Page 1

MICROLINE 3320/3321

Troubleshooting Manual

with Components Parts List

All specifications are subject to change without notice.

Page 2

HP, LaserJet and PCL5e are trademarks of Hewlett-Packard Co.

Page 3

PREFACE

This manual describes in detail troubleshooting of the component parts for Microline

320/321 TURBO printer and provides a parts list.

Page 4

TROUBLESHOOTING MANUAL

Page 5

CONTENTS

1. OUTLINE ...................................................................................................1

2. TOOLS ......................................................................................................5

3. TROUBLESHOOTING TABLES ...............................................................5

4. TROUBLESHOOTING FLOWCHART ......................................................7

5. CIRCUIT DIAGRAM

6. COMPONENT PARTS LIST

Page 6

1. OUTLINE

This troubleshooting flowchart has been prepared for the repair of each board assembly of the

Microline 320/321 TURBO printer. The repairmen using this manual are assumed to be familiar

with certain techniques.

1.1 Items to Check Before Repair

• Check the inspection items specified in the instruction manual.

• Find out as many details of the trouble as possible from the customer.

• Inspect in the conditions as close as possible to those at the time the trouble occurred.

• Proceed with the repair as follows:

Check the trouble status according to Table 1.1 for the details of the trouble. Then, locate the

trouble position according to the detailed flowchart.

• Carry out a thorough test after the repair to check for correct functioning.

1.2 Troubleshooting

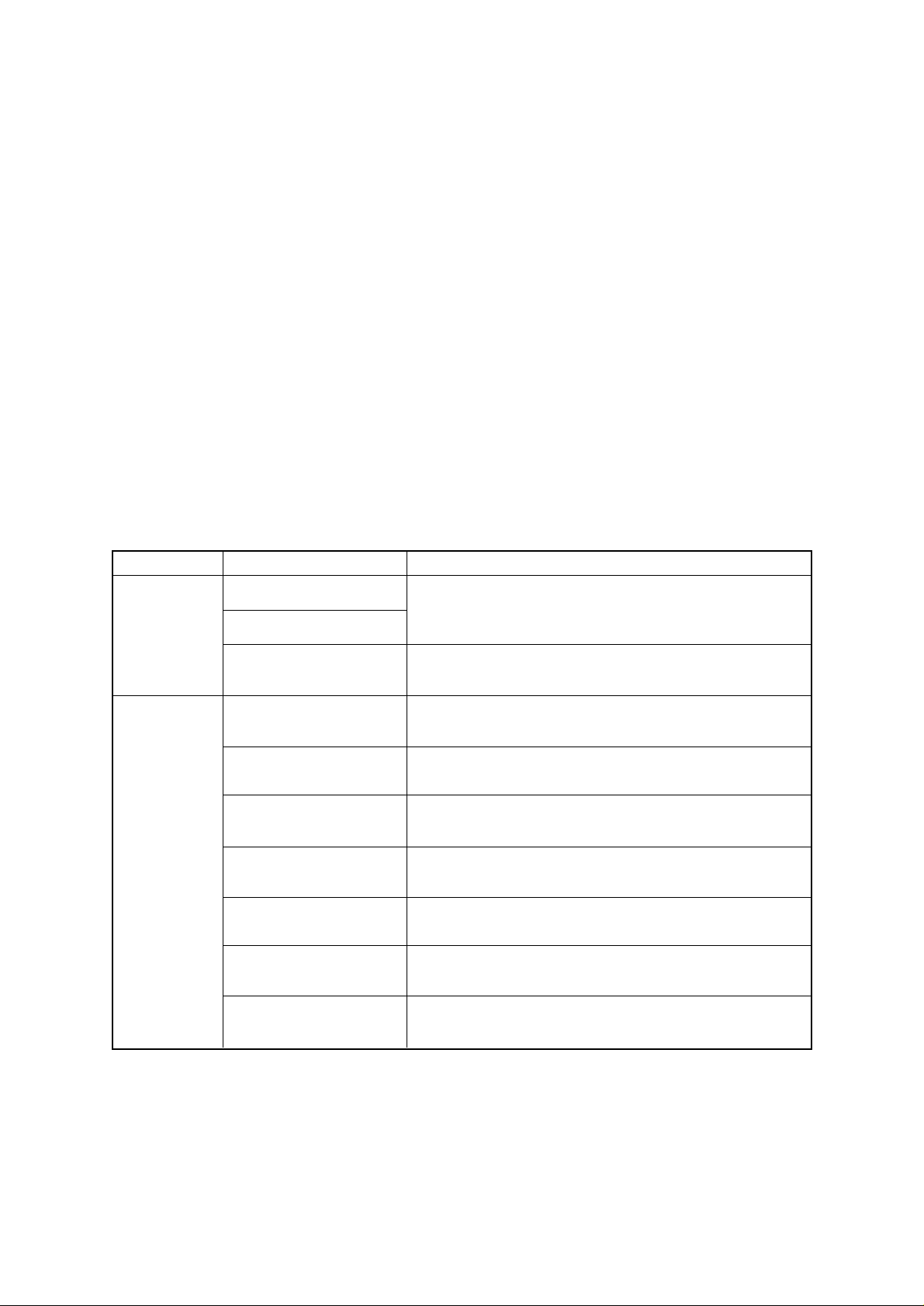

Trouble contents Surmise of troublleStatus

Table 1.1

Trouble upon

power on

Trouble

during

printing

Power is not supplied

No spacing operation

Homing does not end

normally

Paper jam while paper

insertion

Smearing/Missing dots

Faint or dark print

Ribbon feed trouble

Line feed trouble

Malfunction of switch on

operation panel.

Data receiving failure

Transformer, Power & Control Board, Driver Board, Operation Panel.

Space motor, carriage Cable, Print Head.

Space Motor, Carriage Cable, Spacing Mechanism, Driver Board

Pressure roller Mechanism, Support Protector, Pull up roller cover.

Print Head, Power & Control Board, Space Motor, Carriage Cable,

Driver Board

Print Head, Ribbon feed assembly, Power & Control Board, Driver

Board

Ribbon feed assembly, Space motor, Power & Control Board, Driver

Board

LF motor, Platen assy, LF mechanism, Power & Control Board, Driver

Board

Operation Panel, Power & Control Board, Driver Board

Power & Control Board, (I/F/P.C.B), I/F Cable, Menu setting, Driver

Board

Note: Refer to the Maintenance Manual for the troubleshooting flow chart of this table.

- 1 -

Page 7

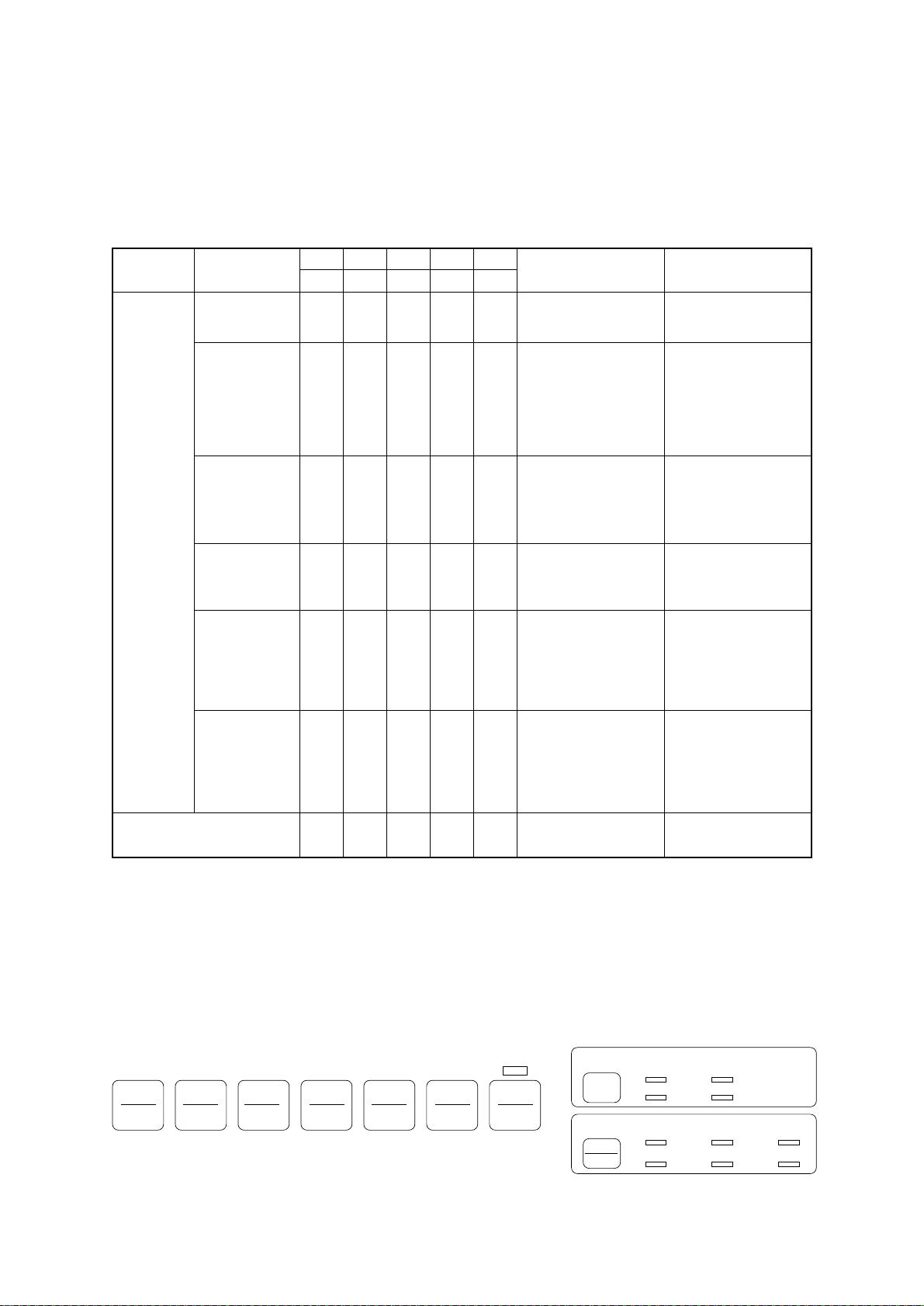

1.3 Lamp Display

(1) Printer mode display

Table 1.2

ALARM

CATEGORY

OPERATOR

ALARM

ALARM CONTENTS TROUBLESHOOTING

Paper end

alarm

Paper

change lever

alarm

ALARM MENU 10 CPI 15 CPISEL

ON

—

ON

OFF

—

—

—

BLINK

1

—

From, cut sheet or

bottom paper end

OFF

Change lever is set to

TOP position while

paper is already inserted

from rear or bottom.

Set New paper.

• Set the lever to

specified position.

• Check rear sensor

lever.

• Replace Power &

Control Board.

Paper jam alarm

Print Head

thermal alarm

ON

OFF

OFF

—

—

BLINK

1

OFF

—

BLINK

• Cut sheet could not be

1

ejected.

• Cut sheet could not be

fed properly.

—

Print head temperature

exceeds 119°C.

• Remove the paper or

check feed

Mechanism.

• Press SEL key.

• Wait until it is cooled.

• Replace P.H. or Power

& Control Board.

Space motor

thermal alarm

OFF

—

BLINK

1

—

—

Temperature of space

motor and driver

exceeds specified value.

• It is recovered

automatically.

• Replace SP motor or

Power &Control

Board.

LF motor

temperature

OFF

—

BLINK

1

alarm

FATAL ALARM

BLINK

OFF

OFF

2

Note: BLINK 1: 400 ms ON, 400 ms OFF

BLINK 2: 200 ms ON, 200 ms OFF

— : LED is kept in Current Condition (no change)

(2) Fault alarm display

When the printer detects any of the various alarm states, the information is displayed as

shown below on the operation panel. The alarm is specified by lamp combination of PRINT

QUALITY and CHARACTER PITCH. (See Table 1.3 for details.)

SEL

SEL

MENU

EXIT

POWERALARM

SHIFT

LF

Micro Feed

Down

GROUP ITEM SET

FF/LOAD

Micro Feed

Up

TEAR PARK QUIET

MENU

—

PRINT

—

Temperature of LF

motor and driver

exceeds specified value.

Hardware Alarm has

occurred.

TOF

• It is recovered

automatically.

• Replace LF motor or

Power & Control

Board.

See Table 1.3.

PRINT QUALITY

CHARACTER PITCH

RESET

HSD UTILITY

NLQ SSD

10

17

12

20

15

PROP

- 2 -

Page 8

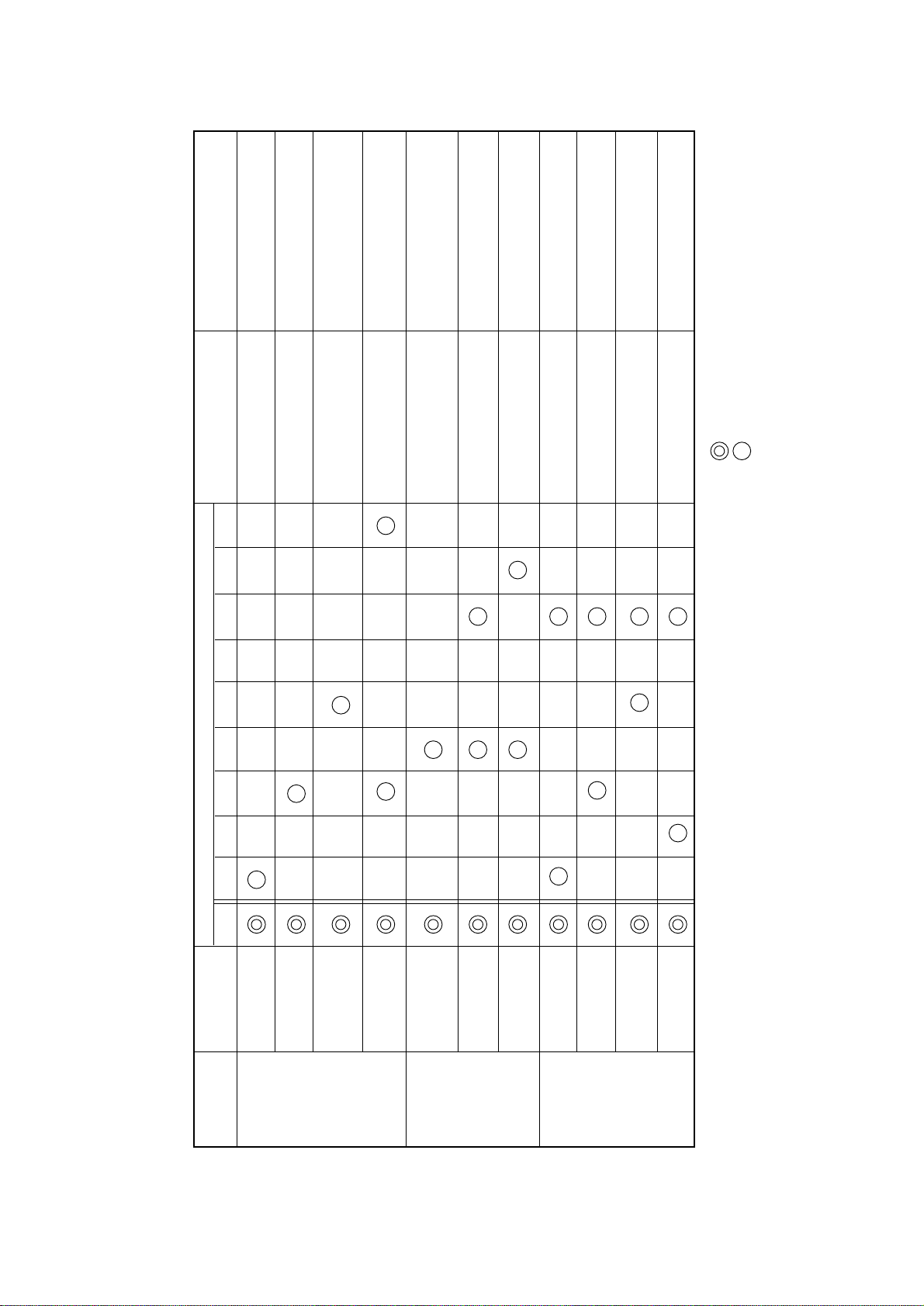

REMARKS TROUBLESHOOTING

Table 1.3 (1/2)

LED DISPLAY

Replace Power & Control Board

Replace ROM or Power & Control

Board

Read/write error

Check sum error

Replace Power & Control Board

Read/write error

Replace Power & Control Board

No reaction when MPU

reads data

Turn the power OFF and ON or

replace Power & Control Board

Replace Power & Control Board

Replace ROM or Power & Control

Board

Replace I/F Board

MPU is locked up and it is

reset after 65 ms.

NMI port of MPU is kept

low level.

FFFF data is detected

due to MPU locked up.

Read/write error

Replace I/F Board

Replace I/F board or Power & Control

Replace ROM on I/F Board or

I/F Board

Read/write error

Check sum error

Board

: LED Blink (200 ms ON, 200ms OFF)

No reaction from serial I/F

Board

: LED Lights up.

(3) Fatal Alarm

ALARM 10 12 15 17 20 PROP HSD UTL NLQ

ALARM

ALARM

CATEGORY

MPU internal

RAM alarm

Program

ROM alarm

RAM on

MAIN

CONTROL

Control Board

alarm

EEPROM

alarm

ALARM

WDT (Watch

Dog Timeout)

alarm

FIRMWARE

DETECTION

- 3 -

NMI signal

alarm

BRK instruction

ALARM

alarm

MPU internal

RAM alarm

ROM alarm

SERIAL

RAM on I/F

board alarm

INTERFACE

ALARM

I/F not

mounted

Page 9

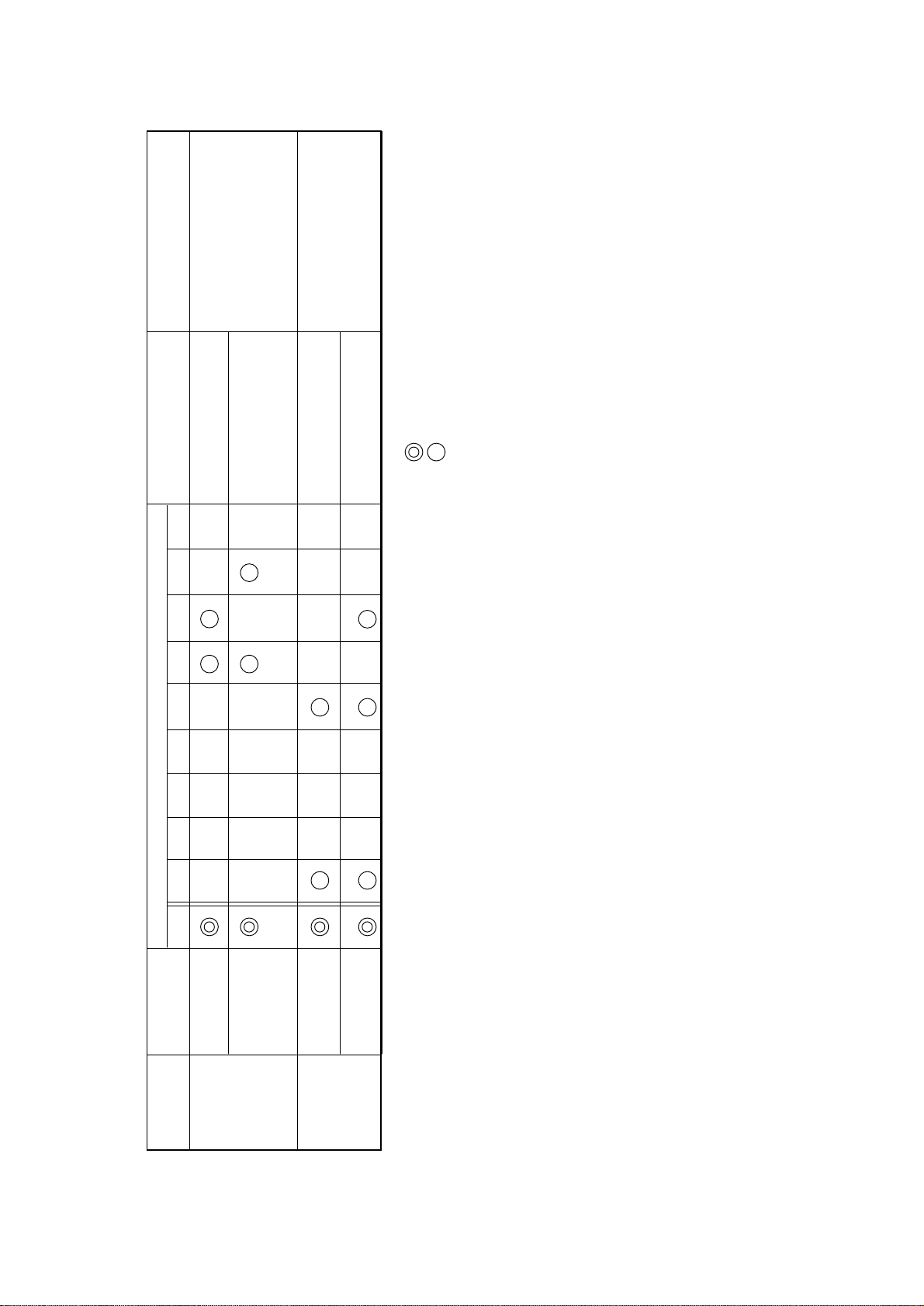

• Replace space motor.

REMARKS TROUBLESHOOTING

Space IPT is not occurred

Table 1.3 (2/2)

LED DISPLAY

• Replace P.H. cable.

• Replace Power & Control Board.

• Replace Driver Board.

• Check the mechanism if

load is too much.

• Check the P.H. connection.

• Replace Print Head.

• Replace P.H. cable.

within in specified timing.

Print head does not reach

to the home position.

Thermister is open, short

with 0V or short with +5V.

• Replace Driver Board.

: LED Blink (200 ms ON, 200ms OFF)

: LED Lights up.

ALARM 10 12 15 17 20 PROP HSD UTL NLQ

ALARM

ALARM

CATEGORY

Spacing alarm

Print Head

mounting alarm

SPACING

ALARM

PRINT HEAD

A/D alarm

Print Head

PRINT HEAD

ALARM

Gap AD alarm

- 4 -

Page 10

2. TOOLS

In addition to the general maintenance tools, the following are necessary:

– Oscilloscope : Approx. 100 MHz or more

– Soldering iron : Standard (A soldering iron with a thin tip is best.)

3. TROUBLESHOOTING TABLES

1 The power source can not be turned on.

2 Only the POWER lamp lights. (The printer does not work.)

3 The printer alarm is displayed.

3-1 Printer Internal RAM Alarm

3-2 S-I/F Internal RAM Error

3-3 S-I/F Connection Alarm

3-4 Program ROM Alarm

3-5 S-I/F ROM Alarm

3-6 EEPROM Alarm

3-7 WDT Alarm, BRK Command Alarm

3-8 NMI Alarm

3-9 Printer External RAM Alarm

3-10 S-I/F External RAM Alarm

3-11 SPACING Alarm, HOMING Alarm

3-12 Head A/D Alarm

3-13 Head Gap A/D Alarm

4 Wrong characters are printed or some characters are not printed.

5 Defective line feed.

6 When pressing the operation switch, it does not work.

6-1 The SEL switch does not work.

6-2 The SHIFT switch does not work.

6-3 The LF switch does not work.

6-4 The FF switch does not work.

6-5 The TEAR switch does not work.

6-6 The PARK switch does not work.

6-7 The QUIET switch does not work.

6-8 The PRINT QUALITY switch does not work.

6-9 The CHARACTER PITCH switch does not work.

- 5 -

Page 11

7 DATA can not be received.

7-1 Parallel interface data can not be received.

7-2 When receiving with the parallel interface, printed data is skipped, or the printer

does not work.

- 6 -

Page 12

4 TROUBLESHOOTING FLOWCHART

1 The power source can not be turned on. (The POWER lamp does not light.)

• Check the connection between Transformer and Power & Control Board and Driver

Board and Operation panel.

• No Be sure the connection.

▼

• Yes Is Fuse (F1) on Filter PCB blown out?

• Yes Replace Fuse (F1).

▼

• No Are the signal level between 1-pin and 8-pin of CN1 on Power & Control Board,

29 Vac, between 3-pin and 6-pin, 8 Vac, and between 4-pin and 5 pin, 10 Vac?

• No Replace Transformer.

▼

• Yes Is the voltage level at VCC (1-pin) of Q6 of the Power & Control Board, +8V?

• No Is fuse (F1) on Power & Control Board blown out?

• Yes Replace Fuse (F1)?

▼

• No Replace D6, D7, D8 and D9 of the Power & Control Board.

▼

• Yes Is the voltage level between one side and the other of C25 of the Power &

Control Board, +5V?

• No Replace Q6 or TR6 of the Power & Control Board.

▼

• Yes Is +5V supplied for CN3 of the Driver board?

+5V (CN3 – 3 pin)

0V (CN3 – 2 pin)

• No Check +5V supplied for the Driver board or replace Driver board?

▼

• Yes Is +5V supplied for CN1 of the operation panel board?

+5V (CN1 – 5 pin)

0V (CN1 – 6 pin)

• No Replace a cable in the operation panel or replace the operation panel.

▼

• Yes Replace D2 or R2 on the operation panel.

- 7 -

Page 13

2 Only the POWER lamp lights. (The printer does not work.)

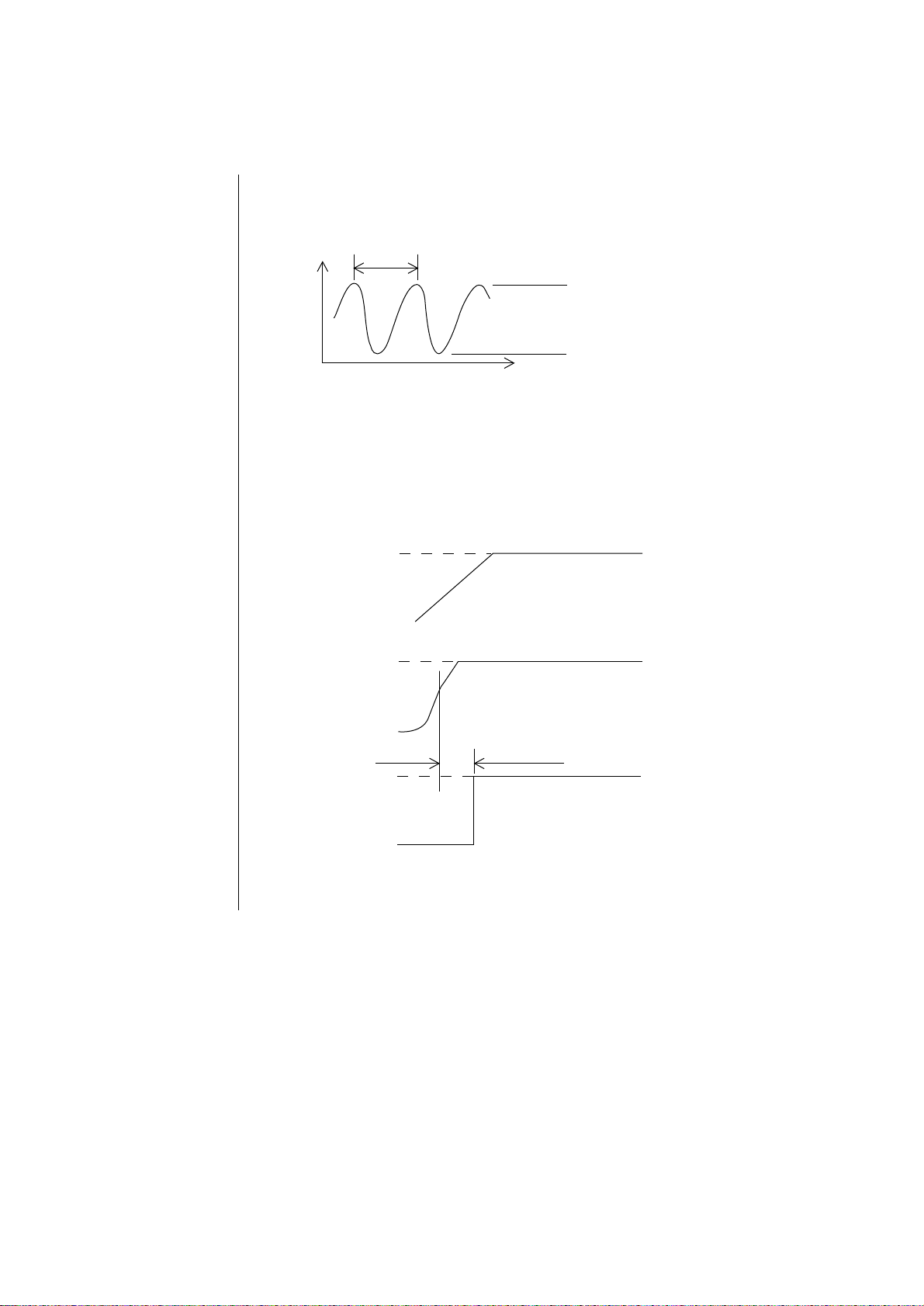

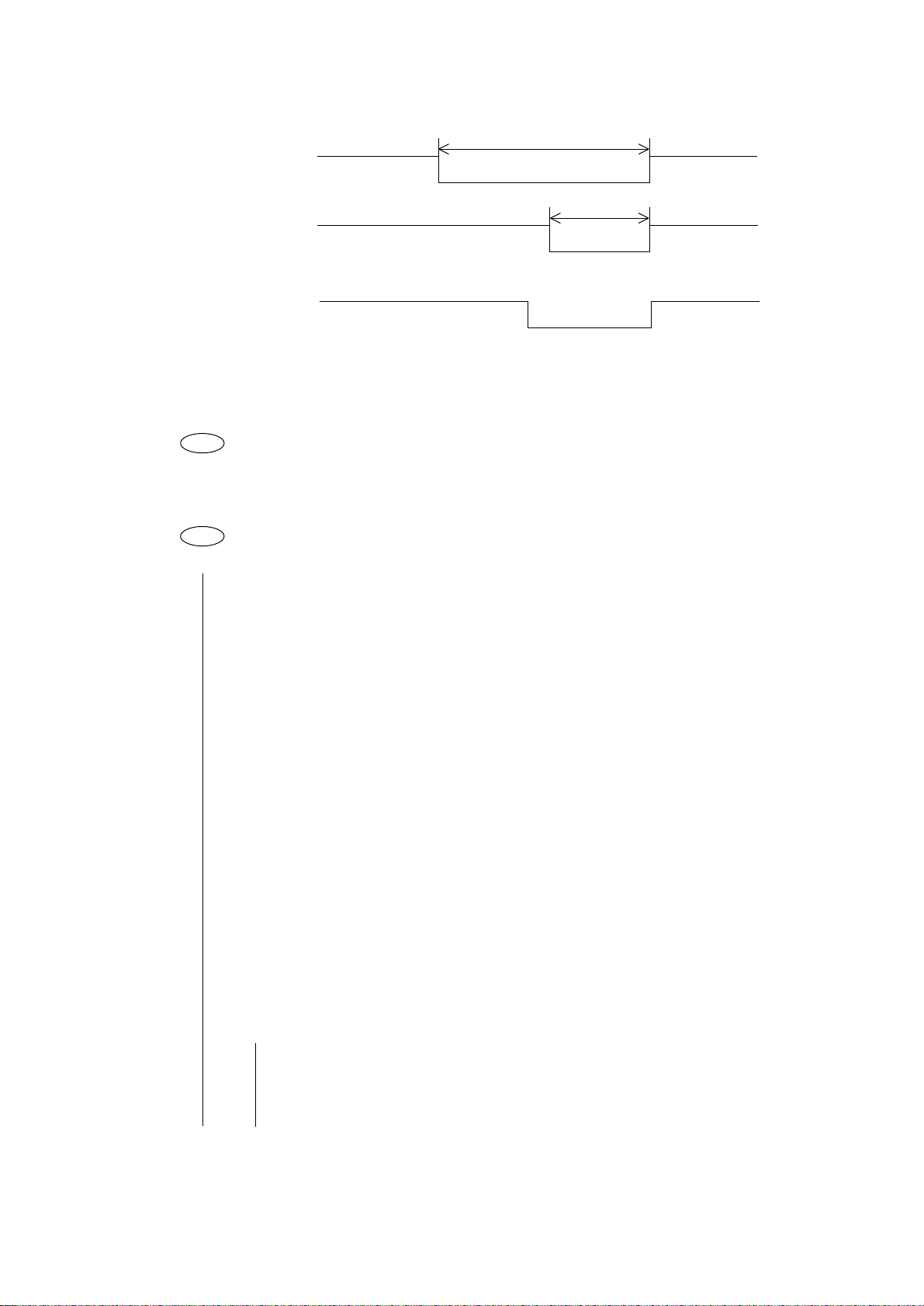

• Does the oscillating waveform from OSC of the Power & Control Board have the form

shown in Figure 1 below?

81.4 ns

V

(V)

T(ns)

+4 V ~ +5 V

0 V ~ 1V

Fig. 1

• No Replace OSC of the Power & Control Board.

▼

• Yes Does the RST-N signal have the waveform shown in Figure 2 below (with

+5 V and +8V signals as reference)?

+8 V

+8 V

0

+5 V

+5 V

0

+5 V

RST-N

0

Fig. 2

▼

• No If RS232C PCB is available, replace the RS232C PCB.

If the RS232C PCB is not available, replace the Power & Control

Board.

- 8 -

Page 14

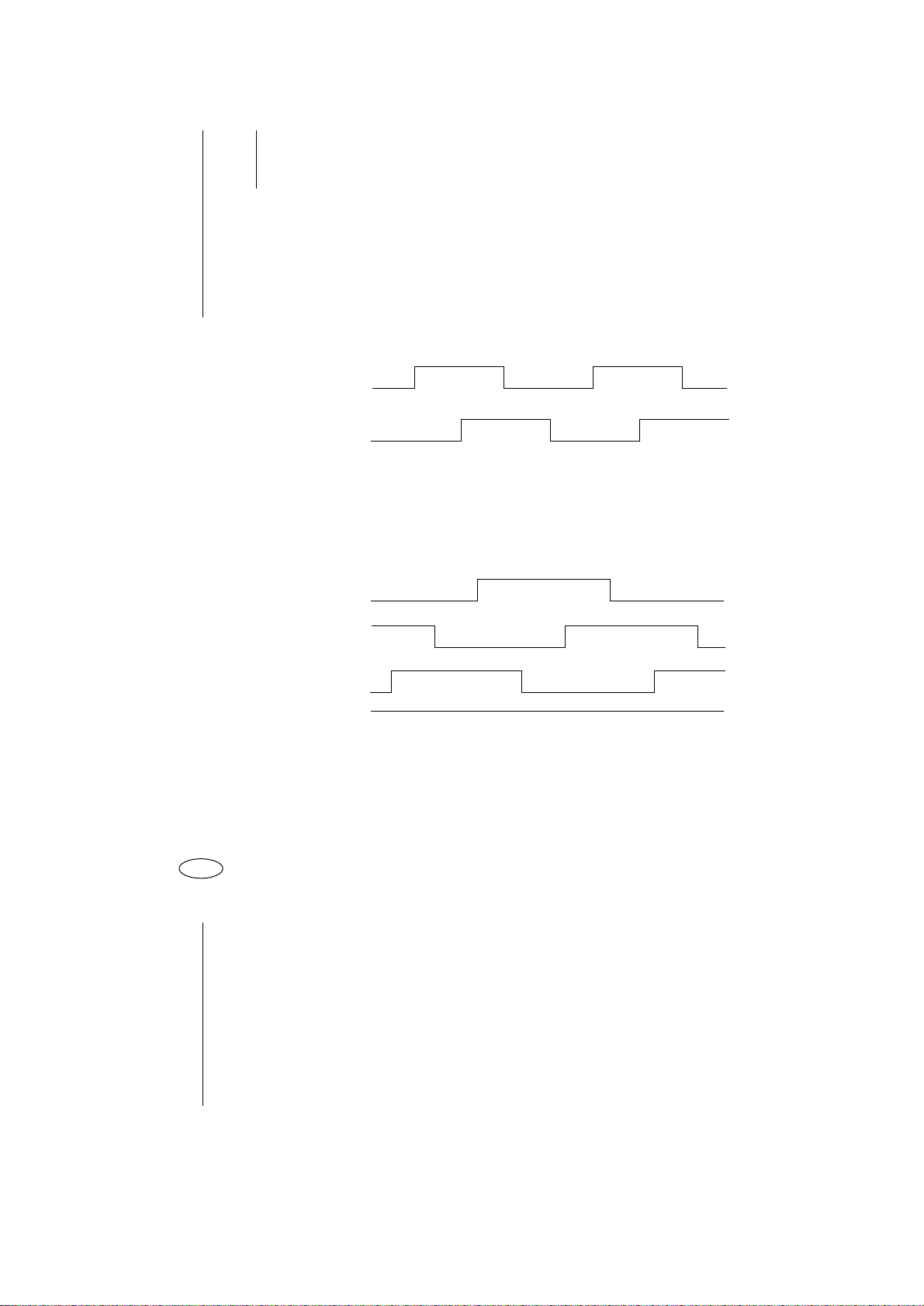

▼

• Yes Do bus line signals of 4C (67 x 640) of the Power & Control Board such as ALEP, PSEN-N, LSICS-N and RDN/WRL-N have waveforms as shown in Fig. 4?

62 ms

ALE-P

102 ms

PSEN-N

203 ms

LSICS-N

76 ms

RD-N/WRL-N

+5V

0V

+5V

0V

+5V

0V

+5V

0V

Fig. 4

At the rising edge of PSEN-N and RD-N/WRL-N, the bus line level is decisively

set to “H” or “L”.

• No Replace Q501 of the Power & Control Board.

▼

• Yes Does the OPCLK-N/OPTXD signal arrive at CN1 of the operation panel?

See Fig. 5.

OPCLK-N (CN1-3 pin)

OPTXQ (CN1-4 pin)

• No Is the flexible calbe of the operation panel connected without break?

• No Replace the flexible cable.

▼

• Yes Replace CN3 of the Driver Board.

▼

• Yes Does the OPRXD signal arrive at CN1 of the operation panel? See Fig. 5.

OPRXD (CN1-2 pin)

• No Replace IC1 of the operation panel.

▼

• Yes Does the OPRXD signal arrive at CN3 of the Driver Board? See Fig. 5.

• No Is the flexible cable of the operation panel connected without break?

• No Replace the flexible cable

▼

• Yes Replace CN3 of the Driver Board.

▼

• Yes Replace Q501 of the Power & Control Board.

- 9 -

Page 15

OPTXD

DATA

DATA

+5V

0V

OPCLK-N

OPRXD

DATA

Fig. 5

DATA

+5V

0V

+5V

0V

- 10 -

Page 16

3 The printer alarm is displayed.

3-1 Printer internal RAM alarm

• Replace Q501 of the Power & Control Board.

3-2 S-I/F internal RAM alarms.

• Replace Q3 of the LXHI board.

3-3 S-I/F connection alarm.

• Replace the LXHI board.

3-4 Program ROM alarm.

• Replace Q1 of the Power & Control Board (EPROM).

3-5 S-I/F ROM alarm.

• Replace Q3 of the LXHI board.

3-6 EEPROM alarm.

• Is the voltage of Q5-8pin +5V?

• No Check TR5 and TR7 and pattern on the Power & Control Board.

Correct pattern or replace parts.

▼

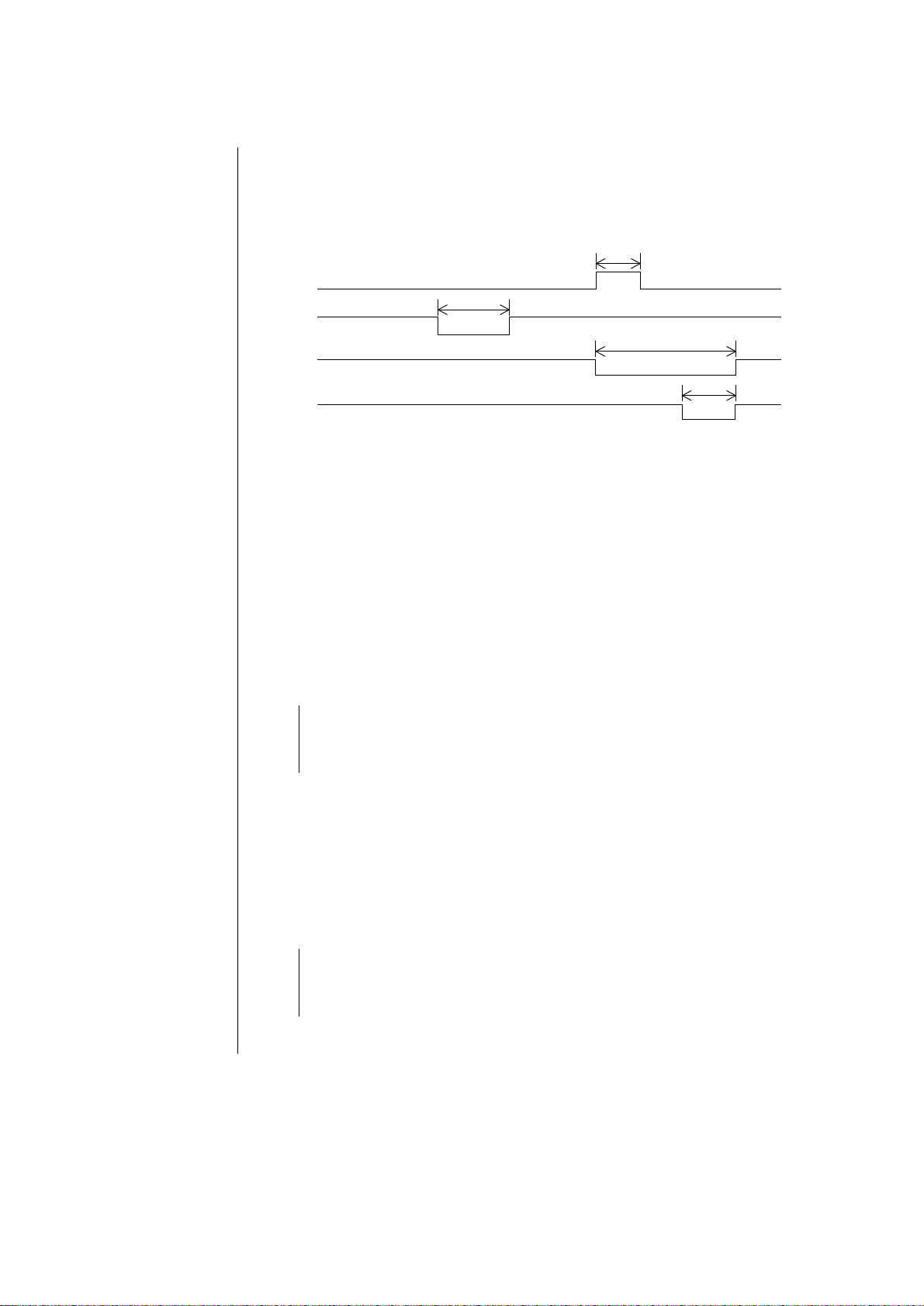

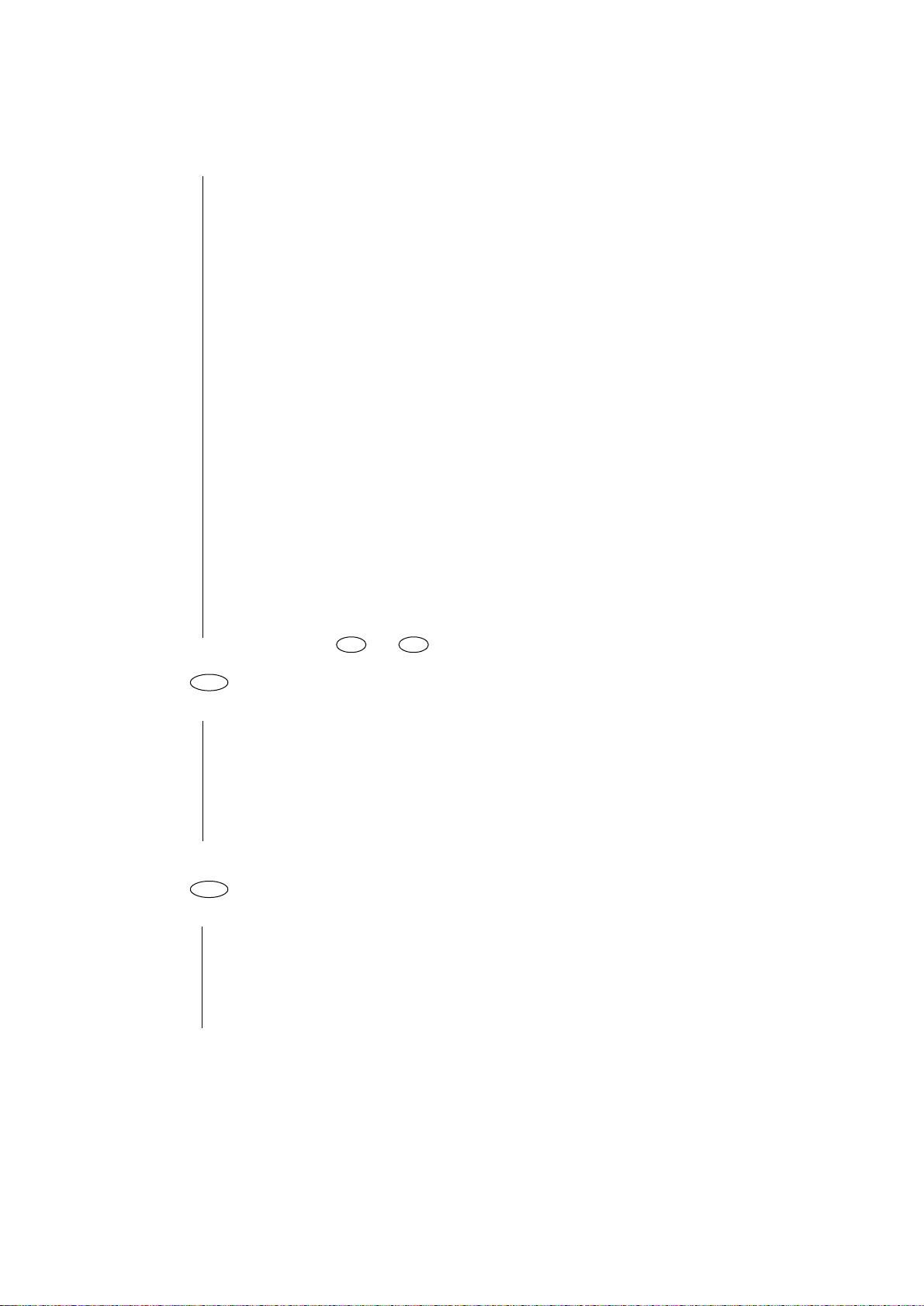

• Yes Do signals of Q501 of the Power & Control Board (67 x 640) such as EECLKP and EEDIN-P and EECS-P have the waveforms shown in Fig. 6?

• No Replace Q501 of the Power & Control Board.

▼

• Yes Do signals of Q5 of the Power & Control Board (EEPROM) such as EEDINP, EECS-P, EECLK-P and EEDOUT-P have the waveforms shown in Fig. 6?

• No Check EEDIN-P, EECS-P and EECLK-P patterns and parts

connected to the pattern. Correct pattern or replace parts.

▼

• Yes Replace Q501 of the Power & Control Board.

- 11 -

Page 17

EECS-P

+5V

0V

EECLK-P

EEDIN-P

EEDOUT-P

MIN

50 ns

MIN

100 ns

MIN

450 ns

MIN

100 ns

MIN

500 ns

Fig. 6

3-7 WDT alarm, BRK command alarm

• Is the alarm canceled by turning on power?

• No Replace ROM, Q1 or the Power & Control Board.

3-8 NMI alarm

• Is the alarm canceled by turning on power?

MIN

450 ns

MIN

500 ns

MIN

0 ns

MIN

100 ns

+5V

0V

+5V

0V

+5V

0V

• No Replae Power & Control Board.

3-9 Printer external RAM alarm.

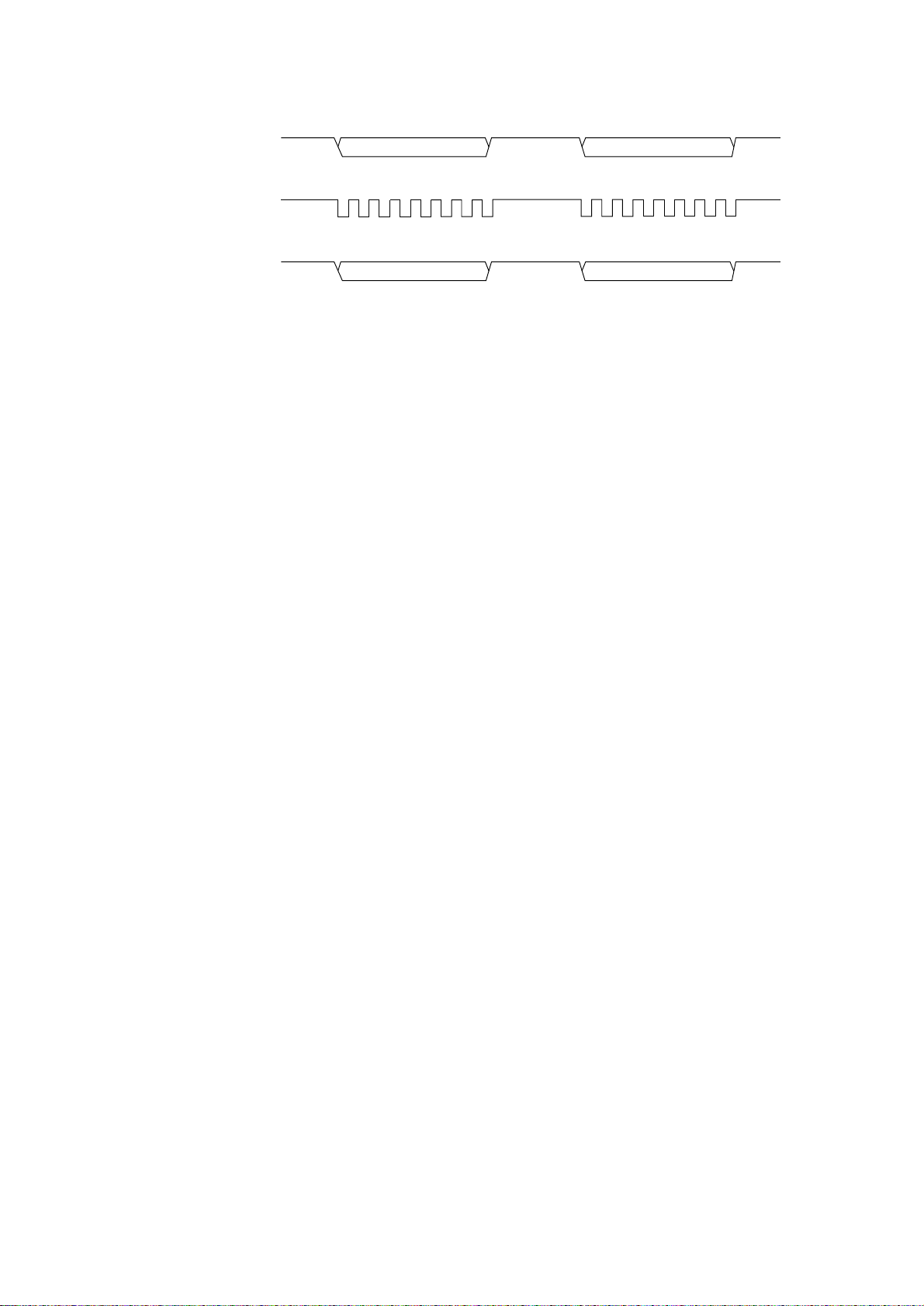

• Do signal of Q3, Q4 (DRAM) of the Power & Control Board such as RAS-N, CAS-N, OE,

WE have the waveforms shown in Fig. 7?

RAS-N (Q3, Q4-5)

CAS-N (Q3, Q4-16)

RD-N (Q3, Q4-1)

WRL-N (Q3, Q4-4)

• No Is the dumping resistance of each signal broken?

Check Q502 (Power & Control Board)?

• Yes Replace the dumping resistance or Q502

▼

• No

▼

• Yes Replace Q3, Q4.

- 12 -

Page 18

RAS-N

CAS-N

103 ns

41.4 ns

+5V

0V

+5V

0V

RD-N/WRH-N/WRL-N

At the rising edge of OE, WE, the bus line level is decisively set to “H” or “L”.

Fig. 7

3-10 S-I/F external RAM alarm.

• Replace Q9 of the LXHI board.

3-11 SPACING alarm, HOMING alarm

• Is the fuse (F1) on the Driver board blown?

• Yes Replace F1.

▼

• No Is VNF of MTDV (HA13412) short-circuited to U0, V0, or W0?

VNF (MTDV-11 pin)

U0 (MTDV-13 pin)

V0 (MTDV-15 pin)

W0 (MTDV-17 pin)

+5V

0V

• Yes Replace MTDV

▼

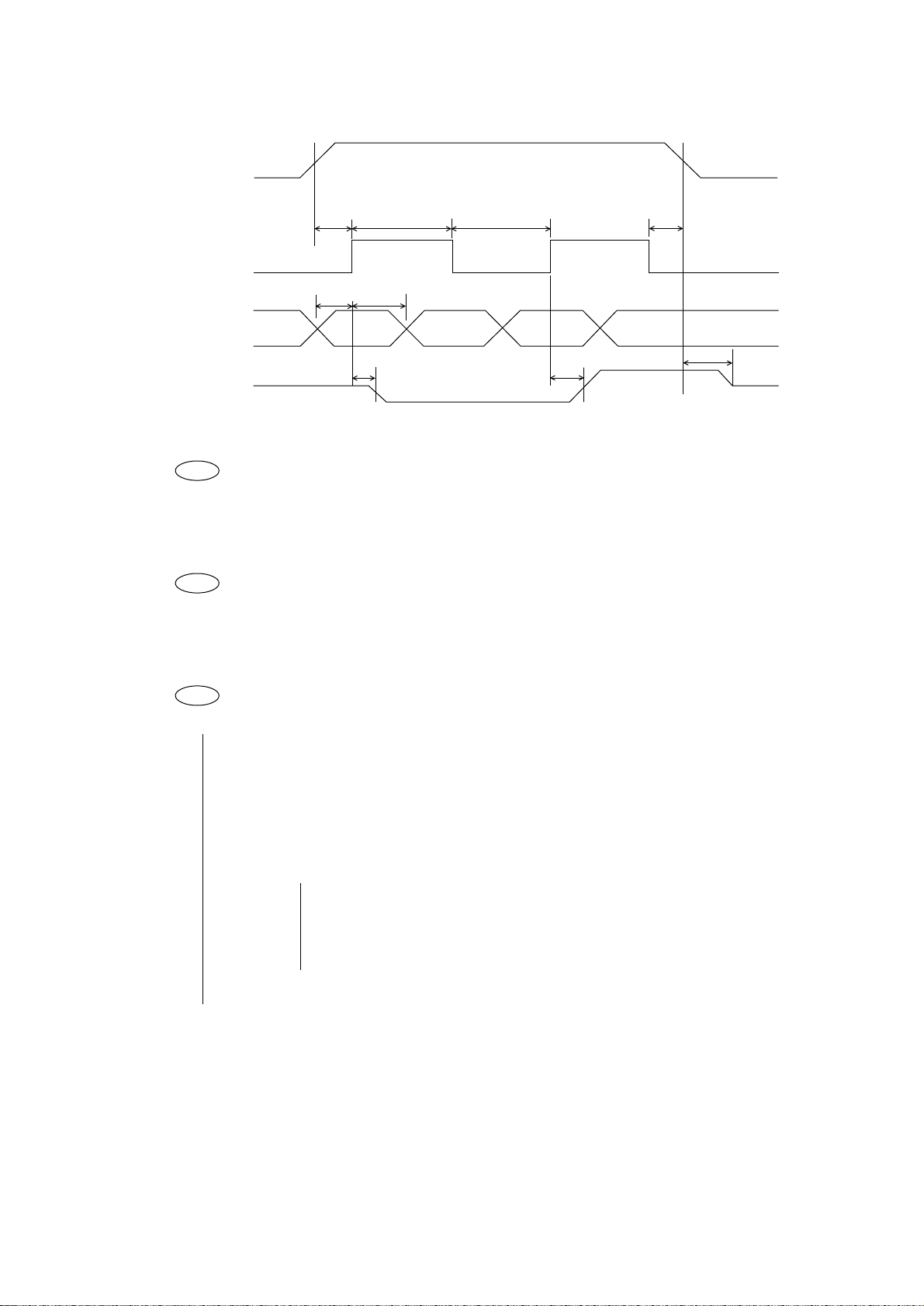

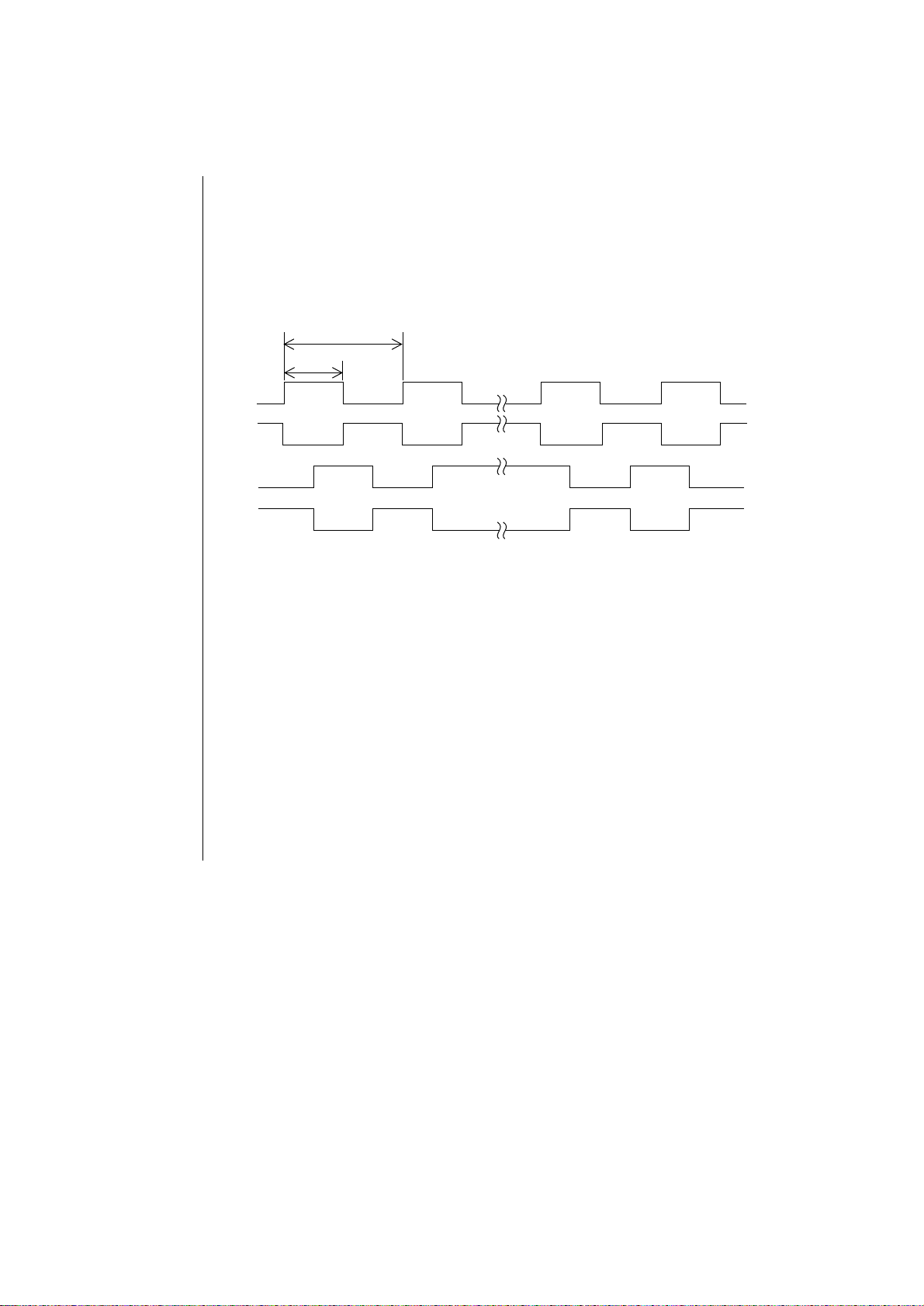

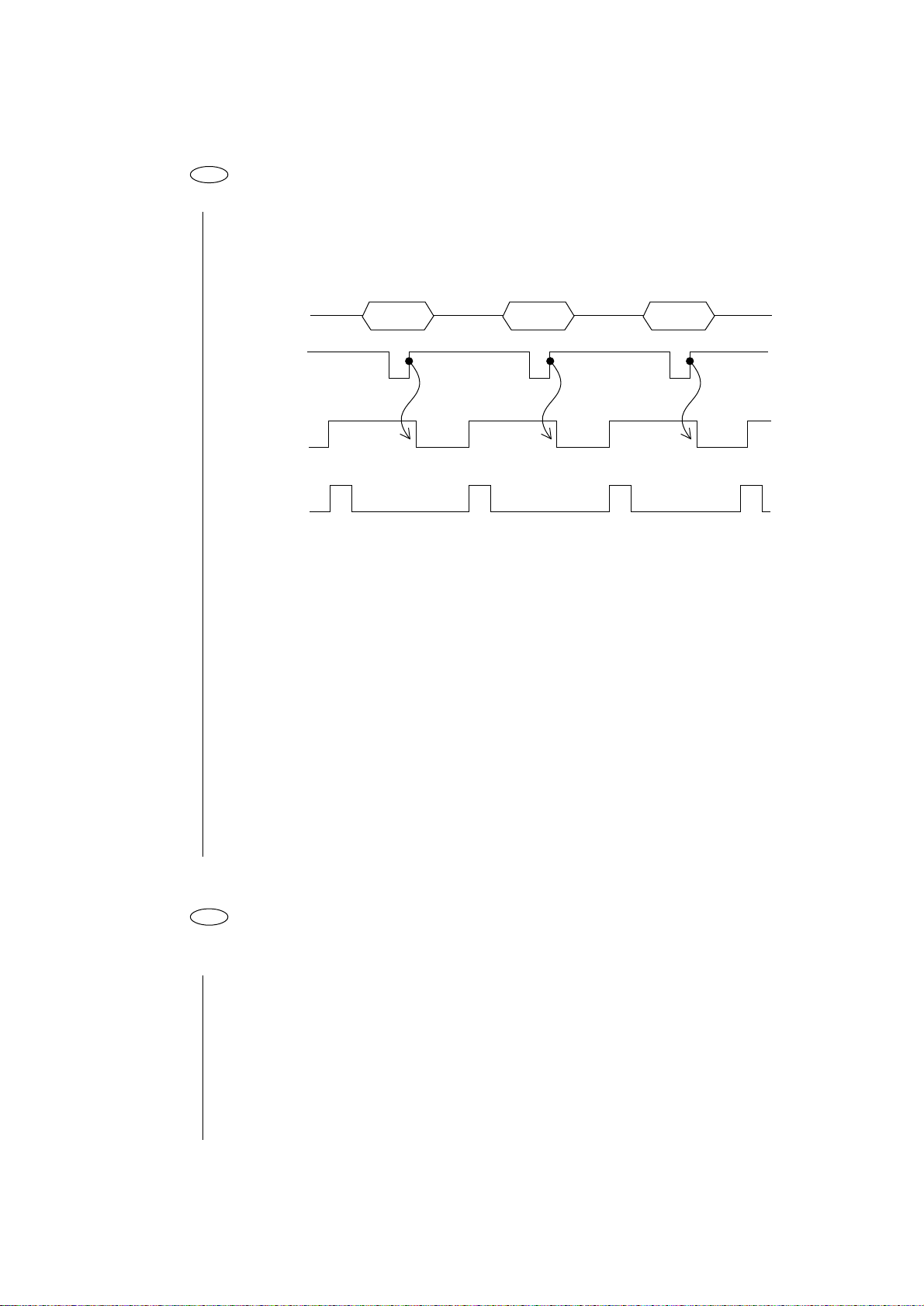

• No Do signals of SPU, SPV, SPW and SPD-A of MTDV have the wave forms shown in

Fig. 10?

• No Check patterns SPU, SPV, SPW between Q501 and MTDV. When they are

OK, replace the Driver PCB Q501.

▼

• Yes Do signals of U0, V0, and W0 of the MTDV have the wave forms shown in Fig. 10?

• No Replace the HTDV PCB.

▼

• Yes Do signals of PHASE A and PHASE B have the wave forms shown in Fig. 9?

• No Is the connection between CN5 on the Driver Board, and the CN on the

carriage are OK?

• No Secure the connection.

▼▼

• Yes Is there any disconnection of cable between the Driver Board and the

carriage?

- 13 -

Page 19

• No Replace the Carriage.

▼

• Yes Replace the Cable.

▼

• Yes Do signals of PHASE A, PHASE B of Q501 have the wave forms shown in Fig. 9?

• No Check the parts and pattern between Q501 and CN6. Correct

pattern or replace parts.

▼

• Yes Replace Q501.

PHASE A

PHASE B

When the carriage is manually move.

Fig. 9

SPU

SPV

SPW

SPD-A

When the carriage is manually move.

+5V

0V

+5V

0V

+5V

0V

+5V

0V

+5V

0V

+5V

0V

Fig. 10

3-12 Head A/D alarm

• Is the voltage of the HTEMP-N signal of Q501 of the Power & Control Board (67 X 640) +5V?

HTEMP-N (Q501-62 pin)

• No Replace Q501.

▼

• Yes Is the connection of CN5 of the Driver Board secured?

• No Secure the connection of CN5.

▼

• Yes Replace the head.

- 14 -

Page 20

3-13 Head Gap A/D alarm

• Is the voltage of HDGAP-N Signal of Driver Board CN5 22 pin +5V?

• Yes Replace the Head cable or the carriage.

▼

• No Replace the Power & Control Board.

- 15 -

Page 21

4 Wrong characters are printed or some characters are not printed.

• Do signals of Q501 of the Power & Control Board (67 X 640) such as PSEN-N, LSICS-N,

RD-N, WRL-N, RAS-N and CAS-N have the wave forms shown in Figs. 4 and 7?

• No Replace Q501.

▼

• Yes Replace the head, Q501 of Driver board or the space motor.

- 16 -

Page 22

5 Defective line feed.

• Do signals of LFDV (Driver board) such as A1, A2, B1 and B2 have the waveforms shown

in Fig. 11?

A1 (LFDV-3 pin)

A2 (LFDV-7 pin)

B1 (LFDV-8 pin)

B2 (LFDV-12 pin)

4.44 ms

2.22 ms

A1

A2

+40V

0V

+40V

0V

B1

B2

Forward Reverse

Fig. 11

• No Replace LFDV.

LFDV (Driver Board)

When it does not work properly, replace Q501 or the Driver Board.

▼

• Yes Is the flexible cable connected without break?

• No Replace the flexible cable.

▼

• Yes Is the CN4 of the Driver Board broken?

• No Replace CN4

▼

• Yes Replace the LF motor.

+40V

0V

+40V

0V

- 17 -

Page 23

6 The printer does not operate though the operation switch is pressed.

• Do the OPCLK-N and OPTXD signals arrive at CN3? See Fig. 5.

• No Replace Q501 of the Driver board.

▼

• Yes Do the OPCLK-N and OPTXD signals arrive at CN1 of the operation panel?

See Fig. 5.

• No Is the flexible cable of the operation panel connected without break?

• No Replace the flexible cable.

• Yes Replace CN3 of the Driver board.

▼

• Yes Does the OPRXD signal arrive at CN1 of the operation panel?

• No Replace IC1 of the operation panel.

▼

• Yes Does the OPRXD signal arrive at CN3 of the Driver board? See Fig. 5.

• No Is the flexible cable of the operation panel connected without break?

• No Replace the flexible cable.

• Yes Replace CN3 of the Driver board.

▼

• Yes Go to steps 6-1 to 6-9 .

6-1 SEL SW does not work.

• When SWC2 of IC1 (Bu5148S) is set to “L”, is SWI4 set to “L” by pressing SEL SW?

SWC2 (C1-7 pin)

SWI4 (IC1-3 pin)

• No Replace SEL SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

6-2 SHIFT SW does not work.

• When SWC2 of IC1 is set to “L”, is SWI3 set to “L” by pressing SHIFT SW?

SWI3 (IC1-10 pin)

• No Replace SHIFT SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

- 18 -

Page 24

6.3 LF SW does not work.

• When SWC2 of IC1 is set to “L”, is SW1 set to “L” by pressing LF SW?

(IC1-18 pin)

SWI4 (ICI-3 pin)

• No Replace LF SW.

▼

• Yes Does LF SW recover IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-4 FF SW does not work.

• When SWC2 of IC1 is set to “L”, is SWI2 set to “L” by pressing FF SW?

SWI2 (IC1-23 pin)

• No Replace FF SW.

▼

• Yes Does FF SW recover with IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-5 TEAR SW does not work.

• When SWC1 of IC1 is set to “L”, is SWI4 set to “L” by pressing TEAR SW?

SWC1 (IC1-31 pin)

• No Replace TEAR SW.

▼

• Yes Does TEAR SW recover with IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-6 PARK SW does not work.

• When SWC1 of IC1 is set to “L”, is SW2 set to “L” by pressing PARK SW?

• No Replace PARK SW.

▼

• Yes Does PARK SW recover with IC1 or Q501 of the Driver board replaced?

• No Go to step 5.

6-7 QUIET SW does not work.

• When SWC1 of IC1 is set to “L”, is SWI1 set to “L” by pressing QUIET SW?

• No Replace QUIET SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

- 19 -

Page 25

6.8 PRINT QUALITY SW does not work.

• When SWC3 of IC1 is set to “L”, is SWI1 set to “L” by pressing PRINT QUALITY SW?

• No Replace PRINT QUALITY SW.

▼

• Yes Replace IC1 or Q501 of the Driver board?

6-9 CHARACTER PITCH SW does not work.

• When SWC1 of IC1 is set to “L”, is SWI3 set to “L” by pressing CHARACTER PITCH SW?

• No Replace CHARACTER PITCH SW.

▼

• Yes Replace IC1 or Q501 of the Driver board.

- 20 -

Page 26

7 Data can not be received.

7-1 Parallel interface data can not be received.

• Do the IFDATA 1 to 8 signals of Q501 of the Driver board have the waveform shown in Figure

12 below?

IFD1 ~ 8

STB-N

BUSY-N

ACK

Valid Valid Valid

Fig. 12

• No Replace either relative electric component to the DATA 1 to 8 signals, or

replace CN6 of the Driver board.

▼

• Yes Does the STB-N signal of Q501 have the waveform shown in Fig. 12?

• No Replace either resistor or capacitor of the STB-N signal.

▼

• Yes Do the BUSY-N and ACK signals have the waveforms shown in Fig. 12?

H

L

H

L

H

L

H

L

• No Replace Q501.

BUSY-N (Q501-64 pin)

ACK (Q501-63 pin)

▼

• Yes Replace Q3.

7-2 When receiving with the parallel interface, printed data is skipped, or the printer

does not work.

• Gap in the self-test?

• Yes To step 4.

▼

• No Does the signal of BUSY-N or ACK of Q501 of the Driver board have the waveform

shown in Figure 12?

• No Replace Q501.

▼

• Yes Replace either relative electric component to ACK or BUSY-N signal, or replace Q3

of the Driver board.

- 21 -

Page 27

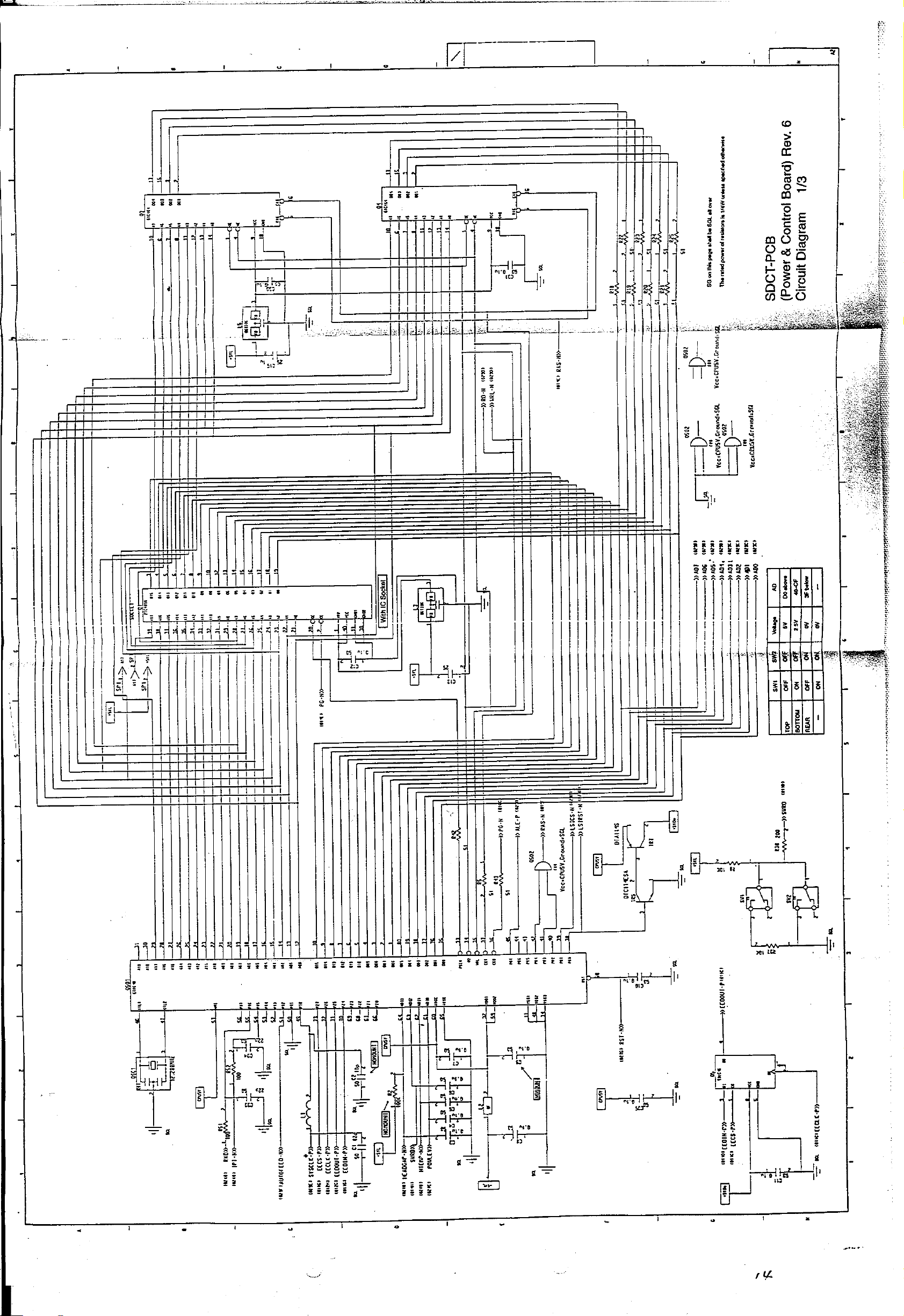

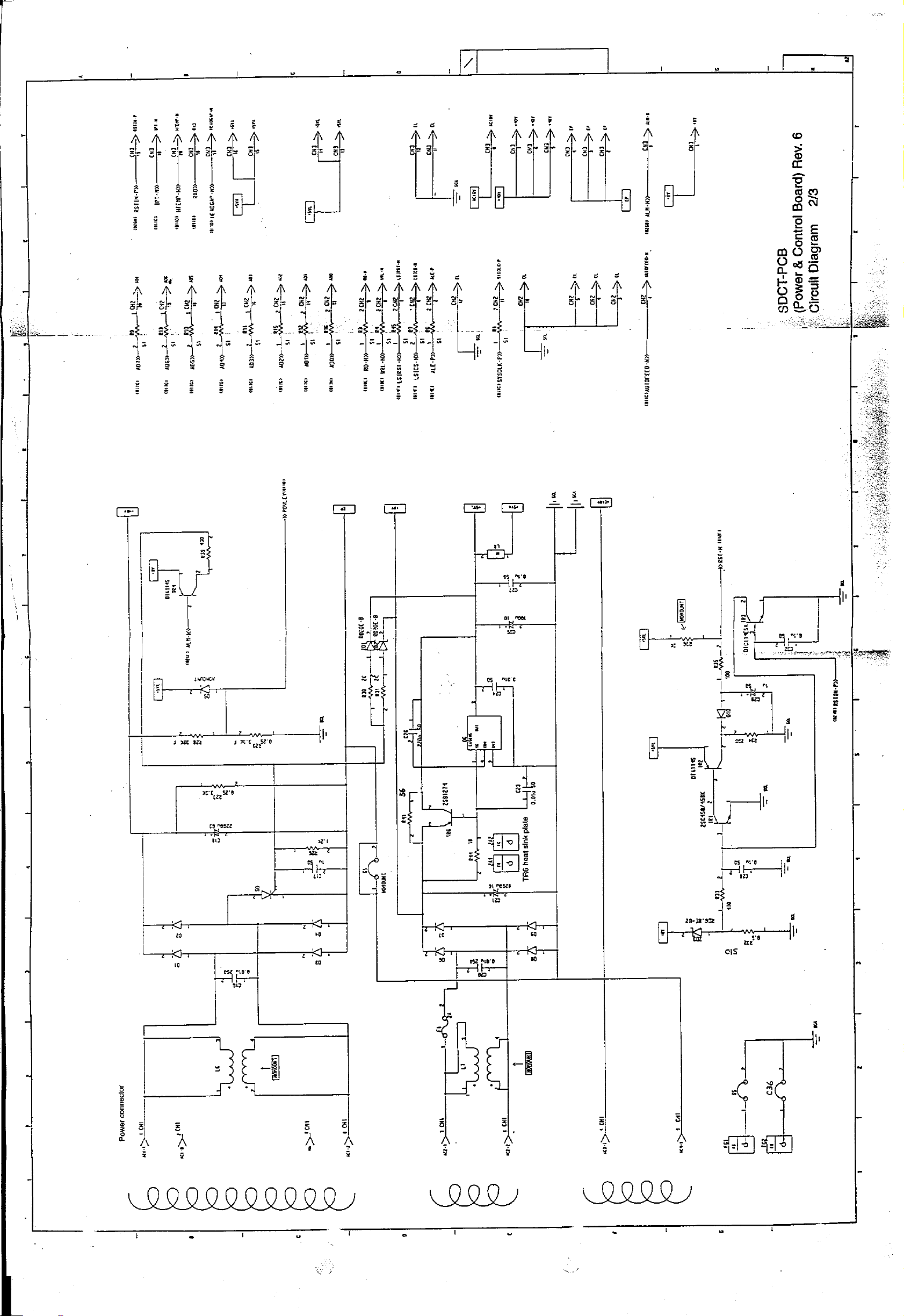

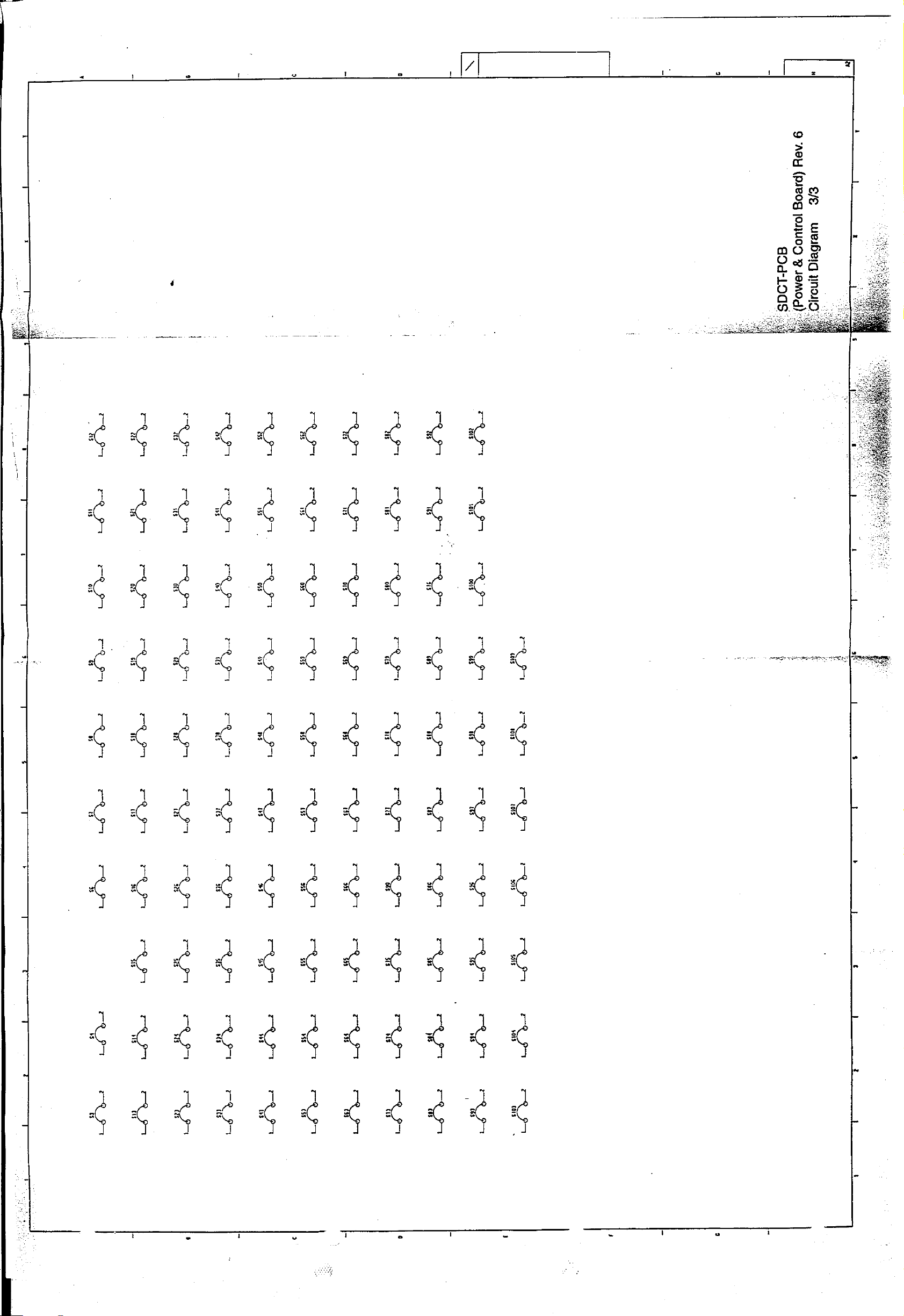

5. CIRCUIT DIAGRAM

SDCT-PCB (Power & Control Board) Rev. 6

SDDV-PCB (Driver Board) Rev. 4

LEOP-3 PCB (Operation Panel) Rev. 5 & 6

LXHI-PCB (Serial I/F Board) Rev. 7

Rev. 7

Rev. 8

Rev. 5

Rev. 6

Rev. 7

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

COMPONENT PARTS LIST

Page 64

6. COMPONENT PARTS LIST

SDCT-PCB (Power & Control Board) Rev. 6 4YA4042-1543 Gxxx

SDDV-PCB (Driver Board) Rev. 4 4YA4042-1549 G001

LEOP-3 PCB (Operation Panel) Rev. 5 & 6 4YA4042-1516 G003

LXHI-PCB (Serial I/F Board) Rev. 7 4YA4021-1050 G001

Drawing List

Rev. 7 (ODA, OEL, OKI-INT)

Rev. 8

Rev. 5

Rev. 6

Rev. 7

Page 65

Page 66

SDCT-PCB (Power & Control Board) Rev. 6

(4YA4042-1543Gxxx -2/6)

REF.

NO.

1

2

3

4

5

6

7

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D6-D9

D1-D4

D10

D5

ZD3

ZD1, ZD2

R26

EM01Z/SM1XN02/DSM1D2

Rectifier DI

DSA3A2

Rectifier DI

1SR004-40

Rectifier DI

1S953/1S2075K/1S2473

Signal DI

RD6.8E-B2

Zener DI

RD20E-B

Zener-DI

RD14DX2E-1.2KΩJ

RD Resistor

610A0003M0001

610A0021L0092A

610A0303M0004

611A0003L0001

613A1231L0142B

613A1231L0252

321A1023J0122

4

4

1

1

1

2

1

8

R35, R51, R52, R5

9

R8, R37

10

R34, R38

11

R30, R31

12

R36

13

R39

14

R33

15

R1, R3, R4, R5, R7,

R9-R16, R18-R25,

R42, R43, R45

R44

16

RD14DX2E-100ΩJ

RD Resistor

RD14DX2E-10KΩJ

RD Resistor

RD14DX2E-200ΩJ

RD Resistor

RD14DX2E-2KΩJ

RD Resistor

RD14DX2E-27KΩJ

RD Resistor

RD14DX2E-430ΩJ

RD Resistor

RD14DX2E-470ΩJ

RD Resistor

RD14DX2E-51ΩJ

RD Resistor

RD14DX2E-18ΩJ

RD Resistor

321A1023J0101

321A1023J0103

321A1023J0201

321A1023J0202

321A1023J0273

321A1023J0431

321A1023J0471

321A1023J0510

321A1023J0180

4

2

2

2

1

1

1

24

1

- 2 -

Page 67

SDCT-PCB (Power & Control Board) Rev. 6

(4YA4042-1543Gxxx -3/6)

REF.

NO.

17

R32

18

R29

19

R28

20

R27

21

R41

22

S50

23

C16, C20

24

C3-C8, C10, C12, C17,

C27, C28, C30-C32,

C35

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

RD1/2Y110ΩJ

RD Resistor

RNM1/4C2-3.3KΩJ

RD Resistor

RNM1/4C2-39KΩJ

RD Resistor

MOR2B3.3KΩJ

RS Resistor

MOR2B56ΩJ

RS Resistor

RD1/4Y100ΩJ

RD Resistor

TCK45F2E103ZYA 250V

CK Capacitor 10000PF

CK92F1H104ZY 50V

CKCapacitor 0.1UF

321A1431J0111

323A4024F0332

323A4024F0393

324A1121J0332

324A1121J0560

321A1421J0101

302A4027Z5103

303A0420Z3104

1

1

1

1

1

1

4

15

25

C1

C13, C15

26

27

C23, C24

C33, C34, C38, C39

28

29

C26

30

C25

C21

31

32

C29

C18

33

FK16C0G1H820J 50V

CC Capacitor 82PF

CK92F1E105ZS 25V

CK Capacitor 1UP

CK92C1H103MS 50V

CK Capacitor 0.01UF

CC122CH1H220K 50V

CC Capacitor 22PF

FK16C0G1H221J 50V

CC Capacitor 220PF

SME10VB-100-OA 10V

CE Capacitor 100UP

16VBSN-8200 (M) 16V

CE Capacitor 8200UF

50MS5-1M 50V

CE Capacitor 1UF

UVX1J222MRAY-1CA 63V

CE Capacitor 2200UF

303A1014C3820

303A4117Z2105

303A4115M3103

303A1006C9220

303A1014C3221

304A1123A1101

304A1037C9822

304A1046H1109

304A1086J1222

1

2

2

4

1

1

1

1

1

- 3 -

Page 68

SDCT-PCB (Power & Control Board) Rev. 6

(4YA4042-1543Gxxx -4/6)

REF.

NO.

34

35

36

37

38

39

40

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C11

Q6

Q3, Q4

Q5

Q501

Q502

Q1

CK92C1H102MS 50V

CK Capacitor 0.001UF

LA5005

BIP Linear IC

MSM51C464A-80RS

MOS-D-RAM

93LC46A-NW

MOS-EEPROM

MSM67X640GS-BK

MOS-CPU (FP)

74F08FP

BIP Digital IC (SO)

DICF-40CS-E

IC Socket

303A4115M3102

720A1033M0001

802A0024F8301

816A0303M0000

851A0324N0007

700A9703N0008

245A1221P0400

1

1

2

1

1

1

1

41

L3, L5

42

L1

43

L2, L8

44

S3-S20, C36

45

S21-S33

46

S34-S46

47

S47-S49, S51-S63

48

S64-S75

DST306-55F103Z

EMI Filter

SBT-0210

Noise Filter

ZBF253D-01

Beads Filter

0.65 Tin-plated Annealed Copper

Wire

0.65 Tin-plated Annealed Copper

Wire

0.65 Tin-plated Annealed Copper

Wire

0.65 Tin-plated Annealed Copper

Wire

0.65 Tin-plated Annealed Copper

Wire

342A1004P2103

377A1108P0005

377A1115P1309

TA-0.65

TA-0.65

TA-0.65

TA-0.65

TA-0.65

2

1

2

19

13

13

16

12

- 4 -

Page 69

SDCT-PCB (Power & Control Board) Rev. 6

(4YA4042-1543Gxxx -5/6)

REF.

NO.

49

50

51

52

53

54

55

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

S77-S90

S76, S90-S109

F1

TR2, TR4, TR7

TR1

TR3, TR5

TR6

0.65 Tin-plated Annealed Copper

Wire

0.65 Tin-plated Annealed Copper

Wire

230002

Glass Tube Fuse

DTA114S

PNP-HF-TR

2SC458/458K

NPN-HF-TR

DTC114ESA

NPN-HF-TR

2SB1274

PNP-LF-TR

TA-0.65

TA-0.65

540A5013T2104

600A1035M0005

602A1003M0003

602A1035M0007

601A1232M0004

14

20

1

3

1

2

1

56

57

58

59

60

61

SO

SW1, SW2

CN1

CN2, CN3

TP1

SP1

CR3CM-8

Gate Thyristor OFF

D2A-1220

Microswitch

00-8263-0812-00-000

PC Connector

20FE-BT-VK-N

PC Connector

IMSA-9206H-GF

PC Connector

IMSA9202B-1-03Z013GF

PC Connector

620A0022M0006E

207A1041P0001

224A3357P0080

224A4134P0200

224A4080P0020

224A4082P0030

1

2

1

2

1

1

- 5 -

Page 70

SDCT-PCB (Power & Control Board) Rev. 6

(4YA4042-1543Gxxx -6/6)

REF.

NO.

6263OSC1

2

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

CST12.288MTW

Ceramic Oscillator

Heat Sink (GOT-2325-SPL)

381A1045B0017

PB4042-1548P001

1

1

- 6 -

Page 71

Page 72

Page 73

SDCT-PCB (Power & Control Board) Rev. 7 & 8

(4YA4042-1543Gxxx-3/6)

REF.

NO.

1

2

3

4

5

6

7

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D6-D9

D1-D4

D5, D10, D11

ZD3

ZD1, ZD2

R26

R35, R51-R53, R5

EM01Z/SM1XN02/DSM1D2

Rectifier DI

DSA3A2

Rectifier DI

1S953/1S2075K/1S2473

Signal DI

RD5.6E-B

Zener DI

RD20E-B

Zener DI

RD14DX2E-1.2KΩJ

RD resistor

RD14DX2E-100ΩJ

RD resistor

610A0003M0001

610A0021L0092A

611A0003L0001

613A1231L0122

613A1231L0252

321A1023J0122

321A1023J0101

4

4

3

1

2

1

5

R8, R37

8

R38

9

R30, R31, R34

10

R36

11

R39

12

R33

13

R1, R3, R4, R6, R7,

14

R9-R16, R18-R25,

R42, R43, R45, S111

R54

15

R44

16

RD14DX2E-10KΩJ

RD resistor

RD14DX2E-200ΩJ

RD resistor

RD14DX2E-2KΩJ

RD resistor

RD14DX2E-27KΩJ

RD resistor

RD14DX2E-430ΩJ

RD resistor

RD14DX2E-4.3KΩJ

RD resistor

RD14DX2E-51ΩJ

RD resistor

RD14DX2E-5.6KΩJ

RD resistor

RD14DX2E-18ΩJ

RD resistor

321A1023J0103

321A1023J0201

321A1023J0202

321A1023J0273

321A1023J0431

321A1023J0432

321A1023J0510

321A1023J0562

321A1023J0180

2

1

3

1

1

1

25

1

1

- 9 -

Page 74

SDCT-PCB (Power & Control Board) Rev. 7 & 8

(4YA4042-1543Gxxx-4/6)

REF.

NO.

17

R32

18

R29

19

R28

20

R27

21

R41

22

C28

24

C16, C20

25

C3-C8, C10-C12, C27,

C30-C32, C35, C40

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

RD14DX2E-510ΩJ

RD resistor

RNM1/4C2-3.3KΩF

RN resistor

RNMI/4C2-39KΩF

RN resistor

MOR2B3.3KΩJ

RS resistor

MOR2B56ΩJ

RS resistor

SME16VB-10-0A16V

CE capacitor 10µF

TCK45F2E103ZYA 250V

CK capacitor 10000pF

CK92F1H104ZY 50V

CK capacitor 0.1µF

321A1023J0511

323A4024F0332

323A4024F0393

324A1121J0332

324A1121J0560

304A1123C1100

302A4027Z5103

303A0420Z3104

1

1

1

1

1

1

2

15

26

C1

27

C13, C15, C17

28

C23, C24

C33, C34, C38, C39

29

30

C26

31

C25

32

C21

33

C29

C18

34

FK16C0G1H820J 50V

CC capacitor 82pF

CK92F1E105ZS 25V

CK capacitor 1µF

CK92C1H103MS 50V

CK capacitor 0.01µF

CC122CH1H220K 50V

CC capacitor 22pF

FK16C0G1H221J 50V

CC capacitor 220pF

SME10VB-100-0A 10V

CE capacitor 100µF

16VBSN-8200(M) 16V

CE capacitor 8200µF

50MS5-1M 50V

CE capacitor 1µF

UVX1J222MRAY-1CA 63V

CE capacitor 2200µF

303A1014C3820

303A4117Z2105

303A4115M3103

303A1006C9220

303A1014C3221

304A1123A1101

304A1037C9822

304A1046H1109

304A1086J1222

1

3

2

4

1

1

1

1

1

- 10 -

Page 75

SDCT-PCB (Power & Control Board) Rev. 7 & 8

(4YA4042-1543Gxxx-5/6)

REF.

NO.

35

36

37

38

39

40

41

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C42

Q6

Q3, Q4

Q5

Q501

Q502

3

CK92C1H102MS 50V

CK capacitor 0.001µF

LA5005

BIP linear IC

MSM51C464A-80RS

MOS-D-RAM

93LC46A-NW

MOS-EEPROM

MSM67X640GS-BK

MOS-CPU (FP)

74F08FP

BIP digital IC (SO)

DICF-40CS-E

IC socket

303A4115M3102

720A1033M0001

802A0024F8301

816A0303M0000

851A0324N0007

700A9703N0008

245A1221P0400

1

1

2

1

1

1

1

42

L3, L5

43

L1

44

L2, L8

45

S3, S4, S6-S19, S110,

C36, C37, S26

46

S21, S25, S27-S33,

S112

S34-S44, S46

47

S47-S49, S51-S63

48

S64-S75, S86

49

S77-S85, S87-S90,

50

S113

S76, S91-S109, S114

51

DST306-55F103Z

EMI filter

SBT-0210

Noise filter

ZBF253D-01

Beads filter

0.65 Tin-plated annealed copper wire

0.65 Tin-plated annealed copper wire

0.65 Tin-plated annealed copper wire

0.65 Tin-plated annealed copper wire

0.65 Tin-plated annealed copper wire

0.65 Tin-plated annealed copper wire

0.65 Tin-plated annealed copper wire

342A1004P2103

377A1108P0005

377A1115P1309

TA-0.65

TA-0.65

TA-0.65

TA-0.65

TA-0.65

TA-0.65

TA-0.65

2

1

2

20

13

12

16

13

14

21

- 11 -

Page 76

SDCT-PCB (Power & Control Board) Rev. 7 & 8

(4YA4042-1543Gxxx-6/6)

REF.

NO.

52

53

54

55

56

57

58

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

F1

TR4, TR7

TR1, TR2

TR3, TR5

TR6

S0

SW1, SW2

230002

Glass tube fuse

DTA114S

PNP-HF-TR

2SC458/458K

NPN-HF-TR

DTC114ESA

NPN-HF-TR

2SB1274

PNP-LF-TR

CR6CM-8

Gate thyristor OFF

D2A-1220

Microswitch

540A5013T2104

600A1035M0005

602A1003M0003

602A1035M0007

601A1232M0004

620A0022M0007

207A1041P0001

1

2

2

2

1

1

2

59

60

61

62

63

64

CN1

CN2, CN3

TP1

SP1

OSC1

2

00-8263-0812-00-000

PC connector

20FE-BT-VK-N

PC connector

IMSA-9206H-GF

PC connector

IMSA9202B-1-03Z013GF

PC connector

CST12.288MTW

Ceramic oscillator

Heat Sink (GOT-2325-SPL)

224A3357P0080

224A4134P0200

224A4080P0020

224A4082P0030

381A1045B0017

PB4042-1548P001

1

2

1

1

1

1

- 12 -

Page 77

Page 78

SDDV-PCB (Driver Board) Rev. 4

(4YA4042-1549G001 -2/7)

REF.

NO.

1

2

3

4

5

6

7

8

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D501-D503

D2

D1

ZD504

ZD502

ZD501

ZD503

ZD4

MA151WK/N202K/2838

Signal DI (CP)

EM01Z/SM1XN02/DSM1D2

Rectifier DI

DFM1E1

Rectifier DI

MA3100/RD10M-B

Zener DI (CP)

MA3300/RD30M-B

Zener DI (CP)

RD2.7M-B1

Zener DI (CP)

MA3300-M

Zener DI (CP)

RD20E-B

Zener DI

611A0003N0003

610A0003M0001

610A0221M0001

613A0103M0182

613A0103M0292

613A0233M0042A

613A0291M0292M

613A1231L0252

3

1

1

1

1

1

1

1

9

ZD1, ZD2

10

ZD3

11

DA2, DA3

12

R545

13

R512

14

R502

15

R551, R565, R567

16

R544, R546, R547,

R552, R561

RD39E-B7

Zener DI

RD110E-B

Zener DI

D1CA20

Diode Ary

RM73B2A101J

RN Resistor (CP)

RM73B2A201J

RN Resistor (CP)

RM73B2A471J

RN Resistor (CP)

RM73B2A511J

RN Resistor (CP)

RM73B2A102J

RN Resistor (CP)

613A1231L0322G

613A1231L0432

761A2232M0401

32A5003J0101

323A5330J0201

323A5003J0471

323A5003J0511

323A5003J0102

2

1

2

1

1

1

3

4

- 14 -

Page 79

SDDV-PCB (Driver Board) Rev. 4

(4YA4042-1549G001 -3/7)

REF.

NO.

17

R518

18

R522, R532, R533,

R559, R560

19

R516, R519

20

R517, R531

21

R501, R503, R504

22

R527, R554

R530

23

24

R514, R523, R564

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

RM73B2A122J

RN Resistor (CP)

M73B2A152J

RN Resistor (CP)

RM73B2A202J

RN Resistor (CP)

RM73B2A222J

RN Resistor (CP)

RM73B2A272J

RN Resistor (CP)

RM73B2A302J

RN Resistor (CP)

RM73B2A332J

RN Resistor (CP)

RM73B2A512J

RN Resistor (CP)

323A5003J0122

323A5003J0152

323A5003J0202

323A5003J0222

323A5003J0272

323A5003J0302

323A5003J0332

323A5003J0512

1

5

2

2

4

2

1

3

R534, R535, R553,

25

R557, R558, R562,

R563

R513, R515, R521,

26

R524, R536-R543,

R548-R550

R529

27

R555, R556

28

R520

29

R528

30

R525, R526

31

R505-R508

32

R511

33

RM73B2A562J

RN Resistor (CP)

RM73B2A103J

RN Resistor (CP)

RM73B2A223J

RN Resistor (CP)

RM73B2A513J

RN Resistor (CP)

RM73B2A104J

RN Resistor (CP)

RM73B2A224J

RN Resistor (CP)

RM73B2A242F

RN Resistor (CP)

RM73B2A243F

RN Resistor (CP)

RM73B2A563F

RN Resistor (CP)

323A5003J0562

323A5003J0103

323A5003J0223

323A5003J0513

323A5003J0104

323A5003J0224

323A5003F0242

323A5003F0243

323A5003F0563

7

15

1

2

1

1

2

4

1

- 15 -

Page 80

SDDV-PCB (Driver Board) Rev. 4

(4YA4042-1549G001 -4/7)

REF.

NO.

34

35

36

37

38

39

40

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R509, R510

R6

R4, R5

R1-R3

RM2, RM3

RM1

C521

RM73B2A204F

RN Resistor (CP)

RD1/2Y2KΩJ

RD Resistor

RD1/2Y1.3KΩJ

RD Resistor

MSF1/2B0.51ΩJ

RS Resistor

MRM-8-332JA

Block Resistor

MRM-8-104JA

Block Resistor

CC2012CH1H100D 50V

CC Capacitor (CP)

323A5003F0204

321A1431J0202

321A1431J0132

324A1001J0518

334A3268J0332

334A3268J0104

303A3007C0100

2

1

2

3

2

1

1

41

C505-C509

42

C510, C511

43

C524

44

C517, C526, C533,

C534

45

C522

C514

46

47

C515, C516, C520,

C504

48

C501-C503, C512,

C513, C518, C519,

C527-C529, C532,

C535

C5, C6

49

CC2012CH1H220J 50V

CC Capacitor (CP)

CC2012CH1H101J 50V

CC Capacitor (CP)

CC2012SL1H561J 50V

CC Capacitor (CP)

CC2012SL1H102J 50V

CC Capacitor (CP)

CK2012B1H102K 50V

CK Capacitor (CP)

CK2012B1H152K 50V

CK Capacitor (CP)

CK2012B1H103K 50V

CK Capacitor (CP)

CK2012F1E104Z 25V

CK Capacitor (CP)

TCK45F2E103ZYA 250V

CK Capacitor 10000PF

303A3007C0220

303A3007C0101

303A3007K0561

303A3007K0102

303A6008K3102

303A6008K3152

303A6008K3103

303A6008Z2104

302A4027Z5103

5

2

1

4

1

1

4

12

3

- 16 -

Page 81

SDDV-PCB (Driver Board) Rev. 4

(4YA4042-1549G001 -5/7)

REF.

NO.

50

51

52

53

54

55

56

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C8

C3

C2

C7

C4, C12

Q501

Q3

CK92F1E105ZS 25V

CK Capacitor 1UF

SXE50VB-100 50V

CE Capacitor 100UF

SME100VB-3R3BP-OA

CE Capacitor 2.2UF

SME25VB-10-OA 25V

CE Capacitor 10UF

KMG63VB-22M 63V

CE Capacitor 22UF

MSM10S0110-080GS-BK

MOS Digital IC (FP)

74LS06P

BIP Digital IC

303A4117Z2105

304A1034H1101

304A1122A2339

304A1123E1100

304A1164J1220

702A4524N1082

700A0503M0006

1

1

1

1

2

1

1

57

Q1, Q2

58

LFDV

59

MTDV

60

L3

61

L7

62

L1, L2, L4-L6, L9

63

S1-S17

LB1731-H

BIP-INF-IC

MTD2005F

BIP Linear IC (SO)

HA13412

BIP Linear IC

DST306-55F103Z

EMI Filter

RSL1513N102K/OL1614

H Coil

ZBF253D-01

Beads Filter

JPW02

Short Wire

710A2031M0002

720A1816N0001

720A4021E0004

342A1004P2103

353A3040K0102

377A1115P1309

321A1520P0001

2

1

1

1

1

6

17

- 17 -

Page 82

SDDV-PCB (Driver Board) Rev. 4

(4YA4042-1549G001 -6/7)

REF.

NO.

64

65

66

67

68

69

70

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

F1, F2

TR501, TR503

TR504

TR505

TR502

TR506

TR507

251-002

Fuse

A1344/UN2111/DTA114K

PNP-HF-TR (CP)

2SA1163

PNP-HF-TR (CP)

2SC3361/2SC2412KVL

NPN-HF-TR (CP)

2SC2713

NPN-HF-TR (CP)

DTC114EKA

NPN-HF-TR (CP)

2SD1472

NPN-LF-TR (CP)

540A2208S1202

600A1003N0003

600A1025N0033

602A1003N0002

602A1025N0050

602A1035N0005

603A1121N0007

2

2

1

1

1

1

1

71

72

73

74

75

76

77

TR4

TR1

TR3

PE

CN6

CN8

CN7

2SB740

PNP-LF-TR

2SB1225/2SB1351

PNP-LF-TR

2SB1274

PNP-LF-TR

SG-206

Photo Coupler

57RE-40360-730B-D29A

Square-shaped Connector

TCS7588-01-201

Round-shaped Connector

MCR69-30D-2.54DS

PC Connector

601A1121M0004

601A1203M0003

601A1232M0004

652A0114M0003

220A1783P0360

221A1525P0080

224A1052P0300

1

1

1

1

1

1

1

- 18 -

Page 83

SDDV-PCB (Driver Board) Rev. 4

(4YA4042-1549G001 -7/7)

REF.

NO.

78

79

80

81

82

83

84

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

CN4

CN3

CN5

CN1, CN2

3

2

C11

00-8263-0412-00-000

PC Connector

07FE-ST-M

PC Connector

23FE-BT-VK-N

PC Connector

00-5062-301-020-000

PC Connector

TW-VFM-20-100-B

Fuji Card

TW-VFM-20-130-B

Fuji Card

Short wire (U-shape) 0.65 P=5.0

224A3357P0040

224A4135P0070

224A4134P0230

224A5114P0200

238A1122P0001

238A1122P0002

KH-31036-50

1

1

1

2

1

1

1

85

86

87

6

5

4

Wire (green)

Acetate cloth tape (white)

RD14DX2E-100ΩJ

RD Resistor

LY-6507

YC4061-1004P001

321A1023J0101

1

1

1

- 19 -

Page 84

Page 85

SDDV-PCB (Driver Board) Rev. 5 & 6

(4YA4042-1549G001 -2/7)

REF.

NO.

1

2

3

4

5

6

7

8

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D501-D503

D2

D1

ZD504

ZD502

ZD501

ZD503

ZD4

MA151WK/N202K/2838

Signal DI (CP)

EM01Z/SM1XN02/DSM1D2

Rectifier DI

DFM1E1

Rectifier DI

MA3100/RD10M-B

Zener-DI (CP)

MA3300/RD30M-B

Zener DI (CP)

RD2.7M-B1

Zener DI (CP)

MA3300-M

Zener DI (CP)

RD20E-B

Zener DI

611A0003N0003

610A0003M0001

610A0221M0001

613A0103M0182

613A0103M0292

613A0233M0042A

613A0291M0292M

613A1231L0252

3

1

1

1

1

1

1

1

9

ZD1, ZD2

10

ZD3

11

DA2, DA3

12

R545

13

R512

14

R502

15

R551, R565, R567

16

R544, R546, R547,

R552, R561

RD39E-B7

Zener DI

RD110E-B

Zener DI

D1CA20

Diode array

RM73B2A101J

RN resistor (CP)

RM73B2A201J

RN resistor (CP)

RM73B2A471J

RN resistor (CP)

RM73B2A511J

RN resistor (CP)

RM73B2A102J

RN resistor (CP)

613A1231L0322G

613A1231L0432

761A2232M0401

323A5003J0101

323A5003J0201

323A5003J0471

323A5003J0511

323A5003J0102

2

1

2

1

1

1

3

5

- 21 -

Page 86

SDDV-PCB (Driver Board) Rev. 5 & 6

(4YA4042-1549G001 -3/7)

REF.

NO.

17

R518

18

R522, R532, R533,

R559, R560

19

R516, R519

20

R517, R531

21

R501, R503, R504

22

R527, R554

R530

23

24

R514, R523, R564

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

RM73B2A122J

RN resistor (CP)

RM73B2A152J

RN resistor (CP)

RM73B2A202J

RN resistor (CP)

RM73B2A222J

RN resistor (CP)

RM73B2A272J

RN resistor (CP)

RM73B2A302J

RN resistor (CP)

RM73B2A332J

RN resistor (CP)

RM73B2A512J

RN resistor (CP)

323A5003J0122

323A5003J0152

323A5003J0202

323A5003J0222

323A5003J0272

323A5003J0302

323A5003J0332

323A5003J0512

1

5

2

2

3

2

1

3

R534, R535, R553,

25

R557, R558, R562,

R563

R513, R515, R521,

26

R524, R536-R543,

R548-R550

R529

27

R555, R556

28

R520

29

R528

30

R525, R526

31

R505-R508

32

R511

33

RM73B2A562J

RN resistor (CP)

RM73B2A103J

RN resistor (CP)

RM73B2A223J

RN resistor (CP)

RM73B2A513J

RN resistor (CP)

RM73B2A104J

RN resistor (CP)

RM73B2A224J

RN resistor (CP)

RM73B2A242F

RN resistor (CP)

RM73B2A243F

RN resistor (CP)

RM73B2A563F

RN resistor (CP)

323A5003J0562

323A5003J0103

323A5003J0223

323A5003J0513

323A5003J0104

323A5003J0224

323A5003F0242

323A5003F0243

323A5003F0563

7

15

1

2

1

1

2

4

1

- 22 -

Page 87

SDDV-PCB (Driver Board) Rev. 5 & 6

(4YA4042-1549G001 -4/7)

REF.

NO.

34

35

36

37

38

39

40

41

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R509, R510

R6

R4, R5

R1-R3

RM2, RM3

RM1

C521

C505-C509

RM73B2A204F

RN resistor (CP)

RD1/2Y2KΩJ

RD resistor

RD1/2Y1.3KΩJ

RD resistor

MSF1/2B0.51ΩJ

RS resistor

MRM-8-332JA

Block resistor

MRM-8-104JA

Block resistor

CC2012CH1H100D 50V

CC capacitor (CP)

CC2012CH1H220J 50V

CC capacitor (CP)

323A5003F0204

321A1431J0202

321A1431J0132

3234A1001J0518

334A3268J0332

334A3268J0104

303A3007C0100

303A3007C0220

2

1

2

3

2

1

1

5

42

C510, C511

43

C524

44

C517, C526, C533,

C534

C522

45

46

C514

47

C515, C516, C520,

C504

C501-C503, C512,

48

C513, C518, C519,

C527-C529, C532,

C535

C5, C6

49

CC2012CH1H101J 50V

CC capacitor (CP)

CC2012SL1H561J 50V

CC capacitor (CP)

CC2012SL1H102J 50V

CC capacitor (CP)

CK2012B1H102K 50V

CK capacitor (CP)

CK2012B1H152K 50V

CK capacitor (CP)

CK2012B1H103K 50V

CK capacitor (CP)

CK2012F1E104Z 25V

CK capacitor (CP)

TCK45F2E103ZYA 250V

CK capacitor 10000pF

303A3007C0101

303A3007K0561

303A3007K0102

303A6008K3102

303A6008K3152

303A6008K3103

303A6008Z2104

302A4027Z5103

2

1

4

1

1

4

12

2

- 23 -

Page 88

SDDV-PCB (Driver Board) Rev. 5 & 6

(4YA4042-1549G001 -5/7)

REF.

NO.

50

51

52

53

54

55

56

57

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C8

C3

C2

C7

C4, C12

Q501

Q3

Q1, Q2

CK92F1E105ZS 25V

CK capacitor 1µF

SXE50VB-100 50V

CE capacitor 100µF

SME100VB-3R3BP-0A

CE capacitor 3.3µF

SME25VB-10-0A 25V

CE capacitor 10µF

KMG63VB-22M 63V

CE capacitor 22µF

MSM10S0110-080GS-BK

MOS digital IC (FP)

74LS06P

BIP digital IC

LB1731-H

BIP-INF-IC

303A4117Z2105

304A1034H1101

304A1122A2339

304A1123E1100

304A1164J1220

702A4524N1082

700A0503M0006

710A2031M0002

1

1

1

1

2

1

1

2

58

59

60

61

62

63

64

65

66

LFDV

MTDV

L3

L7

L1,L2, L4-L6, L9

S501, R570

S1-S17

C11

F1, F2

MTD2005F

BIP linear IC (SO)

HA13412

BIP linear IC

DST306-55F103Z

EMI filter

RSL1513N102K/OL1614

H Coil

ZBF253D-01

Beads filter

2125JPW

Chip jumper (CP)

JPW02

Jumper wire

Short wire (U-shape) 0.65

P=5.0

251-002

Fuse

720A1816N0001

720A4021E0004

342A1004P2103

353A3040K0102

377A1115P1309

323A5003P0001

321A1520P0001

KH-31036-50

540A2208S1202

1

1

1

1

6

2

17

1

2

Rev. 5: R570

NOT MOUNTED

- 24 -

Page 89

SDDV-PCB (Driver Board) Rev. 5 & 6

(4YA4042-1549G001 -6/7)

REF.

NO.

67

68

69

70

71

72

73

74

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

TR501, TR503

TR504

TR505

TR502

TR506

TR507

TR4

TR1

A1344/UN2111/DTA114K

PNP-HF-TR (CP)

2SA1163

PNP-HF-TR (CP)

2SC3361/2SC2412KVL

NPN-HF-TR (CP)

2SC2713

NPN-HF-TR (CP)

DTC114EKA

NPN-HF-TR (CP)

2SD1472

NPN-LF-TR (CP)

2SB740

PNP-LF-TR

2SB1225/2SB1351

PNP-LF-TR

600A1003N0003

600A1025N0033

602A1003N0002

602A1025N0050

602A1035N0005

603A1121N0007

601A1121M0004

601A1203M0003

2

1

1

1

1

1

1

1

75

76

77

78

79

80

81

82

83

TR3

PE

CN6

CN8

CN7

CN4

CN3

CN5

CN1, CN2

2SB1274

PNP-LF-TR

SG-206

Photo coupler

57RE-40360-730B-D29A

Square-shaped connector

TCS7588-01-201

Round-shaped connector

MCR69-30D-2.54DS

PC connector

00-8263-0412-00-000

PC connector

07FE-ST-M

PC connector

23FE-BT-VK-N

PC connector

00-5062-301-020-000

PC connector

601A1232M0004

652A0114M0003

220A1783P0360

221A1525P0080

224A1052P0300

224A3357P0040

224A4135P0070

224A4134P0230

224A5114P0200

1

1

1

1

1

1

1

1

2

- 25 -

Page 90

SDDV-PCB (Driver Board) Rev. 5 & 6

(4YA4042-1549G001 -7/7)

REF.

NO.

84853

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

TW-VFM-20-100-B

Fuji card

2

TW-VFM-20-130-B

Fuji card

238A1122P0001

238A1122P0002

1

1

- 26 -

Page 91

Page 92

SDDV-PCB (Driver Board) Rev. 7

(4YA4042-1549G001 -2/7)

REF.

NO.

1

2

3

4

5

6

7

8

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D501-D503

D2

D1

ZD504

ZD502

ZD501

ZD503

ZD4

MA151WK/N202K/2838

Signal DI (CP)

EM01Z/SM1XN02/DSM1D2

Rectifier DI

DFM1E1

Rectifier DI

MA3100/RD10M-B

Zener DI (CP)

MA3300/RD30M-B

Zener DI (CP)

RD2.7M-B1

Zener DI (CP)

MA3300-M

Zener DI (CP)

RD20E-B

Zener DI

611A0003N0003

610A0003M0001

610A0221M0001

613A0103M0182

613A0103M0292

613A0233M0042A

613A0291M0292M

613A1231L0252

3

1

1

1

1

1

1

1

9

ZD1, ZD2

10

ZD3

11

DA2, DA3

12

R545

13

R512

14

R502

15

R551, R565, R567

16

R544, R546, R547,

R552, R561

RD39E-B7

Zener DI

RD110E-B

Zener DI

D1CA20

Diode array

RM73B2A101J

RN resistor (CP)

RM73B2A201J

RN resistor (CP)

RM73B2A471J

RN resistor (CP)

RM73B2A511J

RN resistor (CP)

RM73B2A102J

RN resistor (CP)

613A1231L0322G

613A1231L0432

761A2232M0401

323A5003J0101

323A5003J0201

323A5003J0471

323A5003J0511

323A5003J0102

2

1

2

1

1

1

3

5

- 28 -

Page 93

SDDV-PCB (Driver Board) Rev. 7

(4YA4042-1549G001 -3/7)

REF.

NO.

17

R518

18

R522, R532, R533,

R559, R560

19

R516, R519

20

R517, R531

21

R501, R503, R504

R527, R554

22

23

R530

24

R514, R523, R564

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

RM73B2A122J

RN resistor (CP)

RM73B2A152J

RN resistor (CP)

RM73B2A202J

RN resistor (CP)

RM73B2A222J

RN resistor (CP)

RM73B2A272J

RN resistor (CP)

RM73B2A302J

RN resistor (CP)

RM73B2A332J

RN resistor (CP)

RM73B2A512J

RN resistor (CP)

323A5003J0122

323A5003J0152

323A5003J0202

323A5003J0222

323A5003J0272

323A5003J0302

323A5003J0332

323A5003J0512

1

5

2

2

3

2

1

3

25

R534, R535, R553,

R557, R558, R562,

R563

26

R513, R515, R521,

R524, R536-R543,

R548-R550

R529

27

R555, R556

28

R520

29

R528

30

R525, R526

31

R505-R508

32

R511

33

RM73B2A562J

RN resistor (CP)

RM73B2A103J

RN resistor (CP)

RM73B2A223J

RN resistor (CP)

RM73B2A513J

RN resistor (CP)

RM73B2A104J

RN resistor (CP)

RM73B2A224J

RN resistor (CP)

RM73B2A242F

RN resistor (CP)

RM73B2A243F

RN resistor (CP)

RM73B2A563F

RN resistor (CP)

323A5003J0562

323A5003J0103

323A5003J0223

323A5003J0513

323A5003J0104

323A5003J0224

323A5003F0242

323A5003F0243

323A5003F0563

7

15

1

2

1

1

2

4

1

- 29 -

Page 94

SDDV-PCB (Driver Board) Rev. 7

(4YA4042-1549G001 -4/7)

REF.

NO.

34

35

36

37

38

39

40

41

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R509, R510

R6

R4, R5

R1-R3

RM2, RM3

RM1

C521

C505-C509

RM73B2A204F

RN resistor (CP)

RD1/2Y2KΩJ

RD resistor

RD1/2Y1.3KΩJ

RD resistor

MSF1/2B0.51ΩJ

RS resistor

MRM-8-332JA

Block resistor

MRM-8-104JA

Block resistor

CC2012CH1H100D 50V

CC capacitor (CP)

CC2012CH1H220J 50V

CC capacitor (CP)

323A5003F0204

321A1431J0202

321A1431J0132

324A1001J0518

334A3268J0332

334A3268J0104

303A3007C0100

303A3007C0220

2

1

2

3

2

1

1

5

42

C510, C511

43

C524

44

C517, C526, C533,

C534

C522

45

46

C514

47

C515, C516, C520,

C504

C501-C503, C512,

48

C513, C518, C519,

C527-C529, C532,

C535

C5, C6

49

CC2012CH1H101J 50V

CC capacitor (CP)

CC2012SL1H561J 50V

CC capacitor (CP)

CC2012SL1H102J 50V

CC capacitor (CP)

CK2012B1H102K 50V

CK capacitor (CP)

CK2012B1H152K 50V

CK capacitor (CP)

CK2012B1H103K 50V

CK capacitor (CP)

CK2012F1E104Z 25V

CK capacitor (CP)

TCK45F2E03ZYA 250V

CK capacitor 10000pF

303A3007C0101

303A3007K0561

303A3007K0102

303A6008K3102

303A6008K3152

303A6008K3103

303A6008Z2104

302A4027Z5103

2

1

4

1

1

4

12

2

- 30 -

Page 95

SDDV-PCB (Driver Board) Rev. 7

(4YA4042-1549G001 -5/7)

REF.

NO.

50

51

52

53

54

55

56

57

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C8

C3

C2

C7

C4, C12

Q501

Q3

Q1, Q2

CK92F1E105ZS 25V

CK capacitor 1µF

SXE50VB-100 50V

CE capacitor 100µF

SME100VB-3R3BP-0A

CE capacitor 3.3µF

SME25VB-10-0A 25V

CE capacitor 10µF

KMG63VB-22M 63V

CE capacitor 22µF

MSM10S0110-080GS-BK

MOS digital IC (FP)

74LS06P

BIP digital IC

LB1731-H

BIP-INF-IC

303A4117Z2105

304A1034H1101

304A1122A2339

304A1123E1100

304A1164J1220

702A4524N1082

700A0503M0006

710A2031M0002

1

1

1

1

2

1

1

2

58

59

60

61

62

63

64

65

66

LFDV

MTDV

L3

L7

L1,L2, L4-L6, L9

S501, R570

S1-S17

C11

F1, F2

MTD2005F

BIP linear IC (SO)

HA13412

BIP linear IC

DST306-55F103Z

EMI filter

RSL1513N102K/OL1614

H Coil

ZBF253D-01

Beads filter

2125JPW

Chip jumper (CP)

J1/4Z

Jumper wire

Short wire (U-shape) 0.65

P=5.0

251-002

Fuse

720A1816N0001

720A4021E0004

342A1004P2103

353A3040K0102

377A1115P1309

323A5003P0001

3211520P0001

KH-31036-50

540A2208S1202

1

1

1

1

6

2

17

1

2

- 31 -

Page 96

SDDV-PCB (Driver Board) Rev. 7

(4YA4042-1549G001 -6/7)

REF.

NO.

67

68

69

70

71

72

73

74

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

TR501, TR503

TR504

TR505

TR502

TR506

TR507

TR4

TR1

A1344/UN2111/DTA114K

PNP-HF-TR (CP)

2SA1163

PNP-HF-TR (CP)

2SC3361/2SC2412KVL

NPN-HF-TR (CP)

2SC2713

NPN-HF-TR (CP)

DTC114EKA

NPN-HF-TR (CP)

2SD1472

NPN-LF-TR (CP)

2SB740

PNP-LF-TR

2SB1225/2SB1351

PNP-LF-TR

600A1003N0003

600A1025N0033

602A1003N0002

602A1025N0050

602A1035N0005

603A1121N0007

601A1121M0004

601A1203M0003

2

1

1

1

1

1

1

1

75

76

77

78

79

80

81

82

TR3

PE

CN6

CN8

CN7

CN4

CN3

CN5

2SB1274

PNP-LF-TR

SG-206

Photo coupler

57RE-40360-730B-D29A

Square-shaped connector

TCS7588-01-201

Round-shaped connector

MCR69-30D-2.54DS

PC connector

00-8263-0412-00-000

PC connector

07FE-ST-M

PC connector

23FE-BT-VK-N

PC connector

601A1232M0004

652A0114M0003

220A1783P0360

221A1525P0080

224A1052P0300

224A3357P0040

224A4135P0070

224A4134P0230

1

1

1

1

1

1

1

1

- 32 -

Page 97

SDDV-PCB (Driver Board) Rev. 7

(4YA4042-1549G001 -7/7)

REF.

NO.

83

84

85

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

CN1, CN2

3

2

00-5062-301-020-000

PC connector

TW-VFM-20-100-B

Fuji card

TW-VFM-20-130-B

Fuji card

224A5114P0200

238A1122P0001

238A1122P0002

2

1

1

- 33 -

Page 98

Page 99

LEOP-3PCB (Operation panel) Rev. 5 & Rev. 6

(4YA4042-1516G003 -2/2)

REF.

NO.

1

R2, 3, 4-15, 17

2

R20

3

R19

4

SEL, SHIFT, LF, FF,

TEAR, PARK, QUIET,

PQ, CP

5

C1

6

D1, D2, D3-D13, D16,

D17

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

RD1/4Y150ΩJ

RD Resistor

RD1/4Y130ΩJ

RD Resistor

RD1/4Y560ΩJ

RD Resistor

SOA-113HS

Push-button Switch

TCK45F2E103ZYA 250V

CK Capacitor 10000PF

SEL3913KYZ/GL3HY47BC

LED

321A1421J0151

321A1421J0131

321A1421J0561

205A1162P1001

302A4027Z5103

650A0203M0001

14

1

1

9

1

14

10

11

7

D3

IC1

8

S1-S24

9

CN1

2

SEL3213C/GL3HD47/LED

BU5148S

MOS Digital IC

0.65 Tin-plated annealed Copper

Wire

00-5062-301-007-000

PC Connector

TW-VF-7-70-B-R

Toku-Juji Card

650A0103M0001

702A4733M0001

TA-0.65

224A5114P0070

238A1120P0001

1

1

24

1

1

- 35 -

Page 100

Loading...

Loading...