OJ Electronics OJ-DV-1013, OJ-DV-1005, OJ-DV-1007, OJ-DV-1011, OJ-DV-3016 Instructions Manual

...Page 1

INSTRUCTIONS

OJ-DV

67393C 12/16 (OSH) © 2016 OJ Electronics A/S

OJ Drives

A DRIVES PROGRAMME DEDICATED TO VENTILATION SOLUTIONS

®

Page 2

INSTRUCTIONS OJ-DV

Contents

1. Product presentation ...............................................................3

2. Introduction ......................................................................3

3. Key to symbols....................................................................3

4. Ensuring safety before installation .....................................................3

5. Product use ......................................................................4

6. Prohibition on use .................................................................4

7. EMC – Electromagnetic compatibility ..................................................4

8. Approvals and certifications..........................................................4

9. Product programme ................................................................5

10. Rating plate ......................................................................6

11. Exploded and dimensioned drawings ..................................................7

12. Mechanical installation..............................................................9

13. Electrical installation...............................................................10

13.1 Dangerous induced voltage (Windmilling) ........................................10

13.2 EMC-compliant installation ...................................................10

13.3 Short-circuit protection - Power supply..........................................10

13.4 Personal protection - use of RCD’s (TT-system), direct current (AC/DC) risk .............10

13.5 Potential equalisation........................................................11

13.6 Grounding hazard (PE) leakage current hazard....................................11

13.7 Cable requirements .........................................................11

13.8 Opening the OJ-DV .........................................................12

13.9 Cable entries – cable glands – strain relief .......................................12

13.10 Spring terminals............................................................13

13.11 Terminal and connector overview ..............................................13

13.12 Motor connection...........................................................13

13.13 Mains voltage connection ....................................................14

13.14 Modbus connection.........................................................14

13.15 A/D control signal connections ................................................15

13.16 Closing of OJ-DV ...........................................................16

14. Checklist – mechanical and electrical installation ........................................17

15. Hand terminal (Hterm) – connection and functions .......................................18

16. PCTool – connection and functions ...................................................18

17. Optional modules – connection and function ...........................................18

18. Functions .......................................................................19

18.1 Analogue/digital control......................................................19

18.2 Modbus control ............................................................19

18.3 Switching frequency ........................................................19

18.4 Braking power .............................................................20

18.5 Fire mode ................................................................20

18.6 Frequency converter mode – for asynchronous motors ............................20

18.7 Electronically commutated mode (EC mode) – for PM and BLDC motors ...............21

19. Built-in protection ................................................................22

20. Alarms .........................................................................22

21. Modbus addressing of OJ-DV ......................................................24

22. Maintenance.....................................................................24

23. Troubleshooting ..................................................................25

24. Disposal ........................................................................27

25. Technical specifications............................................................28

© 2016 OJ Electronics A/S

2

Page 3

INSTRUCTIONS OJ-DV | General

1. Product presentation

OJ-DV is a range of controllers suitable for regulating the speed of an electric motor in a wide variety

of applications.

OJ-DV is highly versatile as it can control various motor types, including:

• ACIM - asynchronous induction motors

• PMSM - permanent magnet synchronous motors

• BLDC - brushless DC motors

2. Introduction

• Read this manual thoroughly and follow the instructions it contains before taking OJ-DV into use.

• This manual contains important information and should be used when installing, connecting and

commissioning the OJ-DV as well as during maintenance, service and troubleshooting.

• If the instructions contained in this manual are not observed, the liability of the supplier and the

warranty shall be voided (see also Section 6. Prohibition on use).

• Technical descriptions, drawings and figures must not be wholly or partly copied or disclosed to

third parties without the permission of the manufacturer.

• All rights are reserved if the product is included in patent rights or other form of registration.

3. Key to symbols

Particular attention should be paid to the sections in these instructions which are marked with

symbols and warnings.

Warning

3.1. This symbol is used where there is a risk of severe or fatal personal injury.

Caution

3.2. This symbol is used where potentially dangerous situations may result in minor or moderate personal

injury. The symbol is also used to warn against unsafe and hazardous conditions.

Note

3.3. This symbol is used to indicate important information and in situations which may result in serious

damage to equipment and property.

Warning

4. Ensuring safety before installation

4.1. OJ-DV must only be installed by qualified personnel or people who have received appropriate

training and have thus become qualified to install the product.

4.2. Qualified personnel have knowledge of the installation practices used and can perform installation in

accordance with relevant local and international requirements, laws and regulations.

4.3. Qualified personnel are familiar with the instructions and safety precautions described in this manual.

4.4. OJ-DV contains dangerous high voltage when connected to the mains.

4.5. Mains voltage must always be disconnected before any installation, service or maintenance tasks are

performed on the product.

4.6. When OJ-DV is connected to the mains, there is a risk that the motor could start unintentionally,

causing a risk of dangerous situations and personal injuries.

4.7. Unintentional start during programming, service or maintenance may result in serious injury or

damage to equipment and property.

4.8. The motor/fan can be started via an external input signal, Modbus or a connected control panel.

4.9. Before connecting mains voltage to OJ-DV, all OJ-DV, motor and fan components must be properly

fitted.

4.10. Before connecting mains voltage to OJ-DV, all openings, covers and cable glands must be properly

fitted and closed. Unused cable glands must be replaced with blank glands.

© 2016 OJ Electronics A/S

3

Page 4

INSTRUCTIONS OJ-DV | General

4.11. OJ-DV contains capacitors which become charged during operation. These capacitors can remain

charged even after the power supply has been cut o. There is a risk of severe personal injury if

the connection terminals or wire ends are touched before these capacitors have been completely

discharged. The discharge time is about 3 minutes under normal conditions.

5. Product use

5.1. OJ-DV is especially used in ventilation applications (fans).

5.2. OJ-DV can also be used in other applications. If OJ-DV is used in applications where it cannot be

positioned directly in a flow of air, impaired OJ-DV cooling must be taken into account. This can

be countered by creating additional ventilation around the product or by reducing performance

requirements. See Section 25. Technical specifications.

5.3. OJ-DV is an electronic motor controller used to regulate fan speed. OJ-DV can be used to control AC

asynchronous motors, BLDC motors and PM motors.

5.4. Depending on what is needed, OJ-DV is suitable for stand-alone applications or as part of larger

systems/machines.

5.5. The product can be used under various environmental conditions. See Section 25. Technical

specifications.

5.6. OJ-DV can be fitted directly to the frame of the fan motor, thus saving space.

5.7. Motor operation can be regulated by commands from an external controller.

5.8. OJ-DV has built-in motor protection.

5.9. OJ-DV can be used in domestic and industrial environments and has a built-in EMC filter.

5.10. The OJ-DV is developed for use in industry and defined as professional equipment according to

EN 61000-3-2:2014, it is not intended for sales to the general public.

Warning

6. Prohibition on use

• The OJ-DV must not be taken into use until the machine or product into which it is incorporated

has in its entirety been declared to be in conformity with all relevant national and international

regulations.

• The product must not be energised until the entire installation complies with ALL relevant EU

directives.

• The product carries a manufacturer's warranty if installed in accordance with these instructions

and applicable installation regulations.

• If the product has been damaged in any way, e.g. during transport, it must be inspected and

repaired by authorised personnel before being connected to the power supply.

• If OJ-DV is built into machinery with rotating parts, e.g. a ventilation system, transport system,

etc., the entire system must comply with the Machinery Directive.

7. EMC – Electromagnetic compatibility

• OJ-DV has built-in EMC filter.

8. Approvals and certifications

CE marking

• OJ Electronics A/S hereby declares under sole responsibility that the product complies with the

following European Parliament directives:

• LVD - Low voltage: 2006/95/EU

• EMC - Electromagnetic compatibility: 2004/108/EU

• RoHS - Hazardous substances: 2011/65/EU

Product standard

• In accordance with EN 61800-2 – Adjustable speed electrical power drive systems. Part 2. General

requirements.

© 2016 OJ Electronics A/S

4

Page 5

INSTRUCTIONS OJ-DV | General

Safety

• In accordance with EN 61800-5-1 – Adjustable speed electrical power drive systems. Part 5.

Safety requirements – Electrical, thermal and energy.

EMC - Electromagnetic compatibility

Table 8.1

OJ-DV size Motor cable length Intended use PDS of category

EN-61800-3

0.55…..1.3 kW <5.0 m First environment C1 & C2 EN-61000-6-2 EN-61000-6-3

1.5…..3.0 kW <5.0 m First environment C1 & C2 EN-61000-6-2 EN-61000-6-3

4.0…..7.5 kW <5.0 m First environment C1 & C2 EN-61000-6-2 EN-61000-6-3

11.0 kW <5.0 m First environment C1 & C2 EN-61000-6-2 EN-61000-6-3

15.0 kW <4.0 m First environment C1 & C2 EN-61000-6-2 EN-61000-6-3

11.0…..15.0k W >4.0 Second environment C3 EN-61000-6-2 EN-61000-6-4

• In accordance with EN 61800-3 – Adjustable speed electrical power drive systems. Part 3. EMC

requirements and specific test methods. See table 8.1

• The OJ-DV product line fulfils the “residential level” for emissions as per EN-61000-6-3 and the

“industrial level” for immunity as per EN-61000-6-2 with up to 5 metre shielded motor cables.

(15kW is limited to up to 4 metre motor cables).

• Longer motor cables can be used. Industrial level for both immunity and emissions can be fulfilled,

depending on the cable capacity as well as the motor capacity.

By reducing the motor cable length, it is possible to install up to 6 OJ-DVs in the same unit with EN-618003 C1 & C2 still being fulfilled.

RoHS compatible

• Contains no hazardous substances according to the RoHS Directive.

Immunity Emission

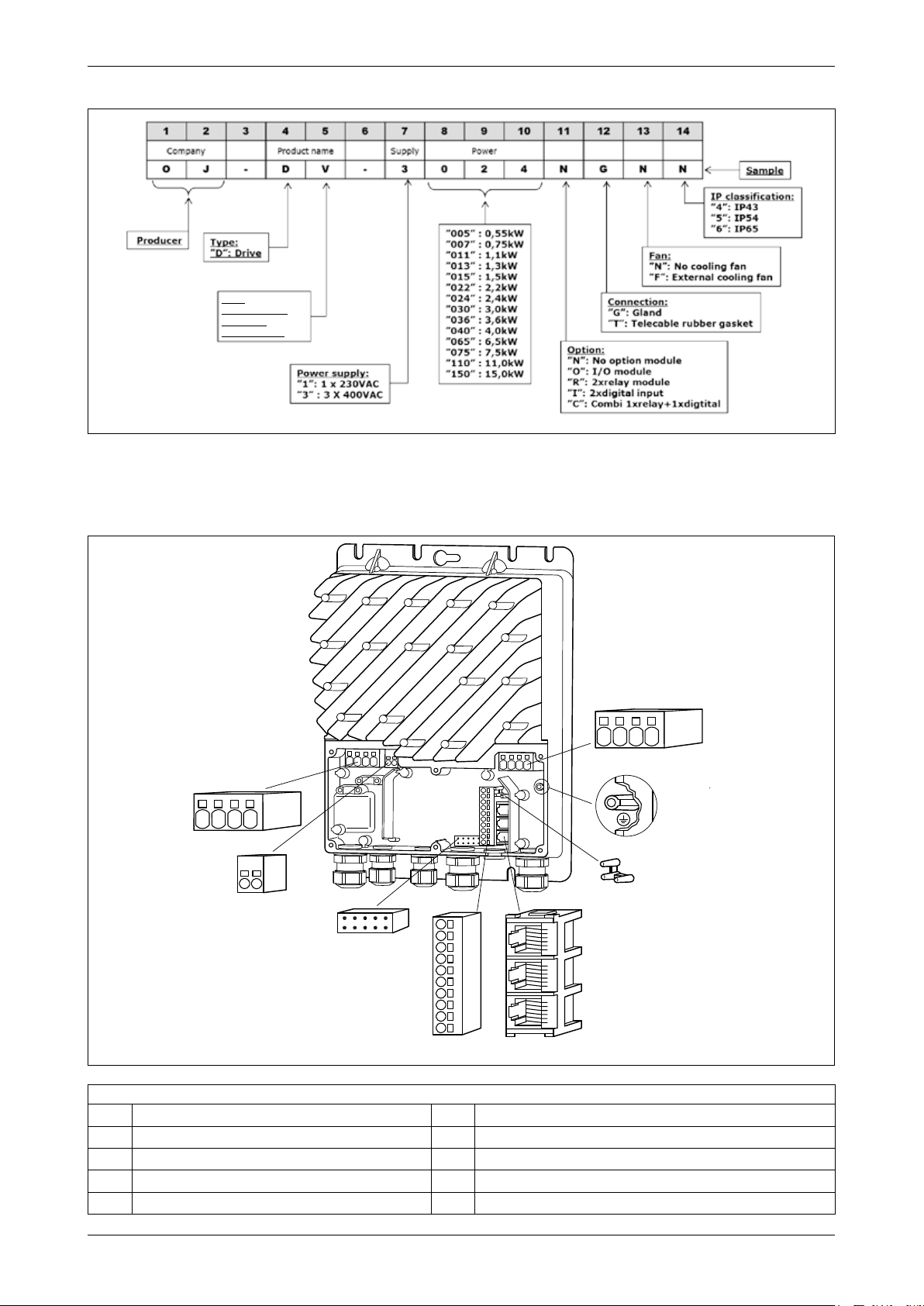

9. Product programme

• OJ-DV is available in four dierent enclosures, whose size depends on the rated power of the

OJ-DV.

• The product programme contains 12 power sizes ranging from 0.55 kW to 15.0 kW, see table 9.

• Enclosures are designated ”H1”…”H5”, where ”H1” is the smallest and ”H5” is the largest.

• All enclosures are made of die-cast aluminium.

Table 9

Product name Enclosure Power Supply voltage Dimensions (w, h, d)

OJ-DV-1005 H1 0.55 kW 1 x 230 V 185 x 230.5 x 90 mm

OJ-DV-1007 H1 0.75 kW 1 x 230 V 185 x 230.5 x 90 mm

OJ-DV-1011 H1 1.1 kW 1 x 230 V 185 x 230.5 x 90 mm

OJ-DV-1013 H1x 1.3 kW 1 x 230 V 185 x 265 x 125 mm

OJ-DV-3016 H3 1.6 kW 3 x 400 V 185 x 265 x 100 mm

OJ-DV-3024 H3 2.4 kW 3 x 400 V 185 x 265 x 100 mm

OJ-DV-3030 H3 3.0 kW 3 x 400 V 185 x 265 x 100 mm

OJ-DV-3040 H4 4.0 kW 3 x 400 V 220 x 294 x 107 mm

OJ-DV-3055 H4 5.5 kW 3 x 400 V 220 x 294 x 107 mm

OJ-DV-3065 H4 6.5 kW 3 x 400 V 220 x 294 x 107 mm

OJ-DV-3075 H4 7.5 kW 3 x 400 V 220 x 294 x 107 mm

OJ-DV-3110 H5 11.0 kW 3 x 400 V 244 x 399 x 144 mm

OJ-DV-3150 H5 15.0 kW 3 x 400 V 244 x 399 x 144 mm

All 3x400V versions can also be connected to 3x230V. The power output (kW) will, however, be limited to

max. 58% (1/√3) of the rated power output at 3x400V.

© 2016 OJ Electronics A/S

5

Page 6

INSTRUCTIONS OJ-DV | General

Caution

With enclosure sizes H3 ... H5, OJ-DV operating and motor parameters are set for connection to a supply

voltage of 3x400V.

If these types are connected to a 3x230V power supply, operating and motor parameters must therefore be

changed for optimum operation.

Motor parameters can be changed by the installer via the hand terminal (OJ-DV Hterm), OJ-Drives-Tool or

OJ-DV PCTool. Configuration parameters can only be changed by the manufacturer.

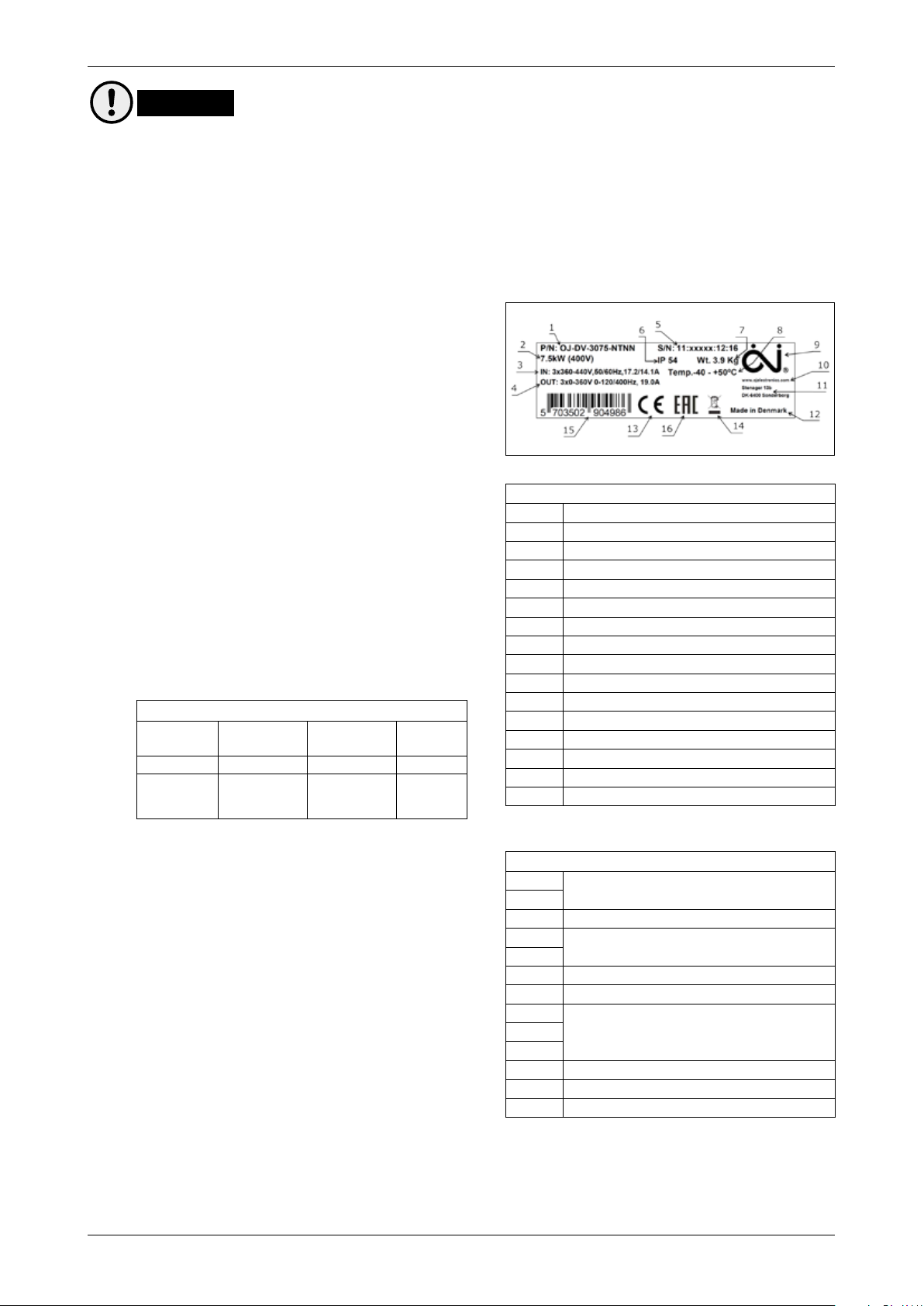

10. Rating plate

10.1. OJ-DV is equipped with a silver-coloured rating

plate.

See the example in fig. 10.1 and explanation in

table 10.2.

Check that the information specified on the rating

plate is as expected.

10.2. Rating plate, information and explanation

10.3. Explanation of product code

Each and every OJ-DV is given its own product

code during manufacture.

The product code (see table 10.3) gives precise

information on the specific OJ-DV.

The product code contains the following

information:

Table 10.3

Week number

W W B B B B B S S S S S Y Y

Week of

production

Batch Serial no. Year

Manufacturer's order

number

Unit

number

Year of

manufacture

Figure 10.1

Table 10.2

1 Product ID = see table 10.4.

2 Shaft power at nominal voltage

3 Max. input voltage, Hz/A

4 Max. output voltage/Hz/A

5 Product code = see table 10.3.

6 Enclosure rating

7 Weight

8 Temperature range, operating

9 Manufacturer's logo

10 Manufacturer's web address

11 Manufacturer's postal address

12 Country of manufacture

13 CE approved, logo

14 Disposal, logo

15 Bar code

16 EAC approved, logo

10.4. The product ID consists of a combination of 14

numbers and letters, each of which provides

information about the specific product, see fig.

10.4 and table 10.4.

© 2016 OJ Electronics A/S

Table 10.4

1

2

3

4

5

6

7

8

9

10

11

12

13

Manufacturer's initials

Product type

Electrical connection

Controller power/size

Optional module type

Cable entry

Integrated cooling fan

6

Page 7

INSTRUCTIONS OJ-DV | Installation

Figure 10.4

Type:

“V”: Ventilation

“R”: Rotor

“C”: Conveyor

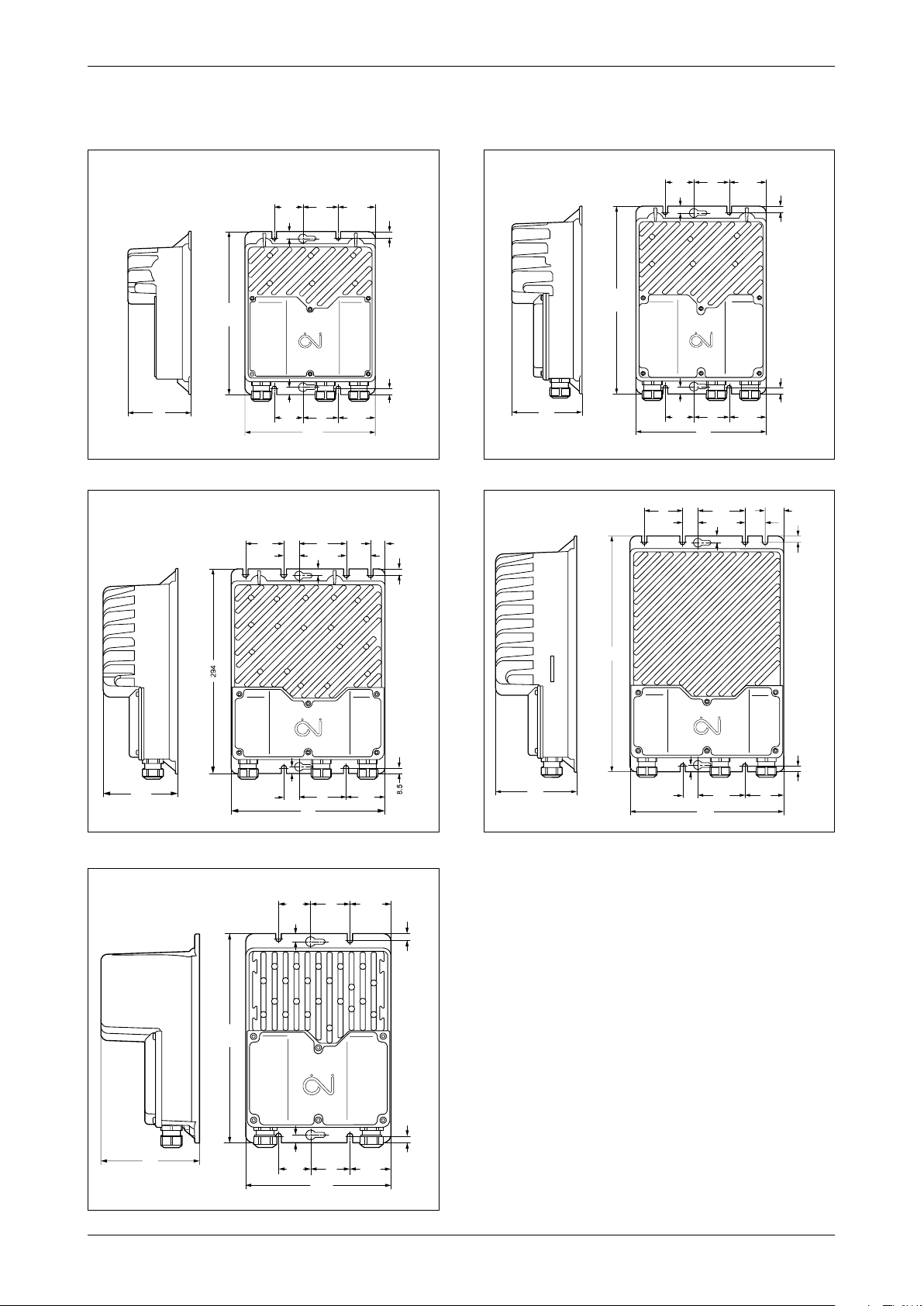

11. Exploded and dimensioned drawings

Figure 11.1

1

2

BR1014A21b

© 2016 OJ Electronics A/S

7

8

6

3

4

Table 11.1

No. Description No. Description

1 Motor connection terminals 5 RJ12 Modbus connectro (2 x xslave/1 x Master)

2 Connections for future use 6 3-point stain relief for Modbus connector cable (ribbon cable)

3 Connector for optional modules 7 Power terminals (H1=L, N, PE); (H3, H4, H5=L1, L2, L3, PE)

4 Terminal strip for Modbus and A/D control signals 8 Connector for the earth (PE) protective conductor

© 2016 OJ Electronics A/S

5

BR1014A21b

7

Page 8

INSTRUCTIONS OJ-DV | Installation

© 2015 OJ Electronics A/S

Dimensioned drawings

Figure 11.2

Figure 11.4

Figure 11.3

52.25

50

40.5

40.5

10

10

185

52.25

50

10

230.5

90

40.5

10

185

52.25

50

BR1014A25a

8.5

© 2015 OJ Electronics A/S

265.5

8.5

100

52.25

50

40.5

BR1014A25a

BR1014A23a

8.5

8.5

© 2015 OJ Electronics A/S

BR1014A23a

Figure 11.5

29.5

66.5

10

BR1014A22b

8.5

33

35

54.5

47

34.5

20.7

BR1014A24a

8.5

© 2015 OJ Electronics A/S

67

22

10

107.5

Figure 11.6

399

10

220

55.222

67

144

BR1014A24a

50 52.25

40.5

10

265.5

8.5

BR1014A43a

© 2016 OJ Electronics A/S

21.5

10

68.5

244

8.5

66

BR1014A22b

125

40.5

10

50

52.25

8.5

184.5

BR1014A43a

© 2016 OJ Electronics A/S

8

Page 9

INSTRUCTIONS OJ-DV | Installation

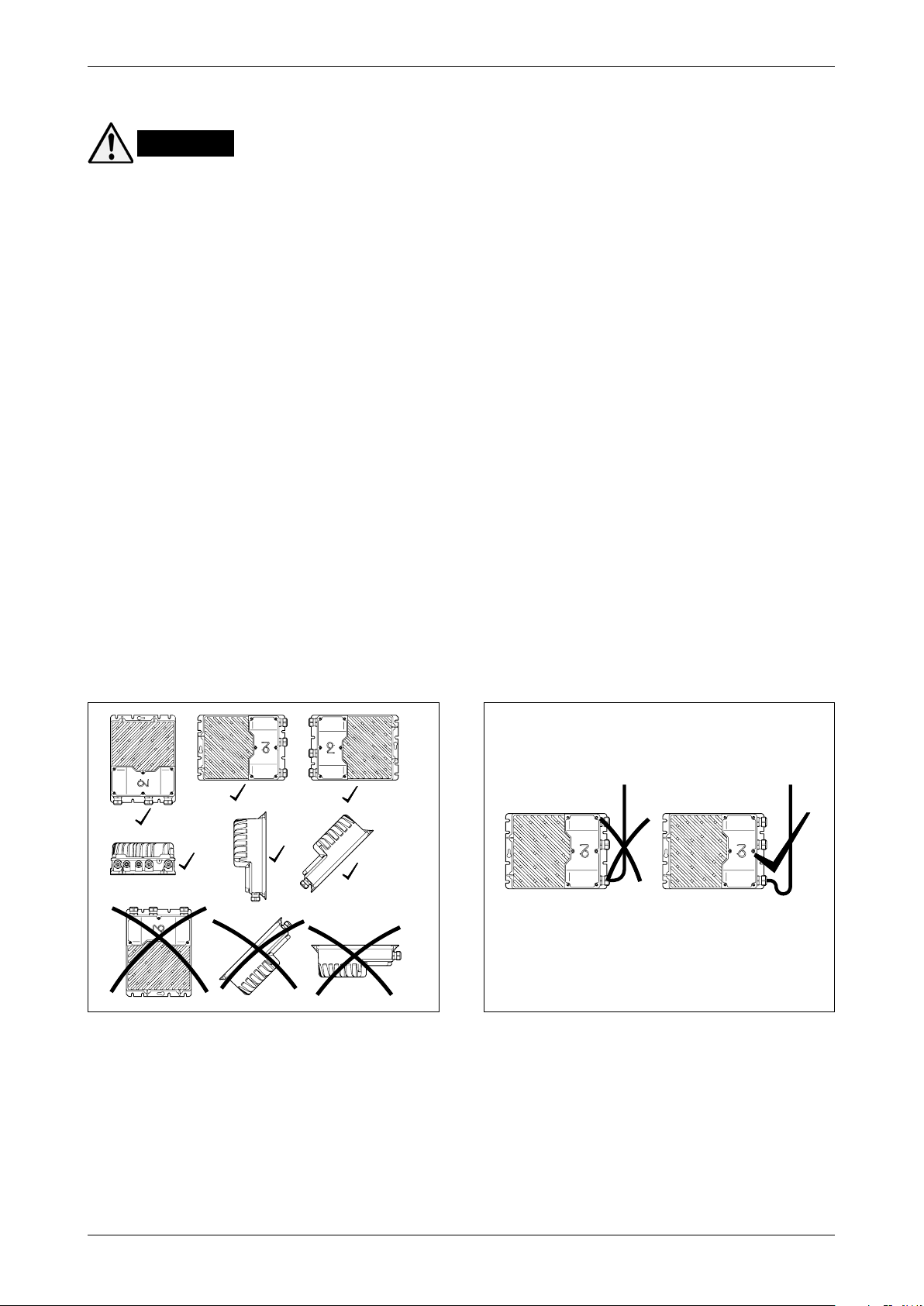

12. Mechanical installation

Incorrect mechanical installation may cause overheating and impaired performance.

Warning

• OJ-DV must only be installed by trained/experienced personnel.

• To ensure proper cooling of the OJ-DV, it must be positioned in such a way that the passing air

flow (> 3 m/s turbulent air speed) can cool the OJ-DV cooling fins. (3 m/s turbulent air speed is

equivalent to 6.5 m/s laminar air speed). If the OJ-DV is installed in a reduced air flow (< 3 m/s

turbulent air speed) or mounted outside a direct airstream, the output power (kW) will be reduced.

External on-board cooling fan can be added.

• Only OJ-DV-1013 can be installed without considering the above requirements for sucient air

flow over the cooling fins. OJ-DV-1013 is supplied with extra large cooling fins and can therefore

be mounted in still air with an air temperature of max. 40°C.

See Section 25: Technical Specifications.

• To facilitate future service and maintenance tasks, ensure that there is sucient space around the

unit after it has been installed.

• To achieve the specified enclosure rating, the cable glands must not point upwards (see fig. 12.4).

• To prevent water from entering OJ-DV via cables and cable glands, ensure that connection is

performed in such a way that water is prevented from accumulating around the cable in the gland.

See fig. 12.5.

• Check that the surface to which OJ-DV is attached is capable of supporting the entire weight of

the unit.

• OJ-DV can be mounted vertically, horizontally or at an incline. See fig. 12.4.

• OJ-DV must be installed on a flat solid surface.

• To avoid unnecessarily long motor cables (max. 5 m), OJ-DV should be installed as close to the

motor as possible.

• Use only the pre-cut installation holes/screw holes to secure OJ-DV in place.

• Dimensioned drawings, see figs 11.2 to 11.6.

Figure 12.4

BR1014A05a

© 2015 OJ Electronics A/S

BR1014A05a

Figure 12.5

BR1014A26a

© 2015 OJ Electronics A/S

BR1014A26a

© 2016 OJ Electronics A/S

9

Page 10

INSTRUCTIONS OJ-DV | Installation

13. Electrical installation

Warning

• OJ-DV must only be installed and commissioned by trained/qualified personnel.

• Check that the data specified on the rating plate of the motor matches the data specified on the

OJ-DV rating plate.

• Incorrect electrical installation may cause a risk of severe or fatal personal injury.

Warning

13.1 Dangerous induced voltage (Windmilling)

• If natural drafts through the duct system cause the fan to rotate even when it has not received an

operating signal (called windmilling), there is a risk that the motor will induce voltage on the OJ-DV

motor terminals, making them dangerous to touch.

Caution

13.2 EMC-compliant installation

• Always use shielded cables as motor cables.

• Shielded cable is not necessary for I/O signal cables and Modbus cables.

• Cable shields must always be electrically connected to the earthed product enclosure.

• Use the internal, factory-fitted cable clamps to ensure proper shield connection.

• Never convey mains voltage, motor connections and control signals in the same cable.

• The +24 VDC from the OJ-DV is not intended to be used as power supply for third party products.

If the +24 is used for power supply to third party products, the product might not fulfill the EMC

regulations.

Note

13.3 Short-circuit protection – Power supply

• Short-circuit protection for the supply side of OJ-DV is not provided together with the product.

• Correct short-circuit protection at the power supply input side on the OJ-DV must always be used

in accordance with local and international regulations.

• Short-circuit protection equipment must as a minimum have a tripping curve “C” conforming to

IEC 60898-1.

• Short-circuit protection is supplied by the installer.

Warning

13.4 PERSONAL PROTECTION - USE OF RCDs (TT-system), DIRECT CURRENT (AC/DC) RISK

This product can cause a DC current in the ground protective conductor in the event of a ground

fault.

If the 3 phases to the OJ-DV are not switched in at exactly the same time, then there will be a

generated current in the earthing/ground conductor during the switching time until all 3 phases are

connected.

Take notice of the following precautions:

• If a residual current device (RCD) is used for extra personal protection, use only an RCD of Type

B on the supply side of this product (B type, for alternating and/or pulsating current with DC

components and continuous fault current).

• RCDs of type B must comply with all provisions of IEC 61008/9

• Protective earthing of the OJ-DV in combination with the use of RCDs must always be performed

in accordance with the relevant local and international requirements, laws and regulations

• Failure to follow these precautions can lead to severe or fatal injuries to persons and animals.

© 2016 OJ Electronics A/S

10

Page 11

INSTRUCTIONS OJ-DV | Installation

Warning

13.5 Potential equalisation

• There is a risk of electrical interference if the ground potential between the OJ-DV and the air handling

unit or duct dier from each other. In the event of potential dierences between system components,

an equalisation conductor must always be fitted.

• Recommended cable cross section: 10 mm2.

• Lugs should be used, and the equalisation conductor should be attached to the OJ-DV enclosure via

one of the screws used to mechanically install the unit.

Warning

13.6 GROUNDING HAZARD (PE) LEAKAGE CURRENT HAZARD

Follow national and local regulations regarding protective earthing of equipment with a leakage current

exceeding 3.5 mA.

The OJ-DV technology causes switching at high frequency. This will generate a leakage current in the

earth/grounding connection, PE. (PE=Protective Earth).

This ground leakage current is dependant on the dierent configurations, including RFI filtering, shielded

motor cables and the motor type.

EN/IEC61800-5-1 (Power Drive System Product Standard) requires special emphasis because the

leakage current in the OJ-DV possibly exceeds 3.5 mA. See EN60364-5-54 paragraph 543.7 (Reinforced

protective conductors for protective conductor currents exceeding 10 mA) for further information.

Earth/grounding connection must be made in one of the following 3 ways:

• When connecting only one (1) PE conductor, the minimum cross-section should be at least 10 mm2,

or

• When connecting 2 separate ground conductors, both should comply with the dimensioning rules.

• If 2 conductors are used, they must be connected to individual earth/grounding connectors in the OJ-

DV controller.

• External grounding connection. If the machine housing is approved as a grounding connector, then

the OJ-DV can be grounded to the machine.

• Grounding connectors must always be made in accordance with applicable local and international

standards and directives.

• Follow all local and national electrical regulations for earth/grounding the OJ-DV properly.

• Establish well-executed protective grounding for this OJ-DV that has a leakage current exceeding 3.5

mA.

• A dedicated ground conductor is required for input power, motor power and control wiring.

• Use the clamps and connectors on the OJ-DV for proper ground connections.

• Do not “daisy chain” the ground connection between 2 or more OJ-DV controllers.

• Keep the ground conductor connections as short as possible.

• Always use shielded cables between the OJ-DV and motor, to reduce electrical noise.

• Follow motor manufacturer wiring requirements.

.

Note

13.7 Cable requirements

• All cables and conductors used in connection with the OJ-DV must comply with local and national rules

and regulations.

• The OJ-DV product line fulfils the “residential level” for emissions as per EN-61000-6-3 and “industrial

level” for immunity as per EN-61000-6-2 with up to 5 metre shielded motor cables. (15 kW is limited

to up to 4 metre motor cables). Longer motor cables can be used but it is the installer’s responsibility

to ensure the standards in EN-61000-6-2 are complied with. Industrial level for both immunity and

emissions can be fulfilled, depending on the cable capacity as well as the motor capacity.

• A 6-core, unshielded, 30 AWG/0.066 mm² telecommunications cable can be used as a Modbus cable.

• Generally, cable types with copper conductors are recommended.

• For recommended cable dimensions, see table 13.7.

© 2016 OJ Electronics A/S

11

Page 12

INSTRUCTIONS OJ-DV | Installation

Table 13.7

Power cable

Cable gland Cable diameter Cable size, min. Cable size, max. Core sleeve/stripped min.

H1/H1x M20 6-12 mm 3x1.5 mm

H3 M20 6-12 mm 4x1.5 mm

H4 M20 6-12 mm 4x1.5 mm

H5 M25 11-18 mm 4x2.5 mm

Motor cable

Cable gland Cable diameter Cable size, min. Cable size, max. Core sleeve/stripped min.

H1/H1x M20 6-12 mm 3x1.5 mm

H3 M20 6-12 mm 4x1.5 mm

H4 M20 6-12 mm 4x1.5 mm

H5 M25 11-18 mm 4x2.5 mm

A/D control cable

Cable gland Cable diameter Cable size, min. Cable size, max. Core sleeve/stripped min.

H1/H1x M20 6-12 mm 2x2x0.7 mm

H3 M20 6-12 mm 2x2x0.7 mm

H4 M20 6-12 mm 2x2x0.7 mm

H5 M20 6-12 mm 2x2x0.7 mm

Modbus round cable

Cable gland Cable diameter Cable size, min. Cable size, max. Core sleeve/stripped min.

H1/H1x M16 4-8 mm 3x2x0.7 mm

H3 M16 4-8 mm 3x2x0.7 mm

H4 M16 4-8 mm 3x2x0.7 mm

H5 M16 4-8 mm 3x2x0.7 mm

Modbus ribbon cable

H1 ... H5: Telecommunication cable/ribbon cable, 6-core, unshielded, 30 AWG/0.066 mm²

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

3x2.5 mm

4x2.5 mm

4x4 mm

4x10 mm

3x2.5 mm

4x2.5 mm

4x4 mm

4x10 mm

10x2x0.7 mm

10x2x0.7 mm

10x2x0.7 mm

10x2x0.7 mm

10x2x0.7 mm

10x2x0.7 mm

10x2x0.7 mm

10x2x0.7 mm

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

10 mm

10 mm

10-15 mm

10-18 mm

10 mm

10 mm

10-15 mm

10-18 mm

10 mm

10 mm

10 mm

10 mm

10 mm

10 mm

10 mm

10 mm

13.8 Opening the OJ-DV

• Check that the voltage supply to OJ-DV has been disconnected before opening the cover.

• Wait approx. 3 minutes after disconnecting mains voltage before removing the cover.

• OJ-DV is opened by loosening the six Torx 20 screws holding the plastic cover in place.

• Carefully remove the loosened cover.

13.9 Cable entries – cable glands – strain relief

Figure 13.9

• The factory-fitted cable glands should be used

when inserting power, motor and control cables into

OJ-DV.

• Remember to re-tighten the cable glands to ensure

OJ-DV låg

ingress protection and strain relief.

• If Modbus communication is based on 6-core,

unshielded, 30 AWG/0.066 mm² telecommunication

Gummipakning

Modbus kabel

cable, the cable must be inserted through the

purpose-moulded rubber seal. See fig. 13.9.

• The rubber seal has a cut insertion slit and assure

1

23

the product enclosure rating if properly fitted. See

fig. 13.9.

• The Modbus cable entry features 3-point strain

relief, which must be used.

OJ-DV låg

4

-DA

BR1014A06a

© 2015 OJ Electronic A/S

BR1014A07a

© 2016 OJ Electronics A/S

12

Page 13

INSTRUCTIONS OJ-DV | Installation

© 2016 OJ Electronics A/S

Control signals

13.10 Spring terminals

• If multi-core cables/leads are used, core sleeves/

end sleeves must always be used.

• The connection terminals are spring loaded and

the stripped wire can be easily inserted into the

terminal by carefully pushing the wire into the

terminal without using tools. Alternatively, the

terminal spring can be loosened by pressing it

lightly with a screwdriver or similar implement. See

fig. 13.10.

• Solid and multi-core cables/leads can be used.

• Stripped wire ends or end sleeves must be

between 8 and 15 mm.

• Wires can be removed by carefully loosening

the terminal spring by pressing lightly with a

screwdriver or similar implement. See fig. 13.10.

13.11 Terminal and connector overview

Figure 13.11

OJ-DV

Motor

U

V

W

PE

Future use

Open

collector

BR-

BR+

Modbus

Gnd

U

V

W

PE

A

B

A

+10Vdc

0-10Vin

Gnd

Din2

Din1

Dout1

Gnd

B

C

-V+

Adr.Pin1

-Add. Pin1

-Bus B

-Bus A

Adr.Pin2

-Add. Pin2

-Gnd

Adr.Pin1

-Add. Pin1

-Bus B

-Bus A

Adr.Pin2

-Add. Pin2

-Gnd

-V+

-Gnd

-Bus B

-Bus A

-V+

-Gnd

Figure 13.10

L1

L2

L3

PE

3-Phase

connection

L1

L2

L3

PE

PE

RJ12 Modbus Slave

RJ12 Modbus Slave

RJ12 Modbus Master

e.g. PTH/VOC

2

1

BR1014A01a

© 2015 OJ Electronic A/S

1

BBR1014A01a

-GB

BR1014A03c

BR1014A03c

13.12 Motor connection

• The motor cable must be connected to the

• When the stripped wire is properly inserted into

• IMPORTANT! The motor cable must always be

• Remember to re-tighten the cable glands to

terminals marked ”U”, ”V”, ”W” and ”PE”.

the terminal (see section 13.10), the terminal

tensions automatically with the correct torque.

a shielded cable and the shield must be ended

in the clamp intended for that purpose. See fig.

13.12.

ensure ingress protection and strain relief.

© 2016 OJ Electronics A/S

Figure 13.12

BR1014A09a

© 2015 OJ Electronic A/S

8-15mm

BR1014A09a

13

Motor

BR- BR+

PE

U

VW

Page 14

INSTRUCTIONS OJ-DV | Installation

© 2016 OJ Electronics A/S

13.13 Mains voltage connection

• With 3-phase OJ-DV units, connect the power

cable to the terminals marked ”L1”, ”L2”, ”L3” and

”PE”. See fig. 13.13.1. On 1-phase OJ-DV units,

the terminals are marked ”L”, ”N” and ”PE”. See fig.

13.13.2.

• Pay special attention to section 13.6 in these

instructions, in particular:

• Earth/grounding connection must be made in one

of the following 3 ways:

• When connecting only one (1) PE conductor,

the minimum cross-section should be at least

10 mm2, or

• When connecting 2 separate ground

conductors, both should comply with the

dimensioning rules.

• If 2 conductors are used, they must be

connected to individual earth/grounding

connectors in the OJ-DV controller.

• External grounding connection. If the

machine housing is approved as a grounding

connector, then the OJ-DV can be grounded

to the machine.

• Grounding connectors must always be made

in accordance with applicable local and

international standards and directives.

• It is recommended that the PE wire is 20 mm longer

than the other wires in the cable. If the cable is

accidentally pulled out of the OJ-DV while there is

voltage on the cable and terminals, the PE wire will

then be the last to be disconnected. OJ-DV is thus

prevented from causing electric shock.

• When the stripped wire is properly inserted into the

terminal (see section 13.10), the terminal tensions

automatically with the correct torque.

• Remember to re-tighten the cable glands to ensure

ingress protection and strain relief.

Figure 13.13.1

L1

L2 L3

MAINS

8-15mm

BR1014A08b

Figure 13.13.2

BR1014A08b

PE

© 2016 OJ Electronics A/S

PE

L

N

MAINS

12mm

BR1014A27b

BR1014A27b

13.14 Modbus connection

• OJ-DV is equipped with four connectors for

Modbus connection.

• It also features 3 x RJ12 connectors and one strip

of spring terminals.

• On the terminal strip with spring terminals

for control signals (A/D I/O), the terminals for

connecting Modbus are marked ”Bus A”, ”Bus B”

and ”GND”. See fig. 13.14.1.

• If wanted, a round cable can be used for Modbus

communication, connected to terminals marked

”Bus A” and ”Bus B” on the OJ-DV terminal strip.

• The Modbus terminals are internally connected in

parallel to the Modbus pins in the RJ12 connectors

marked ”A” and ”B”.

• The three 3 RJ12 connectors are marked ”A”, ”B”

and ”C”.

• ”A”: Modbus connection, slave, +24 V voltage in

connector.

© 2016 OJ Electronics A/S

Figure 13.14.1

Bus A

Bus B

GND

+10Vdc

A

B

C

-V+

-Add. Pin1

-Bus B

-Bus A

-Add. Pin2

-Gnd

-

-Add. Pin1

-Bus B

-Bus A

-Add. Pin2

-Gnd

-V+

-Gnd

-Bus B

-Bus A

-V+

-Gnd

BR1014A16a

© 2015 OJ Electronics A/S

BR1014A16a

14

Page 15

INSTRUCTIONS OJ-DV | Installation

• ”B”: Modbus connection, slave, no +24 V voltage in connector.

• ”C”: Modbus connection, Master, external equipment, e.g. PTH/VOC. See fig. 13.11.

• A 6-core, unshielded, 30 AWG/0.066 mm² telecommunications cable or similar type of ribbon

cable can also be used for Modbus communication.

• Attach RJ12 connectors to both ends using a special-purpose tool.

• The OJ-DV is prepared to be installed in Modbus networks either in daisy chain or star

networks. Every OJ-DV has a preinstalled Modbus termination resistor of size 1 kΩ, which in

most applications would be sucient.

• Extra Modbus termination resistor is not to be used, except in installations where the Modbus

exceeds >100 m in a daisy chain Modbus connection.

• If the Modbus exceeds >100 m, it might be necessary to install an extra Modbus termination

resistor of size 180 Ω. This resistor is only to be installed in the last OJ-DV in the chain.

• In Modbus star connection installations, a Modbus termination resistor is mostly not to be used.

Note

IMPORTANT! RJ12 connectors must be fitted to the ends

in such a way that both connectors have the same colour

sequence as the cable.

See fig. 13.14.2.

13.15 A/D control signal connections

• Connect A/D control signals to the terminal strip,

see fig. 13.15.1

• For further information on using the spring

terminals, see section 13.10.

• The function/programming of A/D inputs and

outputs can be changed via Modbus.

For further information on the Modbus protocol,

contact OJ Electronics A/S

• +10Vdc = Constant + 10 VDC for control signal

and NOT intended as power supply for other

purposes.

• Short-circuit proof also short-circuit between

+24 VDC and +10 VDC

• Tolerance ± 3%

• 0-10V In = Analogue 0-10V control input for

speed

• Potentiometer, electrical connection, see fig.

13.15.2.

Figure 13.14.2

Figure 13.15.1

Bus A

Bus B

GND

+10Vdc

0-10V In

GND

Din2

Din1

Dout1

GND

Figure 13.15.2

Bus A

Bus B

GND

+10Vdc

0-10V In

GND

Din2

Din1

Dout1

GND

Same colour sequence

Samme farverækkefølge

8-15mm

A

B

C

-V+

-Add. Pin1

-Bus B

-Bus A

-Add. Pin2

-Gnd

-

-Add. Pin1

-Bus B

-Bus A

-Add. Pin2

-Gnd

-V+

-Gnd

-Bus B

-Bus A

-V+

-Gnd

BR1014A02a

© 2015 OJ Electronic A/S

BR1014A02a

BR1014A15a

© 2015 OJ Electronics A/S

BR1014A15a

BR1014A20a

© 2015 OJ Electronics A/S

© 2016 OJ Electronics A/S

BR1014A20a

15

Page 16

INSTRUCTIONS OJ-DV | Installation

• Potentiometer: min. 500 Ω, recommended

4.7kΩ

• Internal input impedance: 60 kΩ

• External controller, electrical connection,

see fig. 13.15.3

• GND = Ground (-)

• Din2 = Alarm reset (factory setting)

• Digital input

• Internal input impedance: 60 kΩ

• Electrical connection, see fig. 13.15.4

• Din1 = Start/Stop (factory setting)

• Digital input

• Internal input impedance: 60 kΩ

• Electrical connection, see fig. 13.15.4

• Dout1 = Tacho Out; Open Collector (factory

setting)

• Digital output

• Pull-up resistance range 1.5-22 kΩ

• Pull-up voltage range 0-24 V DC

• Pull-up current range 1-20 mA

• Logical low for high stability after 1 ms

• If EMC sensitive equipment is to be connected,

then an external RC filter must be mounted

with a time constant of 1 µs.

• Electrical connection, see fig. 13.15.5

• GND = Ground (-).

Figure 13.15.3

Bus A

Bus B

GND

+10Vdc

0-10V In

GND

Din2

Din1

Dout1

GND

Figure 13.15.4

Bus A

Bus B

GND

+10Vdc

0-10V In

GND

Din2

Din1

Dout1

GND

Figure 13.15.5

+10Vdc

0-10V In

Bus A

Bus B

GND

GND

Din2

Din1

Dout1

GND

Controller

+Vout

GND

Controller

Controller

+24V

BR1014A18a

© 2015 OJ Electronic A/S

AoutX

BR1014A18a

BR1014A19a

© 2015 OJ Electronic A/S

DoutX

DoutX

BR1014A19a

BR1014A17a

© 2015 OJ Electronics A/S

RΩ

BR1014A17a

13.16 Closing of OJ-DV

• When all electrical connections have been

correctly mounted, OJ-DV can be closed again

• Fasten the blue plastic cover with the associated 6

TX20 screws.

• Tightening torque on the screws in the blue cover

is 2 Nm. To ensure that the product constantly

maintains the IP enclosure rating specified for

the product, it must be ensured that the 6 TX20

screws are suciently tightened to the tightening

torque. At the same time, it must be ensured that

the tightening torque is not so high that the blue

plastic cover is deformed.

© 2016 OJ Electronics A/S

16

Page 17

INSTRUCTIONS OJ-DV | Installation

14. Checklist – mechanical and electrical installation

• Before OJ-DV is energized for the first time, installation and connection must be checked.

• Use the table below as a checklist.

Item to be checked Description of check √

Completion Check that the entire installation is ready to be commissioned, both electrically and mechanically, before

Product conformity Check that the mains voltage on the supply terminals corresponds to the rated input voltage of the OJ-

Mechanical

installation

Ambient conditions Check that requirements on the surrounding environment have been met.

Cabling Check that all cabling has been fitted correctly and that motor and control cables are kept apart in

Electrical installation Check that cables have been correctly inserted into OJ-DV and that the cable glands have been correctly

energizing the installation.

Check that no people or animals are present in the vicinity of moving parts.

DV.

Check the rating plates of the motor and OJ-DV to ensure that the units have been sized correctly.

Check that OJ-DV is correctly and securely attached to a flat surface.

See Section 12 in this manual.

Check that there is a free, unobstructed passage of air to the cooling fins.

See Section 12 in this manual.

Check that the blue plastic cover on OJ-DV is correctly mounted and that all screws are suciently

tightened before switching the power on to the product. Tightening torque on the screws is 2 Nm.

Check that all unused cable glands and other unused openings are appropriately blanked o in

accordance with the applicable enclosure rating.

Check that temperature and other environment specifications are observed.

See technical specifications, Section 25 in this manual.

separate cable conduits.

Check that the motor cable is a shielded cable and that its length is no longer than 5 metres.

Check that all cables are securely attached and relieved of tension and torsion.

tightened.

Check that the OJ-DV voltage supply terminals have been connected to the correct mains voltage level.

Check that all cables are correctly ended and securely attached.

Check that all cables are free of visible damage throughout their length.

Check whether there are any loose connections, which may cause overheating and serious damage to

the product and property.

Mains voltage Check that the mains voltage wires have been correctly fitted to the supply terminals: one-phase on

Motor connection Check that motor cables are correctly connected to ”U”, ”V”, ”W” and ”PE” – and check that tightening

Control and signal

wires

Shield Check that the motor cable shield is ended correctly and use continuity measurement to check that the

Fuses and circuit

breakers

Earthing Check that all earth connections in the motor and OJ-DV are correctly connected and free of oxidation.

terminals ”L”, ”N” and ”PE” and three-phase on terminals ”L1”, ”L2”, ”L3” and ”PE”.

Check by means of voltage measurement that there is the correct voltage on the terminals.

Check short-circuit protection and supplementary protection.

torque is correct on the spring terminals of the motor.

Check that control cables are ended correctly and securely attached.

Check that both ends of the Modbus cable have been attached to the correct connectors.

shield is connected to an active earth connection at both ends.

Check that active short-circuit protection has been correctly fitted and sized.

Check that all safety equipment is operative and set correctly.

Check by means of continuity measurement that the earth connection is active and that the contact

resistance complies with applicable local and international directives and regulations.

© 2016 OJ Electronics A/S

17

Page 18

INSTRUCTIONS OJ-DV | Operation

15. Hand terminal (Hterm) – connection and functions

• The OJ-DV range can be connected to an OJ-DV Hterm hand terminal via Modbus RJ12

connector ”A”. See fig. 15.1.

• If an OJ-DV Hterm is connected, the hand terminal will act as master and the OJ-DV as slave.

• Only one master at a time can be connected to the RJ12 connectors marked ”A” and ”B”. It

is thus not possible to connect both a hand terminal to connector ”A” and an active Modbus

communication cable to connector ”B” at the same time.

• OJ-DV Hterm has the following menu options:

• Status: Control and operating parameters

for connected OJ-DV

• Setup: Setting application parameters

• Alarm: Read-out of alarm log for connected

OJ-DV

• Modbus: Changing Modbus settings for OJ-

DV

• About: Read-out of software version no.

and type for connected OJ-DV

• Config: Changing OJ-DV/motor settings

Note

For further information on OJ-DV Hterm operation and

menus, contact OJ Electronics A/S.

Figure 15.1

A

B

C

-V+

-Add. Pin2

-Bus B

-Bus A

-Add. Pin2

-Gnd

-

-Add. Pin2

-Bus B

-Bus A

-Add. Pin2

-Gnd

-V+

-Gnd

-Bus B

-Bus A

-V+

-Gnd

BR1014A11a

© 2015 OJ Electronic A/S

BR1014A11a

16. PCTool – connection and functions

• The OJ-DV range can be configured using OJ-DV PCTool, which must be connected to Modbus

RJ12 connector ”B”.

• OJ-DV PCTool allows motor and controller parameters to be viewed and set, including:

• Status: Control and operating parameters for connected OJ-DV

• Setup: Setting application parameters

• Alarm: Read-out of alarm log for connected OJ-DV

• Modbus: Changing Modbus settings for OJ-DV

• About: Read-out of software version no. and type for connected OJ-DV

• Config: Changing OJ-DV/motor settings

• Log data: Read-out of log files

• Firmware: Updating firmware

• Motor: Configuring motor parameters

• Fan: Configuring fan parameters

• Hardware: Configuring OJ-DV hardware

OJ-DV PCTool is used solely by fan and system manufacturers.

For further information on OJ-DV PCTool operation and menus, contact OJ Electronics A/S.

17. Optional modules – connection and function

• Various optional modules can be connected to OJ-DV, providing extra versatility where the unit is

to be built into systems and applications that require additional inputs and outputs.

For further information on the possibilities oered by optional modules, contact OJ Electronics A/S.

© 2016 OJ Electronics A/S

18

Page 19

INSTRUCTIONS OJ-DV | Functions

18. Functions

18.1 Analogue/digital control

• OJ-DV can be controlled via analogue/digital (A/D) inputs or via Modbus.

• The factory setting is analogue/digital (A/D) control.

• Connect A/D control signals to the terminal strip, see section 13.15.1.

0-10V In

• Is used to control motor speed in relation to a 0-10V signal.

Note

• With A/D control, functions such as alarm read-out and acknowledgement are still possible via

Modbus even though "Modbus control" is not activated.

• The relationship between the 0-10V control signal and motor speed depends on the settings for

min./max. speed and ramp up/ramp down times. See figs 18.1 and 18.2.

• The ”+10Vdc”, ”0-10V In” and ”GND” terminals can be connected to a potentiometer, see

electrical connection in fig.13.15.2.

The function of the digital inputs and outputs has been defined by OJ Electronics A/S as follows:

• Din1 = Start/Stop (1 = Start)

• Din2 = Alarm reset (1 = Alarm reset)

• Dout1 = Tacho Out (1 pulse per motor revolution)

Note

The digital inputs and outputs can be given alternative functions via Modbus.

Relationship between control signal (0-10V In) and speed –

see fig. 18.1.

The control signal regulates motor speed between the set

minimum and maximum speeds (AC motor=Hz; PM/BLDC

motor=rpm) and the set ramp times – see fig.18.2.

18.2 Modbus control

• OJ-DV can be controlled via Modbus

commands according to the Modbus protocol.

• Control of motor speed via Modbus

communication is factory disabled.

• If OJ-DV is to be controlled via Modbus,

Coil Stat Bit register 8 must be set to ”0” =

”Modbus control”.

• Other functions, such as alarm read-out

and acknowledgement, are still possible via

Modbus even though "Modbus control" is not

activated.

• NOTE! Contact OJ Electronics A/S if you

require the Modbus protocol.

•

18.3 Switching frequency

Switching frequency is crucial in determining the

amount of audible acoustic noise emitted by OJ-DV.

The higher the switching frequency, the less audible

noise will be emitted by OJ-DV. At the same time,

however, internal losses will be increased, reducing

eciency.

Figure 18.1

Frequency/revolutions

Frekvens/

omdrejninger

Max. Hz/Rpm

Min. Hz/Rpm

0%

0V

Figure 18.2

Speed out

Max. Speed

Min. Speed

Setpoint

100%

0%

Up

Ramp

100%

9.5V

Down

Ramp

-DA

BR1014A13a

© 2015 OJ Electronics A/S

Setpoint

BR1014A13a

-GB

BR1014A12a

© 2015 OJ Electronic A/S

Time

Time

BR1014A12a

© 2016 OJ Electronics A/S

19

Page 20

INSTRUCTIONS OJ-DV | Functions

OJ-DV can be set to operate constantly with a switching frequency of either 4 kHz or 8 kHz, or it

can be set to change switching frequency automatically depending on motor speed (AUTO setting).

Switching frequency (switching mode) is set via Modbus:

• Setting ”4kHz” = Constant 4kHz switching frequency

• Setting ”8kHz” = Constant 8kHz switching frequency

• Setting ”AUTO” = Switching frequency is changed automatically:

• At motor speeds higher than 60% of rated speed, switching frequency is changed to 4 kHz

• At motor speeds lower than 50% of rated speed, switching frequency is changed to 8 kHz

18.4 Braking power

• The electronics within OJ-DV can as a starting point supply braking power corresponding to its

own consumption. It is expected that an air flow capable of maintaining typically up to 30% of

nominal fan speed can be braked by this function.

18.5 Fire mode

• Fire mode designates a function in which OJ-DV is kept operating by an emergency program

which disables the alarm monitor.

• The fire mode function can be activated via Modbus or via digital input.

• Among other things, the function can be used in connection with smoke extraction from a burning

property. When fire mode is activated, an extraction fan will continue to remove smoke from the

property for as long as possible.

• In fire mode, OJ-DV is able to maintain operation for at least an hour even when OJ-DV and the

fan motor are overheated (max. 70°C).

• Upon activation of fire mode operation the output signal to the motor remains the same value as it

was just before the fire mode condition was activated, and any alarms will be suppressed.

• During fire mode operation the output signal to the motor will at any time be the selected voltage

of 0-10V input, or if the OJ-DV is controlled via Modus, it will be the control signal from a potential

Modbus Master. If there is a communication failure on the Modbus, the output signal to the motor

will be the same value as it was just before the Modbus communication was disconnected.

• If the motor is not operating when fire mode is activated, the motor will remain stopped upon

activation of fire mode.

18.6 Frequency converter mode – for asynchronous motors

The OJ-DV factory-set to frequency converter mode for

standard asynchronous induction motors (AC-IM) and

the control mode is 0-10VDC input.

This can be changed using the OJ-DV-PCTool or OJ-

DCV-HTERM (Hand terminal).

If you use the OJ-DV in frequency converter mode, you

must connect a standard 3 phase~ AC-IM motor. Pay

special attention to the information that you will find on

the nameplate of the motor.

The voltage output from the OJ-DV is for the OJ-

DV-1005…..OJ-DV-1011 maximum 250 VAC.

For the OJ-DV-3015…..OJ-DV-3150 the maximum

voltage output is 364 VAC.

If the supply voltage is higher than the rated voltage of

the single windings in the connected motor, then the

motor will be damaged.

Pay special attention if the motor is connected in “star”

or “delta” connections.

On a standard AC-IM motor, the “star”/“delta”

connection often can be changed by rearranging

the jumpers on the motor terminal, see figure 18.6.

With the OJ-DV in frequency converter mode, it is the

installer’s responsibility to enter the correct control and

motor parameters.

Figure 18.6.1

BR1014A41a

© 2016 OJ Electronics A/S

BR1014A41a

© 2016 OJ Electronics A/S

20

Page 21

INSTRUCTIONS OJ-DV | Functions

Pay special attention to the following parameters:

Minimum frequency Even if the control signal is e.g. 0% or 0.0V and the OJ-DV has an activated start signal, the motor will not

run slower than the value in this parameter.

Maximum frequency Even if the control signal is e.g. 100% or 10.0V and the OJ-DV has an activated start signal, the motor will

not run faster than the value in this parameter.

Ramp-up time Ramp-up time is the time (in seconds) from when the OJ-DV gets the start signal until the speed has been

reached according to the setpoint. The ramp-up time is used to avoid overload and damage to the controller

and motor. The ramp-up time is also used in upward jumps between speed setpoints.

If this ramp-up is too short, the OJ-DV could possibly trigger a current limit alarm

Ramp-down time. Ramp-down time is the time (in seconds) from when the OJ-DV receives a stop signal until the motor comes

to a halt. The ramp-down time is used to avoid overload and damage to the controller and motor. Rampdown time is also used in connection with downward jumps between speed setpoints.

If this ramp-down is too short, the OJ-DV will use power to stop or slow down the motor. This could possibly

trigger a current limit alarm from the OJ-DV.

Switch frequency Switch frequency is a parameter that has an influence on the eciency and the audible noise from the con-

nected motor and/or the OJ-DV controller.

In the OJ-DV it is possible to select “Auto”, “4 kHz” or “8 kHz”.

Activating the “Extra high” Modbus parameter makes it possible to select “Auto”, “4 kHz” or “10 kHz”.

The higher the switch frequency, the lower the audible noise from the OJ-DV controller system, but the consequence of lower audible noise is decreasing eciency of the OJ-DV controller system.

In “Auto” the OJ-DV will automatically switch between “4 kHz” and “8/10 kHz”. During start-up from 0 – 60%

speed, the switch frequency will be “8/10 kHz” and this will make for less audible noise from the connected

motor and/or the OJ-DV controller. When the speed has increased and passes 60%, the switch frequency

will then switch to “4 kHz”. The noise from the fan and airflow will now drown out the audible noise from the

OJ-DV controller system.

In the speed-down sequence, the OJ-DV will switch to “8/10 kHz” when the speed of the motor passes 50%

downwards.

It is also possible to select a fixed switch frequency of “4 kHz” or “8/10 kHz”.

U-min Hz This parameter selects the voltage to the motor at minimum frequency.

Freq U-max This parameter selects the frequency to the motor at maximum voltage.

V/F characteristic The “V/F characteristic” parameter is a parameter

that makes it possible to change the ratio between

voltage and frequency for the motor.

The “V/F characteristic” is factory-set to the value 0

(zero), which means that the ratio between the voltage and the frequency is linear.

At the other end, the value “100” is equal to a parabolic relation between voltage and frequency.

For a standard fan application, the value of the “V/F

characteristic” should be 75. AC motors with poor

eciency require a higher “V/F characteristic”.

Figure 18.6.2

For further information about parameters in the OJ-DV, see OJ-DV Modbus protocol.

18.7 Electronically commutated mode (EC mode) – for PM and BLDC motors

The OJ-DV factory-set to frequency converter mode for standard asynchronous induction motors

(AC-IM) and the control mode is 0-10 VDC input.

This can be changed using the OJ-DV-PCTool or OJ-DCV-HTERM (Hand terminal).

The dierence between an AC-IM motor and a PM-SM/BLDC is basically the rotor.

In the PM-SM/BLDC motor, the windings in the rotor are replaced with permanent magnets, but

the control system has to be and is very dierent. Due to the permanent magnets in the rotor, they

will induce voltage in the stator windings as they rotate and as a result also voltage back to the

controller. This is what is called back EMF (EMF = electromotive force) and describes an important

and special characteristic of the motor.

The controller has to be able to handle this back EMF and that is why you cannot control a PM-SM/

BLDC motor with an OJ-DV controller in frequency converter mode.

© 2016 OJ Electronics A/S

21

Page 22

INSTRUCTIONS OJ-DV | Functions

Before operation, select and load the correct fan and motor parameter files using the OJ-DV

Handterminal or OJ-DV-PCTool. It is the installer’s responsibility to enter the correct control and

motor parameters.

Pay special attention to the following parameters:

Minimum rpm Even if the control signal is e.g. 0% or 0.0V and the OJ-DV has an activated start signal, the motor will not

run slower than the value in this parameter.

Maximum rpm Even if the control signal is e.g. 100% or 10.0V and the OJ-DV has an activated start signal, the motor will

not run faster than the value in this parameter.

Ramp-up time Ramp-up time is the time (in seconds) between the OJ-DV gets the start signal until the speed has been

reached according to the setpoint.

The ramp-up time is used to avoid overload and damage to the controller and motor. The ramp-up time is

also used in upwards jumps between speed setpoints.

If this ramp up is too short, the OJ-DV possibly could trigger an current limit alarm.

Ramp-down time Ramp-down time is the time (in seconds) from when the OJ-DV receives a stop signal until the motor comes

to a halt. The ramp-down time is used to avoid overload and damage to the controller and motor. Rampdown time is also used in connection with downward jumps between speed setpoints.

If this ramp-down is too short, the OJ-DV will use power to stop or slow down the motor. This could possibly

trigger a high voltage alarm (Vhi), from the OJ-DV.

Switch frequency Switch frequency is a parameter that has an influence on the eciency and the audible noise from the con-

nected motor and/or the OJ-DV controller.

In the OJ-DV it is possible to select “Auto”, “4 kHz” and “8 kHz”.

The higher the switch frequency, the lower the audible noise from the OJ-DV controller system, but the consequence of lower audible noise is decreasing eciency of the OJ-DV controller system.

In “Auto” the OJ-DV will automatically switch between “4 kHz” and “8 kHz”. During start-up from 0 - 60%

speed, the switch frequency will be “8kHz” and this will make for less audible noise from the connected

motor and/or the OJ-DV controller. When the speed has increased and passes 60%, the switch frequency

will then switch to “4 kHz”. The noise from the fan and airflow will now drown out the audible noise from the

OJ-DV controller system.

In the speed-down sequence, the OJ-DV will switch to “8 kHz” when the speed of the motor passes 50%

downwards.

It is also possible to select a fixed switch frequency of “4 kHz” or “8 kHz”.

In the speed-down sequence, the OJ-DV will switch to “8/10 kHz” when the speed of the motor passes 50%

downwards.

It is also possible to select a fixed switch frequency of “4 kHz” or “8/10 kHz”.

For further information about parameters in the OJ-DV, see OJ-DV Modbus protocol.

19. Built-in protection

• If the temperature inside OJ-DV exceeds 95°C, OJ-DV will attempt to reduce its internal heat

generation by reducing motor speed (rpm).

• OJ-DV has built-in current limitation for the protection of motor and cables and cannot therefore

supply more current than it is set to.

• In the event of lacking phase on the supply input, OJ-DV will reduce speed and activate a non-

critical alarm.

• The OJ-DV motor output terminals are short-circuit protected against phase-to-phase short

circuiting.

20. Alarms

• OJ-DV has a built-in alarm monitor, which monitors optimal fault-free operation and triggers an

alarm if operating or performance problems are observed.

• Alarms are either ”Critical” alarms or ”Non-critical” alarms.

• ”Critical” alarms stop the motor.

• ”Non-critical” alarms reduce motor performance.

• The built-in alarm monitor stops the OJ-DV.

• If the alarm situation passes, the alarm is automatically reset and OJ-DV restarted.

• If the maximum number of restarts (5 times/60 min) is exceeded, the alarm must be reset

manually.

© 2016 OJ Electronics A/S

22

Page 23

INSTRUCTIONS OJ-DV | Alarms

• The alarm can be reset by means of a Modbus command.

• The alarm is automatically reset if the power is disconnected for longer than 60 seconds.

• Alarms can be read via Modbus, see Modbus protocol.

• Alarm overview, see table 20.

Table 20

Alarm overview Trigger Alarm priority Motor operation/

response

Supply voltage too low

Supply voltage too high

The motor’s power use is too high

Internal temperature in OJ-DV too high (>95 °C)

Phase error; one or more phases disconnected

(L1, L2, L3)

Blocked rotor

Motor power has reached it’s limit

Earth fault

(Only OJ-DV-3110 & OJ-DV-3150)

Running in the wrong direction

Fault in internal EEPROM circuit

Stopped after 5 re-start attempts within 60min N/A

Phase error in motor supply (U, V, W)

Internal communication fault

Ripple voltage too high

External 24VDC supply overloaded.

✓ Supply voltage to OJ-DV is too low.

✓ OJ-DV is mistakenly connected to

mains voltage 3 x 230VAC.

✓ Supply voltage to OJ-DV is too high.

✓ Short circuit in motor cable.

✓ Short circuit in one or more motor

windings.

✓ Cooling of OJ-DV enclosure too low.

✓ Insucient air circulation around

OJ-DV.

✓ Air temperature around OJ-DV is

too high.

✓ Missing phase in supply voltage to

OJ-DV

✓ Large imbalance in supply voltage.

✓ The rotor is unable to rotate due to

a mechanical blockage of the rotor

or fan.

✓ OJ-DV has reached the limit for

maximum output power.

✓ The connected motor is larger than

allowed for the chosen OJ-DV

✓ The load is too big for the

connected motor.

✓ Earth fault on motor cables or motor

windings

✓ Windmilling in the opposite direction

during the start up process.

✓ Incorrectly chosen configuration file

- tried to download a configuration

file which is not contained in OJ-DV

✓ OJ-DV is defective.

✓ One or more motor phases / motor

cables is disconnected.

✓ One or more motor windings is

disconnected.

✓ During the process of updating

the MOC configuration file,

communication was inadvertently

disconnected.

✓ If the alarm goes o during normal

operation, it usually indicates a

defective OJ-DV.

✓ Imbalance on voltage supply.

✓ Overloading or short circuit on +24V

voltage supply.

”NC” ”RP”

”C” ”SA5”

”C” ”SA5”

”NC” ”RP”

”C” ”SA5”

”C” ”SA5”

”NC” ”RP”

”C” ”SA5”

”C” ”SA5”

”NC” ”RP”

”C” ”S”

”C” ”SA5”

”C” ”SA5”

”NC” ”RP”

”NC” ”RP”

Abbreviations:

”C”=Critical alarm

”NC”=Non-critical alarm

”RP”=Reduced performance

”SA5”=Motor stops after 5 restarts caused by same fault within 60 min

”S”=Motor stops immediately

© 2016 OJ Electronics A/S

23

Page 24

INSTRUCTIONS OJ-DV | Maintenance and troubleshooting

LED indications

• OJ-DV is equipped with a two-colour LED which

Figure 18.5

LED

indicates operating status.

• The LED is located on the underside of OJ-DV

beside the entry for the mains cable.

See fig. 18.5.

• Lights constantly green when mains voltage is

connected

• Flashes green when Modbus communication is

active

• Lights constantly red when at least one critical

alarm is active

• Flashes red when at least one non-critical

alarm is active

21. Modbus addressing of OJ-DV

Modbus addressing of OJ-DV can be accomplished in two dierent ways.

• Via the addressing pins of the ”A” or ”B” connectors – see fig. 13.14.1 and table 20.1.

Table 20.1

Add.

Pin. no.

0X36 (54 dec) 0X37 (55 dec) 0X38 (56 dec) 0X39 (57 dec)

BR1014A06a

© 2015 OJ Electronic A/S

BR1014A06a

Add.Pin1

Add.Pin2

= No connection between ”GND” and Add.Pin1/ Add.Pin2

= Connection between ”GND” and Add.Pin1/ Add.Pin2

• Via OJ-DV PCTool, where OJ-DV can be set to other Modbus addresses – see instructions for OJ-

DV PCTool.

Modbus protocol

• Contact OJ Electronics A/S if you require a complete Modbus protocol.

22. Maintenance

22.1. OJ-DV is maintenance free under normal operating conditions and load profiles.

22.2. The cooling fins must be kept free of dust, dirt and other foreign matter so that air can pass freely

over them. Deposits of dust, dirt or other foreign matter on and between the cooling fins will prevent

cooling of the OJ-DV and thus impair performance.

Caution

22.3. The cooling fins may become very hot. (Max. 95°C under normal operating conditions.)

Warning

22.4. OJ-DV cannot be repaired on site. Never attempt to repair a defective unit. Contact your supplier to

obtain a replacement.

22.5. Additional technical data are available on request from OJ Electronics A/S.

© 2016 OJ Electronics A/S

24

Page 25

INSTRUCTIONS OJ-DV | Maintenance and troubleshooting

23. Troubleshooting

Warning

23.1. Before opening OJ-DV, the mains voltage must be disconnected for at least 3 minutes to ensure

there is no risk of dangerous residual currents in electronic circuits or capacitors.

23.2. If natural drafts through the duct system cause the fan to rotate even though it has received no

operating signal, there is a risk that the motor will induce voltage on the OJ-DV motor terminals,

making them dangerous to touch.

23.3. Troubleshooting when OJ-DV is controlled via A/D signals:

Symptom Cause Action

Motor inoperative Lacking supply voltage Check the voltage supply to OJ-DV terminals ”L” and ”N” on 230V

models (H1) or terminals ”L1”, ”L2” and ”L3” on 3x400V and 3x230V

models (H3…H5).

(Nominal supply voltage is stated on the rating plate.)

Check whether short-circuit protection has been activated.

Check that the voltage supply to OJ-DV has not been cut o by

other components.

Poor electrical connections Check electrical connections.

Wrong motor for OJ-DV setup Check that the correct motor settings have been read into and stored

in the OJ-DV setup.

Lacking operating signal A/D control:

Check that OJ-DV can receive an operating signal.

With A/D control, OJ-DV must have a signal connected to the "Start/

Stop" input – digital input Din1 or Din2 depending on the setup.

Lacking 0-10VDC control signal Check that an operating signal is connected to ”0-10V In”.

Potentiometer control:

Check that the potentiometer is correctly connected to

terminals ”+10Vdc”, ”0-10V In” and ”GND” on the terminal strip.

Active alarm Read out active alarms and remedy their cause.

The motor has been stopped 5 times

by the built-in motor protector

because of overloading or other

alarm

Defective OJ-DV controller Replace OJ-DV.

Defective motor Replace motor.

Motor running in

wrong direction

Symptom Cause Action

OJ-DV noisier than

acceptable

Wrong phase sequence in motor

cable

Switching frequency too low Increase switching frequency.

Reset the alarm by short-circuiting the ”Alarm reset” input – digital

input Din1 or Din2 depending on the setup.

The alarm can also be reset by disconnecting the power supply to

the OJ-DV and reconnecting it after approx. 60 seconds.

Never attempt to repair a defective OJ-DV controller.

Contact your supplier for replacement/repair.

Interchange two phase wires on the motor or the OJ-DV terminal strip.

0 = Auto

1 = Low = 4 kHz

2 = High = 8 kHz

Increasing switching frequency increases losses within OJ-DV, thus

reducing eciency.

OJ-DV switching frequency can be changed via OJ-DV Hterm or via

Modbus.

© 2016 OJ Electronics A/S

25

Page 26

INSTRUCTIONS OJ-DV | Maintenance and troubleshooting

Symptom Cause Action

OJ-DV cuts out due

to an alarm

At least one alarm active Use OJ-DV Hterm to view the alarm and determine which alarm has

stopped the controller/motor.

Reset the alarm by short-circuiting the ”Alarm reset” input – digital

input Din1 or Din2 depending on the setup.

The alarm can also be reset by disconnecting the power supply to

the OJ-DV and reconnecting it after approx. 60 seconds.

The alarm is re-activated after reset Use OJ-DV PCTool to view the alarm and determine which alarm has

stopped the controller/motor.

Remedy the cause of repeated alarm activation.

23.4. Troubleshooting when OJ-DV is controlled via Modbus:

Symptom Cause Action

Motor inoperative Lacking supply voltage Check the voltage supply to OJ-DV terminals ”L” and ”N” on 230V

models (H1) or terminals ”L1”, ”L2” and ”L3” on 3x400V and 3x230V

models (H3…H5).

(Nominal supply voltage is stated on the rating plate.)

Check whether short-circuit protection has been activated.

Check that the voltage supply to OJ-DV has not been cut o by

other components.

Poor electrical connections Check electrical connections.

Wrong motor for OJ-DV setup Check that the correct motor settings have been read into and stored

in the OJ-DV setup.

Lacking operating signal Check that OJ-DV can receive an operating signal.

Coil Stat Bits Register 0X0001: Motor start/stop (1=On).

Lacking % control signal from Modbus controller

The motor has been stopped 5

times by the built-in motor protector

because of overloading

Defective OJ-DV controller Replace OJ-DV.

Defective motor Replace motor.

Check the Modbus control signal at Modbus address: Holding registers; Register 3X0001: PrcSet 0-10000 (0-100%).

Reset alarm: Coil Stat Bits Register 0X0002: Reset (1 pulse = Reset).

The alarm can also be reset by disconnecting the power supply to

the OJ-DV and reconnecting it after approx. 60 seconds.

Never attempt to repair a defective OJ-DV controller.

Contact your supplier for replacement/repair.

Motor running in

wrong direction

OJ-DV noisier than

acceptable

OJ-DV cuts out due

to an alarm

Wrong phase sequence in motor cable

Switching frequency too low Increase switching frequency.

At least one alarm active Use OJ-DV Hterm to view the alarm and determine which alarm has

The alarm is re-activated after reset Read out the alarm via Modbus registers and determine which alarm

Interchange two phase wires on the motor or the OJ-DV terminal strip.

0 = Auto

1 = Low = 4 kHz

2 = High = 8 kHz

Increasing switching frequency increases losses within OJ-DV, thus

reducing eciency.

OJ-DV switching frequency can be changed via OJ-DV Hterm or via

Modbus.

stopped the controller/motor.

Reset the alarm by short-circuiting the ”Alarm reset” input – digital

input Din1 or Din2 depending on the setup.

The alarm can also be reset by disconnecting the power supply to

the OJ-DV and reconnecting it after approx. 60 seconds.

has stopped the controller/motor.

Remedy the cause of repeated alarm activation.

© 2016 OJ Electronics A/S

26

Page 27

INSTRUCTIONS OJ-DV | Maintenance and troubleshooting

24. Disposal

• OJ-DV contains electronic components and must not be disposed of together with

household waste.

• OJ-DV must be disposed of in accordance with applicable local rules and regulations.

• OJ-DV meets the requirements on marking of electronic waste contained in the

European WEEE Directive 2012/19/EU.

© 2016 OJ Electronics A/S

27

Page 28

INSTRUCTIONS OJ-DV | Technical specifications

25. Technical specifications

Type DV-1005 DV-1007 DV-1011 DV-1013 DV-3015 DV-3024 DV-3030 DV-3040 DV-3055 DV-3065 DV-3075 DV-3110 DV-3150

Enclosure H1 H1x H3 H4 H5

Power size kW 0.5 0.75 1.1 1300 1.5 2.4 3.0 4.0 5.5 6.5 7.5 11 15

Eciency % > 94% > 96,5% > 96,5% > 97%

Power supply

Voltage VAC 1 x 230 VAC 50/60 Hz +/-10% 3 x 400 VAC 50/60 Hz +/-10%

Supply current at max. load A 3.0 4.4 6.5 8.5 3.1 5.0 6.3 8.4 11.5 13.6 15.7 24.4 33

Power factor

(cos-phi) at max. load

Motor output

Nominal motor power (on shaft) *1 kW 0.5 0.8 1.15 1.3 1.5 2.4 3.0 4.0 5.5 6.5 7.5 11 15

Frequency Hz AC motor: 0-120 | PM motor: 0-400

Max. output voltage Vrms 3 x 0 - 250 VAC 3 x 0 - 364 VAC

Max. output current Arms 2 3.2 4.5 5.2 4.5 6.4 8.0 10.0 12.0 15.0 19.0 27 35.0

Protection

Max. fuse A 16 32

Motor output Short-circuit protected between phases

Motor Protected by current limit

Impulse protection Protected against transient voltages by VDR

Over-voltage protection Yes, 400 V (PTC) Yes, 565 V

Overload protection Current and temperature overload protection

Environment

Operating temperature °C -40°C to +50°C

Starting temperature °C -40°C to +50°C

Storage temperature °C -40°C to +70°C

Dimensions mm 185 x 230.5 x 90 mm

Protection rating IP 54 & 65

Enclosure material Aluminium

Front cover Plastic

Weight kg 2.0 3.6 3.0 3.9 9.5

Humidity % rh 10-95% rh, non-condensing

Surface Corrosion resistant to EN/ISO 12944-2:1998 Category C4

Air flow / cooling

Interfaces

Digital communication MODBUS RTU RS485 (baud rate: 9.6, 19.2, 38.4, 115.2 Kbaud)