Okina SEIMW36T-V53DN Operation Manual

36x Wide Dynamic ICR IR

PTZ Camera

OPERATION MANUAL

SEIMW36T-V53DN

OKINA

TO REDUCE THE RISK OF FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS

PRODUCT TO RAIN OR MOISTURE. DO NOT INSERT ANY METALLIC OBJECTS

THROUGH THE VENTILATION GRILLS OROTHER OPENINGS ONTHE EQUIPMENT.

FCC COMPLIANCE STATEMENT

CE COMPLIANCE STATEMENT

CAUTION: CHANGES OR MODIFICATIONS NOT EXPRESSLY APPROVED BY THE PARTY RESPONSIBLE FOR COMPLIANCE COULD VOID THE USERS‘S AUTHORITY TO

OPERATE THE EQUIPMENT.

FCC INFORMATION: THIS EQUIPMENT HAS BEEN TESTED AND FOUND TO COMPLY WITH THE LIMITS FOR A CLASS A DIGITAL DEVICE, PURSUANT TO PART 15 OF

THE FCC RULES. THESE LIMITS ARE DESIGHEND TO PROVIDE REASONABLE PROTECTION AGAINST HAMRFUL INTERFERENCE WHEN THE EQUIPMENT IS

OPERATED IN A COMMERCIAL ENVIRONMENT. THIS EQUIPMENTGENERATES, USES, AND CAN RADIATE RADIO FREQUENCY ENGERGY AND IF NOT INSTALLED AND

USED IN ACCORDANCE WITH THE INSTRUCTION MANUAL, MAY CAUSE HARMFULINTERFERENCE TO RADIO COMMUNICATIONS. OPERATION OF THIS EQUIPMENT

IN A RESIDENTIAL AREA IS LIKELY TO CAUSE HARMFUL INTERFERENCE IN WHICH CASE THE USER WILL BE REQUIRED TO CORRECT THE INTERFERENCE AT HIS

OWN EXPENSE.

WARNING: THIS IS A CLASS A PRODUCT. IN A DOMESTIC ENVIRONMENT THIS PRODUCT MAY CAUSE RADIO INTERFERENCE IN WHICH CASE THE USER MAY BE

REQUIRED TO TAKEADEQUATE MEASURES.

CAUTION: TO REDUCETHE RISK OF ELECTRIC SHOCK, DO

NOT REMOVE COVER ( OR BACK). NO USER SERVICEABLE

PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL

This symbol indicates that dangerous voltage constituting a risk

of electric shock is present within this unit.

This symbol indicates that there are important operating and

maintenance instructions in the literature accompanying this

unit.

CAUTION: BEFOREATTEMPTING TO CONECT OR OPERATE THIS PRODUCT, PLEASE READ THE LABELON THE BOTTOMAND USER'S MANUALCAREFULLY

Technical specification are subjects to change without prior notice. Manual may contain mistake or print error.

All trademarks mentioned belong to their respective owners.

• All installation works should be done by qualified service person or system installer.

Do not try to open or disassemble the PTZ. To prevent electric shock, do not remove the screws or cover. There are no userserviceable parts inside. In case of maintenence, contact qualified service personnel.

Handle the PTZ carefully. Do not hit, strike or shake the PTZ. This will cause damage the mechanic parts and avoides the warranty.

During the transport or storage, the PTZ should be packed in original packing, which will protect from pressure, vibration and

humidity.

Do not use strong or excessive liquid to clean the PTZ and cover. Use dry cloth or mild cleaning lotion, and wipe gently.

Do not operate the PTZ among the specified condition. Please refer to the section “Specification” for detailed information.

The indoor version of PTZ is not designed to resist high humidy and water, these

may cause permanent damage and avoids the warranty. For indoor application with extrem wet condition or area contains water or

high-humidity, use the outdoor model instead. When the indoor PTZ get wet, turn off the power immediatly and send to qualified

service personnel .

Do not point the camera to strong light source ( e.g. Sun-Light, Beamer or laser pointer). This will cause permanent damage to the

sensor and avoids the warranty.

Read this user's manual carefully before operating, and make sure that the operation and installation follow your local electric safety

standards or regulation.

Do not install the PTZ in orientation other than designed. The PTZ is designed for operation looking-down. Other orientation of

installation will prevent the heat-sink function and cause damage.

Do not touch the PTZ clear cover with bare hands or any object. These will leave permanent scratches on the surface and decrease

the image quality. Scratches are not covered by the warranty.

•

•

•

•

• Do not expose the indoor PTZ to water or moisture.

•

•

•

•

Do not install and operate this PTZ in a flammable and explosive environment.

Make sure that the installation is done according to the local electricity safety regulation of your country.

Before installation or mentainence, make sure that the PTZis disconnected from the power source.

Do not use any power source other than specified in the specification, in order to prevent damages. In case of doubt, see section

“Specification” for details.

Handle the device during the installation carfully. Falls or extreme vibration will cause irrepairable damages and avoid the warranty.

Do not install or operate the PTZ near any high-voltage devices or high-voltage cable. The safety distance should remain at least 50

m.

To archive best image quality, its recommanded to use underground cable shielded with steel tube. Do not install the cable without

any protection.

In area or region which has high inductive power, such as high voltage transformer stations, or high electrostatic discharges, such as

thunder, it is necessary to use additional lighning-proof equipments or lightning rob for protection.

For outdoor installation, lightning-proof and grounding of the device should be considered. Please refer to the industrial saftey

regulation and request of your country

Grounding of the PTZ should consider with anti-interference and fulfill the saftey requirements. Do not connect the ground with

short-circuited or other high-voltage electric network.

The resistance of down conductor should not exceed 4 Ohm, and its thickness should be at least 25mm²

This PTZ is protectd against high-voltage pulse up to 1500V

The outdoor model meets the Ip66 standard for water and dust proof. Do not install the in-door model for out-door application. Make

sure that the installation is protected from long-time water-drop or spatter, which may damage the appliance.

Make sure that the enviroment of installation meets the requirement of the appliance, such as holding the weight, enough spaces for

bracket and power supply.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

WARNING

English

PRECAUTION

Installation

Unpacking .................................................................................................. 1

I/O Interface ...

Basic Setup

Telemetric

ID / Protocol

RS-485Termination

Mounting

Application Example .

RS-485Transmission

VideoTransmission

OPERATION

Powering the PTZ

Workwith PTZ

Camera functions

OSD

Enter the OSD

Main Menu

System Setting

Edit dome label

Initial Info

Display Setup

Motion

Motion -Advanced

Setting

Clear

Password Setting

Clock Setting

Camera Setting

IR CUT Filter

Function Setting

Presets

Scan

Pattern

Tour

Zones

TimeRunning

Window Blanking

Alarms

Language

Appendix

OSD Map

Dip Switch settings

ID Settings

............................................................................................ 1

.................................................................................................1

.................................................................................................. 1

................................................................................................ 1

..................................................................................... 1

..................................................................................................... 1

................................................................................... 2

...................................................................................2

.....................................................................................2

........................................................................................3

............................................................................................. 3

........................................................................................ 3

............................................................................................. 4

..................................................................................................4

............................................................................................4

......................................................................................4

.............................................................................................. 4

................................................................................................... 5

..................................................................................5

.................................................................................................. 5

..................................................................................................... 5

................................................................................... 5

......................................................................................... 5

......................................................................................... 6

Advance Setting ................................................................................... 6

................................................................................................ 6

.................................................................................................... 6

................................................................................................. 7

..................................................................................................... 7

.................................................................................................. 7

........................................................................................ 7

........................................................................................ 8

....................................................................................................... 8

.................................................................................................. 8

.................................................................................................. 9

SPECIFICATIONS

............................................................................................ 11

WARRANTY

..................................................................................................... 11

.................................................................................... 9

................................................................................................10

CONTENT

English

SEIMW36T-V53DN

Manual

HIGH-SPEEDPTZ

CAMERASERIES

OPERATIONMANUAL

Ver.1.0

GERMAN

G50IR-MKII

ENGLISH

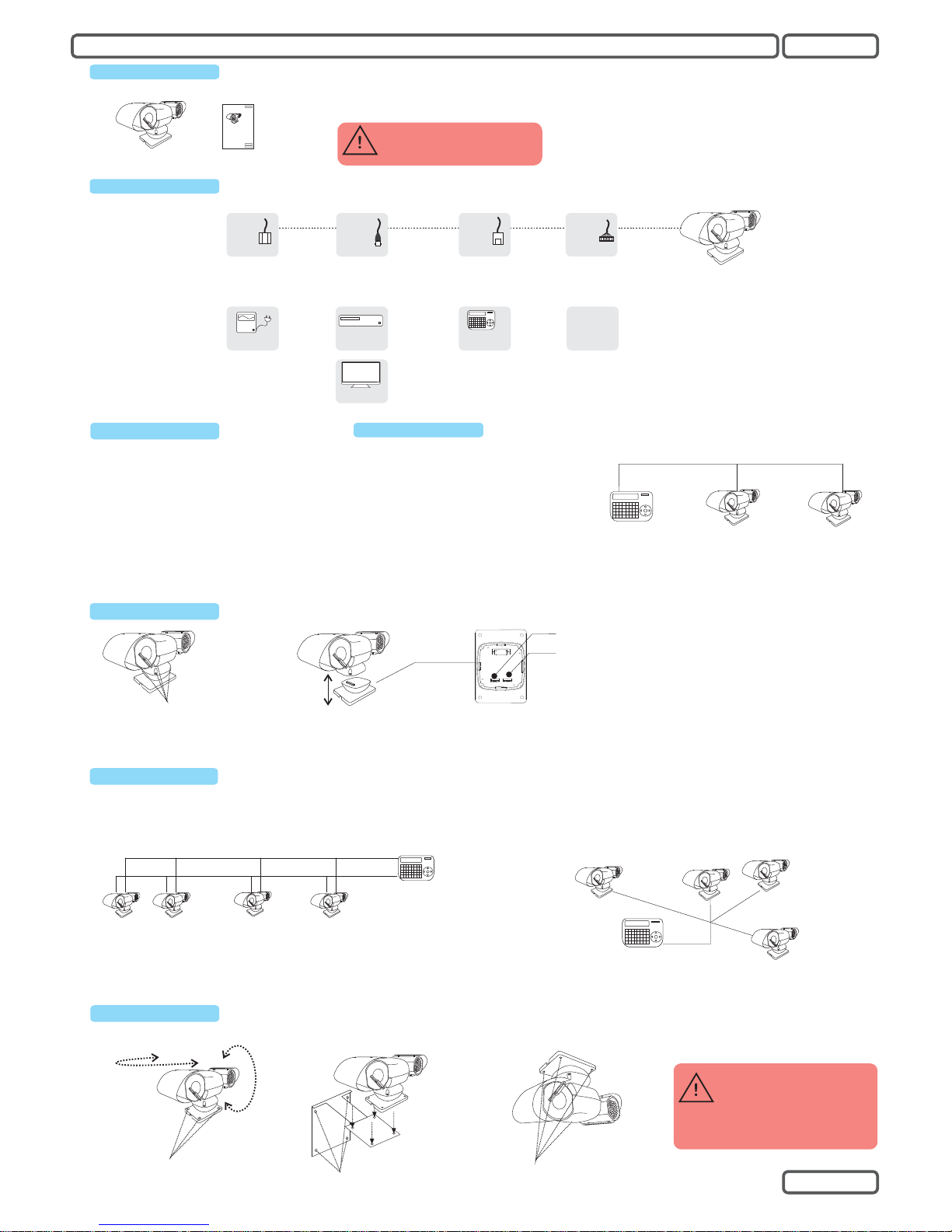

INSTALLATION

English

Keep the original box for

possible transport in the future.

Switch 1:

Switch 2:

ID Setup

Digit 1 to 5: Protocol setup

Digit 6,7: Baud-Rate

Digit 8: RS485 Termination(default:off)

For setting details, please refer to

ID & protocol setup

Step 1

Loose the screws (4 pcs)

and open the base-part

Step 2

Takeoff thebase

part for configuration

Step 3

Set the ID, Protocol

Baud-Rate and Termination

For a smooth telemetric operation, it is necessary to set the termination properly.

RS485 Termination

1. Chain Connection

RS 485+

RS 485-

ID:1

Termination

ON

ID:2

Termination

OFF

ID:3

Termination

OFF

ID:4

Termination

OFF

Keyboard

Termination

ON

2. Star-Form Connection

Keyboard

Termination

ON

ID:1

Termination

ON

ID:2

Termination

ON

ID:3

Termination

ON

ID:4

Termination

ON

Use 4 Screws

to fix (not

included)

Wall-MountBracket

(optional accessory)

Reverse-Mount

Use 4 Screws to fix

(not included). Change SETTING in OSD

Mounting

Use 4 Screws to fix

(not included)

360°

Pan

180°

Tilt

Surface-Mount

Wall-Mount

Make sure the installation

enviroment provide enough

space for pan and tilt

movement, else it might

damage the mechanic parts.

Sensor

Switch

I/O Interface

Red:AC24V

Black:AC24V

24VAC/2A

24V

AC

POWER

BNC

VIDEO

RJ-11

RS-485

ALARM

Inner Pin: Video +

Outer Conn.:Video -

Green: RS-485 +

Yellow: RS-485 -

Power

Keyboard

Controller

Monitor

DVR

Connectors

Accessories

Unpacking

Basic Setup

Check-List before installation:

1.TelemetricProtocol setting

2. Dome ID setting

3.Terminationsetup

3. NecessaryAccessories ( e.g Power

supply)

For telemetric control, make sure that:

1.All devices are setwith sameprotocol

and comm setting.

2.All PTZ devices havean uniqueID.

3. Control cable (Rs485) are connected

properly.

For controller setup, please refer tothe

operation manual

Example:

Protocol: B02

Baud-Rate: 9600

ID:1

ID:2

Telemetric

1

INSTALLATION

English

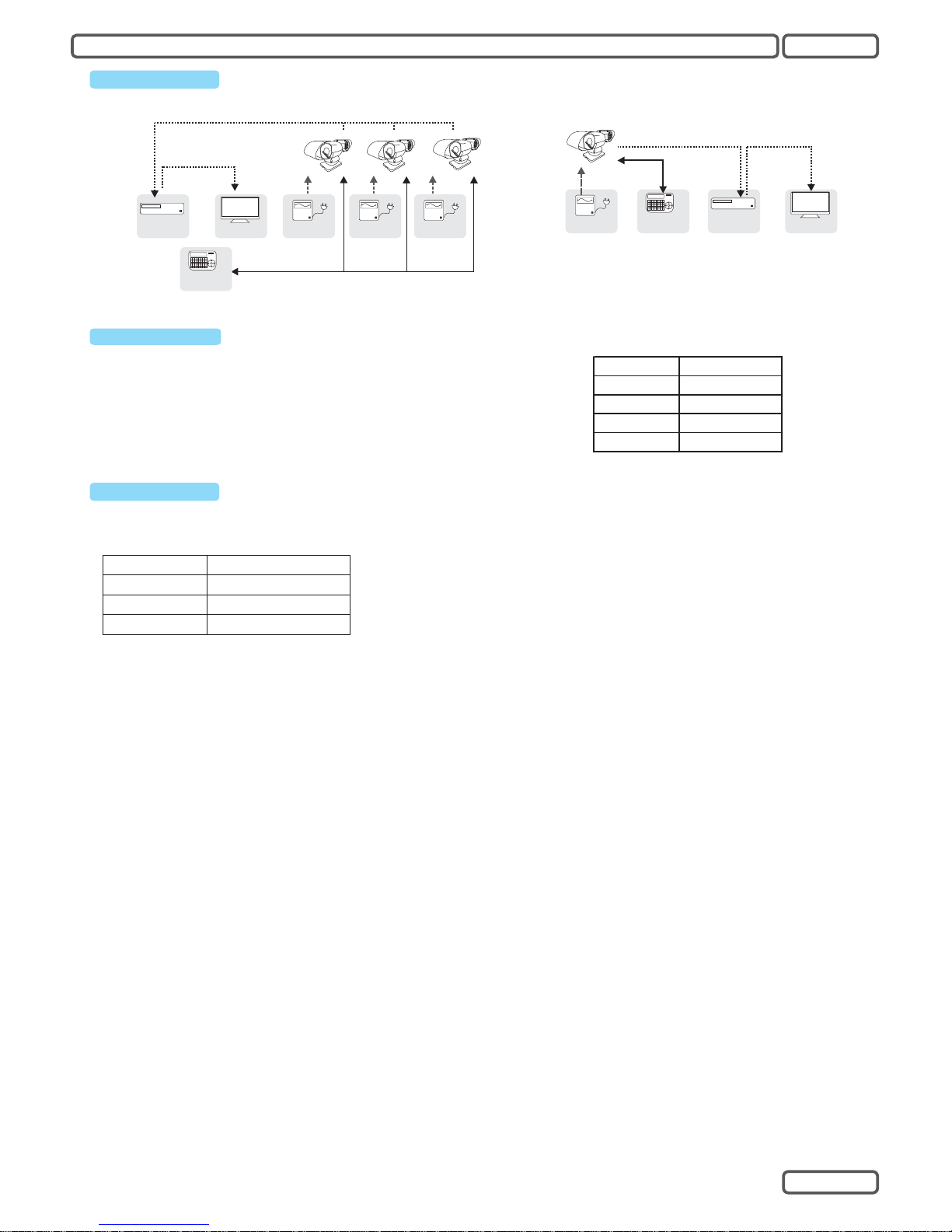

Monitor

Keyboard

Controller

DVR

Power

RS-485

Line

Video output

Simple PTZ

RS-485 Daisy-Chain or Star-Form

connection, Termination on the ends.

Video output

Power Power Power

DVR

Monitor

Keyboard

Controller

Multiple PTZ

Application Example

For video signal transmission, coaxial cable with 75 Ohm impedence is recommended. Depends on the cable type, the transmission

distance might be different:

RG6/U

Cable standard

RG 11 /U

229m / 750 ft

Max. Distance (m /ft )

305m/ 1000 ft

457m / 1500 ft

RG 59 /U

Video Transmission

The actually transmission distance can vary from the data shown on the table left. It is

necessary to consider the environmental in fluences when planning the installation. If

the transmission requires a larger distance, you may use video-balun or fiber-transmitter

to extend the distance. Contact your local sales representative for further information.

RS485 Transmission

The distance of RS485 transmission between 2 nodes depends on the baudrate. The table on the right side shows the maximum range of every baudrate, assuming a AWG24 wire-pair is used. Note the range might be shorter

than given here, since the cable quality or interferences may affect the

transmitted data, and cause invalid command.

In star-form connection, it might be necessary to use RS-485 Distributor, to

ensure the signal quality of the transmission.

2400 bps

1100 m

700m

4oom

4800 bps

1700m

9600 bps

19200 bps

Baud Rate

Max. Distance

2

Loading...

Loading...