Okofen PE 32, PE 15, PE 36, PE 48, PE 56 Operating Manual

...

Operating

Manual

+ Initial start up Pellet

heating system with auger

delivery system or vacuum

suction system for

professionals

PELLEMATIC®

PE(S)(K)(B) 10 — 56

FA_V2.03

Pelletronic TOUCH

ENGLISH

PE 567 EN 1.1 · www.oekofen.com

Title:

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

Article number:

PE 567 EN 1.1

Version valid

from:

06/2015

Approved: Wohlinger Christian

Author

ÖkoFEN Forschungs- &.

EntwicklungsgesmbH

A-4133 Niederkappel, Gewerbepark 1

Tel.: +43 (0) 72 86 / 74 50

Fax.: +43 (0) 72 86 / 74 50 – 10

E-Mail: oekofen@pelletsheizung.at

© by ÖkoFEN Forschungs- und EntwicklungsgesmbH

www.oekofen.com Subject to modifcations

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

11DDeeaarrCCuussttoommeerr .................................................................... .............. .............................................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .................................. 55

22UUsseeoonnllyyffoorrtthheeppuurrppoosseeiinntteennddeedd .............. .............. ........................................................................ .............. .............. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 66

33TTyyppeessooffssaaffeettyywwaarrnniinnggssiiggnn...................................................................... ............................ .............................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 77

44SSyysstteemmoovveerrvviieeww .......................................................... .............. ........................................................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ...... .................. 88

55CCoonnttrrooll ssyys

stteemm ........................ ............................ .............. ............................ .................................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..............................1100

66PPaarraammeetteerrAAddjjuussttmmeennttss ............................................ ............................ .............. ............................ .............. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ..1111

77TThheebbooiilleerrccoonnttrroolllleerr .......................... ...................................................................................................... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ............ 1122

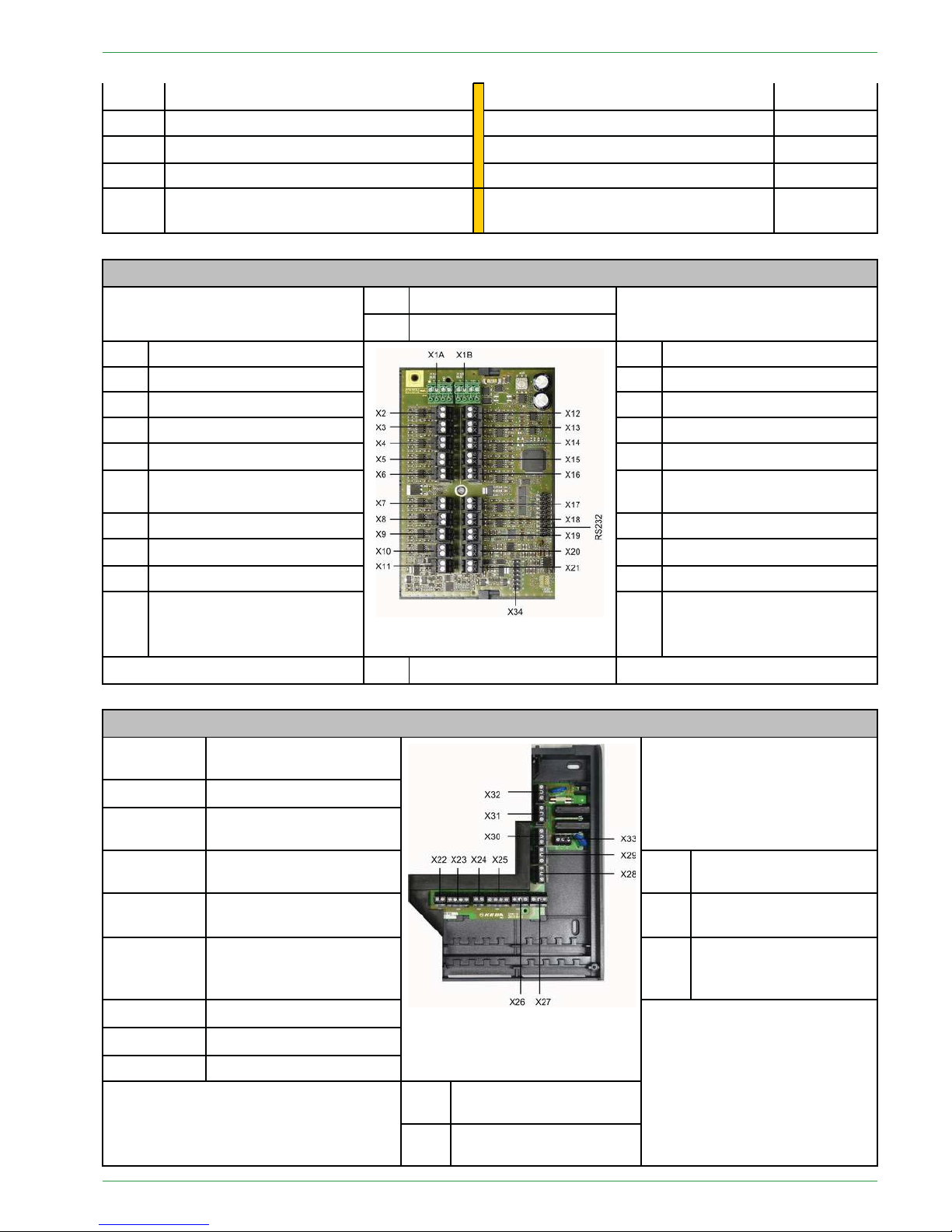

7.1 Plugs on the boiler control unit ......................... . . . . . ....................... . . . . . ........................ . . ................................ 13

7.2 Wiring diagrams .... . . .................................................................................................................................... 15

7.3 LED status boiler controller....... . . . . . . ........................ . . .......................... . . ......................... . . . .......................... 19

7.4 Cable Routing.................. . . ........................... . .............................................................................................. 19

88TThheehheeaattiinnggccoonnttrroolllleerr .............................................................................. .............. ............................ ........ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ....2200

8.1 LED status heating controller . . . ................................................................................................................... 21

8.2 Connection plan .................. . . . . . ....................... . . . .......................... . . ......................... . . . .................................22

8.2.1 Jumper X34 for analog voltage outputs X11 (OUT1) and X21 (OUT2) . ....................... . . . . .............25

8.3 Rules of wiring for micronetwork with 1,2 or more heating controllers ... . . . . ...............................................25

8.4 Wiring diagrams. . ....................... . . . . . ........................ . . . ......................... . . ..................................................... 26

8.5 Assembly and disassembly of the heating controller circuit board .......................................................... 28

8.6 Cable specification Pelletronic Touch...... . . ....................... . . . . . ........................ . . . . ........................................ 30

8.7 Sensor values..... . . .......................... . . ....................... . . . . . . ....................... . . . ..................................................... 31

8.8 Hydraulic connecting diagrams ..................................................................................................................32

8.8.1 Hydraulic connecting diagrams Pelletronic Touch ............... . . . ...................................................32

99TThheeTToouucchhooppeerraattiinnggddeevviiccee........ ............................ .............. .............................................................................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 4411

9.1 User controls and their function ........ . . ........................ . . . . ........................ . . . . ........................ . . . .................... 43

9.2 Main Menu .................................................................................................................................................. 45

9.3 Replacing a Touch operating device . . ......................... . . . ....................... . . . . . ............................................... 46

9.4 Backside of the Touch operating device .. . . . . ........................ . . ................................................................... 47

9.5 Calibration .................................................................................................................................................. 48

1100DDeeffaauullttvvaalluueessaannddsseettttiinnggss........................................................................ ............................ ............................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 4499

1111DDeeffaauullttvvaalluueessaannddsseettttiinnggss .......... ............................ .............. ........................................................................ .... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 5533

1122OOnnlliin

neeTToouucchh .......................................... .............. ............................ .............. .............................. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ................................ 5577

12.1 Product Description . . . .................................................................................................................................57

12.1.1 Installation Requirements ... . . . . ........................ . . . . ........................ . . . .......................... . ...................57

12.1.2 System Description .................................................................................................................... 58

12.2 Settings on the Touch Operating Device. ........................ . . . .......................... . ........................................... 59

12.3 Opening the Password-Protected Remote Maintenance Website ................... . . . . ...................... . . . . . . ........ 61

12.4 Description of the Pelletronic Online Website.......................................................................................... 62

12.4.1 Making Settings ........... . . . ....................... . . . . . . ....................... . . . .................................................... 63

12.4.2 Adjustment of the power rating . . ............................................................................................. 64

12.4.3 Error Messages by E-mail . . . . . ........................ . . . . ........................ . . .............................................. 65

12.4.4 Quit malfunction ........................ . . . . . . ......................................................................................... 67

12.4.5 Code input................................................................................................................................. 68

1133SSttaarrttiinngguuppffoorrtthheeffiirrssttttiimmee.......................................... .............. ............................ ............................................ .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. 6699

13.1 Performance adjustment ...................... . . . . ........................ . . ....................................................................... 70

13.2 Setting the adresses of the Bus-participants............................................................................................ 70

13.2.1 Setting the address at the burner controller . . ...........................................................................70

13.2.2 Setting the address at the heating controller ......................... . . . . ............................................... 71

13.2.3 Setting the adress for the remote control . . . . ......................... . ........................... . . ......................72

13.2.4 Settings before starting up........................................................................................................72

13.2.5 Setting the adress for remote control Touch ...... . . . ...................................................................73

13.2.6 Setting the adress for remote control ...... . . ......................... . . . .................................................. 74

13.2.7 Code Input. ....................... . . . . . .....................................................................................................75

13.2.8 Periphery Learning.................. . . . .......................... . .....................................................................77

13.2.9 Flowtronic ........................ . . ........................... . ......................... . . . . ....................... . . . . . .................. 84

13.3 Mode.......................................................................................................................................................... 84

13.3.1 Operation mode.. . ........................... . . ....................... . . . . . . ...................... ...................................... 85

13.3.2 Operation mode HC 1 .... . . . . . ....................... . . . . ......................... . ........................... . . ..................... 85

Contents

Contents

13.3.3 Operation mode HC 2–6 ........................................................................................................... 85

13.3.4 Operation Mode DHW .............................................................................................................. 86

13.3.5 Operation mode solar ............................................................................................................... 86

13.3.6 Operation mode Pellematic . . ........................ . . .......................... . . .............................................. 87

13.4 Measuring values....................................................................................................................................... 87

13.5 Weather..................................................................................................................................................... 88

13.6 Eco Mode .................................................................................................................................................. 89

13.7 Heating Circuit.. . . . . . ........................ . . . ......................... . . ........................... . ................................................... 91

13.7.1 Screed programme . . ......................... . . . . ...................... . . . . . . ........................ . . ............................... 94

13.8 Solar Heating.... . . . .......................... . ......................... . . . . ...................... . . . . . . .................................................. 94

13.8.1 Menu Solar Heating...... . . . ....................... . . . . . . ....................... . . . . ......................... . ......................... 95

13.9 DHW settings ........................ . . . . . . ....................... . . . . ......................... . ........................... . . ............................ 96

13.10 DHW Return Pump settings . . ....................... . . . .......................... . . ......................... . . . ................................ 97

13.11 Solar settings .............. . ........................ . . . . . ....................... . . . . . ........................ . . .......................................... 98

13.12 Accumulator settings...................... . . . . ......................... . . .......................... . . .............................................104

13.13 System Regulation ................. . . . . ...................... . . . . . ......................... . . .......................... . . ...........................106

13.13.1 Cascade settings.................. . . . . ........................ . . . .......................... . ......................... . . . . ............. 107

13.13.2 Existing Boiler ...........................................................................................................................111

13.14 Pellematic settings ................................................................................................................................... 113

13.14.1 Outertemperature control... . . ................................................................................................... 114

13.14.2 External Power Ventilator........................................................................................................ 115

13.14.3 Permanent operation. . .......................... . ......................... . . . . ..................................................... 115

13.14.4 Ignition settings .......................................................................................................................116

13.14.5 Full power settings .................................................................................................................. 117

13.14.6 Run Down Time settings.. . . . . ........................ . . . . ........................ . . . .......................... . .................. 118

13.14.7 De-ashing system settings ................. . . . ....................... . . . . . . ....................... . . . . .......................... 119

13.14.8 Boiler cleaning ....................... . . . . . ........................ . . . ......................... . . ....................................... 121

13.14.9 Negative Draft . .......................... . ........................... . . ....................... . . . . . . .................................. 122

13.14.10 FRT Controller . . ........................ . . . . ........................ . . . .......................... . . .................................. 123

13.14.11 Level detection system ....... . . . . ...................... . . . . . . ........................ . . .......................... . . ............. 125

13.14.12 Boiler Controlled Pump . ......................... . . ........................... . ........................ . . . . . .................... 126

13.14.13 Suction turbine ....................... . . . ............................................................................................ 128

13.14.14 Output Settings ................. . . . . . ............................................................................................... 129

13.14.15 Output Test......... . . .................................................................................................................130

13.14.16 Maintenance .. . . . ....................... . . . ........................................................................................... 132

13.14.17 Calibrate........... . ..................................................................................................................... 133

13.14.18 Magnet Valve..................... . ................................................................................................... 134

13.14.19 Settings....................... . .......................................................................................................... 135

13.15 Heating Main Pump...................... . . . ........................................................................................................ 137

13.16 General settings .... . . . . . ......................... . . .................................................................................................. 138

13.16.1 Chimney................... . . . . . . ........................ . . . ................................................................................ 141

13.16.2 Datalog........... . . . . ........................ . . . . ........................ . . ........................... . . .................................. 142

13.16.3 Delete Log............. . . . . . ....................... . . . . .................................................................................. 143

13.16.4 ModBUS . . . ....................... . . . . . ........................ . . .........................................................................144

13.16.5 E-Mail ........ . . . . . ........................ . . . .......................... . ......................... . . . . ...................................... 146

13.16.6 IP Config .................... . . . ........................ . . . . . ....................... . . . . ......................... . ........................ 147

13.16.7 USB ............... . . . .......................... . ......................... . . . . ...................... . . . . . ....................................150

13.17 Software settings ............................ . . ........................ . . . . ........................ . . . . ............................................... 151

13.17.1 Configuration .......................... . . ....................... . . . . . ........................ . . . . .......................

................. 151

13.17.2 Function room sensor ................ . . . . . ....................... . . . . ......................... . . ......................... . . ....... 152

13.17.3 Update Heating Controller, Touch Operating device and Remote Control . . . . . . ..................... 152

13.17.4 Software Update................. . ........................ . . . . . ....................... . . . . . ........................ . . ................ 153

1144AAppppeennddiixx.... .............. ............................ .............. .................................................................... .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. ................ ..........................115544

14.1 Malfunctions.............................................................................................................................................. 154

14.1.1 Malfunctions - what to do............. . . . ......................... . . ......................... . . . . ...................... . . . . . . ...... 154

14.1.2 Fault texts ........... . . . ................................................................................................................... 154

14.1.3 Malfunction report .................................................................................................................... 155

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

Dear Customer 5

11 Dear Customer

ÖkoFEN is Europe’s leading specialist in pellet heating.

Proficiency, innovation and quality combined. This is the tradition on which ÖkoFEN shapes the future.

We are very pleased that you too have decided to purchase a product from ÖkoFEN.

• This manual is intended to help you operate the product safely, properly and economically.

• Please read this manual right through and take note of the safety warnings.

• Keep all documentation supplied with this unit in a safe place for future reference.

Please pass on the documentation to the new user if you decide to part with the unit at a later date.

• Please contact your authorised dealer if you have any questions.

ÖkoFEN attaches great importance to the development of new products. Our R&D Department repeatedly

challenges the effectiveness of tried-and-tested systems and works continuously on improvements. In this

way, we secure our technological advantage. We have already received many national and international

awards for our products.

All our products comply with European standards in respect of quality, efficiency and emissions.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

6

Use only for the purpose intended

22 Use only for the purpose intended

The pellet heating system is designed to heat water for central or other indirect heating systems and hot

water supply for buildings. It is not permissible to use the pellet heating system for any other purpose.

Reasonable foreseeable inadvertent uses for the heating system are not known.

PE 567 EN 1.1

Types of safety warning sign

7

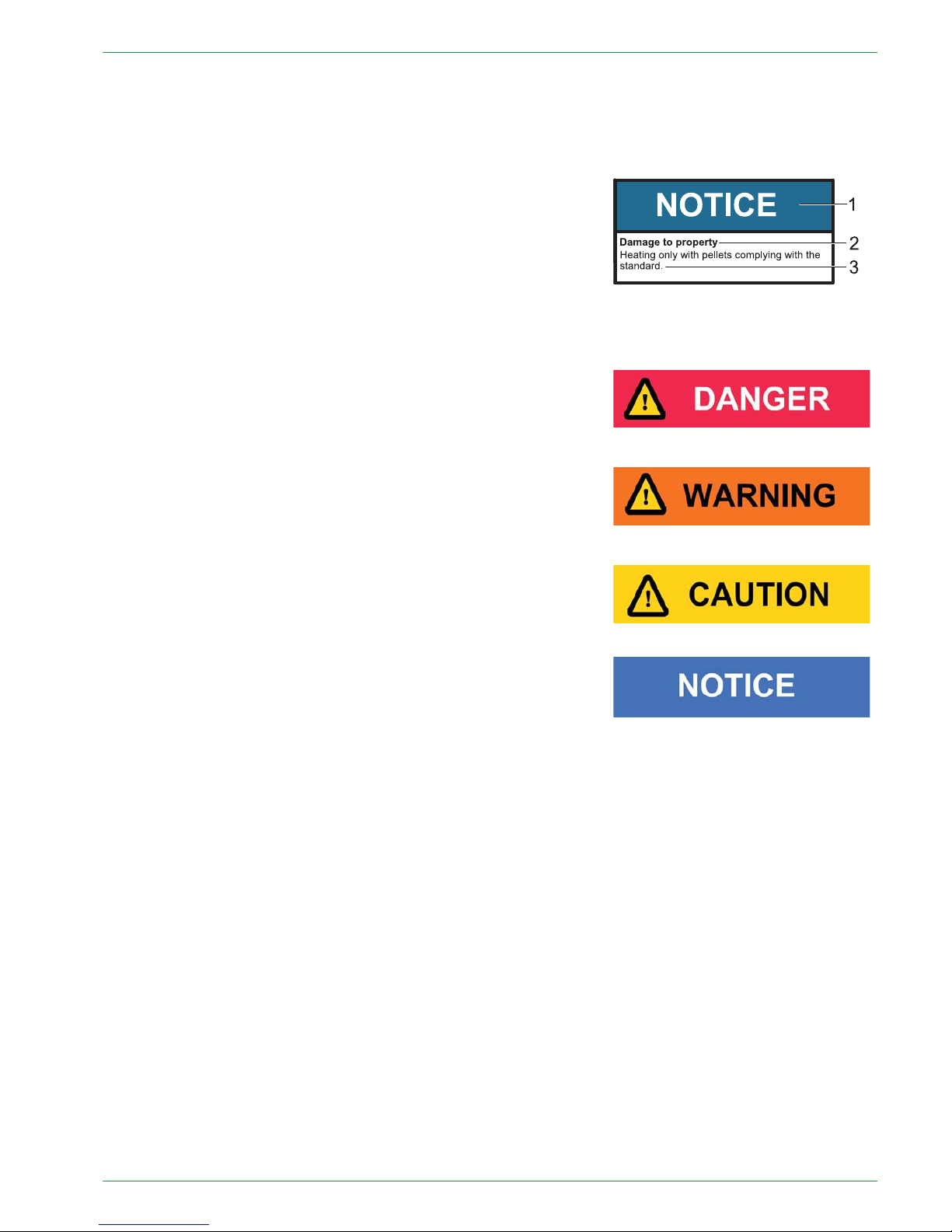

33 Types of safety warning sign

The warning signs use the following symbols and texts.

Types of safety warning sign

1. Risk of injury

2. Consequences of risk

3. Avoiding risk

1. Risk of injury:

Danger - indicates a situation that could lead to death or lifethreatening injury.

Warning - indicates a situation that could lead life-threatening or

serious injury.

Caution - indicates a situation that could lead to injury.

Note - indicates a situation that could lead to property damage.

2. Consequences of risk

Effects and consequences resulting from incorrect operation.

3. Avoiding risk

Observing safety instructions ensures that the heating system is

operated safely

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

8

System overview

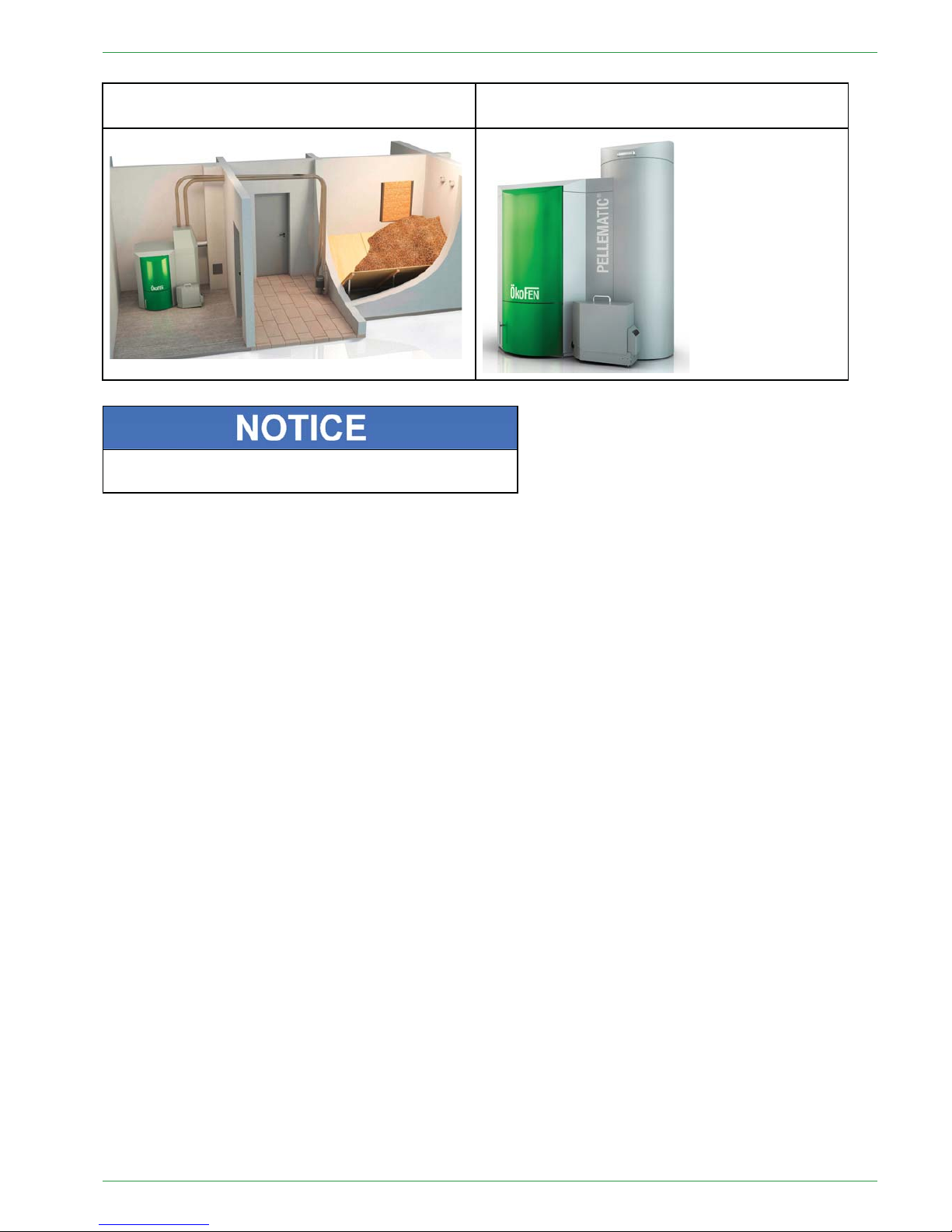

44 System overview

The whole system consists of following components:

ଉ Pellematic boiler:

• PE - Boiler with pellets transport auger as delivery system

• PES - Boiler with vacuum suction system as delivery system

• PEB - Boiler with hopper for hand filling

• PESKA - cascade with up to 4 possible boilers

ଉ Pellet storage room with pellet-delivery system:

• Storage room

• Textile tank

ଉ Possible additional components:

• Domestic hot water

• Accumulator

• Solar thermal panel

• Existing external boiler

Pellematic with storage room and auger delivery Pellematic with textile tank and auger delivery

Pellematic with storage room and vacuum

suction

Pellematic with textile tank and vacuum suction

PE 567 EN 1.1

System overview

9

Pellematic cascade with textile tank and auger

delivery system

Pellematic with hopper for hand filling

There are seperate manuals for all components, which

describe functions and installation in detail.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

10

Control system

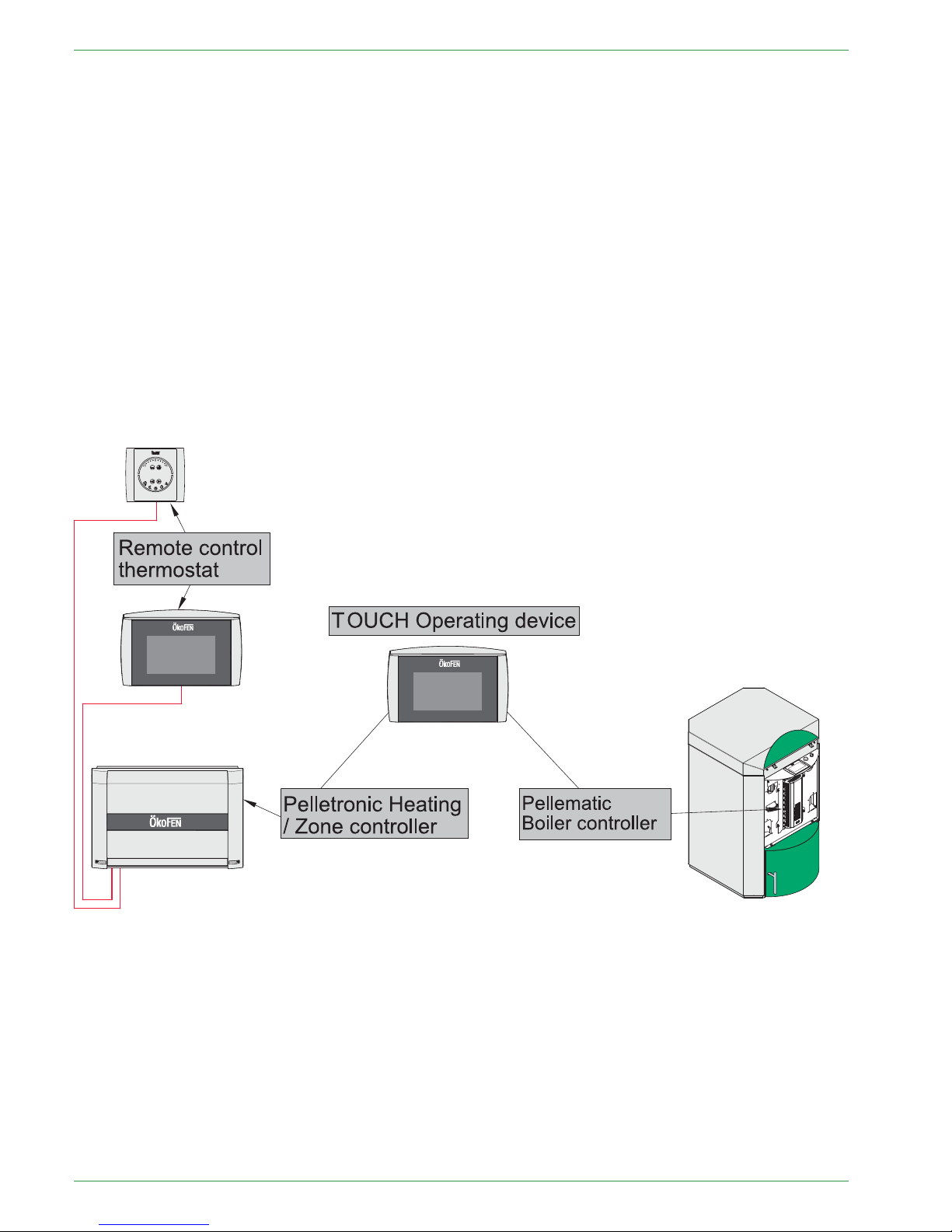

55 Control system

Basically the Controlsystem consists of following components:

• Pellematic boiler controller:

The boiler controller controls all boiler functions (pellet feed system, combustion, deashing, etc.)

• Pelletronic heating controller (max. 3 wall boxes = 6 zones, 3 domestic hot water, 3 accumulators)

The heating controller regulates the whole heat distribution system. (Room temperature, domestic hot

water, time programmes, solar, accumulator management, etc.)

Additionally remote controls can be installed in the system. These can be connected to the heat controller

by a bus-connection.

• Touch Operating Device

The Touch Operating Device is in the boiler. It is connected by a bus-connection with both, heating- and

boiler controller. It serves for:

– visualizing the measuring values

– adjusting the desired values and the time programme on the heating controller.

– adjusting the parameters of the boiler controller

PE 567 EN 1.1

Parameter Adjustments

11

66 Parameter Adjustments

There are two areas in which adjustments can be set:

• User-specific adjustments: e.g. Room temperature, Time program, Domestic hot water temperature,

Domestic hot water time program, Party-function etc.

• System-specific adjustments: e.g. combustion temperature regulation, deashing, ignition parameters,

suction interval, etc.

Ex works, adjustments are basically set, so no further adaption is neccessary.

A detailed description of all important setting options for the end user is to be found in the operating manual

of the End User.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

12

The boiler controller

77 The boiler controller

The boiler controller is directly on the Pellematic boiler behind the half-round front cover of the boiler.

It is used to control the combustion process and the fuel-feeding system.

The boiler controller is connected to the touch operating device by a bus-connection.

The Touch allows the owner / operator to see important measured values and Change to "Provides for

adjustment of desired values and parameters of boiler operation. Only authorized installers should adjust

boiler operating parameters."

1 F1: Fuse T10A

2 F2: Fuse T8A

DDaammaaggeeooffpprrooppeerrttyy

Fuses must be replaced only with fuses having the same

current and voltage ratings.

PE 567 EN 1.1

Plugs on the boiler control unit

13

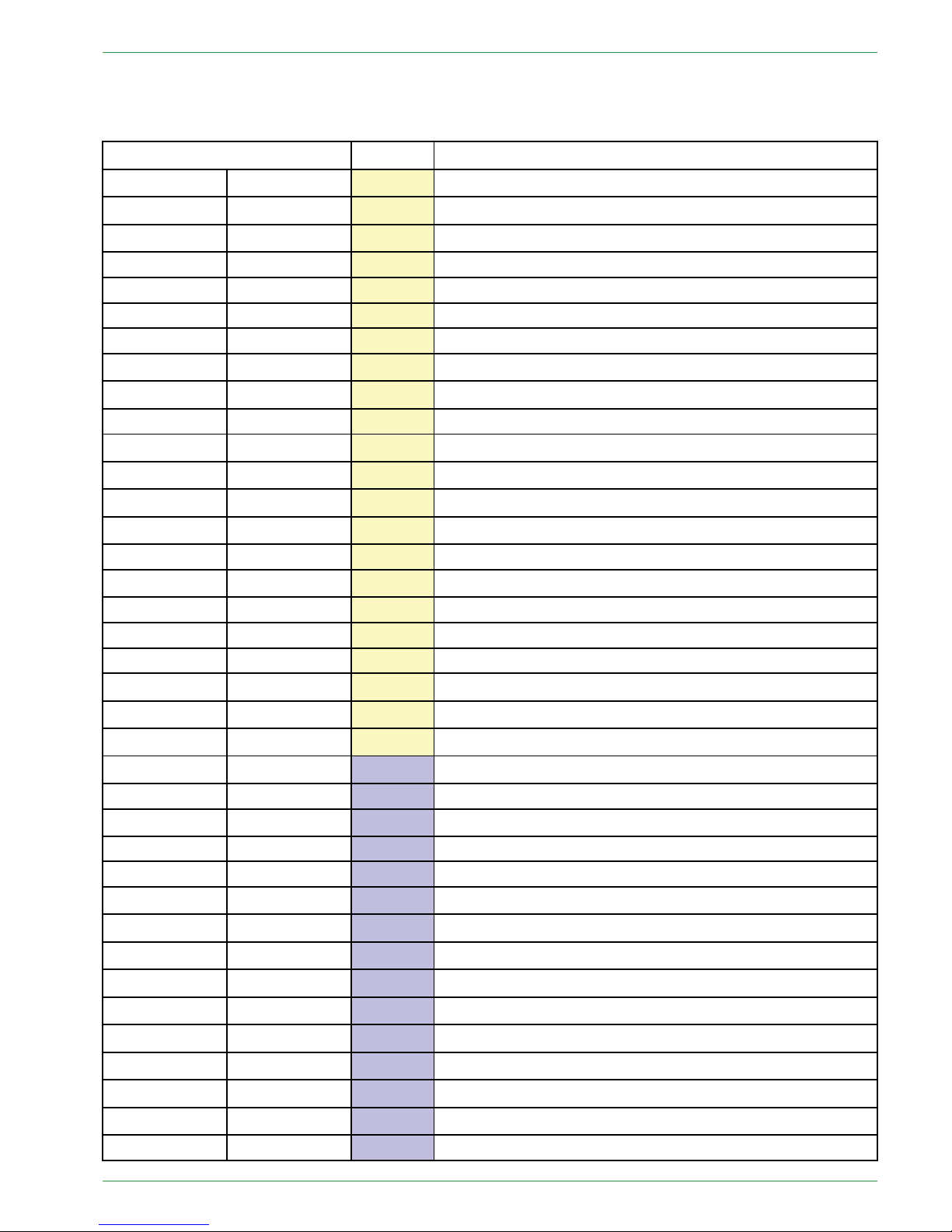

7.1 Plugs on the boiler control unit

The designation of the plugs must correspond with the labeling of plug-in positions.

Designation of plug-in position Voltage Name of sensors, motors and pumps

X1A

3 2 GND 1

24 Volt Operating display

X1B 3 2 GND 1

24 Volt Heating controller (BUS)

X2 5 4

24 Volt Power supply display

R1 46 45

24 Volt Not used

R2 44 43

24 Volt Not used

AF 42 41

24 Volt Not used

KF

89

24 Volt Boiler sensor

UP

234

24 Volt Negative draft measuring

AE2 5 6 7

24 Volt Level detection system

AE1

10 9 8

24 Volt Not used

FRT 12 13

24 Volt Combustion chamber temperature sensor

RGF 14 15

24 Volt Flue gas temperature sensor (optional)

PWM 16 17

24 Volt PWM for speed controlled high-efficiency pump

Analog IN

18 19

24 Volt Not used

BR1 7 8

24 Volt

Burner contact

AK 11 12

24 Volt Existing boiler (optional)

ESAV 32 33 34

24 Volt End switch ash box

DE 1 37 36 35

24 Volt Not used

DE 2 40 39 38

24 Volt Not used

KAPZW 26 25 24

24 Volt Capacitive sensor – hopper

KAPRA 5 4 3

24 Volt Capacitive sensor – burner

BSK 654321

24 Volt Flame return gate

X21 PE L N

230 Volt Power supply

VAK 56 PE 55

230 Volt Vacuum turbine

ZUEND

NPE22

230 Volt

Ignition

AV 52 PE 51

230 Volt Motor ashbox

RES 2 54 PE 53

230 Volt Not used

MA 48 PE 47

230 Volt Magnetic valve (Cleaning nozzle, heat exchanger)

RM 15 PE N

230 Volt Motor boiler cleaning device

SM 19 20

230 Volt Relay fault signal (optional)

SZ 17 PE N

230 Volt Flue gas fan

UW 13 PE N

230 Volt Boiler controlled pump

STB 17 PE 19

230 Volt Safety temperature sensor

NOT 41 43

230 Volt Emergency stop heating

RA1 N PE 14 15 16

230 Volt Fuel transport system

RES1 50 PE 49

230 Volt Motor hopper – PES 36–56 only

ZW

NPE262524

230 Volt Vibration motor

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

14

Plugs on the boiler control unit

ES 1 2 3 N PE 6

230 Volt

Burner motor

LUFT N PE 11

230 Volt Burner fan

PE 567 EN 1.1

Wiring diagrams

15

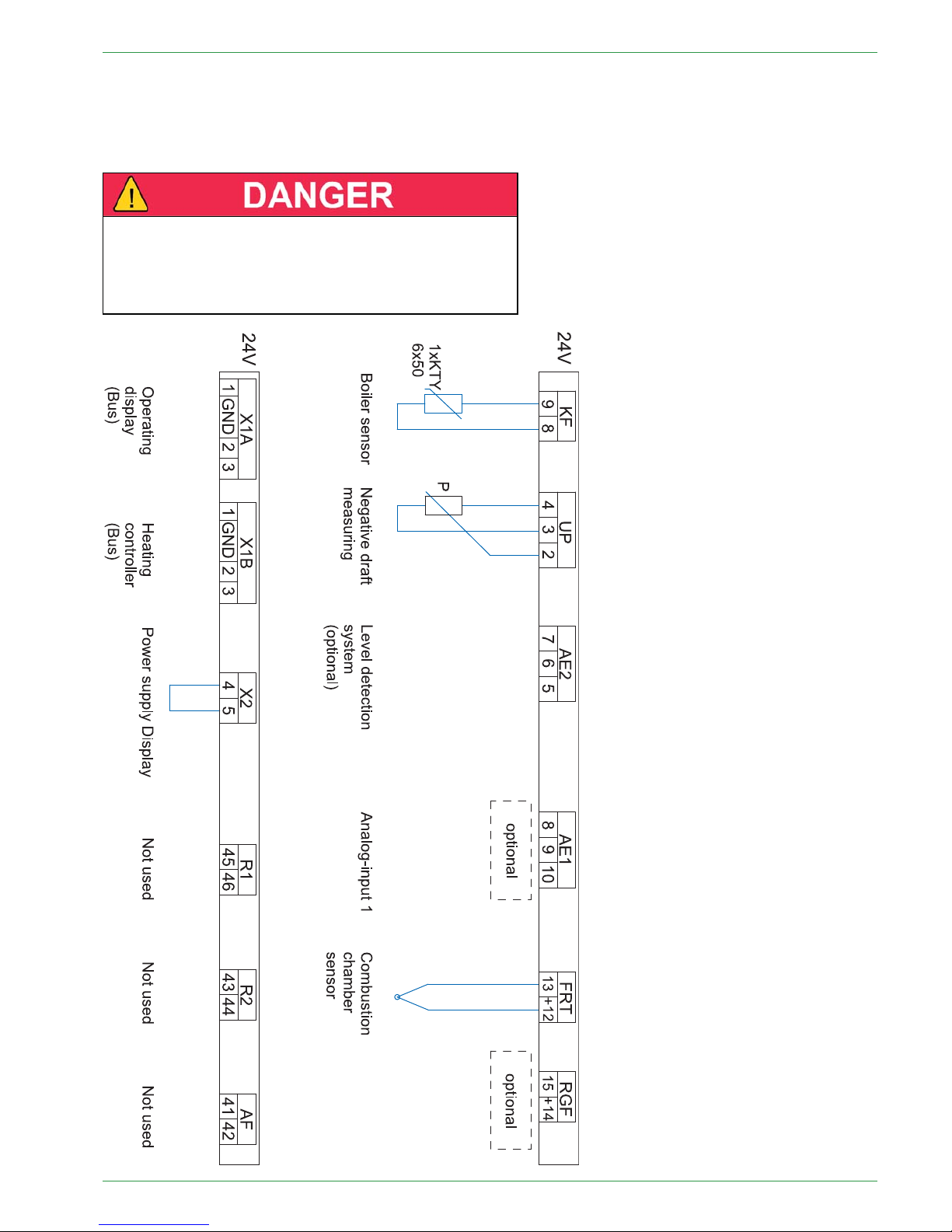

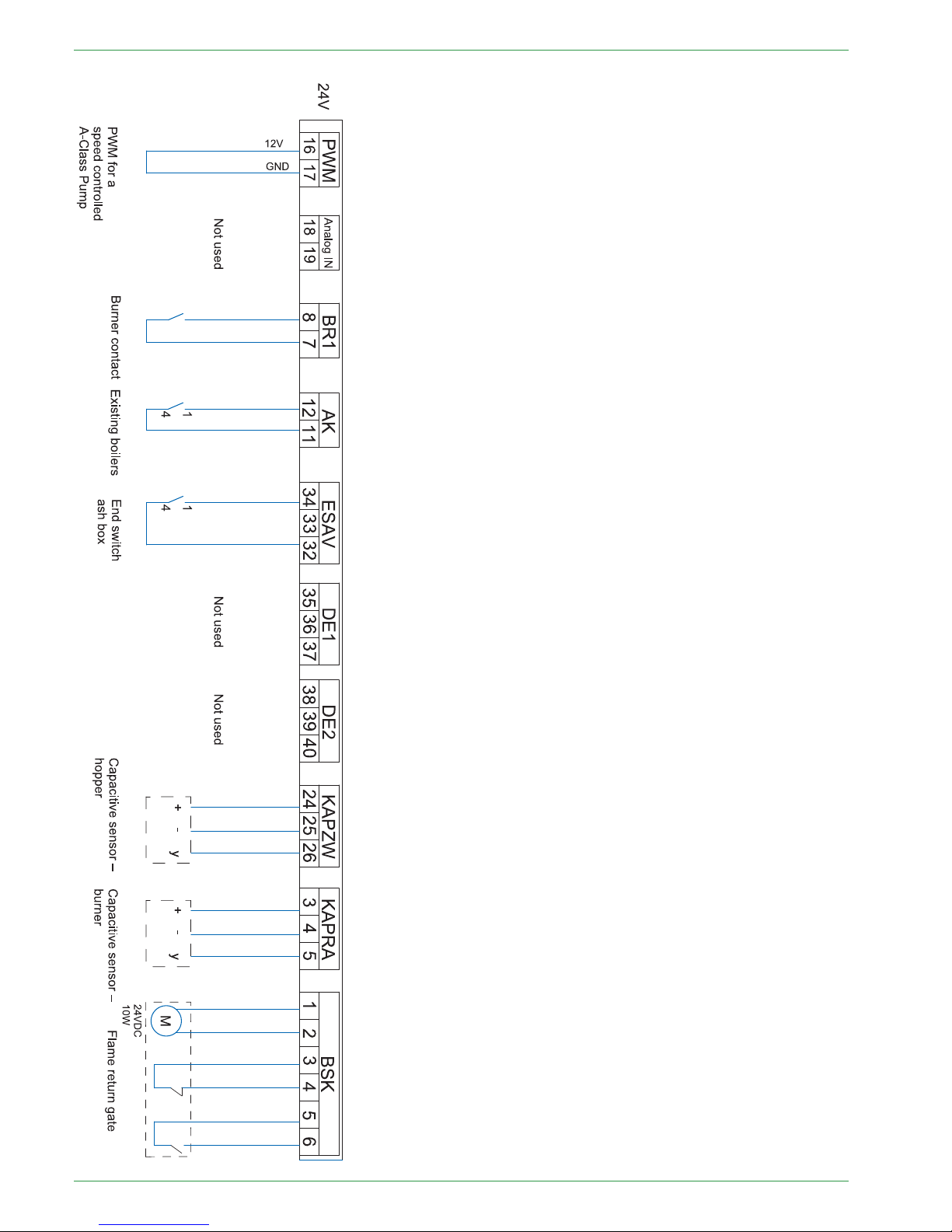

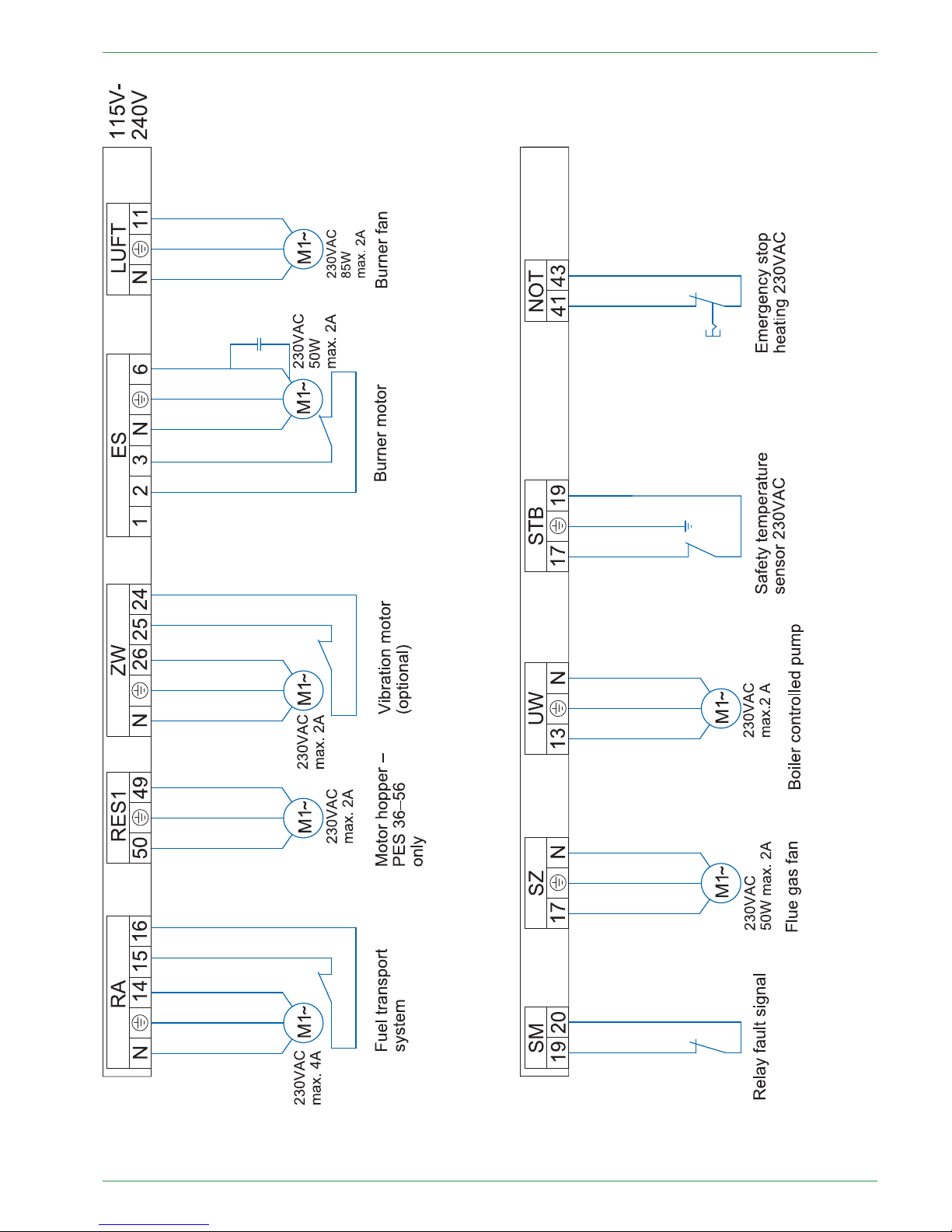

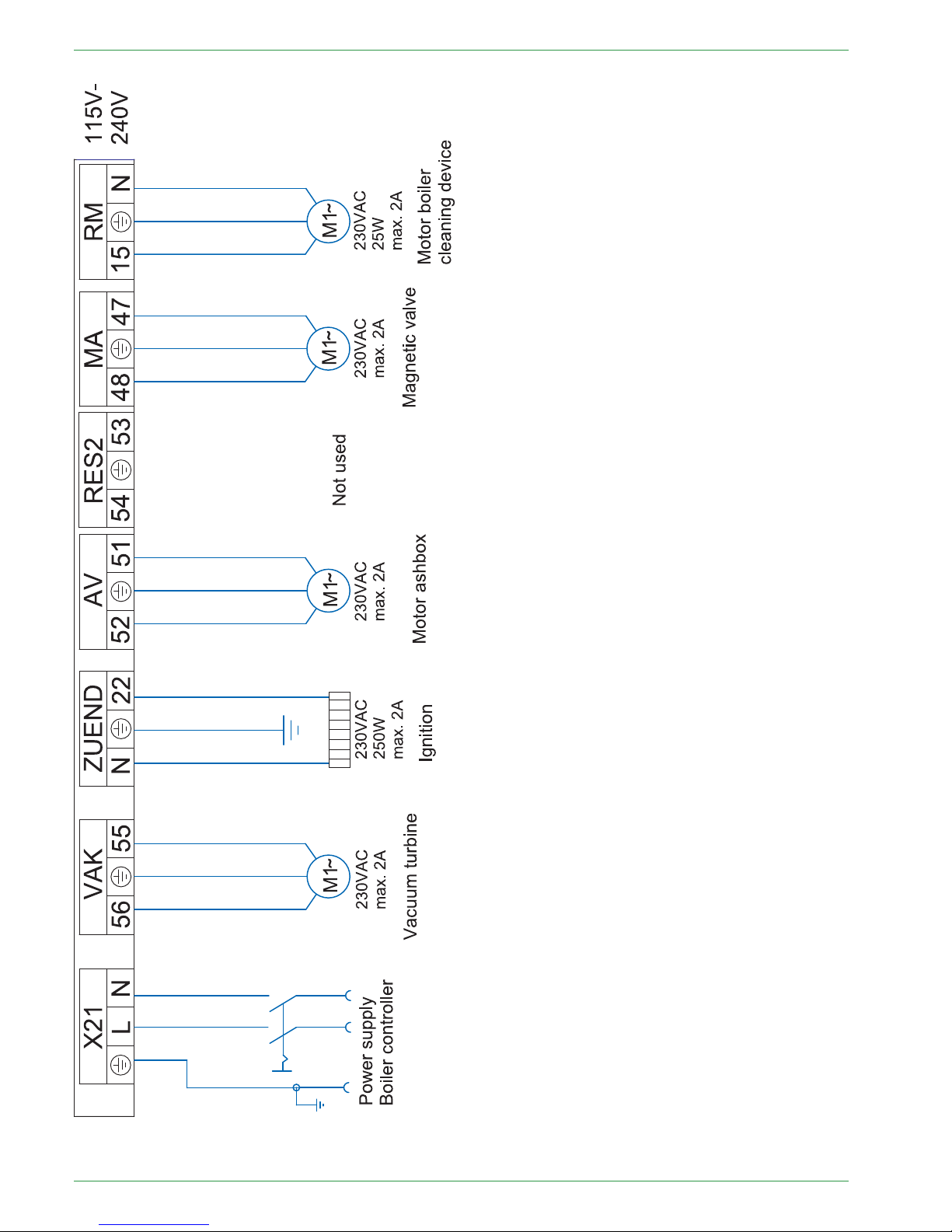

7.2 Wiring diagrams

The wiring diagrams for the boiler control unit provide detailed technical information for certified installers.

Only certified installers or electricians under the direction of a certified installer may connect to the

controller.

RRiisskkooffeelleeccttrriiccsshhoocckk

Only an authorised installer may connect the pellet boiler to the power supply.

Always disconnect / de-energize the power supply before working on the boiler.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

16

Wiring diagrams

PE 567 EN 1.1

Wiring diagrams

17

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

18

Wiring diagrams

PE 567 EN 1.1

LED status boiler controller 19

7.3 LED status boiler controller

Display Description Cause and remedy

red Power supply present

—

red flashing Error condition

no communication possible

Check the software version

Check the bus wiring

Check the address

red / orange flashing

In the bus systems are devices using

the same address

Change the address

orange

Power supply present

Processor runs

No bus communication

Check the software version

Check the bus wiring

Check the address

orange flashing Firmware- update is in progress

—

green flashing Initialization (Firmware boots) If state is unchanged, software must

be checked.

green

Operation

Cyclic communication possible

—

7.4 Cable Routing

Th cable routing and the connection of the motors and sensors is precisely described in the Installation manual .

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

20

The heating controller

88 The heating controller

The heating controller is in a wall box, which is in most cases installed nearby the heating circuit distributor.

It is used to control the whole heat distribution system for example: domestic hot water, room temperature,

solar system, accumulator, etc

It consists of a casing with an internal circuit board and terminals.

The cover plate of the casing is removable.

EElleeccttrriiccsshhoocckkddaannggeerr

Before opening, make sure that the whole heating

system is powerless.

Note:

The heating controller is limited to 8 amps total current draw. Also, each output is rated at 2 amps max.

Make sure that these values are not exceeded to avoid fuse failure.

PE 567 EN 1.1

LED status heating controller

21

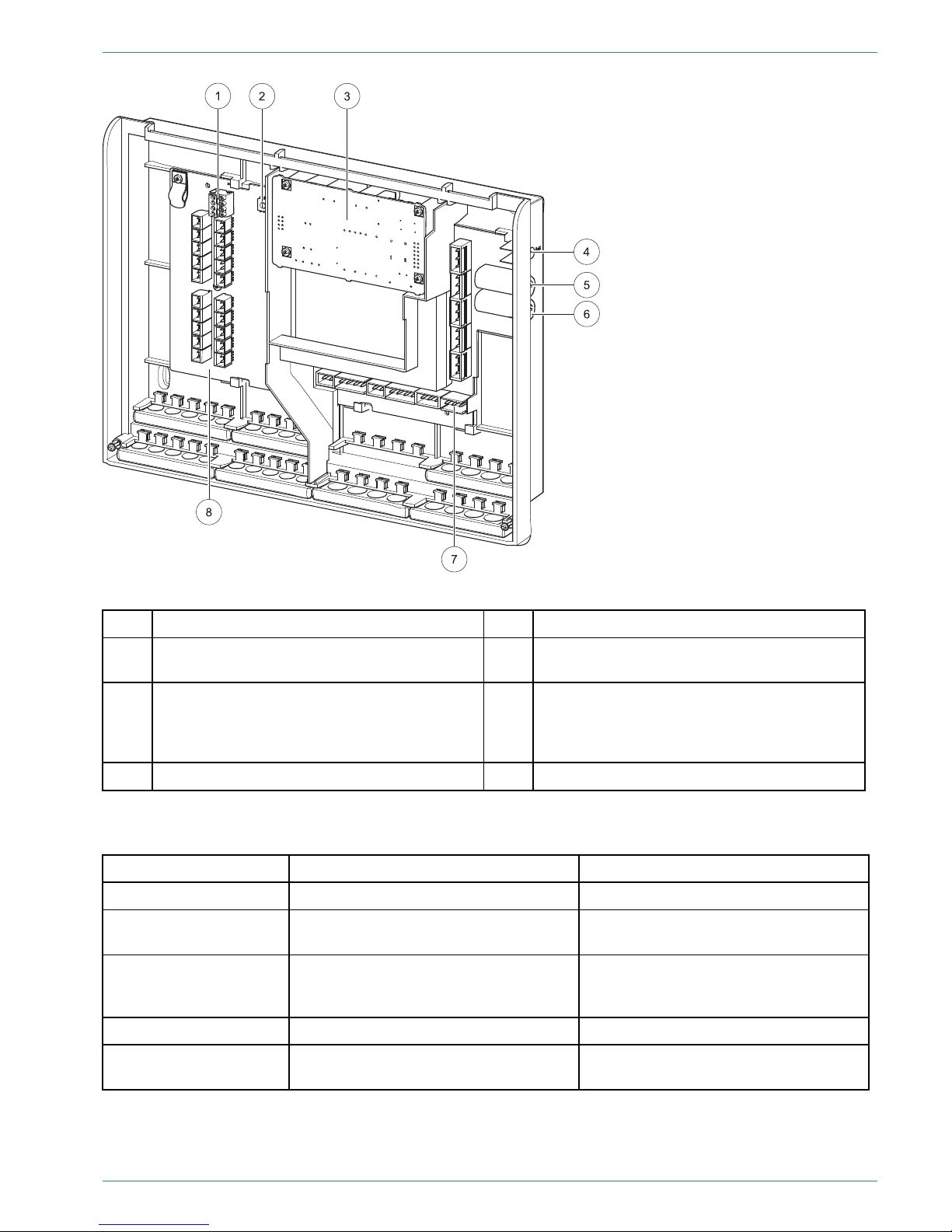

1

Bus connecting terminal RS485 A and B

5

Fuse 6,3 A (fast) for X31 and X33

2

Address switch

6

Fuse 8 A (slow-acting) limits the current

consumption of the heating controller.

3

Slot for an optional power supply

(The power supply is needed when the

burner control CMP 06.2 is used. The power

supply takes over the bus supply.)

7

Low voltage – area (dangerous voltage)

4 Status-LED 8

Extra low voltage (PELV)

8.1 LED status heating controller

Display Description Cause and remedy

red Power supply present

—

red flashing Error condition

no communication possible

Check software version

Check bus wiring

orange

Power supply present

Processor runs

no communication possible

Check bus wiring

green flashing Initialization (Firmware boots)

—

green

Operation

Cyclic communication possible

—

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

22

Connection plan

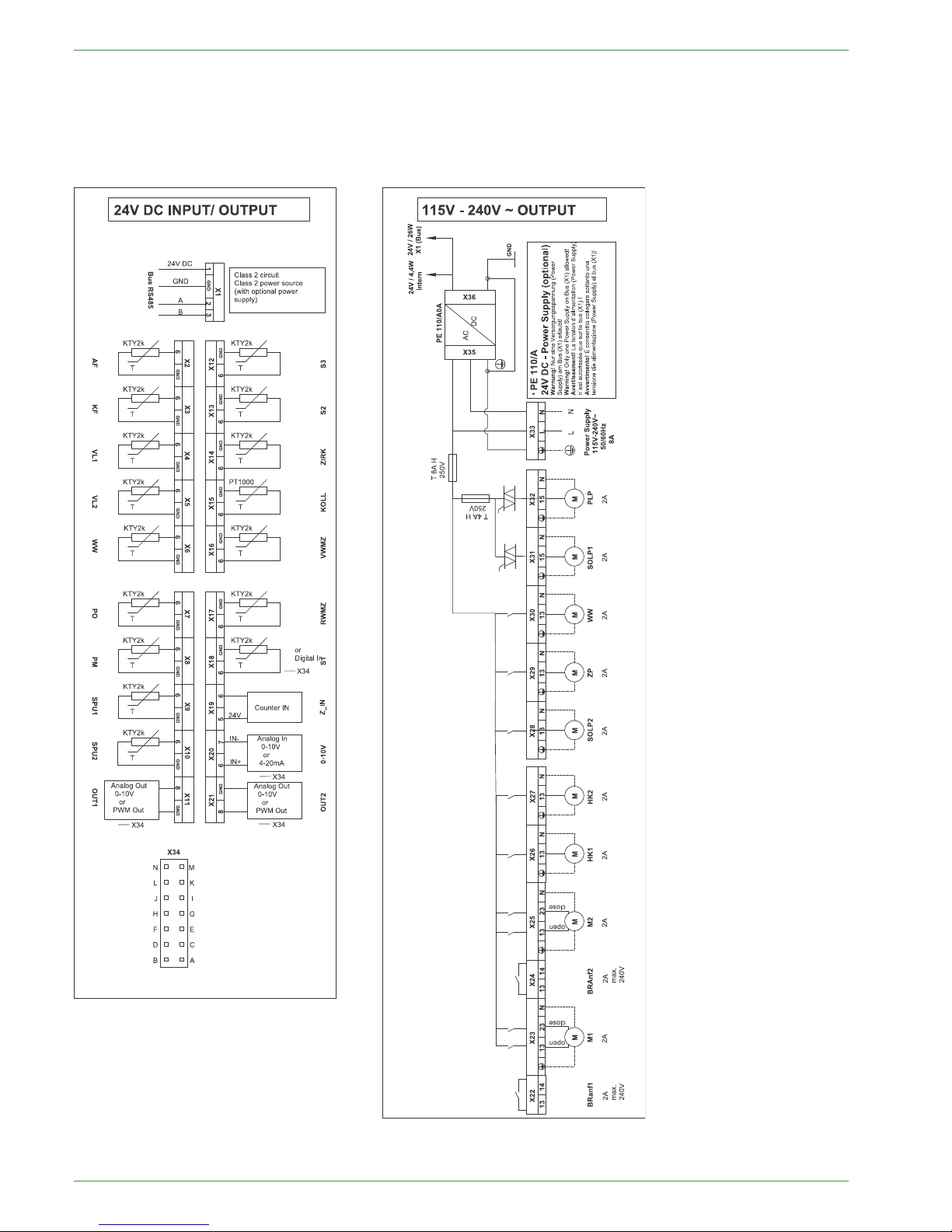

8.2 Connection plan

The Connection plan is a description of all the electrical connections from the Pelletronic heating controller:

Only an authorised installer may install and connect the

heating controller to the power supply.

Isolate the entire heating system from the power supply

before starting work on the heating controller.

Boiler sensor + outside sensor must be connected on

the first heating controller!

Terminals extra-low voltage zone Terminals low voltage zone - 120VAC

X1A Bus wiring – Bus RS485

Burner demand 1 – BRanf 1

X22

X1B Bus wiring – Bus RS485 Mixer HK1 opening – M1

X23 – 13/N

X2

Outdor sensor – AF Mixer HK1 closing – M1

X23 – 23/N

X3

Boiler sensor – KF Burner demand 2 – BRanf 2

(Potencial free contact)

X24

X4

Flow sensor HK1 – VL1

Mixer HK2 opening – M2

X25 – 13/N

X5

Flow sensor HK2 – VL2 Mixer HK2 closing – M2

X25 – 23/N

X6

DHW sensor – WW Heating circuit pump – HK1 X26

X7

AC upper sensor – PO Heating circuit pump – HK2 X27

X8

AC middle sensor – PM Solar pump 2 – Sol P2

X28

X9

AC lower sensor 1 – SPU1

Return pump – Heat main pump – ZP X29

X10

AC lower sensor 2 – SPU2 Domestic hot water – WW

X30

X11

Solar pump 1 A-class Solar pump 1– Sol P1

X31

X12 Reserve – S3

Accumulator pump – PLP

X32

X13 Reserve – S2

Power supply 115V – 240V~

X33

X14 Return sensor – ZIRK

X15

Collector sensor – KOLL

X16

Solar energy Flow – VWMZ

PE 567 EN 1.1

Connection plan

23

X17

Solar energy Return – RWMZ

X18 Reserve – S1

X19

Flow rate 24V – Z_IN

X20 Reserve – 0-10V

X21

Solar pump 2 A-class or Accumulator

pump A-class

Terminals extra-low voltage zone

X1A Bus wiring – Bus RS485

X1B Bus wiring – Bus RS485

X2

Outdor sensor – AF

X12 Reserve – S3

X3

Boiler sensor – KF

X13 Reserve – S2

X4

Flow sensor HK1 – VL1

X14 Return sensor – ZIRK

X5

Flow sensor HK2 – VL2

X15

Collector sensor – KOLL

X6

DHW sensor – WW

X16

Solar energy Flow – VWMZ

X7

AC upper sensor – PO

X17

Solar energy Return–

RWMZ

X8

AC middle sensor – PM

X18 Reserve – S1

X9

AC lower sensor 1 – SPU1

X19

Flow rate 24V – Z_IN

X10

AC lower sensor 2 – SPU2

X20 Reserve – 0-10V

X11

Solar pump 1 A-class

X21

Solar pump 2 A-class or Accumulator pump A-class

X34 Jumper

Terminals low voltage zone - 120VAC

X32

Accumulator pump –

PLP

X31

Solar pump 1– Sol P1

X30

Domestic hot water –

WW

X25 – 23/N

Mixer HK2 closing – M2

X33

Power supply 115V –

240V~

X25 – 13/N

Mixer HK2 opening – M2 X29

Return pump – Heat

main pump – ZP

X24

Burner demand 2 –

BRanf 2

(Potencial free contact)

X28

Solar pump 2 – Sol P2

X23 – 23/N

Mixer HK1 closing – M1

X23 – 13/N

Mixer HK1 opening – M1

X22

Burner demand – BRanf 1

X26 Heating circuit pump –

HK1

X27 Heating circuit pump –

HK2

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

24

Connection plan

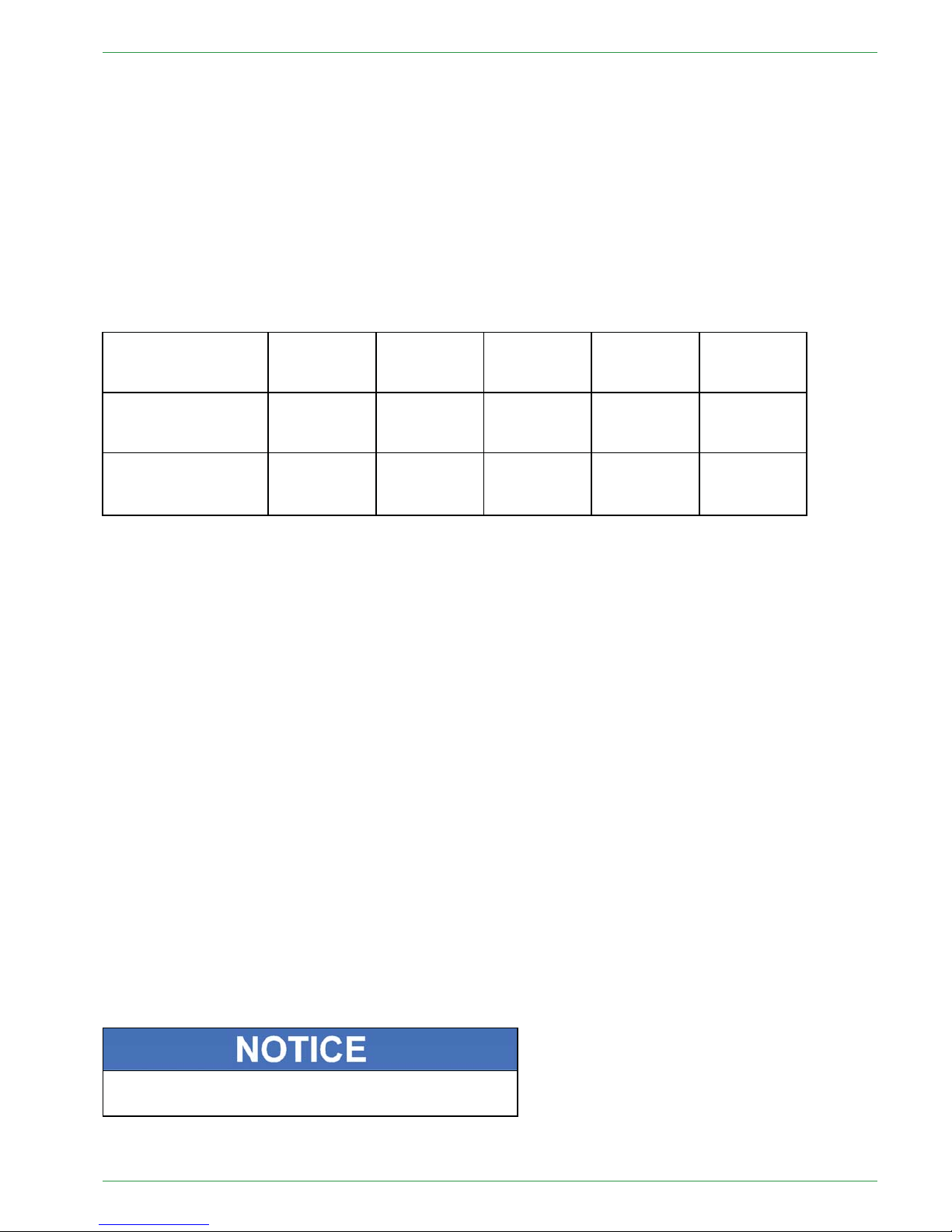

Electrical wiring diagrams heating controller

The wiring diagrams are also located on the inside of the cover of the heating controller.

Be aware of the instructions and diagrams illustrated there.

PE 567 EN 1.1

Jumper X34 for analog voltage outputs X11 (OUT1) and X21 (OUT2)

25

88..22..11JJuummppeerrXX3344ffoorraannaallooggvvoollttaaggeeoouuttppuuttssXX1111((OOUUTT11))aannddXX2211((OOUUTT22))

The different types of high-efficiency pumps: Analog pumps with 0-10 V control and PWM pumps with 24V.

For each type of pump you have to adjust the signal at the heating controller.

The plug connector X34 is for the Jumper-settings. Use a jumper with a grid dimension of 1 inch. The terminals X11 and X21 can receive or export a different signal depending on the jumper position.

Note:

When using PWM-pumps for a voltage up to 15V, adapter-cables must be connected at the slots X11 and

X12.

These cables limit the output voltage from 24V to 15V.

Jumpersettings X34:

The male connector X34 serves for jumper-adjustments. Please use jumper with a contact spacing of 1 inch

(included in delivery of heating controller)

High-efficiency

pump with external

control function

Terminal Designation Function Plug

connector

Position

Solar pump 1

X11 Out 1 PWM Out

Analog Out

0-10V

A-B and C-D

A-B and C-D

0

X

Solar pump 2

(or accumulator

pump)

X21 Out 2 PWM Out

Analog Out

0-10V

E-F and G-H

E-F and G-H

0

X

0.... Jumper is not set, pins open.

X.... Jumper is set, pins closed.

8.3 Rules of wiring for micronetwork with 1,2 or more heating

controllers

The boiler controller suplies the touch operating device and up to two remote controls.

• The order of devices in the bus-wiring is free. The station-numbers for the heating controller and the digital

remote controls have to be assigned uninterrupted.

• The number of heating controllers is independent from the numbers of the digital remote controls and independent from the numbers of boiler controllers.

•Adouble allocation is not acceptable.

• The maximum limit of bus-participiants is 16.

• The maximum length of a bus-cable is 200 metres.

• The maximum cable-length depends on:

– A solid point-to-point topology allows the fullmax. length.

–Astar-topology does not allow the max. length.

– We recommend a twisted-pair cable, especially for long cables (e.g. in buildings) and if the cable runs paralell to other cables.

– Correct bus-connection resistance, which is always existing on boiler operating device.

For long cables or communication problems occur, a additional resistor with 120 Ohm has to be clamped

between wire A and B at the last bus-participant.

When controlling a cascade-system, a bridge must be

installed at boiler controller port X2.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

26

Wiring diagrams

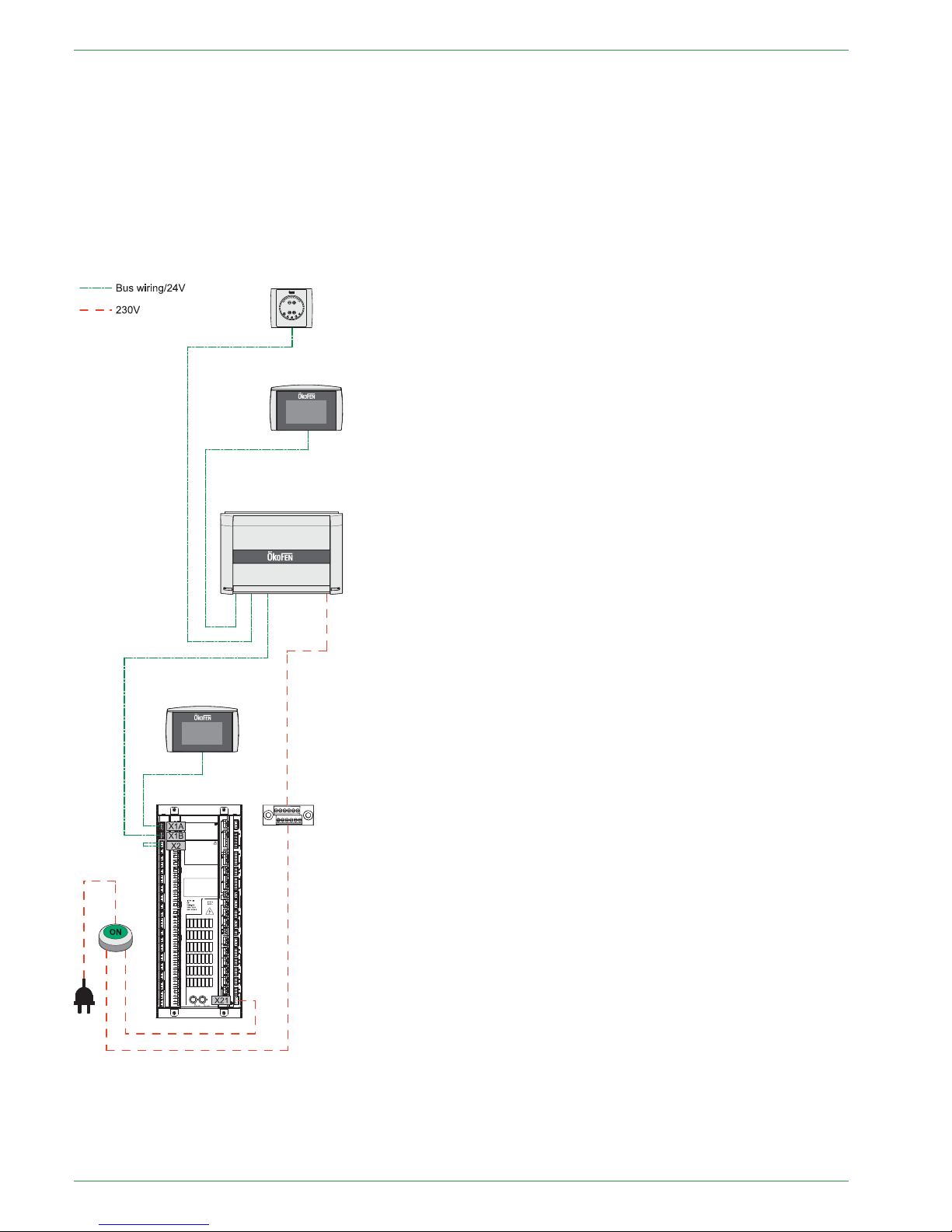

8.4 Wiring diagrams

Wiring diagram with:

• 1x Boiler controller FA

• 1x Heating controller Pelletronic

• 1x Touch operating device (Master)

• 1x Touch remote control (Slave)

• 1x Remote controll with LED

Note:

You find more detailed information about wiring in chapter 8.3 Rules of wiring for micronetwork with 1,2

or more heating controllers, page 25

PE 567 EN 1.1

Wiring diagrams

27

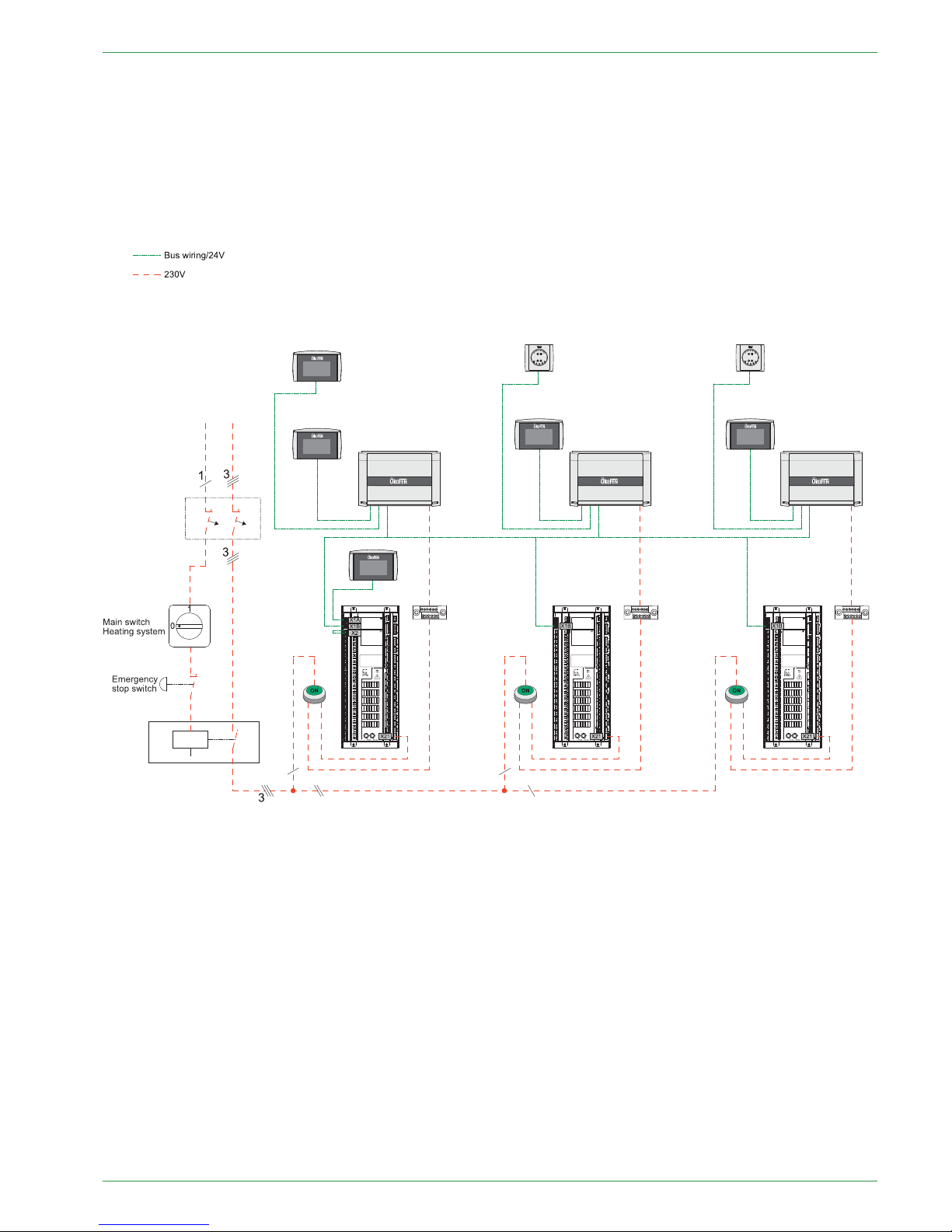

Wiring diagram with:

• 3x Boiler controller FA

• 3x Heating controller Pelletronic

• 1x Touch operating device (Master)

• 4x Touch remote control (Slave)

• 2x remote controll with LED

Note:

You find more detailed information about wiring in chapter 8.3 Rules of wiring for micronetwork with 1,2

or more heating controllers, page 25

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

28

Assembly and disassembly of the heating controller circuit board

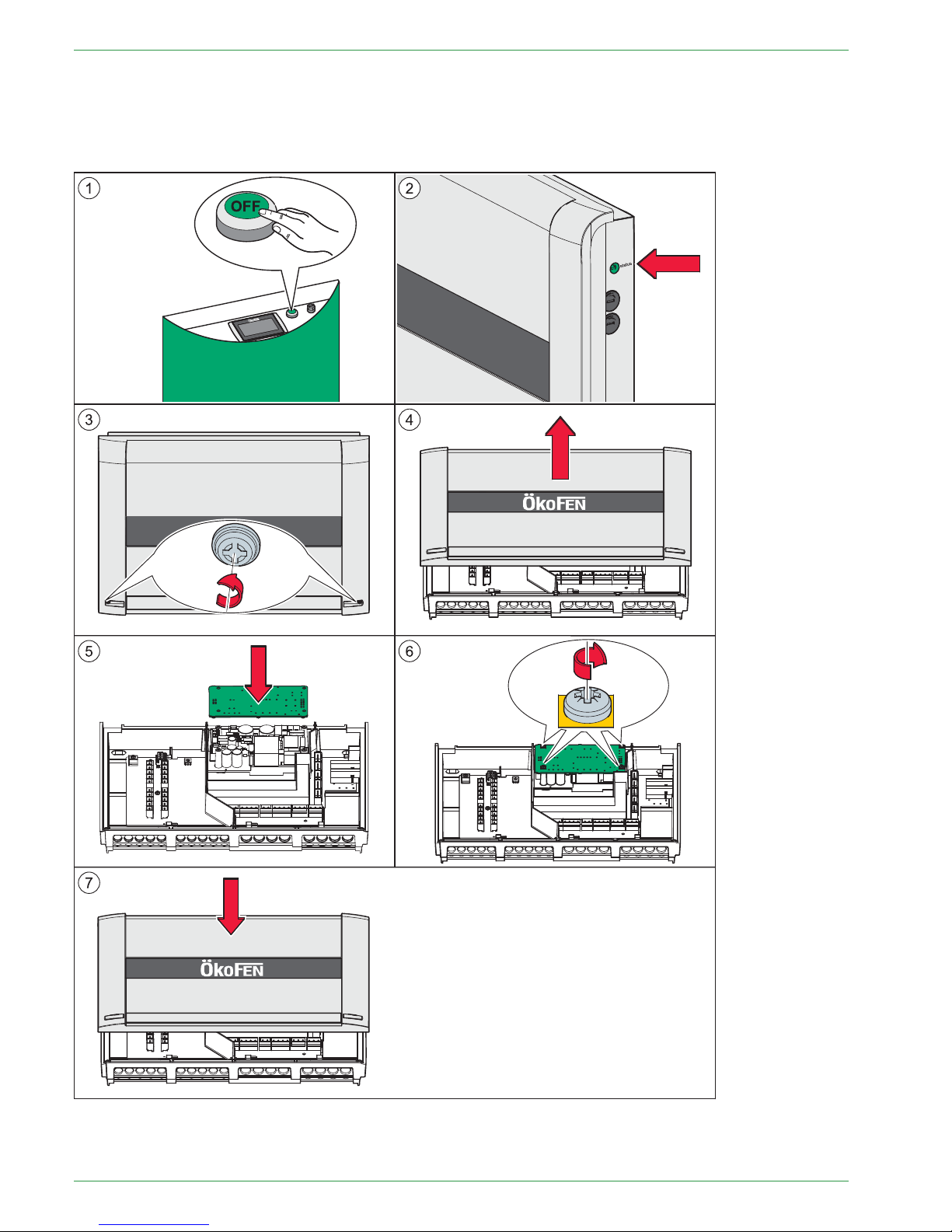

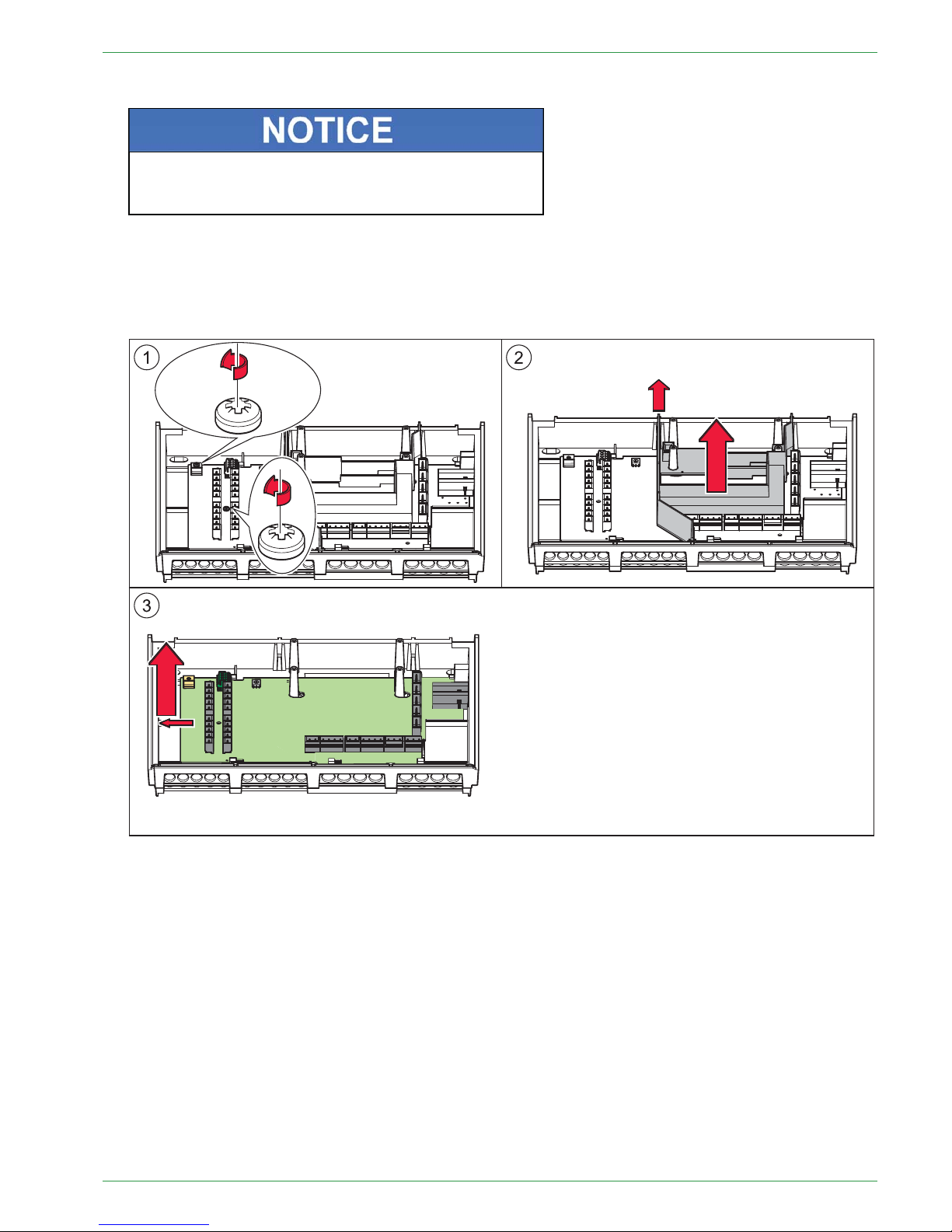

8.5 Assembly and disassembly of the heating controller circuit

board

You can take off the circuit board of the heating controller, without filtering out the inputs and outputs.

Note:

Image 2: Control with the status of the LED that the heating controller is electroless.

PE 567 EN 1.1

Assembly and disassembly of the heating controller circuit board

29

1. Make the complete heating system powerless.

EElleeccttrroossttaattiiccddiisscchhaarrggeeddaammaaggee

Before starting work, touch a grounded object to avoid

damage of circuit board by electrostatic charging.

2. Open the cover plate of the heating controller.

3. Disconnect all plugs from the circuit board. Leave the plugs with the wiring in the casing.

4. Disassembly from the power supply (optional)

5. Disassembly the circuit board from the heating controller.

6. The installation of a new circuit board occurs in reverse order.

Operating Manual PELLEMATIC® PE(S)(K)(B) 10 — 56

30

Cable specification Pelletronic Touch

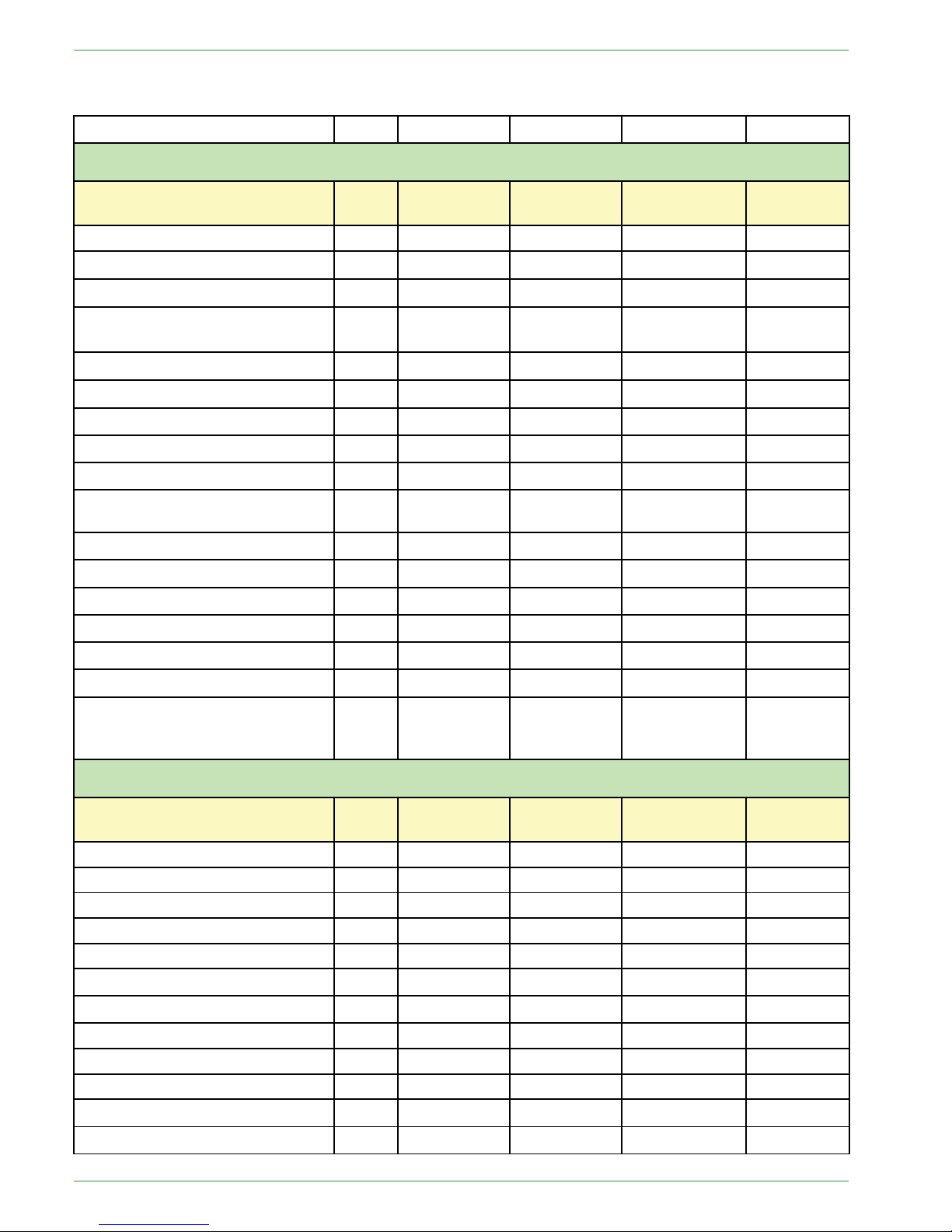

8.6 Cable specification Pelletronic Touch

Power supply

K02

X33 YML-J 3x1

x

OUTPUTS see on wiring diagram on the front side

Function – Shortcut

Cable

Pin I/O BOX

Cable type Section

Max

Ampere

Burner contact 1 – BRanf 1

K 03 X22

YML-J

3x0.75 2A

Mixer HK1 OPEN – M1 K 12

X23 – 13/N

YML-J

3x0.75 2A

Mixer HK1 CLOSED – M1 K 12

X23 – 23/N

YML-J

3x0.75 2A

Burner contact 2 – BRanf 2

(Potencial free contact)

K 30 X24

YML-J

3x0.75 2A

Mixer HK2 OPEN – M2 K 13

X25 – 13/N

YML-J

3x0.75 2A

Mixer HK2 CLOSED – M2

K13

X25 – 23/N

YML-J

3x0.75 2A

Heating circuit pump – HK1 K 14 X26

YML-J

3x0.75 2A

Heating circuit pump – HK2 K 15 X27

YML-J

3x0.75 2A

Solar pump 1 – Sol P1

K 16 X31 YML-J 3x0.75 2A

Return pump – Heat main pump –ZPK 29 X29

YML-J

3x0.75 2A

Domestic hot water pump – WW

K 21 X30

YML-J

3x0.75 2A

Solar pump 2 – Sol P2

K 23 X28 YML-J

3x0.75 2A

Accumulator pump – PLP

K 05 X32 YML-J 3x0.75 2A

Bus wiring – Bus RS485 K 01 X1A YSLCY–0Z 4x0.75

x

Bus wiring – Bus RS485 X1B YSLCY–0Z 4x0.75

x

Solar high-efficiency pump 1

K 28 X11 YML

2x0.75

x

Solar high-efficiency pump 2 or

Accumulator high-efficiency

pump

K 71 X21

YML

2x0.75

x

INPUTS see on wiring diagram on the front side

Function – Shortcut

Cable

Pin I/O BOX

Cable type Section

Max

Ampere

Outdor sensor – AF

K 09 X2 YML 2x0.75

KTY 2k

Boiler sensor – KF

K04

X3 YML

2x0.75

KTY 2k

Flow sensor HK1 – VL1

K 10 X4 YML 2x0.75

KTY 2k

Flow sensor HK2 – VL2

K 11 X5 YML

2x0.75

KTY 2k

DHW sensor – WW

K19 X6

YML

2x0.75

KTY 2k

AC upper sensor (TPO) – PO K 18

X7 YML

2x0.75

KTY 2k

AC middle sensor (TPM) – PM

K 17 X8 YML

2x0.75

KTY 2k

AC lower sensor 1 – SPU1

K20 X9

YML

2x0.75

KTY 2k

AC lower sensor 2 – SPU2

K 22 X10

YML

2x0.75

KTY 2k

Reserve sensor – S3 X12 YML

2x0.75

KTY 2k

Sensor existing boiler – S2

X13 YML

2x0.75

KTY 2k

Sensor return pump – ZIRK K 29 X14 YML 2x0.75

KTY 2k

PE 567 EN 1.1

Loading...

Loading...