OKIDATA 3320, 3321 Troubleshooting Manual

MICROLINE 3320/3321

Troubleshooting Manual

with Components Parts List

All specifications are subject to change without notice.

HP, LaserJet and PCL5e are trademarks of Hewlett-Packard Co.

PREFACE

This manual describes in detail troubleshooting of the component parts for Microline

320/321 TURBO printer and provides a parts list.

TROUBLESHOOTING MANUAL

CONTENTS

1. OUTLINE ...................................................................................................1

2. TOOLS ......................................................................................................5

3. TROUBLESHOOTING TABLES ...............................................................5

4. TROUBLESHOOTING FLOWCHART ......................................................7

5. CIRCUIT DIAGRAM

6. COMPONENT PARTS LIST

1. OUTLINE

This troubleshooting flowchart has been prepared for the repair of each board assembly of the

Microline 320/321 TURBO printer. The repairmen using this manual are assumed to be familiar

with certain techniques.

1.1 Items to Check Before Repair

• Check the inspection items specified in the instruction manual.

• Find out as many details of the trouble as possible from the customer.

• Inspect in the conditions as close as possible to those at the time the trouble occurred.

• Proceed with the repair as follows:

Check the trouble status according to Table 1.1 for the details of the trouble. Then, locate the

trouble position according to the detailed flowchart.

• Carry out a thorough test after the repair to check for correct functioning.

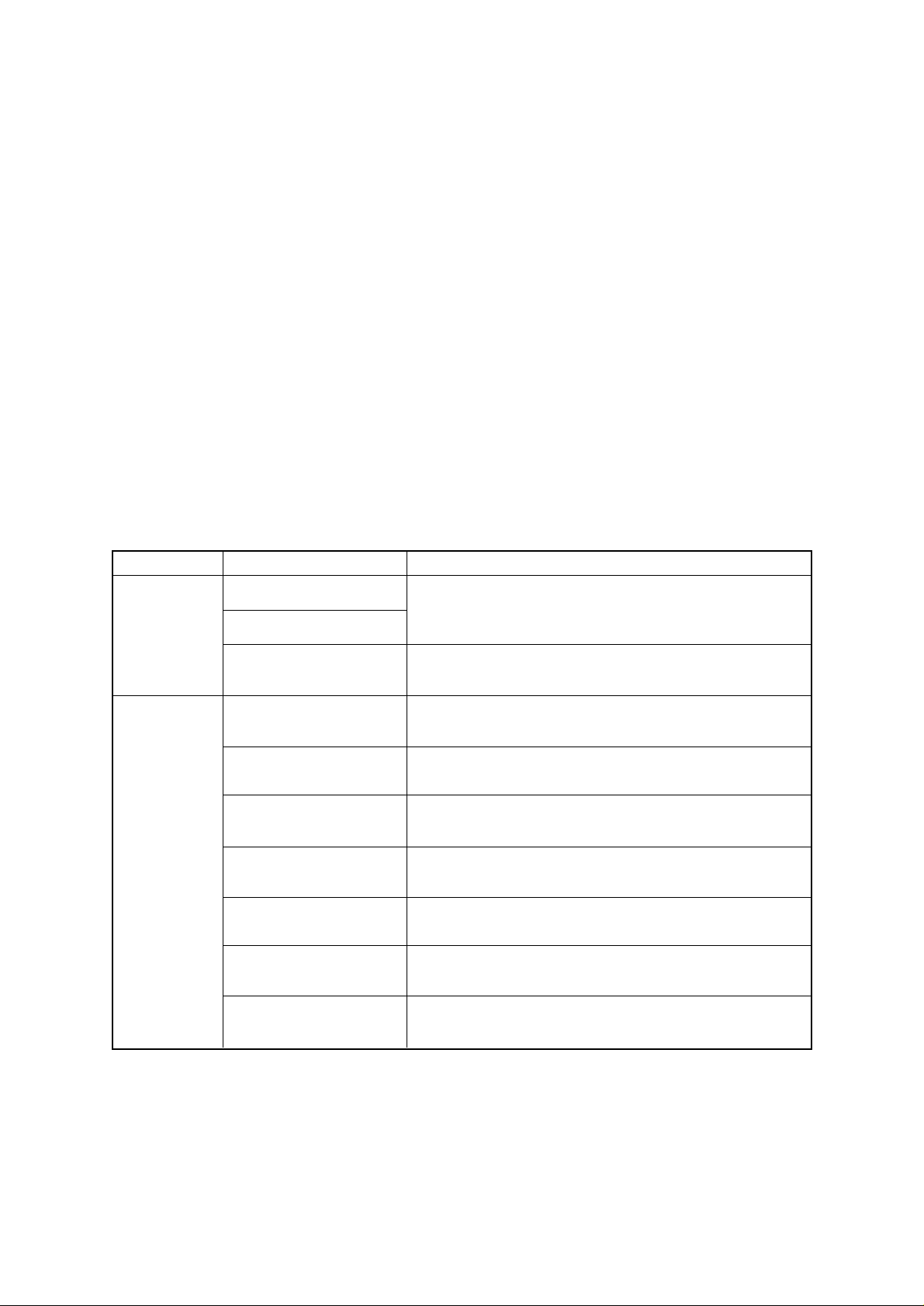

1.2 Troubleshooting

Trouble contents Surmise of troublleStatus

Table 1.1

Trouble upon

power on

Trouble

during

printing

Power is not supplied

No spacing operation

Homing does not end

normally

Paper jam while paper

insertion

Smearing/Missing dots

Faint or dark print

Ribbon feed trouble

Line feed trouble

Malfunction of switch on

operation panel.

Data receiving failure

Transformer, Power & Control Board, Driver Board, Operation Panel.

Space motor, carriage Cable, Print Head.

Space Motor, Carriage Cable, Spacing Mechanism, Driver Board

Pressure roller Mechanism, Support Protector, Pull up roller cover.

Print Head, Power & Control Board, Space Motor, Carriage Cable,

Driver Board

Print Head, Ribbon feed assembly, Power & Control Board, Driver

Board

Ribbon feed assembly, Space motor, Power & Control Board, Driver

Board

LF motor, Platen assy, LF mechanism, Power & Control Board, Driver

Board

Operation Panel, Power & Control Board, Driver Board

Power & Control Board, (I/F/P.C.B), I/F Cable, Menu setting, Driver

Board

Note: Refer to the Maintenance Manual for the troubleshooting flow chart of this table.

- 1 -

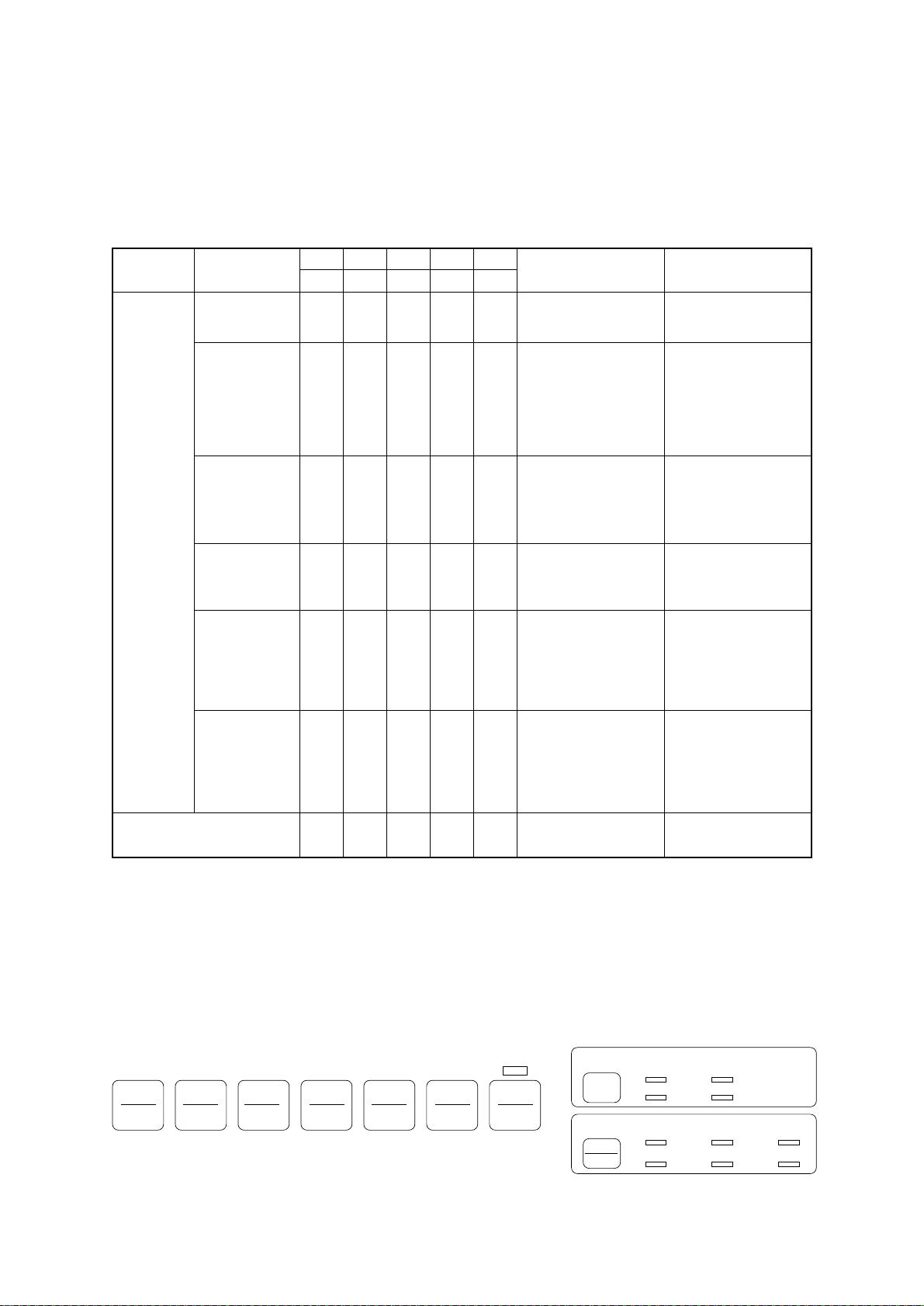

1.3 Lamp Display

(1) Printer mode display

Table 1.2

ALARM

CATEGORY

OPERATOR

ALARM

ALARM CONTENTS TROUBLESHOOTING

Paper end

alarm

Paper

change lever

alarm

ALARM MENU 10 CPI 15 CPISEL

ON

—

ON

OFF

—

—

—

BLINK

1

—

From, cut sheet or

bottom paper end

OFF

Change lever is set to

TOP position while

paper is already inserted

from rear or bottom.

Set New paper.

• Set the lever to

specified position.

• Check rear sensor

lever.

• Replace Power &

Control Board.

Paper jam alarm

Print Head

thermal alarm

ON

OFF

OFF

—

—

BLINK

1

OFF

—

BLINK

• Cut sheet could not be

1

ejected.

• Cut sheet could not be

fed properly.

—

Print head temperature

exceeds 119°C.

• Remove the paper or

check feed

Mechanism.

• Press SEL key.

• Wait until it is cooled.

• Replace P.H. or Power

& Control Board.

Space motor

thermal alarm

OFF

—

BLINK

1

—

—

Temperature of space

motor and driver

exceeds specified value.

• It is recovered

automatically.

• Replace SP motor or

Power &Control

Board.

LF motor

temperature

OFF

—

BLINK

1

alarm

FATAL ALARM

BLINK

OFF

OFF

2

Note: BLINK 1: 400 ms ON, 400 ms OFF

BLINK 2: 200 ms ON, 200 ms OFF

— : LED is kept in Current Condition (no change)

(2) Fault alarm display

When the printer detects any of the various alarm states, the information is displayed as

shown below on the operation panel. The alarm is specified by lamp combination of PRINT

QUALITY and CHARACTER PITCH. (See Table 1.3 for details.)

SEL

SEL

MENU

EXIT

POWERALARM

SHIFT

LF

Micro Feed

Down

GROUP ITEM SET

FF/LOAD

Micro Feed

Up

TEAR PARK QUIET

MENU

—

PRINT

—

Temperature of LF

motor and driver

exceeds specified value.

Hardware Alarm has

occurred.

TOF

• It is recovered

automatically.

• Replace LF motor or

Power & Control

Board.

See Table 1.3.

PRINT QUALITY

CHARACTER PITCH

RESET

HSD UTILITY

NLQ SSD

10

17

12

20

15

PROP

- 2 -

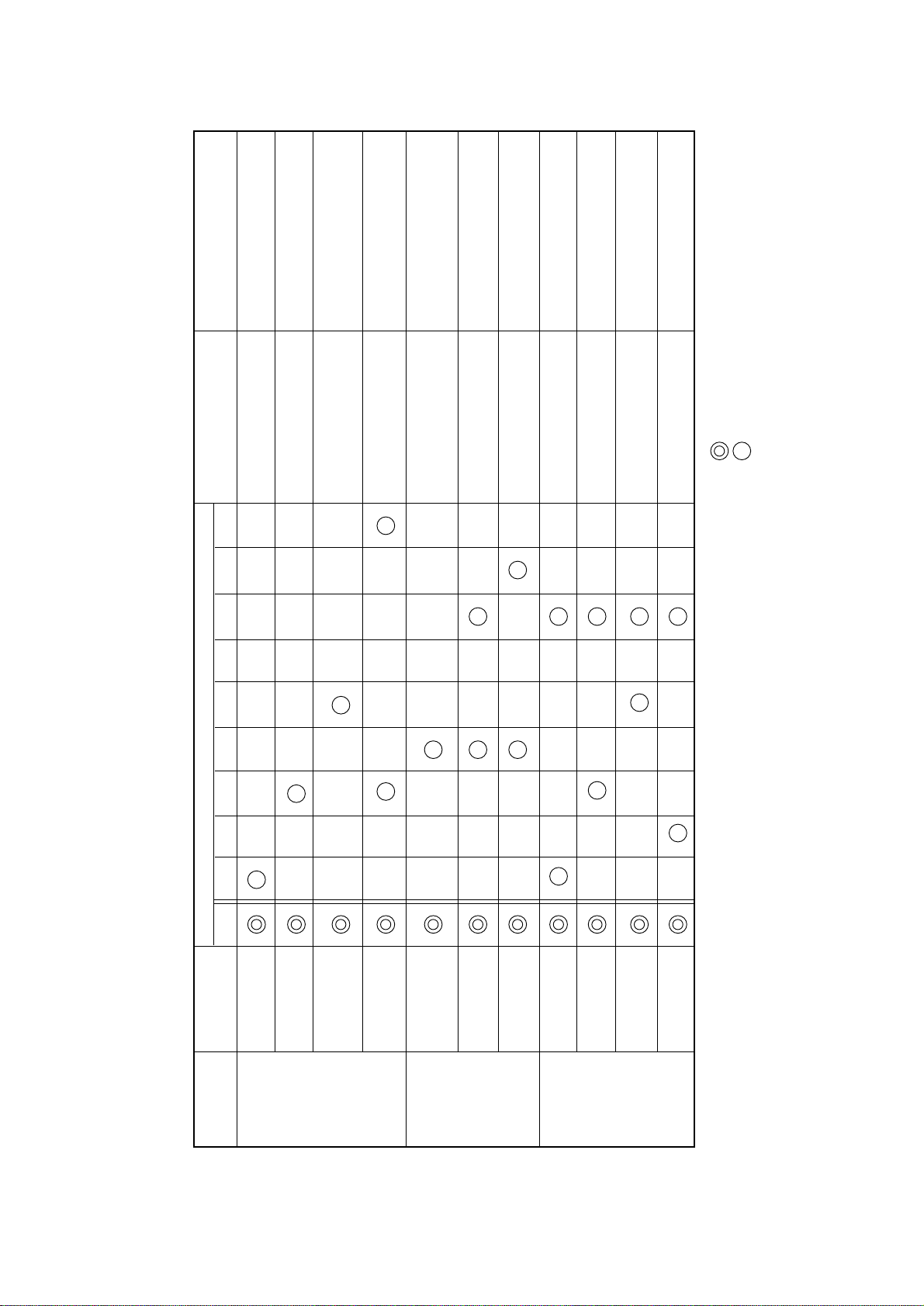

REMARKS TROUBLESHOOTING

Table 1.3 (1/2)

LED DISPLAY

Replace Power & Control Board

Replace ROM or Power & Control

Board

Read/write error

Check sum error

Replace Power & Control Board

Read/write error

Replace Power & Control Board

No reaction when MPU

reads data

Turn the power OFF and ON or

replace Power & Control Board

Replace Power & Control Board

Replace ROM or Power & Control

Board

Replace I/F Board

MPU is locked up and it is

reset after 65 ms.

NMI port of MPU is kept

low level.

FFFF data is detected

due to MPU locked up.

Read/write error

Replace I/F Board

Replace I/F board or Power & Control

Replace ROM on I/F Board or

I/F Board

Read/write error

Check sum error

Board

: LED Blink (200 ms ON, 200ms OFF)

No reaction from serial I/F

Board

: LED Lights up.

(3) Fatal Alarm

ALARM 10 12 15 17 20 PROP HSD UTL NLQ

ALARM

ALARM

CATEGORY

MPU internal

RAM alarm

Program

ROM alarm

RAM on

MAIN

CONTROL

Control Board

alarm

EEPROM

alarm

ALARM

WDT (Watch

Dog Timeout)

alarm

FIRMWARE

DETECTION

- 3 -

NMI signal

alarm

BRK instruction

ALARM

alarm

MPU internal

RAM alarm

ROM alarm

SERIAL

RAM on I/F

board alarm

INTERFACE

ALARM

I/F not

mounted

• Replace space motor.

REMARKS TROUBLESHOOTING

Space IPT is not occurred

Table 1.3 (2/2)

LED DISPLAY

• Replace P.H. cable.

• Replace Power & Control Board.

• Replace Driver Board.

• Check the mechanism if

load is too much.

• Check the P.H. connection.

• Replace Print Head.

• Replace P.H. cable.

within in specified timing.

Print head does not reach

to the home position.

Thermister is open, short

with 0V or short with +5V.

• Replace Driver Board.

: LED Blink (200 ms ON, 200ms OFF)

: LED Lights up.

ALARM 10 12 15 17 20 PROP HSD UTL NLQ

ALARM

ALARM

CATEGORY

Spacing alarm

Print Head

mounting alarm

SPACING

ALARM

PRINT HEAD

A/D alarm

Print Head

PRINT HEAD

ALARM

Gap AD alarm

- 4 -

2. TOOLS

In addition to the general maintenance tools, the following are necessary:

– Oscilloscope : Approx. 100 MHz or more

– Soldering iron : Standard (A soldering iron with a thin tip is best.)

3. TROUBLESHOOTING TABLES

1 The power source can not be turned on.

2 Only the POWER lamp lights. (The printer does not work.)

3 The printer alarm is displayed.

3-1 Printer Internal RAM Alarm

3-2 S-I/F Internal RAM Error

3-3 S-I/F Connection Alarm

3-4 Program ROM Alarm

3-5 S-I/F ROM Alarm

3-6 EEPROM Alarm

3-7 WDT Alarm, BRK Command Alarm

3-8 NMI Alarm

3-9 Printer External RAM Alarm

3-10 S-I/F External RAM Alarm

3-11 SPACING Alarm, HOMING Alarm

3-12 Head A/D Alarm

3-13 Head Gap A/D Alarm

4 Wrong characters are printed or some characters are not printed.

5 Defective line feed.

6 When pressing the operation switch, it does not work.

6-1 The SEL switch does not work.

6-2 The SHIFT switch does not work.

6-3 The LF switch does not work.

6-4 The FF switch does not work.

6-5 The TEAR switch does not work.

6-6 The PARK switch does not work.

6-7 The QUIET switch does not work.

6-8 The PRINT QUALITY switch does not work.

6-9 The CHARACTER PITCH switch does not work.

- 5 -

7 DATA can not be received.

7-1 Parallel interface data can not be received.

7-2 When receiving with the parallel interface, printed data is skipped, or the printer

does not work.

- 6 -

4 TROUBLESHOOTING FLOWCHART

1 The power source can not be turned on. (The POWER lamp does not light.)

• Check the connection between Transformer and Power & Control Board and Driver

Board and Operation panel.

• No Be sure the connection.

▼

• Yes Is Fuse (F1) on Filter PCB blown out?

• Yes Replace Fuse (F1).

▼

• No Are the signal level between 1-pin and 8-pin of CN1 on Power & Control Board,

29 Vac, between 3-pin and 6-pin, 8 Vac, and between 4-pin and 5 pin, 10 Vac?

• No Replace Transformer.

▼

• Yes Is the voltage level at VCC (1-pin) of Q6 of the Power & Control Board, +8V?

• No Is fuse (F1) on Power & Control Board blown out?

• Yes Replace Fuse (F1)?

▼

• No Replace D6, D7, D8 and D9 of the Power & Control Board.

▼

• Yes Is the voltage level between one side and the other of C25 of the Power &

Control Board, +5V?

• No Replace Q6 or TR6 of the Power & Control Board.

▼

• Yes Is +5V supplied for CN3 of the Driver board?

+5V (CN3 – 3 pin)

0V (CN3 – 2 pin)

• No Check +5V supplied for the Driver board or replace Driver board?

▼

• Yes Is +5V supplied for CN1 of the operation panel board?

+5V (CN1 – 5 pin)

0V (CN1 – 6 pin)

• No Replace a cable in the operation panel or replace the operation panel.

▼

• Yes Replace D2 or R2 on the operation panel.

- 7 -

2 Only the POWER lamp lights. (The printer does not work.)

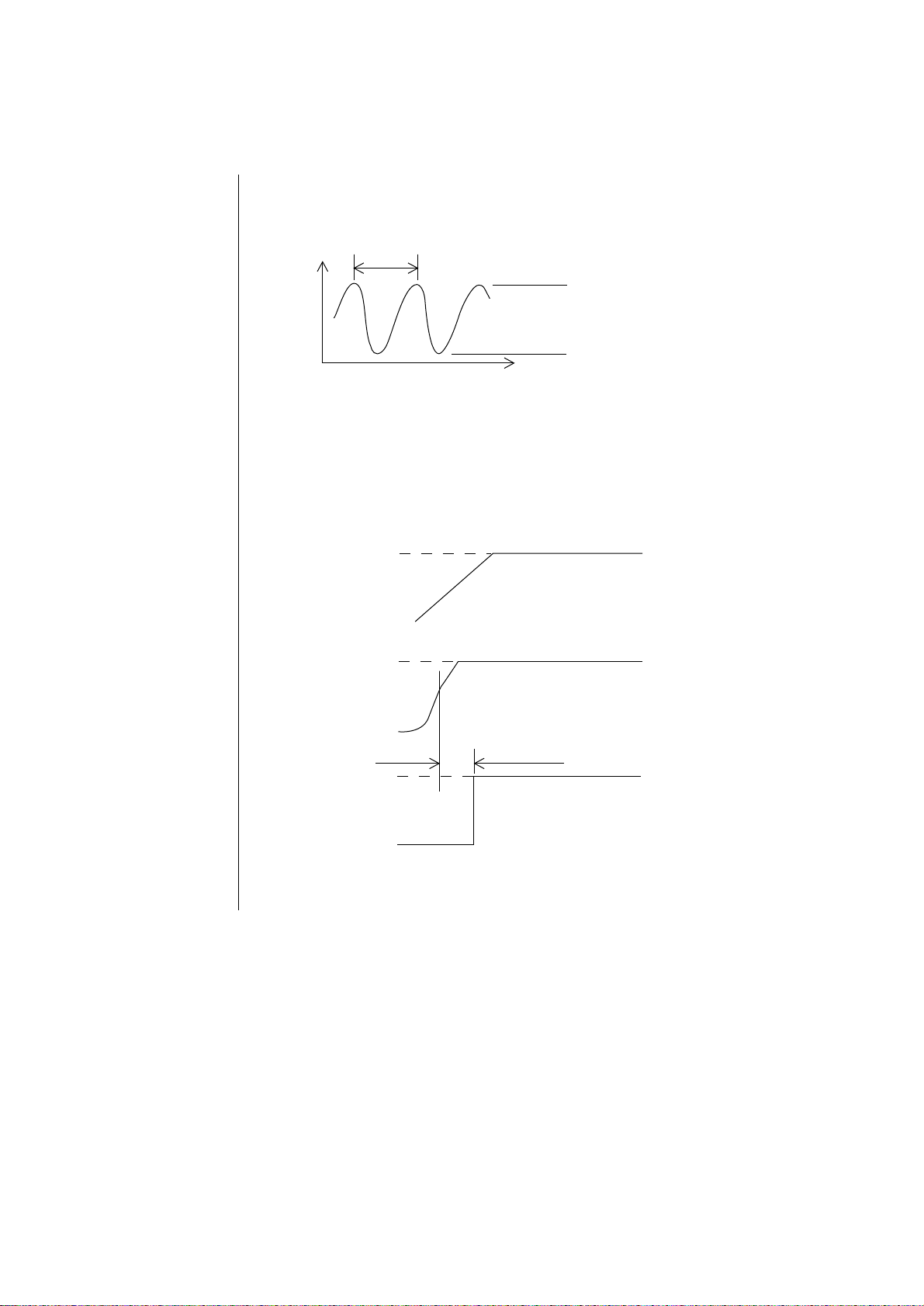

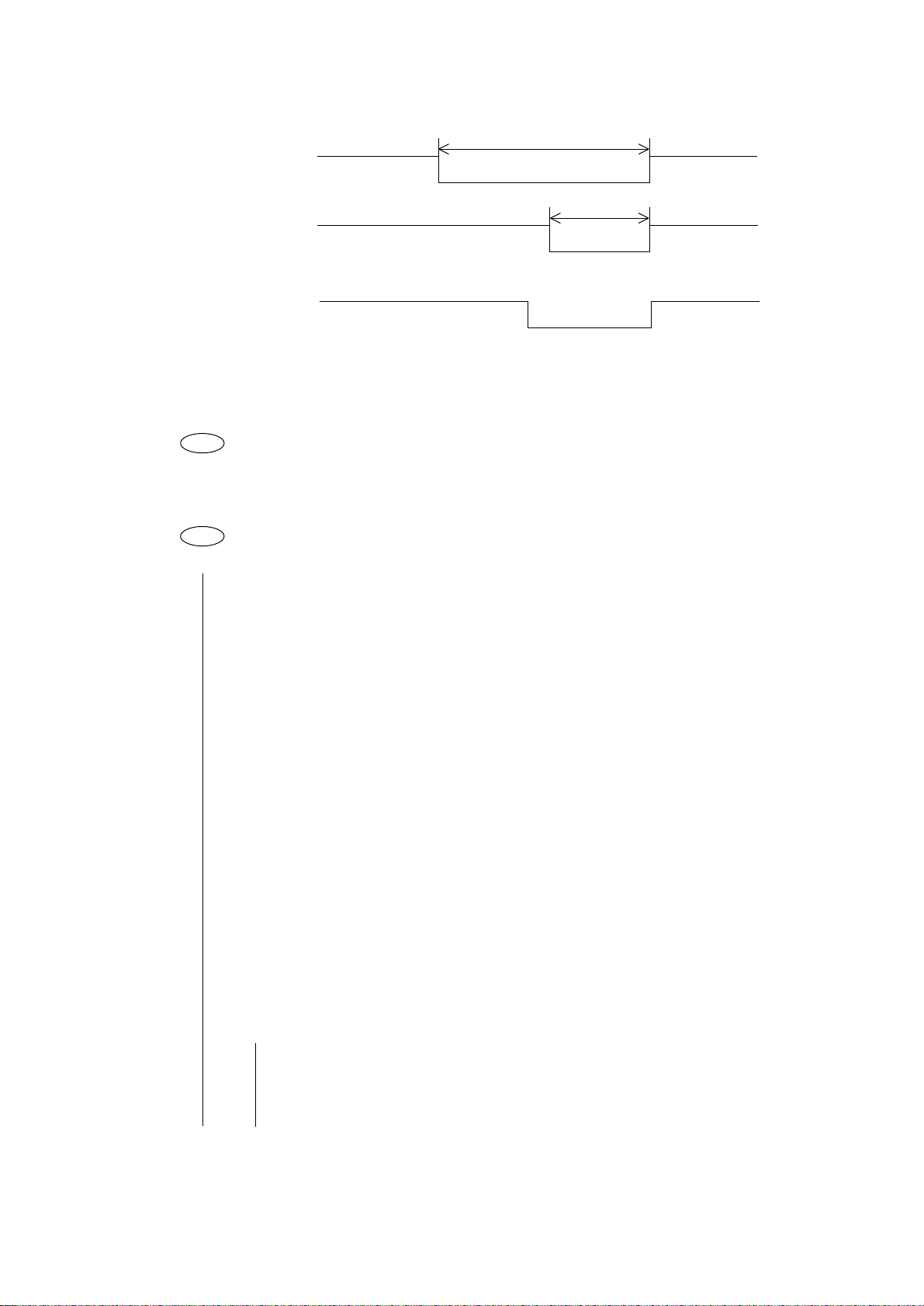

• Does the oscillating waveform from OSC of the Power & Control Board have the form

shown in Figure 1 below?

81.4 ns

V

(V)

T(ns)

+4 V ~ +5 V

0 V ~ 1V

Fig. 1

• No Replace OSC of the Power & Control Board.

▼

• Yes Does the RST-N signal have the waveform shown in Figure 2 below (with

+5 V and +8V signals as reference)?

+8 V

+8 V

0

+5 V

+5 V

0

+5 V

RST-N

0

Fig. 2

▼

• No If RS232C PCB is available, replace the RS232C PCB.

If the RS232C PCB is not available, replace the Power & Control

Board.

- 8 -

▼

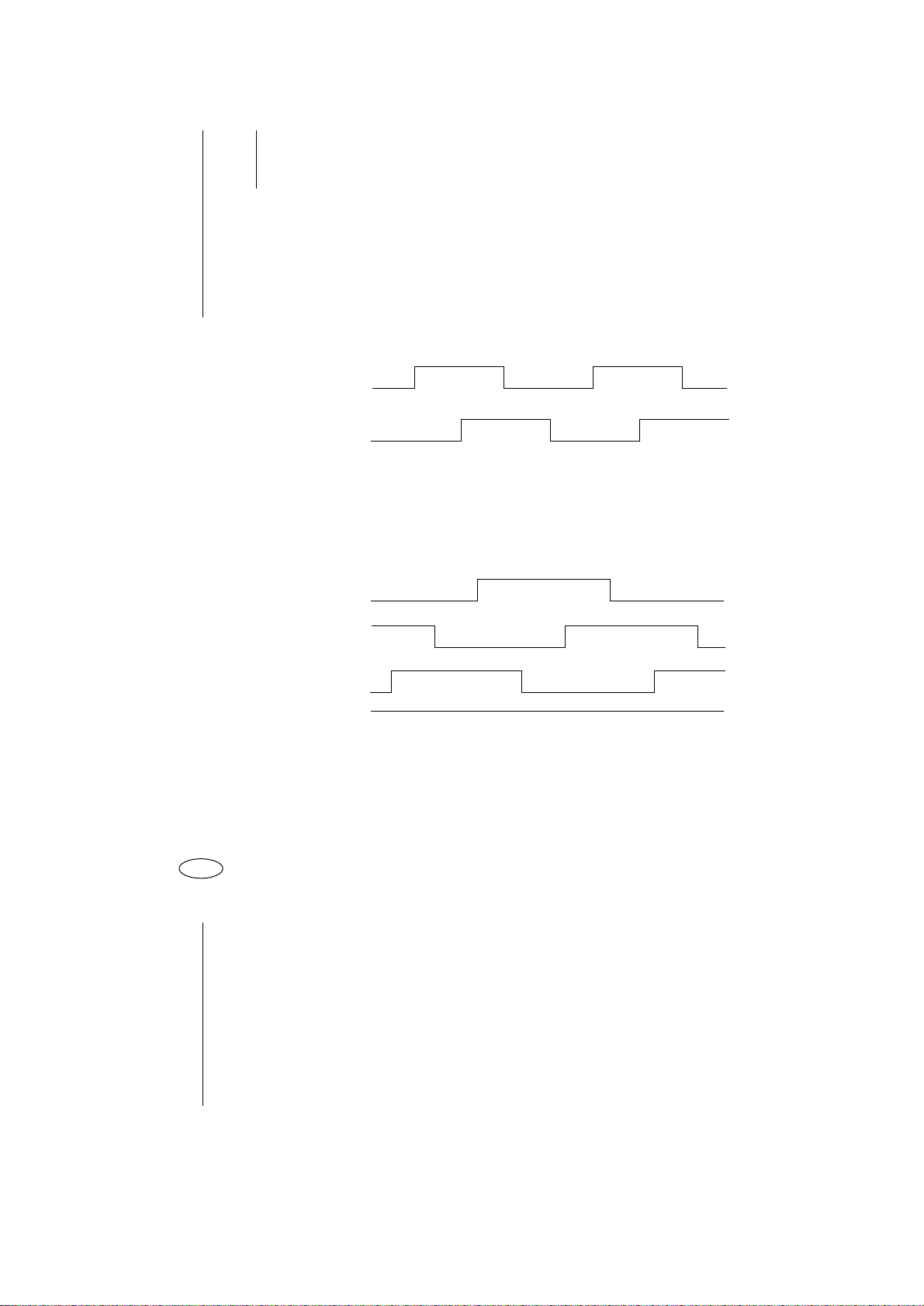

• Yes Do bus line signals of 4C (67 x 640) of the Power & Control Board such as ALEP, PSEN-N, LSICS-N and RDN/WRL-N have waveforms as shown in Fig. 4?

62 ms

ALE-P

102 ms

PSEN-N

203 ms

LSICS-N

76 ms

RD-N/WRL-N

+5V

0V

+5V

0V

+5V

0V

+5V

0V

Fig. 4

At the rising edge of PSEN-N and RD-N/WRL-N, the bus line level is decisively

set to “H” or “L”.

• No Replace Q501 of the Power & Control Board.

▼

• Yes Does the OPCLK-N/OPTXD signal arrive at CN1 of the operation panel?

See Fig. 5.

OPCLK-N (CN1-3 pin)

OPTXQ (CN1-4 pin)

• No Is the flexible calbe of the operation panel connected without break?

• No Replace the flexible cable.

▼

• Yes Replace CN3 of the Driver Board.

▼

• Yes Does the OPRXD signal arrive at CN1 of the operation panel? See Fig. 5.

OPRXD (CN1-2 pin)

• No Replace IC1 of the operation panel.

▼

• Yes Does the OPRXD signal arrive at CN3 of the Driver Board? See Fig. 5.

• No Is the flexible cable of the operation panel connected without break?

• No Replace the flexible cable

▼

• Yes Replace CN3 of the Driver Board.

▼

• Yes Replace Q501 of the Power & Control Board.

- 9 -

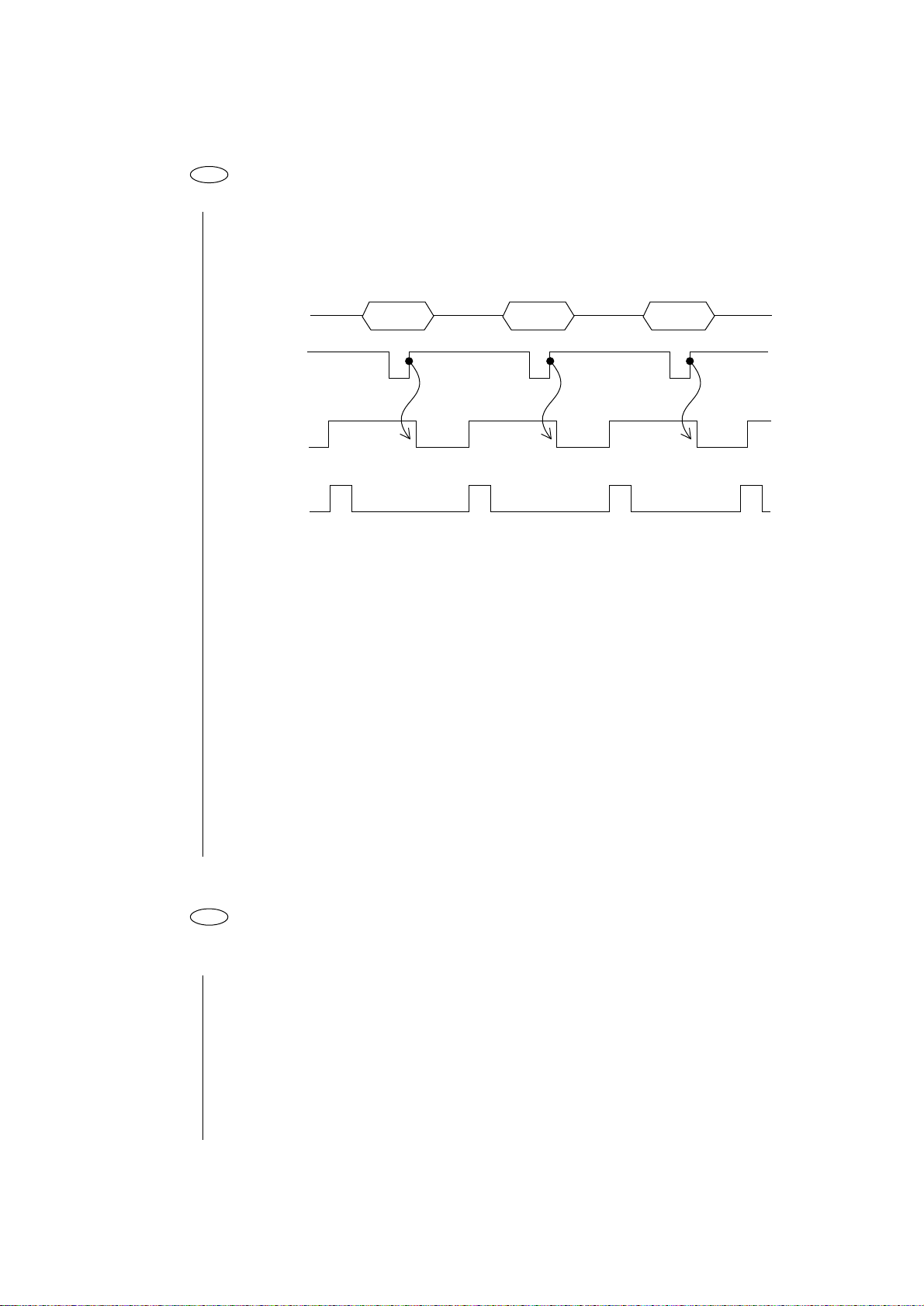

OPTXD

DATA

DATA

+5V

0V

OPCLK-N

OPRXD

DATA

Fig. 5

DATA

+5V

0V

+5V

0V

- 10 -

3 The printer alarm is displayed.

3-1 Printer internal RAM alarm

• Replace Q501 of the Power & Control Board.

3-2 S-I/F internal RAM alarms.

• Replace Q3 of the LXHI board.

3-3 S-I/F connection alarm.

• Replace the LXHI board.

3-4 Program ROM alarm.

• Replace Q1 of the Power & Control Board (EPROM).

3-5 S-I/F ROM alarm.

• Replace Q3 of the LXHI board.

3-6 EEPROM alarm.

• Is the voltage of Q5-8pin +5V?

• No Check TR5 and TR7 and pattern on the Power & Control Board.

Correct pattern or replace parts.

▼

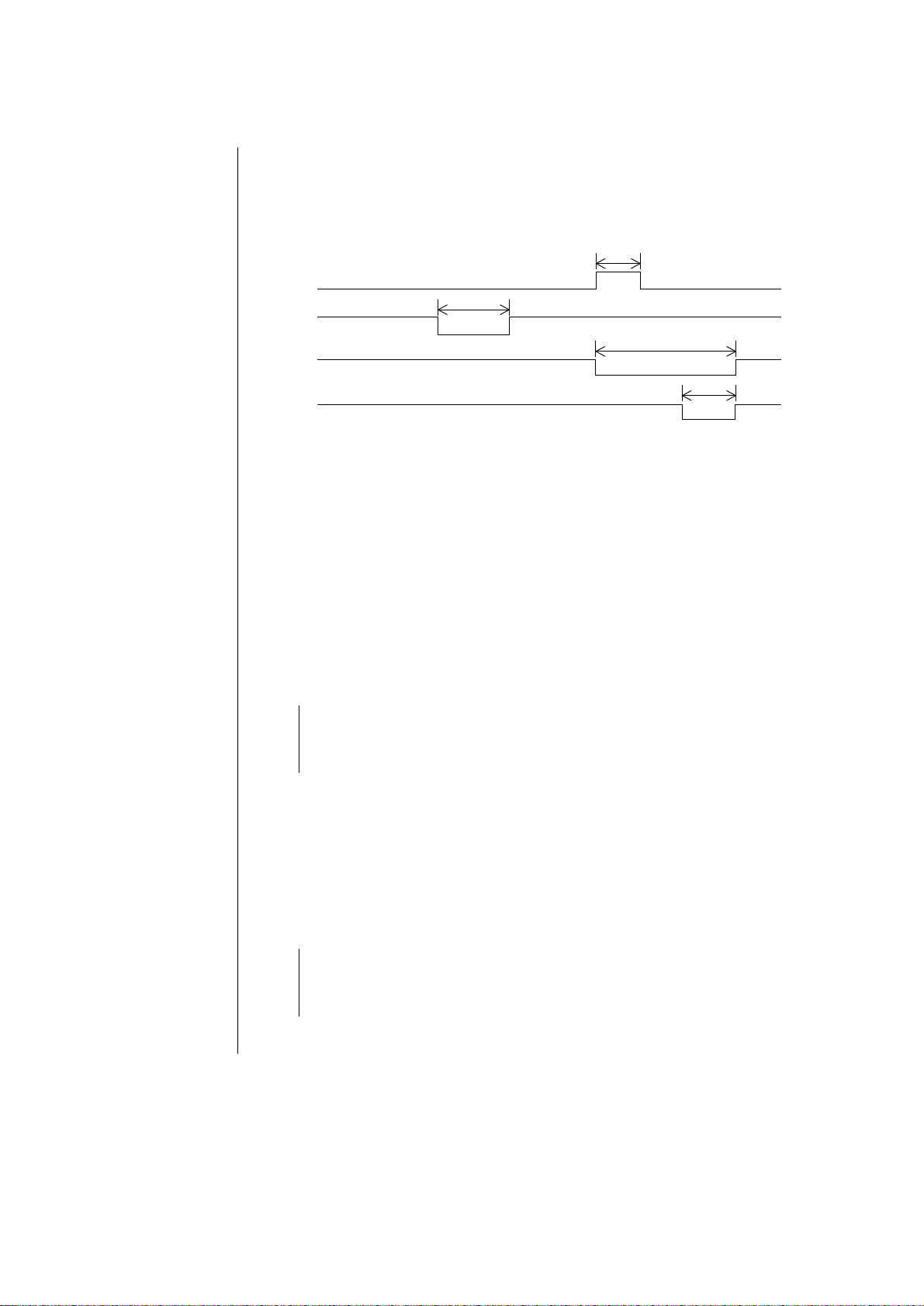

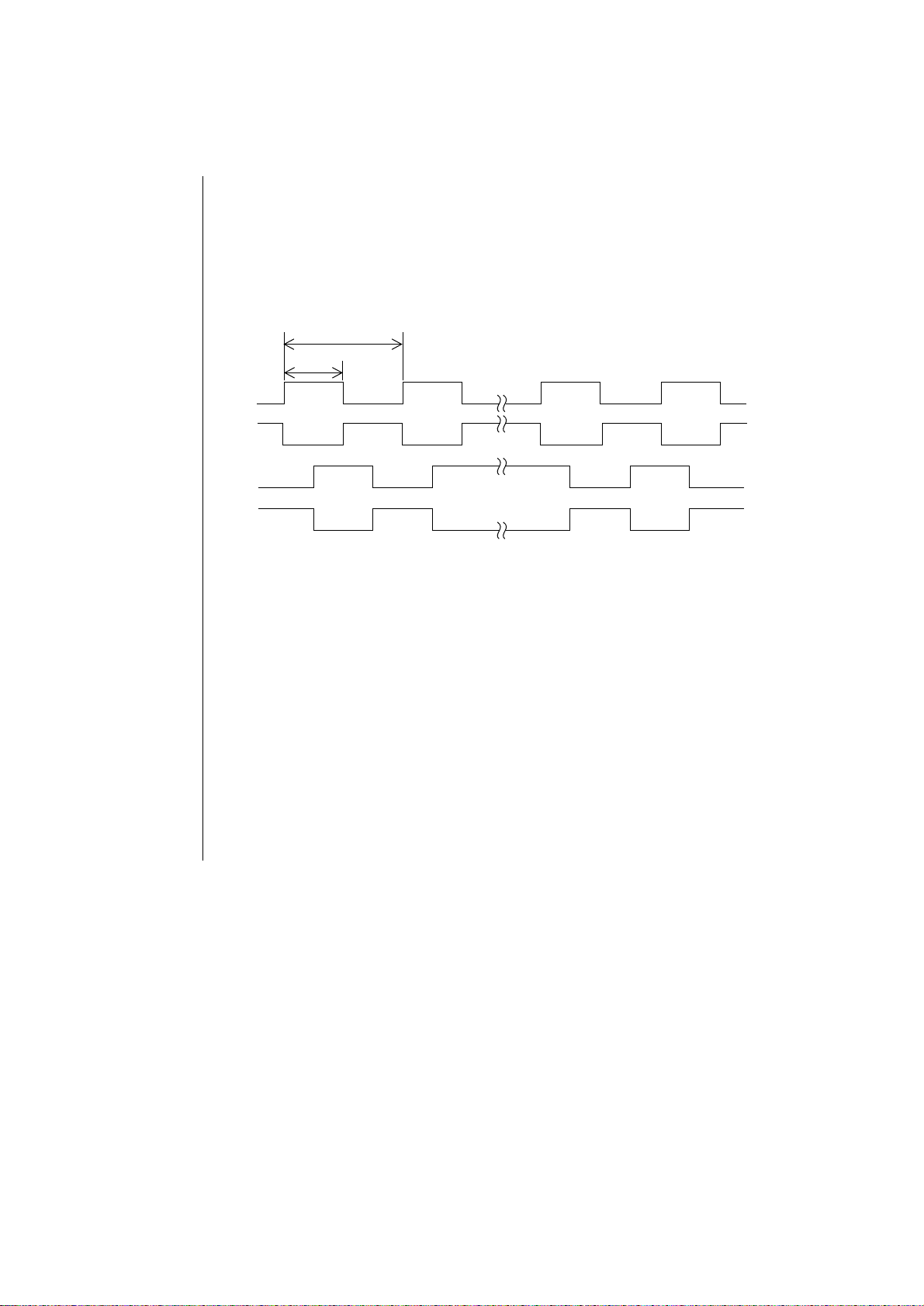

• Yes Do signals of Q501 of the Power & Control Board (67 x 640) such as EECLKP and EEDIN-P and EECS-P have the waveforms shown in Fig. 6?

• No Replace Q501 of the Power & Control Board.

▼

• Yes Do signals of Q5 of the Power & Control Board (EEPROM) such as EEDINP, EECS-P, EECLK-P and EEDOUT-P have the waveforms shown in Fig. 6?

• No Check EEDIN-P, EECS-P and EECLK-P patterns and parts

connected to the pattern. Correct pattern or replace parts.

▼

• Yes Replace Q501 of the Power & Control Board.

- 11 -

EECS-P

+5V

0V

EECLK-P

EEDIN-P

EEDOUT-P

MIN

50 ns

MIN

100 ns

MIN

450 ns

MIN

100 ns

MIN

500 ns

Fig. 6

3-7 WDT alarm, BRK command alarm

• Is the alarm canceled by turning on power?

• No Replace ROM, Q1 or the Power & Control Board.

3-8 NMI alarm

• Is the alarm canceled by turning on power?

MIN

450 ns

MIN

500 ns

MIN

0 ns

MIN

100 ns

+5V

0V

+5V

0V

+5V

0V

• No Replae Power & Control Board.

3-9 Printer external RAM alarm.

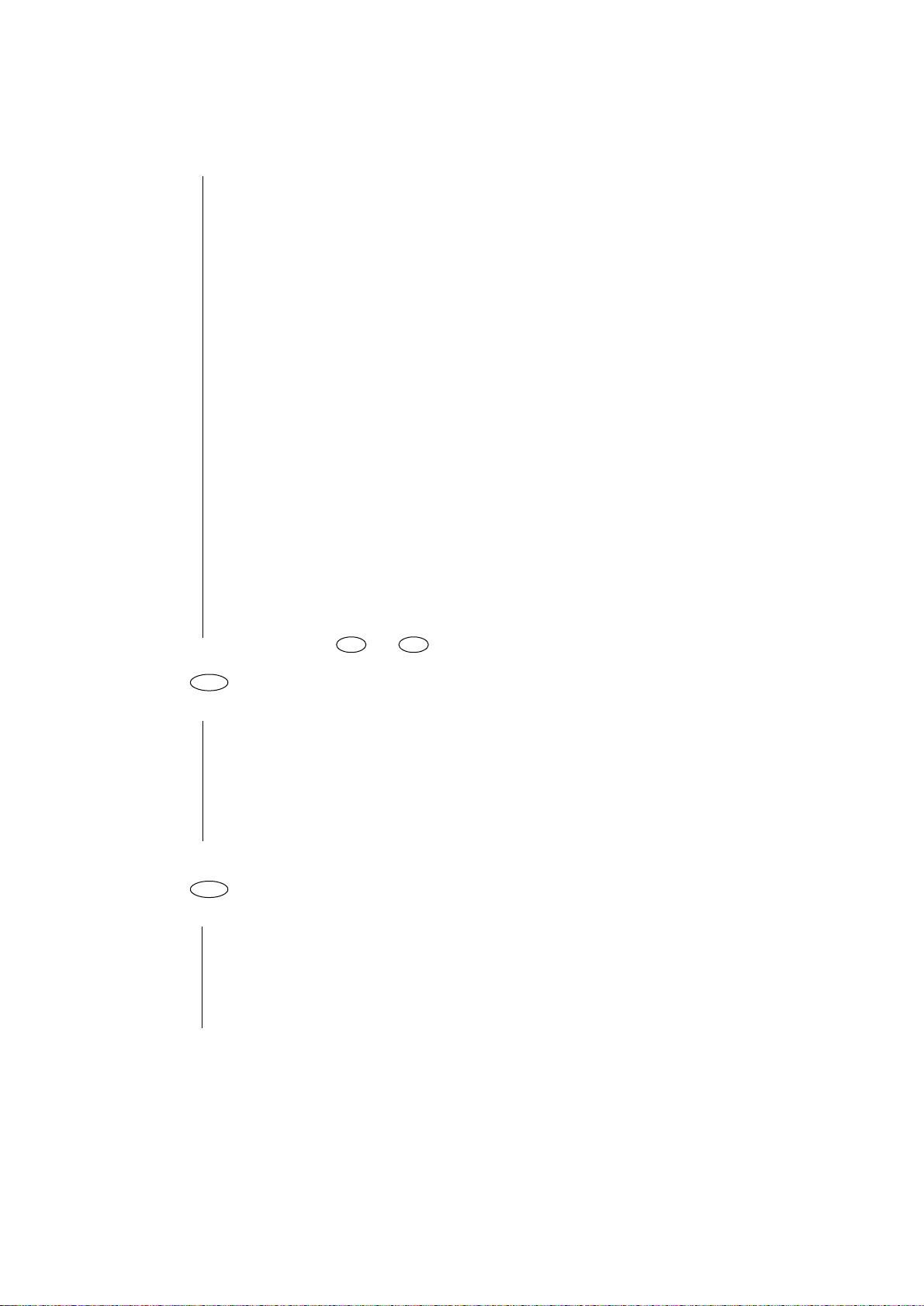

• Do signal of Q3, Q4 (DRAM) of the Power & Control Board such as RAS-N, CAS-N, OE,

WE have the waveforms shown in Fig. 7?

RAS-N (Q3, Q4-5)

CAS-N (Q3, Q4-16)

RD-N (Q3, Q4-1)

WRL-N (Q3, Q4-4)

• No Is the dumping resistance of each signal broken?

Check Q502 (Power & Control Board)?

• Yes Replace the dumping resistance or Q502

▼

• No

▼

• Yes Replace Q3, Q4.

- 12 -

RAS-N

CAS-N

103 ns

41.4 ns

+5V

0V

+5V

0V

RD-N/WRH-N/WRL-N

At the rising edge of OE, WE, the bus line level is decisively set to “H” or “L”.

Fig. 7

3-10 S-I/F external RAM alarm.

• Replace Q9 of the LXHI board.

3-11 SPACING alarm, HOMING alarm

• Is the fuse (F1) on the Driver board blown?

• Yes Replace F1.

▼

• No Is VNF of MTDV (HA13412) short-circuited to U0, V0, or W0?

VNF (MTDV-11 pin)

U0 (MTDV-13 pin)

V0 (MTDV-15 pin)

W0 (MTDV-17 pin)

+5V

0V

• Yes Replace MTDV

▼

• No Do signals of SPU, SPV, SPW and SPD-A of MTDV have the wave forms shown in

Fig. 10?

• No Check patterns SPU, SPV, SPW between Q501 and MTDV. When they are

OK, replace the Driver PCB Q501.

▼

• Yes Do signals of U0, V0, and W0 of the MTDV have the wave forms shown in Fig. 10?

• No Replace the HTDV PCB.

▼

• Yes Do signals of PHASE A and PHASE B have the wave forms shown in Fig. 9?

• No Is the connection between CN5 on the Driver Board, and the CN on the

carriage are OK?

• No Secure the connection.

▼▼

• Yes Is there any disconnection of cable between the Driver Board and the

carriage?

- 13 -

• No Replace the Carriage.

▼

• Yes Replace the Cable.

▼

• Yes Do signals of PHASE A, PHASE B of Q501 have the wave forms shown in Fig. 9?

• No Check the parts and pattern between Q501 and CN6. Correct

pattern or replace parts.

▼

• Yes Replace Q501.

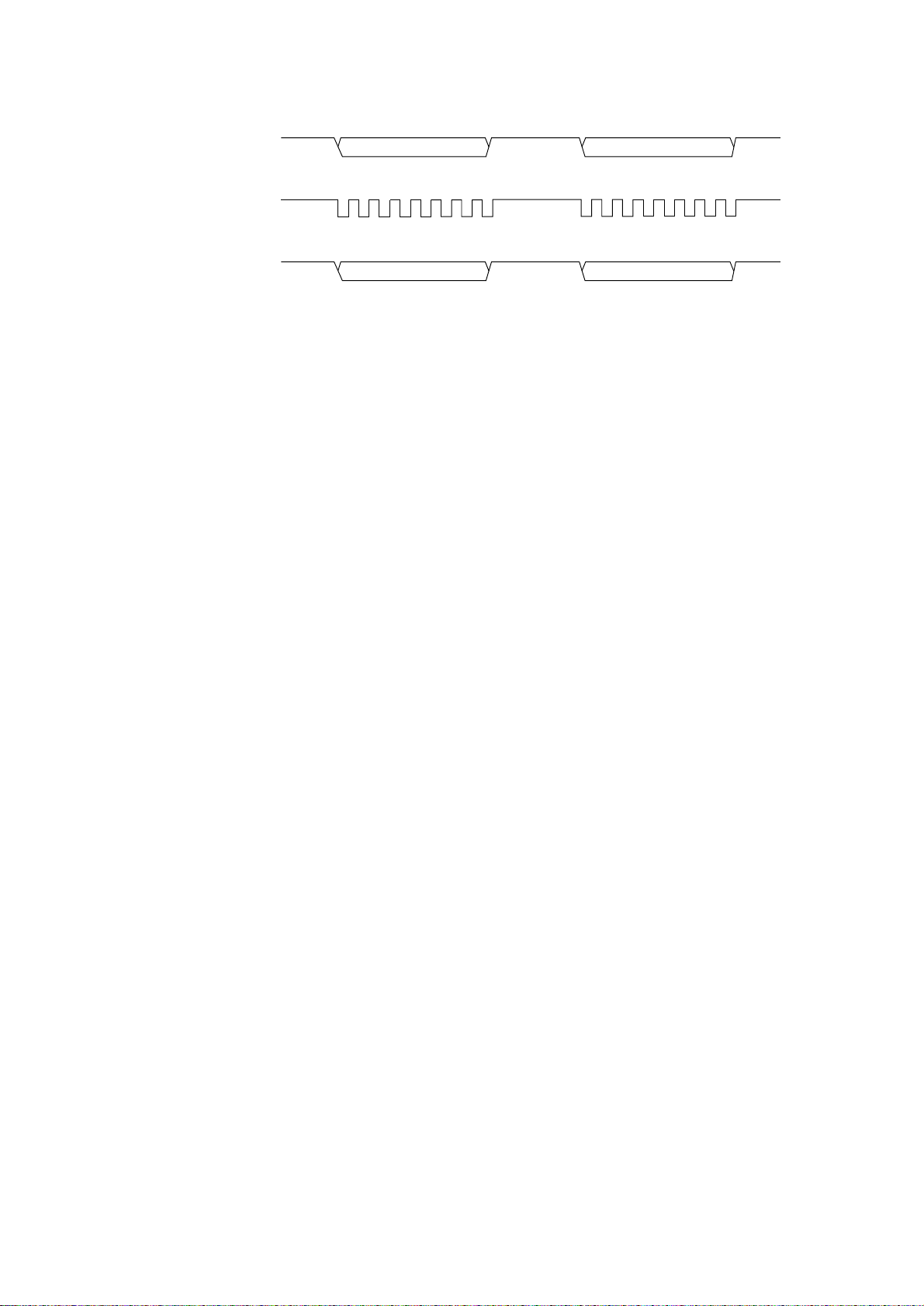

PHASE A

PHASE B

When the carriage is manually move.

Fig. 9

SPU

SPV

SPW

SPD-A

When the carriage is manually move.

+5V

0V

+5V

0V

+5V

0V

+5V

0V

+5V

0V

+5V

0V

Fig. 10

3-12 Head A/D alarm

• Is the voltage of the HTEMP-N signal of Q501 of the Power & Control Board (67 X 640) +5V?

HTEMP-N (Q501-62 pin)

• No Replace Q501.

▼

• Yes Is the connection of CN5 of the Driver Board secured?

• No Secure the connection of CN5.

▼

• Yes Replace the head.

- 14 -

3-13 Head Gap A/D alarm

• Is the voltage of HDGAP-N Signal of Driver Board CN5 22 pin +5V?

• Yes Replace the Head cable or the carriage.

▼

• No Replace the Power & Control Board.

- 15 -

4 Wrong characters are printed or some characters are not printed.

• Do signals of Q501 of the Power & Control Board (67 X 640) such as PSEN-N, LSICS-N,

RD-N, WRL-N, RAS-N and CAS-N have the wave forms shown in Figs. 4 and 7?

• No Replace Q501.

▼

• Yes Replace the head, Q501 of Driver board or the space motor.

- 16 -

5 Defective line feed.

• Do signals of LFDV (Driver board) such as A1, A2, B1 and B2 have the waveforms shown

in Fig. 11?

A1 (LFDV-3 pin)

A2 (LFDV-7 pin)

B1 (LFDV-8 pin)

B2 (LFDV-12 pin)

4.44 ms

2.22 ms

A1

A2

+40V

0V

+40V

0V

B1

B2

Forward Reverse

Fig. 11

• No Replace LFDV.

LFDV (Driver Board)

When it does not work properly, replace Q501 or the Driver Board.

▼

• Yes Is the flexible cable connected without break?

• No Replace the flexible cable.

▼

• Yes Is the CN4 of the Driver Board broken?

• No Replace CN4

▼

• Yes Replace the LF motor.

+40V

0V

+40V

0V

- 17 -

6 The printer does not operate though the operation switch is pressed.

• Do the OPCLK-N and OPTXD signals arrive at CN3? See Fig. 5.

• No Replace Q501 of the Driver board.

▼

• Yes Do the OPCLK-N and OPTXD signals arrive at CN1 of the operation panel?

See Fig. 5.

• No Is the flexible cable of the operation panel connected without break?

• No Replace the flexible cable.

• Yes Replace CN3 of the Driver board.

▼

• Yes Does the OPRXD signal arrive at CN1 of the operation panel?

• No Replace IC1 of the operation panel.

▼

• Yes Does the OPRXD signal arrive at CN3 of the Driver board? See Fig. 5.

• No Is the flexible cable of the operation panel connected without break?

• No Replace the flexible cable.

• Yes Replace CN3 of the Driver board.

▼

• Yes Go to steps 6-1 to 6-9 .

6-1 SEL SW does not work.

• When SWC2 of IC1 (Bu5148S) is set to “L”, is SWI4 set to “L” by pressing SEL SW?

SWC2 (C1-7 pin)

SWI4 (IC1-3 pin)

• No Replace SEL SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

6-2 SHIFT SW does not work.

• When SWC2 of IC1 is set to “L”, is SWI3 set to “L” by pressing SHIFT SW?

SWI3 (IC1-10 pin)

• No Replace SHIFT SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

- 18 -

6.3 LF SW does not work.

• When SWC2 of IC1 is set to “L”, is SW1 set to “L” by pressing LF SW?

(IC1-18 pin)

SWI4 (ICI-3 pin)

• No Replace LF SW.

▼

• Yes Does LF SW recover IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-4 FF SW does not work.

• When SWC2 of IC1 is set to “L”, is SWI2 set to “L” by pressing FF SW?

SWI2 (IC1-23 pin)

• No Replace FF SW.

▼

• Yes Does FF SW recover with IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-5 TEAR SW does not work.

• When SWC1 of IC1 is set to “L”, is SWI4 set to “L” by pressing TEAR SW?

SWC1 (IC1-31 pin)

• No Replace TEAR SW.

▼

• Yes Does TEAR SW recover with IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-6 PARK SW does not work.

• When SWC1 of IC1 is set to “L”, is SW2 set to “L” by pressing PARK SW?

• No Replace PARK SW.

▼

• Yes Does PARK SW recover with IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-7 QUIET SW does not work.

• When SWC1 of IC1 is set to “L”, is SWI1 set to “L” by pressing QUIET SW?

• No Replace QUIET SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

- 19 -

6.8 PRINT QUALITY SW does not work.

• When SWC3 of IC1 is set to “L”, is SWI1 set to “L” by pressing PRINT QUALITY SW?

• No Replace PRINT QUALITY SW.

▼

• Yes Replace IC1 or Q501 of the Driver board?

6-9 CHARACTER PITCH SW does not work.

• When SWC1 of IC1 is set to “L”, is SWI3 set to “L” by pressing CHARACTER PITCH SW?

• No Replace CHARACTER PITCH SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

- 20 -

7 Data can not be received.

7-1 Parallel interface data can not be received.

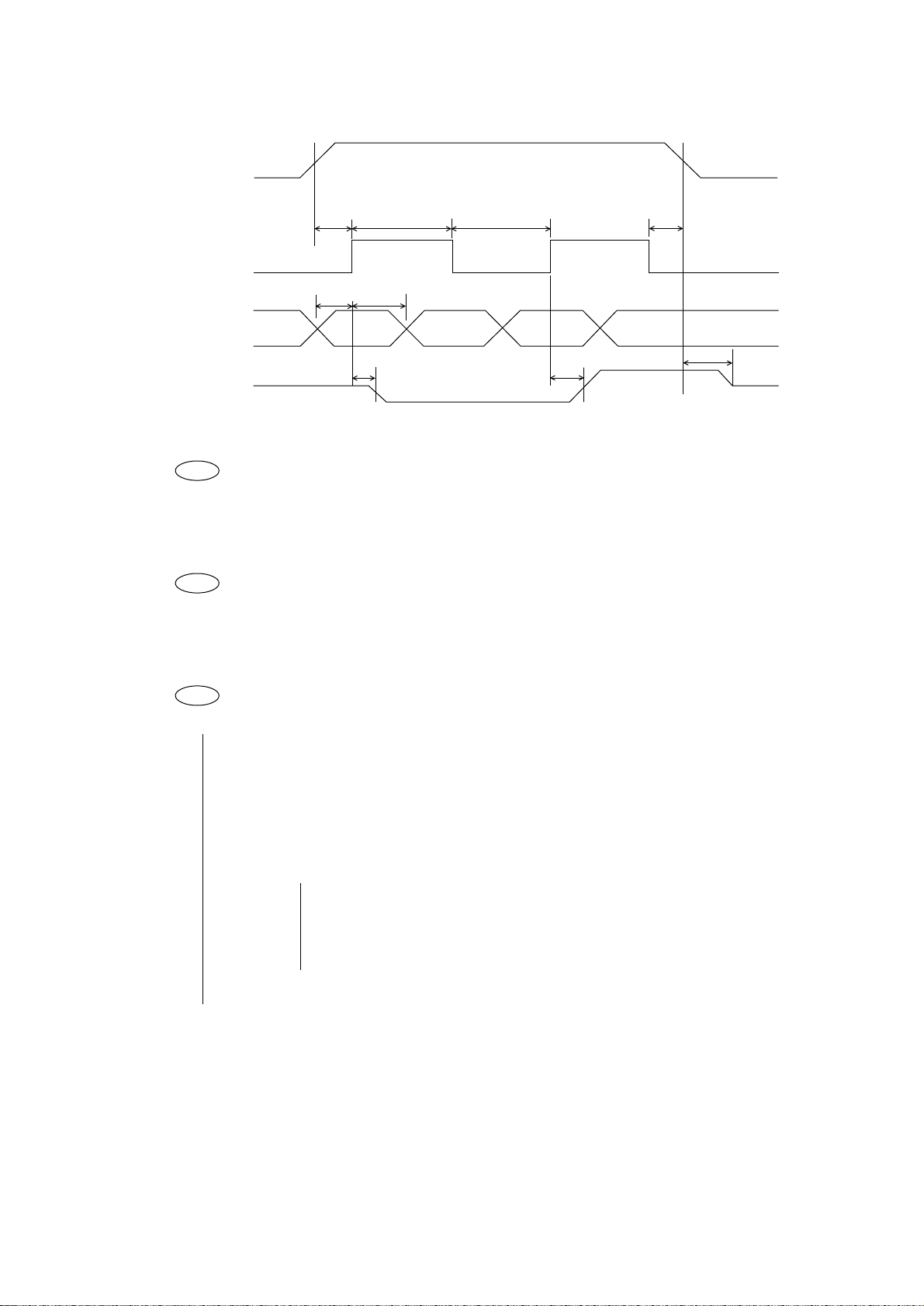

• Do the IFDATA 1 to 8 signals of Q501 of the Driver board have the waveform shown in Figure

12 below?

IFD1 ~ 8

STB-N

BUSY-N

ACK

Valid Valid Valid

Fig. 12

• No Replace either relative electric component to the DATA 1 to 8 signals, or

replace CN6 of the Driver board.

▼

• Yes Does the STB-N signal of Q501 have the waveform shown in Fig. 12?

• No Replace either resistor or capacitor of the STB-N signal.

▼

• Yes Do the BUSY-N and ACK signals have the waveforms shown in Fig. 12?

H

L

H

L

H

L

H

L

• No Replace Q501.

BUSY-N (Q501-64 pin)

ACK (Q501-63 pin)

▼

• Yes Replace Q3.

7-2 When receiving with the parallel interface, printed data is skipped, or the printer

does not work.

• Gap in the self-test?

• Yes To step 4.

▼

• No Does the signal of BUSY-N or ACK of Q501 of the Driver board have the waveform

shown in Figure 12?

• No Replace Q501.

▼

• Yes Replace either relative electric component to ACK or BUSY-N signal, or replace Q3

of the Driver board.

- 21 -

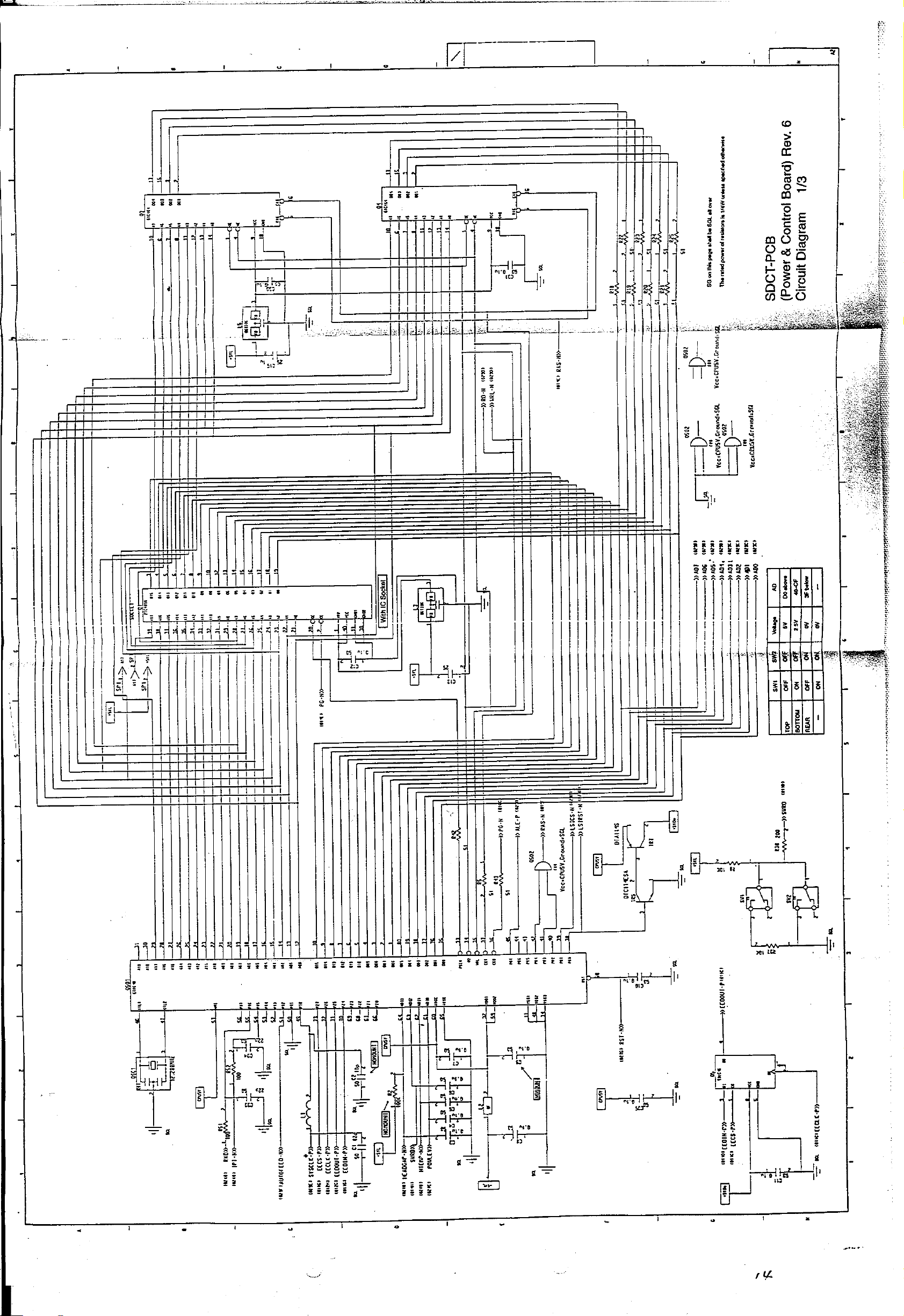

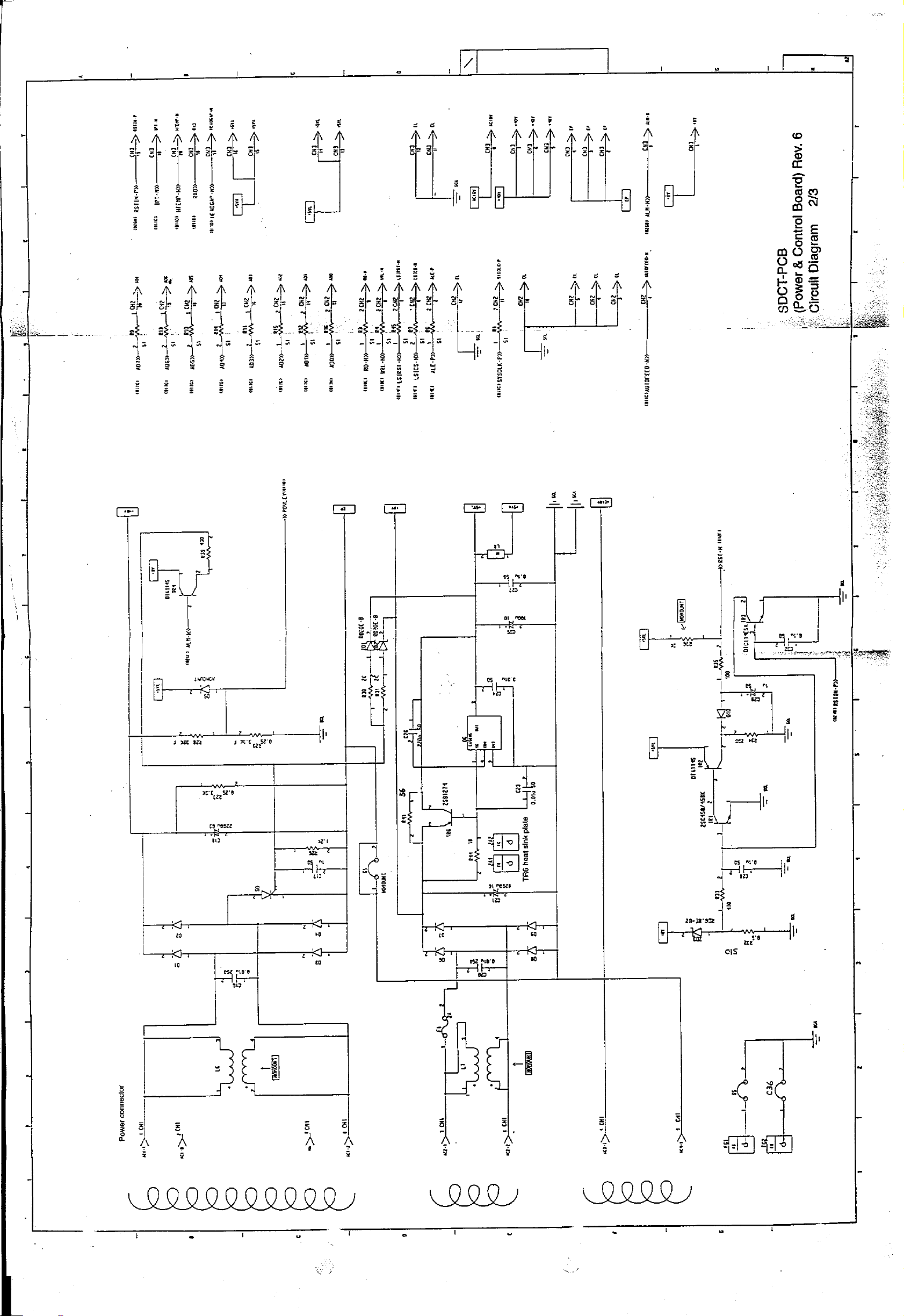

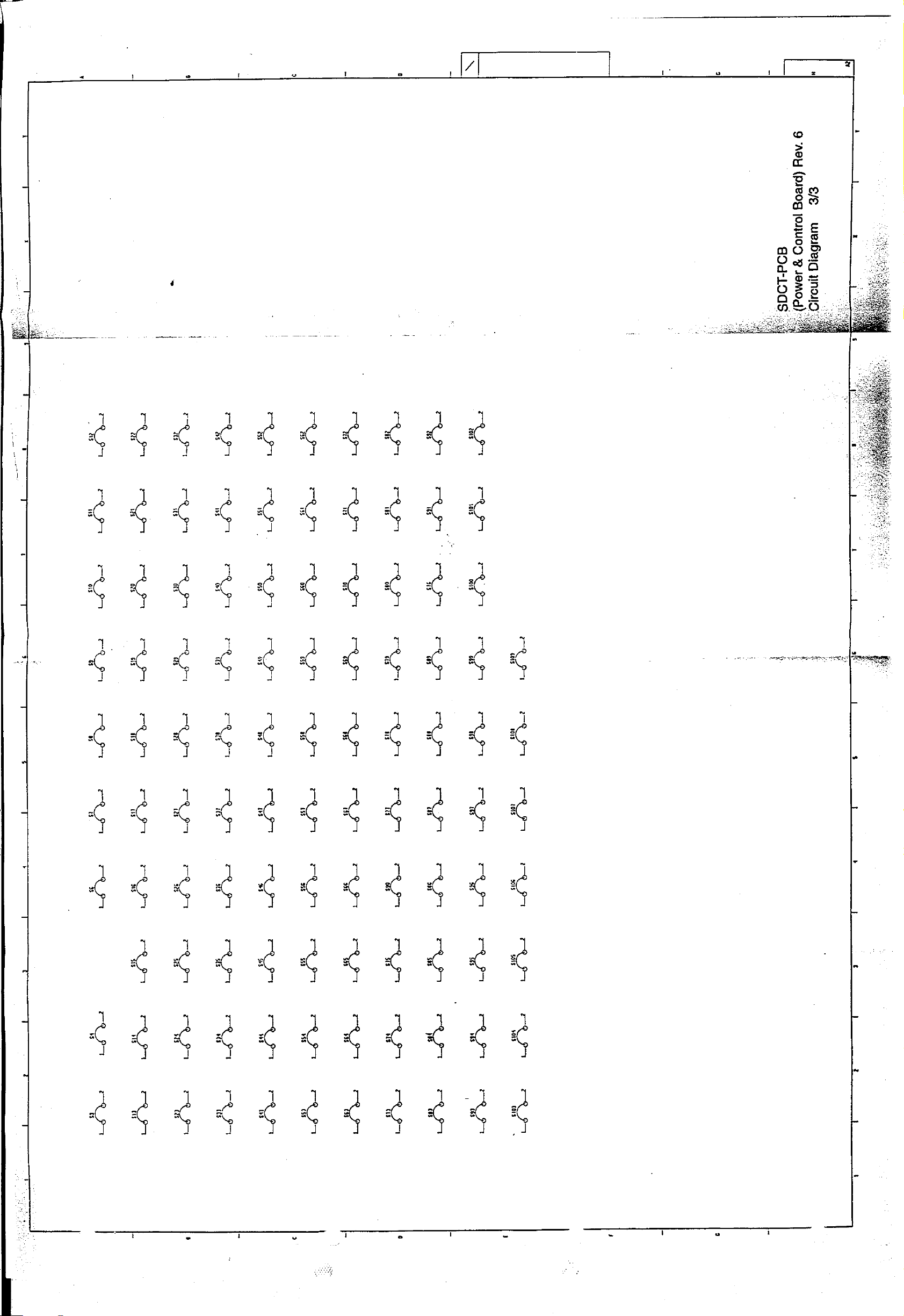

5. CIRCUIT DIAGRAM

SDCT-PCB (Power & Control Board) Rev. 6

SDDV-PCB (Driver Board) Rev. 4

LEOP-3 PCB (Operation Panel) Rev. 5 & 6

LXHI-PCB (Serial I/F Board) Rev. 7

Rev. 7

Rev. 8

Rev. 5

Rev. 6

Rev. 7

Loading...

Loading...