Page 1

OK Industries

Division of Jonard Industries Corp.

PTX Series

Ergonomic Wire Wrapping Tools - User’s Guide

Outils de connexion enroulée ergonomiques - Mode d'emploi

Ergonomische Wire-Wrap Geräte - Bedienanleitung

Attrezzi ergonomici per Wire Wrapping - Guida per l’utilizzatore

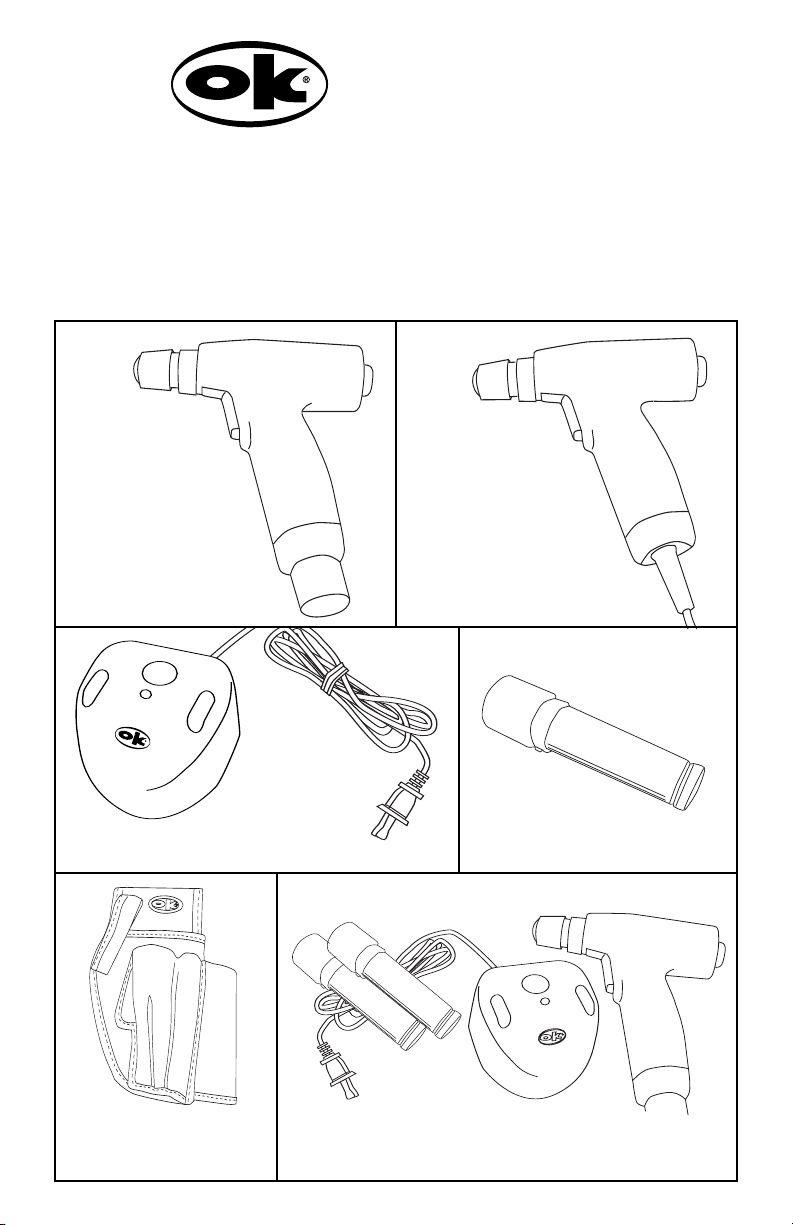

BBaatttteerryy PPoowweerreedd TTooooll

(Model # PTX —

note: battery sold

separately)

BBaatttteerryy CChhaarrggeerr

(Models # PTX-BC1

PTX-BC2 or PTX-BC2-UK)

HHoollsstteerr

(Model # H-1000)

EElleeccttrriicc PPoowweerreedd TToooollss

(Models # PTX-1, PTX-2,

PTX-1BF, PTX-2BF, PTX-2-UK, PTX2BF-UK, PTX-48, PTX-48BF)

LLoonngg--LLiiffee BBaatttteerryy

(Model # PTX-B)

BBaatttteerryy PPoowweerreedd TTooooll KKiittss

(Models # PTX-KIT1, PTX-KIT2, PTX-KIT2I or PTX-KIT2-UK include: PTX tool,

PTX-BC1, PTX-BC2 or PTX-BC2-UK charger, and two PTX-B batteries)

P/N 21553 REV D

Page 2

TABLE OF CONTENTS

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Product Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warranty, Repair & Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wire Wrapping Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

OOvveerrvviieeww:: PPTTXX SSeerriieess TToooollss ffrroomm OOKK IInndduussttrriieess

OK Industries, the worldwide leader in wire wrapping products, offers a

complete range of manual, electric and battery powered tools, bits & sleeves

and other accessories. For more information, please visit our web site at

www.okindustries.com.

The PTX Series wire wrapping and unwrapping tools have been developed to

address ergonomic requirements and boost operator efficiency. With worker

safety in mind, we consulted a certified ergonomist and added features

including the lightweight, well-balanced construction, a dual-finger short-throw

trigger, and a long handle to mitigate pressure on the palm. These features

result in an industry-leading design from a comfort and safety standpoint. The

recessed wrap/unwrap switch is easy to access at the rear face of

the housing, and is protected from impact if the tool

is dropped. The rugged housing encases

a high-torque planetary gear drive

that can wrap or unwrap 18 to 30

AWG (1.0 to .25mm) wire, and

is compatible with the full range

of industry standard bits and

sleeves. The PTX Series is

available in 115 volt and 230V volt

electric versions, as well as a

battery version that is

powered by a long-life 3.6V

NiMH cell and incorporates

an LED indicator for low

y voltage. Backfor

batter

ce is

an available option, to help

prevent overwrapping caused by

excessive for

ce applied by the

operator; batteries and battery

chargers are sold individually.

2

Page 3

Product Selection

Item Description

PTX Battery Powered Wrap/Unwrap Tool

PTX-1 115V Electric Wrap/Unwrap Tool

PTX-1BF 115V Electric Wrap/Unwrap Tool with Backforce

PTX-2 230V Electric Wrap/Unwrap Tool

PTX-2BF 230V Electric Wrap/Unwrap Tool with Backforce

PTX-B Battery for PTX Battery Powered Tool

PTX-BC1 115V Charger for PTX Batteries

PTX-BC2 230V Charger for PTX Batteries

PTX-KIT1 115V kit including: PTX Battery Tool, PTX-BC1 Charger, and two

PTX-KIT2 230V kit including: PTX Battery Tool, PTX-BC2 Charger, and two

H-1000 Holster (cordura pouch which holds a PTX or a manual squeeze tool;

PTX-48 48V Electric Wrap/Unwrap Tool

PTX-48BF 48V Electric Wrap/Unwrap Tool with Backforce

PTX-2-UK 230V Electric Wrap/Unwrap Tool with UK Plug

PTX-2BF-UK 230V Electric Wrap/Unwrap Tool with Backforce and UK Plug)

PTX-KIT2I

PTX-KIT2-UK 230V kit including: PTX Battery Tool, PTX-BC2-UK Charger, and

manual wrap/unwrap tool; bit/sleeve; and 2-3 other misc. tools)

230V kit including:PTX Battery Tool, PTX-BC2 Charger, and one

PTX-B battery)

two (2) PTX-B batteries)

(2) PTX-B Batteries

(2) PTX-B Batteries

The product range includes both battery and electric powered tools, as well as

proprietary batteries and a battery charger. Tool selection is generally determined by

user preference, and includes considerations such as availability of electrical power

outlets and the convenience of cordless operation. The battery powered version (model

# PTX) employs one battery (model # PTX-B) which requires a charger (PTX-BC1, PTXBC2 or PTX-BC2-UK); these are sold separately, but can also be purchased with the tool

in a kit (see models and descriptions above).

All of the tools in the PTX Series have reversible motors, allowing the user

to use the tools to unwrap a wire wrapped termination. (NOTE: unwrapping requires a

separate bit and sleeve or a dedicated manual unwrapping tool; DO NOT attempt to unwrap

with a bit and sleeve that is used for wrapping, this will damage the bit and sleeve and is

detrimental to the reliability of the connection). The Backforce option, available only in the PTX48BF (48V), PTX-1BF (115V) and the PTX-2BF and PTX-2BF-UK (230V) electric power

is a feature that helps to prevent overwrapping. A spring that is mounted internally in the

collet/shaft assembly of the tool helps to absorb pressure that an untrained operator may apply

while wrapping (see page 12 for an illustration of an over

3

wrapped termination).

ed tools,

Page 4

OOppeerraattiioonn

AA)) PPrreeppaarriinngg TThhee WWrraapp//UUnnwwrraapp TTooooll

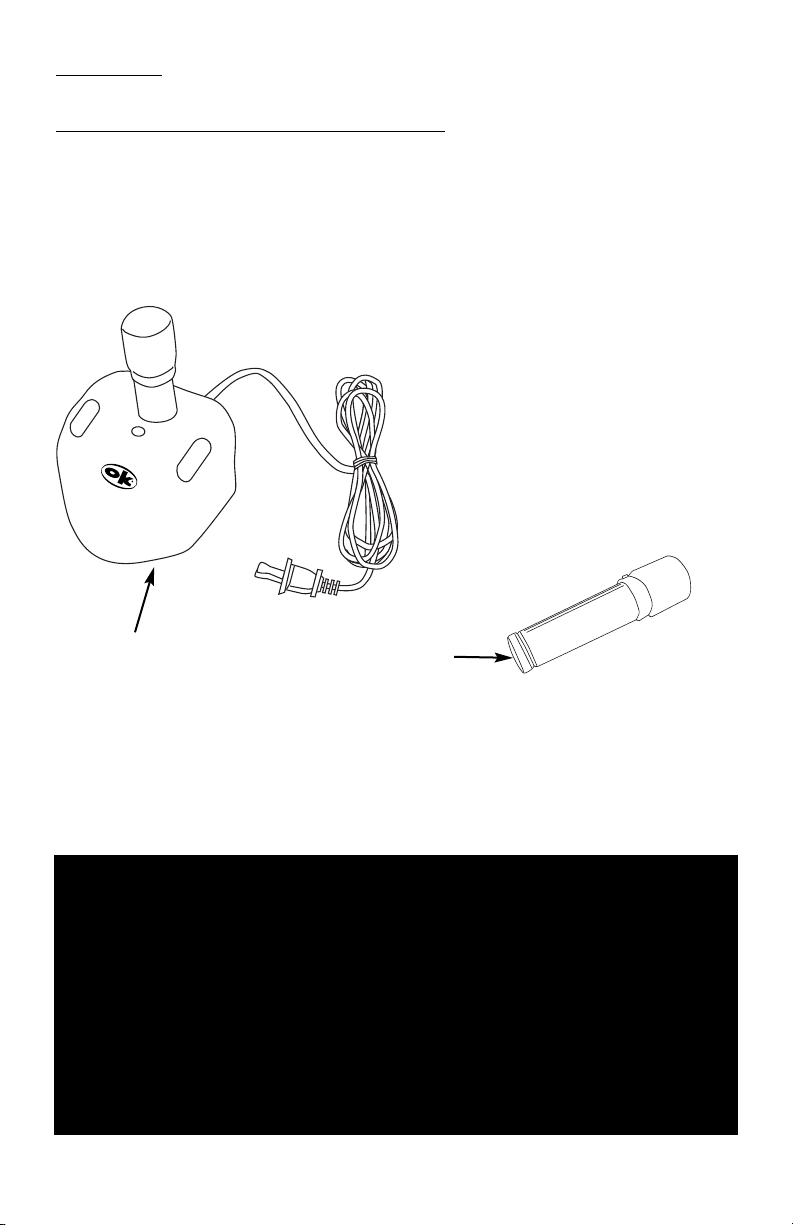

The PTX Series power tools require no assembly and are ready for use out of the

box. The battery powered version (model # PTX) requires an initial charge of the

battery of at least 8 hours. The LED will illuminate to indicate that the battery is

present in the charger. The LED remains lit as long as the battery is present, even

after full charging, but there is no danger in leaving the battery in the charger

for longer than eight hours. Simply plug the charger (115V

model # PTX-BC1 or 230V model # PTX-BC2 or PTX-BC2-UK)

into a power outlet and place the

battery (model # PTX-B) in the charger.

After approximately 500-750 uses,

the battery should be disposed of

and replaced.

Charger

(shown with Battery)

TTeerrmmiinnaallss

ooff BBaatttteerryy

When the battery is not mounted in the tool or charger, it is important to ensure

that the terminals are not shorted by any metal or other conductive object. The

battery could otherwise short circuit, potentially causing fire, burns or battery

damage. The PTX-B is an environmentally friendly NiMH battery which can be

disposed of along with normal refuse.

CAUTION!

Do not attempt to use any other manufacturer’s battery with the PTX, as it will not

perform properly and can damage the tool. Always use model # PTX-B batteries,

employing the model # PTX-BC1, PTX-BC2 or PTX-BC2-UK battery charger, both

manufactured by OK Industries.

Do not use the battery charger with a damaged cord or plug, or in wet or damp or

any outdoor environments, or in the vicinity of sinks or basins or other water

sources. Do not disassemble charger, there are no consumer serviceable parts

inside.

4

Page 5

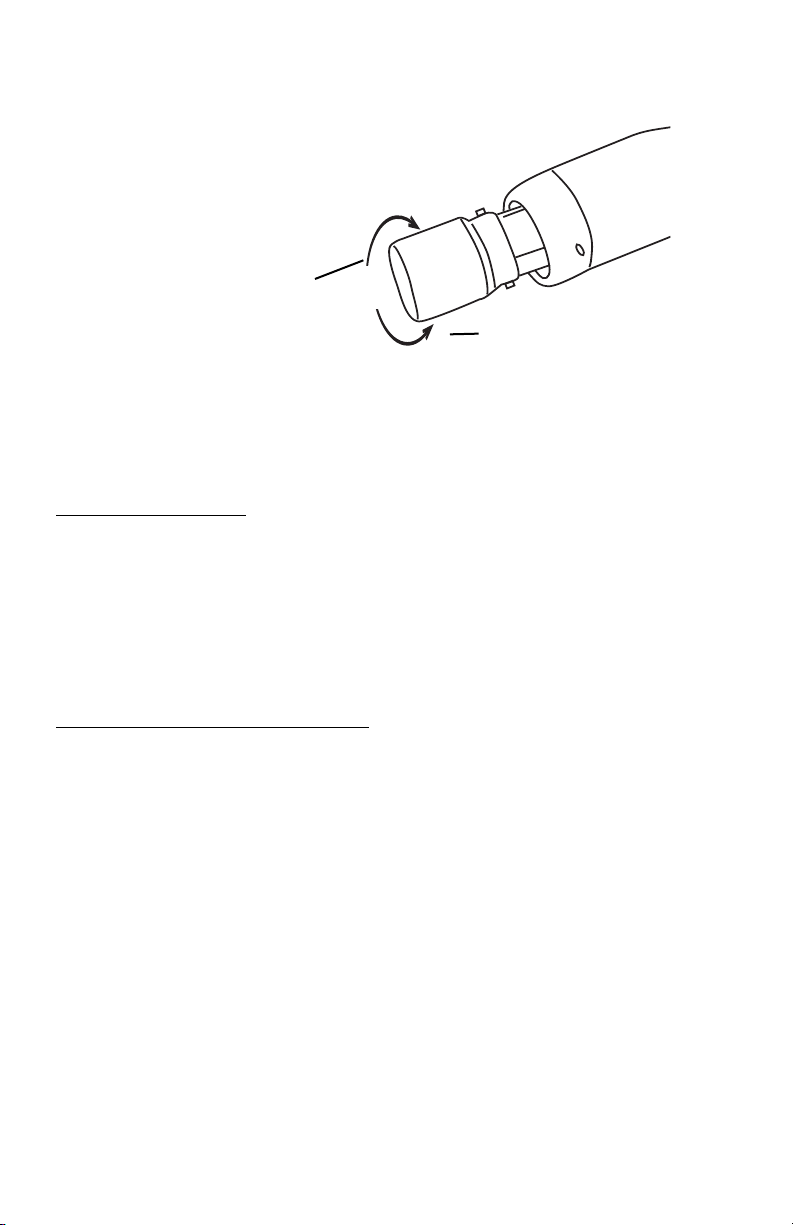

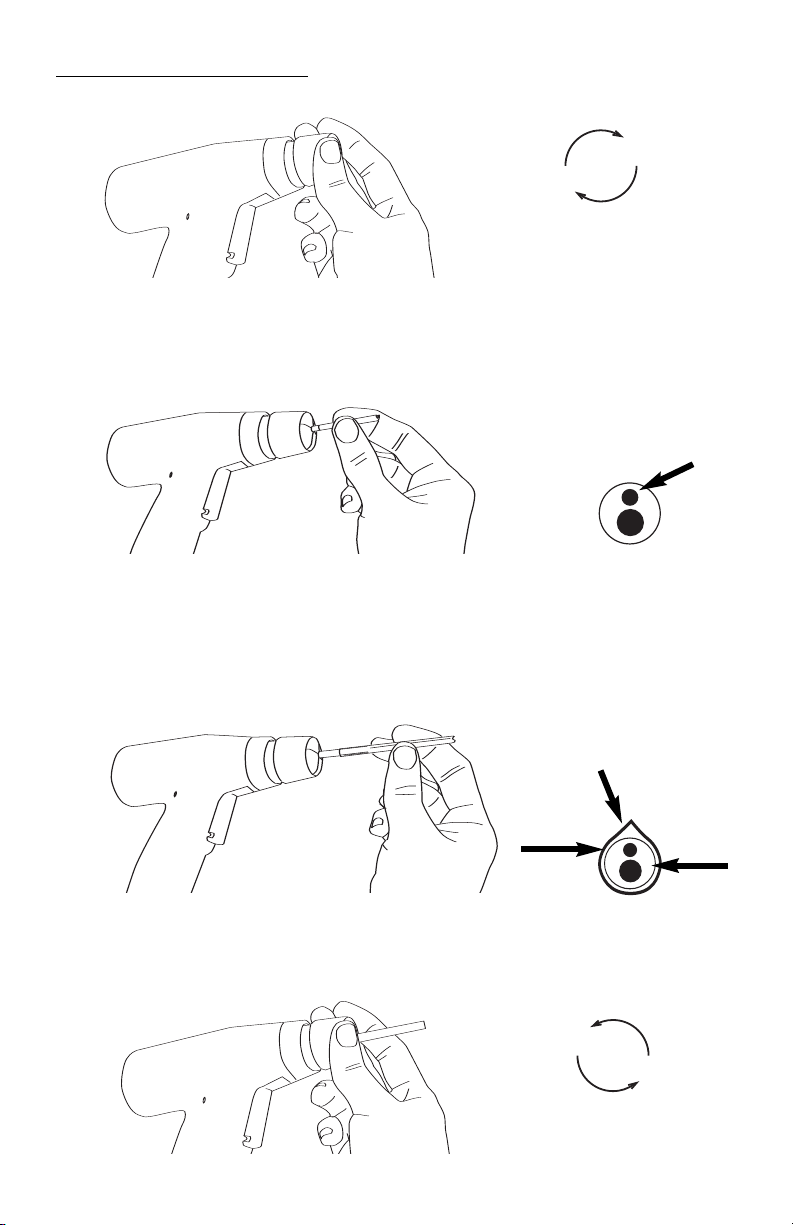

When the battery is charged, remove it from the charger, insert it into the

handle of the PTX tool and rotate the end cap of the battery 90 degrees in the

counterclockwise direction to engage the cap (see below);

then pull back slightly to lock it into the handle of the

tool. To remove battery from tool, press inward

on battery end cap, rotate battery

Tool Handle

90 degrees clockwise and pull out.

Battery

Rotate Counter-clockwise to

engage battery

End Cap

Rotate Clockwise to Remove

Battery

When the battery begins to lose its charge (at about 3.3V), the red LED indicator

located on the top surface of the tool will begin to glow. At this point,

depending on the application, the battery should still contain enough charge for

several hundred additional wrapping or unwrapping operations.

BB)) WWiirree WWrraappppiinngg

Wire wrapping technology, when properly used, provides an interconnection

that is superior in reliability than one made using alternative methods, yet is

easily removed if necessary. It is a process by which a bare end of a wire is

wrapped in a tight helix around a metal terminal. This requires the use of a

proper bit and sleeve in conjunction with the power tool. The selection of the

bit and sleeve should follow the process outlined below:

BIT & SLEEVE SELECTION PROCESS:

1. Determine wire gauge: 18 to 30 AWG

2. Determine terminal post dimensions:

a) Telecom: usually .045” X .045” or .030” X .060”

b) Other: usually .025” X .025”

3. Decide on regular vs. modified wrap:

a) Telecom: usually regular wrap, 22-26 AWG wire

b) Electronics: usually modified wrap, 26-30 AWG wire

4. Once bit is identified, sleeve is listed alongside bit part number in

the Bit & Sleeve Chart (see page 9 -10)

Additional infor

mation r

egar

ding r

egular vs. modified wraps, and

other technical aspects relating to the wrapping process and the resulting

interconnection, can be found in the Section below entitled “Wire

Wrapping Technology.”

5

Page 6

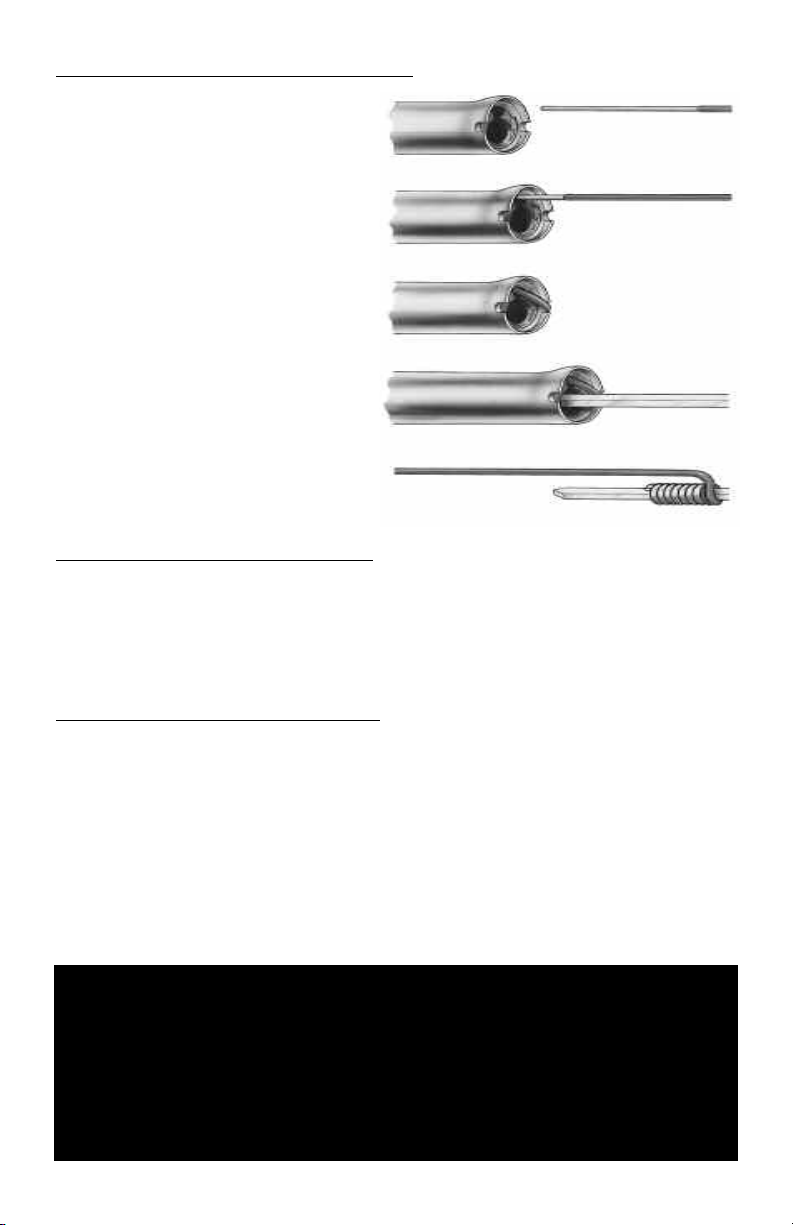

BIT & SLEEVE INSTALLATION:

1. Loosen collet nut by rotating it in the clockwise direction (see below).

Loosen Collet Nut

in Clockwise Direction

2. Insert the bit into the chuck, and rotate the bit while pushing it into

the chuck, until the bit is seated in the drive mechanism. At this point,

the smaller of the two holes in the face of the bit will be at the

twelve o’clock position.

Small hole in bit face in twelve

o’clock position

3. Place the sleeve over the bit and slide the sleeve into the collet. Rotate the

sleeve as you are sliding it into the chuck until the sleeve has engaged with

the locating pin (internal to the collet); the sleeve will then slide further in

and, when fully seated, will be such that the spouted portion of the sleeve

end is in the twelve o’clock position.

Spouted portion of sleeve in

twelve o’clock position

Sleeve

Bit

4. Tighten the collet by rotating the collet nut in the counterclockwise

direction. The tool is now ready for use. To make a wire wrapped

connection, follow the instructions and helpful hints on the pages ahead.

Tighten Collet Nut in Counterclockwise

6

Direction

Page 7

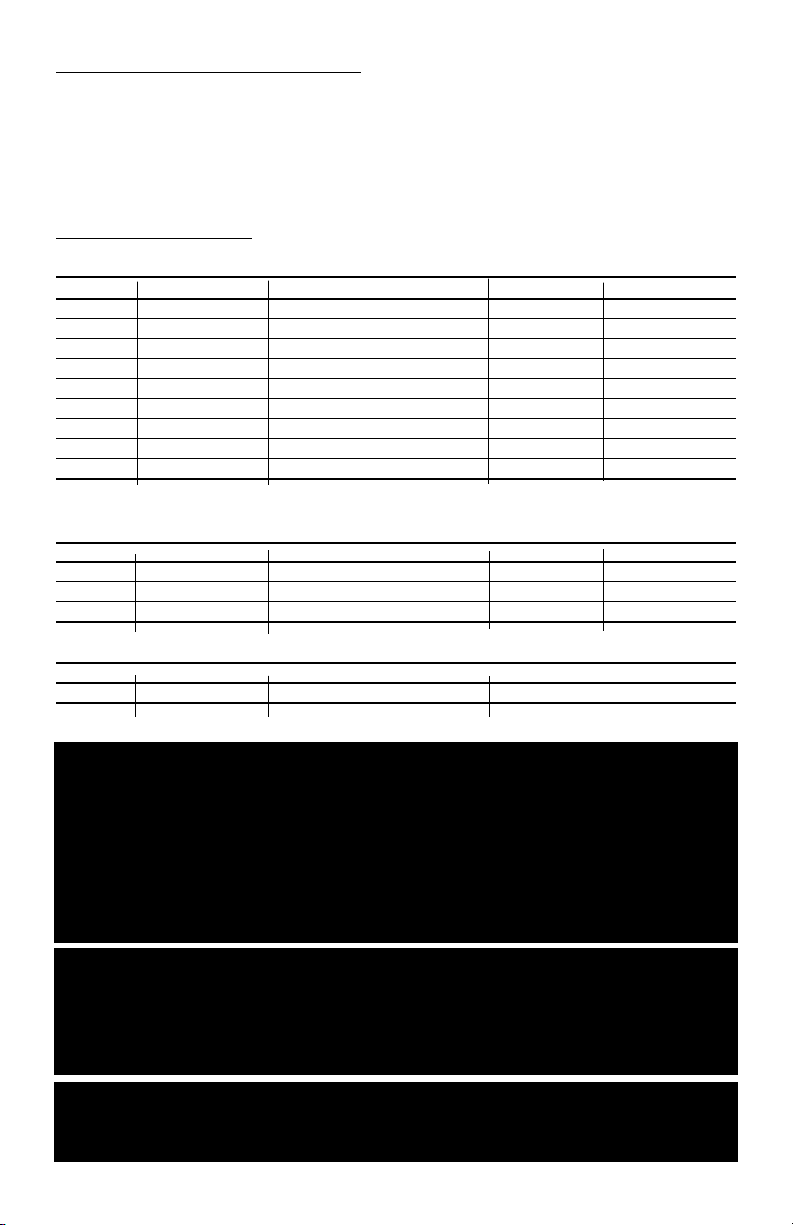

MAKING A WIRE WRAP CONNECTION:

Step 1

Select the Proper Bit and

Sleeve (see above).

Step 1

Bit, Sleeve and

Pre-Stripped Wire

Step 2

Insert the wire into the

Wire Slot.

Step 2

Wire Insertion

Step 3

Anchor the Wire.

Step 3

Wire Anchoring

Step 4

Insert terminal into

large center hole of bit.

Step 5

Step 4

Terminal Insertion

Actuate the wrapping tool.

The connection is completed.

Step 5

Finished Connection

CC)) UUnnwwrraappppiinngg aanndd BBaacckkffoorrccee

Unwrapping and backforce are special features for wire wrapping, and are

available with the PTX Series. All models of the tool, whether battery or electric

powered, have the unwrapping feature built in; the backforce feature is optional,

and is found in models PTX-1BF, PTX-2BF, PTX-2BF-UK and PTX-48BF.

USING THE UNWRAPPING FEA

TURE:

Install unwrapping bit/sleeve in the collet. Flip the switch on the rear face of the

tool into the down position, which reverses the motor direction to change from

‘wrap’ to ‘unwrap.’ Place the unwrapping bit/sleeve over the terminal so that

the hook-shaped portion of the unwrapping bit is positioned to engage the top

end of the wire coil that is to be unwrapped. Squeeze the trigger of the tool

and hold it stationary, allowing the bit to do the work of unraveling the wire coil.

Be sure to remove all of the unwrapped wire from the bit and the work area prior

to proceeding to additional unwrap operations.

CAUTION!

Unwrapping requires a special bit and sleeve or a dedicated manual

unwrapping tool; DO NOT attempt to unwrap with a bit and sleeve that is used

for wrapping only, this will damage the bit and sleeve and is detrimental to the

reliability of the connection.

7

Page 8

USING THE BACKFORCE FEATURE:

‘Backforce’ is a feature that compensates for the unnecessary application of downward

pressure on the tool during wire wrapping. A wire wrapping tool will perform the

wrapping function properly without any downward pressure applied, in fact, such

pressure results in a tendency to ‘overwrap’ (refer to Section entitled Wire Wrapping

Technology for further details). A tool with the backforce option contains a spring

mechanism to absorb downward pressure that an unskilled operator might apply.

Product Specifications:

PPoowweerr TToooollss**

Item Voltage Size Weight RPM

PTX 3.6V battery powered 1.5" W X 6" H X 6.5" L 0.74 lb. 3700

PTX-1 115V electric 1.5" W X 6" H X 6.5" L 0.86 lb. 3700

PTX-1BF 115V electric 1.5" W X 6" H X 6.5" L 0.86 lb. 3700

PTX-2 230V electric 1.5" W X 6" H X 6.5" L 1.0 lb. 4200

PTX-2BF 230V electric 1.5" W X 6" H X 6.5" L 1.0 lb. 4200

PTX-2-UK 230V electric 1.5" W X 6" H X 6.5" L 1.0 lb. 4200

PTX-2BF-UK 230V electric 1.5" W X 6" H X 6.5" L 1.0 lb. 4200

PTX-48 48V electric 1.5" W X 6" H X 6.5" L 0.86 lb. 3700

PTX-48BF 48V electric 1.5" W X 6" H X 6.5" L 0.86 lb. 3700

*Typical operating cycle is 2 seconds on and 18 seconds off (varies with application).

BBaatttteerryy CChhaarrggeerrss

Item Voltage Size Weight Cord

PTX-BC1 115V electric 4.0" round X 2.7" high 0.7 lb. 6.0” long

PTX-BC2 230V electric 4.0" round X 2.7" high 0.7 lb. 6.0” long

PTX-BC2-UK 230V electric 4.0" round X 2.7" high 0.7 lb. 6.0” long

BBaatttteerryy

Item Voltage Size Weight

PTX-B 3.6V 1" diameter X 4.5" L 0.36 lb.

CAUTION! — ALL PTX TOOLS

This equipment is for indoor industrial/laboratory use only at altitudes up to 2000 m, maximum RH of 80% up to 31°C

decreasing to 50% RH at 40°C. Pollution degree 2 in accordance with IEC644. Installation category II. Temperature range:

5°C to 40°C. The user must be aware that, if the equipment is used in any manner not specified by the manufacturer, safety

may be impaired. When using electric tools, basic safety precautions should be used to reduce the risk of fire, electric shock

and personal injury. Keep work areas clean, well lit, off limits to children and visitors. Disconnect unused tools and store them.

Never use accessories or attachments unless recommended by the original manufacturer. If the supply cord is damaged, or

servicing is required, this work must be carried out by the manufacturer or its service agent or a similarly qualified person in

order to avoid a hazard.

230V Tools (PTX-2 & PTX-2BF)

If required, replace the fuse in the main unit with the correct type: T250mA. If a fused mains plug is to be used, ensure

the fuse is of the high breaking capacity type and has a value of no more than: 1A 250V. Any mains plug that requires

emoval or r

r

plug with bar

eplacement must be destr

es is hazardous if engaged in a live socket.

ed wir

emoval of any fuse and fuse car

oyed by r

rier and disposed of immediately, as a

48V PTX Tools

The 48V tools include cor

ce.

sour

ds without plugs, and must never be connected to anything but a 48V A/C or D/C power

8

Page 9

Bits and Sleeves Chart (AWG) Inches

R

EGULAR INSULATION TERMINAL TERMINAL HOLE EFFECTIVE HOLE

W

IRE MODIFIED BIT SLEEVE DIAMETER DIAGONAL DIAGONAL DEPTH RADIUS DIAMETER

GAUGE PART NO. PART NO. INCHES INCHES INCHES INCHES INCHES INCHES

18 • KB18 P194 — 0.06 0.073 1 0.15 0.075

20

20-22

22 • WB22MLD P212 0.58 0.049 0.073 1 0.136 0.075

22 • KB22LT P2224 — 0.061 0.085 1 0.125 0.086

22 • KB22 P2224 — 0.054 0.073 0.75 0.117 0.075

22 • WB2275M P2224 0.052 0.049 0.074 1 0.132 0.075

22-24 • KB224LH P2224 — 0.061 0.085 1 0.117 0.086

22-24 • KB224-1 P2224 — 0.054 0.073 1 0.111 0.075

22--24 • KB224 P2224 — 0.054 0.073 0.807 0.111 0.075

22-24 • WB224M P2224 0.05 0.049 0.074 1.25 0.121 0.075

24 • *KB2444 P3032LN — 0.024 0.043 1 0.083 0.044

24 • WB24DH P2224 0.046 0.054 0.073 1.75 0.117 0.075

24 • KB24 P2426 — 0.055 0.074 0.75 0.1 0.075

24 • *WB24SM P3032LN 0.044 0.024 0.043 0.75 0.098 0.044

24 • WB24DHM P2224 0.05 0.049 0.068 1.12 0.118 0.069

24-26 • WB2426M P2224 0.046 0.054 0.073 0.75 0.118 0.075

24-26

26 • *KB2639 P26LN — 0.023 0.038 0.75 0.068 0.04

26 • KB26 P2426 — 0.058 0.073 1 0.1 0.075

26

26 • WB26M P2224 0.046 0.054 0.073 1 0.118 0.075

26 • *WB2644MP3032LN 0.046 0.024 0.043 0.75 0.098 0.044

26 • WB2669M P2426 0.041 0.053 0.068 1 0.109 0.069

28 • WB2870M P2426 0.034 0.053 0.068 1 0.103 0.07

28-29 • *WB2829M P3032L 0.036 0.033 0.038 0.75 0.091 0.04

30

30

30-32 • *WB3032M P3032 0.027 0.034 0.038 0.75 0.064 0.04

* These tools are recommended for .025” square terminals on .100” centers.

• WB20M P194LN 0.059 0.042 0.073 1 0.15 0.075

• KB2075 P2224 — 0.042 0.073 1 0.123 0.075

• KB2466 OK8519 — 0.054 0.065 1 0.098 0.066

• *WB26SM P26LN 0.031 0.023 0.038 0.75 0.075 0.04

• *SB30MSH-B P3032 0.027 0.031 0.035 0.75 0.064 0.036

• *SB30MMK P3032 0.023 0.031 0.035 0.75 0.064 0.036

MAXIMUM MINIMUM MAXIMUM TERMINAL TERMINAL

Extended Length (5“) Bits and Sleeves Chart

REGULAR

WIRE

SIZE

AWG mm. PART NO. PART NO. In. In. In. In. In. In.

22 0.65

0.50

24

26 0.40

•

•

•

MODIFIED

BIT SLEEVE DIAGONAL DIAGONAL DIAGONAL DEPTH RADIUS DIAMETER

KB22-5 P2224-5 — 0.54 .073 .750 .117 .075

KB24-5

KB26-5 P2426-5 — 0.58 .073 .750 .100 .075

P2426-5

MAXIMUM MINIMUM MAXIMUM TERMINAL TERMINAL

INSULATION TERMINAL TERMINAL HOLE EFFECTIVE HOLE

— 0.55 .073 .750 .100 .075

Insulated Sleeves (1000V dielectric coating)

WIRE SIZE PART NO.

22-24 AWG P2224-INS (or P2224-5INS for 5” version)

24-26 AWG P2426-INS (or P2426-5INS for 5” version)

9

Page 10

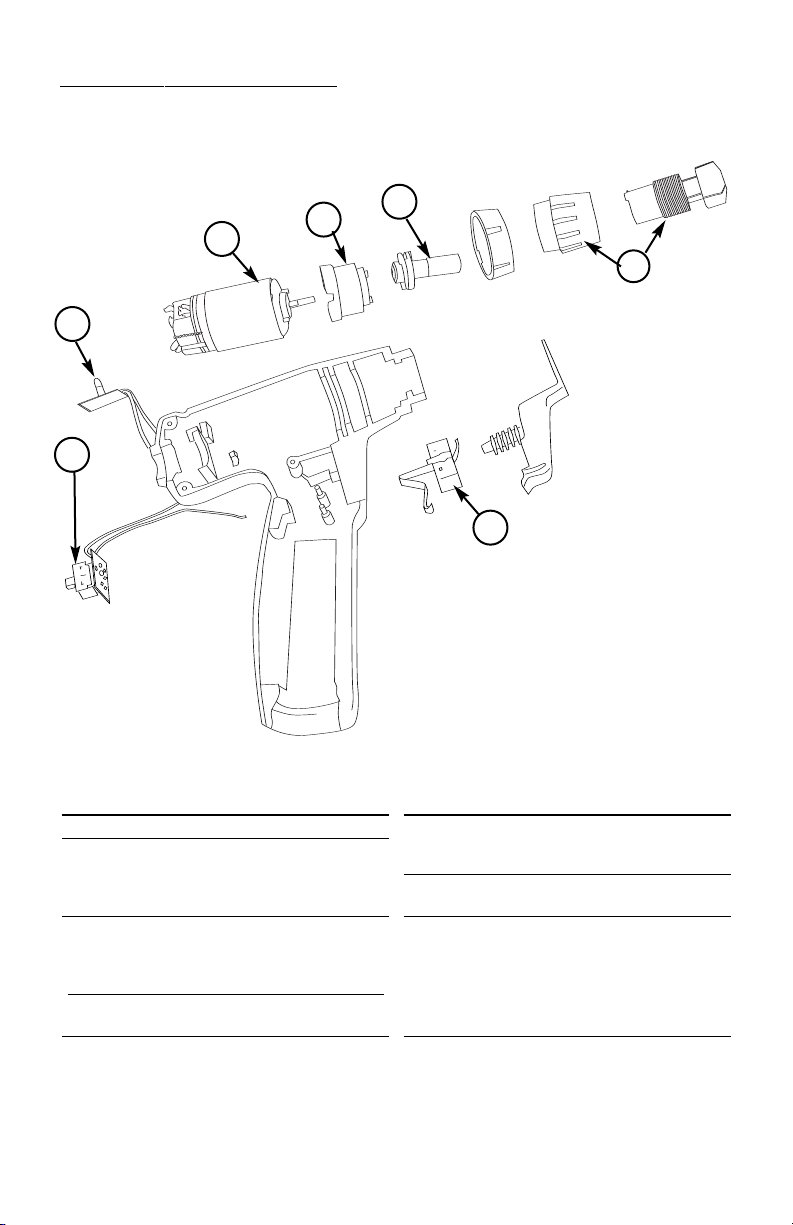

Spare Parts for PTX Series

5

4

2

7

1

3

6

ITEM PART DESCRIPTION

1 21362 Low-battery PCB assembly, PTX

2 21328 Motor, PTX battery tool

16746 Motor, PTX-1 or PTX-1BF

16772 Motor, PTX-2 or PTX-2BF

16771 Motor, PTX-48 or PTX-48BF

3 21363 Wrap-Unwrap switch assembly,

PTX battery tool

21403 Wrap-Unwrap switch assembly,

PTX electric tools

4 21676 Clutch assembly, PTX tools w/backforce

21677 Clutch assembly, PTX tools w/out backforce

5 16765 Gear box assembly, PTX-1, PTX-1BF,

PTX-48 or PTX-48BF

ITEM PART DESCRIPTION

6 21406 Trigger switch assembly, PTX battery

tool

20419 Trigger switch, electric wrap tools

7 21407 Collet assembly (Collet, collet nut

and set screw)

8 16762 Power PCB assembly, PTX-1 or

PTX-1BF (not shown)

18416 Power PCB assembly, PTX-2 or

PTX-2BF (not shown)

18217 Power PCB assembly, PTX-48 or

PTX-48BF (not shown)

9 12446 Power cord, PTX-1 or PTX-1BF

(not shown)

21402 Power cord, PTX-2 or PTX-2BF

(not shown)

21475 Power cord, PTX-2BF-UK or PTX-2BF-UK

(not shown)

10

Page 11

Warranty, Repair and Technical Support

Each PTX power wrapping and unwrapping tool, as well as the battery chargers, are covered with

a six-month warranty from date of purchase.

Repair service and technical support are available from OK Industries, Tuckahoe, NY 10707, phone:

914-793-0700, fax: 914-793-4527. Service and repair may be obtained from one of our many

worldwide facilities, and technical support can be provided by our representatives and distributors.

Please visit our web site at www.okindustries.com to contact a representative in your region.

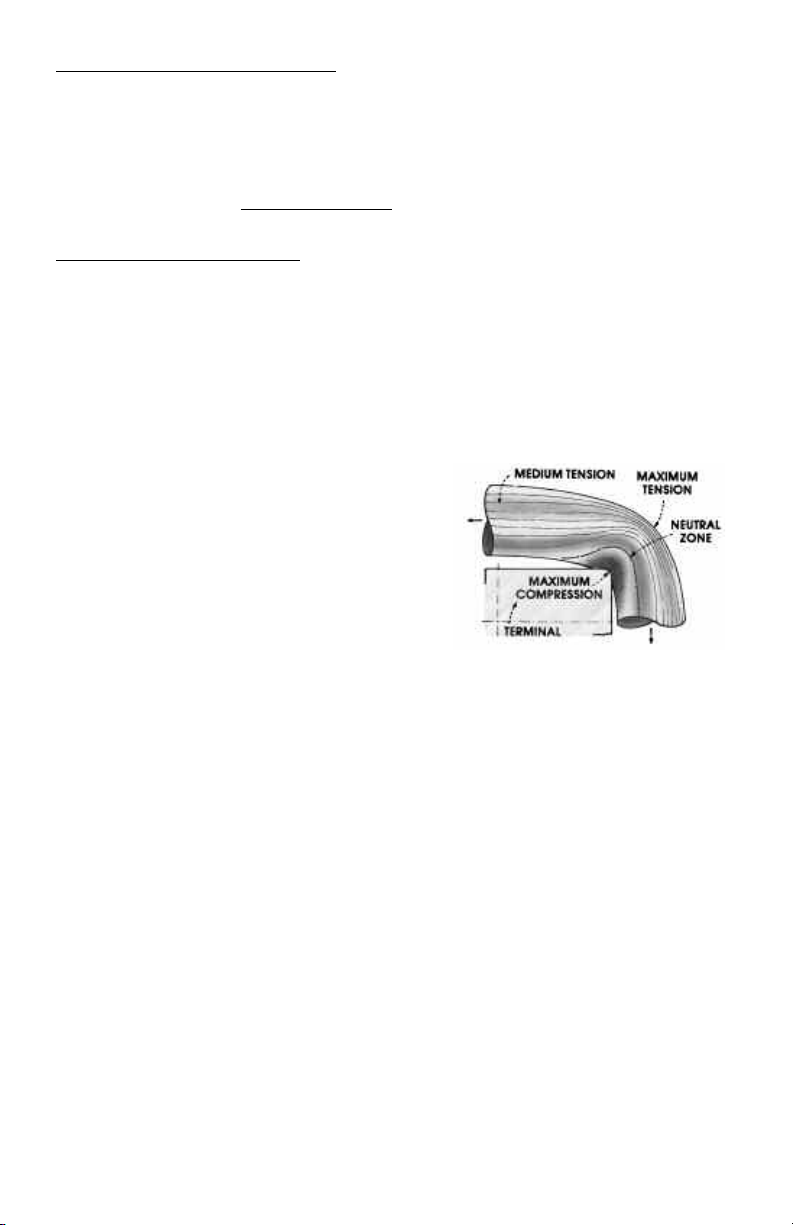

ire Wrapping Technology

W

Wire wrapping is a method of making a wire connection by coiling the bare wire around the sharp

corners of a terminal under mechanical tension. The technology was developed as an alternative to

soldering, which presents various safety and reliability problems in many applications. A principal

advantage of wire wrapping is that it provides a high-reliability connection that is also easily

removed to correct or modify a wiring layout.

Wire wrapping requires a rotating tool, called a bit. The bit has a large central hole in the face for

slipping the tool over the terminal, and it marks the point around which the bit rotates. The top of

the bit has a slot which accepts the wire to be wrapped. The front or face of the bit is shaped to

apply the proper tension to the wire during the wrap. This

contour also guides the wire into a helix that is tightly

spaced and uniform. During use, the bit is housed in a

metal tube called a sleeve. The sleeve retains the bit in the

collet of a wire-wrapping tool, which drives the bit as it

spins. It also keeps the wire in the slot during the wrapping

process and protects the worker from the rotating bit.

Wire wrapping subjects the wire to tremendous tension

and compression forces, typically 100,000 PSI at the

terminal’s edge. The wrapping action causes the oxide layer on both wire and terminal to be

crushed or sheared, resulting in a clean, oxide-free metal-to-metal contact. The number of turns is a

function of the length of uninsulated wire. Pre-stripped wire saves time and improves reliability, since

there is a specified minimum number of’ turns required for each particular wire size. These relate

directly to electrical conductivity and mechanical strength. However, if a manufacturing specification

requires a wrap with more turns, wire with correspondingly longer lengths of bare wire or further

hand stripping may be required.

There are two types of wire-wrapped connections: regular and modified. In a “regular” connection,

only bare (uninsulated) wire is wrapped around the terminal. A “modified” wrap, which requires a

modified bit, coils about 1.5 turns of insulated wire around the terminal in addition to the bare wire.

This method greatly improves a connection’s mechanical stability, such as resistance to vibration, in

cases where the wire diameter is small and its mechanical strength is low. The most important

element to consider when choosing either wrap method, then, is the size wire being used. A

standard wrap is generally used for 24 AWG and larger diameter wires; a modified wrap is

sometimes used for 26 AWG and smaller wires, and is used almost exclusively for 28 to 30 AWG

wires.

The four most common wire wrapping mistakes are (a) pressing too hard, which can lead to

wrapping; (b) not pushing the stripped end of the wir

over

emoving the tool befor

ficient tur

insuf

open wraps; and (d) choosing the wrong bit and sleeve, which can cause problems ranging from

pigtails to loose wraps.

ns; (c) r

e completing the wrap, which can r

11

e all the way into the bit, which causes

esult in spiral and

Page 12

TABLE DES MATIERES

Présentation générale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Choix d'un produit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Spécifications d'un produit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pièces détachées . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Garantie, réparations et support technique . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Technologie du Wrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

PPrréésseennttaattiioonn ggéénnéérraallee :: LLeess OOuuttiillss PPTTXX dd''OOKK IInndduussttrriieess

OK Industries, le leader mondial des outils de câblage par fil enroulé (wire wrapping), offre une

gamme complète d'outils manuels, électriques et sur batterie, de douilles et guide-fil et autres

accessoires. Pour plus d'informations, visitez notre site Web: www.okindustries.com.

La série d'outils de câblage et de décâblage à fil enroulé PTX a été développée pour répondre aux

demandes d'ergonomie et augmenter l'efficacité de l'opérateur. Ayant la sécurité du travailleur à

l'esprit, nous avons consulté un ergonomiste certifié et ajouté des caractéristiques comme une

construction légère et bien équilibrée, un déclencheur à faible course à deux doigts et une grande

poignée pour répartir la pression dans la paume. Ces caractéristiques conduisent à une conception

leader de l'industrie du point de vue du confort et de la sécurité. L'interrupteur

d'enroulement/déroulement en retrait est facile à manipuler en face arrière du boîtier et

est protégé contre les impacts si l'outil tombe. Le boîtier robuste

comporte une boîte de vitesse à engrenages

planétaires qui peut enrouler ou dérouler du

fil de diamètre 1,0 mm à 0,25 mm (18 à

30 AWG), et est compatible avec la

gamme complète de douilles et guide-fil

standards de l'industrie. La série PTX est

disponible en versions électriques 115

volts et 230 volts ainsi que sur batterie

longue durée NiMH 3,6 V et intègre un

indicateur DEL de tension de batterie

faible. Une limitation de force est

disponible en option pour éviter un

enroulement excessif causé par une

force excessive appliquée par

l'opérateur. Les batteries et les chargeurs

de batteries sont vendus séparément.

12

Page 13

Choix du produit

Référence Description

PTX Outil Wrap/Unwrap alimenté sur batterie

PTX-1 Outil Wrap/Unwrap 115V

PTX-1BF Outil Wrap/Unwrap 115 V avec limiteur de force

PTX-2 Outil Wrap/Unwrap 230 V

PTX-2BF Outil Wrap/Unwrap 230 V avec limiteur de force

PTX-B Batterie pour outil PTX alimenté sur batterie

PTX-BC1 Chargeur 115 V pour batteries PTX

PTX-BC2 Chargeur 230 V pour batteries PTX

PTX-KIT1 Kit 115 V comprenant : outil PTX alimenté sur batterie, chargeur

PTX-KIT2 Kit 230 V comprenant : outil PTX alimenté sur batterie, chargeur

H-1000 Holster (pochette cuir pour un outil PTX ou un outil de serrage manuel,

PTX-48 Outil Wrap/Unwrap 48 V

PTX-48BF 4Outil Wrap/Unwrap 48 V avec limiteur de force

PTX-KIT2I Kit 230 V comprenant:outil PTX alimenté sur batterie, chargeur PTX-

PTX-BC1 et deux (2) batteries PTX-B

PTX-BC2 et deux (2) batteries PTX-B

outil manuel Wrap/Unwrap, douille et guide-fil et 2 ou 3 autres outils).

BC2 , et une (1) batterie PTX-B)

La gamme de produits comporte des outils alimentés sur batterie et sur secteur, ainsi que

des batteries et un chargeur de batteries spécifiques. Le choix des outils est

généralement déterminé par la préférence de l'utilisateur et prend en compte des

éléments comme la disponibilité de prises de courant et la facilité du fonctionnement sur

batterie. La version alimentée sur batterie (modèle PTX) utilise une batterie (modèle PTXB) et nécessite un chargeur de batterie (PTX-BC1 ou PTX-BC2) qui sont vendus

séparément mais qui peuvent aussi être achetés avec l'outil sous forme de kit (voir

modèles et descriptions plus haut).

Tous les outils de la série PTX ont des moteurs réversibles, permettant à l'utilisateur de

démonter une connexion enroulée. (Note : ce démontage nécessite une douille et un

guide-fil séparés ou un outils manuel spécial de déroulement. NE PAS essayer de

déconnecter avec une douille et un guide-fil qui sont utilisés pour l'enroulement, ceci

pourrait endommager la douille et le guide-fil et compromettre la fiabilité de la

connexion. L'option de limitation de force (Backforce) disponible uniquement sur les

outils sur secteur PTX-1BF (115 V) et PTX-2BF (230 V), est une fonction qui per

t monté à l'intérieur de l'assemblage

d'éviter un enr

bague/axe de l'outil permet d'absorber la pression qu'un opérateur peu entraîné peut

appliquer lors de l'enroulement.

oulement excessif. Un r

essor

13

met

Page 14

FFoonnccttiioonnnneemmeenntt

AA)) PPrrééppaarraattiioonn ddee ll''oouuttiill dd''eennrroouulleemmeenntt//ddéérroouulleemmeenntt

Les outils de la série PTX ne nécessitent aucun assemblage et sont prêts à être

utilisés dès le déballage. La version alimentée sur batterie (modèle PTX) nécessite

une charge initiale de la batterie d'au moins 8 heures. La DEL s'allume pour

indiquer que la batterie est présente dans le chargeur. Elle reste allumée tant que

la batterie est présente, même une fois la charge complète, mais il n'y a aucun

danger à laisser la batterie dans le chargeur plus longtemps que

huit heures. Branchez simplement le chargeur (modèle 115 V

PTX-BC1 ou modèle 230 V PTX-BC2) dans une prise

de courant et placez la batterie dans le

chargeur. Après environ 500 à 750

utilisations, la batterie doit être retirée

et remplacée.

Chargeur

(montré avec une batterie)

TTeerrmmiinnaaiissoonnss

ddee bbaatttteerriiee

Quand la batterie n'est pas montée dans l'outil ou le chargeur, il est important de

s'assurer que ses terminaisons ne sont pas mises en court circuit par un objet

métallique ou conducteur. Un court circuit de la batterie peut provoquer un incendie,

des brûlures ou endommager la batterie. La batterie PTX-B est un modèle NiMH qui

peut être jetée et incinérée sans effet nocif pour l'environnement.

ATTENTION!

N'essayez pas d'utiliser avec le PTX une batterie d'un autre fabricant, parce qu'elle

ne fonctionnerait pas correctement et pourrait endommager l'outil. Toujours utiliser

des batteries modèle PTX-B, avec le chargeur de batterie PTX-BC1 ou PTX-BC2 tous

fabriqués par OK Industries.

Ne pas utiliser la batterie avec un cordon ou une prise endommagés, dans un

environnement humide ou extérieur, ou à proximité de réservoirs ou bassins ou

d'autres sources d'eau. Ne pas démonter le chargeur, il n'y pas de composants

réparables à l'intérieur. .

14

Page 15

Quand la batterie est chargée, la retirer du chargeur, l'insérer dans la poignée de

l'outil PTX et tourner le capuchon à l'extrémité de la batterie de 90 degrés dans le

sens inverse des aiguilles d'une montre pour engager le capuchon (voir ci-dessous),

puis le tirer légèrement en arrière pour le verrouiller dans la

poignée de l'outil. Pour retirer la batterie de l'outil, presser

vers l'intérieur le capuchon à l'extrémité de la batterie,

tourner la batterie de 90 degrés dans le

sens des aiguilles d'une montre

Poignée de l'outil

et la tirer vers l'extérieur.

apuchon

C

e la

Tourner dans le sens inverse des

aiguilles d'une montre pour engager

la batterie.

d

batterie

Tourner dans le sens des aiguilles

d'une montre pour retirer la batterie.

Quand la batterie commence à être déchargée (à environ 3,3 V), l'indicateur

DEL rouge situé sur la face supérieure de l'outil commence à rougir. A ce

point, selon l'application, la batterie contient encore suffisamment d'énergie

pour plusieurs centaines d'enroulements ou de déroulements.

BB)) CCoonnnneexxiioonn àà ffiill eennrroouulléé ((WWiirree WWrraappppiinngg))

La connexion à fil enroulé, lorsqu'elle est utilisée correctement, fournit une

interconnexion dont la fiabilité est supérieure à celle des autres méthodes tout

en étant facile à démonter si nécessaire. C'est un processus par lequel

l'extrémité dénudée d'un fil est enroulée en hélice serrée autour d'une

terminaison métallique. Ceci nécessite l'utilisation d'une broche et d'un mandrin

appropriés en plus de l'outil de bobinage. La choix de l’enrouleur et manchon

doit être effectué selon le processus indiqué ci-dessous :

CHOIX DE L’ENROULEUR ET DU MANCHON :

1. Déterminer la section du fil : 1,0 mm à 0,25 mm (18 à 30 AWG)

2. Déterminer les dimensions de la terminaison :

a) Télécom : habituellement 1,14 mm X 1,14 mm ou 0,76 mm X 1,52 mm

b) Autres : habituellement 0,63 mm X 0,63 mm

3. Se décider sur une connexion ordinaire ou modifiée :

a) Télécoms : habituellement une connexion ordinaire en fil 22 - 26 AWG

b) Electronique : habituellement une connexion modifiée en fil 26 - 30 AWG

4. Une fois l’enrouleur identifié le guide-fil est listé en regard du numéro de

référence de l’enrouleur dans le tableau des enrouleurs et manchons.

Des infor

mations supplémentair

es concernant les connexions ordinaires ou

modifiées et d'autres aspects techniques concernant le processus de connexion

par fil enroulé et les interconnexions obtenues peuvent être trouvées dans le

chapitr

e plus loin : "T

echnologie de connexion par fil enr

15

oulé".

Page 16

INSTALLATION DE LA DOUILLE ET DU GUIDE-FIL :

1. Desserrer l'écrou de la bague en le tournant dans le sens inverse des aiguilles

d'une montre

esserrer l'écrou de la bague dans le

D

sens des aiguilles d'une montre

2. Insérer le guide-fil dans le mandrin et tourner la douille tout en la poussant

dans le mandrin jusqu'à ce que le guide-fil soit placé dans le mécanisme

de commande. A ce point, le pus petit des deux trous en face du guide-fil

est en position douze heures.

Le petit trou en face du guide-fil est

en position douze heures

3. Placer le guide-fil sur la douille et glisser la douille dans la bague. Tourner la

douille lorsque vous la glissez dan le mandrin jusqu'à ce que la douille soit

engagée avec la broche de localisation (interne à la bague). La douille va

ensuite glisser encore et, une fois totalement en place, sera telle que la partie

en saillie de l'extrémité de la douille soit dans la position douze heures.

La portion en saillie de la douille est

en position douze heures

Sleeve

Bit

4. Serrer la bague en tournant l'écrou tournant dans le sens inverse des aiguilles

d'une montre. L'outil est maintenant prêt à être utilisé. Pour faire une connexion

par fil enroulé, suivre les instructions et lire les astuces utiles sur les pages qui

suivent.

ou de la bague dans le

er l'écr

r

Ser

sens inverse des aiguilles d'une

montre

16

Page 17

EFFECTUER UNE CONENXION PAR FIL ENROULE :

Etape 1

Choisir la douille et le guide-fil

appropriés (voir plus haut).

tape 1

E

it, Sleeve et fil pré-

B

dénudé

Etape 2

Insérer le fil dans le trou de fil.

Etape 2

Insertion du fil

Etape 3

Accrocher le fil.

Etape 4

Etape 3

Accrochage du fil

Insérer la terminaison dans le

grand trou de centrage du guide-fil.

Etape 5

Actionner l'outil de connexion.

Etape 4

Insertion de la terminaison

La connexion est achevée.

Etape 5

Connexion terminée

CC)) DDéérroouulleemmeenntt eett lliimmiittaattiioonn ddee ffoorrccee

Le déroulement et la limitation de force sont des fonctions spéciales qui sont

disponibles sur la série PTX. Tous les modèles de l'outil, qu'ils soient sur batterie

ou sur secteur, ont la fonction déroulement intégrée. La fonction de limitation de

force est en option, et est disponible sur les outils PTX-1BF, PTX-2BF et PTX-48BF.

UTILISA

TION DE LA FONCTION DECONNEXION :

Installer la douille et le guide-fil de déroulement dans la bague. Placer

l'interrupteur sur la face arrière de l'outil dans la position bas, qui inverse le

sens du moteur d'enroulement à déroulement. Placer la douille et le guide-fils

de déroulement sur la terminaison de manière à ce que la partie en forme de

crochet du guide-fils de déroulement soit positionnée pour engager l'extrémité

en haut du bobinage qui doit être déroulé. Presser la gâchette de l'outil et la

maintenir appuyée, permettant au guide-fil de dérouler le fil. S'assurer de bien

retirer tout le fil déroulé du guide-fil et de la zone de travail avant de procéder

à d'autres opérations de déroulement.

ATTENTION !

Le déroulement nécessite un jeu de douille/guide-fil séparé ou un outil de

déroulement manuel, ou dans le cas de la série DFB, voir à la page 12, mais ne

JAMAIS essayer de déconnecter avec un jeu de douille/guide-fil qui est

normalement utilisé pour la connexion, parce que cela pourrait endommager la

douille et le guide-fil et compromettre la fiabilité de la connexion.

17

Page 18

UTILISATION DE LA FONCTION LIMITATION DE FORCE :

La limitation de force (Backforce) est une fonction qui compense l'application non

nécessaire d'une pression vers le bas sur l'outil pendant l'enroulement du fil. Un outil de

connexion enroulée assure correctement l'enroulement du fil sans nécessiter de pression

vers le bas, en fait, une telle pression a tendance à sur-enrouler (voir le chapitre

Technologie de la connexion par fil enroulé pour de plus amples détails. Un outil avec

l'option limitation de force contient un mécanisme à ressort pour absorber la pression

vers le bas qu'un opérateur inexpérimenté peut appliquer.

SPECIFICATIONS DES PRODUITS :

OOuuttiillss**

Référence Tension Taille Poids Tr/mn

PTX Alimenté sur batterie 3,6 V 38 mm X 152 mm X 165 mm 336 g 3700

PTX-1 secteur 115 V 38 mm X 152 mm X 165 mm 390 g 3700

PTX-1BF secteur 115 V 38 mm X 152 mm X 165 mm 390 g 3700

PTX-2 secteur 230 V 38 mm X 152 mm X 165 mm 454 g 4200

PTX-2BF secteur 230 V 38 mm X 152 mm X 165 mm 454 g 4200

PTX-2-UK secteur 230 V 38 mm X 152 mm X 165 mm 454 g 4200

PTX-2BF-UK secteur 230 V 38 mm X 152 mm X 165 mm 454 g 4200

PTX-48 secteur 48 V 38 mm X 152 mm X 165 mm 390 g 3700

PTX-48BF secteur 48 V 38 mm X 152 mm X 165 mm 390 g 3700

*Cycle de fonctionnement typique de 2 secondes "on" et de 18 secondes "off" (varie avec l'application).

CChhaarrggeeuurrss ddee bbaatttteerriiee

Référence Tension Taille Poids Cordon

PTX-BC1 secteur 115 V diamètre 102 mm x 69 mm 317 g 1,80 m

PTX-BC2 secteur 230 V diamètre 102 mm x 69 mm 317 g 1,80 m

PTX-BC2-UK secteur 230 V diamètre 102 mm x 69 mm 317 g 1,80 m

BBaatttteerriiee

Item Tension Taille Poids

PTX-B 3.6V diamètre 254mm x 114mm 163 g

ATTENTION ! — TOUS OUTILS PTX

Cet équipement est destiné à une utilisation industrielle ou en laboratoire à l'intérieur, à des altitudes inférieures à 2000 m, avec une

humidité relative de 80 % jusqu'à 31 °C, se réduisant à 50 % à 40 °C. Degré de pollution 2 conformément à la norme IEC644.

Catégorie d'installation II. Gamme de températures : 5

manière non spécifiée par le fabricant, la sécurité peut être compromise. Lors de l'utilisation d'outils électriques, les précautions

de sécurité de base doivent être prises pour réduire les risques d'incendie, choc électrique et blessures. Maintenez les zones de

travail propres, bien éclairées, hors d'atteinte des enfants et des visiteurs. Déconnectez les outils non utilisés et rangez-les.

N'utilisez jamais des accessoires ou des fixations qui ne sont pas recommandés par le fabricant. Si le cordon secteur est

endommagé, ou si une réparation est nécessaire, ce travail doit être effectué par le fabricant ou une personne habilitée pour ce service, ou encore une

personne qualifiée de façon similaire pour éviter tout danger..

°C à 40 °C. L'utilisateur est averti que si l'équipement est utilisé d'une

PRECAUTIONS SUPPLEMENTAIRES ! — Outils 230 V (PTX-2 & PTX-2BF)

Si nécessair

vous que le fusible a une capacité de coupur

nécessitant un démontage ou un remplacement doit être détruite par démontage de tous les fusibles et porte fusibles et jetée immédiatement. De

même, une prise avec des fils dénudés est dangereuse si elle est branchée sur le secteur.

e et a une valeur qui n'est pas supérieure à : 1 A, 250 V. Toute prise de courant

e supérieur

emplacez le fusible de l'unité principale par le modèle cor

e, r

rect : T250 mA. Si une prise de courant à fusible est utilisée, assurez-

OUTILS PTX 48 V

Le pistolet 48 V est fournit avec un cordon sans prise et ne doit en aucun cas être raccordé à une alimentation autre que 48V

A/C ou D/C

18

Page 19

Enrouleurs et Manchons (AWG) mm

R

EGULAR INSULATION TERMINAL TERMINAL HOLE EFFECTIVE HOLE

W

IRE MODIFIED BIT SLEEVE DIAMETER DIAGONAL DIAGONAL DEPTH RADIUS DIAMETER

GAUGE PART NO. PART NO. INCHES INCHES INCHES INCHES INCHES INCHES

18 • KB18 P194 — 1,524 1,854 25,4 3,81 1,905

20

20-22

22 • WB22MLD P212 1,473 1,245 1,854 25,4 3,454 1,905

22 • KB22LT P2224 — 1,549 2,159 25,4 3,175 2,184

22 • KB22 P2224 — 1,372 1,854 19,05 2,972 1,905

22 • WB2275M P2224 1,321 1,245 1,88 25,4 3,353 1,905

22-24 • KB224LH P2224 — 1,549 2,159 25,4 2,972 2,184

22-24 • KB224-1 P2224 — 1,372 1,854 25,4 2,819 1,905

22--24 • KB224 P2224 — 1,372 1,854 20,5 2,819 1,905

22-24 • WB224M P2224 1,27 1,245 1,88 31,75 3,073 1,905

24 • *KB2444 P3032LN — 0,609 1,092 25,4 2,108 1,118

24 • WB24DH P2224 1,168 1,372 1,854 44,45 2,972 1,905

24 • KB24 P2426 — 1,397 1,88 19,05 2,54 1,905

24 • *WB24SM P3032LN 1,118 0,609 1,092 19,05 2,489 1,118

24 • WB24DHM P2224 1,27 1,245 1,727 28,45 2,997 1,753

24-26 • WB2426M P2224 1,168 1,372 1,854 19,05 2,997 1,905

24-26

26 • *KB2639 P26LN — 0,584 0,965 19,05 1,727 1,016

26 • KB26 P2426 — 1,473 1,854 25,4 2,54 1,905

26

26 • WB26M P2224 1,168 1,372 1,854 25,4 2,997 1,905

26 • *WB2644MP3032LN 1,168 0,609 1,092 19,05 2,489 1,118

26 • WB2669M P2426 1,041 1,346 1,727 25,4 2,769 1,753

28 • WB2870M P2426 0,863 1,346 1,727 25,4 2,616 1,778

28-29 • *WB2829M P3032L 0,914 0,838 0,965 19,05 2,311 1,016

30

30

30-32 • *WB3032M P3032 0,685 0,863 0,965 19,05 1,626 1,016

* Ces outils sont recommandés pour des terminaisons carrées de 0,635mm espacées de 2,54mm.

• WB20M P194LN 1,499 1,067 1,854 25,4 3,81 1,905

• KB2075 P2224 — 1,067 1,854 25,4 3,124 1,905

• KB2466 OK8519 — 1,372 1,651 25,4 2,489 1,676

• *WB26SM P26LN 0,787 0,584 0,965 19,05 1,905 1,016

• *SB30MSH-B P3032 0,685 0,787 0,889 19,05 1,626 0,914

• *SB30MMK P3032 0,584 0,787 0,889 19,05 1,626 0,914

MAXIMUM MINIMUM MAXIMUM TERMINAL TERMINAL

Enrouleurs et Manchons grande longueur (127mm)

WIRE

REGULAR

SIZE

AWG mm. PART NO. PART NO. In. In. In. In. In. In.

22 0.65

24 0.50

26 0.40

MODIFIED

•

•

•

BIT SLEEVE DIAGONAL DIAGONAL DIAGONAL DEPTH RADIUS DIAMETER

KB22-5 P2224-5 — 13,72 1,854 19,05 2,972 1,905

KB24-5 P2426-5 — 13,97 1,854 19,05 2,54 1,905

KB26-5 P2426-5 — 14,73 1,854 19,05 2,54 1,905

MAXIMUM

INSULATION TERMINAL TERMINAL HOLE EFFECTIVE HOLE

MINIMUM

MAXIMUM TERMINAL TERMINAL

Manchons isolés (revêtement diélectrique 1000 V)

WIRE SIZE PART NO.

22-24 AWG P2224-INS (ou P2224-5INS pour la version 127mm )

WG

24-26 A

P2426-INS (ou P2224-5INS pour la version 127mm )

19

Page 20

Pièces détachées pour la série PTX

5

4

2

7

1

3

6

REFERENCE DESCRIPTION

1 21362 Circuit imprimé batterie faible, PTX

2 21328 Moteur, outil PTX sur batterie

16746 Moteur, PTX-1 ou PTX-1BF

16772 Moteur, PTX-2 ou PTX-2BF

16771 Moteur, PTX-48 ou PTX-48BF

3 21363 Assemblage commutateur Wrap-

Unwrap, outils PTX sur batterie

21403 Assemblage commutateurWrap-

Unwrap outils PTX sur secteur

4 21676 Assemblage embrayage, outils PTX

avec limiteur de force

21677 Assemblage embrayage, outils PTX

sans limiteur de force

5 16765 Assemblage boîte de vitesse, PTX-1,

PTX-1BF, PTX-48 or PTX-48BF

REFERENCE DESCRIPTION

6 21406 Assemblage interrupteur gâchette,

7 21407 Assemblage de bague (Bague, écrou

8 16762 Assemblage circuit imprimé alimentation,

9 12446 Cordon secteur, PTX-1 ou PTX-1BF

outil PTX sur batterie

20419 Interrupteur gâchette, outils de

connexion sur secteur

de bague et jeu de vis)

PTX-1 ou PTX-1BF (non montré)

18416 Assemblage circuit imprimé alimentation,

PTX-2 ou PTX-2BF (non montré)

Assemblage cir

18217

PTX-48 ou PTX-48BF (non montré)

(non montré)

21402 Cordon secteur, PTX-2 ou PTX-2BF

(non montré)

21475 Cordon secteur, PTX-2BF-UK ou

PTX-2BF-UK non montré)

cuit imprimé alimentation

20

,

Page 21

Garantie, réparation et support technique

Chaque outil de connexion et de déconnexion à fil enroulé PTX, ainsi que les chargeurs de batterie

sont garantis six mois à partir de la date d'achat.

Un service de réparation et un support technique sont disponibles chez OK Industries ; visitez notre

site Web à www.okindustries.com pour contacter un représentant dans votre région.

Technologie de la connexion à fil enroulé (wire wrapping)

La connexion à fil enroulé est une méthode de connexion par enroulement sous tension mécanique

d'un fil dénudé autour des arêtes vives d'une terminaison. Cette technologie a été développée

comme alternative à la soudure qui pose divers problèmes de sécurité et de fiabilité dans de

nombreuses applications. Un avantage principal de la connexion par fil enroulé est qu'elle fournit

une connexion de haute fiabilité qui peut être facilement démontée pour corriger ou modifier

l'implantation d'un câblage.

La connexion par fil enroulé nécessite un outil tournant

appelé guide-fil (bit). Ce guide-fil a un grand trou central

pour englober la terminaison et qui constitue l'axe de

rotation du guide-fil. La partie supérieure du guide-fil a

une fente dans laquelle passe le fil à enrouler. La face

avant du guide-fil est formée de façon à appliquer une

tension adéquate au fil lors de l'enroulement. Ce contour

guide également le fil pour qu'il forme une hélice à pas uniforme et serré. Lors de l'utilisation, le

guide-fil est logé dans un tube métallique, la douille (sleeve). Cette douille maintient le guide-fil

dans la bague de l'outil de connexion par fil enroulé qui entraîne le guide-fil en rotation. Elle

maintient aussi le fil dans la fente pendant le processus d'enroulement et protège l'opérateur de la

rotation du guide-fil.

TENSION MOYENNE

COMPRESSION

MAXIMUM

TERMINAISON

TENSION MAXIMUM

ZONE

NEUTRE

La connexion par fil enroulé soumet le fil à des forces de traction et de compression importantes,

habituellement 700 newtons par mm2. L'enroulement écrase et cisaille la couche d'oxyde sur le fil

et la terminaison, réalisant un contact propre, sans oxyde, métal à métal. Le nombre de tours est

fonction de la longueur de fil dénudé. Du fil pré-dénudé permet d'économiser du temps et améliore

la fiabilité, parce qu'un nombre de tours minimum est nécessaire pour chaque taille de fil, en

fonction de la conductivité électrique et de la force mécanique. Toutefois, si une spécification du

fabricant nécessite un enr

oulement avec plus de tours, des fils avec des longueurs dénudées plus

grandes ou un dénudage manuel peuvent être nécessaires.

21

Page 22

INHALTSVERZEICHNIS

Überblick . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Produktauswahl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Bedienung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Produktspezifikationen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Ersatzteile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Garantie, Reparatur & technische Unterstützung . . . . . . . . . . . . . . . . . . 31

Wire-Wrap-Technologie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

OOvveerrvviieeww:: PPTTXX SSeerriieess TToooollss ffrroomm OOKK IInndduussttrriieess

OK Industries, marktführender Anbieter von Wire-Wrap-Produkten, bietet eine

vollständige Palette manueller, elektrisch und batteriebetriebener Geräte,

entsprechender Bits & Muffen und anderem Zubehör. Detaillierte Informationen

finden Sie auf unserer Website www.okindustries.com.

Die Wire-Wrap- und Unwrap Geräte der PTX Serie wurden entwickelt, um

ergonomischen Anforderungen zu entsprechen und die Bedienereffizienz zu

steigern. Mit Blick auf die Arbeitssicherheit haben wir einen zertifizierten

Ergonomiespezialisten konsultiert und zu dessen Empfehlungen weitere

Merkmale hinzugefügt; wie die leichte, gut ausbalancierte Konstruktion, der

Zwei-Finger Triggerschalter und einen verlängerten Griff zur Reduzierung des

Drucks auf den Handballen. Unter den Gesichtspunkten Komfort und Sicherheit

weisen diese Geräte damit ein marktführendes Design auf. Der versenkte

Wrap/Unwrap-Schalter kann problemlos auf der Rückseite des

Gehäuses betätigt werden und ist durch seine

Versenkung gegen Aufprallschäden

geschützt. Das stabile Gehäuse

umfaßt ein Planetengetriebe mit

hohem Drehmoment, mit dem 18

bis 30 AWG Drähte (1,0mm bis

25mm) verbunden oder getrennt

werden können. Das Gerät ist mit

allen Standard Bits & Muffen

kompatibel. Geräte der PTX Serie

sind als 115V und 230V Versionen

erhältlich sowie als

batteriebetriebenes Modell,

das von einer Langzeit- 3,6V

NiMH Batterie betrieben wir

d

und eine LED Anzeige für

Niederspannung aufweist.

Gegendruck ist eine verfügbare

Option, die Overwrapping durch

zu hohe Kraftausübung des

Bedieners zu vermeiden hilft.

Batterien und Batterieladegeräte

werden separat angeboten.

22

Page 23

Produktauswahl

Produkt Beschreibung

PTX Batteriebetriebenes Wrap/Unwrap Gerät

PTX-1 115V Elektrisch betriebenes Wrap/Unwrap Gerät

PTX-1BF 115V Elektrisch betriebenes Wrap/Unwrap Gerät mit Gegendruck

PTX-2 230V Elektrisch betriebenes Wrap/Unwrap Gerät

PTX-2BF 230V Elektrisch betriebenes Wrap/Unwrap Gerät mit Gegendruck

PTX-B Batterie für PTX batteriebetriebenes Gerät

PTX-BC1 115V Ladegerät für PTX Batterien

PTX-BC2 230V Ladegerät für PTX Batterien

PTX-KIT1 115V Kit, einschließlich: PTX Batteriebetriebenes Gerät, PTX-BC1

PTX-KIT2 230V Kit, einschließlich: PTX Batteriebetriebenes Gerät, PTX-BC2

H-1000 Halfter (Tasche aus Cordura für ein PTX oder ein Handklemmgerät;

PTX-48 48V Elektrisch betriebenes Wrap/Unwrap Gerät

PTX-48BF 48V Elektrisch betriebenes Wrap/Unwrap Gerät mit Gegendruck

PTX-KIT2I 230V Kit, einschließlich: PTX Batteriebetriebenes Gerät, PTX-BC1

Ladegerät und zwei (2) PTX-B Batterien

Ladegerät und zwei (2) PTX-B Batterien

manuelles Wrap/Unwrap Gerät; Bit/Muffe und 2-3 sonstige Geräte.)

Ladegerät und ein (1) PTX-B Batterie

Die Produktpalette umfaßt sowohl elektrisch wie auch batteriebetriebene Geräte sowie

die entsprechenden Batterien und Batterieladegeräte. Die Auswahl des richtigen Geräts

wird hauptsächlich von Bedienervorlieben bestimmt und schließt solche Aspekte wie

Verfügbarkeit von elektrischer Stromversorgung vor Ort und die Bequemlichkeit des

schnurlosen Betriebs ein. Die batteriebetriebene Version (Modell PTX) arbeitet mit einer

Batterie (Modell PTX-B), und erfordert ein Ladegerät (PTX-BC1 oder PTX-BC2); diese

werden separat verkauft bzw. sind im Komplettpaket enthalten (siehe Modelle und

Beschreibung oben).

Alle Geräte der PTX Serie sind mit Umkehrmotoren ausgestattet, so daß mit den Geräten

Wire-Wrap-Verbindungen auch gelöst werden können. (Hinweis: Das UnwrapVerfahren erfordert separate Bits und Muffen oder ein spezielles manuelles Unwrap

Gerät; versuchen Sie NICHT, eine Verbindung mit Wrap-Bit oder Muffe zu trennen. Bit

und Muffe werden dabei beschädigt und die Zuverlässigkeit des Anschlusses

beeinträchtigt). Mit der Gegendruckoption (nur für die Elektro-Geräte PTX-48BF (48V),

PTX-1BF (115V) und PTX-2BF (230V) ver

den. Eine Feder

wer

einen Teil der überschüssigen Kraft auf, die ein Bediener eventuell während des WrapVerfahrens ausübt.

, die inner

halb der Patr

fügbar) kann Over

onen/Schafteinheit angebracht ist, nimmt

23

wrapping vermieden

Page 24

BBeeddiieennuunngg

AA)) VVoorrbbeerreeiittuunngg ddeess WWrraapp//UUnnwwrraapp GGeerräättss

Die Geräte der PTX Serie werden betriebsbereit geliefert und erfordern keine

Montage. Die batteriebetriebene Version (Modell PTX) muß vor dem Ersteinsatz

mindestens 8 Stunden aufgeladen werden. Die LED Anzeige leuchtet und zeigt

damit an, daß die Batterie momentan im Ladegerät ist. Die LED Anzeige leuchtet

immer, wenn die Batterie geladen wird, auch nach Ablauf der 8 Stunden. Es

besteht kein Schadensrisiko, wenn Sie die Batterie über diesen

Zeitraum hinaus im Ladegerät lassen. Schließen Sie das Ladegerät

(115V Modell PTX-BC1 oder 230V Modell PTX-BC2)

einfach an eine Stromquelle an und

stecken Sie die Batterie (Modell Nr. PTX-

B) in das Ladegerät. Nach etwa 500750 Arbeitseinsätzen sollte die Batterie

entsorgt und eine neue eingesetzt

werden.

Ladegerät

(mit Batterie abgebildet))

BBaatttteerriieeppoollee

Wenn die Batterie sich weder im Gerät noch im Ladegerät befindet, müssen

Sie sicherstellen, daß die beiden Pole nicht durch ein Metallstück oder ein

anderes leitendes Material kurzgeschlossen werden. Sonst kann ein

Kurzschluß möglichweise zu Brand, Verbrennungen und Batterieschäden

führen. PTX-B ist eine umweltfreundliche NiMH Batterie, die problemlos

entsorgt werden kann.

VORSICHT!

Benutzen Sie keine Batterien eines anderen Herstellers in dem PTX Gerät, da dies

den ordungsgemäßen Betrieb des Geräts beinträchtigt und zu Geräteschäden

führen kann. Benutzen Sie immer die PTX-B Batterien und die PTX-BC1 oder PTXBC2 Batterieladegeräte, die beide von OK Industries hergestellt werden.

Benutzen Sie das Ladegerät nicht, wenn Kabel oder Stecker beschädigt sind, unter

feuchten Bedingungen, außerhalb von Gebäuden oder in der Nähe von

Spülbecken oder einer anderen Wasserzufuhr. Nehmen Sie das Ladegerät nicht

auseinander, es enthält keine austauschbaren Ersatzteile.

24

Page 25

Nachdem die Batterie aufgeladen ist, entfernen Sie sie aus dem Ladegerät und

setzen Sie sie in den Griff des PTX Geräts ein. Drehen Sie den Batteriedeckel um

90° gegen den Uhrzeigersinn, bis er einrastet (siehe unten); und

ziehen Sie ihn dann leicht zurück, so daß er in den

Gerätegriff einrastet. Um die Batterie aus dem Gerät

zu entfernen, drücken Sie auf den Batteriedeckel,

drehen die Batterie um 90° im

Werkzeuggriff

Uhrzeigersinn und ziehen sie

heraus.

Batterie-

Gegen den Uhrzeigersinn

drehen, bis die Batterie einrastet

deckel

Drehen Sie den Einsatz im Uhrzeigersinn

um die Batterie zu entfernen

Sobald sich die Batterieladung verringert (bei etwa 3,3V), leuchtet die roten LED

Anzeige auf der Oberseite des Geräts auf. Zu diesem Zeitpunkt sollte die

Batterie noch immer genug Ladung (abhängig von der jeweiligen Anwendung)

für mehrere Hundert weitere Wrap- oder Unwrap-Vorgänge aufweisen.

BB)) WWiirree--WWrraapp--VVeerrffaahhrreenn

Bei ordnungsgemäßer Ausführung bildet die Wire-Wrap-Technologie eine

Verbindung, die gegenüber alternativen Methoden eine höhere Zuverlässigkeit

aufweist und dabei problemlos wieder gelöst werden kann. Bei dem Verfahren

wird das freiliegende Ende eines Drahts in einer engen Spirale um einen

metallenen Anschluß gewickelt. Dazu müssen geeignete Bits und Muffen

zusammen mit dem Gerät benutzt werden. Wählen Sie ein geeignetes Bit und

eine geeignete Muffe gemäß dem folgenden Verfahren aus:

Auswahl von Bit & Muf

fe:

1. Bestimmen Sie die Drahtstärke: 18 bis 30 AWG (American Wire Gauge)

2. 2. Bestimmen Sie die Maße des Anschlußstifts:

a) Telekom: üblicherweise 1,14mm X 1,14mm oder 0,76mm X 1,52mm

b) Sonstige: üblicherweise 0,63mm X ,63mm

3. Entscheiden Sie sich zwischen regulärer oder modifizierter Wicklung:

a) Telekom: üblicherweise reguläre Wicklung, 22-26 AWG Draht

b) Elektronik: üblicherweise modifizierte Wicklung, 26-30 AWG Draht

enn das Bit dementspr

4. W

echend definier

t ist, können Sie die

entsprechende Muffe neben der Artikelnummer des Bits in der Bit &

Muffen Tabelle ablesen

icklung sowie

Zusätzliche Infor

mationen bzgl. r

er oder modifizier

egulär

ter W

anderer technischer Aspekte des Wrap-Verfahrens und der resultierenden

Verbindungen finden Sie unter “Wire-Wrap-Technologie”.

25

Page 26

Installation von Bit & Muffe:

1. Lösen Sie die Patronenmutter, indem Sie sie im Uhrzeigersinn drehen (siehe

unten).

Patronenmutter im

Uhrzeigersinn lösen

2. Setzen Sie das Bit in das Futter ein. Drehen Sie es, während Sie es

gleichzeitig in das Futter drücken, bis es im Antriebsmechanismus sitzt. Das

kleinere der beiden Löcher auf der Stirnseite des Bits sollte nun in der 12

Uhr Position (oben) sein.

Kleines Loch auf der Stirnseite

des Bits auf 12 Uhr

3. Schieben Sie die Muffe über das Bit und in die Patrone. Drehen Sie die

Muffe, während Sie sie in das Futter schieben, bis die Muffe an dem

Positionierstift (innerhalb der Patrone) eingerastet ist; die Muffe gleitet

dann weiter in die Patrone hinein. Wenn sie ihre entgültige Position

erreicht, ist die angespitzte Seite der Muffe in der 12 Uhr Position (oben).

Angespitzte Seite der Muffe auf

12 Uhr

Muffe

Bit

4. Ziehen Sie die Patrone fest, indem Sie die Patronenmutter gegen den

Uhrzeigersinn drehen. Das Gerät ist nun betriebsbereit. Um eine WireWrap-Verbindung herzustellen, befolgen Sie die Anleitungen und

hilfreichen Tips auf den folgenden Seiten.

Patronenmutter gegen den

zeigersinn festziehen

Uhr

26

Page 27

Wire-Wrap-Verbindung herstellen:

Schritt 1: Wählen Sie ein geeignetes

Bit und die ensprechende Muffe aus

S

chritt 1

Bit, Muffe und abisolierter Draht

(siehe oben).

Schritt 2 : Schieben Sie den Draht

in den Drahtschlitz.

Schritt 3 : Verankern Sie den Draht.

Schritt 4 : Schieben Sie den Anschluß

in die größere Öffnung des Bits.

Schritt 5 : Aktivieren Sie das Gerät.

Die Wire-Wrap-Verbindung ist

Schritt 5

Fertige Verbindung

Schritt 2

Einsetzen des Drahts

Schritt 3

Verankerung des Drahts

Schritt 4

Einsetzen des Anschlusses

vervollständigt.

CC)) UUnnwwrraapp--VVeerrffaahhrreenn uunndd GGeeggeennddrruucckk

Das Unwrap-Verfahren und der Gegendruck sind Spezialfunktionen der WireWrap-Technologie und sind auf den Geräten der PTX Serie verfügbar. Bei allen

Gerätemodellen, sowohl elektrisch als auch batteriebetrieben, ist die UnwrapFunktion bereits integriert; die Gegendruckfunktion ist optional zu bestellen und für

die Modelle PTX-1BF, PTX-2BF und PTX-48BF erhältlich.

Unwrap-V

erfahren:

Setzen Sie die Unwrap-Bit/Muffe in die Patrone ein. Drücken Sie den Schalter auf

der Rückseite des Geräts in die untere Position, um vom Wrap- in den UnwrapModus zu wechseln. Schieben Sie die Unwrap-Bit/Muffe über den Anschluß, so

daß der hakenförmige Teil des Unwrap-Bits so positioniert ist, daß das obere

Ende der Drahtspule, die gelöst werden soll, einrastet. Aktivieren Sie das Gerät

und halten Sie es still, so daß das Bit die Spule abwickeln kann. Entfernen Sie den

gesamten, abgewickelten Draht von dem Bit und der Arbeitsfläche, bevor Sie

weitere Unwrap-Verfahren durchführen.

VORSICHT!

Bei Unwrap-Verfahren muß ein separates Bit/Muffen Set oder ein UnwrapHandgerät benutzt werden – bzw. bei Geräten der DFB Serie, siehe Seite 12.

Benutzen Sie hierfür NIE ein Bit/Muf

da Bit und Muffe sonst beschädigt werden und die Verbindung nicht zuverlässig ist.

fen Set, das für W

27

rap-Verfahren ausgelegt ist,

Page 28

Gegendruckfunktion

‘Gegendruck’ ist eine Funktion, mit der überschüssige, nach unten gerichtete Kraft, die

auf das Gerät ausgeübt wird, kompensiert wird. Ein Wire-Wrap Gerät führt die Wrapfunktion ordnungsgemäß aus, ohne daß Kraft auf das Gerät ausgeübt werden muß.

Tatsächlich führt überschüssige Kraftausübung zu ‘Overwrap’ (weitere Informationen

hierzu unter ‚Wire-Wrap-Technologie’). Ein Gerät mit der Gegendruckfunktion enthält

einen Federmechanismus, der die Kraft aufnimmt, die ein unerfahrener Bediener

eventuell ausübt.

PRODUKTSPEZIFIKATIONEN:

EElleekkttrroo--GGeerräättee**

Produkt Spannung Maße Gewicht RPM

PTX 3,6V Batterie betrieben 38mm B X 152mm H X 165mm L 336g 3700

PTX-1 115V elektrisch 38mm B X 152mm H X 165mm L 390g 3700

PTX-1BF 115V elektrisch 38mm B X 152mm H X 165mm L 390g 3700

PTX-2 230V elektrisch 38mm B X 152mm H X 165mm L 454g 4200

PTX-2BF 230V elektrisch 38mm B X 152mm H X 165mm L 454g 4200

PTX-2-UK 230V elektrisch 38mm B X 152mm H X 165mm L 454g 4200

PTX-2BF-UK 230V elektrisch 38mm B X 152mm H X 165mm L 454g 4200

PTX-48 48V elektrisch 38mm B X 152mm H X 165mm L 390g 3700

PTX-48BF 48V elektrisch 38mm B X 152mm H X 165mm L 390g 3700

*Typischer Betriebszyklus ist 2 Sekunden an und 18 Sekunden aus (vaiiert je nach Anwendung).

BBaatttteerriieellaaddeeggeerräättee

Produkt Spannung Maße Gewicht Kabel

PTX-BC1 115V elektrisch 102mm Umfang X 69mm hoch 317g 1,8m lang

PTX-BC2 230V elektrisch 102mm Umfang X 69mm hoch 317g 1,8m lang

PTX-BC2-UK 230V elektrisch 102mm Umfang X 69mm hoch 317g. 1,8m lang

BBaatttteerriiee

Produkt Spannung Maße Gewicht

PTX-B 3.6V 254mm Durchmesser X 114mm L 163g

Vorsicht! — Alle PTX Geräte

Diese Geräte sind ausschließlich für den industriellen/Laborbetrieb in Innenräumen bestimmt, für Höhen bis zu 2000m, bei einer maximalen Luftfeuchte

von 80% und Temperaturen bis 31°C, abfallend auf 50% Luftfeuchte bei 40°C. Verschmutzungsgrad 2 gemäß IEC644. Installationskategorie II.

Temperaturbereich: 5°C bis 40°C. Jede Person, die mit oder in der Nähe des Geräts arbeitet, muß wissen, daß nicht ordnungsgemäßer Betrieb gemäß

dieser Bedienanleitung zu Sicherheitsrisiken führen kann. Während des Betriebs elektrischer Geräte müssen zu jeder Zeit grundlegende

Sicherheitsmaßnahmen angewendet werden, um Brandgefahr, Elektroschock und Personenschäden zu vermeiden. Halten Sie den Arbeitsbereich

sauber, gut beleuchtet und verbieten Sie den Zugang für Kinder und Besucher. Trennen Sie nicht benutzte Geräte von der Stromzufuhr und räumen Sie

sie weg. Benutzen Sie kein Zubehör oder Anbauten, die nicht vom Hersteller empfohlen oder genehmigt sind. Ein schadhaftes Stromkabel muß repariert

werden; diese Reparatur muß durch den Hersteller oder einen Servicerepräsentanten des Herstellers oder einer entsprechend qualifizierten Person

durchgeführt werden, um Gefahren zu vermeiden.

VORSICHT! — 230V Geräte (PTX-2 & PTX-2BF)

Falls erforderlich, ersetzen Sie die Sicherung in der Haupteinheit mit dem korrekten Sicherungstyp: T250mA. Wird ein abgesicherter Netzstecker

eingesetzt, stellen Sie sicher, daß die Sicherung eine hohe Abschaltfähigkeit und einen Wert von nicht mehr als 1A 250V aufweist. Alle

Netzstecker, die entfernt oder ausgetauscht werden, müssen durch Entfernen der Sicherung und des Sicherungschalters betriebsunfähig gemacht

und ordnungsgemäß entsorgt werden, da ein schadhafter Stecker, der in eine stromführende Steckdose gesteckt wird, ein hohes Risiko darstellt.

48V

Geräte

Die 48 Volt Wickelpistole wird mit einer Netzleitung ohne Netzstecker geliefert und darf nur an einer Stromquelle mit 48 V Gleich-oder

Wechselstrom angeschlossen werden.

28

Page 29

Bits und Muffen Tabelle (AWG) mm

REGULÄR ISOLIER- ANSCHLUSS- ANSCHLUSS LOCH EFFEKTIVER LOCH

DRAHT MODIFIZIERT BIT MUFFE DURCHMESSER DIAGONALE DIAGONALE TIEFE RADIUS DURCHMESSER

STÄRKE ARTIKELNR ARTIKELNR MM MM MM MM MM MM

18 • KB18 P194 — 1,524 1,854 25,4 3,81 1,905

20

20-22

22 • WB22MLD P212 1,473 1,245 1,854 25,4 3,454 1,905

22 • KB22LT P2224 — 1,549 2,159 25,4 3,175 2,184

22 • KB22 P2224 — 1,372 1,854 19,05 2,972 1,905

22 • WB2275M P2224 1,321 1,245 1,88 25,4 3,353 1,905

22-24 • KB224LH P2224 — 1,549 2,159 25,4 2,972 2,184

22-24 • KB224-1 P2224 — 1,372 1,854 25,4 2,819 1,905

22--24 • KB224 P2224 — 1,372 1,854 20,5 2,819 1,905

22-24 • WB224M P2224 1,27 1,245 1,88 31,75 3,073 1,905

24 • *KB2444 P3032LN — 0,609 1,092 25,4 2,108 1,118

24 • WB24DH P2224 1,168 1,372 1,854 44,45 2,972 1,905

24 • KB24 P2426 — 1,397 1,88 19,05 2,54 1,905

24 • *WB24SM P3032LN 1,118 0,609 1,092 19,05 2,489 1,118

24 • WB24DHM P2224 1,27 1,245 1,727 28,45 2,997 1,753

24-26 • WB2426M P2224 1,168 1,372 1,854 19,05 2,997 1,905

24-26

26 • *KB2639 P26LN — 0,584 0,965 19,05 1,727 1,016

26 • KB26 P2426 — 1,473 1,854 25,4 2,54 1,905

26

26 • WB26M P2224 1,168 1,372 1,854 25,4 2,997 1,905

26 • *WB2644MP3032LN 1,168 0,609 1,092 19,05 2,489 1,118

26 • WB2669M P2426 1,041 1,346 1,727 25,4 2,769 1,753

28 • WB2870M P2426 0,863 1,346 1,727 25,4 2,616 1,778

28-29 • *WB2829M P3032L 0,914 0,838 0,965 19,05 2,311 1,016

30

30

30-32 • *WB3032M P3032 0,685 0,863 0,965 19,05 1,626 1,016

* Diese Geräte sind für 0,635mm Rechteckanschlüsse mit 2,54mm Raster ausgelegt.

• WB20M P194LN 1,499 1,067 1,854 25,4 3,81 1,905

• KB2075 P2224 — 1,067 1,854 25,4 3,124 1,905

• KB2466 OK8519 — 1,372 1,651 25,4 2,489 1,676

• *WB26SM P26LN 0,787 0,584 0,965 19,05 1,905 1,016

• *SB30MSH-B P3032 0,685 0,787 0,889 19,05 1,626 0,914

• *SB30MMK P3032 0,584 0,787 0,889 19,05 1,626 0,914

MAXIMALER MINIMALE MAXIMALE ANSCHLUSS ANSCHLUSS

Erweiterte (127mm) Bits und Muffen Tabelle

DRAHT

STÄRKE

AWG mm. ARTIKELNR. ARTIKELNR.. MM MM MM MM MM MM

Isolierte Muf

REGULÄR

22 0.65

0.50

24

26 0.40

MODIFIZIERT

•

•

•

BIT SLEEVE DIAGONALE DIAGONALE DIAGONALE TIEFE RADIUS DIAMETER

KB22-5 P2224-5 — 13,72 1,854 19,05 2,972 1,905

KB24-5

KB26-5 P2426-5 — 14,73 1,854 19,05 2,54 1,905

P2426-5

fen (1000V dielektrische Beschichtung)

DRAHTSTÄRKE ARTIKEL-NR.

WG

22-24 A

WG P2426-INS (oder P2426-5INS für 127mm Version)

24-26 A

P2224-INS

MAXIMALE MINIMALE MAXIMALE ANSCHLUSS- TERMINAL

ISOLIER ANSCHLUSS- ANSCHLUSS- LOCH EFFEKTIVER HOLE

— 13,97 1,854 19,05 2,54 1,905

(oder P2224-5INS für 127mm V

29

ersion)

Page 30

Ersatzteile für die PTX Serie

5

4

2

7

1

3

6

ARTIKEL-NR. BESCHREIBUNG

1 21362 Niederspannung PCB Einheit

2 21328 Motor, PTX Gerät Batteriebetrieb

16746 Motor, PTX-1 oder PTX-1BF

16772 Motor, PTX-2 oder PTX-2BF

16771 Motor, PTX-48 oder PTX-48BF

3 21363 Wrap-Unwrap Schaltereinheit,

4 21676 Kupplungseinheit, PTX Geräte mit

5

PTX Batteriebetriebenes Gerät

21403 Wrap-Unwrap Schaltereinheit,

PTX Elektro-Geräte

Gegendruck

21677 Kupplungseinheit, PTX Geräte ohne

Gegendruck

Getriebeinheit, PTX-1, PTX-1BF,

16765

PTX-48 oder PTX-48BF

ARTIKEL-NR. BESCHREIBUNG

6 21406 Triggerschaltereinheit, PTX Gerät

Batteriebetrieb

20419 Triggerschaltereinheit, Elektro-Wrap Geräte

7 21407 Patroneneinheit (Patrone,

Patronenmutter und Einstellschraube)

8 16762 Strom-PCB-Einheit, PTX-1 oder

PTX-1BF (nicht abgebildet)

18416 Strom-PCB-Einheit, PTX-2 oder

PTX-2BF (nicht abgebildet)

18217 Strom-PCB-Einheit, PTX-48 oder

PTX-48BF (nicht abgebildet)

9 12446 Stromkabel, PTX-1 oder PTX-1BF

(nicht abgebildet)

21402 Stromkabel, PTX-2 oder PTX-2BF

(nicht abgebildet)

21475 Stromkabel, PTX-2BF-UK or

PTX-2BF-UK (nicht abgebildet)

30

Page 31

Garantie, Reparatur und Technische Unterstützung

Jedes PTX Wrap und Unwrap Gerät sowie alle Batterieladegeräte sind mit einer sechsmonatigen

Garantie ab Kaufdatum abgedeckt.

Reparaturservice und technische Unterstützung sind verfügbar von OK Industries ; Über unsere

Website unter www.okindustries.com können Sie einen Repräsentanten in Ihrer Nähe kontaktieren.

Wire-Wrap-Technologie

Das Wire-Wrap-Verfahren ist eine Methode der Drahtverbindung, bei der ein bloßer Draht unter

mechanischer Spannung um die scharfen Kanten eines Anschlusses gewickelt wird. Diese

Technologie wurde als Alternative zum Löten entwickelt, das bei vielen Anwendungen verschiedene

Sicherheits- und Zuverlässigkeitsprobleme mit sich bringt. Einer der Hauptvorteile des Wire-WrapVerfahrens ist, daß es eine äußerst zuverlässige Verbindung produziert, die gleichzeitig problemlos

wieder gelöst werden kann, wenn dies für Korrekturen oder Modifikationen notwendig ist.

Das Wire-Wrap-Verfahren erfordert eine Drehwerkzeug, das Bit genannt wird. Dieses Bit weist eine

große, mittig angeordnete Öffnung auf der Stirnseite auf,

über die das Werkzeug über den Anschluß gestülpt wird

und die den Punkt darstellt, um den das Bit rotiert. Im

oberen Bereich des Bit ist ein Schlitz, in den der Draht für

MITTLERE

SPANNUNG

MAXIMALE

SPANNUNG

NEUTRALE

ZONE

den Wire-Wrap-Vorgang eingesetzt wird. Die Stirnseite

des Bits ist so geformt, daß während des Wrap-Vorgangs

MAXIMALEN

DRUCK

eine angemessene Spannung auf den Draht ausgeübt

wird. Durch diese Formgebung wird der Draht außerdem

TERMINAL

in Spiralform aufgewickelt, die eng und gleichmäßig ausgebildet wird. Während des Betriebs

befindet sich das Bit in einer Metallhülse, der Muffe. Die Muffe fixiert das Bit in der Patrone des

Wire-Wrap Geräts, das die Rotation des Bits antreibt. Außerdem hält sie den Draht während des

Wire-Wrap-Prozesses in dem dafür vorgesehenen Schlitz und schützt den Bediener vor dem

rotierenden Bit.

Der Draht wird während des Verfahrens einer enormen Spannung und hohen Druckkräften

ausgesetzt, normalerweise 100.000 PSI (6.895 bar) an der Anschlußkante.

Durch den Wrap-Prozeß wird die Oxidschicht auf dem Draht und dem Anschluß zerdrückt oder

abgeschert, so daß ein sauberer, oxidfreier Metall-an-Metall Kontakt zustande kommt. Die Anzahl

der Windungen ist eine Funktion aus der Länge des abisolierten Drahts. Vor-abisolierte Drähte

ersparen Zeit und optimieren die Zuverlässigkeit der Verbindung, da es eine bestimmte

Mindestanzahl von Windungen für jede spezifische Drahtstärke gibt. Diese haben direkte

Auswirkung auf die elektrische Leitfähigkeit und mechanische Festigkeit. Wenn allerdings eine

derlich macht, sind eventuell Drähte mit einem

Anwendungsspezifikation mehr W

icklungen er

for

längeren abisolierten Bereich notwendig.

31

Page 32

INDICE ARGOMENTI

Panoramica . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Lista dei Prodotti . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Modalità d’uso . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Specifiche di prodotto . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Parti di Ricambio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Garanzia, Riparazioni & Supporto Tecnico . . . . . . . . . . . . . . . . . . . . . 41

Tecnologia Wire Wrapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

PPaannoorraammiiccaa:: AAttttrreezzzzii ddeellllaa SSeerriiee PPTTXX ddaa OOKK IInndduussttrriieess

OK Industries, leader a livello mondiale di prodotti per wire wrapping, offre una

completa gamma d’attrezzi manuali, elettrici e con alimentazione a batteria, bit

& sleeve ed altri accessori. Per ulteriori informazioni, vogliate visitare il nostro

sito web www.okindustries.com.

Gli attrezzi per wrapping e unwrapping della Serie PTX sono stati sviluppati

tenendo conto dei requisiti ergonomici e per aumentare l’efficienza

dell’operatore. Tenendo ben presente la sicurezza dell’operatore, abbiamo

consultato un noto ergonomista ed aggiunto prestazioni che includono la

costruzione leggera e ben bilanciata, oltre ad una lunga impugnatura per

minimizzare la pressione sul palmo. Queste caratteristiche hanno portato ad

un progetto all’avanguardia nell’industria, dal punto di vista della comodità e

della sicurezza. L’interruttore wrap/unwrap, in posizione rientrata sulla parte

posteriore del corpo attrezzo, è di facile accesso; è inoltre protetto dai colpi,

nel caso l’attrezzo debba cadere. Il robusto contenitore

include un ingranaggio planetario ad alta

coppia, che può wrappare (wrap avvolgere) o swrappare (unwrap svolgere) fili di diametri compresi

fra AWG 18 ed AWG 30 (da

1,0 a 0,25mm), ed è compatibile

con l’intera gamma di bit e

sleeve, standard industriali. La

Serie PTX è disponibile nelle

versioni 115V e 230V, oltre che

nella versione a batteria, che è

alimentata da una cella NiMH

da 3,6V di lunga durata, ed

incorpora un LED per la

segnalazione di batteria

scarica. E’ disponibile

l’opzione “backfor

ce” (forza

opposta), che aiuta a

prevenire l’overwrapping (sovra

avvolgimento), causato

dall’eccessiva forza applicata da

parte dell’operatore; le batterie ed

i carica batterie sono venduti

singolarmente.

32

Page 33

Lista dei prodotti

Item Descrizione

PTX Attrezzo per Wrap/Unwrap Alimentato a Batteria

PTX-1 Attrezzo per Wrap/Unwrap con Alimentazione da Rete 115V

PTX-1BF Attrezzo per Wrap/Unwrap con Backforce ed Alimentazione da Rete 115V

PTX-2 Attrezzo per Wrap/Unwrap con Alimentazione da Rete 230V

PTX-2BF Attrezzo per Wrap/Unwrap con Backforce con Alimentazione da Rete

230V

PTX-B Batteria per Attrezzo PTX Alimentato a Batteria

PTX-BC1 Caricabatterie a 115V per Batterie PTX

PTX-BC2 Caricabatterie a 230V per Batterie PTX

PTX-KIT1 Kit 115V includente: Attrezzo PTX a Batteria, Caricabatterie PTX-BC1,

PTX-KIT2 Kit 230V includente: Attrezzo PTX a Batteria, Caricabatterie PTX-BC2,

H-1000 Fondina (tasca in velluto a coste che puo contenere un attrezzo PTX od

PTX-48 Attrezzo per Wrap/Unwrap con Alimentazione da Rete 48V

PTX-48BF Attrezzo per Wrap/Unwrap con Backforce ed Alimentazione da Rete 48V

PTX-KIT2I Kit 230V includente: Attrezzo PTX a Batteria, Caricabatterie PTX-BC2,

e due (2) Batterie PTX-B

e due (2) Batterie PTX-B

uno manuale; un attrezzo a mano per wrap/unwrap; bit/sleeve; e 2-3

altri attrezzi vari)

e 1 Batterie PTX-B