Page 1

OKIPAGE4w

LED Page Printer

Troubleshooting Manual

with Component Parts List

(ODA/OEL/INT)

APPROVAL

All specifications are subject to change without notice.

Page 2

Page 3

CONTENTS

1. OUTLINE..................................................................................................... 1

2. TOOLS........................................................................................................ 1

3. CIRCUIT DESCRIPTION............................................................................ 2

4. TROUBLESHOOTING.............................................................................. 21

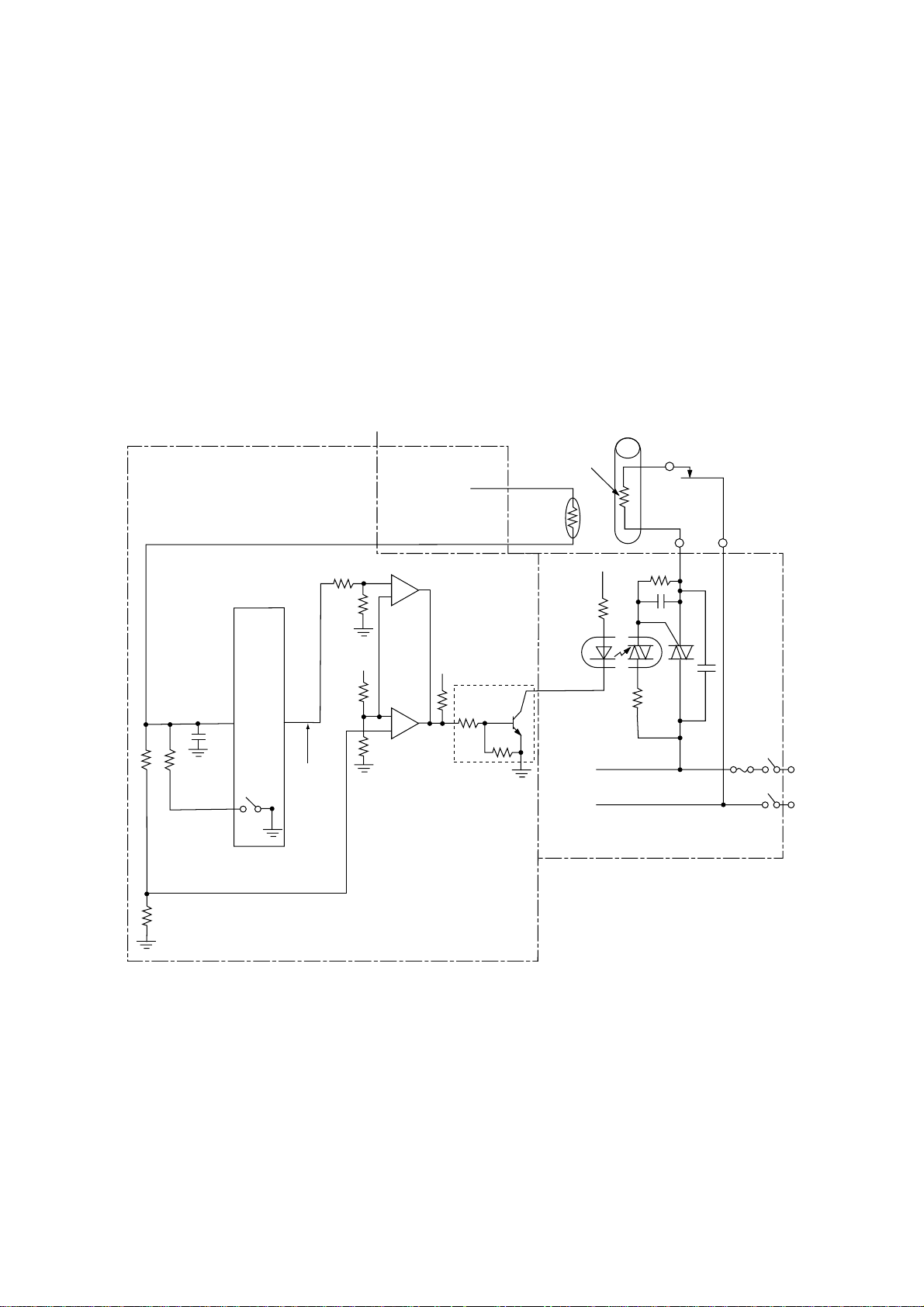

5. CIRCUIT DIAGRAM.................................................................................. 27

6. COMPONENT PARTS LIST

Page 4

1. OUTLINE

This manual has been written to provide guidance for troubleshooting of the OKIPAGE4w Plus

Printer (primarily for its printed circuit boards), on an assumption that the reader is knowledgeable

of the printer. Read the maintenance manual for this printer P/N M-521426 if necessary.

Note:

1. High voltage power supply board and power supply unit containing a high voltage power

supply is dangerous. From the viewpoint of the safety standards, the local repairing of a

defective board is not allowed. Thus, the objects to be locally repaired as a result of

troubleshooting are switches and fuses.

2. TOOLS

For troubleshooting the printer, the tools listed below may be needed in addition to general

maintenance tools.

Oscilloscope Frequency response 100 MHz or higher

Soldering iron A slender tip type, 15-20 watts

Extension code kit P/N : 40105501

Tool Remarks

- 1 -

Page 5

3. CIRCUIT DESCRIPTION

3.1 Outline

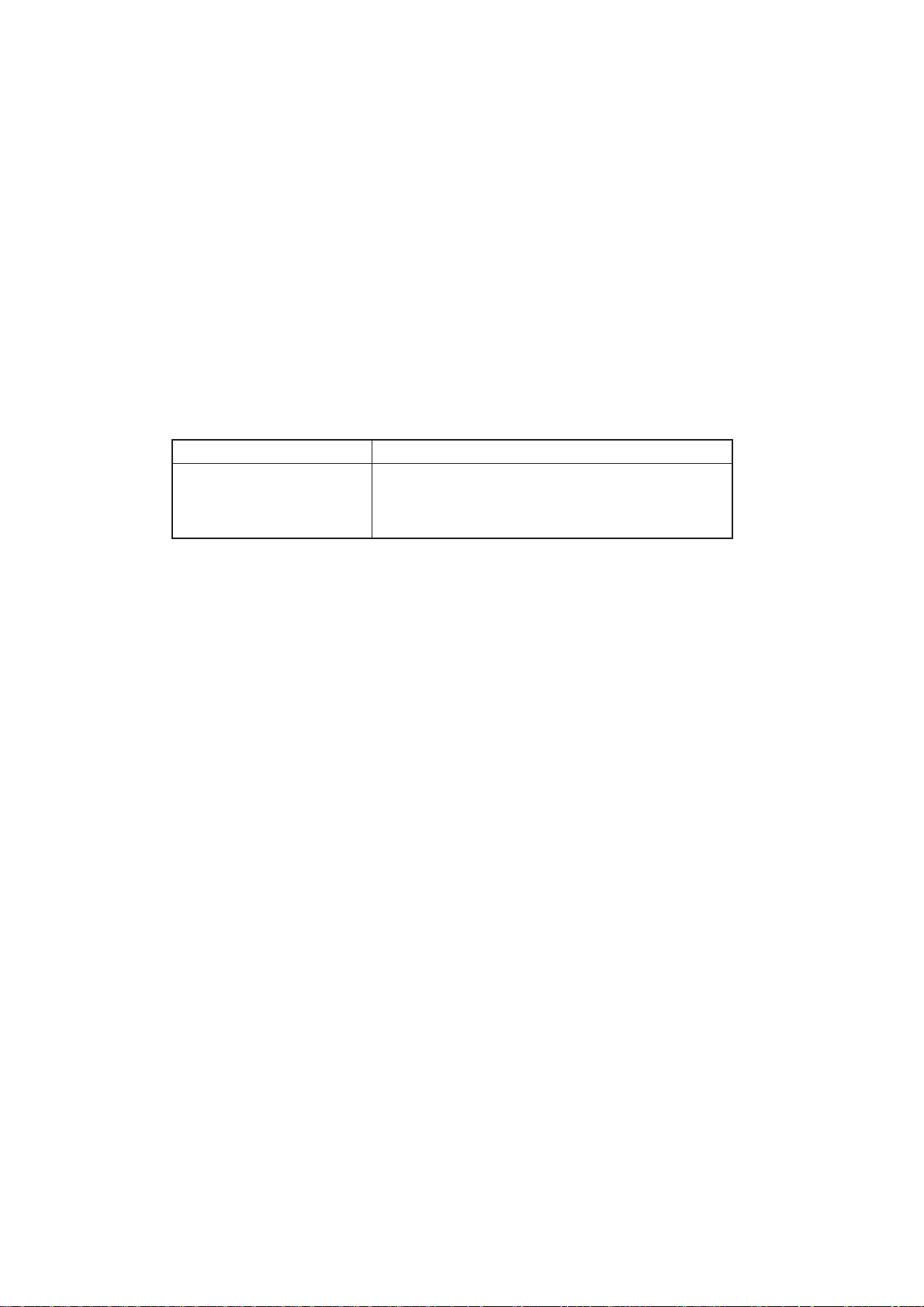

The circuit of OKIPAGE4w Plus consists of a main control board, a high voltage power supply

board and a power supply unit. The block diagram is shown in Fig. 3-1. The main control board

controls the reception and transmission of data with a host I/f and processes command analysis,

bit image development, raster buffer read. It also controls the engine and high voltage outputs.

(1) Reception and transmission control

The main control board has one parallel I/F port which is compliant to the IEEE 1284

specification.

An interface task stores all data received from the host into a receive buffer first, and returns

the printer status upon request of the host.

(2) Command analysis processing

The OKIPAGE4w Plus printer has the following emulation mode.

Hiper-W: OKI original

An edit task fetches data from the receive buffer, analizes commands, and sets I/O registers.

(3) Raster data processing

The decompression circuit in the CPU expands the compressed data and stores the data into

the raster buffer.

(4) Raster data transfer

The LED head control circuit in the CPU sends the data stored in the raster buffer to the LED

head.

(5) High voltage control

The high voltage control circuit in the CPU.

The high voltage power supply board generates high voltage outputs, and have sensors, LED for

display.

The power supply unit generates +24VDC output, +5DC output.

- 2 -

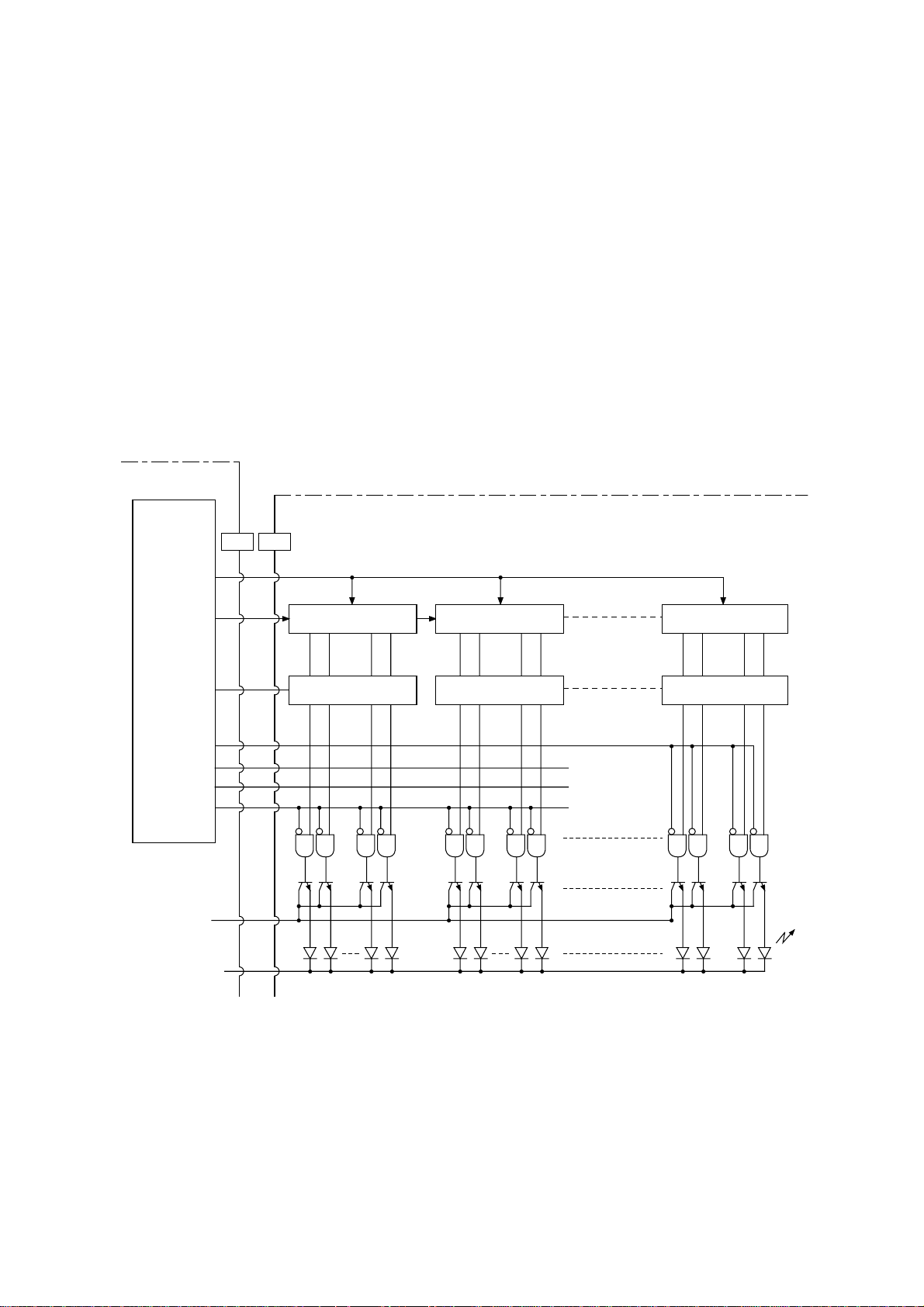

Page 6

10MHz

CPU

(MSM65917)

EEPROM

Parallel

Figure 3-1 OKIPAGE4w Plus Block Diagram

I/F

A8 ~ A15

AD0 ~ AD7

Address

latch

A0 ~ A7

EPROM

(64 KByte)

D0 ~ D7

CN

Parallel

I/F

LS07

LED head LED head

Parallel

I/F

- 3 -

LED head

Main motor

Electromagnetic

5V

clutch

Sensors

TEMP

TR-VSEN

TR-ISEN

Reset

circuit

5V

0VL

A0 ~ A9

Driver

D0 ~ D3

D-RAM

128 KByte

or

512 KByte

High-voltage power I/F

LED

HEAT ON

<Main Control Board>

HEAT ON

Main motor

Electromagnetic

clutch

LED

Sensors

TEMP

High-voltage

power

TR-VSEN

TR-ISEN

Driver

+24V

+5V

0VL

0VP

Driver

Driver

Manual feed sensor

LED

Paper sensor

Outlet sensor

Toner sensor

Cover open switch

HIgh voltage

power

supply

<High-voltage Power Supply Board>

AC output ON/OFF

Switching

power supply

<Power Supply Unit>

Main motor

M

Electromagnetic

clutch

Thermistor

EP cartridge

Heater

(Halogen lamp)

AC

(120 V/230 V)

Page 7

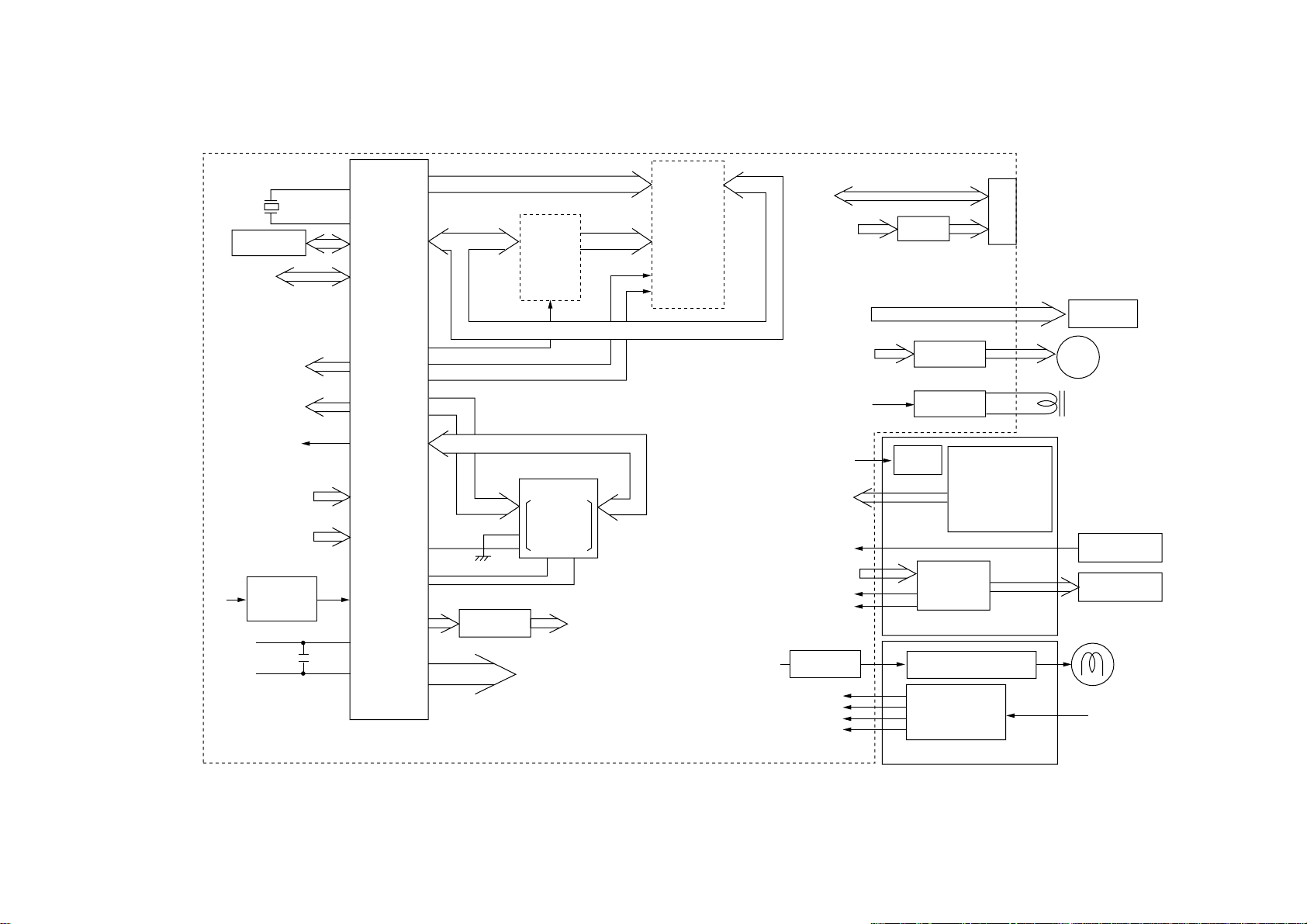

3.2 CPU and Memory

(1) CPU (MSM65917)

CPU core nX-8

CPU clock 10 MHz

Data bus width External 8 bits, Internal 8 bits

(2) Program ROM

ROM capacity 64k-bytes (512-kbit EPROM)

ROM type 512 kbits (64k x 8 bits)

Access time 150 nsec

When mask ROM in the CPU is valid, the EPROM is not mounted.

(3) Resident RAM

RAM capacity 128k bytes (256k x 4 bits D-RAM one piece)

RAM type 1M bits (256k x 4 bits) or 4M bits (1M x 4 bits)

Access time 70 ns, 60 ns

The block diagram of CPU and memory circuit is shown in Fig. 3-2.

or 512k bytes (1M x 4 bits D-RAM one piece)

- 4 -

Page 8

CPU

IC 6

ALE

RDN

ROCS

DA10

DWR

CAS

RAS0

RAS1

RAS2

AD00 to AD07

LS373

IC3

A08 to A15

DD00 to DD03

DA00 to DA09

A00 to A07

IC2

EPROM

(64k x 8 bits)

IC11

DRAM

256k x 4 bits

or

1M x 4 bits

Main Control Board

Figure 3-2 Block Diagram of CPU & Memory in OKIPAGE4w Plus

- 5 -

Page 9

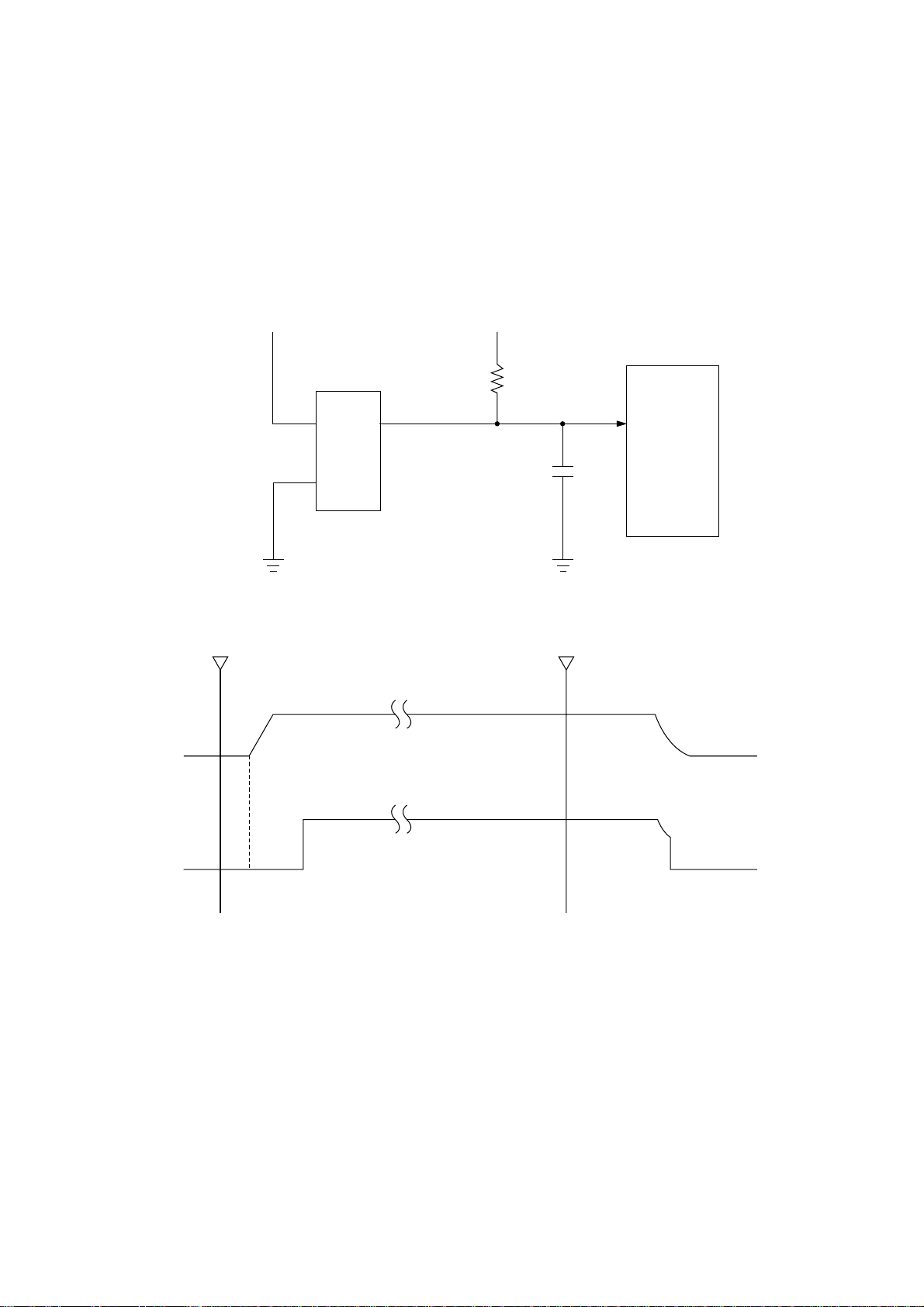

3.3 Reset Control

When power is turned on, RST-N signal is generated by IC5.

+5V+5V

+5V

Power ON

IC5

1

3

2

Power OFF

63

CPU

RSTN

RST-N

- 6 -

Page 10

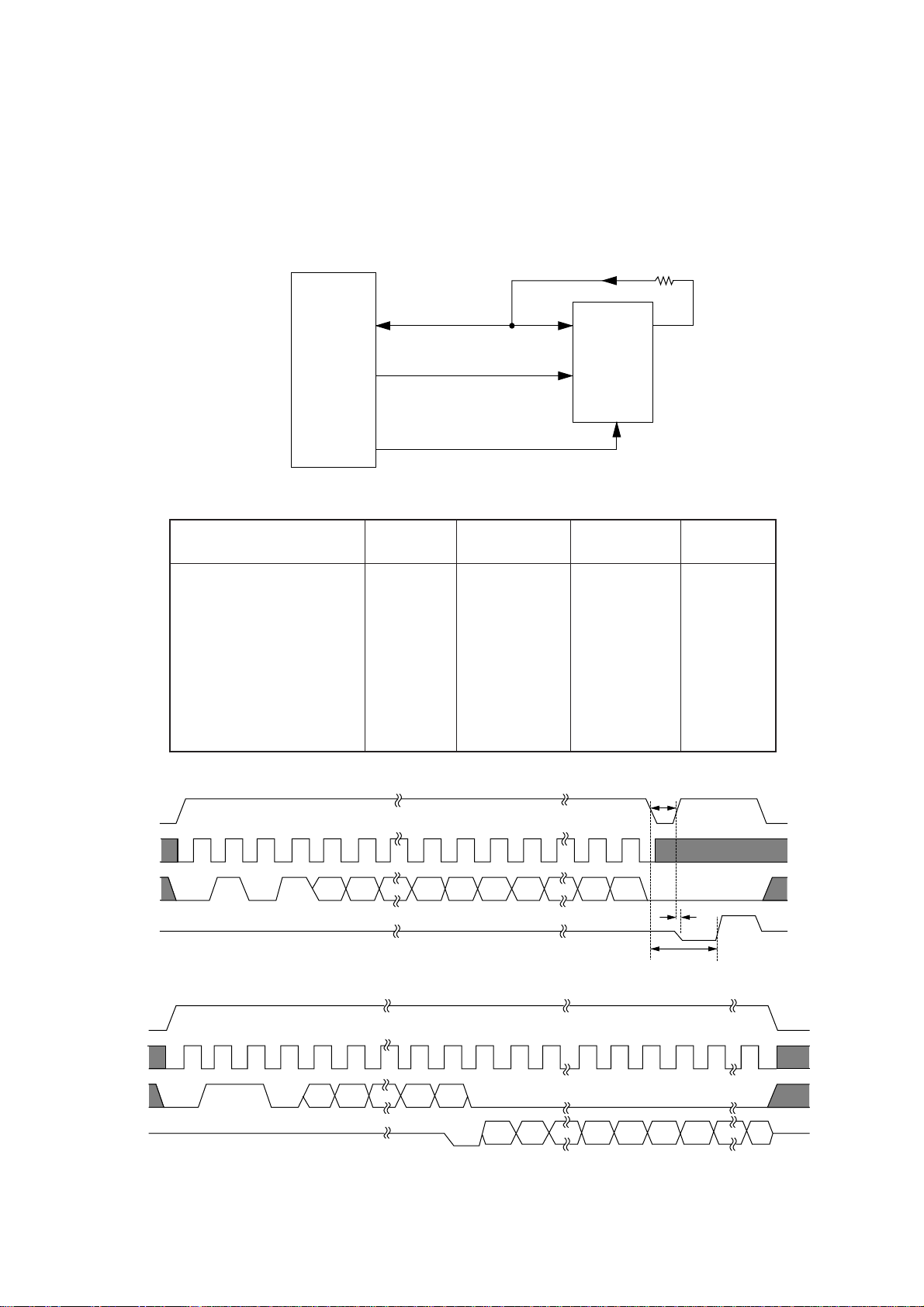

3.4 EEPROM Control

The BR93LC46A on the main control board is an electrical erasable/programmable ROM of 64bit x 16-bit configuration. Data input to and output from the ROM are bidirectionally transferred

in units of 16 bits through I/O port (EEPRMDT-P) in serial transmission synchronized with a clock

signal from the CPU.

The EEPROM operates in the following instruction modes.

Instruction Start bit Operation Address Data

Read (READ) 1 10 A5 to A0

Write Enabled (WEN) 1 00 11XXXX

Write (WRITE) 1 01 A5 to A0 D15 to D0

CPU

39

38

37

EEPRMDT-P

EEPRMCS-P

EEPRMCLK-P

code

3

DI DO

EEPROM

1

CS

IC4

4

SK

2

CS

SK

DI

Write All Address (WRAL) 1 00 01XXXX D15 to D0

Write Disabled (WDS) 1 00 00XXXX

Erase 1 11 A5 to A0

Chip Erasable (ERAL) 1 00 10XXXX

Write cycle timing (WRITE)

CS

SK

DI

DO

1 2 4 9 10 25

10 1

HIGH-Z

Read cycle timing (READ)

12

110

A5 A4 A1 A0 D15

4

A5 A4 A1 A0

910

D14

Min. 450 ns

STATUS

D1 D0

Max. 500 ns

BUSY READY

Max. 10 ms

25 26

DO

HIGH-Z

D15 D14 D1 D00 D15 D14

- 7 -

Page 11

3.5 Parallel Interface

N

Parallel data is received from a host system via parallel interface which is compliant to the

IEEE1284 specification.

CPU

65 to 68, 71 to 74

64

78

77

79

80

81

82

83

84

PDATA1-P to PDATA8-P

PSTB-N

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

IPRIME-N

SELIN-N

AUTOFD-N

IC7

2 to 9

CN4

DATA8-P

to

DATA1-P

STB-N

1

11

10

12

13

31

BUSY-P

ACK-N

PE-P

SEL-P

FAULT-N

32

IPRIME-N

SELIN-N

36

AUTOFEED-

14

+5V

+5V

18

Compatible mode

The CPU sets a BUSY-P signal to ON at the same time when it reads the parallel data (PDATA1P to PDATA 8-P) from the parallel port at the fall of PSTB-N signal. Furthermore, it makes the

store processing of received data into a receive buffer terminate within a certain fixed time and

outputs an ACK-N signal, setting the BUSY-P signal to OFF.

PARALLEL DATA

(DATA BITs 1 to 8)

0.5 µs min.

DATA STROBE

0.5 µs min.

0.5 µs max.

BUSY

0 min.

ACKNOWLEDGE

0.5 µs to 10 µs

0.5 µs min.

0.5 µs min.

0 min.

0 min.

0 min.

- 8 -

Page 12

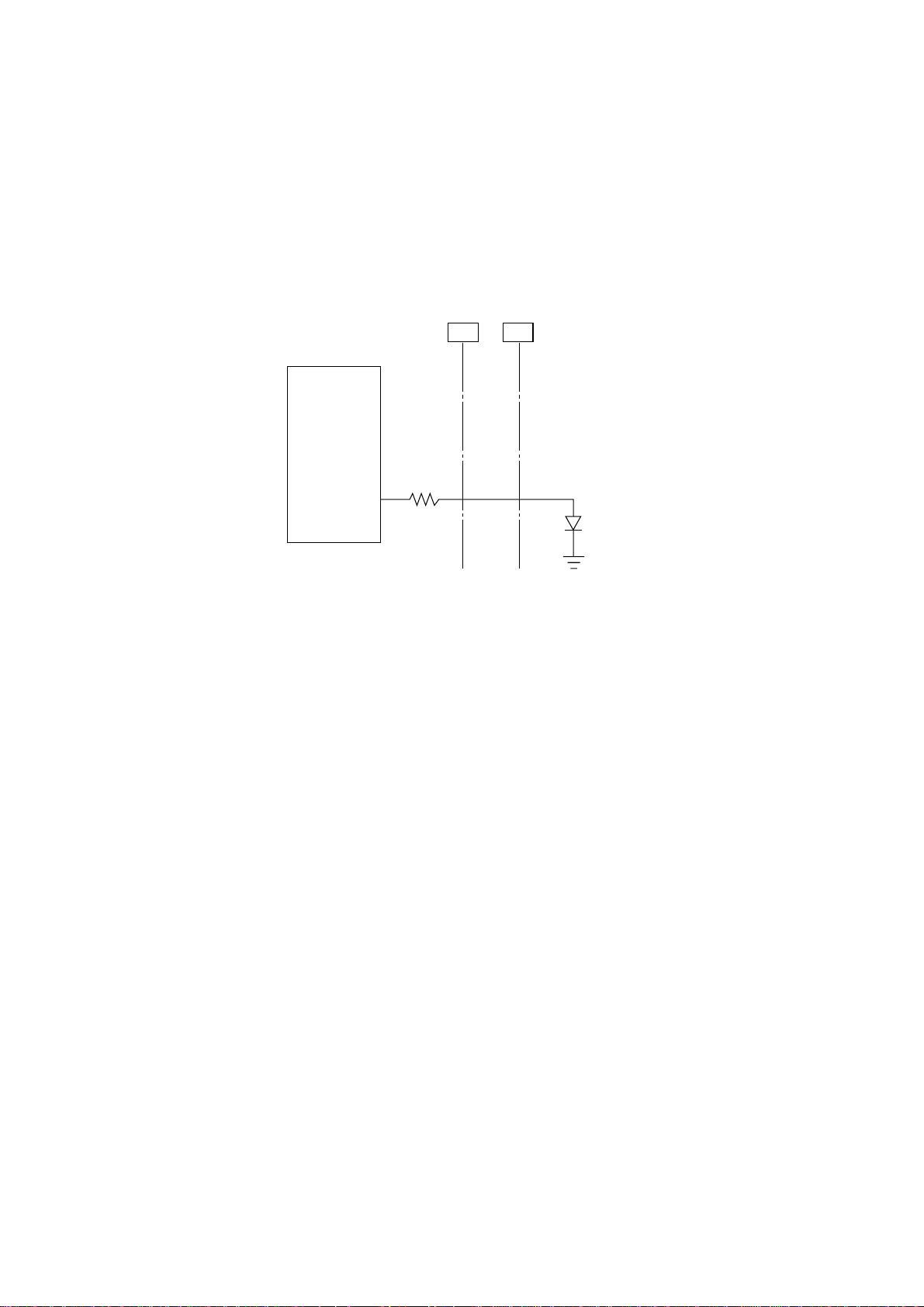

3.6 LED Lamp Control

There is an LED lamp on the high voltage power supply board which is connected to and controled

by the CPU on the main control board.

The light from the LED lamp can be seen on the Lens Cover through the LED Lens.

CN1

main control board high voltage power supply board

CPU

LED-P

41

CN1

- 9 -

Page 13

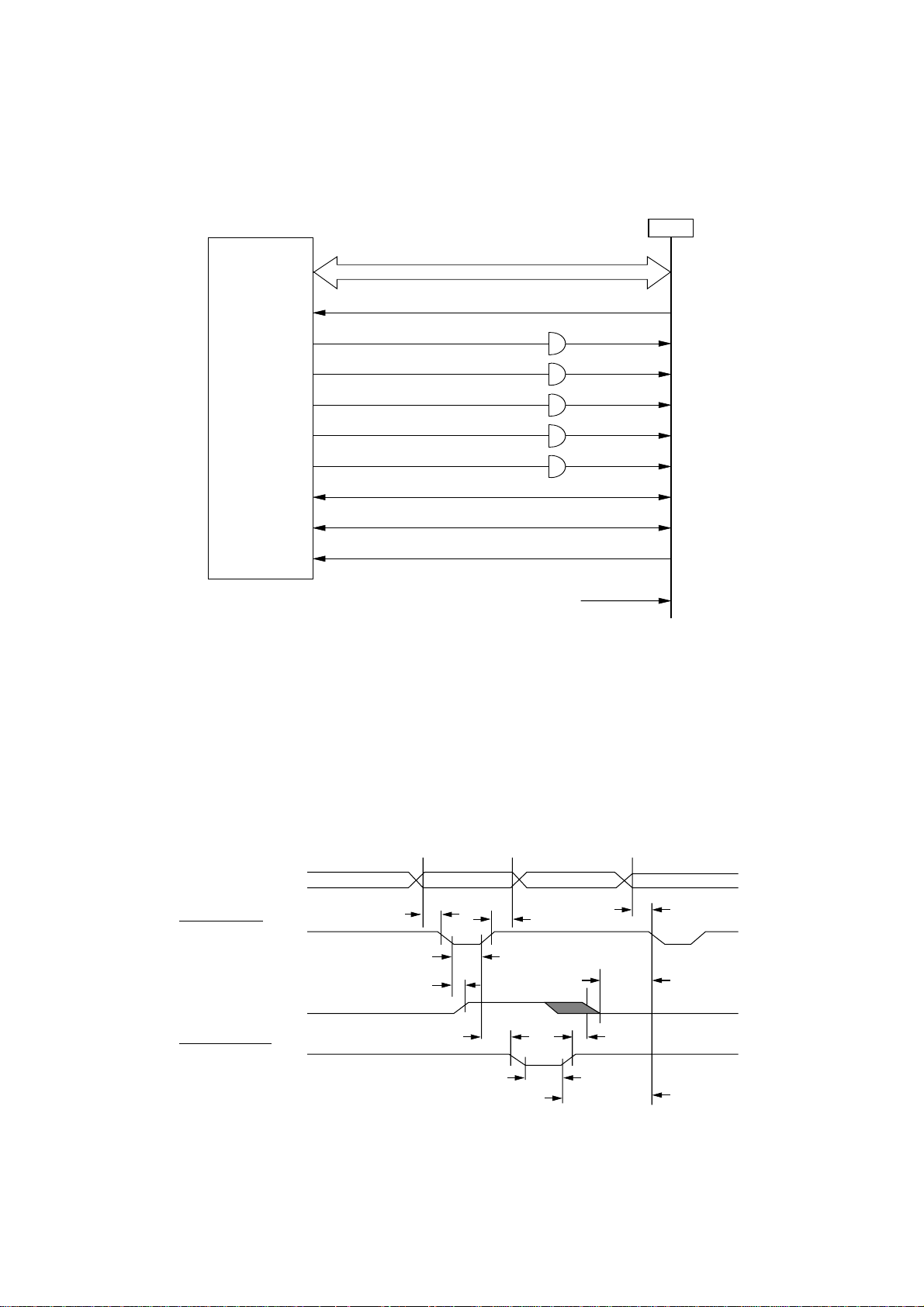

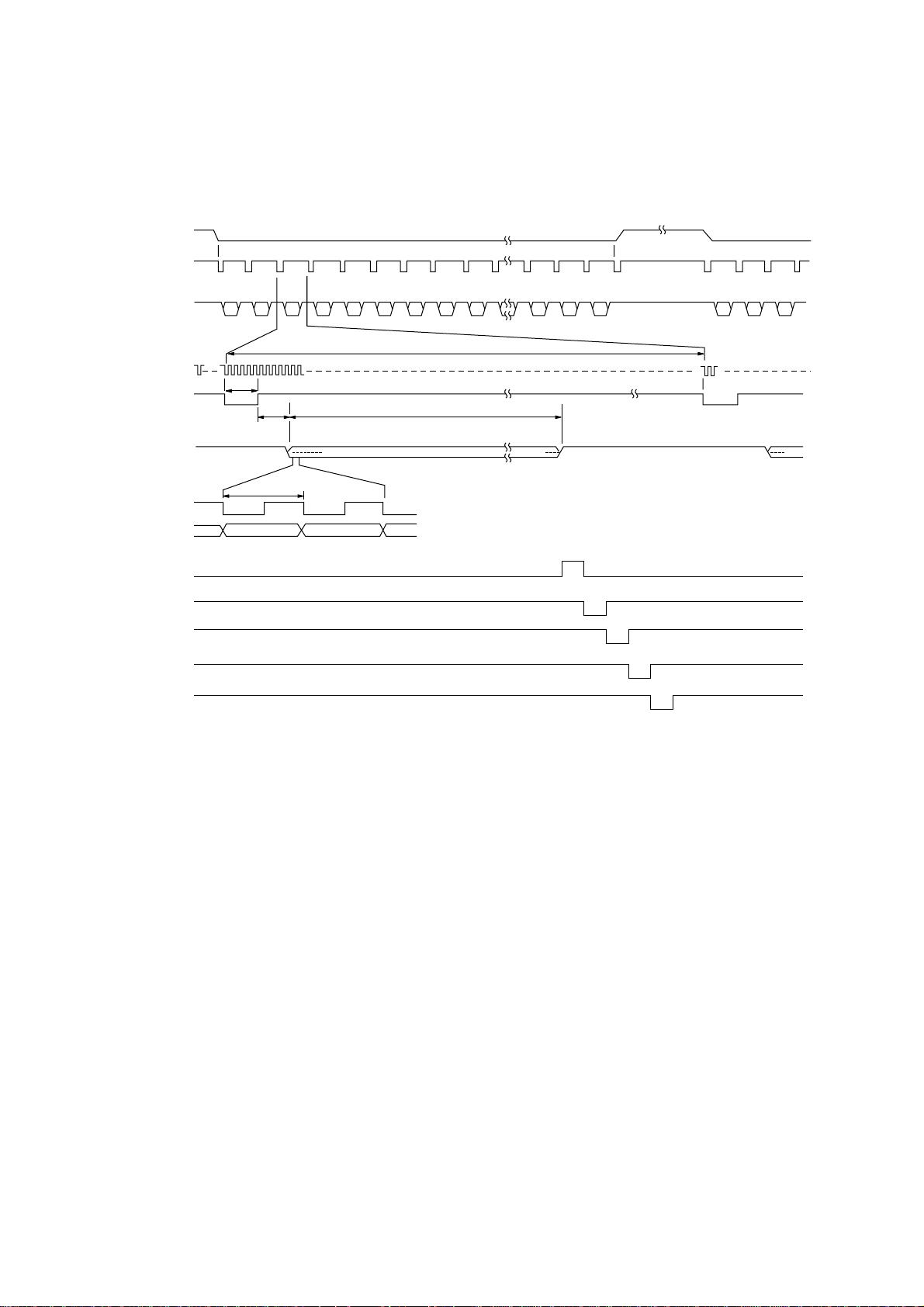

3.7 LED Head Control

When a paper form is made to arrive at the data write position on print start, the sending of data

to the LED head starts as synchronized with the page synchronous signal/line synchronous signal

(CPU internal signal).

Bit image data developed on the raster buffer in the CPU are DMA-transferred to the register of

a video interface controller (CPU built-in) and then sent to the shift register of the LED head in a

serial transmission synchronized with the VCLK-P signal by the VD0-P signal.

When 1-dot line data (2560 bits) is completely shifted, it is latched by means of the VLD-P signal,

causing LEDs to be driven by the VSTB1-N through VSTB4-N signals in different timing for each

signal.

Some of LED heads have 2496 dots rather than 2560 dots. The controls regarding the number

of dots are adjusted to the LED head installed when the printer is shipped from the factory.

Main control board

CPU

CN6 CN1

LED Head

VCLK-P

VD0-P

VLD-P

VSTB 1-N

VSTB 2-N

VSTB 3-N

VSTB 4-N

+5V

0V

90

89

91

92

93

94

95

Chip 40

64 bit shift REG

LATCH

Bit 2560

Chip 1

1 to 640 bits

641 to 1280

1281 to 1920

1921 to 2560

Bit 1

- 10 -

Page 14

Page

synchronous

signal*

Line

synchronous

signal*

VDT-P

3.33 msec

VCLK-P

VDT-P

VCLK-P

VDT-P

VLD-P

VSTB1-N

VSTB2-N

VSTB3-N

VSTB4-N

* CPU internal signal

8 bits

8 bits

0.2 µs

2560 bits

- 11 -

Page 15

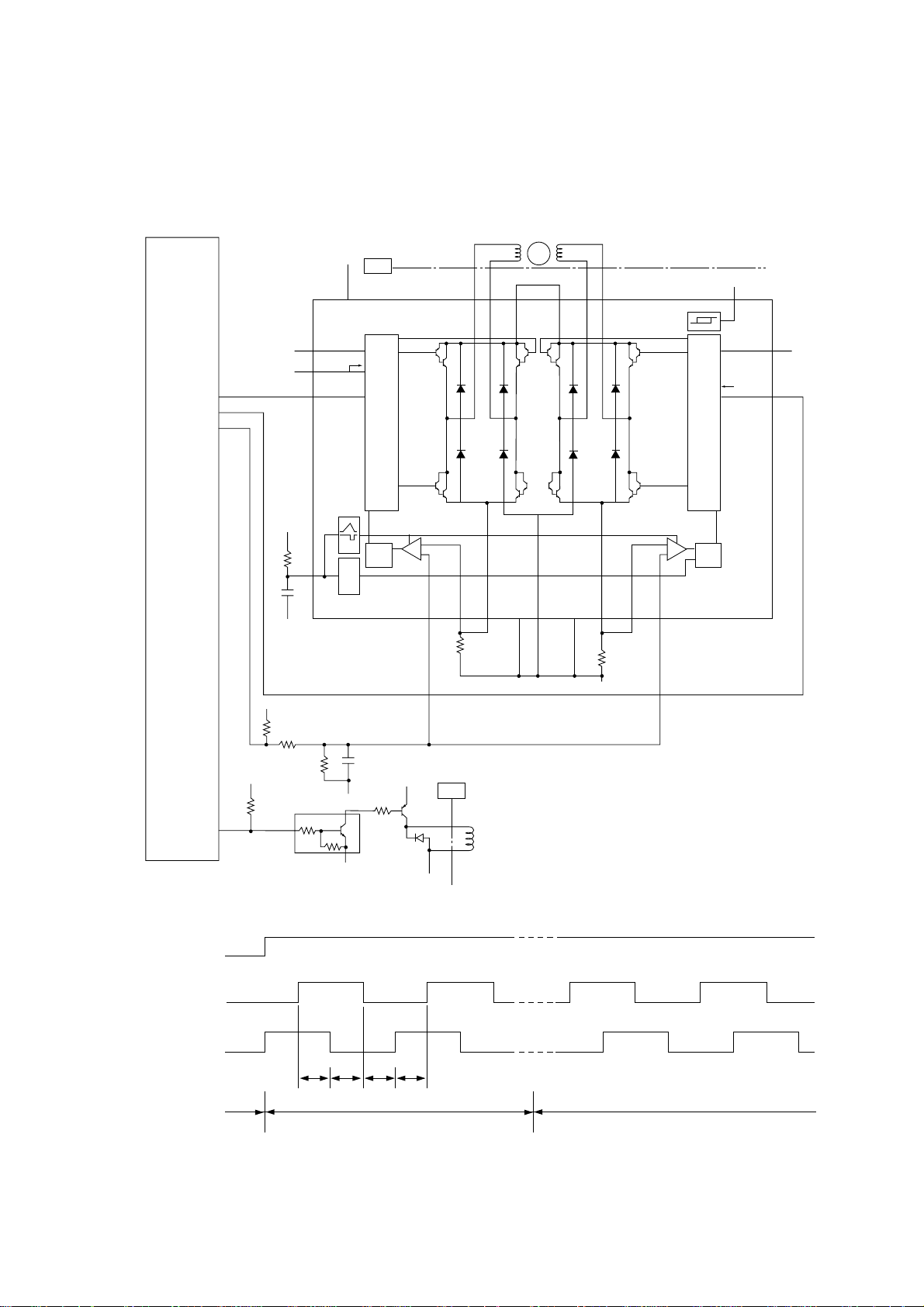

3.8 Motor and clutch control

The electromagnetic clutch is driven by a control signal from the CPU and the drive circuit shown

below.

The main motor is driven by the control signals from the CPU and the driver IC.

CPU

DMP1

DMP2

DMP3

96

97

98

Out4Vmm A Vmm B

Main Motor

8

ALARM

120 140

GATE CIRCUIT

ENA B

Signal of

DECACY

+5V

CN7

IC10

27

0V 0V

18

+5V

26

19

ENA A

To Out3, 4Logic

DECAY

37 1 1412 24

Out2 Out3

Out1

SW1 SW3

M

+24V OPEN

SW1 SW3

PHASE A PHASE B

GATE CIRCUIT

SW4SW2

SW4SW2

+5V

0V

25

BRUNK

OSC

Current

Q

-

R

+

S

Vref A Vref B

Sensor

Vs A Vs BRs A Rs BLG A PG LG B

23 22 28 15 10 21 20TAB5

Current

Sensor

RQ

+

S

0V

+5V

16

17

RMON

(1) Main motor

DMON-P

DMPH1-P

DMPH2-P

Rotation

+5V +24V

0V

99

0V

T0 T1 T2 T3

Forward rotation

CN8

Electromagnetic clutch

0VP

Reverse rotationStop

Operation at normal speed: T0 to T3 = 1.515 ms

- 12 -

Page 16

(2) Motor drive control

Time T0 to T3 determines the motor speed, while the phase different direction between

phase signals DMPH1-P and DMPH2-P determines the rotation direction. DMON-P signal

control a motor coil current. According to the polarity of the phase signal, the coil current flow

as follows:

1) +24V → SW1 → motor coil → SW4 → resistor → earth, or,

2) +24V → SW3 → motor coil → SW2 → resistor → earth

The drop voltage across the resistor is input to comparator, where it is compared with a

reference voltage. If an overcurrent flows, a limiter operates to maintain it within a certain

fixed current.

(3) Electromagnetic clutch control

Mechanical operation mode is switched by the combination of the clutch status and the

direction of motor rotation.

clutch status

off

off

on

on

rotation direction

Forward

Reverse

Forward

Reverse

operation mode

cleaning

Hopping from manual

feed slot

illegal operation

Hopping from tray

- 13 -

Page 17

3.9 Fuser Temperature Control

The temperature change in a heat controller is converted into the electric potential TEMP

corresponding to the change in the resistance value of a thermistor, and the resultant potential

is fed back to the control circuit. The CPU performs ON/OFF control of the HEATON-P signal to

keep the heat roller temperature constant in accordance with the state at which the thermistor

voltage (TEMP) is read into directly by the AD converter of the CPU.

THCHK-N signal is fixed to “0”.

When the paper thickness is set on the menu of the host, the temperature is adjusted to the

targeted thickness accordingly.

Main Control Board

CPU

TEMP

27

AI4

(A/D)

THCHK-N

34

85

HEATON-P

High voltage power

supply board

IC20

5

+

6

-

7

+5V +5V

IC20

3

+

2

-

1

+5V

Thermistor

HEATON-N

Heater

Thermostat

Heat Roller

+5V

ACIN

Power supply unit

- 14 -

Page 18

Flowchart of Thermistor Circuit Check

START

HEATER OFF

Short check timer(t16)set

No

Time-out ?

Short error TEMP ?

Thermistor error check

timer (t2) set

Thermistor disconnection

check timer (t35) set

Heater On

Temperature > Tn

No

No

Yes

Yes

Yes

Tn...T0 =

T2 =

T4 =

Thermistor short error

End

Light

Medium

Heavy

To constant

temperature control

Thermistor

error check timer (t2)

within time

Yes

Thermistor

disconnection check timer

(t35) within time

Yes

t2 =

t16 =

t35 =

90 sec

520 msec

10 sec

No

No

Time-out

A/D value changed?

Yes

- 15 -

No

Fuser error

End

Thermistor disconnection

error

End

Page 19

Temperature

Controlled

Temperature

T

HEATER ON

OFF

Time

Temperature table

THCHK-N

O

Z

Heater control mode

Normal operation

Not used

T

145˚C:

150˚C:

155˚C:

160˚C:

165˚C:

Paper Thickness

light

medium light

medium

medium heavy

heavy

- 16 -

Page 20

3.10 Sensor Control

The CPU supervises the state of each sensor every 40 ms.

Main Control Board High Voltage Power Supply Board

CN1 CN1

+5V

CPU

Sensor

signal

47

44

46

48

OFF

+5V

+5V

+5V

+5V

TNRSNS-N

PSIN-N

PSOUT-N

WRSNS-N

TransparentShield

PS1

PS2

PS3

PS4

ON

- 17 -

Page 21

3.11 Cover Open

When the cover is opened, a cover open microswitch is opened. This makes a CVOPN-N signal

low, thereby the CPU detects that cover is open. Furthermore, opening the cover stops applying

a +5V power to the high voltage power supply part, resulting in stopping all high voltage outputs.

CN1 CN1

CVOPN-N

Main Control Board

45

CPU

+5V

0V

High Voltage Power Supply Board

CVOPN-N

+5V

+5V

Cover

Open

Microswitch

Cover close Cover open

High

Voltage

Power

Supply

Part

High

voltage

output

- 18 -

Page 22

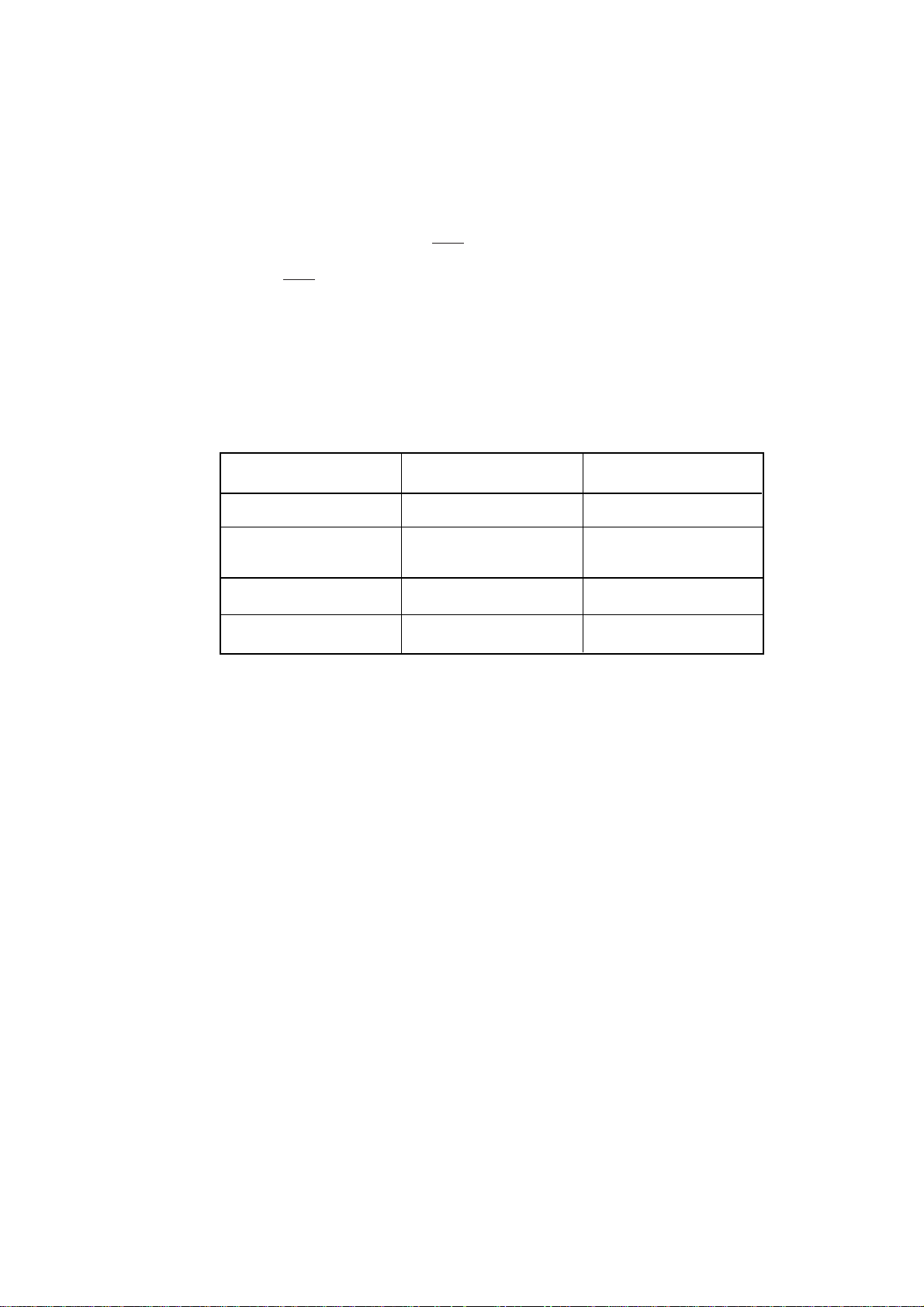

3.12 Power Supply Part

(1) Power supply unit

An AC power from an inlet is input to Switching Reg. part .AC power is converted to a +24

VDC output and +5 VDC output.

ACIN

F1 F2L

FG

N

Circuit

Filter

Power supply unit

+24V

+5V

0V

Switching Reg. Part

HEATON-N

to AC output

Fuse Ratings

AC Input

Fuse

F1

F2

HEATER

CONTROLER

230 V

250 V 6.3 A

250 V 2 A

120 V

125 V 10 A

250 V 2 A

(2) High voltage power supply board

The +5 VDC power supplied to the high voltage power supply part via the cover open

microswitch as source voltage. The high voltage power supply part supplies necessary

voltage for electro-photography print to output terminals CH, DB, SB, TR, and CB according

to a control signal from the CPU. The table on the next page shows the relationship between

control signals and high voltage outputs.

CN1

MainControl Board High Voltage Power Supply Board

TR1PWM-P

55

TR2PWM-P

59

CHPWM-P

56

SDB1-P

53

CPU

52

54

SDB2-P

DBPWM-P

CVOPN-N

45

CN1

High Voltage

Power Supply

Part

CH

DB

SB

TR

CB

Cover Open

Microswitch

+5V

- 19 -

Page 23

Control Signals and High Voltage Outputs

Control signal name Level Function

TR1PWM-P

TR2PWM-P

CHPWM-P

SDB1-P

SDB2-P

DBPWM-P

H/L

(PWM)

L

H/L(PWM)

L

H/L(PWM)

L

H

L

H

L

H/L(PWM)

L

Makes the part put out a power to TR.

+3 to 5 µA

+0.5 to 4 KV

Makes the part put out a -750V power to TR.

Makes the part put out a -1.35 KV power to CH.

Makes the part put out the following power:

+450V or 0V power to SB

+300V power to DB

Makes the part put out the following power:

-450V power to SB

-300V power to DB

+400V power to CB

Makes the part put out the power to SB, DB, CB.

- 20 -

Page 24

4. TROUBLESHOOTING

4.1 Troubleshooting Table

(A) High Voltage Power Supply Board

Note:

A malfunction of the power supply is not repaired by an agency. The abnormality to be

treated here is that of sensors only.

Failure PC Display Message

A paper input jams occur frequently.

PAPER

Flowchart

No.

A - 1

INPUT JAM

A paper feed jams occur frequently.

PAPER

A - 2

FEED JAM

A paper-exit jams occur frequently.

PAPER

A - 3

EXIT JAM

A paper size errors occur frequently. A - 4

PAPER

SIZE ERROR

Paper can not be fed from the manual feed slot . A - 5

The message "COVER OPEN" remains displayed on

the PC display.

COVER OPEN

A - 6

The message "TONERLOW" remains displayed on

the PC display.

The message "TONERSNS" remains displayed on

the PC display.

TONER LOW

TONER SENSOR

- 21 -

A - 7

A - 8

Page 25

(B) Main Control Board

Failure PC Display Message

Initialization error and not restored

INITIALIZATION

Flowchart

No.

B - 1

ERROR

Program ROM error

ROM CHECK

B - 2

ERROR

Resident RAM error

RAM CHECK

B - 3

ERROR

EEPROM error B - 4

EEPROM CHECK

ERROR

Fuser error B - 5

Watchdog timer timeout occurs frequently. B - 6

FUSER ERROR

WATCHDOG

Data sent through the Parallel I/F cannot

be received.

TIMER ERROR

INITIALIZATION

ERROR

B - 7

- 22 -

Page 26

4.2 Troubleshooting Flowchart

A-1 Paper input jams occur frequently.

• Is PS4 (Write Sensor ) operating normally?

• No Replace PS4.

▼

• Yes Is Pin1 of CN8 in main control board operating normally?

• No Replace Q4 or Q5 in main control board.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

A-2 A paper feed jams occur frequently.

• Is PS4 (Write Sensor ) operating normally?

• No Replace PS4.

▼

• Yes Is PS3 (Outlet Sensor ) operating normally?

• No Replace PS3.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

A-3 A paper exit jams occur frequently.

• Is PS3 (Outlet Sensor) operating normally?

• No Replace PS3.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

A-4 A paper size errors occur frequently.

• Is PS4 (Write Sensor ) operating normally?

• No Replace PS4.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

A-5 Paper can not be fed from manual feed slot.

• Is PS2 (Manual Feed Sensor) operating normally?

• No Replace PS2.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

- 23 -

Page 27

A-6 The message “COVER OPEN” remains displayed on the PC display.

• Is CVSW (Cover Open Switch) operating normally?

• No Replace CVSW.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

A-7 The message “TONERLOW” remains displayed on the PC display.

• Is PS1 (Toner Sensor) operating normally?

• No Replace PS1.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

A-8 The message “TONERSNS” remains displayed on the PC display.

• Is PS1 (Toner Sensor) operating normally?

• No Replace PS1.

▼

• Yes Failure of IC6 (MSM65917) in main control board.

- 24 -

Page 28

B-1 Initialization error and not restored

• Replace IC2.

▼

• OK?

▼

• No Is the 10-MHz clock signal being put out to pin 3 of OSC1?

• No Replace OSC1 (CST 10.0MTW).

▼

• Yes Failure of IC6 (MSM65917)

B-2 Program ROM error

• Replace IC2.

B-3 Resident RAM error

• Are negative pulses being put out to Pin 4 , 23 (RAS0-N , CAS-N) of IC11?

• No Failure of IC6 (MSM65917)

▼

• Yes Are the signals at pins, 9 TO 12 , 14 TO 18 , 5

(DA00-P to DA09-P) of IC11 being changed?

• No Failure of IC6 (MSM65917)

▼

• Yes Replace IC11.

B-4 EEPROM error

• Replace IC4.

▼

• OK?

▼

• No Failure of IC6 (MSM65917)

B-5 Fuser error

• Is the heater on?

▼

• No Is the voltage at Pin 40 (HEATON-P) of IC6(MSM65917) 5V?

• Yes Replace Q3 or IC20

▼

• No Failure of IC6 (MSM65917)

B-6 Watchdog timer timeout occurs frequently.

• Replace IC2.

▼

• OK?

▼

• No Failure of IC6 (MSM65917)

- 25 -

Page 29

B-7 Data sent through the Parallel I/F cannot be received.

• Is the signal at Pin 11 (BUSY-P) of CN4 being at low level?

• No Is the signal at Pin 13 (BUSY-P) of IC7 (7407) changed as shown

below, at data reception?

ON-LINE OFF-LINE

BUSY-P Low High

• No Failure of IC6 (MSM65917)

▼

• Yes Replace IC7 (7407).

▼

• Yes Is the level of the signal at Pin 1 (STB-N) of CN4 changed at data reception?

• No Make sure of the connection of I/F cable or the operation of the h ost

computer.

▼

• Yes Are the signals at Pin 1 (ACK-N), Pin 9 (FAULT-N) of IC7 (7407) being

respectively at low level and high level in on-line mode?

• No Replace IC7 (7407).

• OK?

▼

▼

• Yes Failure of IC6 (MSM65917)

• No

- 26 -

Page 30

5. CIRCUIT DIAGRAM

Figure5-1~5-7 Main Control PCB (HBMC or HBMC-2) Circuit Diagram (Rev. 4)

Figure5-8 High voltage Power Supply PCB (OLHV-) Circuit Diagram (Rev.7)

(TLHV-) Circuit Diagram (Rev.3)

- 27 -

Page 31

A

+5V

+5V

IC5

Not Mounted (HIGH-LEVEL)

Mounted (LOW-LEVEL)

0V

0V

0V

CH1

0V

0V

+5V

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

SIGNAL

OPEN

EAN

Pin-No Short-Wire

MSM65917 Mode change

Tool not connected

Tool connected

Internal ROM External ROM External ROM

61 R53

SP1 B Side A Side A Side62

OSC1

R510

R53

1

1

0

2

2

13

2

1

1

1

2

R533

C15

0.1µ 50

5.1K 0.1

112

R52

0

0

12

R51

3.6K 0.1

12

R50

12

2

C14

0.1µ 50

1

2

C12

0.1µ 50

1

2

C13

0.1µ 50

1

2

C509

0.1µ 50

1

2

C503

0.1µ 50

1

2

C511

0.1µ 50

1

2

C510

0.1µ 50

2

1

C514

0.1µ 50

1

2

C504

0.1µ 50

2

1

C513

0.1µ 50

1

2

R511

12

3

3

141824231720192122

131211

10

151635

36

3738394349

3442408586

41

105

102

976

5

8

87

1

111

CH5

CH4CH6CH7

11

CH2 CH3

2

4

1

606162

63

454746

48

27282930312632

7670585125

7569575033

44

106

104

103

108

107

PST592

VCC

GND

OUT

CST10.0MTW

CST

0

R526

12

150 0.1

10K 0.1

CH8

SP1 (Short-plug)

SP1 SP1 SP1

123

AB

(074G) CVOPN-N

(076F) TNRSNS-N

(076G) WRSNS-N

(076G) PSOUT-N

(076F) PSIN-N

(065D) DIPSW2

(065D) DIPSW1

(075F) TEMP

(016F) THCHK-N

(075E) TR-VSEN

(075E) TR-ISEN

GND1

GND2

GND3

GND4

GND5 PU00

P40

P41

P42

P43

P44

P45

P46

P20

P21

P24

P25

P27

INT0

INT1

WRN

RDN

ALE

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

A8

A9

A10

A11

A12

A13

A14

A15

ROCS

CPCK

65917

(1/2)

GND6

GND7

VDD1

VDD2

VDD3

VDD4

VDD5

VDD6

VDD7

AGND

AVDD

AI0

AI1

AI2

AI3

AI4

P30

P31

P32

P33

P34

P35

P36

P37

RSTN

EAN

CPEN

TEST

OSC0

OSC1

IC6

CHPW

DBPW

T2PW

T1PW

SDB2

SDB1

RMON

RMP1

RMP2

DMON

DMP1

DMP2

VSB4

VSB3

VSB2

VSB1

VLDP

VCLK

VD0P

VD1P

FLTN

SELP

PEP

BSYP

ACKN

DWRN

CASN

RAS0

RAS1

RAS2

DA7

DA6

DA5

DA4

DA3

DA2

DA1

DA0

DA10

DA9

DA8

65917

(2/2)

PSBN

AFXN

SLIN

IPRN

PDT2

PDT1

PDT3

PDT4

PDT5

PDT6

PDT7

PDT8

DD0

DD3

DD2

DD1

IC6

LED-P (073E)

XCLK-P (065B)

HEATON-P (076D)

FANALM-N (03XG)

EEPRMDT-P (047A)

EEPRMCS-P (047B)

EEPRMCLK-P (048C)

AD00-P (027B)

AD01-P (027B)

AD02-P (027B)

AD03-P (027B)

AD04-P (027B)

AD05-P (027B)

AD06-P (027B)

AD07-P (027B)

A08-P (02XB)

A09-P (02XB)

A10-P (02XB)

A11-P (02XB)

A12-P (02XB)

A13-P (02XB)

A14-P (02XB)

A15-P (02XB)

ROMCS-N (02XC)

RD-N (02XC)

ALE-P (027C)

FANON-P (037E)

DCLED-P (071F)

THCHK-N (013E)

TXD-P (065B)

BANK (02XB)

RXD-P (065B)

5352555954

56

99

100

101

989697

92939495919089

88

8180797877

120

125

126

127

128

119

118

117

116

115

114

113

112

111

110

109

123

124

121

122

7473727168676665828384

64

(024B) DD01-P

(024B) DD00-P

(024C) DD03-P

(024C) DD02-P

(054B) PDATA8-P

(054B) PDATA7-P

(054B) PDATA6-P

(054C) PDATA5-P

(054C) PDATA4-P

(054C) PDATA3-P

(054C) PDATA2-P

(054C) PDATA1-P

(054E) IPRIME-N

(054F) SELIN-N

(054G) AUTOFD-N

(054E) PSTB-N

DA10-P (024A)

DA09-P (022C)

DA08-P (022C)

DA07-P (022C)

DA06-P (022C)

DA05-P (022C)

DA04-P (022C)

DA03-P (022C)

DA02-P (022D)

DA01-P (022D)

DA00-P (022D)

RAS2-N (025D)

RAS1-N (025E)

RAS0-N (023E)

CAS-N (023E)

DWR-N (022D)

ACK-N (057E)

BUSY-P (057D)

PE-P (057E)

SEL-P (057F)

FAULT-N (057F)

VD1-P (041B)

VD0-P (041B)

VCLK-P (041B)

VLD-P (041C)

VSTB4-N (041D)

VSTB3-N (041D)

VSTB2-N (041C)

VSTB1-N (041C)

PJON-P (037B)

CHPWM-P (071D)

DBPWM-P (071B)

TR2PWM-P (071E)

TR1PWM-P (071C)

SDB2-P (071B)

SDB1-P (071A)

DMPH1-P (033C)

DMON-P (031D)

DMPH2-P (033C)

B

C

D

E

F

G

H

Y

Y

(HBMC- or HBMC-2 1/7) Rev. 4

Circuit Diagram

Figure 5-1 Main controller PCB

456 879X

3

2

1

A

B

C

D

- 28 -

E

F

3456 879X

2

1

G

H

Page 32

A

+5V

+5V

+5V

0V

0V

0V

0V

CN9

Option-RAM

(01XB) DA10-P

(018B) DD00-P

(01XB) DA09-P

(01XC) DA08-P

(01XC) DA07-P

(01XC) DA06-P

(01XC) DA05-P

(01XC) DA04-P

(01XC) DA03-P

(01XC) DA02-P

(01XC) DA01-P

(01XC) DA00-P

(01XD) DWR-N

(018B) DD01-P

(018C) DD02-P

(018C) DD03-P

DRAM-A10

DRAM-A09

DRAM-A08

DRAM-A07

DRAM-A06

DRAM-A05

DRAM-A04

DRAM-A03

DRAM-A02

DRAM-A01

DRAM-A00

DRAM-D03

DRAM-D02

DRAM-D01

DRAM-D00

RAS2N

RAS1N

CASN

DRAM-WRNOEVCC

VCC

VCC

GND

GND

GND

GND

GND

GND

GND

GND

GND

CN924CN925CN926CN927CN928CN929CN930CN912CN9

11

21

CN910CN99CN93CN92CN97CN9

6

CN9

8

CN91CN94CN9

5

CN919CN917CN918CN913CN914CN915CN9

16

CN920CN922CN923CN931CN932CN9

R548

1

2

0

R546

1

2

0

R549

1

2

0

R550

1

2

0

IC11

A9A8A7A6A5A4A3A2A1A0WEOEVCC

VSS

RAS CAS

I/O4

3

22

13

423

1

2

24

25

26

5

18171615141211

10

9

I/O3

I/O2

I/O1

514400J

C520

0.1µ 50

1

2

R547

100

12

(01XD) RAS0-N

(01XD)CAS-N

(01XC) RAS2-N

(01XC) RAS1-N

<512>

<128>

DQ1DQ1

DQ2DQ2

WEWE

RASRAS

NCA9

A0A0

A1A1

A2A2

A3A3

Vcc

1

2

3

4

5

9

10

11

12

13

26

25

24

23

22

18

17

16

15

14Vcc

VssVss

DQ4DQ4

DQ3DQ3

CASCAS

OEOE

A8A8

A7A7

A6A6

A5A5

A4A4

IC11

1M Mask

27C1001

27512

IC2

123 (1)

4 (2)

5 (3)

6 (4)

7 (5)

8 (6)

9 (7)

10 (8)

11 (9)

12 (10)

13 (11)

14 (12)

15 (13)

16 (14)

NC

A16

A15

A12A7A6A5A4A3A2A1A0D0D1D2GND

VPP

A16

A15

A12A7A6A5A4A3A2A1A0DOD1D2GND

--A15

A12A7A6A5A4A3A2A1A0DOD1D2GND

--VCC

A14

A13A8A9

A11

OE/VPP

A10CED7D6D5D4D3

VCC

PGMNCA14

A13A8A9

A11OEA10CED7D6D5D4D3

VCCNCNC

A14

A13A8A9

A11

OE/OE

A10

CE/CED7D6D5D4

D3

32

31

(28) 30

(27) 29

(26) 28

(25) 27

(24) 26

(23) 25

(22) 24

(21) 23

(20) 22

(19) 21

(18) 20

(17) 19

(16) 18

(15) 17

GND

VCCNCVPPCEOE

PGM

A0A1A2A3A4A5A6A7A8A9A10

A11

A12

A13

A14

A15

A16 Q7

21

3124221303216

2

3

29

284252326

27

56789

101112

20191817151413

Q6Q5Q4Q3Q2Q1Q0

(016E) RD-N

C501

0.1µ 50

1

2

(016C) ROMCS-N

Vcc=+5V, Ground=0V

SOCKET

IC2

IC3

27C1001

74LS373

1D

2Q3Q4Q5Q6Q7Q8Q

1Q

2D3D4D5D6D7D8DENOC

2

1

1118171413

874

3

569

121516

19

(016D) AD07-P

(016F) BANK

(016C) A15-P

(016C) A14-P

(016C) A13-P

(016C) A12-P

(016C) A11-P

(016C) A10-P

(016C) A09-P

(016C) A08-P

(016D) AD06-P

(016D) AD05-P

(016D) AD04-P

(016D) AD03-P

(016D) AD02-P

(016D) AD01-P

(016D) AD00-P

(016E) ALE-P

B

C

D

E

F

G

H

Y

Y

(HBMC- or HBMC-2 2/7) Rev. 4

Circuit Diagram

Figure 5-2 Main controller PCB

456 879X

3

2

1

A

B

C

D

E

F

G

H

3456 879X

2

1

- 29 -

Page 33

A

NOMOUNT

NOMOUNT

CH10CH9

11

CN7

4M-DMOTOR

IC10

+5V

(01XF) DMON-P

R542

1K 0.1

12

R541

C524

22K

50

2200p

0.1

112

R540

C523

C4

4.3K

0.1µ 50

47µ 50

0.1

1

1

21

+

2

2

2

R543

12

22K 0.1

0V

0V

0V

C525

12

0.1µ 50

+5V

+24V

ZA21

ZA20

1

1

0Vp

30

NC6

13

11

964

2

10

5

24

12

8

7

3

NC5

NC4

NC3

NC2

NC1

RSB

RSA

NALM

OUT4

OUT3

OUT2

OUT1

29

14

1

15

28

19

18

21

20

22

23

25

16

17

27

26

GND2

GND1

VMM2

VMM1

LGB

LGA

VCC

DCAY

VSB

REFB

REFA

CR

NENB

NENA

PHAB

PHAA

VSA

MTD2005F

CN71CN72CN73CN7

4

IM=0.38A

R1

1

2 0.5

2

R2

1

2 0.5

2

0Vp

DMPH2-N

DMPH2-P

DMPH1-N

DMPH1-P

+5V

R54

1

1K

6.2K

0.1

2

R55

1

0.1

2

(01XF) PJON-P

(016E) FANON-P

Q5

22K

22K

2

3

1

0V

OVP

+24V

CN8

2M-PJ

Q4

3

3

2SA1338

SS100MA80VACP

221

1

D3

CN8

1

CN8

2

PJON

OVP

NOMOUNT

CN3

2M-Fan

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

2

2

2

22K

22K

1

1

3

R502

Q502

10K 0.1

+24V

Q501

3

3

112

2SA1338

0V

D501

SS100MA80VACP

FANPOW

R5011

10K 0.1

2

0VP

0VP

+5V

FANALM-N FANALM-N (016F)

CN3

1

CN3

2

CN3

3

(01XF) DMPH1-P

(01XF) DMPH2-P

0V

B

C

D

E

F

G

H

Y

Y

(HBMC- or HBMC-2 3/7) Rev. 4

Circuit Diagram

Figure 5-3 Main controller PCB

456 879X

3

2

1

A

B

D

C

- 30 -

E

F

3456 879X

2

1

G

H

Page 34

A

+5V

R520

12

330

R519

NOMOUNT

12

330

R513

12

330

R512

12

0

(01XE) VD0-P

(01XE) VD1-P

(01XE) VLD-P

(01XE) VCLK-P

(01XF) VSTB1-N

(01XE) VSTB2-N

(01XE) VSTB3-N

(01XE) VSTB4-N

SS100MA80VACP SS100MA80VACP

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

SS100MA80VKCP SS100MA80VKCP

D1 D2

1

3

2

1

3

2

CN6

14F-LED

CN66CN67CN68CN69CN610CN611CN612CN6

13

CN6

3

CN6

4

CN6

5

HDDT0-P

HDDT1-P

HDCLK-P

HDLD-P

STB1-N

STB2-N

STB3-N

STB4-N

D4

1

3

2

D5

1

3

2

0V

5V

5V

0V

CN6

1

0VP

CN6

2

0VP

CN6

14

FG

+5V

11+2

2

C526

C1

0.1µ

3300µ

50

12

C16

0.01µ 250

12

C8

0.01µ 250

10

0V

0VP

FG1

FG2

FG

1

1

(016E) EEPRMDT-P

(016E) EEPRMCS-P

(016E) EEPRMCLK-P

+5V

R537

C522

0.1µ 50

5.1K 0.1

112

R538

5.1K 0.1

12

R539

10K 0.1

12

2

0V

3261857

IC4

93LC46

DIDONC1C8VCC

GND1

NC2

4

0V

B

C

D

E

F

G

H

Y

Y

(HBMC- or HBMC-2 4/7) Rev. 4

Circuit Diagram

Figure 5-4 Main controller PCB

456 879X

3

2

1

A

B

C

D

- 31 -

E

F

G

H

3456 879X

2

1

Page 35

A

+5V

CN4

36F-Centro

PDATA8-P

CN4

9

PDATA7-P

CN4

8

PDATA6-P

CN4

7

PDATA5-P

CN4

6

PDATA4-P

CN4

5

PDATA3-P

CN4

4

PDATA2-P

CN4

3

PDATA1-P

CN4

2

STB-N

CN4

1

IPRIME-N

CN4

31

SELIN-N

CN4

36

AUTOFEED-P

CN4

14

R30

21

22 0.1

R31

21

22 0.1

R29

21

22 0.1

R28

21

22 0.1

R25

21

22 0.1

R26

21

22 0.1

R27

21

22 0.1

R24

21

22 0.1

R528

12

100 0.1

R514

21

1K 0.1

R505

12

3.3K 0.1

R515

12

3.3K 0.1

R522

1

10K 0.1

R521

12

10K 0.1

R527

21

1K 0.1

R506

C515

560p 50

112

2

C506

1000p 50

1

2

C507

560p 50

1

2

C508

560p 50

1

2

1K 0.1

R504

12

1K 0.1

R516

3.3K 0.1

21

R509

3.3K 0.1

21

R507

3.3K 0.1

21

R508

3.3K 0.1

21

R517

3.3K 0.1

21

R518

3.3K 0.1

21

R524

3.3K 0.1

21

R523

3.3K 0.1

21

PDATA8-P(018D)

PDATA7-P (018D)

PDATA6-P(018D)

PDATA5-P (018D)

PDATA4-P(018D)

PDATA3-P (018D)

PDATA2-P(018D)

PDATA1-P (018D)

+5V

0V

0V

0V

0V

+5V

+5V

NOMOUNT

NOMOUNT

Vcc=+5V , Ground=0V

OC

56

IC7

07

AUTOFD-N (018E)

SELIN-N (018E)

IPRIME-N (018E)

PSTB-N (018E)

+5V

+5V

0V

C505

R38

0.1µ 50

112

2

3.3K 0.1

R37

12

3.3K 0.1

R35

12

3.3K 0.1

R36

12

3.3K 0.1

R43

12

3.3K 0.1

R44

12

3.3K 0.1

(01XE) BUSY-P

(01XE) ACK-N

(01XE) PE-P

(01XE) SEL-P

(01XE) FAULT-N

Vcc=+5V , Ground=0V

Vcc=+5V , Ground=0V

Vcc=+5V , Ground=0V

Vcc=+5V , Ground=0V

Vcc=+5V , Ground=0V

OC

13 12

07

IC7

OC

12

07

IC7

OC

34

07

IC7

OC

11 10

07

IC7

OC

98

07

IC7

FG

C7

0.01µ

250

12

C17

0.01µ

250

12

0V

+5V

R42

12

0

CN4

38

FG

CN4

37

FG

CN4

17

FG

CN4

18

5V

CN4

32

FAULT-N

CN4

13

SEL-P

CN4

12

PE-P

CN4

10

ACK-N

CN4

11

BUSY-P

CN4

35

HILEVEL

CN4

34

N/C

CN4

15

N/C

CN4

33

SG

CN4

30

SG

CN4

29

SG

CN4

28

SG

CN4

27

SG

CN4

26

SG

CN4

25

SG

CN4

24

SG

CN4

23

SG

CN4

22

SG

CN4

21

SG

CN4

20

SG

CN4

19

SG

CN4

16

SG

0V

CN4

36F-Centro

B

C

D

E

F

G

H

Y

Y

(HBMC- or HBMC-2 5/7) Rev. 4

Circuit Diagram

Figure 5-5 Main controller PCB

456 879X

3

2

1

A

B

C

D

- 32 -

F

E

G

H

3456 879X

2

1

Page 36

A

+5V

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

IC9

OSC

VOUT

LV

CAP+

CAP-

GND

V+

C512

21

1000p 50

8

756

2

4

3

C6

10µ 16

21+

C5

C516

10µ

0.1µ 50

16

221

1

C517

0.1µ 50

21

+

0V

0V

0V

SW1

2

1

3

4

2

1

DIPSW2 (014D)

DIPSW1 (014D)

+5V

RXD-P (01GF)

R525

12

20 0.1

R532

12

20 0.1

R534

12

20 0.1

R530

12

20 0.1

(016F) TXD-P

(016F) XCLK-P

(06XE) RXD+

(06XF) RXD-

2

IC8

3

4

12

151413

567

11

10916

8

1

7660

DS8925

DIN1

DIN2

RIN1-

RIN2+

RIN2-

RIN3+

VCC

GND

VEE

DEN1

DOUT1+

DOUT1-

DOUT2-

ROUT1

ROUT2

ROUT3

0V

0V

0V

0V

C521

150p 50

1

2

C518

150p 50

1

2

C519

150p 50

1

2

CN5

TCS7187-01-201

CN5

6

TXD+

CN5

3

TXD-

R529

12

20 0.1

R544

12

0

R536

12

0.1200

200

R535

12

0.1

R531

12

20 0.1

CN5

1

XCLK-N

CN5

7

+5V

CN5

4

CN5

8

SG

+5V

RXD+

CN5

5

RXD-

CN5

2

CN5

FGFGFG

FG

9

CN510CN5

11

HSK-IN

RXD+ (065B)

RXD- (065B)

B

C

D

E

F

G

H

Y

Y

(HBMC- or HBMC-2 6/7) Rev. 4

Circuit Diagram

Figure 5-6 Main controller PCB

456 879X

3

2

1

A

B

C

D

- 33 -

E

F

3456 879X

2

1

G

H

Page 37

A

CN1

High-voltage

(01XG) SDB1-P

(01XG) SDB2-P

(01XG) DBPWM-P

(01XG) TR1PWM-P

(01XF) CHPWM-P

(01XG) TR2PWM-P

(016F) DCLED

R39

R40

C11

1122

1K 0.1

R5

12

0

OC

NOMOUNT

LS07

1

1

2

2

34

0.11K

R41

1256

98

11 10

0.1300

R34

12

0.1220

R32

21

0.1300

R33

21

0.1300

R7

12

0

R9

12

0

R13

12

0

R11

12

0

R22

Q2

Q1

12

10K

2SA1338

0.1

0.047µ 50

C10

2

1

0.022µ 50

C18

2

1

0.022µ 50

C19

1

2

2

1

1

2

3

3

0.022µ 50

R3

12

0

OC

NOMOUNT

NOMOUNT

LS07

OC

LS07

NOMOUNT

OC

LS07

IC1

IC1

IC1

IC1

NOMOUNT

OC

LS07

IC1

13 12

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT

NOMOUNT NOMOUNT

NOMOUNT

OC

LS07

IC1

Vcc=+5V , Ground=0V

22K

22K

0V

+24V

+5V

C9

0.1µ 50

12

0V

11

0V

CN1

10

0V

CN1

9

0V

CN1

7

0V

CN1

5

0V

CN1

17

5V

CN1

15

5V

CN1

23

CN1

CVOPN-N (014D)CVOPN-N

1

CN1

PSOUT-N PSOUT-N (014D)

16

CN1

WRSNS-N

19

CN1

PSIN-N

21

CN1

TNRSNS-N

13

CN1

6

CN122CN1

3

CN1

TEMP TEMP (013E)

TNRSNS-N (014D)

PSIN-N (014D)

WRSNS-N (014D)

(016G) LED-P LED-P

DCLED-P

+5V

12

R19

100K 0.1

21

R56

200K 0.1

12

R545

4.7K 0.1

12

R15

10K 0.1

12

R12

510 0.1

12

R14

510 0.1

12

R10

510 0.1

12

R8

3.3K 0.1

12

R4

3.3K 0.1

12

R6

3.3K 0.1

12

R16

10K 0.1

12

R17

10K 0.1

12

R18

10K 0.1

21

R20

1.2K 0.1

21

R21

1K 0.1

12

R503

10K 0.1

1

1

12+

2

2

R23

C502

C3

0.1µ 50

47µ 16

12+

C2

47µ 50

1K 0.1

TR-ISEN (014E)

TR-ISEN

12

CN1

4

CN1

TR-VSEN (014E) TR-VSEN

TR2PWM-P

2

CN1

CHPWM-P

8

CN1

TR1PWM-P

DBPWM-P

14

CN1

SDB2-P

20

CN1

SDB1-P

18

CN1

+5V

+5V

0V

0V

0V

0V

0V

+5V

+5V

+5V

+5V

3

2

4

1

8

+

-

5

6

4

7

8

+

-

(016F) HEATON-P

IC20

IC20

393

393

2.2K

10K

Q3

2

1

3

CN2

8

CN2

NC

7

CN2

0V

4

CN2

0V

3

CN2

5V

2

CN2

5V

1

CN2

0VP

5

CN2

24V

+24V

6

HEATON-N

1

0V

+5V

0VP

CN2

Power

B

C

D

E

F

G

H

Y

Y

(HBMC- or HBMC-2 7/7) Rev. 4

Circuit Diagram

Figure 5-7 Main controller PCB

456 879X

3

2

1

A

B

C

D

- 34 -

E

F

G

H

3456 879X

2

1

Page 38

A

10

DBPWM-P

SDB1-P

CN16CN1

SDB2-P

4

CN1

TR1PWM-P

16

CN1

TR2PWM-P

20

CN1

CHPWM-P

(017D) VSEN TR-VSEN

22

CN1

12

CN1

(01XE) ISEN TR-ISEN

21

CN1

(015G) TNRSNS TNRSNS-N

3

CN1

(015G) PSIN PSIN-N

5

CN1

(015G) WRSNS WRSNS-N

8

CN1

(015G) PSOUT

(012F) THERM TEMP

PSOUT-N

23

CN1

11

CN1

2

CN1

LED

1

CN1

7

CN19CN1

+5V

H5V

H5V

R118

CVOPN-N

12

G

G

G

G

G

5V

5V

4.7K 0.25

CVSW

1

3

2

N.O

N.C

LED-P

18

CN1

DCLED-P

13

CN1

0V

14

CN1

1

CN2

2

CN2

0V

15

CN1

0V

17

CN1

0V

19

CN1

0V

LED24V

12

SEL3910D-YZ

GND

GND

G

GND

CN3

1

GND

CN3

2

+5V

+5V

G

TH

5V

THERM (011D)

GND

GND

GND

GND

GND

GND

GND

H5V

H5V

GND

GND

H5V

G

R47

1

130 0.25

2

R48

C312

0.1µ 50

12

NOMOUNT

1

130 0.25

2

1

2

3

4

PS1

SG-206

1

2

3

4

PS2

SG-206

1

2

3

4

PS3

SG-206

1

2

3

4

PS4

SG-206

G

TNRSNS (011C)

PSIN (011C)

PSOUT (011C)

WRSNS (011C)

G

G

6

5

G

G

G

G

G

G

G

3

3

2

1

3

2

1

Q16

2

21

1

Q17

Q15

2SC2235-Y

2SC2235-Y

2SC2235-Y

D82

D62

C251

0.1µ 50

470p 3.15K

D76

RD27E-B1 RD22E-B

EU02A

EU02A

12

12

12

D71

112

2

1

1

2

2

C311

C117

R119

100M 0.5

0.1µ 50

1

2

C310

C114

C116

C115

D69 D68

D87

RD200E-B

R115

576K 0.25

C119

470p 1K

C301

C111

C302

D67

C112

C300

D61R234

33 0.25

R105

R122

C103

C104

D58

39p 500

470p 1K

C108

0.1µ50

0.1µ50

0.1µ50

0.1µ

50

10µ

63

5.1k 0.25

221

R123

1k 0.25

21

R124

R121

R229

D52

D55

D56

D85

D84

D83

D81

470V

Q11

C105

C241

C102

L10

C237

C236

1

1

12

+

2

2

1000µ

C-14576

1ZB300-Y/Z

5.1K 0.25

1

1

1

1

1

1

1

1

1

1

1122

2

2

2

2

2

2

2

2

3

2

2

2

R112

Q13

C240

C107

5.1k

BCR1AM-12

BCR1AM-12

CR04AM-12

1ZB300-Y/Z

0.25

5.1k 0.25

21

1

2

2

2

10M 0.25

2

2

2

1

12

1

1

1

R111

2

10M 0.25

1

1

3

24K

4700p

470p 6K

1ZB390

D66 D65

1ZB390

R114

470p

0.047µ 50

0.1µ 50

3.15K

DHM3FJ60/ESJA58-06

DHM3FJ60/ESJA58-06

DHM3FJ60/ESJA58-06

DHM3FJ60/ESJA58-06

100

0.25

1

1

11

1

1

1

1

2

12

2

2

2

2

22

2

11

1

1

100M 0.5

2

2

2

2

0.1µ 50

0.1µ 50

0.1µ 50

0.1µ 50

1

1

1

11

1

1

2

2

2

1

2

22

2

2

C118

0.01µ100

1

2

4

3

2

1

1

1

5

5

6

1

12

1

1

22 2

6

2

3

4

2

3

4

1

T4

T3

T2

Hi-Voltage_Trans

Hi-Voltage_Trans

Hi-Voltage_Trans

D72

2

2

1

R228

1M 0.25

D59

EU02A

R104

R102

0.25 75K

1

1

1

2

2

2

VSEN (011C)

D60

1S953/1S2075K

/1S2473

1S953/1S2075K/1S2473

1S953/1S2075K/1S2473

1S953/1S2075K/1S2473

C110

0.1µ

50

C113

D63

R113

470p 3.15K

D74

100K 0.25

+5V

ISEN (011C)

J8

J7

1

12

2

J1

J2

1

12

2

J3

J4

1

12

2

J6

J5

1

12

2

J10

J9

1

12

2

J11

J12

1

12

2

G

12

R103

1K 0.25

12

R116

330

0.25

12

R100

3M

0.25

11

1

2

22

330 0.25

3

2

1

Q21

3

2

1

Q22

3

2

1

1

1

1

1

2

2

2

2

Q10

D51

3

2

1

Q23

H5V

2SC1815-Y

2SC1815-Y

2SC1815-Y

C106

470p 500

D57

EU02A

EU02A

G

G

G

2SC2752

EU02A

EU02A

EU02A

EU02A

EU02A

C101

470p 500

470p 1K

470p 500

39p 500

3

Q12

R233

R231

1M

10M

0.25

0.25

B

C

D

E

F

G

H

Y

Y

(OLHV-1/1) Rev.7

Circuit Diagram

Figure 5-8 High voltage power supply PCB

or (TLHV-1/1) Rev.3

456 879X

3

2

1

A

B

G

H

3456 879X

2

1

C

D

- 35 -

E

F

Page 39

COMPONENT PARTS LIST

Page 40

Drawing List

Main Control Board (HBMC- PCB or HBMC-2 PCB, Rev. 4) 4YA4121-2516G002

High Voltage Power Supply Board (OLHV PCB, Rev.7) 4YA4130-1004G1

or

(TLHV PCB, Rev.3) 4YA4130-1024G1

Page 41

IC2

CN6

R15

R3

R5

R7

R9

R11

R13

C9

R16

R17

R18R19

R56

R20

R21

IC3

IC4

IC10

1

2

13

14

IC7

1

19

18

36

CN4

IC20

OSC1

R33

R23

R24

R27

R26

R25

R28

R29

R31

R30

R37

R38

R35

R36

R43

R44

R42

C19

C18

C10

C11

C15

SP1

3

1

R32

R34

R51

R1

1

12

4

R2

CN7

R50

R52

R54

Q5

Q4 D3

CN8

R55

C13

C12

C14

R39

R40

R41

IC11

1

2

16

151430

2917

CN9

IC5

Q3

C2

IC6

C3

CN2

CN1

18

C7

C17

C4

C16

C8

C1

63

61

64

HBMC or HBMC-2 Printed Circuit Board

R506

R508

R507

R509

R516

R517

R518

R524

R523

R504

R505

R515 R512

R503

C503

C509

C520

R510

R533

R537

R538

R545

C511

C510

R513

R520

R522

R521

R514

C505

C526

C502

C504

C522

R546R547

R526

C513

C501

C514

R549

R548

R550

R528

R539

R540

R541

R542

R543

C523

C524

C525

R527

C515

C506

REV. 4

(4YA4121-2516G002-1/2)

- 1 -

Page 42

HBMC or HBMC-2 Printed Circuit Board Rev. 4

(4YA4121-2516G002-1/4)

REF.

NO.

1

D3

R513, R520

2

R55

3

R24-R31

4

R528, R547

5

6

R526

R3, R5, R7, R9, R11,

7

R13, R42, R50, R52,

R510, R512, R546,

R548-R550

R34

8

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

SS100MA80VACP

DAP202K/1SS181/M

RM73B2A331J

RES-MET RN —

RM73B2A622J

RES-MET RN —

RM73B2A220J

RES-MET RN —

RM73B2A101J

RES-MET RN —

RM73B2A151J

RES-MET RN —

2125JPW

RES-MET RN —

RM73B2A221J

RES-MET RN —

611A0000N0001

323A5003J0331

323A5003J0622

323A5003J0220

323A5003J0101

323A5003J0151

323A5003P0001

323A5003J0221

1

2

1

8

2

1

15

1

R32, R33, R41

9

R23, R39, R40, R54,

10

R504, R506, R514,

R527

R533, R537, R538

11

R15-R18, R503, R521,

12

R522, R539

R543

13

R19

14

RM73B2A301J

RES-MET RN —

RM73B2A102J

RES-MET RN —

RM73B2A512J

RES-MET RN —

RM73B2A103J

RES-MET RN —

RM73B2A223J

RES-MET RN —

RM73B2A104F

RES-MET RN —

323A5003J0301

323A5003J0102

323A5003J0512

323A5003J0103

323A5003J0223

323A5003F0104

3

8

3

8

1

1

- 2 -

Page 43

HBMC or HBMC-2 Printed Circuit Board Rev. 4

(4YA4121-2516G002-2/4)

REF.

NO.

15

16

17

18

19

20

21

22

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R35-R38, R43, R44,

R505, R507-R509,

R515-R518, R523,

R524

R20

R1, R2

R545

R21, R542

R540

R51

R541

RM73B2A332J

RES-MET RN —

RM73B2A122F

RES-MET RN —

MSF1/2B2ohmJ

RES-MET OX —

RM73B2A472J

RES-MET RN —

RM73B2A102F

RES-MET RN —

RM73B2A432F

RES-MET RN —

RM73B2A362F

RES-MET RN —

RM73B2A223F

RES-MET RN —

323A5003J0332

323A5003F0122

324A1001J0209

323A5003J0472

323A5003F0102

323A5003F0432

323A5003F0362

323A5003F0223

16

1

2

1

2

1

1

1

R56

23

C515

24

C506

25

C10, C18, C19

26

27

C9, C12-C15,

C501-C505,

C509-C511,

C513, C514, C520,

C522, C523, C525,

C526

C524

28

C7, C8, C16, C17

29

C1

30

RM73B2A204F

RES-MET RN —

CC2012SL1H561J 50V

CAP-Ceramic —

CK2012B1H102K 50V

CAP-Ceramic —

CK2012R1H223K 50V

CAP-Ceramic —

CK2012F1H104Z 50V

CAP-Ceramic —

CK2012B1H222K 50V

CAP-Ceramic —

TCK45F2E103ZYA 250V

CAP-Ceramic —

UVS1A332MHA 10V

CAP-Alum (CE) —

323A5003F0204

303A3007K0561

303A6008K3102

303A6008K3223

303A6008Z3104

303A6008K3222

302A4027Z5103

304A1137A1332

1

1

1

3

20

1

4

1

- 3 -

Page 44

HBMC or HBMC-2 Printed Circuit Board Rev. 4

(4YA4121-2516G002-3/4)

REF.

NO.

31

32

33

34

35

36

37

38

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C2, C4

C3

C11

IC3

IC4

IC11

IC10

IC7

KME50VB-47 50V

CAP-Alum (CE) — 47µF

SME16VB-47-0A 16V

CAP-Alum (CE) — 47µF

CK2012F1H473Z 50V

CAP-Ceramic —

SN74LS373NS

Digital IC-BIP —

93C46LDP-NW

Memory-MOSEEPR —

514400JP-60

Memory-MOSDRAM-S

MTD2005F

Analog-BIPLIN —

7407FP

Digital IC-BIP —

304A1115H1470

304A1123C1470

303A6008Z3473

700A0550N0373

8160303M0000

8020003N2603

720A1816N0001

700A0003N0007

2

1

1

1

1

1

1

1

39

40

41

42

43

44

45

46

47

IC5

IC20

IC6

SP1

PST592D-2

Analog-BIPLIN —

UPC393G2

Analog-BIPLIN —

MSM65917-016GS-K

CPU-MOS (ROM) — F

IMSA9202B-1-03Z013GF

Connector-PCB —

720A4037M0015

720A0523N0011

8530193N0016

224A4082P0030

1

1

1

1

48

CN1

00-5062-301-023-000

Connector-PCB —

- 4 -

224A5114P0230

1

Page 45

HBMC or HBMC-2 Printed Circuit Board Rev. 4

(4YA4121-2516G002-4/4)

REF.

NO.

49

50

51

52

53

54

55

56

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

CN2

CN6

CN8

CN4

CN7

Q5

B8B-XH-A

Connector-PCB —

ZC-014

Connector-PCB —

00-8263-0211-00-000

Connector-PCB —

57RE-40360-830B-D29A

Connector-RECT

00-8263-0411-00-000

Connector-PCB —

DTC124EK

TR-NPN/H-FREQ —

224A3530P0080

224A3590P0140

224A3358P0020

2201001P0361

224A3358P0040

602A1035N0004

1

1

1

1

1

1

57

58

59

60

61

62

63

64

Q4

Q3

0SC1

2SA1338

TR-PNP/H FREQ —

DTC123YK

TR-NPN/H-FREQ —

CST10.0MTW

0SC-Ceramic —

DICF-28CS-E

Socket-SEMICON —

TW-VF-23-210-B

CONN PAR- —

IMSA-9206H-GF

Connector-PCB —

600A1032N0010

602A1035N0019

381A1045B0014

245A1221P0280

238A1123P0002

224A4080P0020

1

1

1

1

1

1

- 5 -

Page 46

C

LED

PS2

J21

Q22

R122

Q23

Q21

R229

R123

C237

J28

R118

R124

C103

C

R116

R103

R102

PS1

Q13

C108

C104

C105

Q11

Q12

D55

D51

R47

C241

R231

D81

C

C240

J30

J11

PS4

J31

D52

J22

D58

C106

C102

J12

D83

C101

J9

L10

Q10

R104

2

1

J29

J26

J32

D56

R233

J10

D85

J27

R121

C110

D60

R105

D61

D84

C236

CN1

D57

J7

R234

R113

J3

J4

J23

C301

J8

J5

C113

C111

R100

J6

C300

J24

23

D63

C107

R111

Q17

D67

T2

J25

R112

R114

C112

D59

C119

R228

D65

C302

R119

D66

C114

D74

C117

D72

CVSW

PS3

J43

D82

C

J2

Q15

C118

C311

J35J33

C310

J36

J40

D62

D76

D69

J41

Q16

D71

C116

J1

D87

T4

J34

T3

C115

C251

D68

J38

J37

R48

CN2

J42

J39

R115

OLHV Printed Circuit Board or

REV.7

(4YA4130-1004G1-1/2)

- 6 -

TLHV Printed Circuit Board

REV.3

(4YA4130-1024G1-1/2)

Page 47

OLHV Printed Circuit Board Rev. 7

(4YA4130-1004G1-2/2-1/4)

REF.

NO.

1

D60,D61,D68,D69

2

D63, D67, D72, D74

3

D51, D55-59, D62,

D71, D81,D84

4

5

D52,D85

6

D65,D66

D87

7

8

D76

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

1S953/1S2075K/1S2473

Signal Diode

DHM3FJ60/ESJA58-06

Rectifier Diode

EU02A

Rectifier Diode

1ZB300-Y/Z

Zener Diode

1ZB390

Zener Diode

RD200E-B

Zener Diode

RD22E-B2

Zener Diode

611A0003L0001

610A0003M0002

610A0226M0016

613A2003M0001

613A2258M0350

613A1231L0522

613A1231L0262B

4

4

10

2

2

1

1

9

D82

10

11

D83

12

13

R234

14

R47,R48

15

R102,R116,R121

16

R103,R123

R118

17

RD27E-B1

Zener Diode

ERZV05D471

Varistor-Resistor

RD1/4Y33ΩJ

RD Resistor

RD1/4Y130ΩJ

RD Resistor

RD1/4Y330ΩJ

RD Resistor

RD1/4Y1KΩJ

RD Resistor

RD1/4Y4.7KΩJ

RD Resistor

613A1231L0282A

6320229M0001

321A1421J0330

321A1421J0131

321A1421J0331

321A1421J0102

321A1421J0472

1

1

1

2

3

2

1

18

R122,R124,R229

RD1/4Y5.1KΩJ

RD Resistor

- 7 -

321A1421J0512

3

Page 48

OLHV Printed Circuit Board Rev. 7

(4YA4130-1004G1-2/2-2/4)

REF.

NO.

19

20

21

22

23

24

25

26

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R105

R104

R113

R228,R233

R100

R115

R111,R112,R231

R114,R119

RD1/4Y24KΩJ

RD Resistor

RD1/4Y75KΩJ

RD Resistor

RD1/4Y100KΩJ

RD Resistor

RD1/4Y1MΩJ

RD Resistor

RD1/4Y3MΩJ

RD Resistor

RNL1/4C3F576KΩ

RN Resistor

HMP1/4-106J

RN Resistor

HV-38-100MK

RK Resistor

321A1421J0243

321A1421J0753

321A1421J0104

321A1421J0105

321A1421J0305

323A1222F5763

323A1029J0106

326A3021K0107

1

1

1

2

1

1

3

2

27

28

C105,C107,C119

29

C113,C114,C117

30

C112

31

C240,C241

32

C101,C102,C106

33

C103,C104,C108,C110,

C111,C115,C237,C251,

C300,C301,C310,C311

34

35

C116

DE0705B471K1K 1KV

CK Capacitor 470pF

DE0707B471K3K 3.15KV

CK Capacitor 470pF

DE1010B471K6K 6KV

CK Capacitor 470pF

DD05-63SL390J500

CC Capacitor 39pF

DD05-63B471K500 500V

CK Capacitor 470pF

FK16Y5V1H104Z

CK Capacitor

FK16Y5V1H473Z

CK Capacitor

302A4028K0471A

302A4028K2471

302A4028K4471

302A1202K0390

302A4003K6471

303A4019Z3104

303A4019Z3473

3

3

1

2

3

12

1

- 8 -

Page 49

OLHV Printed Circuit Board Rev. 7

(4YA430-1004G1-2/2-3/4)

REF.

NO.

36

37

38

39

40

41

42

43

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C118

C302

C236

Q11,Q13

Q12

Q21-Q23

Q15-Q17

CQMF92PP2A103J-F0

CQ Capacitor 0.010µF

CQMF92PP2A472J-F0

CQ Capacitor 0.0047µF

SME63VB-10-0A 63V

CE Capacitor 10µF

BCR1AM-12/MAC97-008

Gate Thyristor SW

CR04AM-12

Gate Thyristor OFF

2SC1815-Y

NPN-HF-TR

2SC2235-Y

NPN-HF-TR

306A4103J2103

306A4103J2472

304A1123J1100

622A0003M0001

620A0022M0008

602A1025M0006Y

602A1125M0039Y

1

1

1

2

1

3

3

44

45

46

47

48

49

50

51

52

Q10

L10

T2,T3,T4

PS1-PS4

2SC2752

NPN-HF-TR

C-14576

P Coil

High Voltage Transformer

SG-206

Photocoupler

602A1223M0039

350A2511P0102

4YB4049-7078P003

652A0114M0003

1

1

3

4

53

- 9 -

Page 50

OLHV Printed Circuit Board Rev. 7

(4YA4130-1004G1-2/2-4/4)

REF.

NO.

54

55

56

57

58

59

60

61

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

CVSW

LED

CN1

CN2

SS-5GL13

Microswitch

SEL3910D-YZ

LED

23FE-BT-VK-N

PC Connector

53254-0210

PC Connector

207A1025P0001

650A0229M0018

224A4134P0230

224A4407P0020

1

1

1

1

62

63

64

J1,J2

J3-J12

J21-J43

0.65 Tin-plated Annealed Copper

Wire

0.65 Tin-plated Annealed Copper

Wire

0.65 Tin-plated Annealed Copper

Wire

TA-0.65

TA-0.65

TA-0.65

2

10

23

- 10 -

Page 51

TLHV Printed Circuit Board Rev. 3

(4YA4130-1024G1-2/2-1/4)

REF.

NO.

1

2

3

4

5

6

7

8

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

D60,D61,D68,D69

D63, D67, D72, D74

D51, D55-59, D62,

D71, D81,D84

D52,D85

D65,D66

D87

D76

D82

1S953/1S2075K/1S2473

Rectifyingl Diode

DHM3FJ60/ESJA58-06

Rectifying Diode

EU02A

Rectifying Diode

1ZB300-Y/Z

Zener Diode

1ZB390

Zener Diode

RD200E-B

Zener Diode

RD22E-B2

Zener Diode

RD27E-B1

Zener Diode

611A0003L0001

610A0003M0002

610A0226M0016

613A2003M0001

613A2258M0350

613A1231L0522

613A1231L0262B

613A1231L0282A

4

4

10

2

2

1

1

1

9

10

D83

11

R234

12

13

R47,R48

14

R102,R116,R121

15

R103,R123

16

R118

R122,R124,R229

17

ERZV05D471

Zener Diode

RD1/4Y33ΩJ

RD Resistor

RD1/4Y130ΩJ

RD Resistor

RD1/4Y330ΩJ

RD Resistor

RD1/4Y1KΩJ

RD Resistor

RD1/4Y4.7KΩJ

RD Resistor

RD1/4Y5.1KΩJ

RD Resistor

6320229M0001

321A1421J0330

321A1421J0131

321A1421J0331

321A1421J0102

321A1421J0472

321A1421J0512

1

1

2

3

2

1

3

18

R105

RD1/4Y24KΩJ

RD Resistor

- 11 -

321A1421J0243

1

Page 52

TLHV Printed Circuit Board Rev. 3

(4YA4130-1024G1-2/2-2/4)

REF.

NO.

19

20

21

22

23

24

25

26

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

R104

R113

R228,R233

R100

R115

R111,R112,R231

R114,R119

RD1/4Y75KΩJ

RD Resistor

RD1/4Y100KΩJ

RD Resistor

RD1/4Y1MΩJ

RD Resistor

RD1/4Y3MΩJ

RD Resistor

RNL1/4C3F576KΩF

RN Resistor

HMP1/4-106J

RN Resistor

HV-38-100MK

RK Resistor

321A1421J0753

321A1421J0104

321A1421J0105

321A1421J0305

323A1222F5763

323A1029J0106

326A3021K0107

1

1

2

1

1

3

2

27

C105,C107,C119

28

C113,C114,C117

29

C112

30

C240,C241

31

C101,C102,C106

32

C103,C104,C108,C110,

C111,C115,C237,C251,

C300,C301,C310,C311

33

C116

34

C118

35

C302

CCHNY5P4B471KTB 1KV

CK Capacitor 470pF

DE0707B471K3K 3.15KV

CK Capacitor 470pF

DE1010B471K6K 6KV

CK Capacitor 470pF

CCTLSL4B390JTB 500V

CC Capacitor 39pF

CCHLY5P4B471KTB 500V

CK Capacitor 470pF

FK16Y5V1H104Z

CK Capacitor

FK16Y5V1H473Z

CK Capacitor

MY2A103J-T

CQ Capacitor 0.010µF

CQMF92PP2A472J-FO

CQ Capacitor 0.0047µF

302A4058K7471A

302A4028K2471

302A4028K4471

302A1017K6390

302A4057K6471

303A4019Z3104

303A4019Z3473

3062001J2103

306A4103J2472

3

3

1

2

3

12

1

1

1

- 12 -

Page 53

TLHV Printed Circuit Board Rev. 3

(4YA430-1024G1-2/2-3/4)

REF.

NO.

36

37

38

39

40

41

42

43

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

C236

Q11,Q13

Q12

Q21-Q23

Q15-Q17

Q10

UVX1J100MTO511(5.0) 63V

CE Capacitor 10µF

BCR1AM-12/MAC97-008

Bi-Directional Thyristor

CR04AM-12

Gate Thyristor

2SC1740S

Transistor

2SD2451

Trsnsistor

2SC2752

Transistor

3041001J1100

622A0003M0001

620A0022M0008

602A1035M0002

603A1135M0010

602A1223M0039

1

2

1

3

3

1

44

45

46

47

48

49

50

51

52

L10

T2,T3,T4

PS1-PS4

CVSW

C-14576

P Coil

High Voltage Transformer

RPI-574/#9568

Photocoupler

SM-05S-04A-9

Microswitch

350A2511P0102

4YB4049-7078P003

652A0103M0002

207A2020P0001

1

3

4

1

53

- 13 -

Page 54

TLHV Printed Circuit Board Rev. 3

(4YA4130-1024G1-2/2-4/4)

REF.

NO.

54

55

56

57

58

59

60

61

SYMBOL TYPE/NAME PART NO. Q'TY REMARKS

LED

CN1

CN2

J1,J2

J3-J12

SEL3910D-YZ

LED

23FE-BT-VK-N

Printed-Circuit Board Connector

53254-0210

Printed-Circuit Board Connector

0.6

Short Wire

0.6

Short Wire

650A0229M0018

224A4134P0230

224A4407P0020

TA-0.6

TA-0.6

1

1

1

2

10

62

63

64

J21-J43

0.6

Short Wire

TA-0.6

23

- 14 -

Page 55

10-97 Printed in Japan

Loading...

Loading...