Page 1

JOB60851 Starter Kit

User’ s Manual

Version 1.07 (July 27, 2000)

OKI

Oki Electric Industry Co., Ltd..

Technocollage Inc

Page 2

Page 3

OKI

NOTICE

1. The information contained herein can change without notice owing to product and/or technical

improvements. Before using the product, please make sure that the information being referred to is

up-to-date.

2. The outline of action and examples for application circuits described herein have been chosen as an

explanation for the standard action and performance of the product. When planning to use the

product, please ensure that the external conditions are reflected in the actual circuit, assembly, and

program designs.

3. When designing your product, please use our product below the specified maximum ratings and

within the specified operating ranges including, but not limited to, operating voltage, power

dissipation, and operating temperature.

4. Oki assumes no responsibility or liability whatsoever for any failure or unusual or unexpected

operation resulting from misuse, neglect, improper installation, repair, alteration or accident,

improper handling, or unusual physical or electrical stress including, but not limited to, exposure to

parameters beyond the specified maximum ratings or operation outside the specified operating

range.

5. Neither indemnity against nor license of a third party’s industrial and intellectual property right, etc.

is granted by us in connection with the use of the product and/or the information and drawings

contained herein. No responsibility is assumed by us for any infringement of a third party’s right

which may result from the use thereof.

6. The products listed in this document are intended for use in general electronics equipment for

commercial applications (e.g., office automation, communication equipment, measurement

equipment, consumer electronics, etc.). These products are not authorized for use in any system or

application that requires special or enhanced quality and reliability characteristics nor in any system

or application where the failure of such system or application may result in the loss or damage of

property, or death or injury to humans.

Such applications include, but are not limited to, traffic and automotive equipment, safety devices,

aerospace equipment, nuclear power control, medical equipment, and life-support systems.

7. Certain products in this document may need government approval before they can be exported to

particular countries. The purchaser assumes the responsibility of determining the legality of export

of these products and will take appropriate and necessary steps at their own expense for these.

8. No part of the contents contained herein may be reprinted or reproduced without our prior

permission.

Copyright 2000 Oki Electric Industry Co., Ltd.

Page 4

i

Contents

1. Introduction ............................................................................ 1-1

1-1. Cheking Packing List...................................................................................1-2

1-2. Host Environment ........................................................................................1-3

1-3. Precaution for Safe and Proper Use ...........................................................1-4

2. Putting Board through its Paces........................................... 2-1

2-1. Setup.............................................................................................................2-2

2-1-1. Configuring JOB60851 Board........................................................................2-2

2-1-2. Installing Development Software...................................................................2-3

2-1-3. Connecting Board..........................................................................................2-4

2-2. Running Default Program............................................................................2-4

2-2-1. Installing USB Driver......................................................................................2-4

2-2-2. Running Flash Memory Program...................................................................2-4

2-3. Running User Programs ..............................................................................2-6

2-3-1. Connecting Serial Cable................................................................................2-7

2-3-2. Loading Terminal Emulator............................................................................2-7

2-3-3. Synchronizing Link.........................................................................................2-8

2-3-4. Downloading and Executing..........................................................................2-8

2-4. Overwriting Flash Memory Contents ..........................................................2-9

3. System Specifications............................................................ 3-1

3-1. System Components....................................................................................3-2

3-1-1. System Objective...........................................................................................3-2

3-1-2. System Components......................................................................................3-2

3-2. Hardware Specification................................................................................3-3

Page 5

ii

3-2-1. Connectors and Switches.............................................................................. 3-3

3-2-2. Circuit Diagram..............................................................................................3-5

3-2-3. Parts List........................................................................................................3-7

3-2-4. Memory Maps................................................................................................3-8

3-3. System Limitations.....................................................................................3-12

3-3-1. Resources Uses ..........................................................................................3-12

4. Software Development........................................................... 4-1

4-1. USB Basics...................................................................................................4-2

4-1-1. Bus Topology, Addresses, and Hot Plugging................................................ 4-2

4-1-2. Specification Documents...............................................................................4-3

4-1-3. Core Specifications........................................................................................ 4-3

4-1-4. Data Flow Types............................................................................................ 4-4

4-1-5. Bus Transactions...........................................................................................4-4

4-1-6. Packets.......................................................................................................... 4-5

4-1-7. Endpoints.......................................................................................................4-5

4-1-8. Data Rates..................................................................................................... 4-6

4-1-9. Device Class Specifications .......................................................................... 4-6

4-1-10. Device Requests.......................................................................................... 4-7

4-1-11. Standard Device Requests.......................................................................... 4-7

4-1-12. Device Descriptors....................................................................................... 4-8

4-2. Sample USB Firmware ...............................................................................4-10

4-2-1. Setup............................................................................................................ 4-10

4-2-2. Sample Firmware Specifications.................................................................4-10

4-2-3. Sample USB Host Software ........................................................................ 4-11

4-2-4. Compiling and Execitomg Sample USB Firmware......................................4-11

4-2-5. Confirming USB Compliance with Usbcheck.exe .......................................4-11

4-2-6. Creating USB Mouse Demo........................................................................4-13

4-2-7. Modifying Application Layer......................................................................... 4-14

Page 6

iii

4-2-8. Simple Debugging........................................................................................4-16

4-2-9. Evaluating USB Equipment .........................................................................4-16

4-3. USB Bits and Pieces ..................................................................................4-17

4-3-1. Device Controller Specifications..................................................................4-17

4-3-2. Overview of ML60851C Operation..............................................................4-17

4-3-3. Connecting Microcontroller to USB Controller.............................................4-18

4-3-4. Special USB Considerations........................................................................4-19

4-3-5. Building a Product........................................................................................4-20

4-3-6. Vendor and Product IDs ..............................................................................4-20

4-3-7. Other Tools Necessary................................................................................4-20

4-3-8. Note on Porting............................................................................................4-21

4-3-9. Limitations....................................................................................................4-22

4-4. Port 7 LED2 Control ...................................................................................4-22

4-4-1. Port 7 Registers...........................................................................................4-22

4-4-2. Changing LED2 Color..................................................................................4-23

4-5. Standard I/O over Serial Link.....................................................................4-26

4-5-1. JOB60851 Board Standard I/O....................................................................4-26

4-5-2. Serial Port ....................................................................................................4-27

4-5-3. read() and write() Functions.........................................................................4-29

4-5-4. Standard I/O Examples................................................................................4-31

4-5-5. Debugging with Standard I/O.......................................................................4-32

Page 7

1. Introduction

Page 8

Chapter 1 Introduction

1-1. Checking Packing List

Thank you for purchasing the JOB60851 Starter Kit.

The JOB60851 Starter Kit drives an Oki Electric Industry ML60851 Universal Serial Bus (USB)

device controller with an Oki MSM66Q573 microcontroller to create a starting point for developing

products with built-in USB support. The kit also includes sample firmware source code and the C

compiler package for the Oki MSM66 microcontroller Series, so the developer can start writing

firmware right away.

Before starting development, however, check the kit contents against the packing list in Table 1.1.1.

If a component is missing or damaged during shipping, please contact your Oki Electric distributor

or Technocollage and include the JOB60851 serial number. Replacement is free within one (1)

month of delivery.

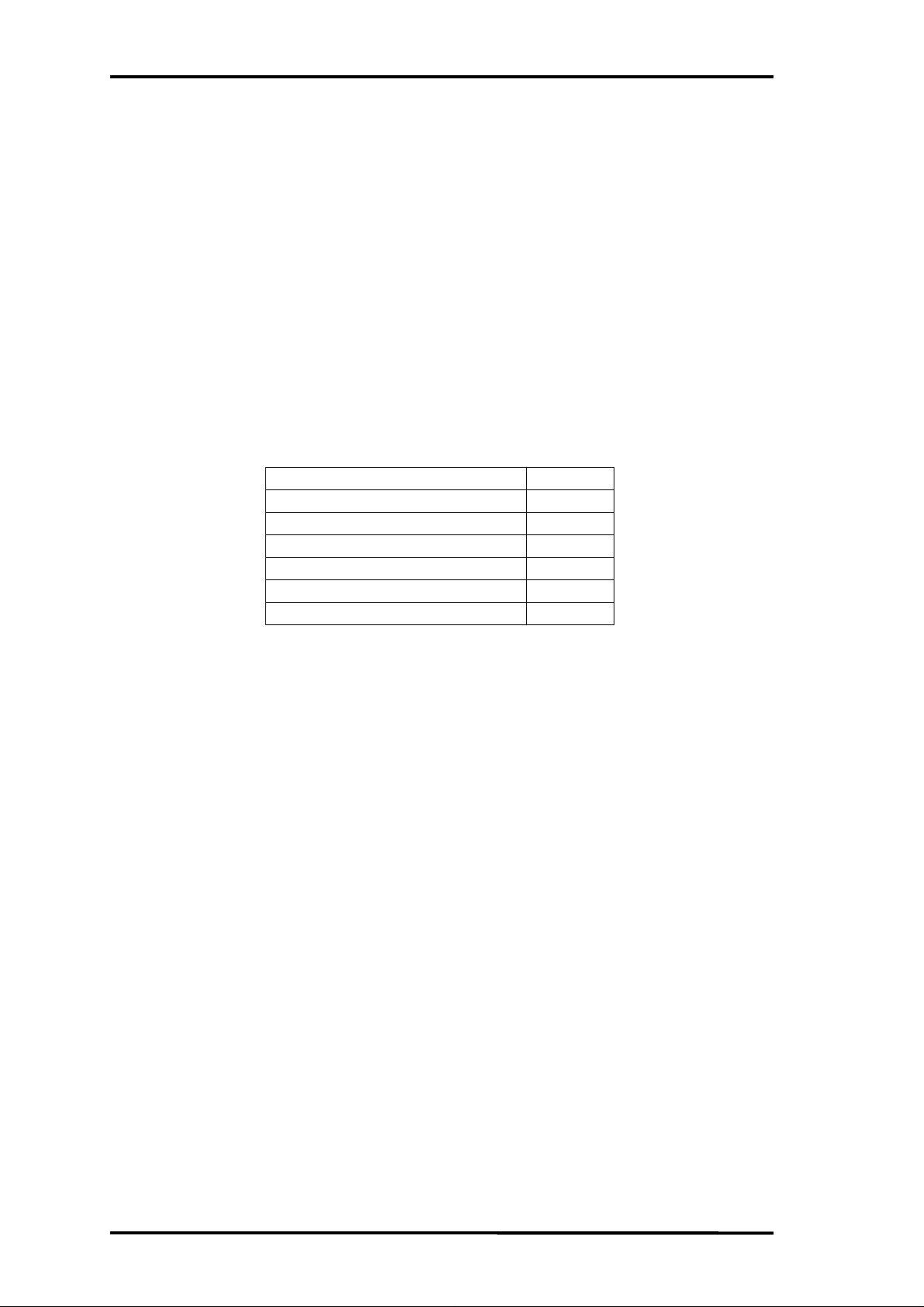

Table 1.1.1. Packing List

JOB60851 1

USB cable 1

RS-232c cable 1

AC adapter 1

CD-ROM 1

Two 60-pin user connectors 2

Introduction (this page) 1

The CD-ROM contains the following directories and files.

\Document Documentation

\CC665S C compiler User's Manual, etc.

\JOB60851 JOB60851 Starter Kit User's Guide, etc.

\M66573 MSM66573 User's Guide, etc.

\ML60851C USB controller documentation, etc.

\Package Compiler package and sample source code

\Cc665s C compiler package, etc.

\Host Sample files for evaluating USB operation, etc.

\Sample Sample programs, etc.

\Usb_firm Sample source code for MSM60851C control software: Hot plugging

(a.k.a. dynamic insertion and removal) capability for USB device, loopback test,

etc.

Before using this product, read through to the end of this section ("Introduction"). Detailed

descriptions start in Section 2 "Putting Board through Its Paces."

If a component is missing or damaged during shipping, please contact your Oki Electric distributor

with the included JOB60851 serial number. Replacement is free within one month of delivery.

Technical support for this product is limited to the product description. We do not offer personalized

support in Japanese or English, not by e-mail or fax and especially not over the telephone.

page 1-2

Page 9

Chapter 1 Introduction

1-2. Host Environment

The JOB60851 Starter Kit assumes the following development environment.

• Microsoft Windows 98

• USB interface fully compatible with Microsoft Windows 98 USB driver

• Terminal emulation software

The compiler package will also run under Microsoft Windows 95 and MS-DOS version 5.0 or later,

but the JOB60851 board will not be accessible as a USB device.

page 1-3

Page 10

Chapter 1 Introduction

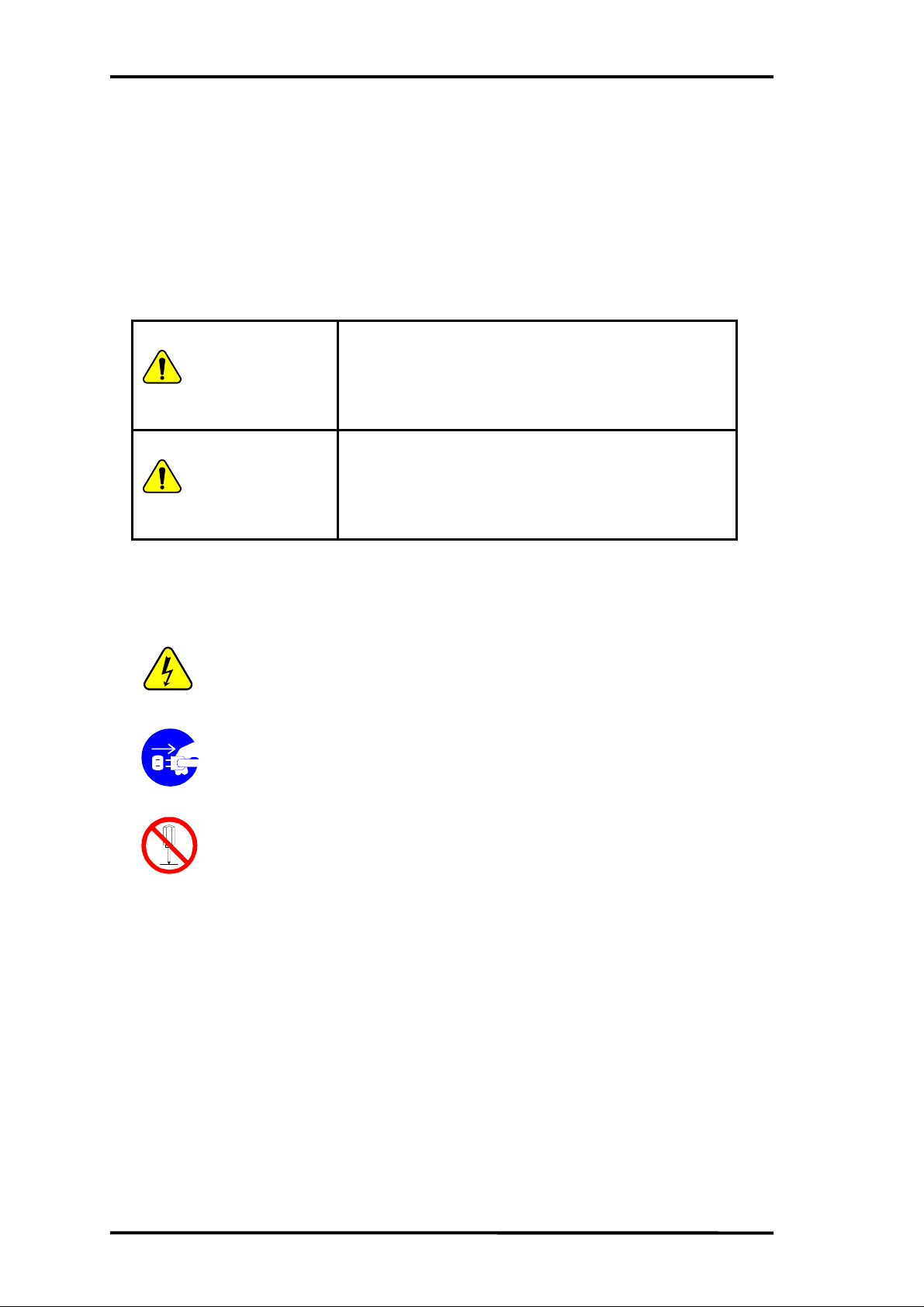

Warning

Caution

1-3. Precaution for Safe and Proper Use

This User’s Guide uses various labels and icons that serve as your guides to operating this product

safely and properly so as to prevent death, personal injury, and property damage. The following

table lists these labels and their definitions.

Labels

This label indicates precautions that, if ignored or

otherwise not completely followed, could lead to

death or serious personal injury.

This label indicates precautions that, if ignored or

otherwise not completely followed, could lead to

personal injury or property damage.

Icons

A triangular icon draws your attention to the presence of a hazard.

The illustration inside the triangular frame indicates the nature of the

hazard—in this example, an electrical shock hazard.

A circular icon with a solid background illustrates an action to be

performed. The illustration inside this circle indicates this action—in

this example, unplugging the power cord.

A circular icon with a crossbar indicates a prohibition. The illustration

inside this circle indicates the prohibited action—in this example,

disassembly.

page 1-4

Page 11

Please read this page before using the product.

Warning

Use only the specified voltage.

Using the wrong voltage risks fire and electrical shock.

At the first signs of smoke, an unusual smell, or other problems,

unplug the emulator and disconnect all external power cords.

Continued use risks fire and electrical shock.

Do not use the product in an environment exposing it to moisture

or high humidity.

Such exposure risks fire and electrical shock.

Chapter 1 Introduction

Do not pile objects on top of the product.

Such pressure risks fire and electrical shock.

At the first signs of breakdown, immediately stop using the

product, unplug the emulator, and disconnect all external power

cords.

Continued use risks fire and electrical shock.

page 1-5

Page 12

Chapter 1 Introduction

Caution

Please read this page before using the product.

Do not use this product on an unstable or inclined base as it can

fall or overturn, producing injury.

Do not use this product in an environment exposing it to

excessive vibration, strong magnetic fields, or corrosive gases.

Such factors can loosen or even disconnect cable connectors, producing a

breakdown.

Do not use this product in an environment exposing it to

temperatures outside the specified range, direct sunlight, or

excessive dust.

Such factors risk fire and breakdown.

Use only the cables and other accessories provided.

Using non-compatible parts risks fire and breakdown.

Always observe the specified order for turning equipment on and

off.

Using the incorrect order risks fire and breakdown.

Do not use the cables and other accessories provided with other

systems.

Such improper usage risks fire.

Before connecting or disconnecting the cables and the

accessories, the power source for the emulator must be turned

OFF.

Connections or disconnections performed while the power source is ON risk

fire and damage to the system.

page 1-6

Page 13

Chapter 1 Introduction

Notation

This manual utilizes the following notational conventions for convenience.

n

Caution

n

A “caution” indicates a section of the manual that

requires special attention.

n

Reference

n

A “reference” provides information related to the current

topic and indicates the page number of a related section

of the manual.

n

Application Example

n

An “application example” indicates an example related

to the current topic.

(note ×) “(note ×)” is a reference to a numbered note that

provides supplementary information lower on the same

page.

n

Note x

n

“Note ×:” provides supplementary information related to

the passage marked with “(note ×).”

The descriptions below indicate keyboard keys with capitalized names inside angle brackets.

Examples

<Enter> Enter (or Return) key

<Space> Space key

<Ctrl> Control key (left or right)

<Shift> Shift key (left or right)

page 1-7

Page 14

2. Putting Board through Its Paces

Page 15

Chapter 2 Putting Board through its Paces

2-1. Setup

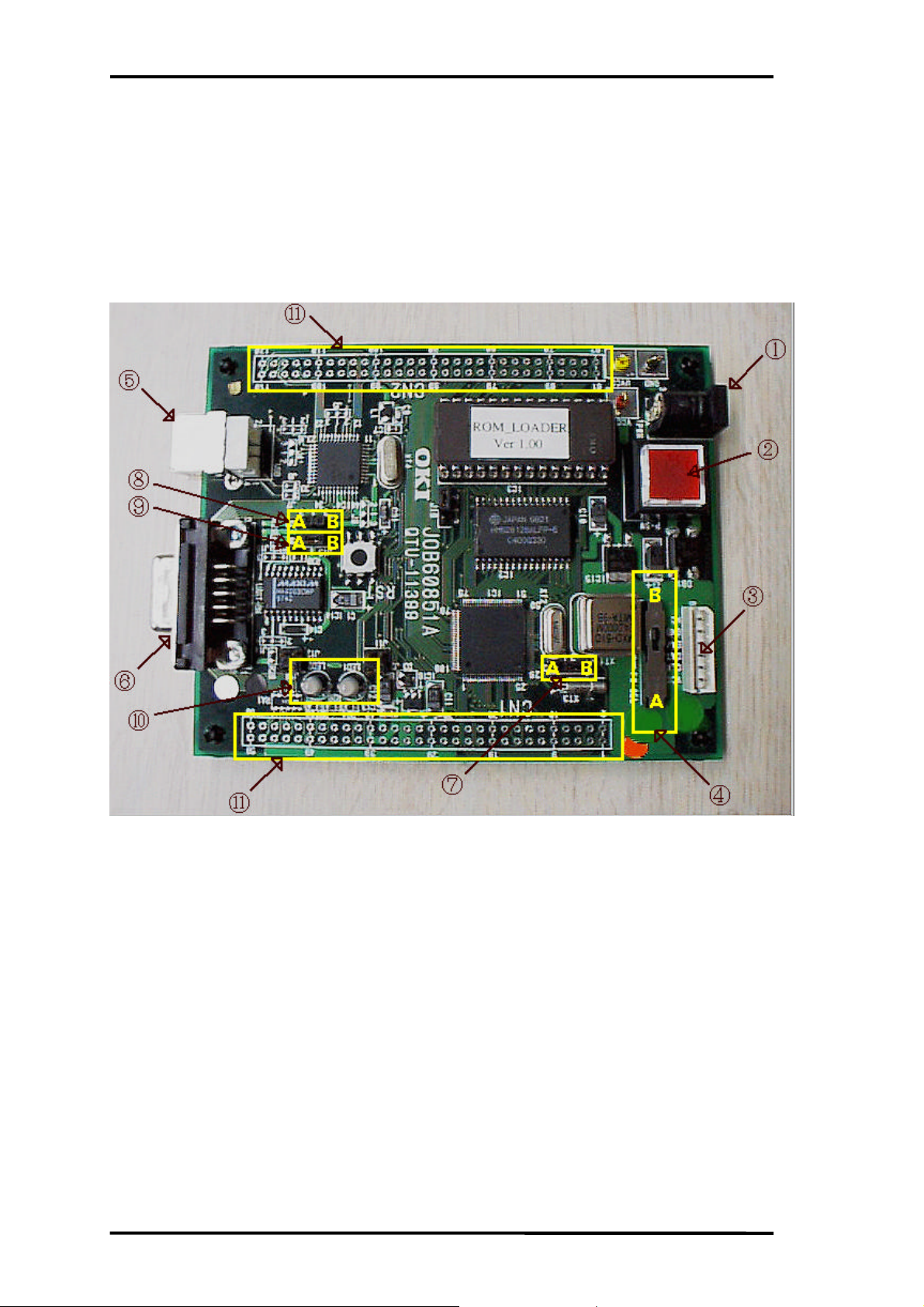

2-1-1. Configuring JOB60851 Board

Make sure that the switches and jumpers numbered 4, 7, 8, and 9 in Figure 2.1.1 are all in their

factory default positions, B.

Figure 2.1.1. JOB60851 Board, Top View

(1) AC adapter jack (6) Serial (RS-232C) connector

(2) Power switch (7) Clock selection jumper

(3) Flash writer connector (8) Power supply jumpers

(4) Flash writer selection switch (FW-SEL) (9) Power supply jumpers

(5) USB connector (10) Indicator LEDs (LED1 and LED2)

(11) User connectors (CN1 and CN2)

page 2-2

Page 16

Chapter 2 Putting Board through its Paces

2-1-2. Installing Development Software

(1) Install CC665S compiler package

1. Create a directory for the package--c:\665s, for example.

2. Copy the contents of the CD-ROM directory \package\cc665s to that directory.

readme.txt

c665spak.exe

mac66k.exe

rtl665s.exe

tgt665s.exe

3. In an MS-DOS compatibility box, switch to the above directory and run the .EXE files, selfexpanding archives that automatically extract compiler files to the appropriate

subdirectories.

C:\665s>c665spak.exe <Enter>

C:\665s>mac66k.exe <Enter>

C:\665s>rtl665s.exe <Enter>

C:\665s>tgt665s.exe <Enter>

(2) Configure environment

1. Make a copy of the standard Windows 9x .PIF file for opening an MS-DOS window and

rename it 665s--665s.pif if you have Explorer set to display file extensions.

2. Create a work directory--c:\test, for example.

3. Using a text editor, create the following batch file in the work directory--c665.bat, for

example. (Modify the c:\665s portions as necessary.)

set path=\665s;c:%path%

set INCL66K=c:\665s\INCLUDE

set LIB66K=c:\665s\LIB

4. Display the Properties for the .PIF file created above, click the Program tab, and set the

Work directory and Batch file fields to the names used above.

c:\test

c:\test\c665s.bat

5. Press <Enter> to save the changes.

(3) Copy sample executables

Copy the contents of the CD-ROM directory \package\sample to the work directory created

above.

The software installation is now complete.

n

Note

n

The above procedures assume that the compiler package is installed in the directory

\665s on drive C:. If you wish to locate this directory on another drive or even change

both drive and directory, simply change all occurrences of c:\665s above to the name

of the new directory.

Page2-3

Page 17

Chapter 2 Putting Board through its Paces

2-1-3. Connecting Board

This section gives the procedures for preparing the JOB60851 board for connection to the

development host.

1. Make sure that the Flash writer selection switch (FW-SEL, #4 in Figure 2.1.1) is in its B

position.

2. Plug the AC adapter into the jack (#1 in Figure 2.1.1) on the board. Make sure that the power

(#2 in Figure 2.1.1) is OFF.

3. Plug one end of the USB cable into the connector (#5 in Figure 2.1.1) on the board. Connect the

other end into the host controller.

2-2. Running Default Program

This section gives the procedures for running the program shipped in the MSM66Q573 Flash

memory.

2-2-1. Installing USB Driver

The included CD-ROM includes the necessary USB driver as well as host software, used in the next

Section, for testing bulk data flow.

1. Create a directory for the host software--c:\usb, for example.

2. Copy the contents of the CD-ROM directory \package\host to that directory.

Rwbulk.exe

Bulkusb.sys

Bulkusb.inf

3. Connect the JOB60851 board as described in Section 2.1.3 above and apply power to it.

4. When Windows 98 automatically detects the new device, install the driver using the Windows

98 driver wizard. (Have the Windows 98 CD-ROM or CABs handy.)

2-2-2. Running Flash Memory Program

The JOB60851 Starter Kit ships with a program already in the MSM66Q573 Flash memory. The

executable Rwbulk.exe installed above is for transferring data to and from this program.

1. Open an MS-DOS window and change to the directory containing Rwbulk.exe--c:\usb in our

example.

C:\usb>rwbulk.exe <Enter>

2. Run Rwbulk.exe to display the built-in help screen.

page 2-4

Usage for RwBulk:

RwBulk type [options]

type : INFO -- dump USB configuration and pipe info

BULK -- Read/Write test

DESC -- Get Descriptor test

CLASS -- Class Request test

Page 18

Chapter 2 Putting Board through its Paces

VENDOR -- Vendor Request test

Detail Usage for -? option:

RwBulk INFO -?

RwBulk BULK -?

RwBulk DESC -?

RwBulk CLASS -?

RwBulk VENDOR -?

Examples:

RwBulk -u

RwBulk DESC 03 00 00 00FF

RwBulk -o Pipe00 -fo out.dat -vl 2

RwBulk -i 1 -r 8192 -fi in.dat -vl 2

RwBulk VENDOR NONE DEVICE -r 00 -v 0000 -i 0000 -l 0000

3. Use the -u command line option to view the USB pipe numbers.

C:\usb>rwbulk.exe BULK –? <Enter>

Usage for Read/Write test:

RwBulk [BULK] [-options]

-i [s] where s is the input pipe

-o [s] where s is the output pipe

-r [n] where n is number of bytes to read

-w [n] where n is number of bytes to write

-fi [fn] where fn is a filename for the input pipe

-fo [fn] where fn is a filename for the output pipe

-vl [n] where n is verbose level(0,2,5, default=2)

-c [n] where n is number of iterations (default=1, 0 is infinity)

The options and the meanings are:

-i [s] To specify the input pipe name the device(JOB60851) to the host direction.

-o [s] To specify the output pipe name the host to the device(JOB60851) direction.

-r [n] To activate operation of n-bytes read from the input pipe

-w [n] To activate operation of n-byte write into the output pipe.

-fi [fn] To specify a file name for bulk in operation using the input pipe.

-fo [fn] To specify a file name for data bulkout operation using bulk out pipe.

-vl [n] To specify verbose level as 0, 2 ro 5

-c [n] To specify the number of iterations of specified write and read operations

3. Use the -u command line option to view the USB pipe numbers.

C:\usb>rwbulk.exe –u <Enter>

Page2-5

Page 19

Chapter 2 Putting Board through its Paces

"USB_ENDPOINT_DESCRIPTOR for Pipe00"

"USB_ENDPOINT_DESCRIPTOR for Pipe01"

"USB_ENDPOINT_DESCRIPTOR for Pipe02"

The software defines three pipes, PIPE00 to PIPE02. The first is for output--that is, from the

development host to the JOB60851 board. The other two are for input (in the opposite

direction).

PIPE00→OUTPUT:PC→From host to JOB60851

PIPE01→INPUT:JOB60851→To host from JOB60851

PIPE02→INPUT:JOB60851→To host from JOB60851

4. Try one data transfer in each direction.

C:\USB>rwbulk.exe -o PIPE00 -w 1024 -i PIPE01 -r 1024

This command line writes one kilobyte of test data using output pipe PIPE00 and then reads the

same amount of data using input pipe PIPE01.

<Enter>

The following messages appear if both operations are successful.

Device Opened successfully.

<pipe00> W (tot:1024 @ 17:04:16) : req 1024 - 1024 written

<pipe01> R (tot:1024 @ 17:04:16) : req 1024 - 1024 read

5. Try multiple transfers.

C:\USB>rwbulk.exe -o PIPE00 -w 1024 -i PIPE01 -r 1024 –c 10

This command line adds a repeat count of ten, so should produce ten such message pairs.

Opened successfully.

Device Opened successfully.

<pipe00> W (tot:1024 @ 17:21:07) : req 1024 - 1024 written

<pipe01> R (tot:1024 @ 17:21:07) : req 1024 - 1024 read

:

:

<pipe00> W (tot:9216 @ 17:21:07) : req 1024 - 1024 written

<pipe01> R (tot:9216 @ 17:21:07) : req 1024 - 1024 read

<pipe00> W (tot:10240 @ 17:21:07) : req 1024 - 1024 written

<pipe01> R (tot:10240 @ 17:21:07) : req 1024 - 1024 read

<Enter>

6. Additional operation

For more detailed operation please refer to readme.txt file in host driver (Package\Host)

directory.

2-3. Running User Programs

This section gives the procedures for downloading a program over a serial link to the JOB60851

board and then running it.

page 2-6

Page 20

Chapter 2 Putting Board through its Paces

IOIO

IOIO

2-3-1. Connecting Serial Cable

1. Disconnect the USB cable from the board and plug the AC adapter into the jack (#1 in Figure

2.1.1). Make sure that the power (#2 in Figure 2.1.1) is OFF.

2. Plug one end of the serial cable into a serial port on the development host. Serial ports usually

have an icon similar to the following, a label (COM1 or COM2), or just a number.

1

2

or

3. Plug the other end of the serial cable into the serial connector (#6 in Figure 2.1.1) on the board.

4. Make sure that the Flash writer selection switch (FW-SEL, #4 in Figure 2.1.1) is in its A

position.

2-3-2. Loading Terminal Emulator

Checking serial link operation requires HyperTerminal, Tera Term Pro, or other terminal emulator

configured to use the following communications parameters for the serial port (COM1 or COM2)

with the serial cable to the JOB60851 board.

Speed 38,400 b/s

Word size 8 bits

Parity check None

Stop bits 2

Flow control None

(1) Loading and configuring HyperTerminal

1. Load HyperTerminal by double-clicking the Hypertrm.exe icon. Many Windows setups

have the HyperTerminal folder on the Start menu under Programs → Accessories →

Communications → HyperTerminal.

2. In the connection name dialog box that appears, either double-click an icon or type a name

and hit <Enter>.

3. In the configuration dialog box that appears, select a direct connection to the serial port

(COM1 or COM2) and hit <Enter>.

4. In the Properties dialog box that appears, configure the serial port.

Speed 38,400 b/s

Word size 8 bits

Parity check None

Stop bits 2

Flow control None

(2) Loading and configuring Tera Term Pro

1. Load Tera Term Pro.

2. In the configuration dialog box that appears, select the serial port (COM1 or COM2) and hit

<Enter>.

3. Choose the Setup menu's Serial port command.

4. In the dialog box that appears, configure the serial port and click the OK button to save the

new settings.

Page2-7

Page 21

Chapter 2 Putting Board through its Paces

Speed 38,400 b/s

Word size 8 bits

Parity check None

Stop bits 2

Flow control None

(3) Activating JOB60851 board

Once the terminal emulator is configured, turn on the power (#2 in Figure 2.1.1).

2-3-3. Synchronizing Link

Before communicating with the JOB60851 board, check that it and the development host are using

the same data transfer speed by downloading the file !zero.dat in the work directory--c:\test in our

example.

(1) Using HyperTerminal

1. Choose the Transfer menu's Send text file command.

2. In the dialog box that appears, double-click the file !zero.dat.

3. Wait for the response OK indicating synchronization.

(2) Using Tera Term Pro

1. Choose the File menu's Send file command.

2. In the dialog box that appears, make sure that the Binary option in the lower left corner is

selected and double-click the file !zero.dat.

3. Wait for the response OK indicating synchronization.

2-3-4. Downloading and Executing

Next repeat the above procedure with the precompiled "Hello world!" program (main.hex) in the

work directory--c:\test in our example.

(1) Using HyperTerminal

1. Choose the Transfer menu's Send text file command.

2. In the dialog box that appears, double-click the file main.hex.

3. Wait for the response "Hello World" indicating successful downloading and execution.

4. To terminate communications, close the window and answer "Yes" to the query asking

permission to break the link.

5. Answering "Yes" to the query asking whether to save the session saves the current settings

under the name first entered or selected above in Section 2.3.2 for reuse next time.

(2) Using Tera Term Pro

1. Choose the File menu's Send file command.

2. In the dialog box that appears, make sure that the Binary option in the lower left corner is

selected and double-click the file main.hex.

3. Wait for the response "Hello World" indicating successful downloading and execution.

(3) Compiling, downloading, and executing a program

The above procedures simply download a precompiled program that was ready to run. Now it is

time to compile an actual user program. By way of illustration, the following simply modifies

page 2-8

Page 22

Chapter 2 Putting Board through its Paces

the above program to display a different string.

1. Copy the source code main.c to a new name, test.c, in the work directory--c:\test in our

example.

2. Open the copy in a text editor.

#include <stdio.h>

#include <stdlib.h>

#include <m66573.h>

void main(void)

{

std_init_573();

S0BUF = 0x0A;/* 1st byte send to get transmit ready status */

printf_c("Hello World!! \n");

for(;;);

}

3. Modify the string in line 10, replacing "World" with your own name.

4. Save the modified version. Exit or minimize the text editor.

5. Double-click the 665s.pif icon and enter the following command line to compile the new

version into test.hex, an executable for downloading to the JOB60851 board.

n

Note

n

Case counts for command line options (/T, /WIN, and /H here), but not for the

command name (cl665s) or file names.

6. Repeat the appropriate download procedure above substituting the new program, test.hex,

for main.hex.

7. Wait for your name to appear.

2-4. Overwriting Flash Memory Contents

As already mentioned in Section 2.2 above, the board ships with a test program in the MSM66Q573

Flash memory. This may be overwritten, however, with a PW66K Flash programmer.

For further details about flash programmer, contact Oki Electric Device Sales or distributor.

Page2-9

Page 23

3. System Specifications

Page 24

Chapter 3 System Specifications

USB link

Serial link

3-1. System Components

3-1-1. System Objective

The JOB60851 board's primary objective is lowering the threshold for developing new USB devices.

3-1-2. System Components

The JOB60851 board has the components shown in Figure 3.1.1.

JOB60851

MSM66Q573

Flash

PC

TERMINAL

ROM

(LOADER)

ExRAM

ML60851C

Figure 3.1.1. System Block Diagram

PC

USB HOST

Windows98

page 3-2

Page 25

3-2. Hardware Specification

3-2-1. Connectors and Switches

Chapter 3 System Specifications

Figure 3.2.1. JOB60851 Board, Top View

(1) AC adapter jack

The included AC adapter has the following specifications.

Input: 100 V AC, 50/60 Hz, 18 VA

Output: 10 V DC, 850 mA

n

Note

n

Use only the AC adapter included with the product.

(2) Power switch

Pressing this switch alternately turns the power to the board on and off. If the indicator fails to

light, check the AC adapter connections.

(3) Flash writer connector

This set of pins connects to the PW66K Flash writer for rewriting the program in the

MSM66Q573 Flash memory. For further details, contact Oki Electric Device Sales at +81-35445-6027.

page 3-3

Page 26

Chapter 3 System Specifications

(4) Flash writer selection switch (FW-SEL)

The B side of this switch is for executing the program in the MSM66Q573 Flash memory or

overwriting it with the PW66K Flash writer (available separately).

(5) USB connector

This Series B connector is for the USB cable.

(6) Serial (RS-232C) connector This 9-pin female DSUB connector is for the RS-232C cable

linking the JOB60851 board to a terminal emulator running on the host personal computer.

n

Note

n

Always include the JOB60851 serial number with any queries. It is printed in black ink

on the underside of the board, near the serial connector.

(7) Clock selection jumper

This jumper offers a choice of two onboard MSM66Q573 microcontroller system clock

frequencies: 16 (A) and 24 (B) MHz.

(8), (9) Power supply jumpers

These jumpers offer a choice of two power supplies: USB (A) and AC adapter (B). Both must

be in the same position.

(10) Indicator LEDs (LED1 and LED2)

LED1 monitors the LOAD_SEL signal

LED2 is connected to Port 7, so is under program control. The built-in loader, for example,

changes it from the default red that it has when the power is first applied to green when a

downloaded program is executing.

(11) User connectors (CN1 and CN2)

These connectors provide access to almost all onboard MSM66Q573 microcontroller pins as

well as to the ML60851C USB controller pins. The JOB60851 Starter Kit even includes the

matching connectors for easily connecting these to the user application circuit under

development.

page 3-4

Page 27

3-2-2. Circuit Diagram

Chapter 3 System Specifications

Figure 3.2.2. Circuit Diagram (1/2)

page 3-5

Page 28

Chapter 3 System Specifications

Figure 3.2.3. Circuit Diagram (2/2)

n

Note

n

An electronic version of this circuit diagram is available in the CD-ROM directory

\document\job60851 as the MS Power Point document cir_j851.ppt.

page 3-6

Page 29

Chapter 3 System Specifications

3-2-3. Parts List

Tables 3.2.1 and 3.2.2 list the parts on the JOB60851 board.

Table 3.2.1. Parts List (1/2)

Item Quantity Reference Part DSCRIPTION

1 15 C13,C15,C16,C17,C18,C19,C20,

C21,C22,C23

C24,C25,C26,C27,C28

2 1 C7 1000pF Ceramic Capacitor

3 1 C6 330pF Ceramic Capacitor

4 3 C4,C5,C8 5pF Ceramic Capacitor

5 2 C2,C3 15pF Ceramic Capacitor

6 1 C31 0.47uF Tantalum Capacitor

7 1 C9 10uF 16v Tantalum Capacitor

8 4 C1,C10,C11,C12 4.7uF 25v Tantalum Capacitor

9 1 C14 0.1uF 35v Tantalum Capacitor

10 15 R1,R2,R3,R4,R7,R8,R12,R17,R18,R19 100K Chip Resistor

R30,R31,R32,R33,R34

11 1 R5 100 Chip Resistor

12 2 R6,R36 51K Chip Resistor

13 3 R9,R22,R23 220 Chip Resistor

14 3 R10,R11,R15 1M Chip Resistor

15 2 R13,R14 1.5K Chip Resistor

16 6 R16,R20,R21,R24,R26,R27 10K Chip Resistor

17 1 R25 12K Chip Resistor

18 2 R28,R29 470K Chip Resistor

19 1 R35 1K Chip Resistor

20 5 RA1,RA2,RA3,RA4,RA5 100K x8 Chip Network Resistor

21 3 D1,D2,D3 DIODE 80v,100mA

22 1 DB1 DIODE 200v,1A Bridge Type

23 2 FB1,FB2 FB Ferrite Bead Inductor

24 1 L1 2.2uH 2.2uH Inductor

25 1 IC1 M66Q573 Micro Controller

26 1 IC2 HM628128AL 128K x 8b SRAM

27 1 IC3 M27C256H 32K x 8 EPROM

28 1 IC4 M60851A USB Device Interface

29 1 IC5 74HC58 Logic Gate

30 2 IC6,IC11 74HC00 Logic Gate

31 1 IC7 74HC04 Logic Gate

32 2 IC8,IC12 74HC08 Logic Gate

33 1 IC9 74HC32 Logic Gate

34 1 IC10 74HC27 Logic Gate

35 1 IC13 TC7S66FU 1ch Analog Switch

36 1 IC14 MAX203CWP RS232 Xlator

37 1 IC15 NJM7805F 3-term 5v(1A) Regulator

38 1 IC16 XC62FP3302 3-term 3.3v(0.5A)

39 2 LED1,LED2 GL3ED8 LED (bright red/green)

40 1 USB USB-212-T USB 'B' type Receptacle

41 2 CN1,CN2 HIF3HB-60DA-

42 1 FW-CN 5267-06A-X 6pin Servo Connector

43 1 UART-CN 17LE-13090-

44 1 FW-SEL MIS-AC-3--2N Slide Switch

45 1 P-SW UB-26SKP1R Power Switch

46 1 RST SMT1-01 Reset Switch

47 1 PWR HEC0470-01-

48 1 XT1 MXO-51C 24MHz 24MHz Crystal Oscillator

49 1 XT2 HC49/U-S 16MHz 48MHz Quartz Crystal

50 1 XT3 DT-38

51 1 XT4 HC49/U-S

52 1 PCB QTU-11399 Printed Circuit Board

0.1uF Ceramic Capacitor

Regulator

2.54DSA

27(D3AB)

630

32.768KHz

48MHz100ppm

60pin Header Connector

9pin RS232C Conn. Female

Power Input Connector

32.768KHz Quartz Crystal

48MHz +/-100ppm

Quartz Crystal

page 3-7

Page 30

Chapter 3 System Specifications

3-2-4. Memory Maps

This Section gives code and data memory maps for the various JOB60851 operation modes.

(1) Download mode

This mode maps the code memory to the EPROM and the data memory to program RAM and

Flash memory. It uses the loader, a program stored in the EPROM, to download a user

application program over a serial link from the development host to program RAM.

Loader Mode 1 memory map

Program Memory

0:0000 h

Ext._EPROM(E)

(Loader Program)

0:7FFFh

( Load_Sel/ = L ) ( EA/ = L )

Data Memory

0:0000 h

0:0200 h

0:1200 h

0:2000 h

0:3000 h

0:8000 h

1:0000 h

1:0200 h

1:1200 h

1:2000 h

1:3000 h

1:8000 h

1:FFFFh

SFR/XSFR

Int._RAM

Ext._SRAM(A)or(B)

ML60851A

Ext._SRAM(A)or(B)

Ext._SRAM(A)or(B)

SFR/XSFR

Int._RAM

Ext._SRAM(C)or(D)

ML60851A

Ext._SRAM(C)or(D)

Ext._SRAM(C)or(D)

0:0000 h

0:8000 h

1:0000 h

1:8000 h

1:FFFFh

Ext._SRAM

(A)

(B)

(C)

(D)

0:0000 h

0:7FFFh

Ext._EPROM

(E)

page 3-8

Figure 3.2.4. Memory Map for Download Mode

Page 31

Chapter 3 System Specifications

(2) Flash execution mode

This mode maps the code memory to the Flash memory and the data memory to work RAM. It

executes the program in Flash memory. Cutting the power does not erase the program, which

starts automatically when the power is next applied.

Loader Mode2 memory map

Program Memory

0:0000h

Int._FlashROM

(Loader Program)

1:0000h

Int._FlashROM

(Only M66Q577)

1:FFFFh

( Load_Sel/ = L ) ( EA/ = H )

Data Memory

0:0000h

0:0200h

0:1200h

0:2000h

0:3000h

0:8000h

1:0000h

1:0200h

1:1200h

1:2000h

1:3000h

1:8000h

1:FFFFh

SFR/XSFR

Int._RAM

Ext._SRAM(A)or(B)

ML60851A

Ext._SRAM(A)or(B)

Ext._SRAM(A)or(B)

SFR/XSFR

Int._RAM

Ext._SRAM(C)or(D)

ML60851A

Ext._SRAM(C)or(D)

Ext._SRAM(C)or(D)

0:0000h

0:8000h

1:0000h

1:8000h

1:FFFFh

Ext._SRAM

(A)

(B)

(C)

(D)

Ext._EPROM

0:0000h

(E)

0:7FFFh

Figure 3.2.5. Memory Map for Flash Execution Mode

page 3-9

Page 32

Chapter 3 System Specifications

(3) Application mode

This mode maps the code memory to program RAM and the data memory to work RAM. It

executes the program in program RAM.

AP Mode 1 memory map

Program Memory

0:0000 h

Ext._SRAM(A)

(AP Program)

0:7FFFh

Ext._SRAM(B)

(AP Program)

1:0000 h

Ext._SRAM(A)

(AP Program)

1:8000 h

Ext._SRAM(B)

(AP Program)

1:FFFFh

( Load_Sel/ = H ) ( EA/ = L )

Data Memory

0:0000 h

0:0200 h

0:1200 h

0:2000 h

0:3000 h

0:8000 h

1:0000 h

1:0200 h

1:1200 h

1:2000 h

1:3000 h

1:8000 h

1:FFFFh

SFR/XSFR

Int._RAM

Ext._SRAM(C)

ML60851

Ext._SRAM(C)

Ext._SRAM(D)

SFR/XSFR

Int._RAM

Ext._SRAM(C)

ML60851

Ext._SRAM(C)

Ext._SRAM(D)

0:0000 h

0:8000 h

1:0000 h

1:8000 h

1:FFFFh

Ext._SRAM

(A)

(B)

(C)

(D)

0:0000 h

0:7FFFh

Ext._EPROM

(E)

Figure 3.2.6. Memory Map for Application Mode

page 3-10

Page 33

Chapter 3 System Specifications

(4) Flash rewrite mode

This mode maps the code memory to the Flash memory and the data memory to work RAM. It

executes the program in Flash memory. Cutting the power does not erase the program, which

starts automatically when the power is next applied.

AP Mode2 memory map

Program Memory

0:0000h

Int._FlashROM

(AP Program)

1:0000h

Int._FlashROM

(Only M66Q577)

1:FFFFh

( Load_Sel/ = H ) ( EA/ = H )

Data Memory

0:0000h

0:0200h

0:1200h

0:2000h

0:3000h

0:8000h

1:0000h

1:0200h

1:1200h

1:2000h

1:3000h

1:8000h

1:FFFFh

SFR/XSFR

Int._RAM

Ext._SRAM(C)

ML60851A

Ext._SRAM(C)

Ext._SRAM(D)

SFR/XSFR

Int._RAM

Ext._SRAM(C)

ML60851A

Ext._SRAM(C)

Ext._SRAM(D)

0:0000h

0:8000h

1:0000h

1:8000h

1:FFFFh

Ext._SRAM

(A)

(B)

(C)

(D)

Ext._EPROM

0:0000h

(E)

0:7FFFh

Figure 3.2.7. Memory Map for Flash Rewrite Mode

page 3-11

Page 34

Chapter 3 System Specifications

3-3. System Limitations

3-3-1. Resources Uses

The user connectors (CN1 and CN2) on the JOB60851 board make available to the user application

system almost all onboard MSM66Q573 microcontroller pins and thus most microcontroller

functionality.

The JOB60851 board, however, monopolizes certain microcontroller resources in running its own

system, making them unavailable to the developer.

Tables 3.3.1 through 3.3.3 list the MSM66Q573 pin assignments.

Table 3.3.1. MSM66Q573 Pin Assignments (1/2)

Pin Number and Name Connections

IC1.1 P10-4 IC12.2(R12)

IC1.2 P10-5 IC5.4

IC1.3 TM5EVT/P10-7 R8,R35

IC1.4 RXD1/P8-0 MAX203.20

IC1.5 TXD1/P8-1 MAX203.2

IC1.6 RXC1/P8-2

IC1.7 TXC1/P8-3

IC1.8 TM4OUT/P8-4

IC1.9 PWM2OUT/P8-6

IC1.10 PWM3OUT/P8-7

IC1.11 PWM0OUT/P7-6 IC11.9 IC11.10

IC1.12 PWM1OUT/P7-7 IC11.12 IC11.13

IC1.13 VDD Vcc

IC1.14 GND Vcc

IC1.15 HLDACK/P9-7

IC1.16 EXINT4-P9-0 IC4.12(R16)

IC1.17 EXINT5/P9-1 IC12.4(R17)

IC1.18 P9-2 FW-SEL.1,2

IC1.19 P9-3 FW-SEL.3,5

IC1.20 EXINT0/P6-0

IC1.21 EXINT1/P6-1

IC1.22 EXINT2/P6-2

IC1.23 EXINT3/P6-3

IC1.24 P6-4

IC1.25 P6-5

IC1.26 P6-6

IC1.27 P6-7

IC1.28 P5-4/CPCM0

IC1.29 P5-5/CPCM1

IC1.30 P5-6/TM0OUT

IC1.31 P5-7/TM0EVT

IC1.32 RESb IC12.8 IC12.12

IC1.33 NM1 R7

IC1.34 EAb FW-SEL.8

IC1.35 VDD Vcc

IC1.36 XT0 XT3

IC1.37 XT1b XT3

IC1.38 GND Vcc

IC1.39 OSC0 J1

IC1.40 OSC1b XT2

(J13.3)

(J14.3)

page 3-12

Page 35

Chapter 3 System Specifications

IC4.25.(J4.2)

Table 3.3.1. MSM66Q573 Pin Assignments (2/2)

IC1.41 VDD Vcc

IC1.42 P11-0/WAIT

IC1.43 P11-1/HOLD

IC1.44 P11-2/CLKOUT

IC1.45 P11-3/XTOUT

IC1.46 P11-6/TM9OUT

IC1.47 P11-7/TM9EVT

IC1.48 P3-1/PSENb IC3.22 IC8.5 IC9.10 R34

IC1.49 P3-2/RDb IC6.12 IC8.9 R26

IC1.50 P3-3/WRb IC6.13 IC7.13 R27

IC1.51 P0-0/D0 IC2.13 IC3.11 IC4.44 RA1.9

IC1.52 P0-1/D1 IC2.14 IC3.12 IC4.43 RA1.2

IC1.53 P0-2/D2 IC2.15 IC3.13 IC4.42 RA1.8

IC1.54 P0-3/D3 IC2.17 IC3.15 IC4.41 RA1.3

IC1.55 P0-4/D4 IC2.18 IC3.16 IC4.38 RA1.7

IC1.56 P0-5/D5 IC2.19 IC3.17 IC4.37 RA1.4

IC1.57 P0-6/D6 IC2.20 IC3.18 IC4.36 RA1.6

IC1.58 P0-7/D7 IC2.21 IC3.19 IC4.35 RA1.5

IC1.59 GND Vcc

IC1.60 P4-0/A0 IC2.12 IC3.10 IC4.32 R33

IC1.61 P4-1/A1 IC2.11 IC3.9 IC4.31 RA2.5

IC1.62 P4-2/A2 IC2.10 IC3.8 IC4.30 RA2.6

IC1.63 P4-3/A3 IC2.9 IC3.7 IC4.29 RA2.4

IC1.64 P4-4/A4 IC2.8 IC3.6 IC4.28 RA2.7

IC1.65 P4-5/A5 IC2.7 IC3.5 IC4.27 RA2.3

IC1.66 P4-6/A6 IC2.6 IC3.4 IC4.26 RA2.8

IC1.67 P4-7/A7 IC2.5 IC3.3

IC1.68 P1-0/A8 IC2.27 IC3.25 RA2.9

IC1.69 P1-1/A9 IC2.26 IC3.24 RA3.5

IC1.70 P1-2/A10 IC2.23 IC3.21 RA3.6

IC1.71 P1-3/A11 IC2.25 IC3.23 RA3.4

IC1.72 P1-4/A12 IC2.4 IC3.2 IC10.3 RA3.7

IC1.73 P1-5/A13 IC2.28 IC3.26 IC8.2 R31

IC1.74 P1-6/A14 IC2.3 IC3.27 IC10.4 R32

IC1.75 P1-7/A15 IC3.1 IC52 R25

IC1.76 A16/P2-0 IC5.9 RA3.3

IC1.77 A17/P2-1 IC10.1 RA3.8

IC1.78 A18/P2-2 IC10.13 RA3.2

IC1.79 A19/P2-3 IC10.2 RA3.9

IC1.80 VDD Vcc

IC1.81 VREF Vcc

IC1.82 A10/P12-0

IC1.83 A11/P12-1

IC1.84 A12/P12-2

IC1.85 A13/P12-3

IC1.86 A14/P12-4

IC1.87 A15/P12-5

IC1.88 A16/P12-6

IC1.89 A17/P12-7 R10

IC1.90 AGND GND

IC1.91 RXD0/P7-0 MAX203.20

(J13.2)

IC1.92 TXD0/P7-1 MAX203.2

(J14.2)

IC1.93 GND Vcc

IC1.94 RXC0/P7-2

IC1.95 TM3OUT/P7-4

IC1.96 TM3EVT/P7-5

IC1.97 SIOCK3/P10-0

IC1.98 SIOI3/P10-1

IC1.99 SIOO3/P10-2

IC1.100 P10-3

RA2.2

page 3-13

Page 36

4. Software Development

Page 37

Chapter 4 Software Development

Section 4-1. "USB Basics" provides an overview of the Universal Serial Bus (USB) specifications as

well as URLs for obtaining detailed specifications.

Section 4-2. "Sample USB Firmware" provides a functional overview of the sample device firmware

shipped with the JOB60851 Starter Kit and procedures for modifying the source code and evaluating

the result.

Section 4-3. "USB Bits and Pieces" covers device controller specifications, device controller

operational overview, notes to device developers. etc.

Sections 4-4. "Port 7 LED2 Control" and 4.5 "Standard I/O over Serial Link" give procedures for

modifying the sample source code for simple debugging with the JOB60851 board. They cover both

procedures controlling the onboard LED2 and those using standard I/O library functions (printf(),

scanf(), etc.) over the serial link to a terminal emulator.

4-1. USB Basics

4-1-1. Bus Topology, Addresses, and Hot Plugging

The Universal Serial Bus (USB) features a tiered star topology with a single host controller (a.k.a.

root or Tier 0 hub) at the top of a device tree consisting of functions branching off hubs(a.k.a.

repeaters).

A tree has up to 127 such devices (hubs and functions) with addresses 1 to 127. The address 0 is

reserved for use as the default control address that USB devices use when they are first powered on

or reset. Requests from the host controller use this default address to determine the structure of this

new device and assign it an address. This highly flexible arrangement holds the key to hot plugging

(a.k.a. dynamic insertion and removal).

HOST

HOST

CONTROLLER

CONTROLLER

ROOT HUB

ROOT HUB

HUB

HUB

HUB

HUB

HUB

DEVICE

DEVICE

DEVICE

DEVICE

DEVICE

DEVICE

HUB

DEVICE

DEVICE

DEVICE

DEVICE

Figure 4.1.1. Bus Topology

The tree can chain hubs to produce up to five tiers. Cables between hubs or between a hub and a

device can be up to five meters long. To prevent the formation of illegal loopback connections at

hubs, the downstream ports on the root and other hubs use a connector (Series A) mechanically

different from those on the upstream ports on devices (Series B).

The JOB60851 board is for developing devices, not hubs, so features a Series B connector for

connection to the Series A one on the root or other hub.

page 4-2

Page 38

Chapter 4 Software Development

4-1-2. Specification Documents

USB specifications have been established by the USB Implementers Forum. These and other

materials are available on the World Wide Web at the following URLs.

Forum top page http://www.usb.org/developers/

Developers section http://www.usb.org/developers/

Developer documentation http://www.usb.org/developers/docs.html

Device classes http://www.usb.org/developers/devclass.html

Compliance testing http://www.usb.org/developers/complian.html

The USB Implementers Forum augments the core specifications, the document specifying

characteristics shared by all USB devices, with separate Universal Serial Bus Device Class

Specifications for specific device types.

4-1-3. Core Specifications

This document covers common characteristics of host controllers, hubs, devices, and transmission

pathways. Specific areas include an overview of USB communications, functionality, and bus

drivers; physical and electrical specifications for connectors, transmission pathways, and other

components; and the standard command-response device requests that all USB devices must support.

The current version number is 1.1.

1

n

Note

n

Note: Version 1.1 superseded version 1.0 in October 1998. The older version is still

available on the World Wide Web. Apart from such additions as InterruptOut transfers,

most changes involve removing ambiguities in the older version. The electrical

specifications in Chapter 7 now provide more detail. The protocol layer specifications

in Chapter 8 add descriptions of STALL operation for the default control pipe and of

the Data stage of control transfers. The device framework specifications in Chapter 9

add descriptions of state processing for request errors. The hub specifications in

Chapter 11 have been completely rewritten.

Chapter 1 Introduction Objectives and target audience for USB specifications

Chapter 2 Terms and

Definitions of key terms used

Abbreviations

Chapter 3 Background Design goals and requirements addressed

Chapter 4 Architectural Overview Overview of USB architecture and key concepts

Chapter 8 Protocol Layer Packet definitions and detailed descriptions of

transaction formats for error detection and recovery,

etc.

Chapter 9 UBS Device Framework Detailed descriptions of device states, device requests,

1

Version 1.1 superseded version 1.0 in October 1998. The older version is still available on the World

Wide Web. Apart from such additions as InterruptOut transfers, most changes involve removing

ambiguities in the older version. The electrical specifications in Chapter 7 now provide more detail.

The protocol layer specifications in Chapter 8 add descriptions of STALL operation for the default

control pipe and of the Data stage of control transfers. The device framework specifications in

Chapter 9 add descriptions of state processing for request errors. The hub specifications in Chapter

11 have been completely rewritten.

page 4-3

Page 39

Chapter 4 Software Development

→

←

→

←

→

standard device requests, and standard device

descriptors

Chapter 10 USB Host: Hardware

and Software

Functions and operation of host hardware and

software

Chapter 11 Hub Specification Hub port operation, requests, and descriptors

Chapter 4 provides a firm grounding in the USB core specifications. All developers of USB

equipment must study Chapter 5 very carefully. Hardware developers must read Chapter 7; firmware

developers, Chapters 8 and 9. Firmware developers must pay particular attention to the timing

specifications in Chapter 7.

What follows are key points from the core specifications. For complete details, refer to the

specifications available from the USB Implementers Forum web site.

4-1-4. Data Flow Types

The USB specifications define four data flow types with the following characteristics. Flexibly

combining these four data flow types provides solutions to the communications needs of a wide

variety of applications.

Table 4.1.2. USB Data Flow Types

Control Communication of commands and responses for device configuration and pipe

control

Bulk Transfer of relatively large, bursty data volumes with wide dynamic latitude in

transmission constraints

Interrupt Transfer of small data volumes within time limits based on human-perceptible echo

or feedback response characteristics

Isochronous Transfer using prenegotiated USB bandwidth with a prenegotiated delivery latency--

audio data, for example--with no procedure for retransmitting data

4-1-5. Bus Transactions

Data transfers consist of bus transactions, exchanges of basic packets between the host and a specific

device. The example below shows two such transactions.

The first data request (IN) from the host arrives when the device has no data for delivery, so the

latter returns a NAK handshake, completing the transaction. The NAK indicates two things: that the

device has no data ready and that the host should resend the request later.

The second data request (IN), in contrast, causes the device to deliver the data (DATA0) that it has

ready. The host acknowledges successful receipt of this data with an ACK, completing the

transaction.

Transactions require cirtain bit time order response, so are implemented in hardware.

Host Device

(1) Data request (IN)

(2) No data (NAK)

(3) Data request (IN)

(4) Data transfer (DATA0)

(5) Successful receipt acknowledgment (ACK)

page 4-4

Page 40

Chapter 4 Software Development

Figure 4.1.2. Two USB Transactions

All bus transactions begin with a token packet from the host. Devices never initiate data transfers on

their own.

The host controller is in charge of scheduling all traffic on the bus. It schedules the appropriate

transactions for the four data flow types at 1-ms intervals, which the USB documentation calls

frames.

Token packet types include data request (IN), data transfer notification (OUT), and command

transfer notification (SETUP).

4-1-6. Packets

A packet is a continuous bit stream starting with the synchronization pattern and flowing in one

direction.

Table 4.1.3. lists the USB packet types.

PID Type PID Name Transmitter Description

Token OUT Host Data transfer notification

IN Host Data request

SOF Host Start of frame

SETUP Host Data transfer notification for control pipe

Data DATA0 Host/Device Data packet PID even

DATA1 Host/Device Data packet PID odd

Handshake ACK Host/Device Receiver accepts error-free packet

NAK Device Transmitter cannot send data

Receiver cannot accept data

STALL Device Control pipe request not supported

Endpoint halted

Special PRE Host

Preamble enabling downstream bus traffic to low-speed devices

4-1-7. Endpoints

The USB provides separate logical communication flows, called pipes, between the host and a USB

function. The function end of a pipe is called the endpoint. This endpoint must provide buffer space

(FIFO) capable of holding at least one data packet (a.k.a. the maximum payload size).

Endpoints and pipes are characterized, at creation, by the direction (from or to host) and by the data

flow type (control, bulk, interrupt, or isochronous). There are provisions for up to 16 pipes in each

direction, for a total of 32 endpoints per function. The token packet that the host transmits to initiate

a transaction specifies the endpoint buffer with the endpoint address made up of the device address

and the endpoint number.

USB device controller capacity is expressed by the number of endpoints it has and such endpoint

specifications as supported data flow types and endpoint buffer sizes. Examining these endpoint

specifications thus reveals whether the USB device controller is suitable for the intended application.

page 4-5

Page 41

Chapter 4 Software Development

4-1-8. Data Rates

The USB supports two data rates: 12 Mb/s and 1.5 Mb/s. Table 4.1.4 lists the maximum payload

sizes for each combination of data flow type and data rate.

Table 4.1.4. Maximum Payload Sizes

Transfer Types

12 Mbps 1.5 Mbps

Control 8/16/32/64 8

Isochronous 1023 or less N/A

Interrupt 64 or less 8 or less

Bulk 8/16/32/64 N/A

A hub determines the data rates supported by an attached function by examining the latter's Non

Return to Zero Invert (NRZI) data signal lines (D+ and D-). A device supporting the high speed

pulls up the D+ line to the 3.3-volt power supply voltage with a 1.5-kΩ resistor; one supporting the

low speed does the same with the D- line.

The ML60851C USB controller operates exclusively at 12 Mb/s, so the JOB60851 board includes

only the D+ pull-up resistor.

4-1-9. Device Class Specifications

The Universal Serial Bus Device Class Specifications complement the core specifications by further

standardizing USB devices for major interfaces and specific applications devices using those

interfaces.

MAX Payload Size

Some interface specifications standardize the communications pathways that the USB hardware

provides for a specific purpose--the exchange of isochronous audio or image data, for example.

Others standardize USB specifications for devices combining multiple interfaces.

Table 4.1.5 lists some of the USB Device Class Specifications currently available. For further details,

refer to the following URL.

Table 4.1.5. USB Device Class Specifications

Device Class Applicable Equipment

Human interface devices (HIDs) Mice, keyboards, joysticks, etc.

Printers Printers

Audio devices Speakers, microphones, etc.

Communications devices Modems, ISDN terminal adapters, etc.

Mass storage devices Fl oppy disk drives, SCSI equipment, ATAPI equipment, etc.

Image devices Digital cameras, scanners, low-rate video, etc.

There is also a standard for downloading programs to devices.

http://www.usb.org/developers/devclass.html

page 4-6

Page 42

Chapter 4 Software Development

4-1-10. Device Requests

Device requests represent commands from the host to USB functions using control transfers. The

USB function parses the request, performs the necessary action, and returns the appropriate

response.

There are three types of device requests.

Table 4.1.6. Device Request Types

Standard Requests that all USB devices must support because they hold the key to hot plugging

(a.k.a. dynamic insertion and removal)

Class-specific Requests required by the USB Device Class Specifications for the general application

Vendor-specific Requests implemented by the vendor for accessing functionality particular to the USB

device

A control transfer starts with a SETUP token packet followed by an 8-byte data packet containing

the following fields. Note that the meaning of the wValue and wIndex fields depends on the request

type.

Table 4.1.7. Control Transfer Data Packet

bmRequestType 1byte

bRequest 1byte

wValue 2byte

wIndex 2byte

wLength 2byte

Transfer direction, request type, and endpoint address

Request number

Value (meaning depends on the request type)

Index or offset (which depends on the request type)

Number of bytes transferred during the Data stage

A control transfer consists of up to three stages.

1. Setup stage: The data packet following the SETUP token packet is an 8-byte command from the

host to the device. The device parses the command and, as necessary, prepares to send or

receive data.

2. Data stage: The pipe transfers the specified data in the direction specified by the command.

Note that commands that do not involve data transfer skip this stage.

3. Status stage: The host initiates a transaction, in the direction opposite the immediately

preceding data transfer, for reporting command success or failure from the device to the host.

4-1-11. Standard Device Requests

The standard device requests are common ones to all USB devices. Most important are those that

support hot plugging (a.k.a. dynamic insertion and removal). Detailed descriptions are in Section 9.4 of the USB version 1.1 specifications.

Table 4.1.8. Standard Device Requests

No. Request Name Description

0 GET_STATUS Return status for specified recipient

1 CLEAR_FEA TURE Clear or disable a specific feature

3 SET_FEATURE Set or enable a specific feature

5 SET_ADDRESS Set device address for al future device accesses

6 GET_DESCRIPTOR Return the specified descriptor, if it exists

page 4-7

Page 43

Chapter 4 Software Development

7 SET_DESCRIPTOR Update or add a descriptor

8 GET_CONFIGURATION Return the current device configuration value

9 SET_CONFIGURATION Set the device configuration value

10 GET_INTERFACE Return the selected alternate setting for the specified interface

11 SET_INTERFACE Set the alternate setting for the specified interface

12 SYNCH_FRAME Set and report an endpoint's synchronization frame

4-1-12. Device Descriptors

When a USB device first connects to the bus, it reports its attributes to the host with a device

descriptor. Figure 4.1.3 illustrates the hierarchical structure of this data structure with the device

descriptor for a bidirectional printer.

Endpoint descriptors give the physical capabilities of the endpoints already discussed in Section

4.1.7 above.

Groups of endpoint descriptors form logical communications functions called interfaces. These

interfaces support alternate settings for changing the interface and thus device characteristics. Note

that these interfaces are mutually exclusive in that only one can be in use at any given time.

n Device

o Configuration #1

u Interface #1

¡ Endpoint #1

alternate setting #0 ; output-only printer

BulkOut

u Interface #1

¡ Endpoint #1

¡ Endpoint #2

alternate setting #1 ; bidirectional printer

BulkOut

BulkIn

u Interface #1

¡ Endpoint #1

¡ Endpoint #2

¡ Endpoint #3

alternate setting #2 ; bidirectional printer

BulkOut

BulkIn

InterruptIn ; Inform of data volumes by interrupt transfer

Figure 4.1.3. Device Descriptor for Bidirectional Printer

Higher up the hierarchy are the configuration and device layers. The same device can have multiple

configurations--drawing its power from the bus or its own local power supply, for example. It can

even start as a power-saving device and later switch to a high-consumption one.

The following are brief listings of descriptor contents. For detailed descriptions, refer to Section 9.4

of the USB version 1.1 specifications.

(1) Device descriptor

USB Specification release number in binary coded decimal

Device class code

Device subclass code

Protocol code

Maximum packet size for endpoint 0 (EP0)

Vendor and product IDs

page 4-8

Page 44

Device release number in binary coded decimal

Index numbers for string descriptors describing manufacturer, product, and device serial

number

Number of possible configurations

(2) Configuration descriptor

Total size of this descriptor in bytes

Number of interfaces supported by this configuration

Unique number for this configuration

Index number for string descriptor describing this configuration

Configuration power supply attributes

Remote wake-up support

Maximum power consumption when using bus power supply

(3) Interface descriptor

Total size of this descriptor in bytes

Number of interface

Number of endpoints used by this interface

Class code

Subclass code

Protocol code

Index number for string descriptor describing this interface

Chapter 4 Software Development

(4) Endpoint descriptor Total size of this descriptor in bytes

Data flow direction (IN or OUT)

Data flow type (control, bulk, interrupt, or isochronous)

Maximum packet size (payload) for this endpoint

Interval for polling this endpoint for interrupt transfers

(5) String descriptor

Total size of this descriptor in bytes

Unicode encoded string

page 4-9

Page 45

Chapter 4 Software Development

4-2. Sample USB Firmware

The JOB60851 Starter Kit includes the complete source code for use as the starting point for the user

USB firmware. To see the effects of user modifications on behavior, edit the source code, compile it,

link it into an executable .HEX file, and then download and execute this file with the procedure in

Section 2.3 "Running User Programs."

This Section outlines the entire cycle.

4-2-1. Setup

Copy the file M851xxxx.exe from the \Usb_firm directory on the CD-ROM to a work directory-c:\work in our example. This file is a self-expanding archive that automatically extracts the sample

source code to the appropriate subdirectories shown in Table 4.2.1.

After executing this file in the work directory, open Readme.txt. This text file lists the contents of

the archive. Be sure to read the disclaimer section about rights to the source code.

Table 4.2.1. Sample USB Firmware

\Work Compiler work directory

\Include Include files

\Src Source files (shared files)

\66573 cc665s source code for 16-bit MSM66573 microcontrollers

\Arm ARM-SDT source code for 32-bit ARM microcontrollers

\Err cc665s assembler error output directory

\Lst cc665s assembler listing file output directory

\Debug ARM-SDT debugging code output directory

\Release ARM-SDT release code output directory

\traffic Sample data for use with the Computer Access Technology

Corporation (CATC) USB evaluation system.

4-2-2. Sample Firmware Specifications

The source code on the CD-ROM produces the sample USB firmware shipped in the MSM66Q573

Flash memory. This firmware is perfectly general code that provides the standard device request

support and standard descriptors required by the USB core specifications. It does not assume any

particular application. It supports the three data flow types (control, bulk, and interrupt) offered by

ML60851 USB controllers.

For the detailed specifications of this sample USB firmware, refer to the text file M852.txt

accompanying it in the work directory. Note that the source code supports both ML60851 and

ML60852 USB controllers and that M852.txt covers the 32-bit ARM microcontroller as well as

these two devices. Read only the sections applicable to the ML60851C USB controller and the 16bit MSM66Q573 microcontroller.

n

Note

n

As of August 1999, operation has been confirmed only for the MSM66Q573 plus

ML60851C combination. The ARM code is a preliminary version that does not

compile.

page 4-10

Page 46

Chapter 4 Software Development

4-2-3. Sample USB Host Software

The CD-ROM directory \package\host contains the following USB host software for testing such

things as bulk data flow. A brief overview of operation appears in Section 2.

Readme.txt Software description, usage notes, etc.

Rwbulk.exe Test application

Bulkusb.sys WDM-USB driver

Bulkusb.inf WDM-USB driver installer information file

This USB host software adopts the following layered approach. For a detailed description, refer to

the accompanying text file Readme.txt.

RWbulk.exe Windows user mode console application

Win32API

BulkUsb.sys Windows kernel mode driver

USB Driver Interface(USBDI)

USB Host Stack Windows WDM USB Host Protocol Stack (Microsoft)

HostController

USB

n

Note

n

This sample host software runs only under Windows 98. It is only for provisional use

by firmware developers pending the completion of proper host drivers and

applications. It is not robust enough for heavy use. In fact, continued use risks

operating system instability and even hang-ups. Note that we are unable to respond

personally to technical queries with regard to this software.

4-2-4. Compiling and Executing Sample USB Firmware

Compiling the sample USB firmware requires the cc665s compiler installed in Section 2.1.2.

Double-check the environment variables from that Section.

The work directory containing the sample USB firmware--c:\work in our example--contains make

files for two popular make utilities (not included in the JOB60851 Starter Kit): Makefile.nmk for use

with nmake from Microsoft and Makefile.bor for use with maker from Inprise (formerly Borland).

Rename or copy the appropriate one to makefile. Also available is the batch file cl665s.bat for users

without either of these make implementations. Successful compilation produces the file USB.HEX

in the work directory. Check the link map file USB.M66 in the same directory for error messages

from the linker.

To test USB.HEX, download it to the JOB60851 board and execute it there with the procedure in

Section 2-3. "Running User Programs." Use Rwbulk.exe and the procedure in Section 2-2-2.

"Running Flash Memory Program" to test bulk data flow.

4-2-5. Confirming USB Compliance with Usbcheck.exe

The USB Implementers Forum web site provides Usbcomp.exe, a self-extracting archive containing

Usbcheck.exe, host software for checking support for USB standard device requests.

page 4-11

Page 47

Chapter 4 Software Development

http://www.usb.org/developers/complian.html

n

Note

n

As of August 1999, this software is at version 3.2 and requires Windows 98 Second

Edition. Users of older Windows 98 versions should download version 2.9 instead.

Once this software has been successfully installed, use the following test procedure to reconfirm the

compliance of the program shipped in the MSM66Q573 Flash memory.

n

Note

n

The procedure for running the program itself is in Section 2.2 "Running Default

Program."

1. Detach all USB devices connected to the personal computer.

2. Double-click the USB Check icon to start the application.

3. Comply with the message box asking you to connect USB devices by plugging in the cable to

the JOB60851 board and applying power to the latter (#2 in Figure 2.1.1).

4. Wait while Windows 98 automatically installs the drivers for the JOB60851 board.

5. When the USB Compliance Tool dialog box appears, click the Full test button at the bottom.

6. When the USB Chapter 9 tests dialog box appears, click the Start automatic testing button at the

bottom.

7. If the tests run successfully to completion and the Full test results dialog box with the Run other

tests button appears, click the OK button to return to the USB Chapter 9 tests dialog box.

8. Click the Cancel automated testing button to display the following information in the Device

info section in the middle of the left side of the dialog box that appears.

If the display matches the information above, the tests are complete.

Usbcheck.exe checks compliance by issuing each USB standard device request. It should, therefore,

always be the first test after downloading a modified version of the sample USB firmware to the

JOB60851 board.

n

Note

n

If Usbcheck.exe aborts in the early stages of dynamic insertion, go back and doublecheck the most recent source code modifications.

page 4-12

Page 48

Chapter 4 Software Development

4-2-6. Creating USB Mouse Demo

The next stage involves modifying the sample program slightly so that the JOB60851 board

emulates a USB mouse. Use the following steps to modify the source code and then recompile.

(1) Modifying source code

The file Include\Class.h under the work directory specifies as its default the device class

BULK_IN_OUT_AND_INT. Comment out that #define and uncomment the

HID_MOUSE_ONLY one.

/* 1. Specify device class */

#define HID_MOUSE_ONLY /* ← Enable this one */

/* #define BULK_AND_HID_MOUSE */

/* #define HID_MOUSE_AND_BULK */

/* #define BULK_IN_OUT_AND_INT */ /* ←Disable this default */

/* #define COMPLEX_ALTERNATE */

/* #define PRINTER */

/* #define ISO_TEST */

(2) Compiling

The supplied make files and compiler do not check for dependencies on files in the include

directory, so first clean the .HEX and .OBJ files from the work directory and then run the make

utility.

n make clean <Enter> or maker clean <Enter>

nmake <Enter> or maker <Enter>

Successful compilation produces the file USB.HEX in the work directory. Check the link map

file USB.M66 in the same directory for error messages from the linker.

(3) Setting up mouse demo

The sample mouse program emulates a USB mouse in response to commands received over a

serial link to the JOB60851 board. It therefore requires connecting both the USB cable and,

using the procedure in subsections 1-3 in Section 2.3 "Running User Programs," the serial

cable.

(4) Downloading program and installing mouse driver

To test USB.HEX, download it to the JOB60851 board and execute it there with the procedure

in Section 2.3 "Running User Programs."

When the JOB60851 board connects the emulated USB mouse to the personal computer,

Windows 98 automatically launches its driver wizard, so install the HID mouse driver from the

CD-ROM.

page 4-13

Page 49

Chapter 4 Software Development

n

Note

n

The Windows 98 CD-ROM is not necessary if the OEM release has copied the

installation image from the CD-ROM to the directory c:\Windows\Option. If so, specify

that directory instead of the CD-ROM.

(5) Operate mouse with terminal emulator

After reading the messages on the terminal emulator screen, enter HELP at the command

prompt to display the commands available. Try RIGHT, LEFT, UP, and DOWN, for example.

Another way to test the emulated USB mouse is with HIDview, the HID class device portion of

Usbcheck.exe.

4-2-7. Modifying Application Layer

This section gives a hints for modifying the application layer. Note that, in practice, such

modifications require careful study of the USB Specifications, M852.txt, and the source code.