sensor HK2 – VL2 Mixer HK2 closing – M2

X25 – 23/N

X6

DHW sensor – WW Heating circuit pump – HK1 X26

X7

AC upper sensor – PO Heating circuit pump – HK2 X27

X8

AC middle sensor – PM Solar pump 2 – Sol P2

X28

X9

AC lower sensor 1 – SPU1

Return pump – Heat main pump – ZP X29

X10

AC lower sensor 2 – SPU2 Domestic hot water – WW

X30

X11

Solar pump 1 A-class Solar pump 1– Sol P1

X31

X12 Reserve – S3

Accumulator pump – PLP

X32

X13 Reserve – S2

Power supply 115V – 240V~

X33

X14 Return sensor – ZIRK

X15

Collector sensor – KOLL

X16

Solar energy Flow – VWMZ

PE 567 EN 1.1

Connection plan

23

X17

Solar energy Return – RWMZ

X18 Reserve – S1

X19

Flow rate 24V – Z_IN

X20 Reserve – 0-10V

X21

Solar pump 2 A-class or Accumulator

pump A-class

Terminals extra-low voltage zone

X1A Bus wiring – Bus RS485

X1B Bus wiring – Bus RS485

X2

Outdor sensor – AF

X12 Reserve – S3

X3

Boiler sensor – KF

X13 Reserve – S2

X4

Flow sensor HK1 – VL1

X14 Return sensor – ZIRK

X5

Flow sensor HK2 – VL2

X15

Collector sensor – KOLL

X6

DHW sensor – WW

X16

Solar energy Flow – VWMZ

X7

AC upper sensor – PO

X17

Solar energy Return–

RWMZ

X8

AC middle sensor – PM

X18 Reserve – S1

X9

AC lower sensor 1 – SPU1

X19

Flow rate 24V – Z_IN

X10

AC lower sensor 2 – SPU2

X20 Reserve – 0-10V

X11

Solar pump 1 A-class

X21

Solar pump 2 A-class or Accumulator pump A-class

X34 Jumper

Terminals low voltage zone - 120VAC

X32

Accumulator pump –

PLP

X31

Solar pump 1– Sol P1

X30

Domestic hot water –

WW

X25 – 23/N

Mixer HK2 closing – M2

X33

Power supply 115V –

240V~

X25 – 13/N

Mixer HK2 opening – M2 X29

Return pump – Heat

main pump – ZP

X24

Burner demand 2 –

BRanf 2

(Potencial free contact)

X28

Solar pump 2 – Sol P2

X23 – 23/N

Mixer HK1 closing – M1

X23 – 13/N

Mixer HK1 opening – M1

X22

Burner demand – BRanf 1

X26 Heating circuit pump –

HK1

X27 Heating circuit pump –

HK2

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

24

Connection plan

Electrical wiring diagrams heating controller

The wiring diagrams are also located on the inside of the cover of the heating controller.

Be aware of the instructions and diagrams illustrated there.

PE 567 EN 1.1

Jumper X34 for analog voltage outputs X11 (OUT1) and X21 (OUT2)

25

88..22..11JJuummppeerrXX3344ffoorraannaallooggvvoollttaaggeeoouuttppuuttssXX1111((OOUUTT11))aannddXX2211((OOUUTT22))

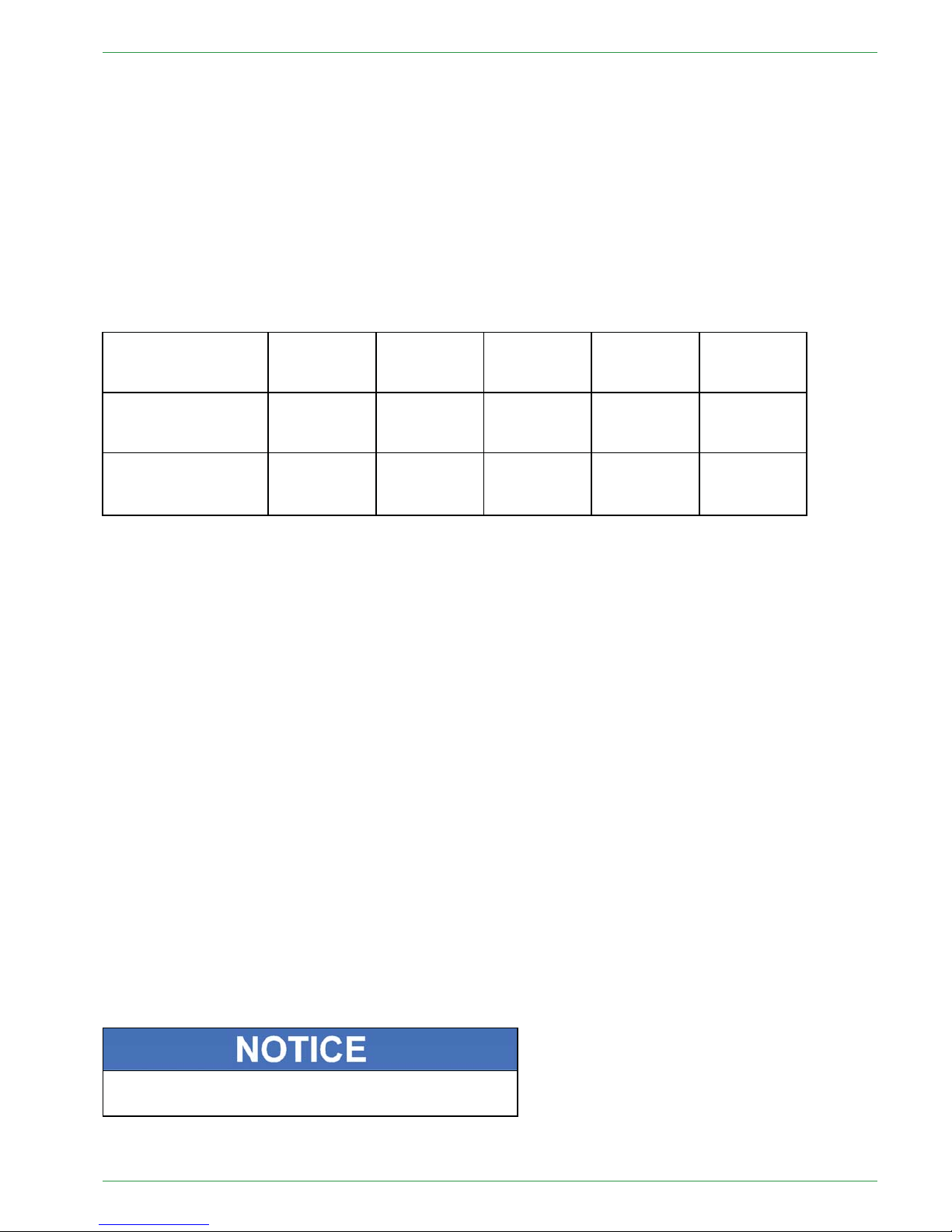

The different types of high-efficiency pumps: Analog pumps with 0-10 V control and PWM pumps with 24V.

For each type of pump you have to adjust the signal at the heating controller.

The plug connector X34 is for the Jumper-settings. Use a jumper with a grid dimension of 1 inch. The terminals X11 and X21 can receive or export a different signal depending on the jumper position.

Note:

When using PWM-pumps for a voltage up to 15V, adapter-cables must be connected at the slots X11 and

X12.

These cables limit the output voltage from 24V to 15V.

Jumpersettings X34:

The male connector X34 serves for jumper-adjustments. Please use jumper with a contact spacing of 1 inch

(included in delivery of heating controller)

High-efficiency

pump with external

control function

Terminal Designation Function Plug

connector

Position

Solar pump 1

X11 Out 1 PWM Out

Analog Out

0-10V

A-B and C-D

A-B and C-D

0

X

Solar pump 2

(or accumulator

pump)

X21 Out 2 PWM Out

Analog Out

0-10V

E-F and G-H

E-F and G-H

0

X

0.... Jumper is not set, pins open.

X.... Jumper is set, pins closed.

8.3 Rules of wiring for micronetwork with 1,2 or more heating

controllers

The boiler controller suplies the touch operating device and up to two remote controls.

• The order of devices in the bus-wiring is free. The station-numbers for the heating controller and the digital

remote controls have to be assigned uninterrupted.

• The number of heating controllers is independent from the numbers of the digital remote controls and independent from the numbers of boiler controllers.

•Adouble allocation is not acceptable.

• The maximum limit of bus-participiants is 16.

• The maximum length of a bus-cable is 200 metres.

• The maximum cable-length depends on:

– A solid point-to-point topology allows the fullmax. length.

–Astar-topology does not allow the max. length.

– We recommend a twisted-pair cable, especially for long cables (e.g. in buildings) and if the cable runs paralell to other cables.

– Correct bus-connection resistance, which is always existing on boiler operating device.

For long cables or communication problems occur, a additional resistor with 120 Ohm has to be clamped

between wire A and B at the last bus-participant.

When controlling a cascade-system, a bridge must be

installed at boiler controller port X2.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

26

Wiring diagrams

8.4 Wiring diagrams

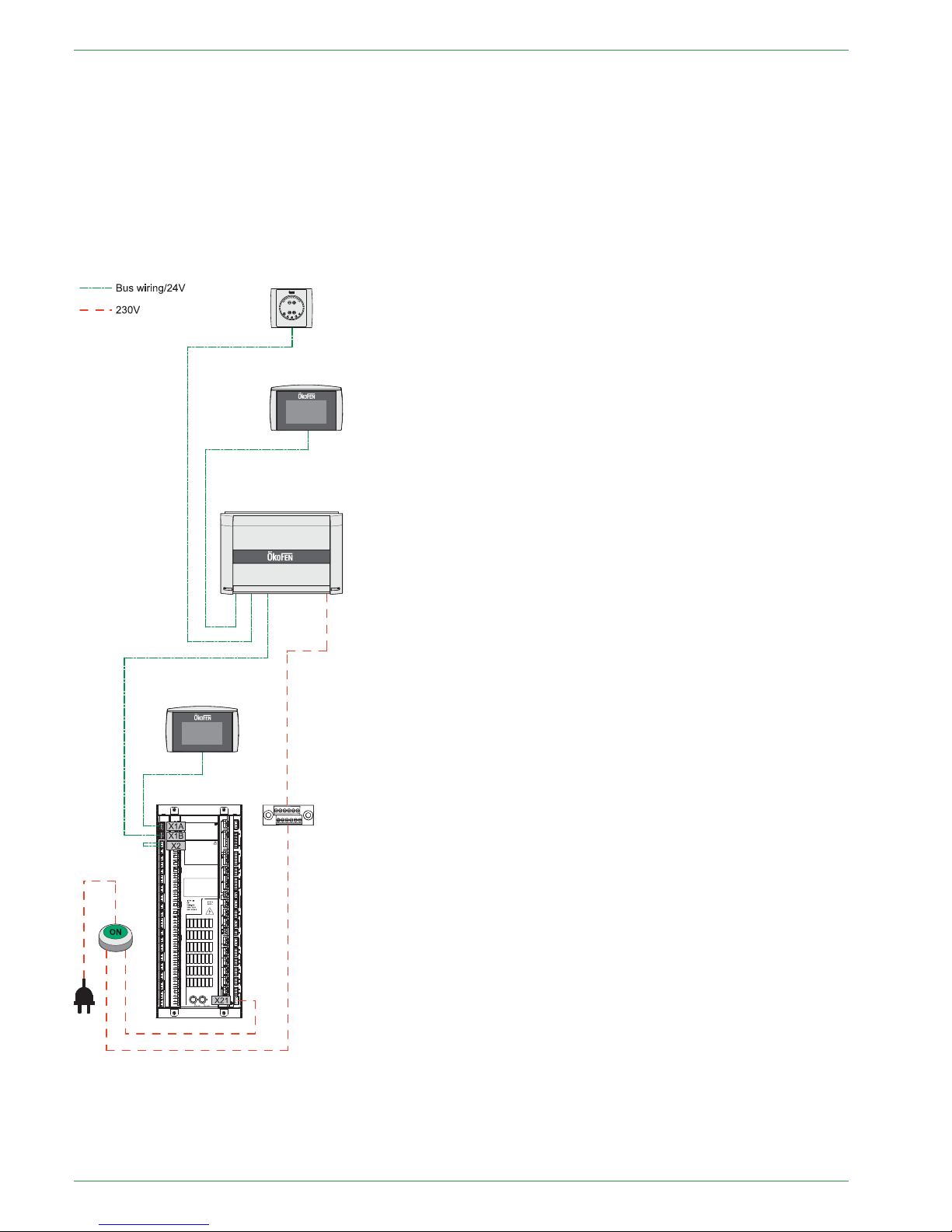

Wiring diagram with:

• 1x Boiler controller FA

• 1x Heating controller Pelletronic

• 1x Touch operating device (Master)

• 1x Touch remote control (Slave)

• 1x Remote controll with LED

Note:

You find more detailed information about wiring in chapter 8.3 Rules of wiring for micronetwork with 1,2

or more heating controllers, page 25

PE 567 EN 1.1

Wiring diagrams

27

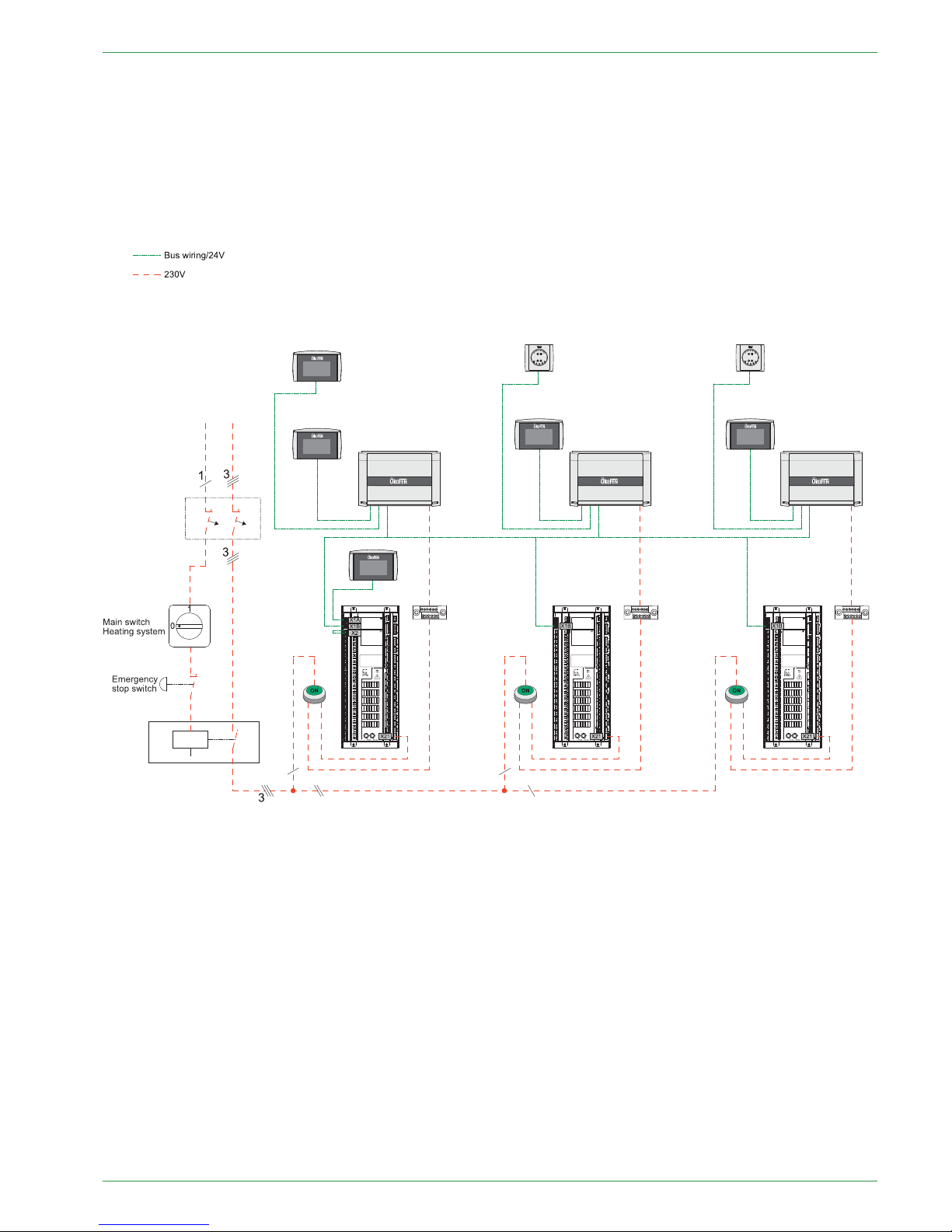

Wiring diagram with:

• 3x Boiler controller FA

• 3x Heating controller Pelletronic

• 1x Touch operating device (Master)

• 4x Touch remote control (Slave)

• 2x remote controll with LED

Note:

You find more detailed information about wiring in chapter 8.3 Rules of wiring for micronetwork with 1,2

or more heating controllers, page 25

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

28

Assembly and disassembly of the heating controller circuit board

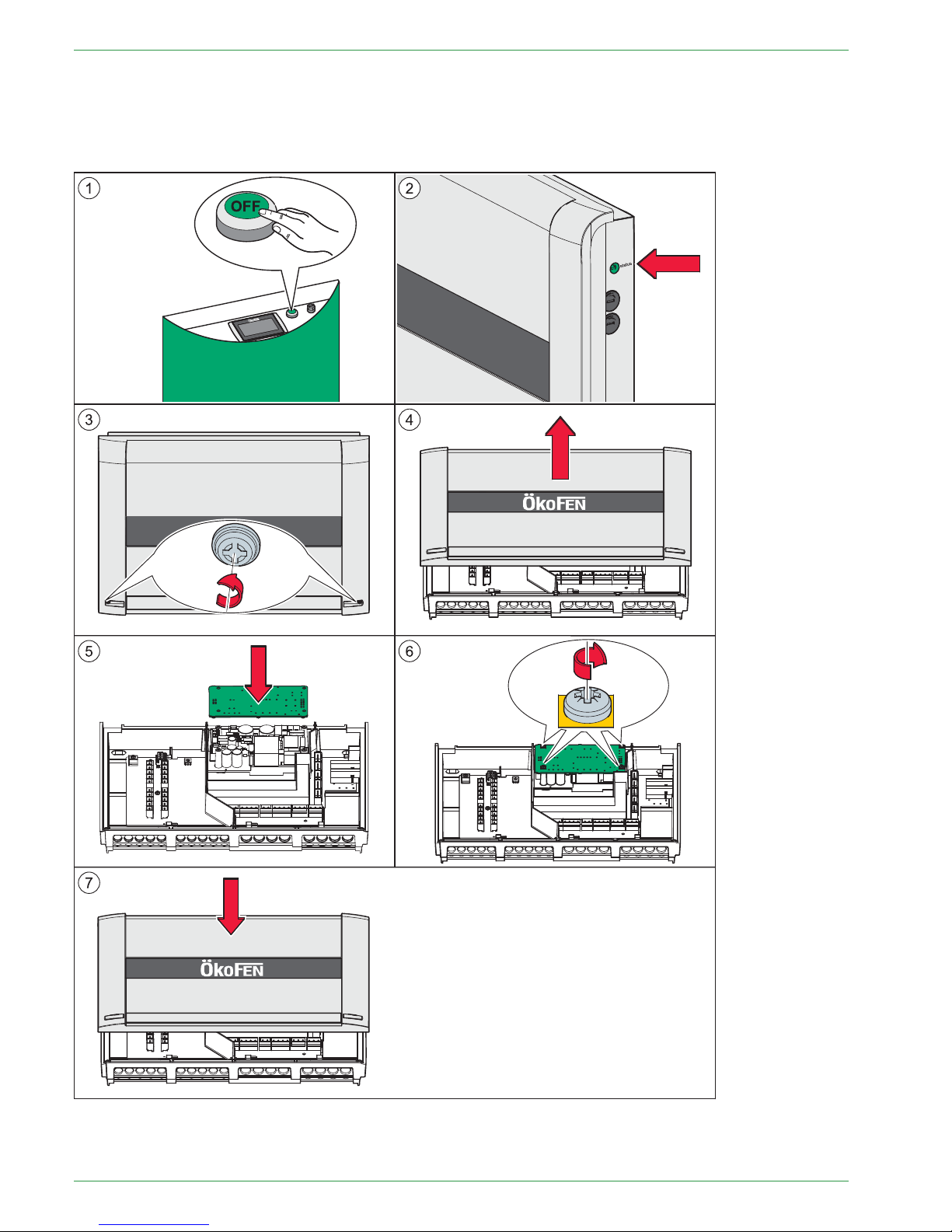

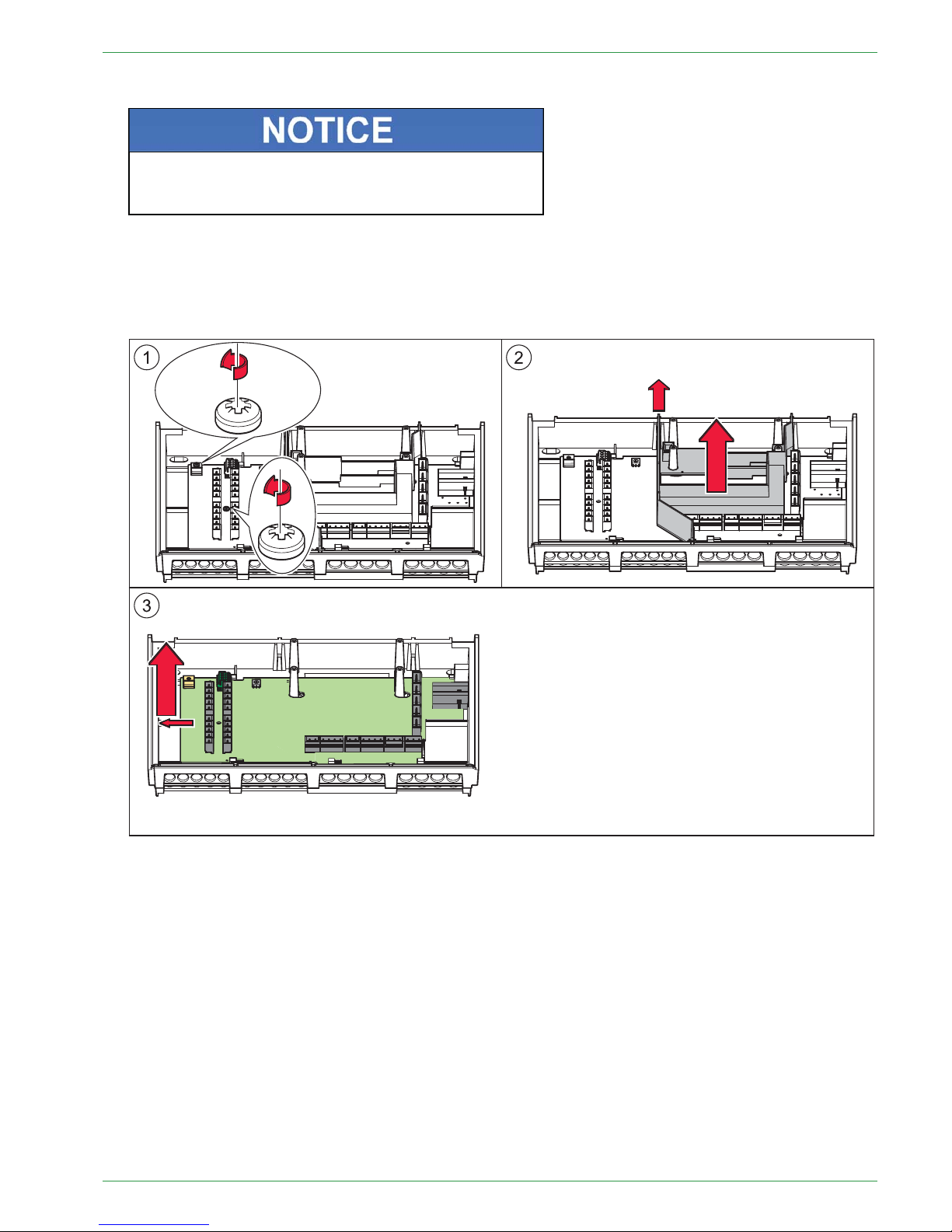

8.5 Assembly and disassembly of the heating controller circuit

board

You can take off the circuit board of the heating controller, without filtering out the inputs and outputs.

Note:

Image 2: Control with the status of the LED that the heating controller is electroless.

PE 567 EN 1.1

Assembly and disassembly of the heating controller circuit board

29

1. Make the complete heating system powerless.

EElleeccttrroossttaattiiccddiisscchhaarrggeeddaammaaggee

Before starting work, touch a grounded object to avoid

damage of circuit board by electrostatic charging.

2. Open the cover plate of the heating controller.

3. Disconnect all plugs from the circuit board. Leave the plugs with the wiring in the casing.

4. Disassembly from the power supply (optional)

5. Disassembly the circuit board from the heating controller.

6. The installation of a new circuit board occurs in reverse order.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

30

Cable specification Pelletronic Touch

8.6 Cable specification Pelletronic Touch

Power supply

K02

X33 YML-J 3x1

x

OUTPUTS see on wiring diagram on the front side

Function – Shortcut

Cable

Pin I/O BOX

Cable type Section

Max

Ampere

Burner contact 1 – BRanf 1

K 03 X22

YML-J

3x0.75 2A

Mixer HK1 OPEN – M1 K 12

X23 – 13/N

YML-J

3x0.75 2A

Mixer HK1 CLOSED – M1 K 12

X23 – 23/N

YML-J

3x0.75 2A

Burner contact 2 – BRanf 2

(Potencial free contact)

K 30 X24

YML-J

3x0.75 2A

Mixer HK2 OPEN – M2 K 13

X25 – 13/N

YML-J

3x0.75 2A

Mixer HK2 CLOSED – M2

K13

X25 – 23/N

YML-J

3x0.75 2A

Heating circuit pump – HK1 K 14 X26

YML-J

3x0.75 2A

Heating circuit pump – HK2 K 15 X27

YML-J

3x0.75 2A

Solar pump 1 – Sol P1

K 16 X31 YML-J 3x0.75 2A

Return pump – Heat main pump –ZPK 29 X29

YML-J

3x0.75 2A

Domestic hot water pump – WW

K 21 X30

YML-J

3x0.75 2A

Solar pump 2 – Sol P2

K 23 X28 YML-J

3x0.75 2A

Accumulator pump – PLP

K 05 X32 YML-J 3x0.75 2A

Bus wiring – Bus RS485 K 01 X1A YSLCY–0Z 4x0.75

x

Bus wiring – Bus RS485 X1B YSLCY–0Z 4x0.75

x

Solar high-efficiency pump 1

K 28 X11 YML

2x0.75

x

Solar high-efficiency pump 2 or

Accumulator high-efficiency

pump

K 71 X21

YML

2x0.75

x

INPUTS see on wiring diagram on the front side

Function – Shortcut

Cable

Pin I/O BOX

Cable type Section

Max

Ampere

Outdor sensor – AF

K 09 X2 YML 2x0.75

KTY 2k

Boiler sensor – KF

K04

X3 YML

2x0.75

KTY 2k

Flow sensor HK1 – VL1

K 10 X4 YML 2x0.75

KTY 2k

Flow sensor HK2 – VL2

K 11 X5 YML

2x0.75

KTY 2k

DHW sensor – WW

K19 X6

YML

2x0.75

KTY 2k

AC upper sensor (TPO) – PO K 18

X7 YML

2x0.75

KTY 2k

AC middle sensor (TPM) – PM

K 17 X8 YML

2x0.75

KTY 2k

AC lower sensor 1 – SPU1

K20 X9

YML

2x0.75

KTY 2k

AC lower sensor 2 – SPU2

K 22 X10

YML

2x0.75

KTY 2k

Reserve sensor – S3 X12 YML

2x0.75

KTY 2k

Sensor existing boiler – S2

X13 YML

2x0.75

KTY 2k

Sensor return pump – ZIRK K 29 X14 YML 2x0.75

KTY 2k

PE 567 EN 1.1

Sensor values 31

Collector sensor – KOLL

K 08 X15 YML 2x0.75 PT 1000

Solar energy Flow – VWMZ

K 25 X16

YML

2x0.75

KTY 2k

Solar energy Return – RWMZ

K 26 X17 YML 2x0.75

KTY 2k

Sensor Reserve – S1 X18

YML

2x0.75

KTY 2k/Dig

I

Flow rate 24V – Z_IN

X19

YML

2x0.75

x

Reserve – 0-10V X20

YML-J 3x1

x

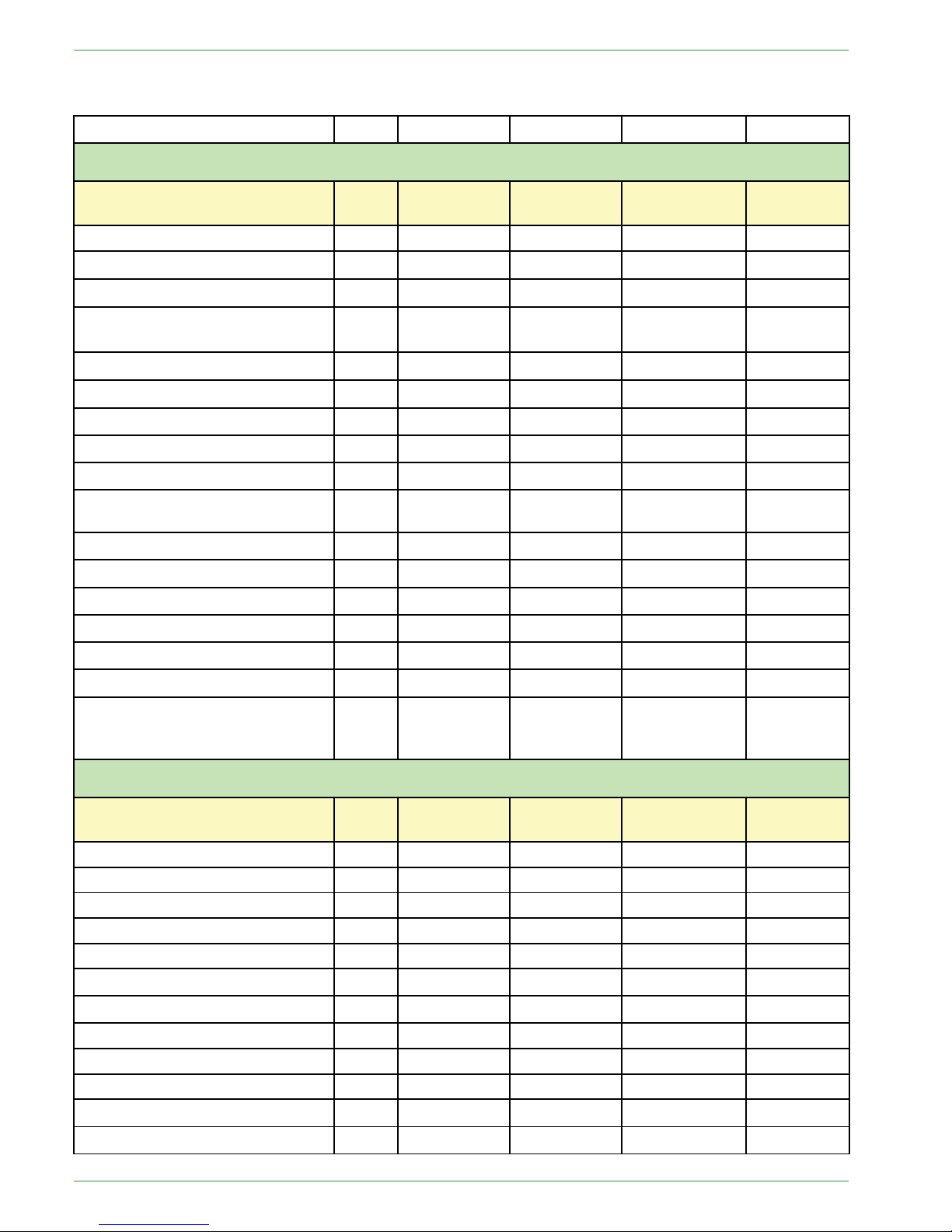

8.7 Sensor values

Values of resistance and thermic voltage of the different sensores can be found in the following table:

Temperature [°C]

Resistance temperature sensor [] thermical voltage [9]

PT 1000

(collector sensor)

KTY

(heating sensor)

NiCr Ni

(combustion

chamber sensor)

-20 922 1396

-777

-15 941 1431 -588

-10 961 1499 -392

-5

980 1562 -196

0 1000 1630 0

5

1020 1700 -199

10 1039 1772 397

15 1058 1846 596

20 1078 1922 798

25 1097 2000 997

30 1117 2080 1203

40 1155 2245 1611

50 1194 2418 2022

60 1232 2599 2436

70 1271 2788 2850

80 1309 2984 3266

90 1347 3188 3681

100 1385 3400 4095

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

32

Hydraulic connecting diagrams

8.8 Hydraulic connecting diagrams

88..88..11HHyyddrraauulliiccccoonnnneeccttiinnggddiiaaggrraammssPPeelllleettrroonniiccTToouucchh

88..88..11..11DDiiaaggrraamm11

1 Boiler Pellematic – 1 Accumulator Pellaqua – 2 Heating circuits – 1 Solar circuit

88..88..11..22DDiiaaggrraamm22

1 Boiler Pellematic – 1 DHW Accumulator – 2 Heating circuits – 1 Solar circuit

PE 567 EN 1.1

Diagram 3

33

88..88..11..33DDiiaaggrraamm33

1 Boiler Pellematic – 1 Accumulator Pellaqua – 2 Heating circuits – 1 Fresh water module – 1 Solar circuit

Pellematic

88..88..11..44DDiiaaggrraamm44

1 Boiler Pellematic – 2 Accumulators Pellaqua – 2 Fresh water module – 4 Heating circuits – 1 Solar circuit

Pellematic

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

34

Diagram 5

88..88..11..55DDiiaaggrraamm55

1 Boiler Pellematic – 1 Accumulator Pellaqua – 1 Fresh water module – 4 Heating circuits – 1 Solar circuit – 1

DHW Accumulator

Solar plant

Pellematic

X4

X26

X23

X5

X27

X25

X30

X6

Outdoor sensor

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

X31

X15

X6

X7

X8

X9

Freshwater

module

BUS

Feeding controller

BUS

Power 230V

X2

UW

TI

X29

Power 230V

PWM

88..88..11..66DDiiaaggrraamm66

1 Boiler Pellematic – 1 Accumulator Pellaqua – 1 DHW Accumulator – 2 Heating circuits – 2 Solar circuits

1

2

Solar plant

Pellematic

X2

TI

TI

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

X15

X6

X16

X17

X19

X28

X31

X9

X10

Outdoor sensor

X7

X8

Power 230V

BUS

Feeding controller

TI

UW

PWM

PE 567 EN 1.1

Diagram 7

35

88..88..11..77DDiiaaggrraamm77

1 Boiler Pellematic – 1 Accumulator Pellaqua – 2 Heating circuits – 1 Layer charge modul

1

2

Solar plant

Pellematic

Outdoor sensor

X2

Power 230V

X6

X7

X8

X10

X4

X5

X9

X29

X28

X15

X31

Power 230V

BUS

Feeding controller

88..88..11..88DDiiaaggrraamm88

1 Boiler Pellematic – 1 Accumulator Pellaqua – 2 Heating circuits – Solar layer device

1

2

Solar plant

Pellematic

Outdoor sensor

X2

Power 230V

X6

X7

X8

X10

X4

X5

X9

X15

X29

X28

X31

X16

X17

X19

Power 230V

BUS

Feeding

controller

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

36

Diagram 9

88..88..11..99DDiiaaggrraamm99

1 Boiler Pellematic – 1 Accumulator Pellaqua – 2 Heating circuits – 1 Heat main pump

1

2

3

4

Pellematic

X2

Power 230V

X6

X7

X8

X4

X5

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

X29

BUS

Stromvers.

230V

Outdoor

sensor

Feeding - controller

88..88..11..1100DDiiaaggrraamm1100

2 Boilers Pellematic – 1 Hydraulic separator – 4 Heating circuits

1

2

3

4

X2

Hydraulic separator

Pellematic

BUS

Pellematic

Power 230V

BUS

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

BUS

BUS

Power 230V

X3

Outdoor sensor

TI

TI

UW

PWM

TI

TI

UW

PWM

Power 230V

Power 230V

PE 567 EN 1.1

Diagram 11

37

88..88..11..1111DDiiaaggrraamm1111

2 Boilers Pellematic – 1 Accumulator Pellaqua – 1 Fresh water module – 2 Heating circuits

1

2

X2

TI

Pellematic

Power 230V

Pellematic

Power 230V

BUS

Power 230V

Fresh water

module

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

Outdoor sensor

X6

X7

X8

TI

TI

TI

UW

PWM

UW

PWM

88..88..11..1122DDiiaaggrraamm1122

4 Boilers Pellematic – 1 Accumulator Pellaqua – 2 Heating circuits

1

2

X2

Pellematic

Pellematic

BUS

Power 230V

X7

X8

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

Pellematic

Pellematic

BUS

BUS

Outdoor sensor

TI

TI

UW

PWM

TI

TI

UW

PWM

TI

TI

UW

PWM

TI

TI

UW

PWM

Power 230V

Power 230V

Power 230V

Power 230V

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

38

Diagram 13

88..88..11..1133DDiiaaggrraamm1133

1 Boiler Pellematic – 1 Wood boiler – 1 Accumulator Pellaqua – 1 DHW Accumulator – 2 Heating circuits – 1 Solar

circuit

1

2

Solar plant

Termix

valve

TI

TI

TI

TI

Pellematic

X13

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

X9

X6

X30

X15

X31

X28

X24*

* Manual

Note:

X24 is a potential free contact to trigger an external heating boiler.

X7

X2

outdoor sensor

X8

X10

Power

230V

BUS

Feeding- controller

TI

TI

UW

PWM

PE 567 EN 1.1

Diagram 14

39

88..88..11..1144DDiiaaggrraamm1144

1 Boiler Pellematic – 1 Wood boiler – 1 DHW Accumulator – 2 Heating circuits – 1 Solar circuit

KW

1

2

Solar plant

Pellematic

Power

230V

BUS

TI

TI

TI

TI

TI

TI

X13

TI

TI

TI

TI

X4

X26

X23

X5

X27

X25

X30

X6

X9

X31

X15

X2

X24*

* Manual

Outdoor sensor

TE

X24*

Feeding - controller

Note:

If the value of the boiler sensor from the existing boiler (X13 S2) rises above the switch temperature, the

Pellematic is switched off.

After reaching the adjusted pump enabling temperature, the diverter valve (X24) switches. Energy can

be taken from the existing boiler.

X24 is a potential–free contact for regulating an external boiler.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

40

Diagram 15

88..88..11..1155DDiiaaggrraamm1155

1 Boiler Pellematic – 1 Accumulator Pellaqua – Circulation on Accumulator Pellaqua – Yield Measuring Solar

1

2

Pellematic

X2

X6

X7

X8

X9

X4

X5

X15

Outdoor sensor

X29

X14

X17

X16

X19

BUS

Power

230V

Feeding - controller

* Manual

Note:

If the value on the boiler sensor from the existing boiler (X13 S2) rise above the switch temperature the pellematic will be switched off.

After reaching the adjusted pump on temperature, the diverter valve (X24), so that the energy can be taken from the existing boiler.

PE 567 EN 1.1

The Touch operating device

41

99 The Touch operating device

The Touch operating device is mounted on the control board of Pellematic.

The 4.7" color display is surrounded by a foil design with logo.

With finger pressure you make settings on the Touch operating device.

1

User control unit Operates the boiler controller and the heating controller.

2

Main switch Switches off the heating system (both poles) including the power supply

to the control panel.

3

Safety

temperature sensor

Switches the heating system off if the boiler temperature reaches 95°C.

The heating controller remains active.

The touch panel is dark during in standby mode.

As soon as you touch the surface of the touch, light turns on and displays the opening window.

1

Measuring values (adjustable)

2

Date

3 Hour

4

The icon house takes to the main menu

5

Weather

Note:

If there is a malfunction, the

corresponding fault message is displayed

at this point instead of the weather icon

6

Favorite 1 (adjustable)

7

Favorite 2 (adjustable)

8

Favorite 3 (adjustable)

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

42

The Touch operating device

Favorit is in the menu General.

With this function you can display most

commonly used menus in the start menu. This

enables you a direct access.

Select 1–3 menu items that should be displayed

as a favorite in the Start menu.

PE 567 EN 1.1

User controls and their function

43

9.1 User controls and their function

1. Navigation-icons

Iconview

If you touch an icon, the icon turns green. The green shows that you are currently on this

icon. You get to the enabled menu item .

The yellow house enters you directly to the main menu.

The horizontal arrow leads you one step back.

With the blue down arrow you get to additional lines of information on this item. (Down scroll down).

With the blue up arrow you get to additional lines of information on this item. (Top of page scroll up)

You get to the respective menu item.

You get to the settings of the parameter. You come either to a numeric keypad, a

time / date block or the text selection.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

44

User controls and their function

2. Numeric keyboard

a. Name of parameter

b. Value of parameter with unit

c. Min/max value – Values outside this ran-

ge are not accepted.

d. Delete input of numbers – per contact

you delete one place.

e. Cancel – You return to the menu item. In-

put of a new value was not accepted.

The original value is.

f. Help function – inactive

g. Confirm

h. Numeric keyboard – used to enter values

within the min - max range.

3. Time and date block

a. Adjustable time or date

b. Cancel

c. Help function – inactive

d. Confirm

With the Plus Minus block you change

numbers.

4. Text selection

a. Name of parameter

b. Status texts

The number of status texts depends of

the parameter.

Choose a status text. The setup menu closes

automatically and the chosen status text is

displayed in the menu.

Note:

Although a scroll down menu is open, the navigation icons, menu items and parameters behind are active

and by touching them it takes you directly there .

PE 567 EN 1.1

Main Menu 45

9.2 Main Menu

In the Main menu you see all submenus. By finger pressure on an icon you reach the respective submenu.

A detailed description of the single meus is to be

found in the Manual for End Users in the chapter

Startup procedure.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

46

Replacing a Touch operating device

9.3 Replacing a Touch operating device

Exchange the integrated operating device (in the control panel) as follows:

EElleeccttrriiccsshhoocckk

Switch off the system when working on the boiler.

BBrreeaakkddoowwnnTToouucchhooppeerraattiinnggddeevviiccee

Before you press out the Touch operating device, you

must unplug all cables from the operating device.

While pressing out the operating device you have to

counter the top with the palm, so that the operating device does not pop out and falls to ground.

If the new operating device has a different software

state, an update has to be done. All Bus-connected

components have to have the same software-state.

PE 567 EN 1.1

Backside of the Touch operating device

47

9.4 Backside of the Touch operating device

1 Bus connection

•1ڃ +24V

• GND ڃ GND

•2ڃ A

•3ڃ B

2

Ethernet port

3 USB-port USB1

4 USB-port USB0

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

48

Calibration

9.5 Calibration

Execute a decalibration as follows:

1. Switch off the whole heating system 4. After a few seconds of waiting time the following

mask appears on the Touch operating device:

2. Press by using a finger on the Touch operating

device.

5. Now press the crosshairs in the row they appearing concentric.

Use a pen or similar for a more precise adjustment.

3. Keep your finger pressed and switch the boiler on

again.

PPrrooppeerrttyyddaammaaggee

Watch for a careful way of dealing with the touch

surface!

DDeeccaalliibbrraattiioonn

Avoid the placing of items on the touch operating

device!

PE 567 EN 1.1

Default values and settings

49

1100 Default values and settings

Customer

Default

System

Boiler 1 Boiler 2 Boiler 3 Boiler 4

Operating mode

Operating mode

Auto

Ignition

Burner Auger Run Time 70 zs

Rest time 20 zs

Fan

100 %

Flue Gas Fan

100 %

Temp Hysteresis Softstart

40 K

Heating Full Power

Brennstoffkorrektur

0

Min Abgastemp.

50 °C

Run on

Speed Flue Gas Fan

100 %

Flue Gas Fan Run On Time

1800 sec

FRT + KT Flue gas fan Off

30 K

Cleaning

Mode Ashbox

Run time min 80 min

Delivery Duration

3 min

Boiler run on time 6 h

Boiler cleaning

Cleaning/Filling

20:00

Cleaning 2

8:00

Run time min

12 h

Cleaning time

120 sec

Negative Draft

Mode

ON

Malfunction time

60 sec

Set Value ++

0EH

Minimum ++ 0 EH

Wash ++

0EH

PID Controller - Amplify

30 %

PID Conttroller - Time Integral

Action

130 sec

PID Controller - Time Differential

Action

20 zs

FRT Control

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

50

Default values and settings

Mode

ON

Temperature min 120 °C

Set Value ++

0K

Limit above

30 %

Limit below

80 %

PID Controller - Amplify

4%

PID Conttroller - Time Integral

Action

200 sec

PID Controller - Time Differential

Action

2zs

Pellet level

Mode Off

Threshold level 400 kg

Correction value 0 kg

Boiler Controlled Pump

On Temp 60 °C

Depends on Require

On

Pump type

Standard

Switch Off Hyst

3K

Run On Time 15 min

Control range

5K

Vacuum turbine

Filling

19:00

Tact RA Motor 55 sec

Pause RA Motor 5 sec

Suction intervall

180 min

Magnetventil

Mode

On

Min runtime

5h

Washing time

60 sec

Settings

Control Temperature

70 °C

Switch Off Temp

76 °C

Malfunction mode

On / Off

Hand filling hopper Off

Capacitive sensor RA -active

Off

Capacitive sensor ZW -active

Off

Switch on hyst

10 K

Output SM

Standard

Input AK

Standard

Outputs

PE 567 EN 1.1

Default values and settings

51

Vacuum turbine - Threshold

current Min

0mA

Vacuum turbine - Threshold

current Max

15000 mA

Vacuum turbine - Malfunction time

min

20 sec

Vacuum turbine - Malfunction time

max

720 sec

Ignition stick - Threshold current

Min

0mA

Ignition stick - Threshold current

Max

2500 mA

Ignition stick - Malfunction time

min

20 sec

Ignition stick - Malfunction time

max

20 sec

Reserve 1 - Threshold current Min

0mA

Reserve 1 - Threshold current Max

2500 mA

Reserve 1 - Malfunction time Min

20 sec

Reserve 1 - Malfunction time Max

20 sec

Magnet valve - Threshold current

Min

0mA

Magnet valve - Threshold current

Max

2500 mA

Magnet valve - Malfunction time

min

20 sec

Magnet valve - Malfunction time

max

20 sec

Flue gas fan - Threshold current

Min

0mA

Flue gas fan - Threshold current

Max

2500 mA

Flue gas fan - Malfunction time min

20 sec

Flue gas fan - Malfunction time

max

20 sec

Boiler controlled pump - Threshold

current Min

0mA

Boiler controlled pump - Threshold

current Max

2500 mA

Boiler controlled pump Malfunction time min

20 sec

Boiler controlled pump Malfunction time max

20 sec

Delivery system - Threshold

current Min

0mA

Delivery system - Threshold

current Max

2500 mA

Delivery system - Malfunction time

min

20 sec

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

52

Default values and settings

Delivery system - Malfunction time

max

20 sec

Delivery - Threshold current Min

0mA

Delivery - Threshold current Max

2500 mA

Delivery - Malfunction time min

20 sec

Delivery - Malfunction time max

20 sec

Optimised stratification Threshold current Min

0mA

Optimised stratification Threshold current Max

2500 mA

Optimised stratification Malfunction time min

20 sec

Optimised stratification Malfunction time max

20 sec

PE 567 EN 1.1

Default values and settings

53

1111 Default values and settings

Customer System

Master operating mode

Master operating

mode

Auto

Heating circuit

HC 1 HC 2 HC 3 HC 4 HC 5 HC 6

Operating mode

Auto

Set room

temperature

22.0°C

Set back

temperature

18.0°C

Time programme 1 active

Time programme 2 inactive

MO - SO 06:00 – 21:00

00:00 – 00:00

00:00 – 00:00

Party function

inactive

Party function till

act. Time

Vacation time OFF

Temperature

15°C

from

act. Date/Time

till

act. Date/Time

Heating curve/

Heating limits

Heating curve 0.4

Base point 20.0°C

H limit heating

18.0°C

H limit set

temperature

minus 5°C

Derivative time 180 min

Room thermostat

influence

1

Room thermostat

hysteresis

0.0°C

Settings

Maximum flow

temperature

55.0°C

Minimum flow

temperature

20.0°C

Temperature of

boiler above heating

circuits

5.0°C

Type of heating

circuit

mixed

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

54

Default values and settings

Mixer opening

5 sec

Mixer off

15 sec

Mixer closing

5 sec

Boiler load range

10.0°C

Flow range

10.0°C

BT smoothing

Temperature

increase

2,5°C

Control range

6.0°C

Screed programme

No. of heating days

21

Flow set every day 20°

C

Screed programme

inactive

Domestic hot water

DHW 1 DHW 2 DHW 3

Operating mode

Auto

DHW boost

OFF

Actual water

temperature

60.0°C

Water temperature

minimum

30.0°C

Time programme 1 active

Time programme 2 inactive

MO - SU 06:00 – 21:00

00:00 – 00:00

00:00 – 00:00

Settings

DHW preference

ON

Temperature of

boiler above heating

circuits

10.0°C

Run on time 10 min

DHC hysteresis

5.0°C

Legionella

protection

Monday

Accumulator

AC 1 AC 2 AC 3

Settings

Accumulator Temp

min ON

10.0°C

Pump release

temperature

20.0°C

Pump Depends on

Require

ON

PE 567 EN 1.1

Default values and settings

55

Pump Speed

Controller

OFF

Pump Switch Off

Hyst

3K

Pump Run On Time 15min

Pump Control Range

5K

Solar

SO 1 SO 2 SO 3 SO 4 SO 5 SO 6

Operating mode

Auto

Sol pump switch on

10.0°C

Sol pump switch off

5.0°C

TPU max

60.0 °C

TPU hyst

5.0°C

Collector smoothing

OFF

Collector Temp Min

60.0°C

Control range

10.0°C

Settings

Limit Sensor

AC lower

sensor

Collector Temp Max

130.0°C

Hysteresis for

maximum collector

temperature

30.0°C

Type of pump Standard

Speed controller

OFF

Collector protection

OFF

Protection

temperature

120.0°C

Protection hysteresis

10.0°C

Scavenging OFF

Rest time SV 10 min

Run time SV 1 min

Coll min SV

20.0°C

Period Scavenging

09:00 - 18:00

Priority

x

Run time

x

Rest time

x

Scavenging time

x

Solar energy

Volume per pulse 1.0 l

Heat main pump

Operating mode

Auto

Member

NO

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

56

Default values and settings

System Controlling

Settings

Boiler Temp Above

10.0°C

Boiler temperature

minimum

60.0°C

System Max 95.0°C

Boiler Pump On

Temp

60°C

Outside

Temperature – Time

of Average

4.0°C

Frost protection

Scavenging time

5 min

Frost protection

Pause Time

60 min

General

Language

Deutsch

(German)

USB

Recording

OFF

Recording interval

1 min

Sensor calibration

Sensor

all sensors 0.0°

C

Existing boiler

Valve switch on

temperature

60.0°C

Valve hysteresis

2.0°C

Inversion UV NO

Delay time

30 min

Pump switch on

temperature

60.0°C

PE 567 EN 1.1

Online Touch 57

1122 Online Touch

12.1 Product Description

Pelletronic Online Touch facilitates remote maintenance at any time and from anywhere via the Internet. You

monitor and operate the pellet heating system by PC via the remote maintenance website. You can check

and set the parameters for the heating controller and the pellet boiler via this password-protected remote

maintenance website. Furthermore, you can receive messages by e-mail, display system data and archive this

data.

1122..11..11IInnssttaallllaattiioonnRReeqquuiirreemmeennttss

The following requirements must be met before you can operate your pellet heating system with Pelletronic

Online:

1. Permanent connection to the Internet via Router (DSL, UMTS, LWL, cable)

2. Fixed Internet IP address or dynamic Internet IP address.

3. Administration access to the router to configure port forwarding.

4. Network connection with network cable (or wireless bridge with a network cable), WLAN–stick or DLAN

between the master control panel and router.

5. On the Internet router, the port 587 for sending E-Mails must be enabled.

6. Fixed Internet IP address (Local Area Network)

7. DNS (Domain Name Service)

8. A field D1 (DNS Server 1) optional D2 (DNS Server 2) has to be set at the IP-Adresses (see adjustments

touch operating device).

Changes to the network and routers may be performed

only by trained personnel.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

58

System Description

1122..11..22SSyysstteemmDDeessccrriippttiioonn

The remote control web site is powered by the Internet-connected touch panel! You can connect the operating device via network cable or wireless stick (Recommendation ÖkoFEN: Allnet ALL0234NANOv2) to the

internet! Assign the server an IP, NM (netmask) and GW (gateway), see Settings on the Operating Device.In

the router settings (router via which you access the Internet - not included in the scope of supply) the port

must be forwarded to the IP address of the web server (any port, it has to be the same port from the operating device)!

PE 567 EN 1.1

Settings on the Touch Operating Device

59

12.2 Settings on the Touch Operating Device

Please choose the submenu item IP Config

in the menu General.

Insert the IP (Adress), NM (Netmask) and

GW (Gateway) , D1 (in most cases similar to

GW) and D2 (optional).

Web: Status or external address.

You need Web User and Web Password to

log into the remote maintenance site.

Set depending of your network DHCP to On

or Off.

Enter the Port. (standard 80)

Activate the Ping function optional.

To prevent modem from switching to

standby mode, every 10 minutes a ping

command is executed.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

60

Settings on the Touch Operating Device

Automatic: This will attempt to automatically set up the router using the UPNP

protocol port forwarding.

If this service is disabled on the router or doesn’t work properly, it is

canceled accompanied by an appropriate error message.

As this function is time-consuming (may take a few minutes), it is

running in the background. Whatever the UPNP

If available, the Touch operating device registers on the ÖkoFEN remote control server with it’s current external IP Address.

In case of change of address by the external provider, this is detected

and sent to the server Ökofen.

Manual: In this mode, the port forwarding must be set manually. (for lack of

UPNP)

The port of the touch panel must correspond to the external shared

port.

The touch then registers with the external IP address and port on ÖkoFEN remote maintenance server.

In case of change of address by the external provider, this is detected

and sent to the ÖkoFEN server.

Static:

In this mode, no connection data is transferred to the ÖkoFEN server

and the online service of ÖkoFEN can not be used.

But the remote controll of the Touch operating device remains active

and can be uses as before via port forwarding, DynDns, fixed external

IP, LAN and so on.

This function determines the network settings automatically.

For this the DHCP mode is activated and the required settings are set automatically.

Afterwards DHCP is deactivated.

Because of this, the IP address of the contol unit can change.

Settings are set as follows:

• DHCP off

• Ping on

• Port 8080

• Remote maintenance: Automatic

All functions who need the network/internet can be disabled here.

These data you get from your network technician.

PE 567 EN 1.1

Opening the Password-Protected Remote Maintenance Website

61

12.3 Opening the Password-Protected Remote Maintenance

Website

The remote maintenance website is accessed by entering the network address as follows:

1. Open the web browser, e.g. Internet Explorer.

2. Enter the address of the Internet connection: http://___________ and press Enter. Your network technician will tell you the address of the Internet connection.

Procedure to follow in the event of error messages:

• Check the Internet connection.

• Check whether the web server is switched on.

3.

The login window appears on the screen.

Enter your User name and Password, see

12.2 Settings on the Touch Operating Device, page 59

• Select the desired Language.

• Click on Login.

You are now logged in to the remote maintenance website.

Procedure to follow in the event of error messages:

You cannot log in to the remote maintenance website.

• Re-enter your User name and Password in the login window. Click on Login.

• Check your user name and password – see 12.2 Settings on the Touch Operating Device, page 59

Enter them in the login window again.

• Call your network technician.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

62

Description of the Pelletronic Online Website

12.4 Description of the Pelletronic Online Website

Start page of your code-protected ÖkoFEN website

1 Logout

Exit your ÖkoFEN website

2

05/28/2015

09:42

Display of date and time

3

Notifications Indication of a malfunction of the heating system.

4

Values Display of all current measuring values and current desired values.

5

Main Menu

Display of all Pelletronic menu items available in your system.

System configuration is used to set up the website.

6

Weather Display current weather (only when weather function is active).

PE 567 EN 1.1

Making Settings

63

1122..44..11MMaakkiinnggSSeettttiinnggss

Description of how you make settings on the remote maintenance website.

Click and select the right submenu to make

the required changes.

Now enter the desired value in the input field

and click OK.

For each variable value, there is a bounded

range of values. If your entered value lies

outside the value range, Pelletronic Online

Touch will not accept the value. The limited

value range prevents the input of implausible settings.

Have you changed and confirmed a value, a

message appears top right of the window:

successful saved value

NNoorreeaall--ttiimmeeccoonnnneeccttiioonn

The PL line guarantees because of the delay through

the Internet no real-time connection.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

64

Adjustment of the power rating

1122..44..22AAddjjuussttmmeennttoofftthheeppoowweerrrraattiinngg

Settings is in the menu Pellematic.

Choose Settings per click.

Note: