Page 1

TF-300P

Field Service Manual

Ver. 02

July 8, 1999

TTIC

I

Page 2

Index

1. INTRODUCTION 1-1

1.1 STANDARD SPECIFICATIONS 1-1

1.2 GENERAL USER FUNCTION 1-6

1.3 GENERAL APPEARANCE 1-7

1.3.1 APPEARANCE 1-7

1.3.2 SHOW THE OPERATION PANEL 1-7

1.4 GENERAL MAINTENANCE FUNCTION 1-8

2. INSTALLATIONS 1-1

2.1 GENERAL 1-1

2.2 SITE SELECTION 1-2

2.3 UNPACKING 1-2

2.4 CHECK OF CONTENTS 1-3

2.5 INSTALLATION OF ATTACHMENTS 1-3

2.5.1 CARTRIDGE AND SIM CARD 1-3

2.5.2 HANDSET AND LINE CORD 1-3

2.5.3 AC CORD CONNECTION 1-4

2.5.4 LOADING PAPER 1-5

3. MAINTENANCE 3-1

3.1 ROUTINE INSPECTION 3-1

4. SYSTEM TEST 4-1

5. MECHANICAL DISASSEMBLY AND REASSEMBLY 5-1

5.1 GENERAL 5-1

5.1.1 PRECAUTIONS PARTS REPLACEMENT 5-1

5.1.2 TOOLS 5-1

5.2 GENERAL MECHANICAL STRUCTURE 5-2

5.3 HOW TO DISASSEMBLE AND REASSEMBLE 5-3

5.3.1 INSTALLING THE INK CARTRIDGE AND SIM CARD 5-3

5.3.2 AC PLUG, HANDSET AND DOC. SUPPORT 5-3

5.3.3 BOTTOM PLATE UNIT 5-3

5.3.4 SIM CARD HOLDER ASSEMBLY 5-4

5.3.5 SCANNER MODE UNIT 5-4

II

Page 3

5.3.6 SCANNER MODE ASM. 5-5

5.3.7 SCANNER UNIT 5-5

5.3.8 LOWER FRAME UNIT 5-5

5.3.9 UPPER FRAME UNIT. 5-6

5.3.10 DOCUMENT GUIDE ASSEMBLY 5-7

5.3.11 OPERATION PANEL UNIT 5-7

5.3.12 UPPER COVER UNIT 5-8

5.3.13 PRINTER MODE UNIT 5-8

5.3.14 PRINTER MODE ASM. 5-8

5.3.15 PAPER FEEDER UNIT 5-9

5.3.16 BASE FRAME UNIT 5-10

5.3.17 BOTTOM COVER UNIT 5-11

6. CIRCUIT DESCRIPTION 6-1

6.1 MAIN BOARD CIRCUIT 6-1

6.1.1 BLOCK DIAGRAM 6-1

6.1.2 INTEGRATED FAX CONTROLLER 6-1

6.1.3 SCANNER CONTROLLER 6-11

6.1.4 MOTOR DRIVERS 6-11

6.1.5 SWITCH AND SENSORS 6-11

6.1.6 BATTERY AND POWER DOWN RESET 6-11

6.1.7 FAX MODEM CIRCUIT 6-11

6.1.8 MEMORY 6-16

6.1.9 NETWORK INTERFACE 6-16

6.1.10 PANEL INTERFACE 6-16

6.2 PRINTER BOARD CIRCUIT DESCRIPTION 6-16

6.2.1 PRINTER BOARD TO INKJET HEAD INTERFACE 6-16

6.2.2 PAPER & CARRIAGE MOTOR 6-16

6.2.3 SENSORS & HOST CONNECTOR 6-16

6.2.4 PRINTER HEAD SUPPLY DETECT 6-16

6.2.5 MICROPROCESSOR AND MEMORY 6-16

6.3 KEY BOARD CIRCUIT DESCRIPTION 6-17

6.4 SIMCRAD BOARD CIRCUIT DESCRIPTION 6-17

6.5 NCU CIRCUIT DIAGRAM DESCRIPTION 6-17

6.5.1 GENERAL FUNCTIONS OF NCU (NETWORK CONTROL UNIT) CIRCUIT 6-17

6.5.2 DIALLING METHOD 6-17

6.5.3 RINGING DETECTION 6-18

6.5.4 FAX MESSAGE RECEIVING 6-18

III

Page 4

6.5.5 FAX MESSAGE TRANSMITTING 6-18

6.5.6 BUILT-IN HANDSET AND SERIAL EQUIPMENT DETECTION 6-18

6.6 TELEPHONE CIRCUIT DIAGRAM DESCRIPTION 6-18

6.6.1 GENERAL FUNCTIONS OF TELEPHONE CIRCUIT 6-18

6.6.2 TELEPHONE IC AS2534 GENERAL DESCRIPTION 6-18

6.6.3 RINGING 6-19

6.6.4 DTMF DIALLING 6-19

6.6.5 PULSE DIALLING 6-19

6.6.6 SPEECH MODE 6-19

6.7 POWER SUPPLY DESCRIPTION 6-20

6.7.1 INPUT SPECIFICATION 6-20

6.7.2 OUTPUT SPECIFICATION 6-20

6.7.3 GENERAL FEATURE 6-21

6.7.4 ENVIRONMENT SPECIFICATION 6-21

6.7.5 INTERNATIONAL STANDARDS 6-22

7. TROUBLESHOOTING 7-1

7.1 LCD FAILS TO DISPLAY AFTER POWER ON 7-1

7.2 HALF OF LCD DISPLAY FULL BLACK AFTER POWER ON 7-2

7.3 LCD DISPLAY NORMAL ON STARTING BUT KEY FAILED 7-3

7.4 TIME DISPLAY ABNORMAL 7-4

7.5 IT WORKS PRESSING KEY BUT SPEAKER REMAINS MUTE 7-5

7.6 RESET ON STARTING 7-6

7.7 LCD DISPLAY “NO PAPER” WHILE RECORDING PAPER IS LOADED 7-7

7.8 C.I.S. MOTOR REMAINS MOTIONLESS 7-8

7.9 FAILED TO FEED DOCUMENT 7-9

7.10 OVER FEEDING DOCUMENT UNTIL “DOCUMENT JAM” 7-9

7.11 COPY QUALITY IS TOO BRIGHT 7-10

7.12 FAILED TO TRANSMIT SUCCESSFULLY 7-10

7.13 FAILED TO RECEIVE SUCCESSFULLY 7-11

7.14 PRINTER ENGINE OFF 7-11

7.15 PRINTER ACTS FAILED 7-12

7.16 CERTAIN BLOCKS FAILED IN PRINTING 7-12

7.17 COPY ALL BLACK 7-13

7.18 ALL WHITE PRINTING 7-14

7.19 PRINTING OR COPYING ERROR DATA 7-14

7.20 PRINTER CAN’ T INITIAL 7-15

7.21 CARRIAGE MOTOR REMAINS MOTIONLESS 7-16

IV

Page 5

7.22 LINE FEED MOTOR REMAINS MOTIONLESS 7-17

7.23 P

7.24 SIMCARD I

7.25 T

7.26 NCU/TEL B

RINTING WITH LINE LOST 7-17

NVALID 7-18

ROUBLE SHOOTING FAX MECHANICAL PROBLEM 7-19

OARD TROUBLE SHOOTING 7-22

7.26.1 R

7.26.2 D

7.26.3 H

INGING 7-22

IALLING 7-22

ANDSET FUNCTION 7-22

8. PART LIST 8-1

8.1 MAIN BOARD PART LIST 8-1

8.2 K

8.3 P

8.4 SIMCARD B

8.5 NCU B

8.6 P

EY BOARD PART LIST 8-4

RINT BOARD PART LIST 8-5

OARD PART LIST 8-6

OARD PART LIST 8-6

OWER SUPPLY PART LIST 8-13

9. MECHENICAL DRAWING AND PARTS LIST 9-1

10. CIRCUIT DRAWING 10-1

V

Page 6

1. INTRODUCTION

Coding method

ECM ON

12 sec

(Option)

ECM ON

8sec

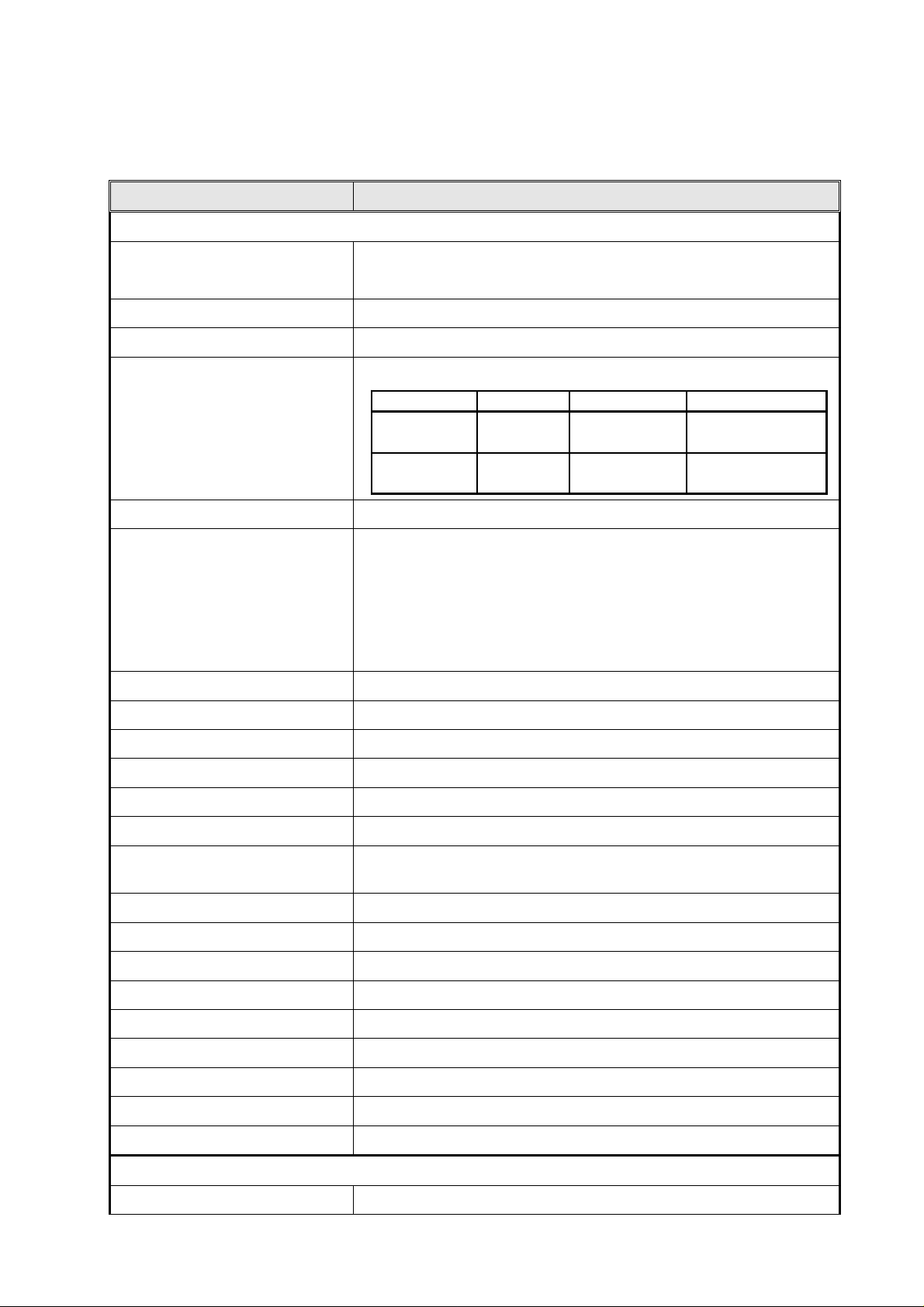

1.1 Standard Specifications

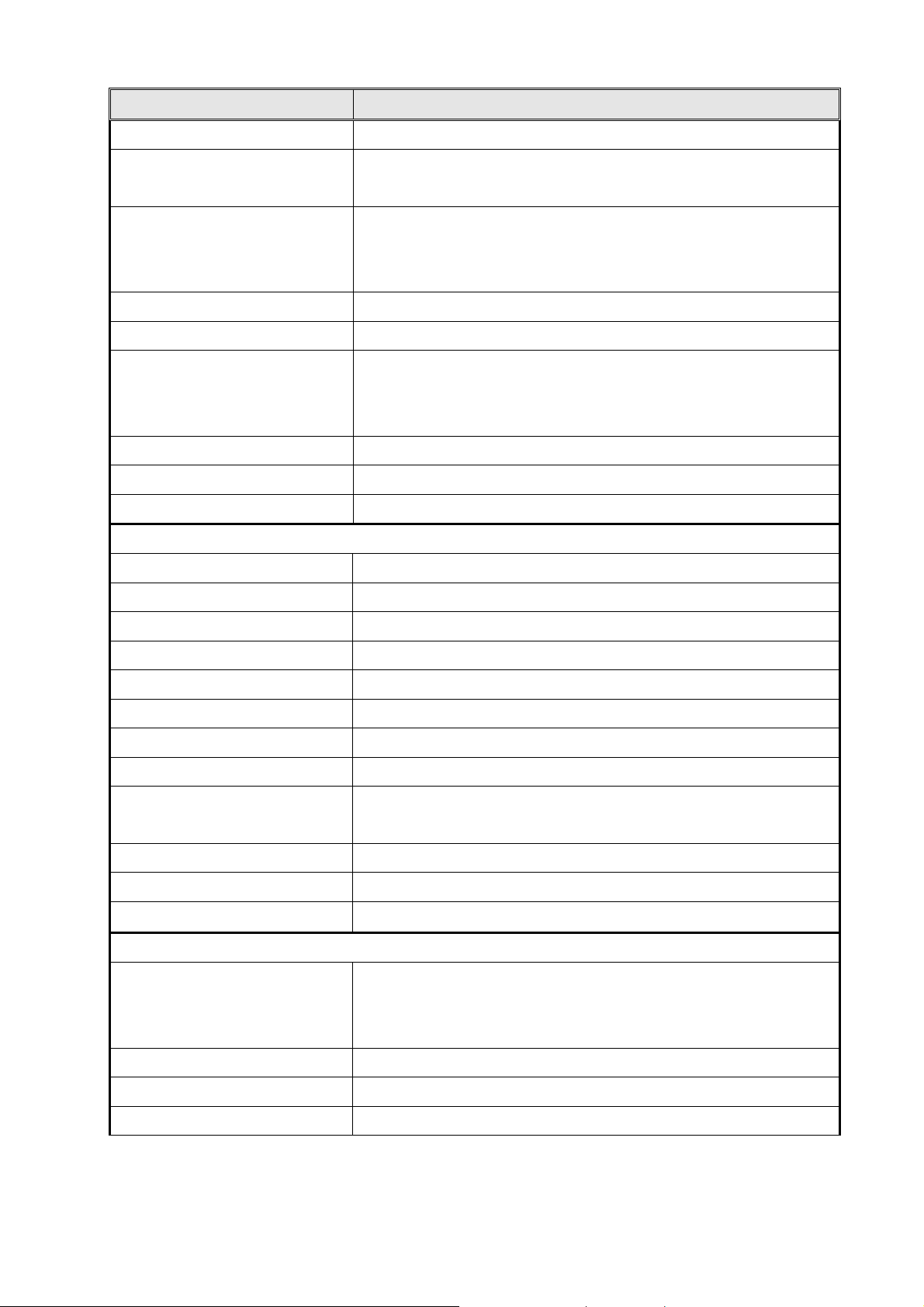

ITEM SPECFICATION

1. General

(1) Type Desk Top Transceiver

Copier

(2) Line PSTN or PABX

(3) Compatibility ITU-T G3

(4) Communication Time Depends on What FAX Engine is selected

Controller Modem

MH: ECM OFF

FC-200 R96DFXL

FC-200M

R144EFXL

(5) LCD 1 × 16

(6) Key Number 32

CCITT key×12 Start Key×1 Stop×1

Function key×1 Redial / Pause×1 Receive Mode key×1

On Hook key×1 One-touch×9 Directory×1

Resolution×1 Recall/Access×1 Cursor×2 (← →)

(7) LED Number 3 (Alarm, Memory, Hook)

(8) Auto Dial Alpha-Search, One-touch, Redial

(9) Automatic Reception Yes

(10) Coding MH/MR/MMR (Option)

(11) ECM User setting for the ON/OFF selection (Option)

(12) Polling Free / Password

MR: ECM OFF

Time

18 sec

10~12 sec

(13) Timer Transmission When there are any transmission files pending in memory, no more

timer transmission can be reserved. (24hrs)

(14) Multi-Copy Up to 50

(15) TTI Inside/Off Date/Time/ID/Name/Page

(16) Languages 3, Any combination

(17) TAD Interface Yes (CNG detection in idle mode)

(18) Buitl-inTAM Only for TF-300PT

(19) SIM CARD Interface Yes

(20) Distinctive Ringing Yes

(21) Parallel Fax pick-up Yes

(22) Caller ID (Option)

2. Scanner Section

(1) Scanning Method CIS

1-1

Page 7

ITEM SPECFICATION

(2) ADF 5 pages (Multi 0.07-0.12 mm / Single 0.06-0.15 mm)

(3) Document A4/Letter

Min. Length 200 mm / Max. Length 600 mm

(4) Resolution Horizontal: 8 dots/mm

Vertical: 7.7 (Photo) l/mm

Vertical: 3.85 (Std), 7.7 (Fine) l/mm

(5) Grey Scale 64 Levels (Error Diffusion)

(6) Auto Background Control Yes

(7) Contrast Light/Normal/Dark (User Selectable)

LIGHT for dark original

DARK for Light original

(8) Document Orientation Face down

(9) Effective Scan Width 210mm

(10) Scanning Speed 20 ms/line

3. Printer Section

(1) Printer Method Ink-jet (HP solution)

(2) Paper Orientation Face Up Print

(3) Resolution 300dpi × 200dpi (Vertical 5 Horizontal)

(4) Recording Paper Pre-cut Plain Paper (A4 / Letter)

(5) Paper Width 216 mm (max)

(6) Recording Width 203 mm

(7) Printable Area Top –4mm/Bottom –7mm /Left and Right side –3mm

(8) Paper Cassette 50 sheets (90g A4)

(9) Inkjet Cartridge 1700 pages (ITU Chart #1) (40cc Pen Cartridge)

850 pages (ITU Chart #1) (20cc Pen Cartridge)

(10) Printing Speed 2 pages/min

(11) Reduction Selectable for user (100, 94, 86, 79%)

(12) Print Density

4. Dialling

(1) Alpha Dialling 20 Locations (40 digit numbers / 20 char. Tel + Fax NR)

OD 1.2 ¡Ó0.2

W/doc. or polling operationà Fax number to be chosen.

W/O doc. and “non-polling” operationà Tel number to be chosen.

(2) One Touch 9 Locations

(3) Group Dialling No

(4) Manual Redial Last No. Dialled

1-2

Page 8

ITEM SPECFICATION

(5) Automatic Redial Redial Countà selectable by the service parameter (1 to 9)

Redial Interval à selectable by the service parameter (1 to 5min)

Redial Conditionà busy tone detection

(6) Dialling DTMF(Pulse Optional)

(7) PABX-> PSTN Access YES (Digit / Flash) (Earth optional)

5. Telephone Features

(1) Built-in Handset Yes

(2) Monitor Speaker Yes

(3) Handsfree Talking No

(4) On-Hook Dialling Yes

(5) Volume Control On-line adjustment (4 levels), automatically fallback to default

value when the call is finished. (Speaker and internal ring signal)

(6) Tel/Fax Switch Yes

(7) Power Off Dial Ten key dial (Option)

(8) Recall Function YES (long or short Flash = fixed by FW) (Earth Option)

(9) Ringer Volume Control YES (ON/OFF only)

(10) Confidence Tone Option

6. Communication

(1) Transmit Level 0dBm to –15dBm

(2) Reception Levels

T.30 Reception

Other Signal

(3) Mo dem Recommendation V29, V27ter, V21 for R96DFXL (Basic)

7. Report/Lists

(1) Activity Report 40 Transactions (On/Off)

(2) Tx/Rx Confirmation Report Yes (On/Off/Error)

(3) Phone Book Alpha dial and One Touch dial printed on different pages.

(4) User Options / Setup Yes

(5) Callback Message No

(6) Service Options / Setup Yes

0 dBm to –43 dBm

-5 dBm to –43 dBm

V29, V27ter, V21, V17 for R144EFXL (option)

(7) Power Failure Report When power-failure happens during the following conditions,

“Power Failure Report” will be printed after power-on.

a) XMTing (ADF or Memory)

b) Redial Waiting

c) Delay XMT pending

d) RCVing

e) Memory Reception file pending

1-3

Page 9

ITEM SPECFICATION

8. Image Memory

(1) Memory Transmission Delayed transmission and “To be Polled” goes through memory.

(2) Memory Reception All reception goes through memory.

Multiple files are possible for memory reception.

When there is no paper, received data is stored into memory and

printing starts whenever paper is set.

(3) Image Memory 512Kbyte D-RAM (20 pages ITU#1) for Non ECM Version

1 MByte – 128 Kbyte for ECM Version

9. Others

(1) Self-diagnosis Yes

(2) Test Mode Yes

(3) Backup Memory SRAM &

RTC

10. Design

(1) Dimensions

(2) Weight 4.7 kg

(3) Power Consumption Max. 9 W (standby)

(4) AC Input 100~240V ± 10%, 50/60Hz

(5) Electro-Static Discharge 8KV (no Malfunction)

(6) Temperature

Operation

Storage

Transfer

(7) Humidity

Operation

Yes (rechargeable NiMH-Battery)

360(L) × 294(D) × 204(H) mm

Max. 40W (all-black)

16KV (no Damage)

15~35ºC

-30~60ºC

-30~60ºC

20~80% R.H

Storage

Transfer

(8) Reliability

MTBF

MTTR

Machine Life

(9) Audible Noise < 55dBA (ISO7779)

(10) Safety Standards USA + CANADA + EUROPE (CE and CB)

(11) EMI Standard EN55022 / VDE 0878 part 1/2/30 + USA + CANADA

20~80% R.H

20~80% R.H

30,000hrs Hours power on (20RX / 20TX / 10 Copy per day)

30 mins

60,000 sheets

1-4

Page 10

(12) CE Mark

ITEM SPECFICATION

EMC

Safety/Low Voltage

11. Accessories

(1) Handset & Cord Yes

(2) Line Cord Yes

(3) Power Cord Yes

(4) User Guide Yes

(5) Ink Cartridge Mono with SIM Card

89/336/EEC (EN5008101, EN50081-2)

93/68/EEC

1-5

Page 11

1.2 General User Function

(1) Auto dial One-touch key: (9 locations)

Alphabetic-search dial: (20 locations)

(2) Manual dial Keypad dial

(3) Receive mode AUTO receive mode

Manual receive mode

TEL/FAX automatic switchover

TAD/FAX automatic switchover

(4) Automatic redial

(5) Last number redial

(6) PHOTO mode

(7) Voice request

(8) Multi-copy

(9) Delay transmission

(10) Polling transmission

(11) Polling reception

(12) Sender identification (Sender ID)

(13) Line monitor

(14) Reports Message confirmation (single location)

Activity report

Function list

Phone Book

Configuration

Power Failure Report

Low/No Ink Report

1-6

Page 12

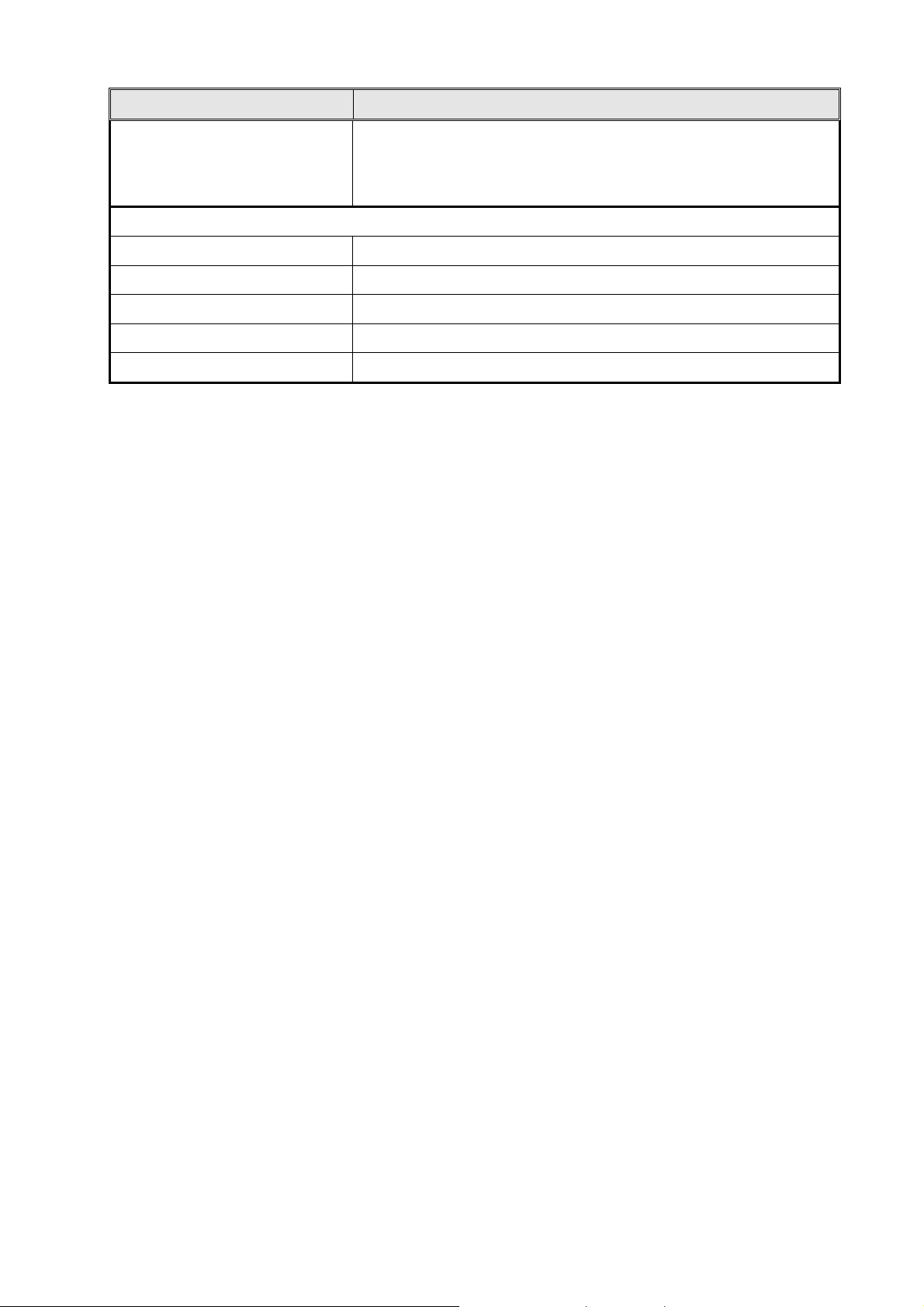

1.3 General Appearance

1.3.1 Appearance

1.3.2 Show the operation panel

1-7

Page 13

1.4 General Maintenance Function

- Self-diagnosis

(1) ROM VERSION

(2) PRINT TEST

(3) CHKSUM DISPLY

(4) LED TEST

(5) KEY TEST

(6) LCD TEST

(7) SENSOR TEST

(8) CCD Calibration

1-8

Page 14

2. INSTALLATIONS

2.1 General

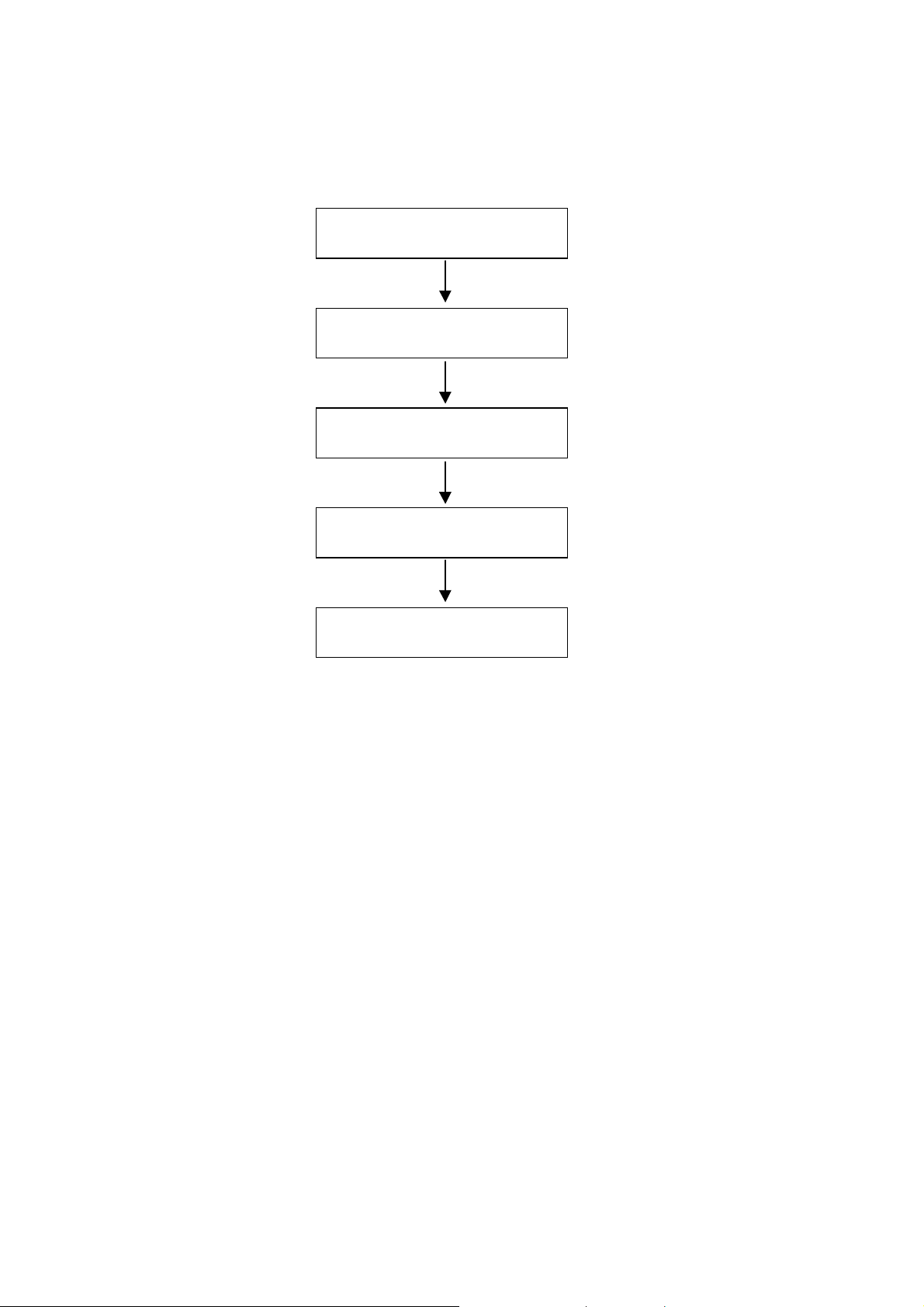

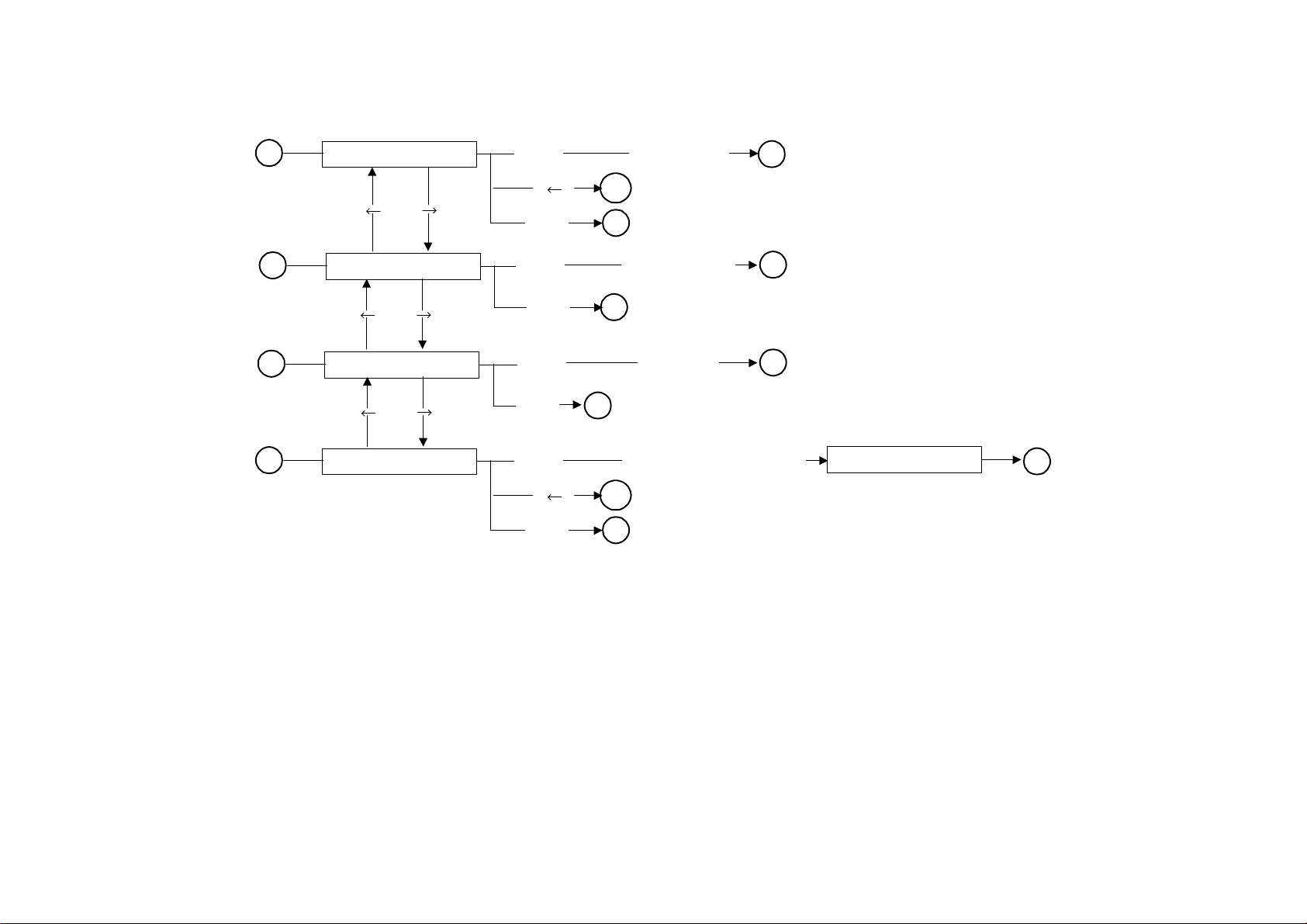

The following flowchart outlines the installation procedure.

Site selection (see 2.2)

Unpacking (see 2.3)

Check of contents (see 2.4)

Installation of attachments (see 2.5)

Initial setting

1-1

Page 15

2.2 Site Selection

The installation site

l Shall be free from outside vibrations, dust, etc.

l Shall not be directly exposed to sunlight and sudden changes in temperature.

l Must be horizontal and flat.

l Should have enough space in front of FAX machine to allow recording paper and

documents to be stacked;

l Shall not have any large, electrical noise-producing machine nearby.

2.3 Unpacking

(1) Open the top cover of the cardboard box.

(2) Take out the machine with Styrofoam from the box.

(3) Take out the machine with plastic wrapper from the box.

1-2

Page 16

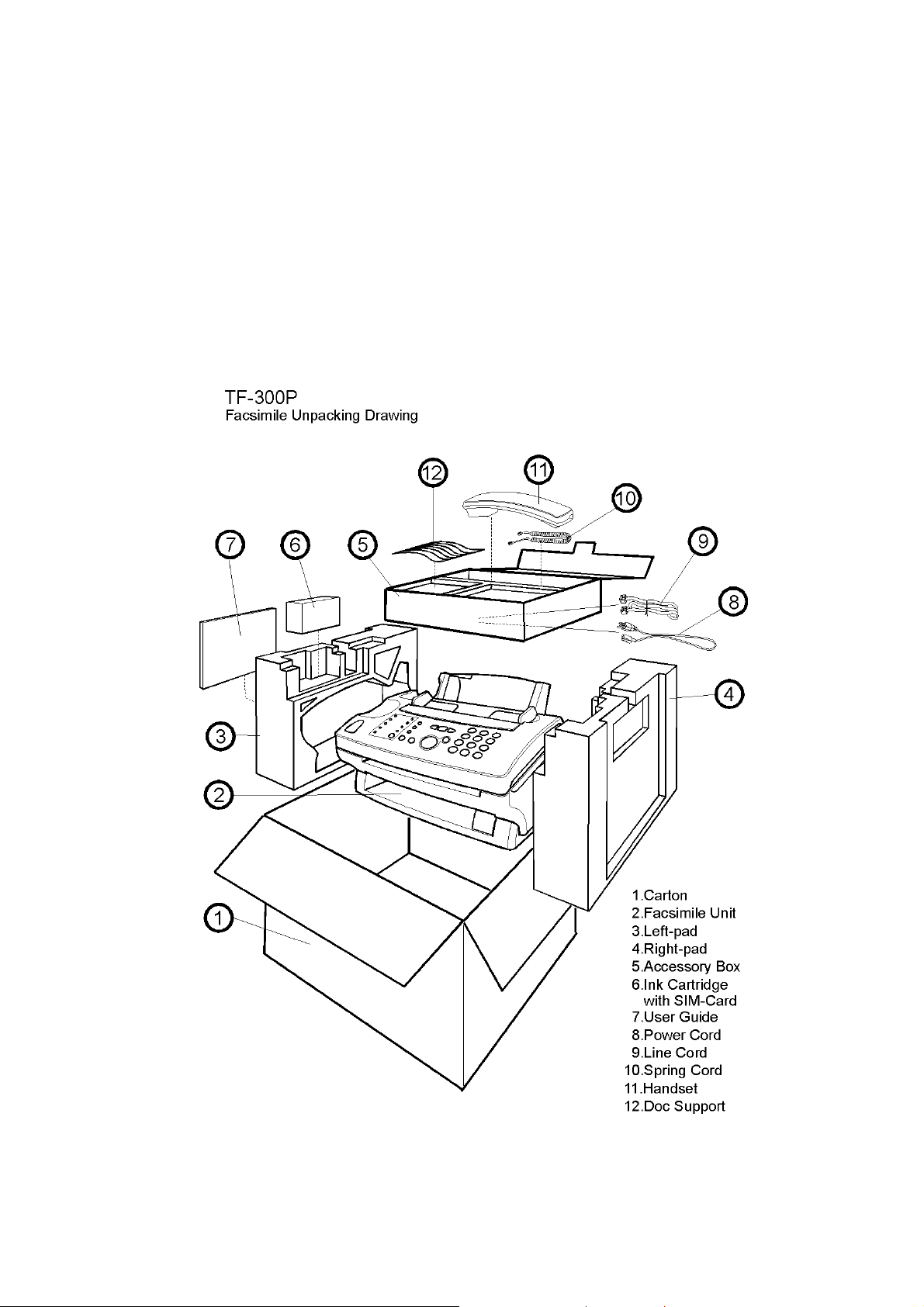

2.4 Check of Contents

After having taken out the machine and accompanied accessories from the cardboard box,

check the contents according to the following list:

(1) FAX machine

(2) Handset and Spring cord

(3) Documents Support

(4) AC cord

(5) Line cord

(6) User manual

(7) Ink Cartridge and SIM Card

2.5 Installation of Attachments

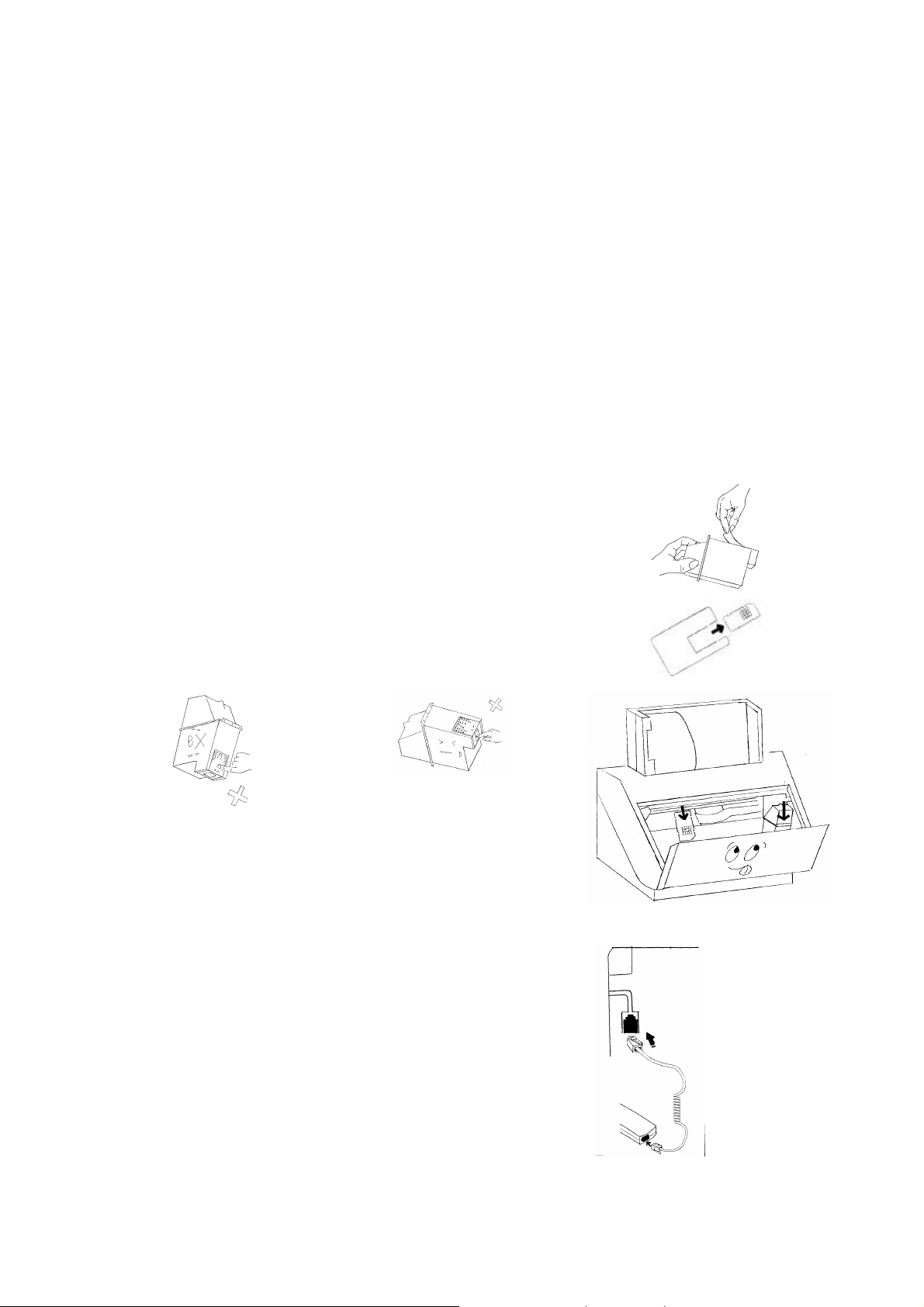

2.5.1 Cartridge and SIM Card

(1) Open the front cover.

(2) Remove the sealing tape from the printer head.

(3) Slide the cartridge in place.

(4) Push the lever up to lock the cartridge in position.

(5) Insert the new SIM card.

(6) Close the front cover properly using both hands.

¡¯ Avoid touching the nozzles and the electrical

contacts.

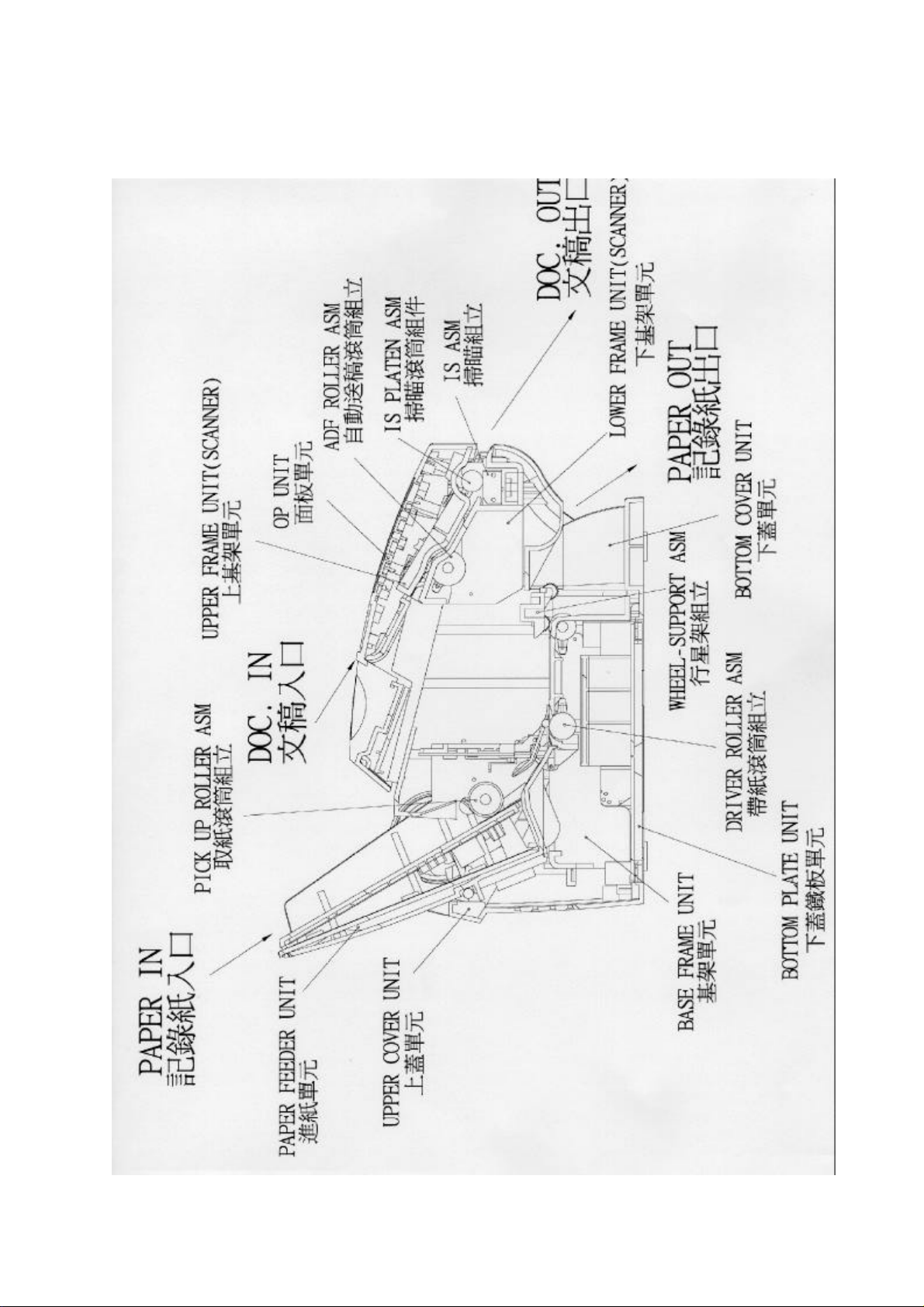

2.5.2 Handset and Line Cord

(1) Insert the handset cord into the socket upon the handset

and the other end into the socket on the base of the

facsimile.

(2) Plug the telephone line cord into the main unit.

(3) Connect the telephone or answering machine set to TEL

jack.

(4) Place handset on top of facsimile and slide the document

support into the holes on the cover of the facsimile.

(5) Plug in power cord and use the supplied cable to connect

the facsimile. (See 2.5.3)

1-3

Page 17

J After power on, the LCD will display the INITIALIZING for a period of time. This time

is used to clean the cartridge and warm up the printer.Insert the paper tray by holding it in an

upright position,

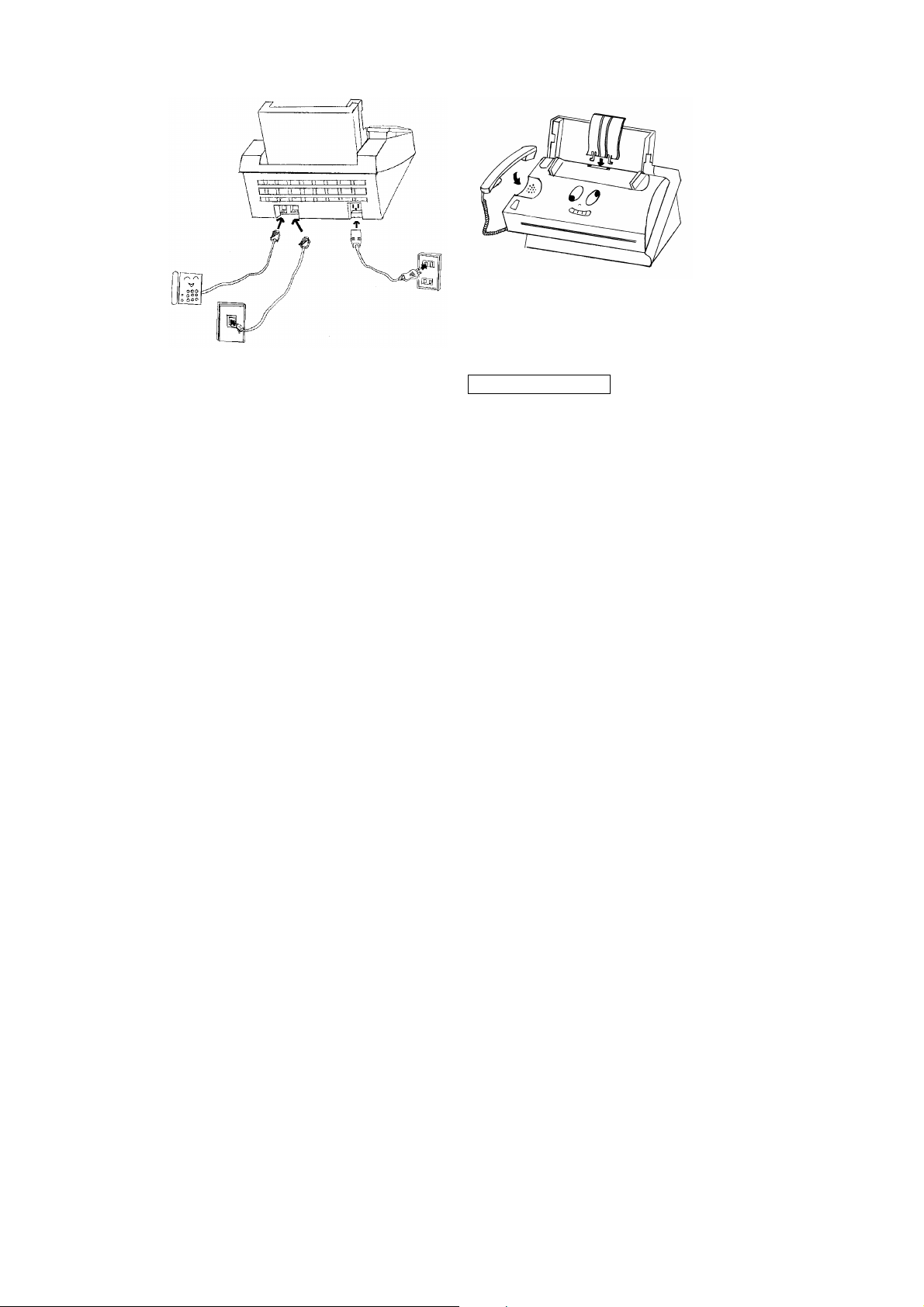

2.5.3 AC Cord Connection

(1) The power supply is provided as follows:

Voltage range 220~240 VAC, 50/60 HZ ± 3 Hz (EUROPE, AUSTRALIA)

or 100~120 VAC,50/60 Hz

(2) Check whether the voltage range of your input is within the above-mentioned voltage range

and if so, insert the mains lead into the power inlet on the back panel of the machine.

(3) Plug the main lead into a single wall outlet with a correct power supply, which is near to the

unit and is easily accessible.

(4) Check the display shows “(Date & Time)” standby mode.

1-4

Page 18

2.5.4 Loading Paper

(1) Pull out the paper support.

(2) Push the lever on the right side of paper cassette

backward.

Place the paper in the cassette so that the side you want

to print on faces you and the top of the page points

downward. Take care to keep the height of the stack below

the mark on the right side of the paper cassette.

(3) The cassette holds up to 50 sheets.

(4) Align the paper on the right side of the cassette and push it

down to the bottom.

(5) Adjust the left paper guide.

(6) Pull the lever toward the front of the machine. The paper is

held in place.

¡¯ If the machine runs out of paper during a print job, the

LCD shows ADD PAPER .

The fax will be stored in the memory and printed when

more papers are refilled.

1-5

Page 19

3. MAINTENANCE

3.1 Routine Inspection

Basically, the routine inspection of following items are performed about every one year after the

machine is installed. The description of routine inspection is shown in table 4.1.1.

Table 3-1 Routine Inspection

NO Inspection Item Procedure Remarks

1 I.S Platen Clean with ethyl alcohol.

2 A.D.F. roller Clean with ethyl alcohol.

Pick up roller Check the pick up rollers for wear.

Exit roller Clean with ethyl alcohol.

3 A.D.F. separation

rubber pad

4 Carrier Transport Check the following parts for wear:

5 Print head carrier

assembly

6 Contact Image Sensor

(C.I.S.)

7 Microswitch operation

Clean with warm or cold water.

If this rubber is worn out, replace this rubber.

·Carrier transport belt.

·Carrier guide rod.

·Idler pulley parts

Check it for a loose or worn wiper and cap.

Clean the contact of print head cable by a clean dry

cloth.

Check the following parts for wear or damage:

·Rubber Backer

·Print Cartridge Latch

·Latch Spring

·Carrier

Check it for stains of paper dust, etc.

Clean it with ethyl alcohol, if necessary.

Cover switch Confirm that the LCD shows “CLOSE COVER”.

When the paper cover opened and that message

disappears when the cover closed.

·Paper sensor

8 Lubrication Apply white grease to the motor gear and all gear

9 Cleaning Remove outside fallen materials, if any, from the

Note:

When returning all rollers to its original position, confirm that its plastic bushing of the roller

properly set into the groove of the frame unit and turn the bushing to make sure the pin point of

tab is tightly inserted to the frame surface.

The LCD shows “ADD PAPER” when runs out of

recording paper.

mounting stud when parts are replaced or as needed.

The carrier to carrier frame engagement.

machine.

3-1

Page 20

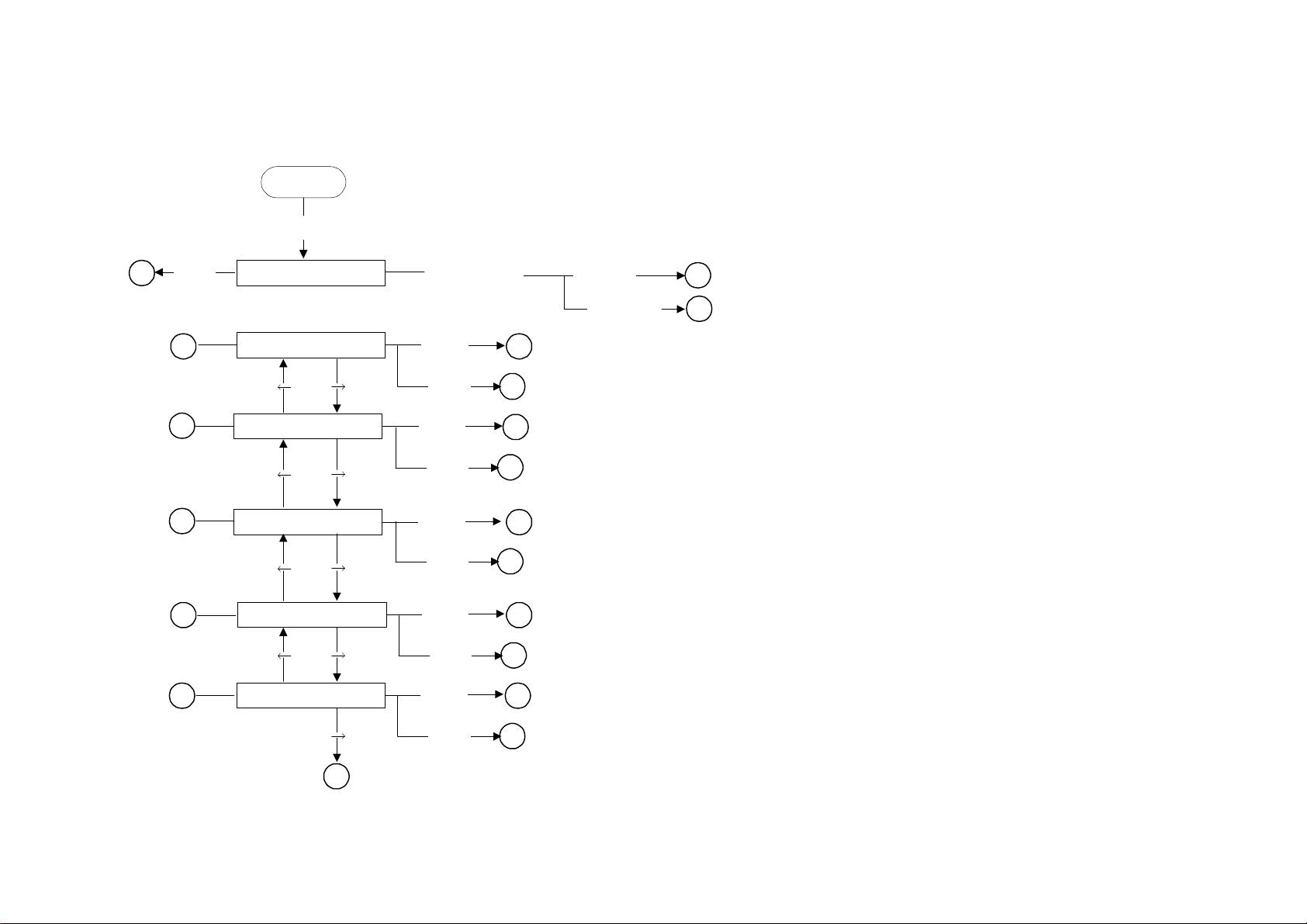

4. SYSTEM TEST

POWER ON

TURN ON THE POWER

AND PRESS FUNCTION

KEY AT THE SAME TIME

<[FUNCTION]>

PRESS AND HOLD 2 SEC

<[STOP]>

A

8.1

8.2

8.3

8.4

SYSTEM TEST

SERVICE SET

<[

<[ ]>

SERVICE LIST

<[ ]>

<[ ]>

SERVICE TEST

<[ ]>

<[ ]>

SERVICE CLEAR

PRESS 54188

<[START]>

]>

<[STOP]>

<[START]>

<[STOP]>

<[START]>

<[STOP]>

<[START]>

8.1.1

A

8.2.1

A

8.3.1

A

8.4.1

CODE ERROR

CODE CORRECT

A

8.1

<[STOP]>

<[START]>

<[STOP]>

AGAIN?

<[ ]>

<[

8.1

]>

<[ ]>

8.5

A

8.1

A

4-1

Page 21

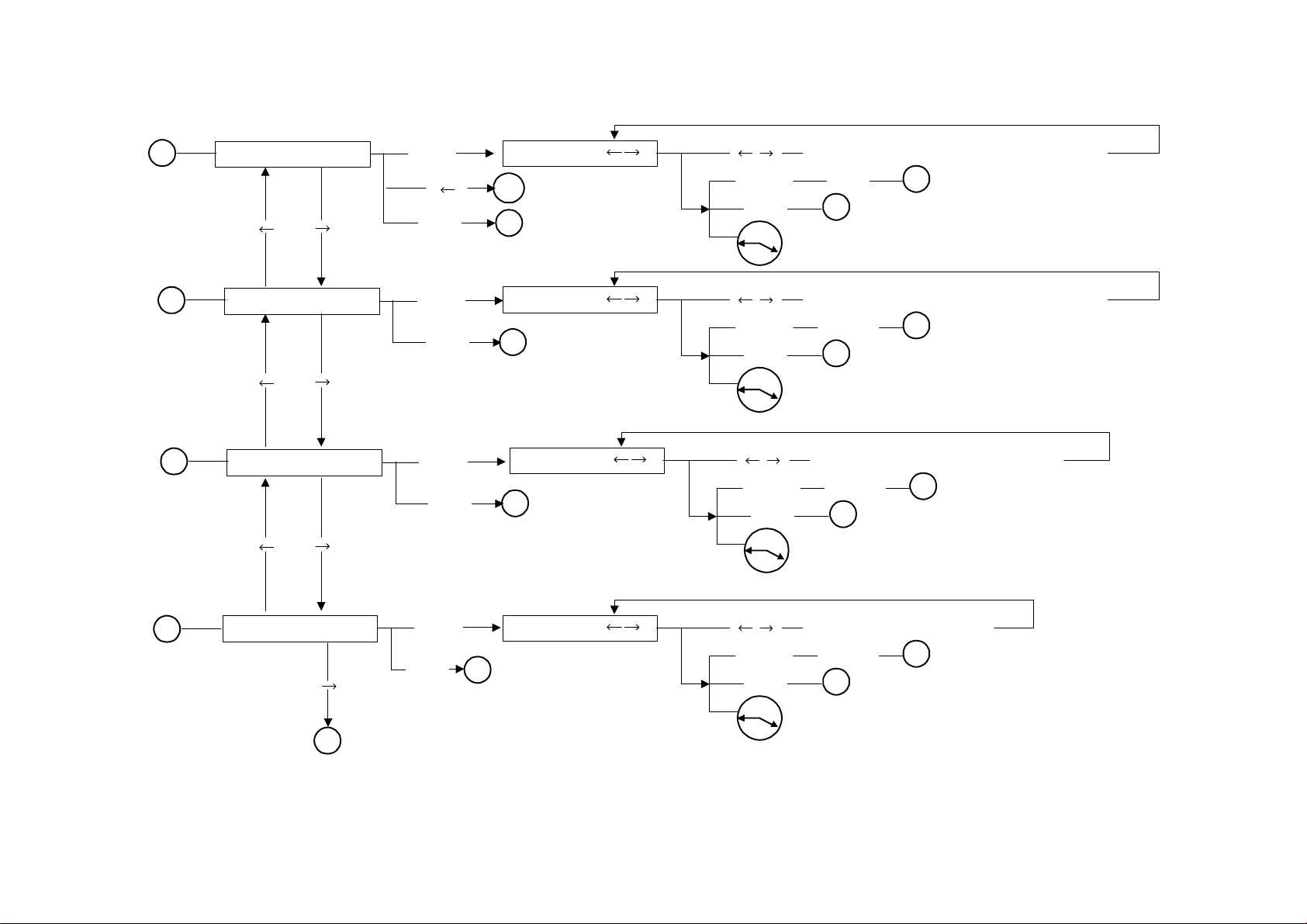

8.1.1

CLOCK FORMAT

<[ ]>

<[ ]>

<[START]>

<[ ]>

<[STOP]>

=D/M/12H [ ]

8.1.11

8.1

<[ ] [ ]>

<[START]> UPADATE

<[STOP]>

60

CHANGE DISPLAY (M/D/12H)/ (D/M/24H)/ (M/D/24H)

8.1.1

A

8.1.2

8.1.2

8.1.3

8.1.4

XMT MODEM SPEED

<[ ]>

<[ ]>

RCV MODEM SPEED

<[ ]>

<[ ]>

MODEM XMT LEVEL

<[ ]>

8.1.5

<[START]>

<[STOP]>

<[START]>

<[STOP]>

<[START]>

<[STOP]> 8.1

=9600 [ ]

8.1

=9600 [ ]

8.1

=-10 [ ]

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

CHANGE SPEED (7200) / (4800)/(2400)

UPADATE

8.1.2

8.1.3

CHANGE SPEED (7200) / (4800)/(2400)

UPADATE

8.1.3

8.1.4

CHANGE DISPLAY ( 0 ~ -15 )

UPADATE

8.1.4

8.1.5

4-2

Page 22

8.1.5

DIAL TONE CHECK

<[ ]>

<[ ]>

<[START]>

<[ ]>

<[STOP]>

=ON PBX/ON PSTN

8.1.4

8.1

<[ ] [ ]>

<[START]> UPADATE

<[STOP]>

60

A

CHANGE COMBINATION

8.1.5

8.1.6

8.1.6

8.1.7

8.1.8

BUSY TONE CHECK

<[ ]>

<[ ]>

CNG DETECT

<[ ]>

<[ ]>

CNG XMT DELAY

<[ ]>

8.1.9

<[START]>

<[STOP]>

<[START]>

<[STOP]>

<[START]>

<[STOP]> 8.1

=ON PBX/ON PSTN

8.1

=ON [ ]

8.1

=ON [ ]

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

CHANGE COMBINATION

UPADATE

8.1.6

8.1.7

CHANGE DISPLAY (ON) / (OFF)

UPADATE

8.1.7

8.1.8

CHANGE DISPLAY (ON) / (OFF)

UPADATE

8.1.8

8.1.9

4-3

Page 23

8.1.9

INT'L DIAL TONE

<[

<[

]>

]>

<[START]>

<[

<[STOP]>

=ON [ ]

]>

8.1.8

8.1

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

CHANGE DISPLAY (ON) / (OFF)

UPADATE

8.1.9

8.1.10

8.1.10

8.1.11

T.30 MONITOR

<[

<[

]>

AUTO REDIAL

<[

8.1.1

<[START]>

<[STOP]>

]>

<[START]>

]>

<[STOP]>

=ON [ ]

8.1

=1 [ ]

8.1

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

<[ ] [ ]>

<[START]>

<[STOP]>

60

A

CHANGE DISPLAY (ON) / (OFF)

UPADATE

8.1.10

8.1.11

CHANGE DISPLAY 1~9

UPADATE

8.1.11

8.1.1

4-4

Page 24

8.2.1

PRT SERVICE LIST

<[START]>

71

PRINT SERVICE LIST

8.2.2

<[STOP]>

<[ ]>

8.2.2 71

PRT TEST PATTERN

<[ ]>

<[START]>

<[STOP]>

8.2

8.2

PRINT TEST PATTERN

8.2.1

4-5

Page 25

8.3.1

SCANNER TEST

<[

<[

]>

<[START]>

<[

]>

]>

<[STOP]>

ROATE SCANNER MOTOR

5SEC THEN STOP

8.3.8

8.3

8.3.2

8.3.2

8.3.3

PRINTER TEST

<[

<[

]>

MODEM TEST

<[

8.3.4

<[START]>

]>

]>

<[STOP]>

<[START]>

<[STOP]>

ROATE PRINTER MOTOR

5SEC THEN STOP

8.3

TX TONE 1100 HZ

8.3

<[

<[

]>

TX TONE 2100HZ

<[

<[

]>

TX DTMF

8.3.3

<[START]>

<[STOP]>

]>

<[START]>

<[STOP]>

]>

<[START]>

<[STOP]>

XMTTING 1100HZ

8.3.3

XMTTING 2100HZ

8.3.3

TX DTMF=_

8.3.3

<[STOP]>

<[STOP]>

<[0~9, ¡¯, # ]>

<[STOP]>

CHANGE

DISPLAY

4-6

Page 26

8.3.4

SENSOR TEST

<[

<[

]>

<[START]>

<[

]>

]>

<[STOP]>

P, D1, D2, C =XXXX

P=PAPER SENSOR

8.3.3

D1=DOC SENSOR 1

D2=DOC SENSOR 2

C=COVER SENSOR

8.3

X=0 OR 1

<[STOP]>

SENSOR TEST END

8.3.5

8.3.5

8.3.6 <[START]>

8.3.7 <[START]>

8.3.8

KEY TEST

<[

<[

]>

]>

LED/LCD TEST

<[

<[

]>

]>

DRAM TEST

<[

<[

]>

]>

CIS CALIBRATION

<[

]>

8.3.1

<[START]>

<[STOP]>

<[STOP]>

<[STOP]>

<[START]>

<[STOP]> 8.3

PLEASE ENTER KEY

8.3

TURN ON ALL LEDS

5SEC THEN TURN OFF

8.3

WRITE DRAM AND

READ DRAM

8.3

PUT WHITE PAPER

ANY KEY IN

<[STOP]>

DISPLAY ASCII CHARACTERS

CONTUNUOUSLY

OK

NG

<INSERT PAPER>

DRAM TEST OK

DRAM TEST NG

X PRESSED

STOP PRESSED KEY TEST END

LED/LCD TEST END

8.3.7

8.3.8

DOCUMENT IN CIS CALIBRATED

8.3.6

8.3.1

4-7

Page 27

8.4.1

USER OPTION

<[START]>

RESET USER OPTION

TO DEFAULT VALUE

8.4.2

8.4.2

8.4.3

8.4.4

<[ ]>

<[ ]>

SERVICE OPTION

<[ ]>

<[ ]>

DRAM

<[ ]>

<[ ]>

ALL RAM

<[ ]>

<[STOP]>

<[START]>

<[STOP]>

<[START]>

<[STOP]>

<[START]>

<[ ]>

<[STOP]>

8.4.4

8.4

RESET SERVICE OPTION

TO DEFAULT VALUE

8.4

INITIALEZE DRAM

8.4

RESET USER OPTION, SERVICE OPTION

TO DEFAULT VALUE & INITIALIZE DRAM

8.4.1

8.4

8.4.3

8.4.4

MEMORY CLEAR

8.4.1

4-8

Page 28

5. MECHANICAL DISASSEMBLY AND REASSEMBLY

This chapter explains the procedures for replacement of parts, assembles and units in the field.

5.1 General

5.1.1 PRECAUTIONS PARTS REPLACEMENT

(1) Before starting disassembly and re-assembly, always turn the AC power switch OFF, and pull

out the AC plug.

(2) Since screws, small parts are likely to be lost, they should temporarily be attached to their

original positions.

(3) When handing items such as circuit boards, do not wear gloves that are likely to generate

static electricity.

(4) Do not place printed circuit boards directly on the equipment or on the floor.

5.1.2 TOOLS

The table shows the tools required for replacement of parts such as circuit boards and

mechanical units.

ITEM SERVICE TOOLS TYPE Q’TY REMARKS

1 PHILIPS SCREWDRIVER (L) RUBICON 107 1 M3 SCREW

2 PHILIPS SCREWDRIVER (M) RUBICON 102 1 M2.6 SCREW

3 PHILIPS SCREWDRIVER (S) RUBICON 104 1 M2.3 SCREW

4 STRAIGHT SCREWDRIVER RUBICON 101 1 E RING

5 RADIO PLIERS 1

6 CUTTING PLIERS 4” 1

7 MULTIMETER 1 SHORT-

CIRCUIT TEST

8 DIGITAL STORAGE

OSCILLOSCOPE 100MHZ(UP)

9 OFFSET TYPE SCREWDRIVER NO.2 1

1

5-1

Page 29

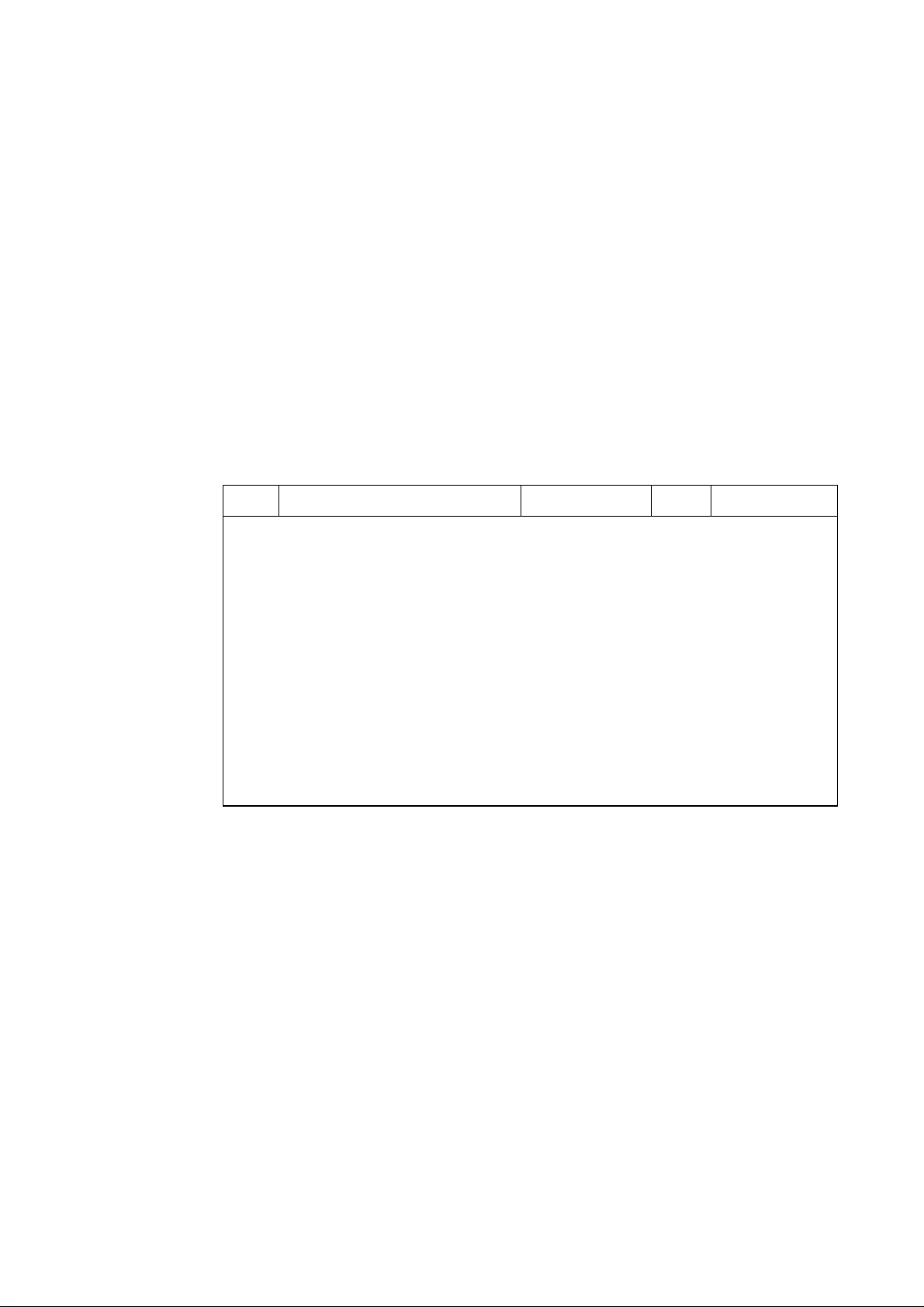

5.2 General Mechanical Structure

The general mechanical structure of the FAX machine is shown:

5-2

Page 30

5.3 How to Disassemble and Reassemble

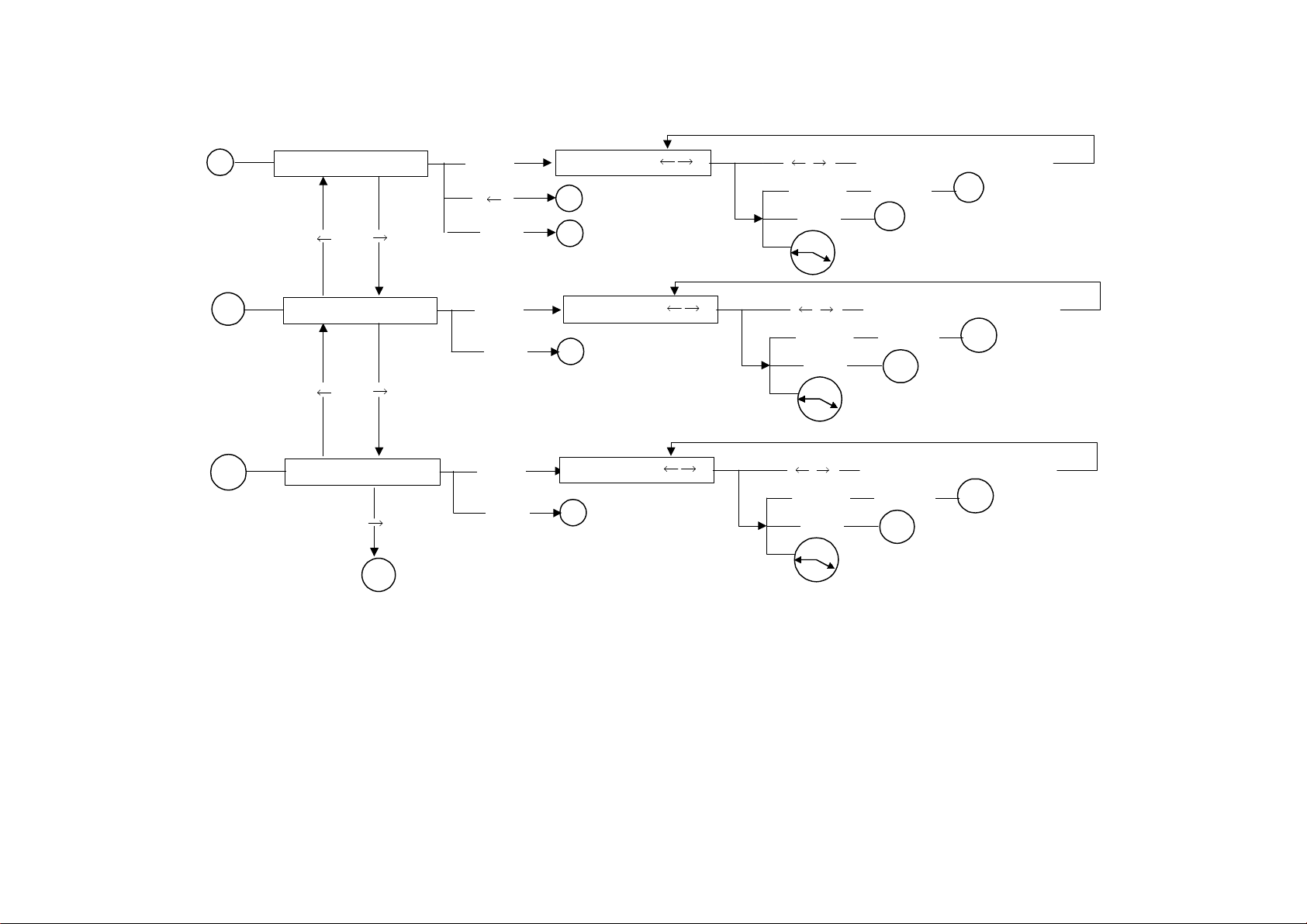

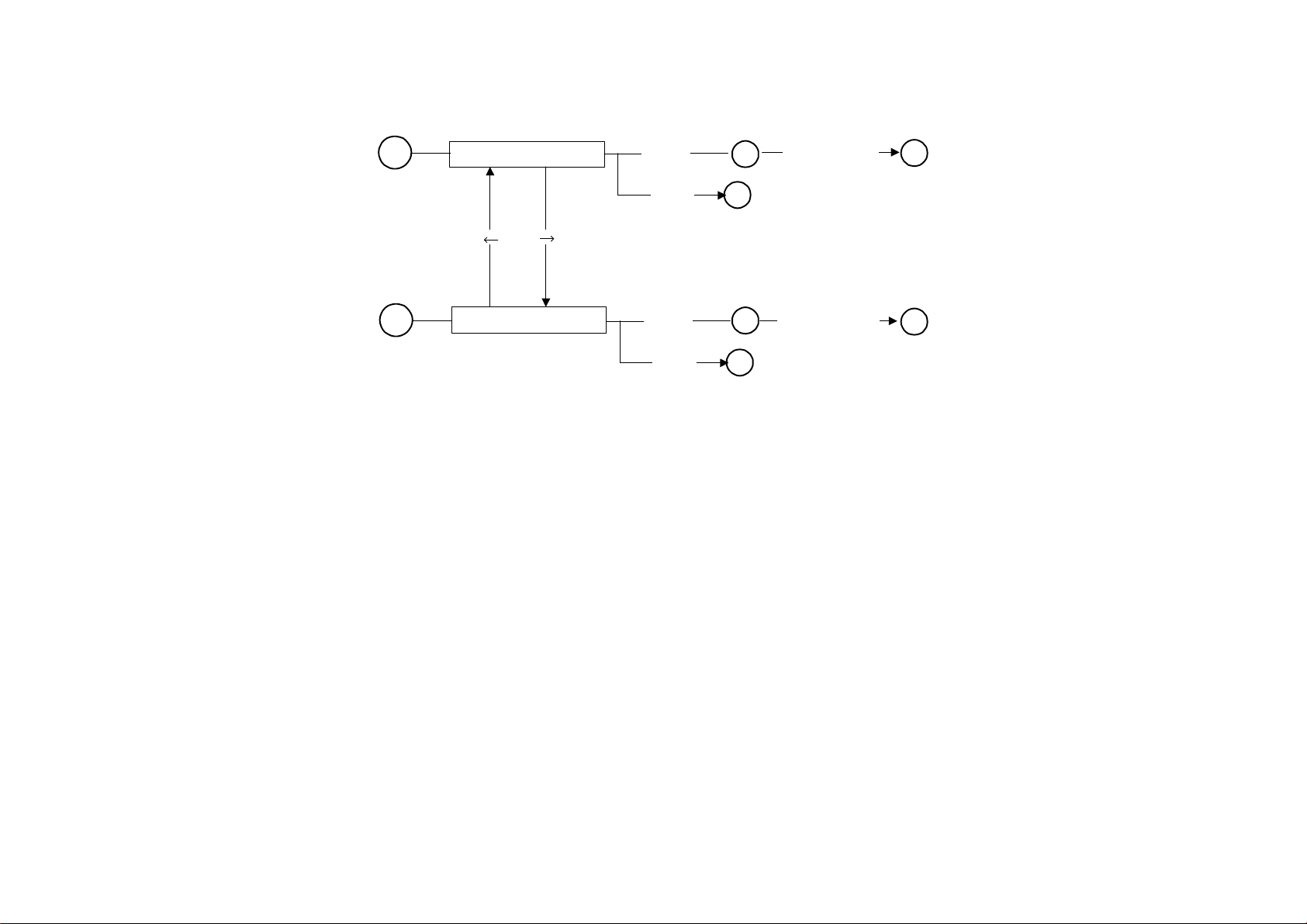

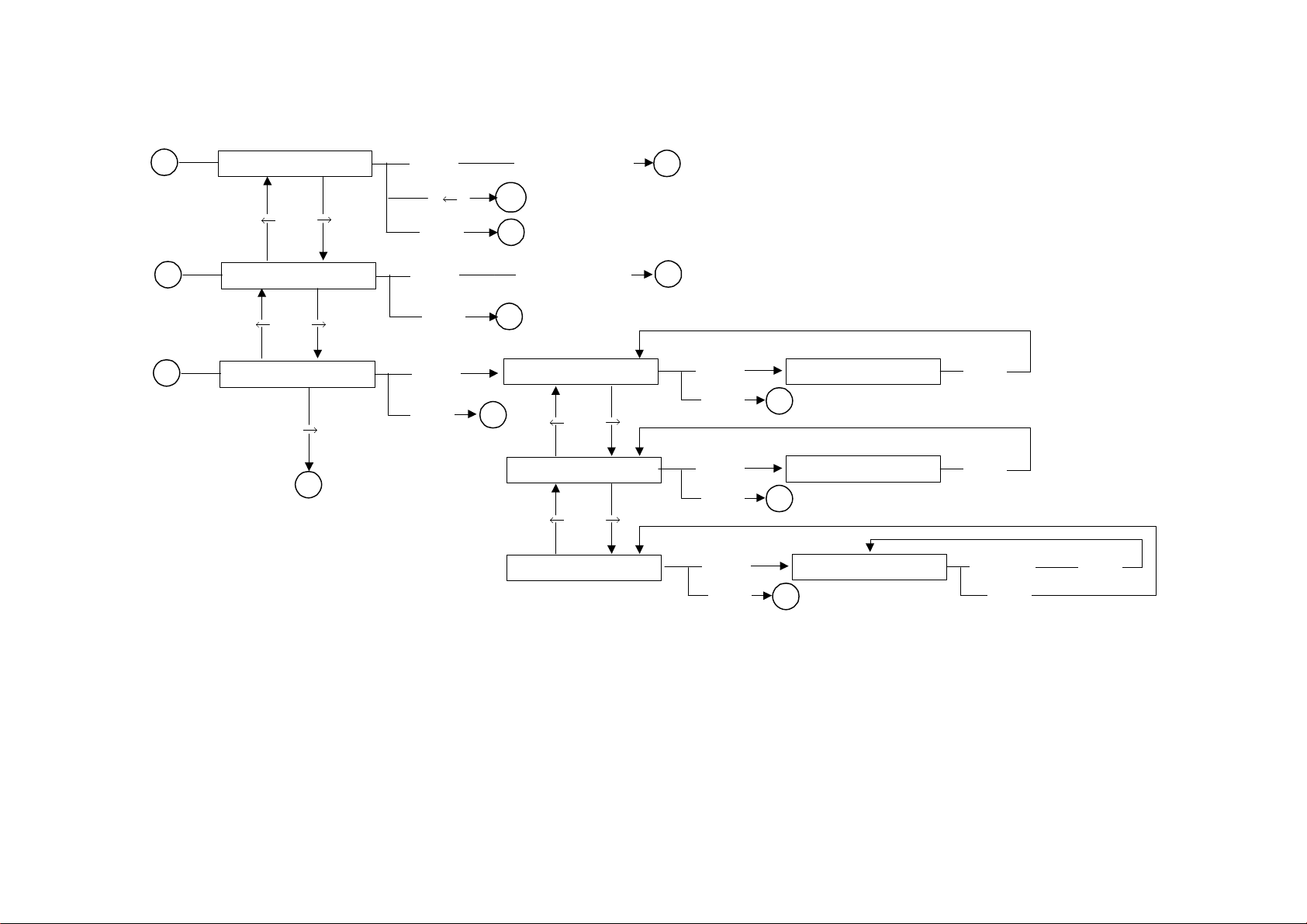

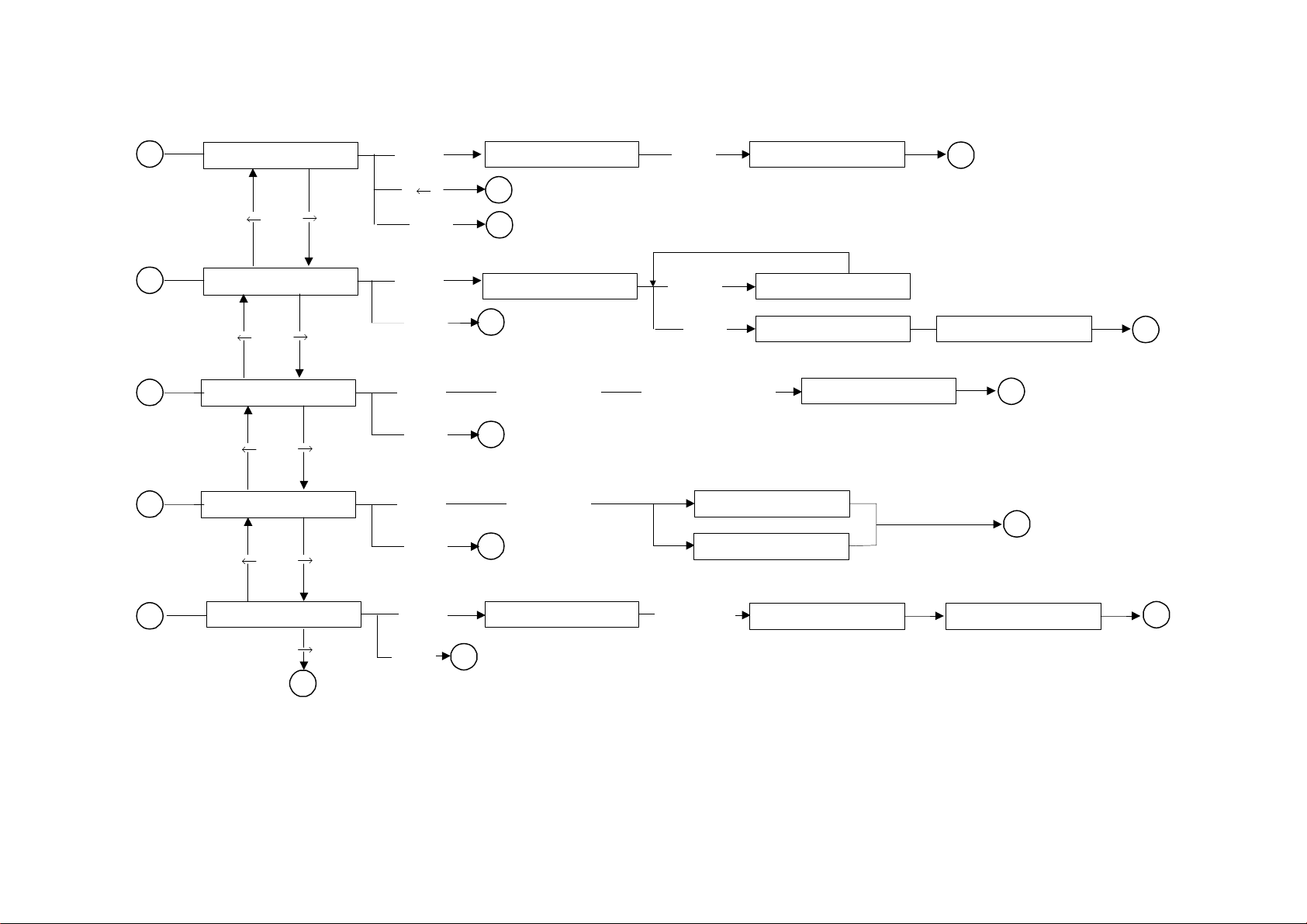

This item explains how to dismantle and assemble this FAX machine. Figure 5-3 Scanner

Mode Unit and Figure 5-7 Printer Mode Unitshow the procedure flow of dismantlement in brief.

The detailed procedure of dismantlement is explained from sub-item 5.3.1 to 5.3.17

The steps of dismantlement, reversing the steps of assembly, are shown as follows. For the

convenience of explanation, some definitions are stated as follows:

1) The Front of machine means the face of operation panel.

2) The Left and Right mean the left and right hand side facing from the front of machine.

3) The directions of Clockwise and Counterclockwise are defined viewing from the right of

machine.

5.3.1 Installing the Ink Cartridge and SIM Card

You can buy replacement mono cartridges from all OKI shops, main electrical retailers and good

stationers.

Black (item code)

1) After lifting the handset , please open the operational panel directly.

2) To install a new Ink Cartridge. Remove the sealing tape from the printed head.

3) Slide the Ink Cartridge into carriage then push it down.

4) Insert new SIM Card

5) Close the Operational Panel.

5.3.2 AC plug, Handset and Doc. Support

1) Face the rear of machine, pull out the AC plug, handset cord and line cord .

2) Take off the power cord, handset and Doc. Support.

Figure 5-1

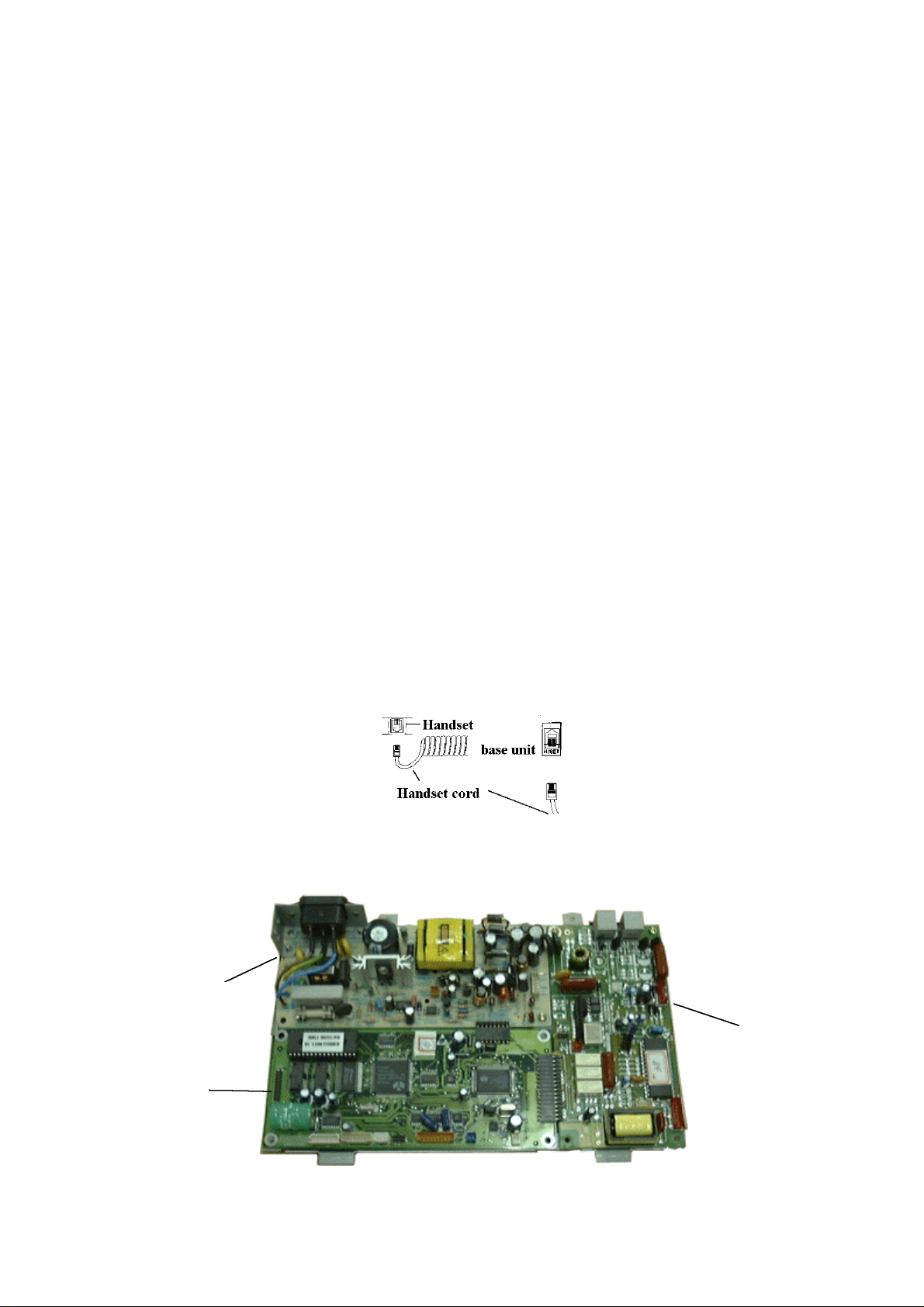

5.3.3 Bottom Plate Unit

Power

Board

NCU

Board

Main

Board

Figure 5-2 Bottom Plate Unit

5-3

Page 31

¡° Note:

Put a softer plate on table to avoid operation panel to be scratched is necessary.

1) Face the bottom of machine, loosen 2 pieces of M3X8 tapping screws then open Bottom Plate

Asm. from Bottom Cover.

2) Bottom Plate Asm.

Pull out all connectors on Main Board, NCU Board and Power Board , then Bottom Plate Asm.

can be taken out from Bottom Cover.

3) NCU Board Asm. , Main Board Asm. , Power Board Asm.

Loosen 3 pieces of M3X6 taptite screw for NCU Board, 2 pieces for Main Board and 2 pieces

for Power Board then NCU Board Asm, Main Board Asm. and Power Board Asm. can be

taken out from Bottom Plate.

4) Insulation

Take out Insulation sheet from Bottom Plate.

5) Separate Rubber Leg and Insulation Sheet.

5.3.4 SIM Card Holder Assembly

(1) Face the bottom of machine, loosen 1 piece of M3X12 tapping cap screw.

(2) SIM Card Holder Asm

Open Operational Panel, loosen 1 piece of M3X12 tapping cap screw for SIM Card Holder

and SIM Card Cover then SIM Card Holder Asm can be take out from machine.

(3) SIM Card Holder, SIM Card Cover and SIM Card PCB Asm.

Loosen 1 piece of M3X8 tapping cap screw for fixing Sim Card Holder and SIM Card Cover

then can separate SIM Card Holder, SIM Card Cover and SIM Card PCB AIM.

5.3.5 Scanner Mode Unit

Upper Cover Unit

Lower Frame Unit

Upper Frame Unit

Figure 5-3 Scanner Mode Unit

(1) Open Operational Panel and rotate Pull Tie that fixed on OP Bracket until one side of Pull Tie

can be taken out from OP Bracket. Loosen 1 piece ofM3X8 tapping screw that fix another

side of Pull Tie on Upper Cover then it can be taken out from Scanner Mode Unit.

(2) Loosen 1 piece of M3X8 tapping screw that fix on right side of Upper Cover and release the 4

latches that fix Upper Cover and Bottom Cover. Lift Scanner Mode Unit and all cables can be

5-4

Page 32

pulled out from Printer Mode Unit then both units can be separated.

(3) Loosen 3 pieces of M3X8 tapping screws that fix Lower Frame and Upper Cover Unit then

Scanner Mode Asm. and Upper Cover Unit can be separated.

5.3.6 Scanner Mode Asm.

Figure 5-4 Scanner Mode Asm.

Scanner Unit

OP Unit

Loosen 4 pieces of M3X8 tapping screws that fix Scanner Unit and O/P Unit. Cut the Cable Tie

that fasten Ground Wire and Cable Tube on left hand side. Pull out two connectors of ADF

sensor and DOC Sensor then Scanner Unit and O/P Unit can be separated.

5.3.7 Scanner Unit

Lower Frame

Upper Frame

Rotate 90°of clockwise for Upper Frame Unit then Lower Frame Unit and Upper Frame Unit can

be separated.

5.3.8 Lower Frame Unit

(1) Loosen 1 piece of M3X6 tapping screw on right side of I.S. Platen then move Ground

Spring.

(2) Loosen 1 piece of M3X6 tapping screw on right side of A.D.F. Roller then move Ground

Spring . Take out Ground wire from indent of Lower Frame.

Figure 5-5 Scanner Unit

5-5

Page 33

(3) Loosen 1 piece of M2.6X5 tapping screw on right side for fix Cover Switch Sensor then

move Cover Switch Sensor.

(4) I.S. Platen Asesmbly

¬ Face white I.S. Platen Asm., Gear is located on left side. With a straight screwdriver, pull

upward the snap of bushings( green )at the left and right ends of I.S. Platen , and grip

bushings with both hands and rotate it upward to vertical direction then take I.S. Platen

Asm. out.

- Use finger to release the Snap of Gear then Gear can be separated from the shaft of I.S.

Platen.

® Use small straight screwdriver to pick E-Ring on both side of I.S. Platen then take out left

and right bushing.

(5) Loosen 1 piece of M2.6X5 tapping cap screw on spindle of gear than take out 1 piece of

70/20 gear and 2 pieces of 36/20 gear.

(6) I.S. Asesmbly

¬ Compress both hinges of the I.S. assembly a bit and push the I.S. assembly from left to

right until the left hinge can be separated with its spindle on the scanner frame, remove

the I.S. assembly from left slantwise.

- Separated I.S. Cable from Tie Mount and pull out the connector of the I.S. cable.

® Release 4 pieces of M2.6X6 tapping screw on both side of I.S. Asm. then these two

Hinges can be separated from I.S.

(7) Loosen 2 pieces of M3X6 taptite screw for fixing I.S. Motor. Separate the cable of Motor

then I.S. Motor can be taken out from Lower Frame.

(8) With a straight screwdriver , pull upward the snap of bushings( black) at the left and right

ends of the A.D.F shaft, and grip bushings with both hands to take A.D.F. assembly out.

(9) Remove a black bushing on one side of the A.D.F assembly. Release the “E” ring on the

outside of gear by straight screwdriver, takes out clutch gear, clutch spring, clutch bushing

and another black bushing.

(10) With a straight screwdriver, press the both side of Flat Spring-IS then Flat Springs can be

picked out of Lower Frame.

(11) Separate Snap Rivet and flat Spring.

5.3.9 Upper Frame Unit.

(1) Ground Wire

Loosen 1 piece of M3X6 tapping screw. Pull out the ground wire pin of Separation Asm then

ground wire can be taken out.

(2) Spring Hook

Loosen both side of M3X6 tapping screws then both spring -hook can be taken out.

(3) A.D.F. sensor Asm.

Release snap-in fingers of ADF sensor assembly by a straight screwdriver then remove the

ADF sensor Asm.

(4) DOC. sensor Asm.

Release snap-in fingers of DOC. sensor assembly by a straight screwdriver then remove the

DOC. sensor Asm.

(5) Separation Asm.

¬ Take out A.D.F. Extension Spring from Upper Frame.

- With a straight screwdriver, take out Separation Asm.

(6) Push up clamping plate then separation plate and backing plate can be pulled out.CIRCUIT

DISCRIPTION

5-6

Page 34

5.3.10 Document Guide Assembly

(1) Use a straight screwdriver to separate Operational Panel and Doc. Guide Asm.

(2) Setting Spring & Spur Gear

Press downward the Setting Spring and move to longer side. Then Setting Spring and Spur

Gear can be taken out at the same time.

(3) DOC. Guide

¬ Lift slightly and pull the left Document Guide outward to take it out.

- Lift slightly and pull the right Document Guide outward to take it out.

(4) DOC. Setting Lable

DOC. Setting Lable can be scratched from DOC. Bracket.

5.3.11 Operation Panel Unit

Figure 5-6 Operation Panel Unit

(1) O/P Bracket & Hook Switch Assembly

With a cross screwdriver, loosen 5 pieces of M3X8 tapping screw for fixing O/P Bracket.

Then O/P Bracket can be taken out from O/P Asm. At the same time, pull out Hook Switch

Asm. from O/P Bracket.

¡°

Note:

Put a softer plate on table to avoid operation panel to be scratched is necessary.

(2) Pull out connectors on the key board and hook switch board . Take out cable from two

mounts.

(3) Buzzer

Loosen two pieces of M2X6 taptite screw for fixing buzzer then buzzer can be taken out.

(4) Key Board, Key Pad, Number Key, Function Key, Facility Key, Stop Key, Start/Copy Key

Use a small cross screwdriver to loosen 10 pieces of M2X6 taptite screw for fixing Key Board

then Key Board, Key Pad, Number Key, Function Key, Facility Key, Stop Key, Start/Copy

Key can be taken out respectively.

(5) Display Panel

Use a straight screwdriver to pick Display Panel from the gap between Display Panle and O/P

on right or left side.

(6) Use a straight screwdriver to peel Quickdial Card Cover from the gap on right side then pick

Quickdial Card.

5-7

Page 35

5.3.12 Upper Cover Unit

(1) Paper Sensor assembly and Bottom Cover

Release snap-in fingers of Paper Sensor Asm. by a straight screwdriver, then can separate

Paper Sensor Asm. and Bottom Cover.

5.3.13 Printer Mode Unit

Printer Mode

Asm.

Bottom Cover

Unit

(1) Printer Mode Asm. & Bottom Cover Unit

Loosen 4 pieces of M3X8 tapping screw then Printer Mode Asm. can be taken out form

Bottom Cover Unit.

5.3.14 Printer Mode Asm.

Figure 5-7 Printer Mode Unit

Figure 5-8 Printer Mode Asm.

(1) Ground Wire

Loosen 1 piece of M3X6 tatite screw for fixing ground wire by a cross screwdriver then

ground wire can be taken out from Printer Bar.

(2) Loosen 2 pieces of M3X10 tapping cap screw on right and left side of Paper Feeder Unit

5-8

Page 36

with a cross straight screwdriver.

(3) Loosen 2 pieces of M3X12 tapping cap screw(with a Spring Washer on right side screw) on

right and left side of Base Frame Unit with a cross straight screwdriver then Paper Feeder

Unit and Base Frame Unit can be separated.

5.3.15 Paper Feeder Unit

Figure 5-9 Paper Feeder Unit

(1) Ground Spring & Ground Wire

Loosen 1 piece of M3X6 tapping cap screw on Handle side by cross screwdriver then

Ground Spring and Ground Wire can be taken out from Paper Feeder Unit.

(2) Pick Up Roller Clutch & E-ring

Face the Gear-Pick Up side of Paper Feeder Unit. Release the E- ring (£X4 )on the outside

of gear by straight screwdriver then take out Pick Up Roller Clutch and E-ring.

(3) E-ring

Release the E- ring (£X4) on the both side of Paper Feeder Unit by straight screwdriver

then take out E-ring.

(4) Sintering Bearing

Move outward two Sintering Bearing then take them out.

(5) Pick Up Roller Asm.

Remove Pick Up Roller Asm. leftward then upward. Pick Up Roller Asm. can be taken out

from Paper Feeder Unit.

(6) Handle & Spring-Handle

Face the Handle side of the Paper Feeder Unit. Loosen 1 piece of M3X6 taptite cap screw

by cross screwdriver then it and Spring-Handle can be taken out.

(7) Spring-Buckle Corner

Take out Spring-Buckle Corner by hook.

(8) Buckle Corner

Face the Plane-Knock Up. Pull Buckle Corner up and outward then it can be taken out.

(9) Plate –Knock Up

Hold left side of Frame-AFP by left hand. Wrench left side of Plate-Knock up by thumb of

right hand then fixed position pin of Plate-Knock Up will be taken out. Face the rear of

Frame-APF, release the snap of Plate-Knock Up from Linkage then Plate-Knock Up can be

taken out from Frame-APF.

(10) Paper Support

5-9

Page 37

Pull Paper Support to highest point. Widen the gap that between Frame and Paper Support

by straight screwdriver then Paper Support can be drawn out from Frame.

(11) Spring-Knock Up

Pull out two Springs-Knock Up from Frame-APF.

(12) Linkage

Face the rear of Frame-AFP, pull linkage out from snap of Frame.

(13) Paper Guide-APF

Face the bear of Plate, pull out the elastic snap by straight screwdriver then Paper Guide

can be taken out from Plate.

(14) Cork Plate

Pull out Cork Plates from Plate.

5.3.16 Base Frame Unit

Figure 5-10 Base Frame Unit

(1) Idle roller

Release 2 pieces of M3X 6 taptite screws from Printer Control Board for fixing Paper guide

Asm. then it can be taken out from Printer Bar. Take 4 Idle Roller out from Baseframe.

(2) Paperguide Asm.

¬ Snap out 4 pieces of Spring from Paperguide Frame by Spring-Hook.

- Paperguide Pin, Paperguide Frame, Paperguide

Draw out Paperguide Pin from Paperguide then Paperguide Frame and Paperguide can

be separated.

® Spring-Paperguide

Take out 4 pieces of Spring-Paperguide from Paperguide.

(3) APF Sensor Asm.

Pull out all connectors on Printer Control Board. Release snap-in fingers of APF sensor

assembly by a straight screwdriver, remove the AFP sensor assembly.

(4) Paper Motor:

5-10

Page 38

¬ Cut Cable Tie for Fixing Cable Asm.

- Loosen 2 pieces of M3×6 taptite screws, remove the motor.

(5) Gear A, Gear B, Gear C

Release 2 pieces of M2X6 tapping screw then Gear B(2X), GEAR A and Gear C can be

taken out in sequence.

(6) Gear D, Driver Roller Gear

Release the snap of Gear D for fixing on Baseframe then Gear D and 2 pieces of Driver

Roller Gear can be taken out from Baseframe.

(7) Print Bar

Release 2 pieces of M3X8 tapping screw for fixing Printer Bar. Remove Print Bar Upward

and Forward then it can be taken out from Bracket-BF-L&R.

(8) Printer Control Board

¬ Drop Detect Cable

Pull out both connectors that connect Service Station and Printer Control Board then Drop

Detect Cable can be taken out.

- Release Flex Cable connector then Carriage Flex Cable can be taken out from Printer

Control Board.

® Release 2 pieces of M3X6 taptite screw for fixing Printer Control Board then it can be

taken out from Print Bar.

(9) Bracket-Bf-R

Release 2 pieces of M3X6 tapping Screw for fixing Bracket-bf-R on Base Frame then it can

be taken out.

(10) Bracket-Bf-L

Release 4 pieces of M3X6 tapping Screw for fixing Bracket-bf-L on Base Frame then it can

be taken out.

(11) Ground Spring & Ground Wire

Release 2 pieces of M3X6 tapping screw for fixing Ground Spring(2X) and Ground Wire

then they can be taken out.

(12) Driver Roller

Face the bottom of Base Frame. With a straight screwdriver, pull upward the snap bushings

at the left and right ends of Driver Roller and grip bushings with both hands to take it out.

(13) Exit Roller

Face the bottom of Base Frame. With a straight screwdriver, pull upward the snap bushings

at the left and right ends of Exit Roller and grip bushings with both hands to take it out.

(14) Wheel Support Asm.

¬ Release 1 piece of M3X6 tapping Screw. Lift left side of Wheel Support then it can be

taken out from fixed position on Base Frame.

- Star Wheel, Star Wheel Spring & Wheel Support

Take out 6 pieces of Star Wheel Spring and Star Wheel from Wheel Support.

5.3.17 Bottom Cover Unit

(1) Speaker Asm.

Release the snap for fixing Speaker Asm. then it can be taken out from Bottom Cover.

(2) EVA-Speaker 1 & EVA-Speaker 2

Pull EVA-Speaker 1 and EVA-Speaker 2 from speaker.

5-11

Page 39

(3) Socket-616E Cable Asm.

Release 2 snap for fixing Socket-616E Cable Asm. then it can be taken out from Bottom

Cover.

(4) Rubber Leg

Face the bottom of Bottom Cover. Take out 4 pieces of Rubber Leg.

5-12

Page 40

6. CIRCUIT DESCRIPTION

6.1 Main Board Circuit

The mother board version is the first version that begins mass-production and the circuit diagrams

consists of 11 schematics which are described in the following sections.

6.1.1 Block Diagram

The extended FAXENGINE chip set consists of an Integrated Fax Controller FC200(-M) and a

modem chip (R96DFXL). The FC200(-M) performs all common facsimile machine control, monitor

and interface function. Additionally, it contains scanner, printer, keyboard, stepping motor and

modem interfaces. These programmable functions and interfaces support a wide range of

peripherals. Integrated 8 bit pipeline ADC, clamp, sample hold and AGC allow minimum external

scanner interface hardware. Built-in DLC and shading correction combined with two-dimensional

Error Diffusion and two-dimensional edge enhancement provides state-of-the-art image processing

performance in half-tone modes. The R96DFXL modem can execute modem can excu 9600bps

fax transmission and reception.

6.1.2 Integrated Fax Controller

The Advanced extended FAXENGINE Integrated Fax Controller (FC200-M) includes following

features.

1) Microprocessor.

The embedded processor MC24TM in FC200(-M) provides 16-Mbyte memory addressing

capability over 24-bit address/8-bit data bus and dedicated control lines.

2) Printer Interface Control.

The FC200(-M) supplies programmable strobe and control signals that interface with most, if not

all, thermal printers. In addition to Standard (non-Split) printing mode, latchless Split-printing

mode and latchless two-clock mode can be supported. The three signals PDAT, PCLK, and PLAT

control the transfer of data to the printer.

3) Scanner Control.

Four programmable control and timing signals supports CIS scanner interface. An internal 8-bit

A/D converter is provided. Video processing supports DLC and two modes of shading correction

for scanner data non-uniformity’ s arising from uneven sensor output or uneven illumination.

Correction may be provided to an 8-pixel group at a time or, separately to each pixel. Less than 1

K of RAM is required to support shading correction. A Digital Adaptive Halftone image processing

is supported. A 2-Dimensional error diffusion algorithm as well as a 2-D Edge Enhancement

control are performed in the hardware. Dynamic background and contrast control is provided for

text images. Multi-level horizontal B4 to A4 reduction is also provided for the scanner data.

4) Motor Control.

Eight outputs are provided to external current drivers; four for scanner motor.

5) Image Coding Schemes.

FC200 (-M) provides MMR data compression and decompression conformed with ITU-T

recommendation T.4.

6) Real Time Clock (RTC).

FC200 (-M) includes a battery backed-up real time clock. The life of the RTC is 32 years, and leap

year compensation is automatic.

7) External Memory Support.

External ROM stores the program object code. External RAM is used by processor for shading

correction and line buffer. DRAM controller supports refresh during battery operation. DRAM

stores image and voice data.

6-1

Page 41

8) Modem Interface.

FC200 (-M) runs at a clock derived from modem clock. FC200 (-M) immediately handles interrupt

request from modem in order to keep constant transmission flow.

9) Panel Interface.

Four inputs, eight strobe outputs, and two control outputs support keys scan and LCD driver.

10) Battery and Power.

FC200 (-M) detects power failure and switches to battery backed-up mode.

Table 6-1 FC200 (-M) Pin Assignments

Pin Name Pin No. I/O

MIRQn 135 I HU -- Modem interrupt, active low. (Hysteresis In, Internal Pullup.)

SYSCLK 133 I H -- System clock. (Hysteresis In.)

TSTCLK 130 O -- 123XT Test clock.

A[23:0] [1:6][8:13]

[15:20][22:27]

D[7:0] [136:139]

[141:144]

RDn 128 O -- 123XT Read strobe.

WRn 127 O -- 123XT Write strobe.

ROMCSn 120 O -- 123XT ROM chip select.

CS1n 122 O -- 123XT I/O chip select.

CS0n 57 O -- 123XT SRAM chip select. (Battery powered.)

MCSn 121 O -- 123XT Modem chip select.

SYNC 126 O -- 123XT Indicates CPU op code fetch cycle (active high).

REGDMA 124 O -- 123XT Indicates REGSEL cycle and DMA cycle.

WATTn 125 O -- 123XT Indicates current TSTCLK cycle is a wait state or a halt

RASn 113 O -- 123XT DRAM row address select. (Battery powered).

CAS[1:0]N [111:112] O -- 123XT DRAM column address select. (Battery powered.)

DWRn 109 O -- 123XT DRAM writ. (Battery powered.)

DEBUGn 129 I HU -- External non-maskable input (NMI).

RESETn 131 I/O HU 2XO FC200(-M) Rest.

TEST 58 I C -- Sets Test mode (battery powered).

XIN 59 I OSC -- Crystal oscillator input pin.

XOUT 60 O -- OSC Crystal oscillator output pin.

PWRDWNn62 I H -- Used by external system to indicate--to FC200(-M)--loss of

BATRSTn 61 I H -- Battery power reset input.

WRPROTn 110 O -- 1XC

START 101 O -- 2XS Scanner shift gate control.

CLK1 100 O -- 2XS Scanner clock.

CLK1n 99 O -- 2XS Scanner clock-inverted.

CLK2 98 O -- 2XS Scanner reset gate control (or clock for CIS scanner).

O TU 123XT Address bus (24-bit)

I/O TU 123XT Data bus (8-bit)

Input

Type

Prime Power Reset Logic and Test

Battery Power Control and Reset Logic

Output

Type

CPU Control Interface

Bus Control Interface

Scanner Interface

(Note: Active low signals have an “n” pin name ending.)

state.

prime power. (Results in NMI).

(Battery powered.) Write protect during loss of VDD power.

NOTE: The functional logic is powered by battery power,

but the output drive is powered by DRAM battery power.

Pin Description

6-2

Page 42

Pin Name Pin No. I/O

FCS1n

/VIDCTL0

FCS2n

/VIDCTL1

PCLK

/ DMAACK

PDAT 30 O -- 2XP Serial printing data (to TPH).

PLAT 31 O -- 3XP TPH data latch.

STRB[3:0] [33:36] O -- 1XP Strobe signals for the TPH.

STRBPOL

/DMARQ

OPO[5]/GP

O[13]

OPO[6]/GP

O[14]

OPO[7]/GP

O[15]

OPI[0]/GPI

O[21]/SSR

XD1

OPI[1]/GPI

O[22]/SSS

TAT1

OPI[2]/GPI

O[23]/SSC

LK1

OPI[3]/GPI

O[24]

LEDCTL 55 O -- 4XC Indicates outputs OPO [7:0] are for LEDs.

LCDCS 54 O -- 1XC LCD chip select.

GPIO[0] 94 I/O H 2XC (Hysteresis In) GPIO[0].

GPIO[1]

/SASTXD

GPIO[2]

/SASRXD

GPIO[3]

/SASCLK

GPIO[4]

/CPCIN

GPIO[5

/SSCLK2

GPIO[6]

/SSTXD2

GPIO[7]

/SSRXD2

GPIO[8]

/FWRn

96 O -- 2XT Flash memory chip select or video control signal.

97 O -- 2XT Flash memory chip select or video control signal.

29 O -- 3XC Thermal Print Head (TPH) clock or external DMAACK.

37 I C -- Sets strobe polarity, active high/low , or external DMA

40 O -- 2XL Keyboard/LED strobe [5] or GPO[13]

39 O -- 2XL Keyboard/LED strobe [6] or GPO[14]

38 O -- 2XL Keyboard/LED strobe [7] or GPO[15]

52 I/O HU 2SC (Pullup, Hysteresis In.) Keyboard return [0] or GPIO[21] or

51 I/O HU 2SC (Pullup, Hysteresis In.) Keyboard return [1] or GPIO[22] or

50 I/O HU 2SC (Pullup, Hysteresis In.) Keyboard return [2] or GPIO[23] or

49 I/O HU 2SC (Pullup, Hysteresis In.) Keyboard return [0] or GPIO[21]

93 I/O H 2XC (Hysteresis In) GPIO[1] or SASTXD (for SASIF).

92 I/O H 2XC (Hysteresis In) GPIO[2] or SASRXD

91 I/O H 2XC (Hysteresis In) GPIO[3] or SASCLK

90 I/O H 2XC (Hysteresis In) GPIO[4] or Calling Party Control Input

89 I/O H 2XC (Hysteresis In) GPIO[5] or SSCLK2

87 I/O H 2XC (Hysteresis In) GPIO[6] or SSTXD2 (for SSIF2).

86 I/O H 2XC (Hysteresis In) GPIO[7] or SSRXD2 (for SSIF2)

85 I/O H 2XC

Input

Type

Output

Type

Printer Interface

Operator Panel Interface

General Purpose I/O

(Note: Active low signals have an “n” pin name ending.)

request.

SSRXD1 (for SSIF1)

SSSTAT1 (for SSIF1)

SSCLK1 (for SSIF1)

(Hysteresis In) GPIO[8] or flash write enable signal for

NAND-type flash memory.

Pin Description

6-3

Page 43

Pin Name Pin No. I/O

GPIO[9]

/FRDn

GPIO[10]/

SSSTAT2

GPIO[11]/B

E

/SERINP

GPIO[12]

/CS[2]n

GPIO[13]

/CS[3]n

GPIO[14]

/CS[4]n

GPIO[15]

/CS[5]n

GPIO[16]

/IRQ[8]

GPIO[17] 75 I/O H 1XC (Hysteresis In) GPIO[17]

GPIO[18]

/IRQ[9]n

GPIO[19]/

RDY/SERO

UT

GPIO[20]/

84 I/O H 2XC

83 I/O H 2XC (Hysteresis In) GPIO[10] or SSSTAT2

82 I/O H 1XC (Hysteresis In) GPIO[11] or bus enable or serial port data

80 I/O H 2XC (Hysteresis In) GPIO[12] or I/O chip select [2].

79 I/O H 2XC (Hysteresis In) GPIO[13]or I/O chip select [3].

78 I/O H 2XC (Hysteresis In) GPIO[14] or I/O chip select [4].

77 I/O H 2XC (Hysteresis In) GPIO[15] or I/O chip select [5].

76 I/O H 1XC (Hysteresis In) GPIO[16] or external interrupt 8.

74 I/O H 1XC (Hysteresis In) GPIO[18] or external interrupt 9.

73 I/O H 1XC (Hysteresis In) GPIO[19] or ready signal or Serial port

107 I/O H 1XC (Hysteresis In) GPIO[20] or ALTTONE.

Input

Type

Output

Type

Pin Description

(Note: Active low signals have an “n” pin name ending.)

(Hysteresis In) GPIO[9] or flash read enable signal for

NAND-type flash memory.

input for autobaud detection.

data output for autobaud detection.

ALTTONE

Miscellaneous

SM[3:0]/

GPO[7:4]

PM[3:0]/

GPO[3:0]

TONE 119 O -- 1XC Tone output signal.

-Verf

/CLREF

ADXG 68 I VXG -- A/D Internal GND.

ADGA 69 VADG A/D Analog Ground.

ADVA 70 VADV A/D Analog Power.

ADGD 72 VADG A/D Digital Ground.

+Vref 71 +VR Positive Reference Voltage for Video A/D.

VIN 67 I VA -- Analog Video A/D input.

THADI 65 I TA -- Analog Thermal A/D input.

VSS(12) 7,21,28,45,53,5

VDD(8) 14,32,41,48,

VBAT 63 Battery power for DRAM refresh.

VDRAM 114 DRAM Battery Power

[103:106] O -- 1XC Programmable: scan motor control pins or GPO pins.

[115:118] O -- 1XC Programmable: print motor control pins or GPO pins.

Power. Reference Voltages. Ground

66 I -VR -- Negative Reference Voltage for Video A/D.

Digital Ground.

6,64,88,95,108,

132,134

Digital Power.

81,102,123,

140

6-4

Page 44

Table 6-2 FC200(-M) Signal Characteristics

Input Signal Characteristics

Input

Type

C CMOS input 0.3*VDD 0.7*VDD - H Hysteresis 0.3*VDD 0.6*VDD 1.0 -

HU Hysteresis/Pull up 0.3*VDD 0.6*VDD 1.0 35-150

T TTL input 0.8 2.0 - -

TU TTL/Pull up 0.8 2.0 - 35-150

OSC CMOS input 0.3*VDD 0.7*VDD - -

Input

Type

TA Thermal A/D input 0.2*VDD 0.8*VDD -0.5 VDD+0.5

VA Video A/D input -VR +VR -0.5 VADV+0.5

+VR Video A/D +Vref 0.8 3.3 -0.5 VADV+0.5

-VR Video A/D -Vref -0.2 2.0 -0.5 VADV+0.5

Description VIL

(V max.)

Absolute Input Range = -0.5 to VDD+0.5

Description Operating

(V min.) (V max.)

(V min.)

VIH

Hysteresis

(V min.)

(V min.) (V max.)

Resistance(K ohm)

Absolute

Pullup

VXG Video Internal ground -- -- -- --

VADV Video A/D power VDD-0.1 VDD+0.1 -0.5 7.0

VADG Video A/D ground -0.1 0.1 -0.5 0.5

VDD Digital power 4.5 5.25 -0.5 7.0

GND Digital ground 0 0 0 0

VDRAM Battery power for DRAM 2.25 5.25 -0.5 7.0

VBAT Battery power for

RTC/SRAM

Output

Type

1XC CMOS output (1X) 0.4 1.6 VDD-1.5 1.6 50

1XP,2XP High capacitance driver 0.4 1.6 VDD-1.5 1.6 200

2XC CMOS output (2X) 0.4 3.5 VDD-1.5 3.5 50

2XT TTL output (2X) 0.4 4 2.4 4 50

Description VOL

2.25 5.25 -0.5 7.0

Output Signal Characteristics

(V max)

IOL

(mA min)

VOH

(V min)

IOH

(mA min)

CL

(pF max)

2XS CMOS output (2X) 0.4 3.5 VDD-1.5

1.5

2XL LED driver 0.7 10 VDD-1.5 3.5 100

6-5

3.5

15

50

50

Page 45

2XO CMOS output, Open drain 0.4 3.5 N/A N/A 50

3XC CMOS output (3X) 0.4 6 VDD-1.5 6 50

3XP High capacitance driver

(3X)

4XC CMOS Output (4X) 0.4 12 VDD-1.0 12 50

123XTT 1/2/3X (Tristate) output 0.4 1.6/4/6 2.4 1.6/4/6 50

Table 6-3 FC200 (-M) Memory Map

Chip select Address (Hex) External to FC200(-M) Internal to FC200(-M)

CS0 000000-007FFF SRAM

00E000-00FBFF RAM

CS1 00FC00-00FCFF I/O (N/C)

CS2-CS4 00FD00-00FDFF I/O (N/C)

00FE00-00FEFF RESISTERS

MCS 00FF00-00FFFF Modem

FCS1 300000-3FFFFF FLASH MEMORY

FCS2 200000-2FFFFF FLASH MEMORY

0.4 6 VDD-1.5 6 700

CAS0- CAS1 400000-BFFFFF DRAM or ARAM

CS5 D00000-DFFFFF I/O (N/C)

ROMCS FE0000-FFFFFF ROM

6-6

Page 46

6.1.2.1. Bus Cycle Timing

The processor and external bus cycle timing is defined by

referenced to

TSTCLK

which is derived by dividing

8.1.1.1-1 and Figure 8.1.1.1-2,respectively.

bclk

SYSCLK

can be extended low (halted state) or stretched

bclk

(an internal signal).

by either 2 or 3,as shown in Figure

bclk

high (wait state) by external and internal conditions that are described later. Both halt and wait state

are indicated on the external pin WAITn.

A standard bus cycle begins at the falling edge of

TSTCLK.

Some memory and peripheral devices require extended bus cycle, which is accomplished

TSTCLK

and ends at the falling edge of the next

by adding wait states. During wait states, the WAITn signal is activated. Wait states can be created

with programmable control provided for external chip selects (ROMCSn, MCSn, CS [5:0]n), by the

DRAM controller (CAS[1:0]n),and with the external RDY input pin. The wait states created by the

RDY input are added to the wait states generated by the chip select control logic.

The bus cycle can be halted by BE pin or by an access conflict (i.e., a CPU or DMA access to

DRAM coincident with a DRAM refresh, or a CPU access to the RAM when a DMA access of the

same RAM is in progress). When the bus cycle is stopped, Halt states are added in increments of 1

TSTCLK

edge

bclk

. When the Halt condition is released, the bus cycle resumes at the next

Figure 6-2

shows an example of a bus cycle with 1Halt state.

TSTCLK

rising

is

TSTCLK

Bus Cycle

WAITn

With one hal t state With one wait state

1060F4-2

Figure 6-1 Bus Cycle (Divide by 2)

6-7

Page 47

bclk

TSTCLK

Bus Cycle

Normal Cycle With 1 Wait State

WAITn

Figure 6-2 Bus Cycle (Divide by 3)

6.1.2.2. External Bus Signal Timing

External bus clock and control timing is provided in Figure 6-3. External bus data access timing is

provided in Figure 6-4, and Table 6-4 provides the external bus signal timing parameters for both

of these figures.

t

SYSCLK

t

SL

SH

t

SC Y

TSTCLK

SYNC

RDY

DEBUGn

EXT I RQ

BE

t

DBS

t

t

t

CD

t

SYD

t

DBH

IS

HS

t

IH

t

HH

t

CD

t

SY D

Figure 6-3 External bus clock and control timing

t

RD Y

6-8

Page 48

TSTCLK

REGDMA

RGD

t

Access with 1 Wait State Access with 0 Wait States

DM A Acc e ssREGSEL

RGD

t

DMD

t

DMD

t

Ac c

DM AREGSEL

WAI Tn

WRn,RDn

A[19:0]

Ext. CS's

CS[4:3]n

D[7:0]

(Read)

D[7:0]

(Wr ite)

D[7:0]

(Inte rnal)

t

t

AD

CSD

WSD

t

SD

t

SDD

t

CGD

t

DDW

t

WSD

t

SDE

t

DS

t

IN IN

SD

t

t

CGD

t

DHR

t

DH

t

Figure 6-4 External bus data access timing

Table 6-4 External Bus Signal Timing Parameters

SD

DDW

t

DDI

t

SD

t

DS

t

t

OU TO U T

t

OU T

DHR

t

DH

DH

Parameter Symbol Min. Max. Units

SYSCLK cycle tSCY 50 - ns

SYSCLK pulse width high tSH 22 - ns

SYSCLK pulse width low tSL 22 - ns

TSTCLK delay tCD - 20 ns

SYNC delay tSYD - 30

ns

tSL+10

RDY access delay tRDY - 7 ns

/DEBUG setup tDBS 20 - ns

/DEBUG hold tDBH 0 - ns

Interrupts setup tIS 15 - ns

Interrupts hold tIH 0 - ns

BE setup tHS 15 - ns

BE hold tHH 0 - ns

REGDMA delay (CPU register

access)

tRGD - 30

tSL+10

ns

6-9

Page 49

Parameter Symbol Min. Max. Units

REGDMA delay (DMA access) tDMD - 30

tSL+10

WAITn delay tWSD - 30

tSL+12

RDn,WRn delay tSD - 5 ns

RDn,WRn delay (Delay On=1) tSDD - 30

tSL+10

RDn,WRn delay(Delay On=2,3) tSDD - 12 ns

WRn delay (Early Off) tSDE - 30

tSL+10

Address delay tAD - 30

tSL+10

Chip Select delay tCSD - 30

tSL+12

Chip select (CSn[4:3]) delay tCGD - 10

Data setup (Read) tDS 12 - ns

Data hold (Read) tDHR 0 - ns

ns

ns

ns

ns

ns

ns

Data delay (Write) tDDW - 20 ns

Data delay(Internal access) tDDI - 30 ns

Data hold (Write, Internal

access)

Notes :

1. Valid value is whichever is the greater of the 2 values listed.

2. Test Conditions: 5.0V +5%/-10%, 70¢J, 50pF on all pins.

6.1.2.3. DRAM Controller

The DRAM chip provided is 1 Mega by 4 bits with maximum access time 100ns. Up to 1 column

chip selects, /CAS0, are supported to access total 1 Mega bytes. For basic memory of 1Mega bytes,

2 DRAM chips are provided, while for extended memory, 2 more chips are provided.

Address bus of DRAM are physically connected to address bit A0 to A9 of FC200(-M). Row

addresses are gated onto the DRAM address bus first, followed by column addresses. The

following operation modes are supported: bytes access mode, early write mode and normal read

mode. One wait state is inserted in each DRAM bus cycle.

DRAM refresh is performed automatically, but only /CAS before /RAS operation is supported.

Refresh cycle time per 1024 cycles is 125ms. During power on when it is time to refresh DRAM and

they are not being accessed, the refresh cycle starts. When power down, no DRAM access occur,

and DRAM can’ t backup the data.

tDH tSL-10 - ns

6.1.2.4. CPU Interrupts

There are two ways to interrupt CPU, maskable interrupt (/MIRQ) and non-maskable interrupt NMI

(/DEBUG,/PWRDWN). Modem interrupt /MIRQ must hold active until the CPU processes the

request. The input /PWRDWN is OR'ed with the input /DEBUG and then synchronized before NMI

input. An active NMI signal branches program execution to the address stored in NMI vector. When

NMI represents power down, indicated by /PWRDWN low, the NMI control firmware performs the

necessary maintenance operation and then enable lockout register to protect battery backed-up

6-10

Page 50

registers during power down.

6.1.2.5. RESET logic and Watchdog Timer

There are two power resets, battery power reset (/BATRST) and prime power reset (/PWRDWN).

The battery power reset initializes battery backed-up logic when battery is first applied or changed.

Prime power reset initializes all non-battery powered logic when system power is turned on.

Another reset is generated by watchdog timer which guards against firmware lockup. /RESET pin

provides a reset signal to external devices when power down or watchdog reset is active. If

/BATRST become low, D2 ON, sothet U2C Op output low and reset modem.

6.1.2.6. Real Time Clock

The Real Time Clock (RTC) circuit is required to maintain current time information under primary

power and battery backup conditions. RTC tracks seconds, minutes, hours, days, months and years

elapsed since the reference year, 1999. The tracking range of RTC is up to 32 years, and

automatic compensation is made for leap years.

6.1.3 Scanner Controller

Only one type of scanner can be applied, Hualing. Power of scanner LED is on/off controlled by

transistor switch Q1 and Q2.

every 10ms. The scanner outputs video signal synchronized to clock. A flash A/D converter in

FC200(-M) samples the video signal. FC200(-M) performs shading correction to correct scanner

data for non-uniformity of 1728 image sensors. State of art image processing on both text and

halftone images are provided. Edge enhancement improves image quality on halftone, and

dynamic contrast control improves text image. An internal dither table programmable up to 8X8

byte matrix is provided to perform halftone process.

CLK2

is 500KHz clock to scanner and

START

is periodic pulse for

The video signal is amplified by adaptive gain in order to let white video level close to reference

level of flash A/D converter.

6.1.4 Motor Drivers

Signal SM[0..3] are selected as scanner control lines. The stepping pattern signals determined by

firmware outputs to scanner motor via current drivers, transistor array.

6.1.5 Switch and Sensors

Cover on/off switch is debounced by a RC couple. Paper sensor output is shunt by a noise-filtering

capacitor.

6.1.6 Battery and Power Down Reset

Prime power failure is detected by a voltage comparator that compares +5V supply with a constant

reference voltage 4.5V provided by transistor voltage source.

Battery BT1 backs up VXFC, and SRAM in the beginning of power down.

6.1.7 Fax Modem Circuit

The Rockwell R96DFXL MONOFAX modem is a synchronous 9600 bits per second (bps) halfduplex modem with error detection and DTMF reception. The modem can operate over the public

switched telephone network (PSTN) through line terminations provided by a data access

arrangement (DAA). The R96DFXL is designed for use in Group 3 facsimile machines. The modem

satisfies the requirement specified in CCITT recommendations V.29, V.27 ter, V.21 Channel in 2,

and T.4, and meets the binary signaling requirements of T.30. The pin assignments for 100-pin

PQFP are listed in table 8.1.7-1, and its digital interface characteristics is listed in table 8.1.7-2,

analog interface is listed in table 8.1.7-3.

Table 6-5 Modem R96DFXL Pin Functions

Pin

No.

1 GP03 Rrelay 1 O General purpose input/output IB OB

Pin Name Signal

Name

I/O Description Input

Type

6-11

Output

Type

Page 51

Pin

RING_OFF

No.

2 GP04 Rrelay 2 O General purpose input/output IB OB

3 GP05 Rrelay 3 O General purpose input/output IB OB

4 GP06

5 GP07 BREAK O General purpose input/output IB OB

6 OVD2 GND GND Connect to digital ground

7 OVD2 GND GND Connect to digital ground

8 D7 D7 I/O Data bus line 7 IA OB

9 D6 D6 I/O Data bus line 6 IA OB

10 D5 D5 I/O Data bus line 5 IA OB

11 D4 D4 I/O Data bus line 4 IA OB

12 D3 D3 I/O Data bus line 3 IA OB

13 D2 D2 I/O Data bus line 2 IA OB

14 D1 D1 I/O Data bus line 1 IA OB

15 D0 D0 I/O Data bus line 0 IA OB

16 OVD2 GND GND Connect to digital ground

17 OVA AGND GND Connect to analog ov ground

18 RAMPIN R Receiver amplifier input

19 NC No connection

20 NC No connection

21 OVA AGND GND Connect to analogy OV ground

22 +5VD2 VDD PWR Connect to digital +5V power

23 OVD1 GND GND Connect to digital ground

24 SWGAINI R Connect to SWGAINO

25 ECLKIN1 R Connect to SWGAINI

26 SYNCIN1 R Connect to EYESYNC

27 NC No connection

28 NC No connection

29 NC No connection

30 OVA AGND GND Connect to analogy OV ground

31 NC No connection

32 NC No connection

33 NC No connection

34 DAIN R Connect to daout

35 ADOUT R ADC output

36 BYPASS GP13 I Receiver highpass filter bypass enable IC

37 RCVI R Connect to RCVO

38 TXLOSS3 I 8dB of analog transmit level attenuation IC

39 TXLOSS2 I 4dB of analog transmit level attenuation IC

40 TXLOSS1 I 2dB of analog transmit level attenuation IC

41 NC No connection

42 NC No connection

43 OVA AGND GND Connect to analog OV ground

44 TXOUT AA Connect to smoothing filter input

45 RXIN AB Connect to anti-aliasinf filter output

Pin Name Signal

Name

I/O Description Input

Type

O General purpose input/output IB OB

Output

Type

6-12

Page 52

Pin

No.

46 +5VA +5VA PWR Connect to analog +5V power

47 OVA GND GND Connect to analog OV ground

48 AGD R +2.5 analog ground

49 AOUT R Smoothing filter output

50 OVD1 GND GND Connect to digital ground

51 NC No connection

52 /IRQ1 /MIRQ O Interrupt request OC

53 /WRITE /WR I Write enable IA

54 /CS /MCS I Chip select IA

55 /READ /RD I Read enable IA

56

57

58

59

60

61 GP13 BYPASS I/O General purpose I/O IA OB

62 +5VD1 VDD PWR Connect to digital +5V power

63 GP11 MUTE O General purpose input/output IA OB

64 /RTS I Request to send IA

65 /EN85 I Enable 8085 bus IA

66 OVD2 GND GND Connect to digital ground

67 /PORI /MRST I Power-on-reset input ID

68 XTLI R Connect to Crystal/Oscillator

69 XTLO R Connect to Crystal/Oscillator

70 XCLK SYSCLK O 19MHz output OD

71 YCLK O 9.5MHz output OD

72 +5VD1 VDD PWR Connect to digital +5V power

73 DCLKI DCLK R Connect to DCLK

74 SYNCIN2 SYNCIN1 R Connect to EYESYNC

75 GP16 I/O General purpose input IA OB

76 GP17 I/O General purpose input IA OB

77 OVD2 GND GND Connect to digital ground

78 /CTS O Clear to send OA

79 TXD I Transmit data IA

80 OVD2 GND GND Connect to digital ground

81 OVD2 GND GND Connect to digital ground

82 DCLK /IRQ2 O Transmit and receive data clock OA

83 EYESYNC O Serial eye pattern strobe (9600Hz) OA

84 EYECLKX O Serial eye pattern clock OA

85 EYECLK O Serial eye pattern clock OA

86 EYEX O Serial eye pattern X output OA

87 ADIN R Connect to ADOUT

88 DAOUT R DAC/AGC output

89 OVD2 GND GND Connect to digital ground

Pin Name Signal

Name

RS4 A4 I Register select 4 IA

RS3 A3 I Register select 3 IA

RS2 A2 I Register select 2 IA

RS1 A1 I Register select 1 IA

RS0 A0 I Register select 0 IA

I/O Description Input

Type

Output

Type

6-13

Page 53

Pin

0.8*Vcc

No.

90 EYEY O Serial eye pattern Y output OA

91 GP21 I/O General purpose input IA OB

92 OVD2 GND GND Connect to digital ground

93 GP20 I/O General purpose input IA OB

94 GP19 I/O General purpose input IA OB

95 RXD O Received data OA

96 /RLSD O Received line signal detected OA

97 OVD2 GND GND Connect to digital ground

98 RCV0 R Mode select output

99 SWGAINO R Connect to SWGAINI

100 GP02 RELAY O General purpose input/output IA OB

Notes:

I/O types:

Pin Name Signal

Name

IA, IB, IC, ID= Digital input.

OA, OB, OC, OD= Digital output.

I(DA)= Analog input.

I/O Description Input

Type

Output

Type

O(DD), O(DF)= Analog output.

R Types

Required overhead connection; no connection to host equipment

Figure 6-5 Digital Interface Characteristics

Parameter Symbol Min. Typ. Max. Units Test Condition

Input High Voltage VIH V

Types IA and IB 2.0 - Vcc

Types IC and ID

Input High Current IIH

Type IB - - 40

Type IC - - 2.5

Input Low Voltage VIL V Vdc

Type IA, IB, ID -0.3 - 0.8

Type IC -0.3 - 0.2*Vcc

- Vcc

£g

A Vcc=5.25V, Vin=5.25V

Input Low Current IIL

Types IB and IC - - -400

Input Leakage Current IIN

Type IB - -

6-14

¡Ó

2.5

£g

A Vcc= 5.25V

£g

A VIN= 0 to +5V

Vcc= 5.25V

Page 54

Parameter Symbol Min. Typ. Max. Units Test Condition

10

Output High Voltage VOH V

Type OA and OB 3.5 - - ILOAD= -100£gA

Type OE 2.4 - - ILOAD= -40£gA

Output High Current

Types OD

Output Low Voltage VOL Vdc

Types OA and OC - - 0.4 ILOAD= 1.6 mA

Types OB - - 0.4 ILOAD= 0.8 mA

Types OE - - 0.4 ILOAD= 0.4 mA

Output Low Current

Types OD

Output Leakage Current ILO

Type OA and OB - Capacitor Load CL pF

Type IA and ID - 5 Type IB - 20 -

IOH - - -0.1 m A

IOL - - 100

¡Ó

£g

A

£g

A VIN= 0.4 to Vcc-1

Capacitor Drive CD pF

Type OA, OB, OC

Types OD

Circuit Type

Type IA TTL

Type IB TTL with pull-up

Type IC CMOS with pull-up

Type ID POR

Type OA and OB TTL with 3-state

Type OC and OE Open drain

Type OD Clock

The modem (R96DFXL) must be connected to an external crystal circuit consisting of a

24.00014MHz crystal and two capacitors. The analog power and ground are decoupled from +5V

and digital ground by bead cores. Power-on reset /PORI is provided by FC200(-M). Output of

received analog signal is available on pin VOICE and is multiplexed with signal TONE before input

to audio amplifier U18B. TXA, RXA, U18B, U18C, U18D is used to adjust the volume of voice. RXA

have to be amplified and modified voltage level according to this signal is different from modem

characteristics.

-

-

100

50

-

6-15

Page 55

6.1.8 Memory

There are 2 chips of 4 Mega bits DRAM mounted on board. SRAM of 32K bytes stores user and

system data. DRAM was not backed up , SRAM is backed up by BT1. EPROM of 128K bits is

installed on socket for various firmware versions are provided.

6.1.9 Network Interface

There are 6 relay drivers implemented by transistors. While power-on reset, control all relays are at

normal state.

6.1.10 Panel Interface

Operation panel output bus OPO[0..7], input bus OPI[0..3] and control output LEDCTL, LCDCS

supports 32-keys keyboard and 3 LEDs. LEDCTL disables LEDs during keyboard strobing in order

to prevent the dim LED glow. Also OPO[0..3] and LCDCS drive LCD module.

6.2 Printer Board Circuit Description

The system architecture is built around the HP ASIC and a MC68EC00 CPU. The ASIC provides

hardware for the control of printing, paper motion, carriage motion, HOST interface, Print head ID

detect, image smoothing, and print head drop detect. The MC68EC000 provides a powerful general

purpose CPU for control of the ASIC and other data processing.

The printer board consists of following parts:

6.2.1 Printer board to Inkjet head interface

The decoders U1~U6 decode the firing pulses which drive nozzles to print out data via J1 and J2.

The U10A gets the HEAD ID signal to detect the cartridge is the HP’ s cartridge or not.

6.2.2 Paper & Carriage motor

The carriage motor is driving by U14.

U13 was the motor driving to control the paper feeding.

6.2.3 Sensors & Host connector

There are two sensors to detect the paper and cartridge status.

The printer status is controlled by main board interface.

6.2.4 Printer head supply detect

Power board provided the printer working voltage.

U15 is a voltage regulator, supplied a accuracy voltage reference.

U11C is a error amplifier amplifies the difference between the VFB voltage and the VREF voltage

and thus regulates the +HV output voltage.

U11D is a ON/OFF controller, controls whether +HV is high or low and the slew rate of the

transitions high and low.

U17 is a current gain stage provides enough current drive to drive the required loads.

6.2.5 Microprocessor and Memory

The interface between driver ASIC U18 and MC68EC000 are address bus SA[0…17] and data bus

SD[0…7]. This ASIC is also the interface used to link MC68EC000 and main system. When

cartridge is installed, The microprocessor is MC68EC000 connecting to other internal and external

printer board functions over an 8 bit data (D0~D7) and 18 bit address bus and dedicate control

lines.

SRAM of 32K byte stores system data and image data which is to be printed out. PROM of 128k

byte is installed on socket for firmware versions which provides general functions for printing.

6-16

Page 56

6.3 Key Board Circuit Description

The keyboard consists of following parts:

(1) Dot Matrix LCD Module

It has character generator and data RAM on board which provide easy interface for host FC200(M). Its bus operation is 4-bit access.

(2) LED Drivers and LEDs

Three LEDs are driven by control LEDCTL via transistor Q1 and strobe by OP05, OP06 and

OP07.

(3) Key Switch Matrix

OP00 to OP07 strobe each key matrix column in sequence, and OPI0 to OPI3 are read by

FC200(-M) to determine which key is pressed.

(4) Document Sensor & ADF Sensor.

Detects any document fed in guide.

6.4 SIMCRAD Board Circuit Description

Used the IC CARD CONNECTOR by OMRON.

The circuit connected to the main board, then main board to read or write the SIM CARD.

6.5 NCU Circuit Diagram Description