Page 1

INSTRUCTIONS

Type PTH

57433B 03/14 (OSH)

English

PTH is a series of electronic pressure transmitters designed primarily to measure total and

differential air pressures in ventilation systems.

The resulting measurements are used for

monitoring, control and regulation purposes via

a regulator, PLC or monitoring system. The resulting measurements are used for monitoring,

control and regulation purposes via a regulator,

PLC or monitoring system.

Typical applications include:

- The maintenance/control of constant pressure

at a given position within the duct system.

- The maintenance/control of desired underpressure within the duct system.

- The measurement of pressure differentials

across filters to determine optimum filter

replacement time.

- Flow determination via differential pressure

measurements across a standard aperture.

PRODUCT PROGRAMME

Type Product

PTH-3202 Pressure transmitter,

0-2500 Pa, 1 channel, IP54

FUNCTION

PTH is a pressure transmitter for comfort

ventilation systems. It provides an active current

or voltage signal proportional to the measured

air pressure. PTH consists of semiconductor elements. There is no air throughput and

the unit is thus protected against dust in the

ventilation system. The pressure element is

temperature compensated to provide accurate

pressure measurement throughout the specified

temperature range.

The required measuring range of the pressure transmitter is set with DIP switches. The

output signal can be changed from voltage

[V] to current [mA] by setting a jumper. A DIP

switch allows two different damping times to be

selected so that pressure fluctuations within the

ventilation system are attenuated in the transmitter output signal. A green LED indicates that

supply voltage has been connected correctly.

If the actual pressure is outside the selected

measuring range, the green LED flashes.

CE MARKING

OJ Electronics A/S hereby declares that the

product is manufactured in accordance with

Council Directive 92/31/EEC on electromagnetic compatibility (and subsequent amendments)

and Council Directive 73/23/EEC on electrical

equipment designed for use within certain

voltage limits.

Applied standards

EN 61000-6-2 and EN 61000-6-3

Electromagnetic compatibility (EMC)

TECHNICAL DATA

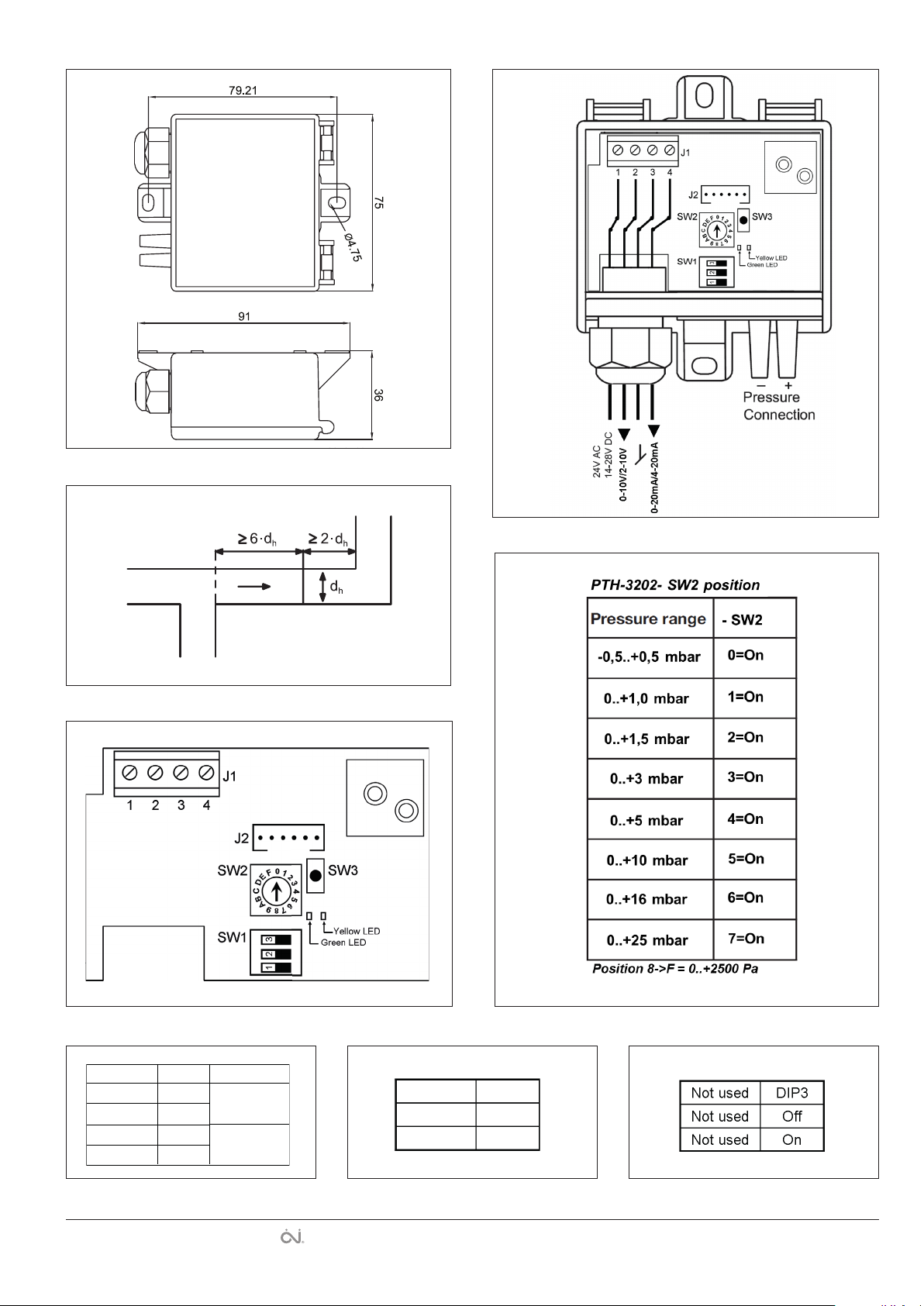

Full scale pressure range PTH-3202 / 0-2500 Pa

Pressure ranges ................ PTH-3202 (see fig. 5)

Supply voltage ............24 V AC ±15%, 50/60 Hz

13.5-28 V DC

Own consumption (-20/+40°C) ...... max. 0,5 VA

Output signal (selectable) ................. 0-10 V DC,

2-10 V DC

4-20 mA, 0-20 mA

Accuracy output signal ........................................

1.5 %xMV+0.3 %xSR+2.5 Pa

(MV = measured value / SR = set measuring range)

Dampening (selectable) ................. 0.4 s or 10 s

Max. pressure .......................................... 20 kPa

Ambient temperature ......................... -20/+40 °C

(constant operation)

-30/+50 °C (transient)

Dimensions .............75 x 36 x 91 mm (see fig. 1)

Cable dimensions ................. 4 x max. 1.5 mm2

Pressure connector ........................ 2 x ø6.2 mm

Enclosure ..................................................... IP54

MOUNTING

PTH must be securely mounted on a level surface using screws. PTH is insensitive to mounting

orientation. However, in order to maintain the

specified enclosure, tubes should be attached

to both tube connectors if the connectors point

upwards. The enclosure is equipped with screw

holes, see fig. 1.

Pressure is connected by means of tubes.

The higher pressure must be connected to the

“+ connector” and the lower pressure to the

“- connector”. If the tubes are unintentionally exchanged, or the pressure is outside the

measuring range, the green LED flashes. See

table 1. The pressure tubes must be as short

as possible and must be secured in position to

prevent vibration. To obtain the best possible

results, pressure must be measured where

there is least risk of turbulence, i.e. in the centre

of the ventilation duct and at a suitable distance

from bends and branches. See fig. 2.

The enclosure is opened without the use of

tools by pressing the snap lock at the side of

the connectors. The transmitter cable may be

up to 50 m in length and must be connected as

shown in fig. 3. The transmitter cable must be

kept separate from mains-carrying cables as

voltage signals from these may affect transmitter function.

SETTINGS

Pressure range is set by turning the dial, SW2

(see fig. 3)

PTH types in this product series, pressure range

can be set to 8 different intervals, ranging from

-50/+50 Pa to 0-2500 Pa (see fig. 5).

If the dial is set to values other than the specified positions (0-7), the pressure transmitter will

interpret the setting as position 7 corresponding

to the highest pressure range.

If the pressure transmitter is inadvertently set

to a pressure range lower than the pressure

encountered in the connectors, the green LED

will light constantly (see table 1).

The screw terminals of the pressure transmitter

can provide a 0/2 - 10 V output signal and/or a

0/4 - 20 mA output signal (see fig. 4).

The 0-10 V output signal is provided by terminal

2 with DIP 1 of SW1 in position “Off”.

The 2-10 V output signal is provided by terminal

2 with DIP 1 of SW1 in position “On”.

The 0-20 mA output signal is provided by terminal 4 with DIP 1 of SW1 in position “Off”.

The 4-20 mA output signal is provided by

terminal 4 with DIP 1 of SW1 in position “On”

(see figs 4 & 7).

Output signal damping time can be set to 0.4

s or 10 s using DIP2 of SW1 (see figs 3 & 8).

The transmitter measures the pressure several

times within the set time and the output signal

consists of the average of these measurements.

This allows any pressure fluctuations within

the ventilation system to be dampened in the

transmitter output signal.

ZEROING

The transmitter can be zeroed after it has

been mounted and the power supply connected. Before zeroing the transmitter, it is

important to ensure that the pressure on the

+ and - connectors is equal (e.g. by stopping

the ventilation system). If the yellow LED is

constantly lit, the transmitter is measuring a

differential pressure of more than 50 Pa. This

may be caused by unintended pressure within

the system (draughts or compressed tubing). It

is recommended that tubes be removed from

the + and - connectors during zeroing. Zeroing

is activated by pressing the integrated zero-set

switch (see fig. 3), after which the yellow LED

will continue to flash until zeroing has been

completed.

LED INDICATION

The green LED is lit when the power supply has

been connected correctly and flashes when the

actual pressure is above or below the selected

measuring range. The yellow LED is lit if pressure exceeds 50 Pa and flashes for approx. 3

seconds during zeroing.

Table 1

LED on

On Flashing Off

Green OK

Yellow >0,5 mbar Zeroing in progress <0,5 mbar

FIGURES

Fig. 1: Dimensioned sketch

Fig. 2: Transmitter position in relation to bends

and branches

Fig. 3: PCB component positions

Fig. 4: Wiring diagram

Fig. 5: Selection of pressure range: PTH-3202

Fig. 6: Selection of output voltage/current

Fig. 7: Selection of damping time

Fig. 8: Free DIP switch

Bailey & Mackey Ltd

Baltimore Road

Birmingham B42 1DE

Tel: 0121-357 5351 · Fax: 0121-357 8319

www.baileymackey.com

Pressure outside

set range

No supply

© 2012 OJ Electronics A/S

1

Page 2

Fig. 1

BR-0996-A07

© 2011 OJ Electronics A/S

Output DIP1 Terminal

0-10 V O Terminal 2

2-10 V On

0-20 mA O Te rminal 4

4-20 mA On

BR-0996-A08

Fig. 2

Fig. 4

BR956A02bBR956A03aBR996A03

BR996A06

Fig. 3

Fig. 5

Fig. 6

2

Fig. 7

Fig. 8

Damping DIP2

0,4 Sec O

10 Sec On

BR996A07

The trademark is registered and belongs to OJ Electronics A/S · © 2014 OJ Electronics A/S

BR996A08

BR996A09 BR996B04

Loading...

Loading...