Page 1

p. 1

Installation Manual

W

LM2 WLTA WLTD WLTP WLCT

www.oj.dk

57641 01/08 (LJE)

Page 2

p. 2

WLM Underfloor Heating Controller ......Page 10

Wiring diagram .......................................Page 10

Description ........................................... Page 13

Product programme .................................Page 13

Technical data ........................................ Page 13

Environment ..........................................Page 14

Recycling of obsolete appliances .................. Page 14

Configuring of the total system .................... Page 14

Installation .....................................Page 15

Electrical installation ................................. Page 15

Boiler demand ........................................ Page 15

Pump output ......................................... Page 16

Free relay function (X-OUTPUT) .................... Page 16

Thermal actuators ................................... Page 17

External switch for night setback .................. Page 18

Room sensors - Bus connection ................... Page 18

Room sensors - Wireless setup .................... Page 19

Setting up which Room sensor/controller

should work with wich thermal actuator .......... Page 20

Supply water temperature sensor

and mixing value ..................................... Page 21

Creating a Network ..........................Page 22

Using cooling function .............................. Page 23

Domestic hot water control ......................... Page 23

Radiator control ...................................... Page 24

2 step heating ........................................Page 24

Commissioning mode ...............................Page 25

Replacing equipment ................................ Page 25

Guidelines and special features .................... Page 26

Factory default settings ............................. Page 27

Error indication ....................................... Page 28

Add On Module ...............................Page 31

Configuring the Total System ....................... Page 31

Outdoor Compensation Module ...........Page 32

Introduction ........................................... Page 32

Mounting .............................................. Page 32

Bus connection - Outdoor

compensation module .............................. Page 32

Interconnection of WLM2 product .................Page 32

Waterline Wireless System .................Page 33

Product Programme ................................. Page 33

Connection of Master and Receiver ...............Page 33

Position ............................................... Page 33

Master ................................................. Page 33

To set up the system ................................Page 33

Type WLCT ....................................Page 34

Introduction ........................................... Page 34

Getting started ....................................... Page 34

Daily Use of the room sensor ....................... Page 36

Programming 4-Event Clock Time

and Temperature ..................................... Page 37

Advanced Settings and Read-out ................. Page 38

Reset to factory Settings - room controllers ...... Page 41

Waterline Room sensors ....................Page 42

Introduction ........................................... Page 42

Set-up ................................................. Page 43

Setting of Room Temperature ...................... Page 44

Setting of Room sensor Operating Mode ......... Page 44

Limit Sensor - WLTD and WLCT ...................Page 45

Quickguides ...................................................................................................... Page 3

Quick Installation Guide ............................................................................................................ Page 3

Setting up the System ..............................................................................................................Page 5

Wireless system only ...............................................................................................................Page 5

Testing the system ..................................................................................................................Page 6

Troubleshooting .....................................................................................................................Page 7

QUICKGUIDES

INSTRUCTIONS

CONTENT INSTALLATION MANUAL

Page 3

B A -- +

Blue Red Brown Yellow

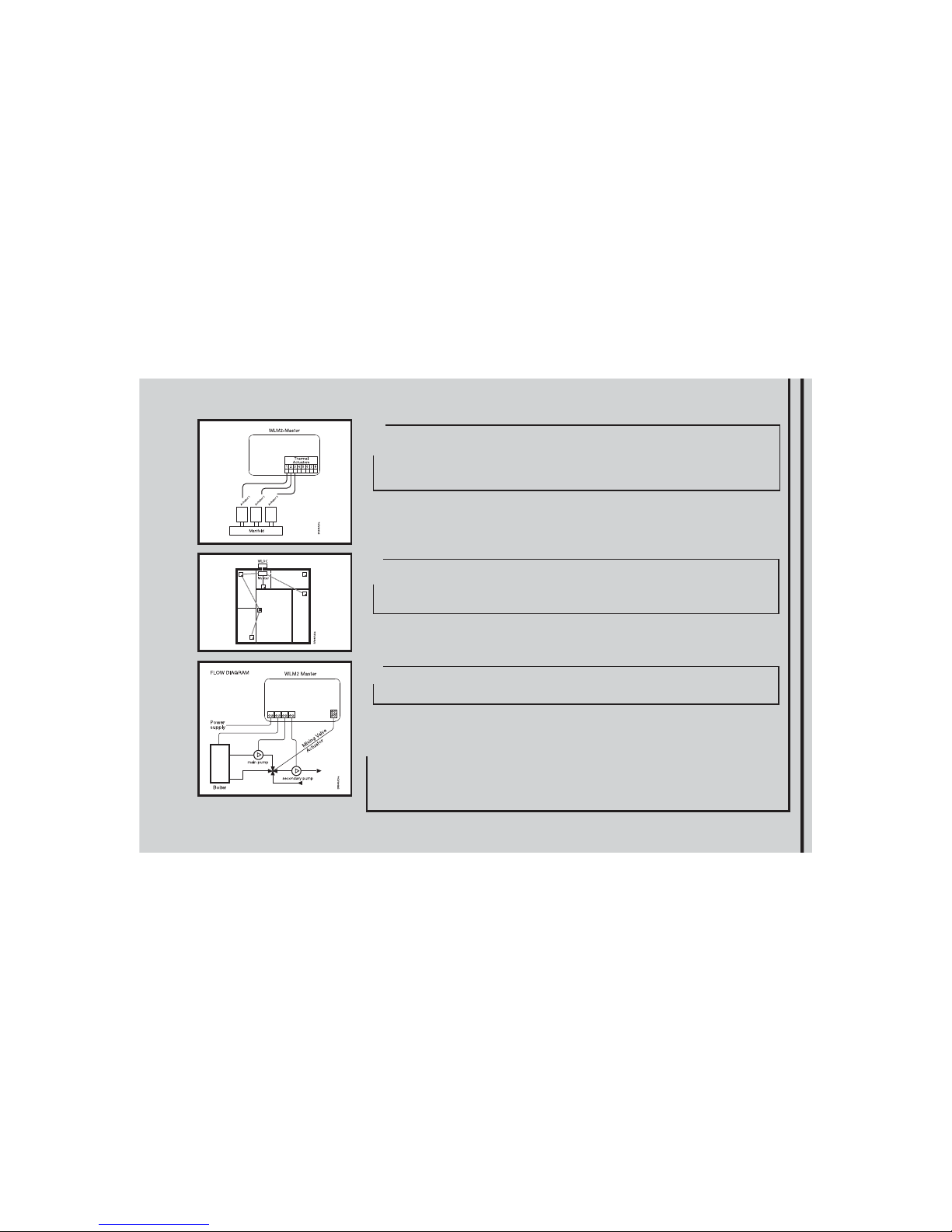

p. 3

We recommend the preparation of an area schedule chart on the backside of the user manual before

commencing the installation. This identifies piping circuits to specific rooms and enables the correct

allocation of a channel number in the WLM system.

Mount the Master and AO modules in the correct way on the wall in accordance with electrical

regulations.

Connect the AO-module, using the special cable included in the box.

Mount the Room sensors/controllers in the rooms, and set the channel switches to correspond with

the number of the actuator controlling that room.

For hardwired Room sensors/controllers now connect the 2-wire bus to the master or the AO module,

maintaining continuity of positive + and negative - connections.

For wireless Room sensors/controllers now insert the batteries.

If the Room sensors/controllers are of wireless type connect the receiver (WLRC-19) using the special

cable enclosed with the receiver.

NB: For Room sensors with floor temperature limiting sensors, please refer to separate instructions

included with Room sensors/controllers.

QUICK INSTALLATION GUIDE

1

2

4

3

QUICKGUIDES

QUICKGUIDES

Page 4

p. 4

Connect the actuators to the channel outputs on the master in accordance with the pipe manifold

layout (please refer to the area schedule).

Actuator no. 1 on the manifold to output no. 1 on the master.

Actuator no. 2 on the manifold to output no. 2 on the master.

etc.

Outdoor module WLOC-19 (FS Master only):

Install on north facing wall, away from direct sunlight.

Connect into 2-wire Room sensor bus or direct to master, maintaining continuity of positive + and

negative - connections.

Connect 230/240Vac power, UFH circulating pump and boiler in accordance with electrical regulations.

(For FS masters, connect the mixing valve and water flow temperature sensors)

6

7

5

Page 5

Button learning mode

p. 5

SETTING UP THE SYSTEM

Turn on the power supply.

Set the clock on any WLCT room controller:

a. If the hour digit is not flashing, press the small pinhole button with the clock symbol, otherwise..

b. Adjust the hours and press OK.

c. Adjust the minutes and press OK.

d. Adjust the day number (1 = Monday) and press OK.

In addition to its own room, the WLCT room controller can be used to set the operating times and temperatures of other Room sensors

(channels).

To achieve this, do the following on the WLCT room controller:

a. Enter the “InFo” menu by pressing the up and down button simultaneously for 4 seconds.

b. Find the “ArEA” menu with the down button and press OK.

c. The display shows “CH 1” (channel 1).

- Press OK button.

- Select “On” if this channel (Room sensor) should be controlled by the WLCT room controller, or “OFF” if not.

- Now press OK button to get to the next channel (CH 2) and repeat this step until all required channels have been selected “On”.

d. After all channels are set up, find the “ESC” menu entry and press OK.

NB: If different times and temperatures are required for other channels (Room sensors) within the system, more than one WLCT room controller can

be used. Care must be taken to ensure that the action of selecting a channel “On” is not made on more than one

WLCT room controller.

Switch on DIP-3 to activate learn mode:

All wireless Room sensors now have to be initialized:

- Analogue Room sensor (TA,TD,TM,TP) by pressing the internal

init button (Button learning mode) until a beep is heard.

- Digital Room sensor (CT) by pressing the pin hole button with the

clock symbol until a beep is heard.

Switch off DIP-3 to de-activate learn mode:

1.

2.

3.

WIRELESS SYSTEM ONLY:

QUICKGUIDES

1.

2.

3.

Page 6

p. 6

TESTING THE SYSTEM:

1. Switch on DIP-3 to activate learn mode: - power light will blink quickly

2. Each red channel light on the master should now be lit if a Room sensor is present on that

channel.

3. Switch off DIP-3 to de-activate learn mode again – power light stops blinking.

4. Turn all adjustable temperature settings on the Room sensors to minimum.

5. Switch on DIP-1 on the master to activate install mode (Install mode will be active for 2 hours

- Pumps, boiler, mixing valve and actuators should now be off)

6. Turn the temperature setting on the adjustable Room sensor in room 1 to maximum. The red

channel 1 light should be lit and the actuator on output nr. 1 will be activated, and will open

after 1-3 minutes, depending on the type of actuator.

Important: If the Room sensor is of a wireless type a delay of up to 5 minutes may occur

before the channel light becomes illuminated .

7. Check that the UHF pump is running and the mixing valve (only FS master) opens .

8. Repeat step 6 on all rooms.

9. Boiler test function:

Switch on DIP-2.

This closes the boiler start relay contacts for 1 minute.

10. To end all tests:

- Switch off DIP-1 to deactivate install mode.

Switch off DIP-2 to deactivate boiler test.

- Set all temperature knobs to default positions

Room sensors (TA,TD,TM,TP) to zero (center position).

Room controllers (CT) recommended to 21˚C.

- Set all override switches on TM and TD Room sensors to automatic position (clock symbol).

11. The system is now operating automatically.

NB: Other important settings can be found in the User manual on the pages shown bellow:

Off temperature (frost protection) page 7

Minimum & Maximum floor temperatures page 7

Maximum supply water temperature page 8

Weather compensation page 8

Page 7

p. 7

Problem Possible cause & solution

Make sure the power light is fast blinking. If not then put DIP-3 to ON position.

2-wire bus may be incorrectly connected. Voltage at each Room sensor should not be

lower than 4.0V (check for + & - continuity and short circuits)

For wireless Room sensors, please check that the batteries have been inserted correctly.

Has the init button been pressed ?

For wireless Room sensor check that the WLRC-19 (receiver) is correctly connected.

For channel 9-14, is the AO module correctly connected to the Master.

Make sure the Room sensor in that room is set to the correct channel number.

The channel selector on the Room sensor may be slightly out of position, try rotating and

the set it again.

Channel light is not coming on.

(When in Learn mode)

(When in Install mode, when the Room

sensor is activated (set to maximum))

Master is not in install mode – after 2 hours the master automatically de-activates install

mode – please reset the DIP-1.

Make sure the Room sensor in that room is set to the correct channel number. (two Room

sensors could be crossed over)

The actuator on the manifold has not

opened after 3 minutes.

Check the red channel light is illuminated.

The actuator for the room is not connected to the correct output on the master.

Bad electrical connection between actuator and terminals.

Actuator may be faulty or manually locked.

UFH Pump not starting in install mode Bad electrical connection between pump and terminals.

Install mode is not activated.

Pump may be faulty.

TROUBLESHOOTING:

QUICKGUIDES

Page 8

p. 8

Output relay for Main pump, Cooling, High

limit valve or other attached device.

Incorrect connection to device (output relay has volt free contacts, see master wiring diagram for

correct connection)

Bad electrical connection between terminals and attached device.

Install mode is not activated.

Attached device may be faulty.

Boiler does not fi re

(LED lit)

Incorrect connection to device (output relay has volt free contacts, see master wiring diagram for

correct connection)

Bad electrical connection between terminals and attached device.

Install mode is not activated.

Attached device may be faulty.

Timing sequence delay is activated

FS master only - mixing valve not open above 20%

No heat demand from Room sensors.

Master is in cooling mode.

(LED not lit)

Mixing valve does not operate correctly

(When in install mode)

Incorrect connection, see master wiring diagram for correct connection.

Valve/actuator assembly is incorrect.

Actuator is faulty.

Check what happens if sensor and/or outdoor module is missing.

(Valve cycles between open and closed in

normal operating mode)

Valve may be oversized.

Supply Limit sensor may be subject to heat migration.

Upstream water temperature is excessively high.

(these problems may be corrected by changing PI settings – please refer to the main manual)

Page 9

p. 9

QUICKGUIDES

Room is too hot

(After running for at least 48 hours)

This could be caused by draughts within the wall cavities.

The Room sensor is placed in a position that does not represent the general temperature in the

room.

If the room is controlled by a CT Room sensor, check that the time and temperatures are set

correctly.

If the Room sensor has got an override switch (TM or TD), the switch may be set in the “day”

position.

For rooms with fl oor sensors, the minimum fl oor limit setting could be increasing the room

temperature above the desired setting.

Solar gain or extraneous heat source.

Room is too cold.

(After running for at least 48 hours)

The Room sensor is placed in a position that does not represent the general temperature in

the room. E.g. mounted on external wall or near an extraneous heat source.

If the room is controlled by a CT Room sensor, check that the time and temperatures are set

correctly.

If the Room sensor has got an override switch (TM or TD), the switch may be set in the “off”

or “night” position.

For rooms with fl oor sensors, the maximum fl oor limit setting could be preventing the room

reaching the desired temperature.

Insuffi cient heating capacity of the system.

Bad insulation creating large heat loss.

Page 10

INSTRUCTIONS

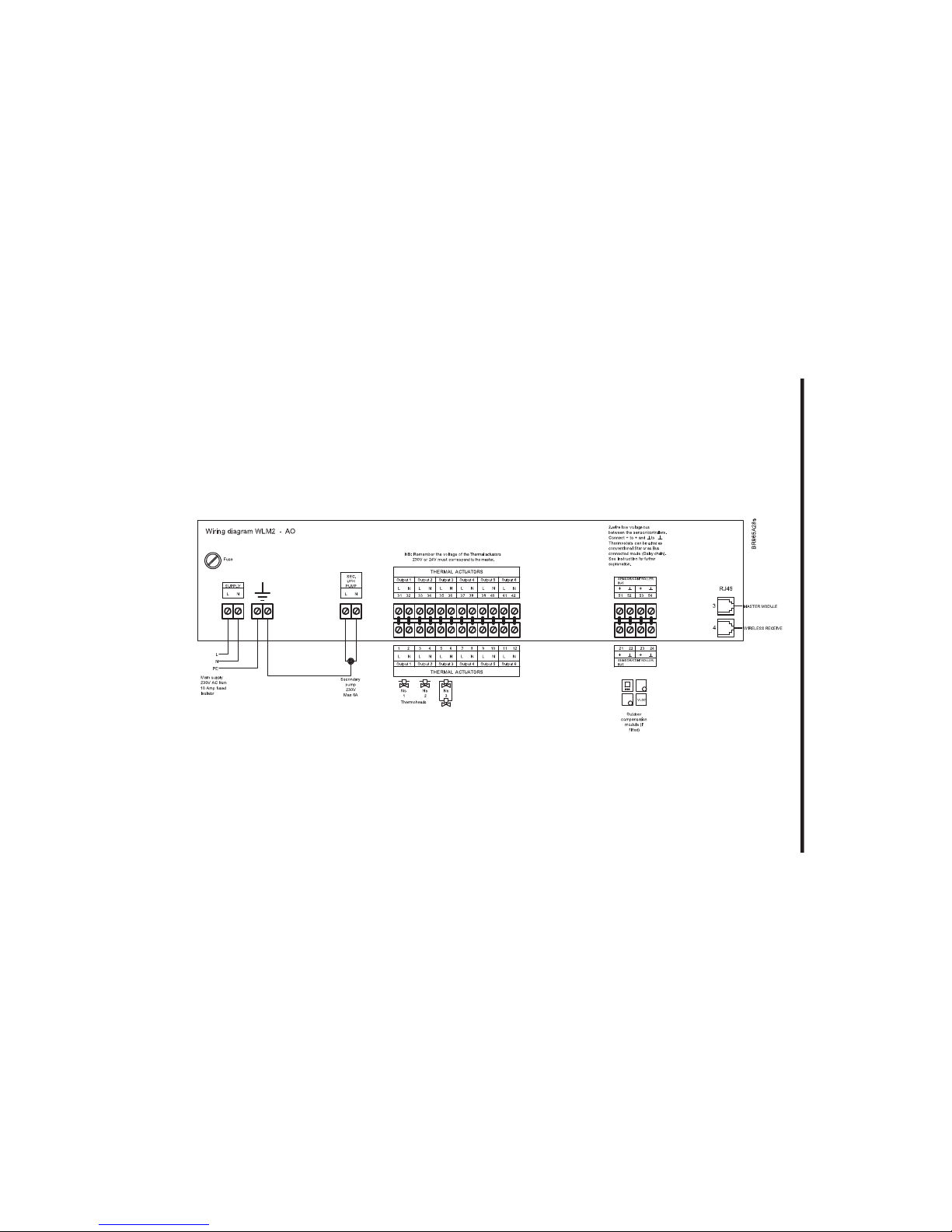

WLM Underfloor Heating Controller

BR965A30b

p. 10

Page 11

p. 11

Page 12

p. 12

Page 13

p. 13

Type WLM underfloor heating controller is suitable for connecting multiple room Room sensors and

electric actuators (thermoheads) for an underfloor or radiator based heating system.

Room sensors requiring a 230 V or 24V live & neutral must NOT be connected.

Only OJ Room sensors type WLxx that are prepared for 2 wire or wireless communication

can be used.

Description

Product Programme

Technical Data

Product Thermo Heads Type

Master for 8 zones 230V AC WLM2-1BA (basic system)

Master for 8 zones with display 230V AC WLM2-1FS (full system)

Master for 8 zones 24V WLM2-3BA (basic system)

Master for 8 zones with display 24V WLM2-3FS (full system)

Add-on module for 6 zones 230V AC WLM2-1AO

Add-on module for 6 zones 24V WLM2-3AO

TECHNICAL DATA

Power Supply ............................................................................................. 230V AC +10/-15%, 50 HZ

Max load pumps and Thermal actuators .......................................................................................

10A

Boiler relay ........................................................................................................Volt free signal. Max 4A

Main pump (free relay) .....................................................................................Volt free signal. Max 4A

Secondary pump .............................................................................................230V AC, 50Hz Max. 4A

Thermal actuators:

WLM2-1BA ........................................................................................................................ 8 x 230V

WLM2-1FS ........................................................................................................................ 8 x 230V

Max. 2A per output. Max. 5A in total

WLM2-3BA .......................................................................................................................... 8 x 24V

WLM2-3FS ...........................................................................................................................8 x 24V

Max. 10VA per output. Max. 35VA in total

Optional External Switch (Timer) for night setback ......................................... Open terminals for NSB

Closed terminals for day operation

Room sensor Bus 2 wire low voltage . . . . . . . . . . . . . . . . . . . . . . . . . . bus signal from Room sensors

Additional data for WLM2-1FS & WLM2-3FS (not applicable to the basic version)

Application sensor and Limit sensor ............................... NTC type ETF-1899A for water temperature

Control signal for mixing valve actuator .................................................................................0-10V DC

Power supply for mixing valve actuator ....................................................................24V AC. Max 6VA

WLM underfloor heating controller

Page 14

p. 14

Please help us to protect the environment by disposing of the packaging in accordance with the

national regulations for waste processing.

Environment

Appliances with this label must not be disposed off with the general waste. They must be collected

separately and disposed off according to local regulations.

Recycling of obsolete appliances

Each master module is capable of controlling 8 heating zones, each of which may use one or more

loops of piping, with one or more thermal actuators.

These zones are referred to later in this instruction as channels 1 to 8. If you wish to control more

than 8 zones, it is necessary to install ADD ON (AO) modules, each of which can provide another 6

outputs. The first AO module then controls channels 9 to 14,

Configuring the Total System

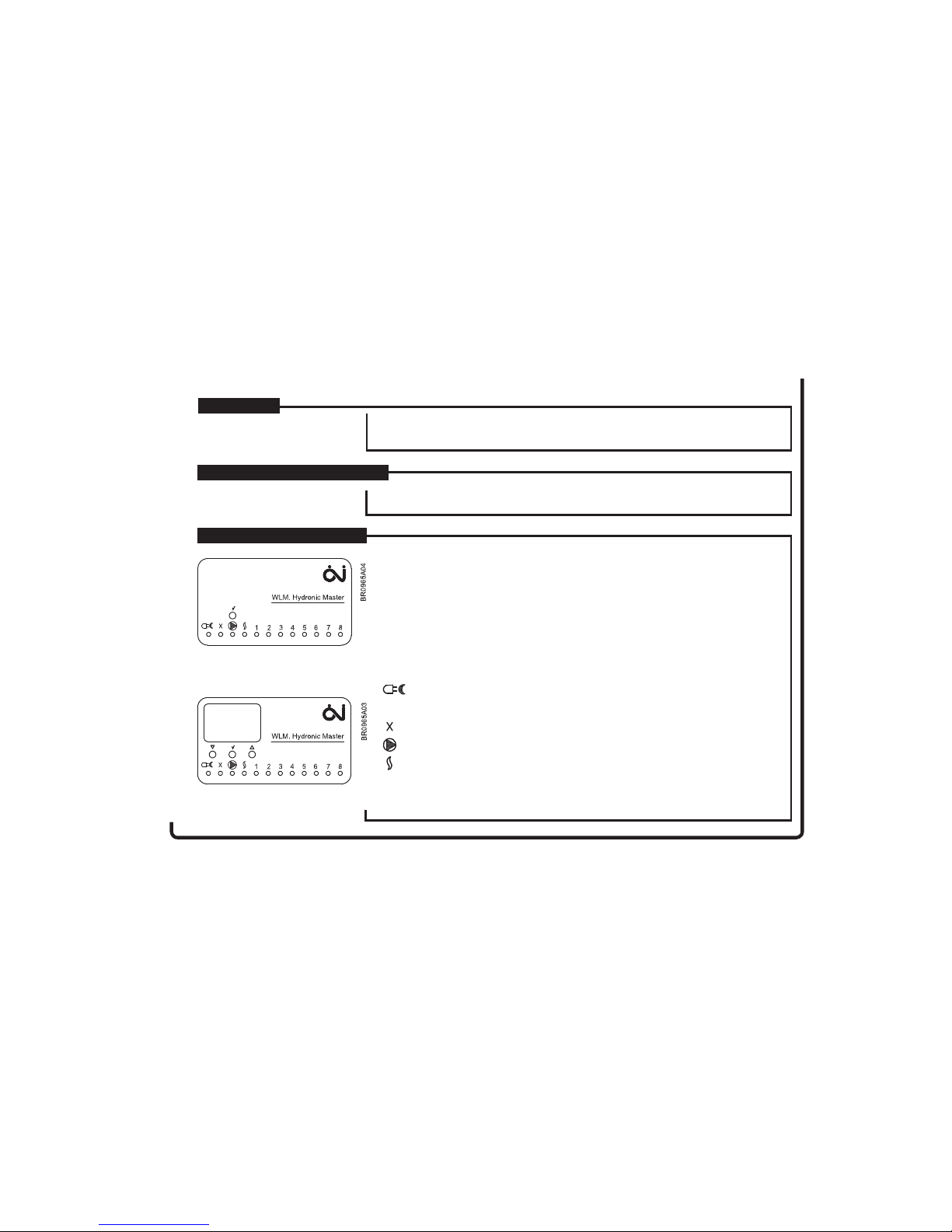

Green: Power supply connected

Red: Night setback active

Red flashing: Indicates error

Main boiler (primary) pump is running (if installed)

Secondary UFH pump is running

Boiler enable signal is activated

Zone 1 to 8 indicating heating is on

1..8

Type WLM-1BA and WLM-3BA

Type WLM-1FS and WLM-3FS

Page 15

p. 15

Fit the WLM master to a suitable wall. It will generally be found more convenient if the unit is within 0.8 metre

of the manifold, as most thermal actuators are supplied with 1m cables. Cables can be run on the surface

into the terminals using either the cable releases in the cover or by pressing out the cable entries in the lower

part of the cover.

PLEASE ENSURE THAT ALL WIRING IS CARRIED OUT IN ACCORDANCE WITH LOCAL

ELECTRICAL REGULATIONS.

When wiring is completed, fit the cover on the master using the screws provided.

Mains supply

WLM requires a 230V AC mains supply connected to the terminals marked L, N, & E.

Electrical Installation

Boiler Demand

The master has a volt-free relay output that can be used to control a boiler, or to open a

motorised valve.

A) To control a boiler that requires switching of the live supply, take a link from L (230V) to the

terminals marked BOILER - B1. Connect the boiler L to the terminal marked BOILER – B2.

Connect the boiler N terminal to the N terminal on the master, and the boiler E to the master

terminal E. (see fig. 7A).

B) To control a boiler that has a pair of dedicated terminals for remote switching (e.g. by a Room

sensor), connect these terminals to B1 and B2 on the master. B1 and B2 terminals are “volt free”

so they can be used for both a 240V and a 24V circuit from the boiler.

Fig. 3

Fig. 4

INSTRUCTIONS

Installation

Page 16

p. 16

C) To control a motorised valve:

Many motorised valves have wires coloured BROWN and BLUE for power connections. In this

case BROWN goes to the terminal B2 under the heading BOILER and BLUE goes to the N

terminal of the master. Then a link from L (230V) to the terminals marked “Boiler B1”. The boiler

relay will be energised after a delay of 10 sec after the start of the main pump.

Basic versions without display. Type WLM2-1BA and WLM2-3BA The boiler relay will stop if

there is no heat demand measured by the Room sensors.

Versions with display. Type WLM2-1FS and WLM2-3FS.

These units have supply water temperature control, and the boiler relay will be ON once the

control valve has reached 20% open, and will remain on as long as a heat demand exists.

The master has an output for the underfloor circulating pump (secondary pump). The output will be

energised after a 180 sec. delay when any connected room sensor calls for heat. The delay is to

allow time for the thermal actuator to start opening.

The 230v AC pump can be connected directly to terminals L and N under the heading “Sec. UFH

Pump”. Connect the pump E (Earth) terminal to E (earth) on the master. The maximum pump load

must not exceed 4 amps , 230v at start up. There is an overrun period of 1 minute after the demand

for heat from the room sensor disappears.

Delay times: Secondary UHF pump 180 sec.

X-output (configured as main pump) 190 sec.

Pump Output

Free relay function (X-OUTPUT):

All WLM master have a relay which can be

utilized for a number of different purposes.

The relay is a volt free output and is positioned

on the PCB as shown on the drawing.

The function of the relay is determined by the

setting of the DIP-switches.

The functions that the relay can perform, and the

appropriate DIP-switch settings, are as follows:

To control: Dip-5 Dip-6

Boiler pump

Off Off

High limit zone valve*

On Off

Cooling device/module**

Off On

Cooling device/module

alternative

On On

Fig. 5

Fig. 8a

Page 17

Fig 6

These actuators are fitted to the underfloor heating manifolds and control the supply of water through the

various loops. The voltage of the thermal actuators, 230V or 24V, must correspond to the master.

Master type WLM-1BA and WLM-1FS are for 230 V thermal actuators, and master type WLM-3BA

and WLM-3FS are for 24V Thermal actuators. Up to 8 different zones can be controlled by the master.

Connect the thermal actuators on the loop(s) for each zone to the corresponding terminals on the master.

Thermal actuators belonging to zone 1 must be connected to output terminal 1, and thermal actuators for

zone 2 must be connected to output terminal 2, etc, etc.

Guideline

More than 1 head can be connected to a single terminal, provided that the heads are to be controlled by

the same room Room sensors.

Connect the Brown wire to the L terminal, and the Blue wire to the N terminal. When the installation is

complete, check that the Room sensor in e.g. room(zone) 1, operates the correct thermo actuator(s) for

that room on the manifold. If the heads appear to be in the wrong position on the manifold, it may be

simpler to change them on the manifold, rather than reconnecting them on the master.

Thermal Actuators [Thermoheads]

p. 17

The X relay output is volt free as shown in fig 8a. If the relay is required to be used as a L & N switch,

connect a link wire from mains L to C1, connect the device L to C2, and the device N to mains N.

Boiler pump:

Where a boiler primary pump is required to be switched on from the master, the relay output can be used

for this purpose. The relay will be activated 10 seconds after the UFH circulating pump has started.

High Limit Zone Valve:

This function is used where an additional protection is required to prevent boiler water entering the

underfloor system, when the system is off or when the supply water exceeds 65 C.

An additional sensor (ETF-1899A) and a zone valve is connected as per attached pic.

Cooling device/module:

The relay output can be used to provide a volt free signal to a heatpump, or to a K-MOD switching

module where a chiller is utilized to provide the cooling water. The relay is on when there is a cooling

demand.

Cooling device/module alternative:

The relay output is always on in cooling mode and off in heating mode.

WLM underfloor heating controller

Page 18

SENSORS/CONTROLLERS CONNECTED IN STAR

SENSORS/CONTROLLERS CONNECTED IN BUS MODE

(DAISY CHAIN)

p. 18

Room sensors - Bus Connection

Only OJ Room sensors type WLxx that are prepared for 2 wire communication can be used. Standard

installation cable, maximum 2 x 0.25 mm

2

can be used. The Room sensors can be connected in the

conventional star wiring format, or in a bus connected mode (Daisy chain) see fig 10 + fig 11. The

master has 4 sets of terminals marked Room sensor BUS that can be used for connecting the 2-wire

signal from the Room sensors.

There are 4 identical sets of terminals for convenient installation. Any Room sensor can be connected

to any pair of terminals. The total length of the 2-wire system can be up to 300 m with a maximum

length of 100mbetween any 2 Room sensors.

Remember to connect + to + and – to – .

Fig 7

From factory the master is delivered with a jumper in the switch/ timer terminals I & O. The day

temperature setpoint is defaulted to 20°C and the night temperature to 15°C. These default settings can

be changed if the master has a display. The current operating set point of the master can be changed

from the day temperature into night temperature, and vice versa by using an input from an external

switch or timer. The input must be a volt free switch, and will need to open circuit for night temperature

and close circuit for day temperature. When the external switch or timer is used to switch to night

setback, this will override any time settings in a WLCT Room controller, including any Room sensors that

are part of a group allocated to that Room controller.

External Switch (TIMER) for night setback

Fig 9

Fig 10

Fig 11

Page 19

Button learning mode

p. 19

Room sensors - Wireless setup:

Where wireless Room sesors/controllers (WLTx-29) are being used is necessary for the WLM master to

“learn” that the Room sensors/controllers are communicating correctly.

To achieve this:

1. On master, switch on DIP-3 to activate learn mode:

2. All wireless Room sensors/controllers now have to be initialized:

Room sensors (WLTA, WLTD, WLTM, WLTP) by pressing the internal init button

(Button learning mode) until a beep is heard. (see fig. 12)

Room controllers (WLCT) by pressing the pin hole button with the clock symbol until a beep is

heard. (see fig. 13)

3. Switch off DIP-3 to de-activate learn mode.

WLM underfloor heating controller

Fig 12

Fig 13

Page 20

Fig 10

p. 20

Setting up Which Room sensor Should Work With Which Thermal Actuator

Each Room sensor can be selected to operate a specific output which in turn controls the thermal

actuators on the manifold. Under the front cover of the Room sensor, a selector can be accessed,

and the number of its output (its CH channel) can be set with a screwdriver. (See fig 10) Up to

14 channels can be set on the selector, and there are two auxiliary channels. (see later). A WLM

master has 8 outputs and additional slave module 6 outputs, and can be connected creating a

system of 14 individual zones.

Please note that channels 10 to 14 are marked as A through E on the selector,

A Room sensor set for CH1 will activate the thermal actuator connected to output 1 on the master.

The channel number can be selected without any power connected to the system. The channel of

the Room sensor can be changed afterwards if needed.

If two Room sensors are placed in the same room and set to the same channel, the temperature

control will work according to the average temperature of both Room sensors.

Channel 0:

Each Room sensor is delivered with the switch in position 0 ensuring that it must be set to operate

correctly. Channel 0 can also be used for a Room controller controlling a group of Room sensors

where the control position should be somewhere central, e.g. the kitchen, rather than in the area

where the Room sensors are installed. Setting it to Ch 0 means that times and temperatures are

set on the WLCT for the group, but that the WLCT will not control a specific output itself.

Channels 1..14:

A Room sensor set for channel 1 will activate the thermal actuator connected to output 1 on

the master. If several Room sensors are set to the same channel number, they will control in the

following way,

- The actual room temperature is calculated as an average.

- The room temperature set point is calculated as an average.

- If a limit sensor is connected to the Room sensors

The lowest value of any Limit sensor is taken as the MIN Limit Temperature.

The highest value of any Limit sensor is taken as the Max Limit Temperature.

Channel 15 (position F on the switch) Party and vacation function.

Special function see FUNCTIONALITY.

Page 21

Supply water temperature sensor and mixing valve

p. 21

Supply water temperature limit sensor

This feature is not available on the basic master’s version WLM2-1BA and WLM2-3BA

The limit sensor is directly connected to the master at the terminals marked limit sensor. Sensor

type ETF-1899A must be used.

The temperature sensor should be placed on the supply water pipe to the underfloor heating

system, If a limit sensor is installed, without a weather compensation module (WLOC) the master

will control the maximum water temperature. The factory default setting is 55°C, but this value can

be changed via the display.

If a weather compensation module (WLOC) is added to the system, the master will vary the supply

water temperature setting based on the outdoor temperature. A standard compensation curve

has been programmed at the factory. If needed the curve can be changed, see separate USER

MANUAL, MASTER TYPE WLM2.

Mixing valve actuator control

Control of a mixing valve actuator is possible using the digital masters WLM2-1FS and WLM2-3FS

The actuator must be 24Vac powered (max 6VA) and positioned via the 0-10V DC signal, and

should be configured so that it closes the valve if there is no heating demand (0Vdc signal). The

control signal can be reversed to 10-0V via the master menu system if required.

Control action of the mixing valve actuator is P + I and the parameters can be

changed if required in the master menu system.

Please contact the supplier for further instructions.

Fig 11

WLM underfloor heating controller

Page 22

p. 22

In large buildings with more than 14 zones where

multiple manifolds are utilized, it is possible to use

multiple masters to create a single network.

One master must be defined as the “network

controlling master” by setting both encoders to zero

(see pic).

Subsequent masters (up to nine) should be

connected as a “string”, where they will all use a

common pump.

If more than one pump is used, a separate string

should be created for each pump.

(se drawing below)

On the first string all left hand encoders must be set

to 1, and the right hand encoders should be set in

sequence from 1 to 9.

On the second string of masters all left hand

encoders should be set to 2, and the right hand

encoders again should be set in sequence from 1

to 9.

This numbering can be continued for up to 15

strings.

All masters are interconnected using special cable

via the RJ45 socket 1 or 2.

The last master of the first string must be connected

to the first master of the second string etc. etc.

An FS master can be used as the “network

controlling master” for central mixing control of

supply water and boiler switching.

Switching between cooling and heating can be done

for the whole network on the “network controlling

master” using the WLAC-1 interface module

connected to the thermostat bus.

Creating a Network

INSTRUCTIONS

Page 23

Domestic hot water control:

p. 23

Using cooling functions

In addition to controlling heating, all WLM2 masters have the ability to control the system for cooling.

• To enable the cooling function an interface module WLAC and humidity sensor WLH have to be

connected.

• On BA masters it is also necessary to install a sensor (ETF-1899) on the return water pipework

from the floor for dewpoint control.

• The WLAC must be fixed in a convenient position for the user, and connected to the sensor/

controller bus as shown in the picture (pic).

• If a BMS system in being used for the heating/cooling decision, the volt free BMS signal should

be connected to WLAC but the slider switch on the right side of the WLAC must be set to the

heating position (in this situation the BMS signal has priority and we recommend that the slider

toggle be removed to avoid incorrect overriding)

• By using the humidity sensor WLH the system limits the formation of condensation on floor

surfaces due to high humidity.

• The WLH must be fixed in a room that represents the general humidity level in the building, and

connected to the sensor/controller bus (more than one WLH can be used if necessary e.g. on

separate floors of the building). Where more than one humidity sensor is used, the master will take

the reading of the sensor detecting the highest humidity level for the controlling action.

• If a dehumidifier is being used it can be connected via a relay using number 1 output on the master

and setting DIP-7 to “on”.

(Note: This output gives either 24Vac or 230Vac depending on the WLM2 master type. Channel

number 1 cannot be used for Room controller control in this situation)

• When cooling is enabled the cooling set point will be pre-determined by the master and will

override any settings in any Room controller to ensure optimum energy efficiency.

(The cooling set point will be +3C above the master day set point)

It is possible to control the domestic hot water temperature with a special Room controller (WLCT/

HW)to ensure optimum energy saving.

A hot water sensor is connected to the Room controller and measures the temperature in the storage

cylinder.

A zone valve is then controlled via the WLM2 master, which in turn activates the boiler on demand.

• Install the hot water senser (ETF) on the hot water take off pipe immediately above the storage

cylinder. Use the fixing strap to mount it tight to the surface.

• The WLCT/HW must be fixed in convenient position for the user

• Connect the hot water controller WLCT2/HW to the WLM2 master using the sensor/controller bus.

Creating a Network

Page 24

p. 24

• Connect the hot water sensor to the controllers sensor terminals.

• Connect the hot water zone valve to an output on the WLM master and set the channel number

on the hot water controller to the corresponding number.

Note: When the WLCT/HW calls for heat it does not start the circulation pump on the under floor

heating system

Radiator control:

It is possible to control a radiator circuit room temperature with a special Room controller (WLCT/R) to

ensure optimum energy saving.

The Room controller measures the temperature in the room, and a zone valve is then controlled via the

WLM master, which in turn activates the boiler on demand.

• The WLCT/R must be fixed in a convenient position for the user, but which is representative

of the room or area temperature.

• Connect the Room controller to the WLM master using the sensor/controller bus.

• Connect the radiator zone valve to an output on the WLM master and set the channel number

on the Room controller to the corresponding number.

Note: When the WLCT/R calls for heat it does not start the circulation pump on the under floor heating

system

2 step heating:

It is possible to control a of a secondary heat source in a room (e.g. a backup radiator), use the

spesial mode in the WLCT/2 Room controller. In addition to the primary underfloor heating output,

this WLCT/2 room controller is able to control a second output as a boost function, witch will be

activated only if the temperature cannot be schieved by the underfloor heating within a preset time

period.

• The WLCT/2 must be fixed in a convenient position for the user, but which is representative of the

room or area temperature.

• Connect the Room controller to the WLM master using the sensor/controller bus.

• Set the channel number on Room controller to correspond with the output on the WLM master that

is connected to the underfloor heating actuator.

• The next numerical output on the WLM master MUST be used for the secondary/boost function.

Note: To avoid overloading the WLM master, we recommend that the secondary output is used as a

signalling function for a remote relay.

Please refer to the technical information.

Page 25

1234566

23˚C

Max.

Supply temp.

BR965A30b

p. 25

Commissioning mode:

Digital masters include a special “commissioning mode”, which allows the temperature of the supply

water to be controlled to assist the drying out of a newly laid concrete floor.

To start this function:

• Set DIP-4 to “on”.

• This will set the supply water temperature at 23c for three days and will fully open all the manifold

actuators.

• Then for a further four days the water will be supplied at the maximum supply water temperature,

as set in the WLM master menu, and during this period the manifold actuators will remain fully open.

• When the WLM master is operating the commissioning function this is indicated by the output

LED’s flashing in rotation and with the word “commissioning” flashing in the display.

• The commissioning function time periods are paused if the power supply is interrupted.

• Should you need to restart the commissioning from the beginning, switch DIP-4 to “OFF” and

back to “ON”.

• To de-activate the function switch DIP-4 to “OFF”.

Note: This function conforms to BS/EN-1264 part 4.

Replacing equipment:

Replacing a faulty sensor/controller:

1. Identify the sensor/controller to be changed by the blinking output LED.

2. Switch OFF power to the master

3. Change the sensor/controller.

4. Switch ON power to the master

5. Set the master into lear nmode and set DIP-3 to ON.

6. On wireless sensor/controller now press the button on the sensor/controller.

On hardwired sensor/controller go to step 7.

7. Check that the corresponding output LED has changed from blinking to permanently ON.

8. Reset the DIP-3 to OFF.

For any other changes in the system use the quick guide and start the install sequence from the

beginning.

Creating a Network

Page 26

p. 26

Guidelines and Special Features

POWER UP RECOMMENDATIONS

When all connections are complete, we recommend to use the quick guide, setting up system.

System check:

Correct operation of the system can be checked using a special “Install Mode”.

This enables the installer to individually test and prove each output.

Testing the system:

1. Switch on DIP-3 to activate learn mode: - power light will blink quickly

2. Each red channel light on the master should now be lit if a sensor/controller is present on that

channel.

3. Switch off DIP-3 to de-activate learn mode again – power light stops blinking.

4. Turn all adjustable temperature settings on the sensor/controller to minimum.

5. Switch on DIP-1 on the master to activate install mode (Install mode will be active for 2 hours).

(Pumps, boiler, mixing valve and actuators should now be off)

6. Turn the temperature setting on the adjustable sensor/controller in room 1 to maximum.

The red channel 1 light should be lit and the actuator on output nr. 1 will be activated, and will

open after 1-3 minutes, depending on the type of actuator.

Important: If the sensor/controller is of a wireless type a delay of up to 5 minutes may occur before

the channel light becomes illuminated .

7. Check that the UHF pump is running and the mixing valve (only FS master) opens .

8. Repeat step 2 on all rooms.

9. Boiler test function:

Switch on DIP-2.

This closes the boiler start relay contacts for 1 minute.

10. To end all tests:

- Switch off DIP-1 to deactivate Install mode

- Switch off DIP-2 to deactivate boiler test.

- Set all temperature knobs to default positions

Room sensors (WLTA, WLTD, WLTM, WLTP) to zero (center position).

Room controllers (WLCT) recommended to 21c.

- Set all override switches on WLTM and WLTD room sensors to automatic position

(clock symbol).

The system is now operating automatically.

Page 27

SettingsMaster

BA/FS

FS

House temperature

Night temperature

Off temperature

Floor Limit temp high

Floor Limit temp low

Max water temperature

Weather compensation

Cold (winter)

Weather compensation

Warm (summer)

Outdoor temperature

water temperature

Outdoor temperature

water temperature

Factory setting Own settings

-3˚C

45˚C

25˚C

30˚C

21˚C

18˚C

5˚C

27˚C

17˚C

55˚C

Factory Default Settings:

p. 27

Creating a Network

Page 28

p. 28

During normal operation the green power LED will be ON when the master control is energised. The red output Channel LED’s

(1 to 8 on the master, and 9 to 14 on the add-on module) will indicate if the channel output relay is ON/OFF.

An error / fault message is shown by flashing the green power LED or one of the 8 red output Channel LED’s. From the number of flashes

on any one LED, the problem can be diagnosed, and identified from the following:

The error number will be indicated by the number of flashes, with a pause of less than a 1/2 second between the flashes. The indication will be followed

by a pause of 2 seconds, following which the sequence will be repeated. The failure code can also be seen in the service menu on WLM-FS MASTERS

(submenu 2).

Flashing Power LED (green)

E1, 1 flash One or more room sensors, room controllers, WLH, WLAC that are set to channel 0 or channel 15 are no longer sending data

to the master control. The fault is corrected by replacing the room sensor. The master will need to be HARD RESET (see below)

(NOTE: If the room sensor is of the WIRELESS type, the error/fault message could be an indication that the power has failed,

and that the internal battery of the room sensor needs to be replaced)

E2, 2 flashes One or more room sensors have been set to a channel number which does not exist in the system. For example, the message

will occur if the units are set to channels 9-14 and the required add on (AO) module are not found in the system. The error is

corrected by setting the channel number of the room sensor to a channel that does exist within the installed master/add on

module system.

E3, 3 flashes Application sensor defect. The fault is corrected by changing the temperature sensor. If the sensor has been removed deliberately to

change the operation of the system, follow the HARD RESET instruction below.

E4, 4 flashes The outdoor compensation module (WLOC) is defective. The fault is corrected by changing the outdoor compensation module.

If the module has been removed deliberately to change the operation of the system, follow the HARD RESET instruction below.

E5, 5 flashes The external Supply limit sensor (type ETF-1899A) is defective. The fault is corrected by changing the temperature sensor. If the

sensor has been removed deliberately to change the operation of the system, follow the HARD RESET instruction below.

E6, 6 flashes Internal overheating. The master has its own internal safety temperature protection system. The problem is corrected by

improving the ventilation around the master module.

E7, 7 flashes Defective internal overheat sensor. The Master will control as normal, however the protection against internal over heating is no

longer active. The fault can only be corrected by replacing the master module.

E8, 8 flashes The communication to the AO module has been lost. The fault is corrected by re-establishing the connection to the AO module

or by changing the AO module if it is defective - or if it has been deliberately removed, with a HARD RESET.

E9, 9 flashes Indicates total number of input units exceeded. Please refer to factory or your local service engineer.

E10, 10 flashes No connection to wireless receiver, type WLRC-19.

E11, 11 flashes Step 2 on 2-step controller (WLCT-X9/2) is used by another room sensor/controller.

Only one error/fault condition can be shown at a time. If more than one error occurs, they will be prioritised in the shown sequence (E1, 2, 3…).

Error Indication

Page 29

p. 29

Flashing output LED (red):

The appropriate output channel LED can flash, indicating that the room sensor or room contoller on that channel has a fault/error. The failure code can

also be seen in the service menu (submenu 2a).

E1, 1 flash The master has lost communication to the room sensor. The fault is corrected by re-establishing the connection to the Room

Sensor and the fault condition will be automatically reset once correct communication is resumed. If the room sensor is

defective and has to be changed, or if it has been deliberately removed, it is necessary to make a HARD RESET. (NOTE: If the

room sensor is of the WIRELESS type, the error/fault message could be an indication that the power has failed, and that the

internal battery of the room sensor needs to be replaced)

E2, 2 flashes The internal sensor in the room sensor/controller is defective. The fault can only be corrected by replacing the room sensor/

Controller. Remember to make a HARD RESET after installing the new room sensor/controller.

E3, 3 flashes The limit sensor on the room sensor/controller is defective. Replace the faulty sensor. Reset is NOT required.

E4, 4 flashes Defective WLCT room controller. If a room controller operating a group of room sensors becomes defective, the remaining

room sensors will continue control within the maximum and minimum limits programmed into the Room controller.

E5, 5 flashes Two or more room controllers are trying to control this output. Check “AREA” setting on the room controllers.

RESET

There are 2 different reset actions that can be used.

RESET

If the ‘

✓’ button is pressed for 5 seconds, a HARD RESET will be initiated. (Indicated by all the red output LED’s(1-8) lighting in sequence). This reset

will remove from the system any room sensor unit with a defective input sensor, or a defective AO module. The fault message will be reset but the

defective items will no longer participate in the system. Once a defective unit is replaced, the new unit will automatically be recognised by the master

control and become part of the system. To erase the identity of the defective component from the master memory a HARD RESET must be performed

Hard resets do not alter the temperature settings already programmed into the master control.

FACTORY RESET

If the (

✓ ) button is pressed for more than 15 seconds, a total factory reset will be initiated. This is indicated through flashes of channel LEDs 1,3, 5

and 7 alternating with channel LEDs 2, 4, 6 and 8 (while the “

✓” button is pressed).

A factory reset will put all programmed temperature settings back to the factory defaults. It will also remove all room sensors/Controllers from the

master memory, and reset the system to accept only those room sensors/Controllers that are functioning correctly.

DEFAULT SETTINGS & SPECIAL FUNCTIONS

The master control has the following default temperature settings:

For the master with display, the setpoints can be altered on the display

DAY SETPOINT 21°C

NIGHT SETPOINT 18°C

OFF (FROST PROTECTION) SETPOINT 5°C

MAX LIMIT 27°C

MIN LIMIT 17°C

MAX SUPPLY WATER TEMP 55°C

WLM underfloor heating controller

Page 30

p. 30

Each Room sensor with manual adjustment is capable of increasing or decreasing the preset DAY & NIGHT setpoints on the master by +/- 4C for

the heating zone which it is controlling.

The Room controller WLCT has its own DAY & NIGHT temperature settings that can be set separately, and if manual Room sensors are attached to

its ”group” these will operate to the same settings as the WLCT, but still with the possibility of local ±4°C adjustment.

CHANNEL 15 OPERATION

It is possible to override all the automatic functions of the master control, and the Room controllers with a single function. This action is used for

holiday periods (e.g. to set the whole system under a frost protection mode), or to temporarily override all the temperature control of the system.

It is achieved by using the any WLTM Room sensor, as this has the override selector. If the cover is removed and the channel selector is set to F

(channel 15), that Room sensor will cease to operate its own output channel but will instead operate all the output channels of the system.

Using the WLTM Room sensor, the slide selector on the right side can be used for as follows:

Auto will allow the whole system to operate to the automatic settings.

DAY will keep the whole system working to the DAY Setpoint, but only for those Room sensors that are set for auto.

NIGHT will keep the whole system working to the NIGHT Setpoint, but only for those Room sensors that are set for either auto or day.

OFF will turn the whole system OFF, but still under a frost protection level of 5°C

NIGHT SETBACK (see also EXTERNAL SWITCH)

The external switch or timer function on the master module allows the whole system to be changed from the DAY Setpoint to the NIGHT Setpoint.

The external switch must have volt free contacts that are OPEN for NIGHT Setpoint, and CLOSED for DAY Setpoint. The factory fitted link wire is

removed when a remote switch/timer is used.

If a WLCT Room controller is employed in a part of the system, the external switch action of going to NIGHT Setpoint will override the Room

controller.

Emergency program for room control

- If a Room sensor/controller is defective or if the communication to the unit is interrupted, an alarm will be triggered. Depending on the system

configuration the regulation will continue in one of the following ways,

- If there are several units on the same channel which have a room sensor (which is still intact), the regulation will continue as before, however

without contribution from the defective unit

- If no valid room sensor/controller is found, the system will run at constantly 20% ON

- If an outdoor sensor is connected, the system will run 40% at 10°C (and Below) decreasing to 0% at 20°C (and above).

The emergency program is only valid for channels with heat control. Channels with cooling control will always run at 100% OFF in connection with

a defective room sensor.

Emergency program for supply limit sensor

- If the supply limit sensor is deffective, the system will run at constantly 20% on for the valve.

- If an outdoor sensor is connected, the system will run 40% at 10°C (and Below) decreasing to 0% at 20°C (and above).

Exercise of valves

If no automatic on/off sequence of valves or pumps occurs over a 72 hour period, an exercise of these components will take place. The actuators

will be activated for 3 minutes. The pumps will be started for 10 secs during that period, and the mixing valve, if fitted will be opened and closed.

Page 31

p. 31

Add On Module

Each master module is capable of controlling 8 heating zones, each of which may use one or more

loops of piping, with one or more thermal actuators. These zones are referred to as channels 1 to

8. If you wish to control more than 8 zones, it is necessary to install an ADD ON (AO)

modules, each of which can provide another 6 outputs.

The first AO module then controls channels 9 to 14,

Connection of master and add on module

Connect the AO-module, using the special cable included in the box.

Mains supply from 230V fused isolator

INSTRUCTIONS

Add ON module

Configuring the Total System

Page 32

p. 32

Outdoor Compensation Module- Type WLOC-19

Introduction

The masters WLM2-1FS and WLM2-3FS are supplied already prepared for weather compensation

and simply by adding the outdoor compensation module on the 2-wire bus and using the water

temperature sensor on the supply water side, you have a control system for weather compensation.

Preset values are programmed at the factory, but these values can easily be adjusted according to

local needs via the display on the master. See the user manual ”Master with display type WLM” for

changing of the default factory settings

Mounting

The outdoor compensation module is mounted under the roof eaves, alternative 2-3 m above ground

level. Direct sunlight or any other direct heating source such as air ventilation must be avoided. The

outdoor compensation module is mounted vertically with the cable entry downwards.

BUS CONNECTION - Outdoor Compensation Module

Only OJ Outdoor Compensation Modules type WLOC-19 that are prepared for 2 wire

communication can be used.

Standard installation cable, minimum 2 x0.25 mm2 can be used. The outdoor compensation module

can be connected in the conventional star wiring format, or in a bus connected mode (Daisy chain).

The master has 4 sets of terminals marked Room sensor BUS that can be used for connecting the

2-wire signal from the Room sensors and the outdoor compensation module.

There are 4 identical sets of terminals for convenient installation. Any Room sensor / outdoor

compensation module can be connected to any pair of terminals. The total length of the 2-wire

system can be up to 300 m with a maximum length of 100 m between any 2 Room sensors / outdoor

compensation module. Remember to connect + to + and - to -.

Outdoor Compensation Module- Type WLOC-19

INSTRUCTIONS

Interconnection of WLM2 products:

For easy installation, interconnections between master modules, master and add on modules, and

master and wireless receivers, are made by pre-wired plug in connectors (RJ45) For connecting

WLM2 add on modules to WLM2 masters, a plug in connector is provided with the add on module.

A WLRC wireless receiver is also connected to a WLM2 master, using the plug in connector provided

with the receiver.

For connecting a WLM2 master to another master, a plug in connector kit is available.

Page 33

p. 33

Do not place the receiver inside a metal box. In case of communication problems it may be necessary

to move the location of the receiver, or to add an additional receiver.

The receiver is connected to the master or the add on module using the included cable.

Max distance between the master/add on module and receiver is 3 m. Up to 5 receivers can be

connected. The wiring of the master, add on module and receiver can be made in either a daisy

chain or in parallel.

WLRC-19 Receiver

Connect the receiver to the master, and the system will reconfigure itself for wireless operation.

Technical Data

Supply Voltage . . . . . . . . . . . . . . 24 V from Master

Distance to master . . . . . . . . . . . . . . . . . . Max 3 m

Enclosure . . . . . . . .... . . . . . . . . . . . . . . . . . . IP 21

Ambient temperature range . . . . . . . . . . 0 to 40°C

Communication Frequency . . . . . . . . . . . 868 MHz

Communication distance . . . . . Up to 30 m inside,

. . . . . . . . . . . . . . . . . . . . . . . . Up to 100 m outside

See Quickguide

Waterline Wireless System

Waterline Wireless System

Product Programme

Connection of Master and Receiver

Position

Master

To set up the system

INSTRUCTIONS

B A -- +

Blue Red Brown Yellow

Page 34

F:E:

B:

C:

D:

A:

Pin button

adjust of

clock

Reset to

factory

setting

Adjustment

down

OK accept

Adjustment

up

Display

p. 34

INSTRUCTIONS

The room controller type WLCT is part of the underfloor heating system type WLM. The room controller

can be set to control one single room, or it can be set as a master to control a group of room sensors

(rooms/zones). Here after referred to as area.

All the room sensors that are part of that area will follow the times and temperatures programmed into

the room controller. For example, if the temperature programmed in the room controller is 22˚C, all the

room sensors (rooms) belonging to that area will then also be controlled at 22˚C. Depending on the types

of room sensors used you can adjust the temperature + or -4˚C in different rooms, giving a possible room

setpoint of +18 to +26˚C.

The room controller can be programmed to work at different temperatures during the day allowing lower

temperatures during times that the room is unoccupied. Lower temperatures will lower your energy

costs without reducing the comfort. All room sensors that are part of the area will follow any new time or

temperatures programmed in the room controller.

When it leaves the factory, the room controller has a preset program suitable for most installations. You

only need to set the clock and day, and define the room sensors (rooms) that should belong to the area.

The room controller has a pin button marked R (see fig. 1), allowing you, at any time, to reset the room

controller to the factory settings. These are listed at the end of this manual with space for you to record

your own weekly schedule.

Introduction

Getting Started

Buttons

Fig1

Type WLCT

Page 35

K

I

G

H

J

G: H: I:

J:

K:

Automatic

mode

Manual

mode

Time and

temperature

Day number 4-event symbol

Wake

Night

Out

Home

g

☞

☞

☞

1-7

Press the UP ( ) or DOWN ( ) buttons to select

the correct hours and press OK button ( ).

Press the UP ( ) or DOWN ( ) buttons to select

the correct minutes and press OK button ( ).

Then press the UP ( ) or DOWN ( ) button to

select the correct day and press OK ( ) button.

First time power is connected the clock and day will be flashing and must be set. If you need to

adjust the time of the thermostat at a later date, insert a pin into the hole marked (see fig. 1)

for setting of time and day. Adjustment should be made for change in summer and winter time.

p. 35

Display

Setting the room controller into operation

AREA SETUP - see page 40

Type WLCT

Page 36

Sleep

Return

Leave

home

Wake up

p. 36

4-event clock mode/

automatic mode:

Comfort mode:

Manual mode:

Temporary override

To temporarily override any temperature in the 4-event schedule program, press the UP ( ) button once, to show

the temperature in the display, and press UP ( ) or DOWN ( ) again to increase or decrease the temperature.

The display will flash for 5 seconds, and will then revert to the time. The override will operate until the next

programmed event when the thermostat will resume the automatic programme.

In automatic mode, the clock function symbol ( ) and one of the 4-event symbols ( ) will be

indicated. Programming page 17.

Cancel comfort mode (temporary override)

To cancel the temporary override, press the OK ( ) button twice.

Permanent override:

During holidays, the scheduled 4-event program can be overridden.

Press the OK ( ) button, and then the UP ( ) or DOWN ( ) button until the override temperature is set. The set

temperature will remain in the display and the unit will now operate to this temperature permanently.

Cancel manual mode

To cancel the permanent override state press the OK ( ) button once, and the unit will resume automatic function.

5 secs.

Daily Use of the room sensor

4-Event Clock Mode

The day has been split into 4 events describing a typical day. When the room

sensor is in this 4-event mode it will change the temperature to the required level

automatically at the programmed times. As standard the room sensor has 5 days

with 4 events (two ON’s and two OFF’s), and 2 days with 2 events (one ON and one

OFF). For programming see page 17. Please, see page 18 - PRO - 4-event sequence

to alter the daily event sequence.

Page 37

Press OK ( ) button for 3 secs. to begin programming

: Time and temperature

: Time and temperature

: Time and temperature

: Time and temperature

Day 1 - 5

Day 6 - 7

: Time and temperature

: Time and temperature

p. 37

Programming 4-Event Clock Time and Temperature

For each event, the start time and required temperature needs

to be set.

For example, in the morning you wish the heating to start at

07:00 and the temperature to rise to 25˚C. Press OK (

✓

) button

for 3 seconds and the start time is displayed. Change this to

07:00 with the UP (

▲ ) or DOWN ( ▼ ) button. Press OK (

✓

) to

confirm.

The temperature is now displayed. Change this to 25˚C with the

UP (

▲ ) or DOWN ( ▼ ) button. Press OK (

✓

) button to confirm.

This action can now be repeated for the second, third and

fourth event.

These settings will be valid for days 1-5 showing on the display.

To program the days 6 and 7, repeat the above. Days 6 and 7

are usually Saturday and Sunday, and only have two events

(generally morning ON and evening OFF).

The temperature can be set within the range of +5 to +35˚C.

It is also possible to select the heating OFF at that event by

reducing the setting to 5˚C, and then pressing the (

▼ ) once

more.

Note that when programming the “Sleep” time (event 4),

please ensure that this time is before midnight (00:00).

Type WLCT

Page 38

INFO - Information

The values of the actual measured room temperature and the floor temperature can be seen.

The floor temperature is only shown if a floor sensor is installed.

PRO - 4-event sequence

It is possible to change the factory event sequence of Days 1-5 - 4 event, and days 6 & 7 – 2 event. Days 1 to 5 are usually Monday to

Friday, whilst days 6 & 7 are usually Saturday & Sunday. An EVENT is either an ON or an OFF operation. You can select from the

following sequences which are displayed in the form of a code.

4 events 5 days, 2 events 2 days indicated by Code 4:52

4 events 6 days, 2 events 1 days indicated by Code 4:61

07:4edoCybdetacidnisyad7stneve4

07:2edoCybdetacidnisyad7stneve2

2 events 5 days, 2 event 2 days indicated by Code 2:52

Select the required sequence with the OK ( ) button.

Press both UP ( ) and DOWN ( ) buttons together for 3 seconds. INFO is displayed.

Continue pressing the UP( ) button until you reach one of the desired sub menus, PRO, Hi Li, Scal, and ArEA (For explanations, see

below. Select the sub menu with the OK ( ) button.

Press UP ( ) or DOWN ( ) button to show the different

readouts.

No changes can be made here. Use the OK ( ) button to end.

Software version

Room temperature

Floor temperature

p. 38

Advanced Settings and Read-out

Page 39

Hi Li - Floor sensor. Max and min allowed temperature of the floor surface

A limit sensor can be connected to the room controller.

Max limitation is used for safety to prevent high floor temperatures. For example wooden floor constructions which should not be

allowed to exceed a maximum of 27˚C. The value can be set from 5˚C up to 55˚C. The value can also be set to OFF (adjust the

temperature to 55˚C and push button up once more).

Low limitation is used where the temperature of the floor is required never to fall below the minimum set temperature. Example in

kitchens or bathrooms with tiles. The value can be set from 5˚C up to 55˚C. The value can also be set to OFF (adjust the

temperature to 5˚C and push button down once more). Remember the max limit temperature must be set higher than the min limit

temperature.

The limit temperatures defined in the room controller will be valid for all the room sensors with limit sensor (type WLTD-19) which

are part of the area allocated to the WLCT unit.

SCAL - Time and temperature scale selection

The maximum allowable floor temperature setting is shown. Use

the UP ( ) or DOWN ( ) button to increase or reduce, and OK

( ) button to accept.

The display will now show LoLi. Press OK ( ) button to continue.

The minimum allowable floor temperature setting. Use the UP ( )

or DOWN ( ) button to increase or reduce and OK ( ) button to

accept.

You can select either ˚C or ˚F scale, and 12 or 24 hour clock as

follows:

Press UP ( ) or DOWN ( ) button to change settings. Confirm

the required scale with the OK button ( ) button.

Adaptive function

This function enables the thermostat to calculate when it needs to switch ON so that the required temperature is reached at the set

time. With a start time of 07:00 therefore, the thermostat may switch ON as early as 06:00 so that the desired temperature of 25˚C is

achieved by 07:00. Without this function set, the thermostat will start to heat at the time you set.

}

Press the DOWN ( ) button to switch between on and off.

Press OK ( ) button to confirm.

p. 39

Type WLCT

Page 40

Set the Channels / Rooms (Ch) to ON if they should follow the

settings of this clock thermostat.

In total 14 channels / rooms can be controlled.

Press OK ( ) button to end programming and to return to

scheduled programme.

ESC - Escape

To do this, enter the ArEA sub menu., and press OK ( ) button. CH 1 will be displayed; use the OK ( ) button and then the UP ( )

ArEA - (Group of rooms)

The rooms that are to be set as part of the WLCT area will follow the temperature settings of the room controller

example, an area could be the living room kitchen, and children’s rooms having a high room temperature during afternoon and ear

evening, and a lower temperature during the early part of the day and at night. Each room sensor will have a channel number,

designated CH1, CH2 etc. The appropriate channel number of any room sensor is determined by the numbered output on the master

control which is actually switching the valve/actuator for that area.

For example, a system may have the kitchen room sensor operating master output # 4, and the childrens room sensor operating

master output #5. If the WLCT room controller is then situated in the living room, and operating output #1, then the WLCT need

be programmed to control outputs 1, 4, & 5. ( Each room sensor will have been set to operate its appropriate output ch

see separate instructions).

button to change the setting to ON. Press OK ( ) and CH 2 is displayed. Use the UP ( ) button until CH4 is displayed, press OK ( ),

and change to ON. Repeat this for CH 5. All three room sensors will now operate under the control of the WLCT room controller.

In total up to 14 Channels can be programmed in this way, and it is possible to have more than a single room controller, each

own sub room sensors operating to its schedule and temperatures.

p. 40p. 40

Page 41

Press the pin button R for 3 secs. and the thermostat returns to

factory settings.

Remember to set time, day and area.

4-event time and temperature

Day 1-5

06:00

Time Temperature

08:00

16:00

22:30

08:00

23:00

27˚C

4:524-event sequence

Day 6-7

21˚C

19˚C

22˚C

17˚C

22˚C

17˚C

Factory settings

Factory reset:

High limit

temperature

Low limit

temperature

Scale

17˚C

24H,˚C

p. 41

Reset to fatctory Settings - room controllers

Type WLCT

Page 42

p. 42

Introduction

Product programme

WLTP-19/29 Room sensor tamper proof

WLTA-19/29 Room sensor with adjustment

WLTM-19/29 Room sensor with adjustment and mode switch Auto, Day, Night, OFF

WLTD-19/29 Room sensor with adjustment, mode switch Auto, Day, Night, OFF and limit sensor

WLCT2-19/29 Room controller with 4-event clock

Mounting of Room sensor fig. 2

The Room sensor is used for comfort temperature control in rooms. The Room sensor is mounted

on an internal wall with free air circulation about 1.6 m above the floor. Draught, direct sunlight, or

any other direct heating source must be avoided.

Wired Room sensors

Only OJ Room sensors type WLxx that are suitable for 2 wire communication can be used.

Standard installation cable, minimum 2 x 0.25 mm2 can be used. The Room sensors can be

connected in the conventional star wiring format, or in a bus connected mode (Daisy

chain). The master has 3 sets of terminals marked Room sensor BUS that can be used

for connecting the 2-wire signal from the Room sensors. There are 3 identical sets of

terminals for convenient installation. Any Room sensor can be connected to any pair of

terminals. The total length of the 2-wire system can be up to 300 m with a maximum length of

100 m between any 2 Room sensors. Remember to connect + to + and – to – .

Wireless Room sensors

Insert batteries.

Waterline Room sensors

INSTRUCTIONS

Room sensors connected

in chain (Daisy Chain)

Room sensors

connected in star

Fig.1

Fig.2

Page 43

Button learning mode

Fig 3

p. 43

Set-up

Setting up which Room sensor should work with which thermal actuator

Each Room sensor can be selected to operate a specific output which in turn controls the thermal

actuators on the manifold. Under the front cover of the Room sensor, a selector can be accessed,

and the number of its output (its CH channel) can be set with a screwdriver. Up to 14 channels can be

set on the selector, and there are two auxiliary channels with special functions. A WLM master has 8

outputs and additional slave modules each with 6 outputs can be connected creating a system of 14

individual zones.

Please note that channels 10 to 14 are marked as A through E on the selector.

A Room sensor set for CH1 will activate the thermal actuator connected to output 1 on the master.

The channel number can be selected without any power connected to the system. The channel of the

Room sensor can be changed afterwards if needed. If two Room sensors are placed in the same

room and set to the same channel, the temperature control will work according to the average

temperature of both Room sensors.

Channel 0:

Each Room sensor is delivered with the switch in position 0 ensuring that it must be set to operate

correctly. Channel 0 can also be used for a Room controller controlling a group of Room sensors

where the control position could be somewhere central, e.g. the kitchen, rather than in the area where

the Room sensors are installed. Setting it to Ch 0 means that times and temperatures are set on the

WLCT for the group, but that the WLCT will not control a specific output itself.

Channel 15 (F):

Special function. Further instructions in the user manual.

To set the Room sensors into learning mode

Standard Room sensors without display: Remove the front cover and push the little leaning mode

button for approx. 2 sec until the Room sensor give a little “bib”

Room controller with display: Press the clock symbol for 2 sec until it says “init”

The Room sensors will now transmit its unique code in the next 30 seconds, and the system has

been set up.

To set up the system for the Master to receive signals from the Room sensors.

(Wireless only)

To set the master into learning mode set DIP-X to “on”.

The master will now look for new Room sensors that also are in learning mode. Remember to set

DIP-X back to “off”...RF LEARNINGMODE.. will be shown in the masters with display.

Waterlilne Room sensors

Page 44

Fig. 3

p. 44

Setting of Room sensor Operating Mode

Setting of Room Temperature

If the WLTM-19 or WLTD-19 Room sensor has been allocated to a WLCT controlled area, then when

AUTOMATIC mode has been chosen with the built-in slide switch, the temperature settings will be as

programmed in the WLCT Room controller and not in the master, but the same local ±4°C adjustment

is available.

On the Master WLM2-1FS and WLM2-3FS, if the temperature setting is changed, then the default

temperature for all the rooms is changed, but each WLTA, WLTM or WLTD Room sensor is locally

adjustable with its own adjustment knob. With this knob the temperature setting from the Master can

be increased or decreased by 4°C for that specific room.

The master is supplied with default temperature settings which are used by all non Room sensors

that are connected to the system. In Master WLM2-1BA & WLM2-3BA, the DAY temperature setting

is fixed at 21°C and the NIGHT temperature is fixed at 15°C.

In Master WLM2-1FS & WLM2-3FS, the DAY, NIGHT and OFF default temperatures are adjustable

through the display.

Automatic switching between DAY and NIGHT temperatures is done by either connecting a separate

timing device to the master, or using a WLCT Room controller and allocating other Room sensors as

part of its group. It is possible to have two or more Room controllers in the system, with each one

having its own group of non Room controllers.

Room sensors type WLTM-19/29 and WLTD-19/29 have a slide switch (see fig. 4) for selecting the mode

of operation of the controller. Four different modes can be selected: Auto, Day, Night and OFF.

Auto: The controller will follow the temperature settings of the master, or if the Room sensors

belongs to a zone group using a WLCT Room controller, it will follow the automatic sequence of

temperatures and timings set in the WLCT.

Day: It will control the room temperature according to the (DAY) setting defined in the master

(typically 21°C).

Night: It will control the room temperature according to the (NIGHT) setting defined in the master

(typically 17°C).

OFF: It will control the room temperature according to the (OFF) setting defined in the master

(typically 5°C). This setting is intended to be a ”frost protection” mode and is used if the room is

to be left unoccupied for long periods.