OPERATING MANUAL

AND FITTING

INSTRUCTIONS

OilQuick quick coupler with automatic

hydraulic connection for excavators

OQ 70/55 and 80

Specifications subject to change without notice.

Please read the instructions carefully

before using the quick coupler.

Dear Customer,

We congratulate you on your purchase of an OilQuick quick coupler system.

OilQuick is the most advanced quick coupler system for excavators and can be supplied in various models for

machines from 1 to 120 tons.

The modular OilQuick system is available as a standard hydraulic hitch or also with OilQuick function, which

allows hydraulic attachments to be connected or disconnected automatically from inside the cab.

Hydraulic attachments that can be used include Grab John buckets, tiltrotators, compactors, sorting grapples

and hydraulic hammers.

The OQ 70/55 model is suitable for excavators from 18 to 28 tons operating weight.

The OQ 80 model is suitable for excavators from 25 to 45 tons operating weight.

OilQuick products bear the CE marking and comply with all the applicable safety regulations.

When installing, using and repairing OilQuick quick coupler systems, please ensure that you meet all the

requirements.

Changes may only be made to OilQuick quick coupler systems with the approval of OilQuick AB.

Any unauthorized changes will void the warranty and CE-marking.

Please send us the completed warranty card as soon as possible.

We hope you enjoy the benefits and wish you every success with your new OilQuick quick coupler system.

Please read the instructions carefully before mounting and using the quick coupler system.

Introduction

These instructions apply to models OQ 70/55 and OQ 80.

Components are also described in the instructions that are optional accessories, which you may not have

ordered with your new quick coupler system. Please observe all the safety regulations and ensure that your

equipment is properly maintained. This will minimize the risk of damage and injury.

Information in boxes as illustrated below are

warnings that you should read particularly

carefully and understand.

Ignoring such warnings may result in personal

injury or damage to property.

Example

Information in boxes as illustrated below

contains important notes that you should read

carefully and understand.

Example

Subject to change without notice. Errors and omissions excepted.

This is a translation of the original manual.

Copyright © OilQuick AB.

Registration card for product warranty

The warranty is only valid if your new OilQuick product is installed correctly on the excavator and

attachment. Completing and sending in the registration card to OilQuick AB registers you as the

warranty holder for this product.

Unless otherwise agreed, the warranty terms included in this product manual shall apply.

The identification plate on the product shows details of the product model and serial number.

If you have any questions, please do not hesitate to contact your excavator dealer.

Detach here

Please send the completed registration card to:

OilQuick AB

Box 1055

82412 Hudiksvall

Sweden

Tel: +46 650 15340

Fax: +46 650 14884

E-mail: information@oilquick.com

Name of excavator dealer:

Name and address of customer:

Tel: Fax:

E-mail:

OilQuick quick coupler model:

Serial no.:

Excavator model: Excavator weight:

Date installed:

Hydraulic attachments used:

Received by OilQuick AB on:

Declaration of Conformity

The company OilQuick AB

Box 1055

SE-824 12

Hudiksvall

hereby certifies that the quick coupler system

SWEDEN

Designation Quick Coupler

Type

Serial no.

Year of manufacture

Weight

conforms to the requirements of Machinery Directive

2006/42/EC and the applicable regulations in

European standards EN 474-1, EN 474-4 and

EN 474-5, and machine regulations 2008:3 issued by

the Swedish Work Environment Authority.

Before operating the quick coupler, additional risks

that may arise from mounting the coupling device on a

machine or other type of attachment carrier must be

investigated and compliance with the regulations

stated in the above guidelines determined.

Name Åke Sonerud

Position General Manager

Hudiksvall, Sweden

Contents

Dear Customer 2

Introduction 2

Registration card for product warranty 3

Contents 5

Declaration of Conformity 6-7

1. OilQuick quick coupler system components 8

1.1 Coupler part 8

1.2 H-cylinder 8

1.3 Attachment frame for mechanical tools 8

1.4 Attachment frame for hydraulic tools 9

1.5 V-90 electric coupling (option) 9

1.6 1/2" electric coupling (option) 9

1.7 Locking hydraulic kit (option) 9

2. Quick coupler functionality 10

3. H-cylinder – function and requirements 11

4. Technical data 12

4.1 General data 12

4.2 Quick coupler 12

4.3.1 Attachment frame for mechanical tools without coupling ramp 13

4.3.2 Attachment frame for hydraulic tools with coupling ramp 13

4.3.3 Hydraulic tool adapter plate with coupling ramp 13

4.3.4 Hydraulic tool special adapter with coupling ramp 13

5. Quick coupler installation 14

6. Hydraulic system installation 15

7. Coupling an attachment 16-17

7.1 Checking hydraulic tools 17

7.2 Checking mechanical tools without hydraulic system 17

8. Lock test for mechanical tools 18

9. Setting down a tool 18-19

10. Using the hoisting hook 20

Version 1.1 6 2011-06-28

11. Checking the attachment frame 21-22

12. Starting and stopping the excavator for maintenance work 22

13. Inspection and maintenance 23

13.1 Daily inspection 23

13.1.1 At the start of the working day 23

13.1.2 At the end of the working day 23

13.2 Monthly inspection 23

14. Maintenance of quick couplers on H-cylinders 24

14.1 Replacing the nose seal in the female connector 24

14.2 Replacing quick couplers secured with circlips 25

14.3 Replacing quick couplers secured with nose nuts 26

15. Troubleshooting 27

16. Plates and stickers 28

17. Terms of warranty 29

Version 1.1 7 2011-06-28

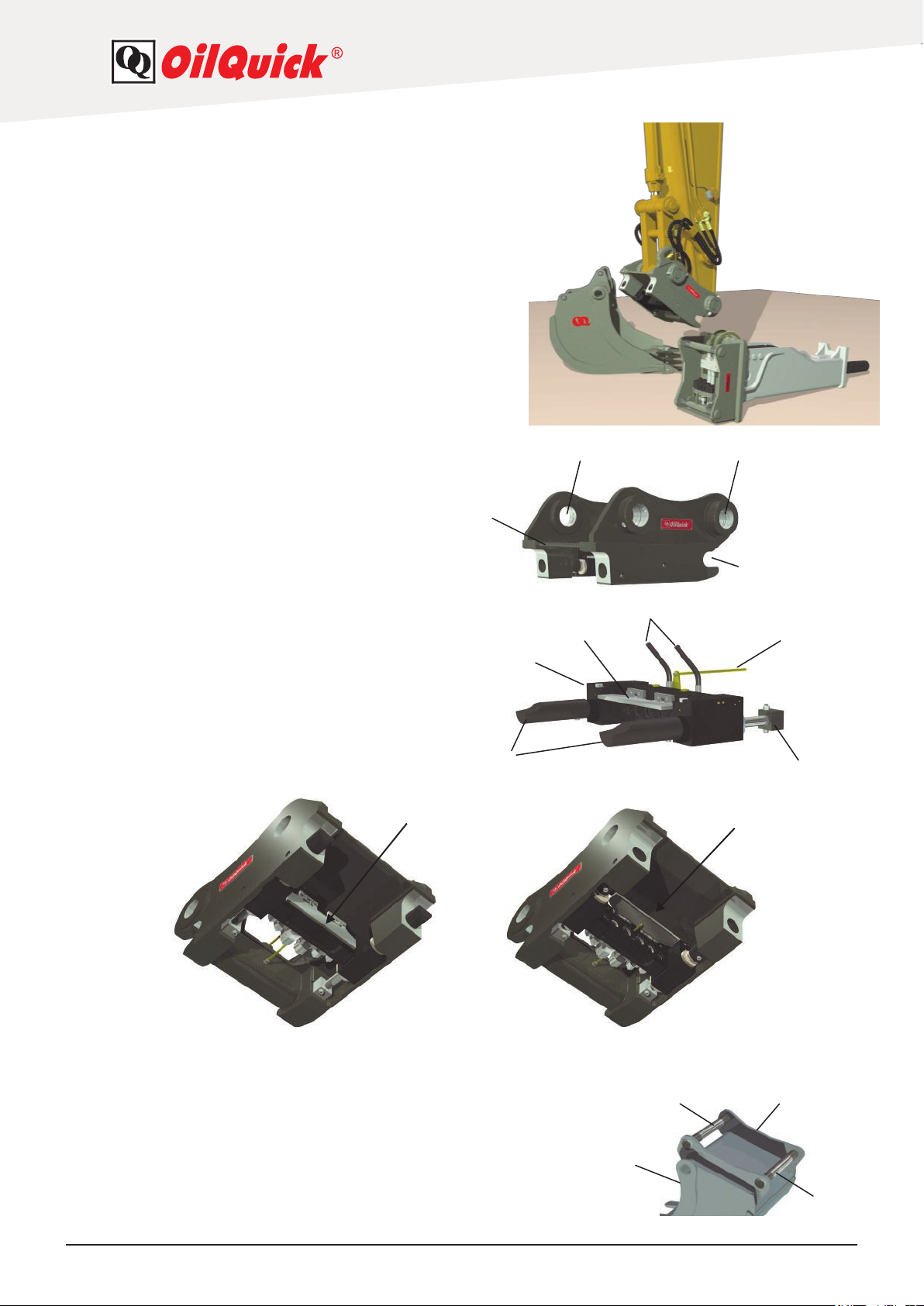

1. OilQuick quick coupler system components

The following section describes the various components in

the OilQuick quick coupler system.

1.1 Quick coupler body

1. Coupler body

2. For attaching to the excavator arm

3. For attaching to the linkage

4. Fingers

1

3

2

4

1.2 H-cylinder

5. H-cylinder

6. Cylinder holder

7. Hydraulic hoses for locking and unlocking

8 Locking plungers

9 Indicator rod

10. Dirt guard

10

Dirt guard closed Dirt guard open

8

5

10

7

9

6

10

1.3 Attachment frame for mechanical tools

11. Attachment

12. Front frame pin

13. Rear frame pin

14. Side part

Version 1.1 8 2011-06-28

11

14 12

13

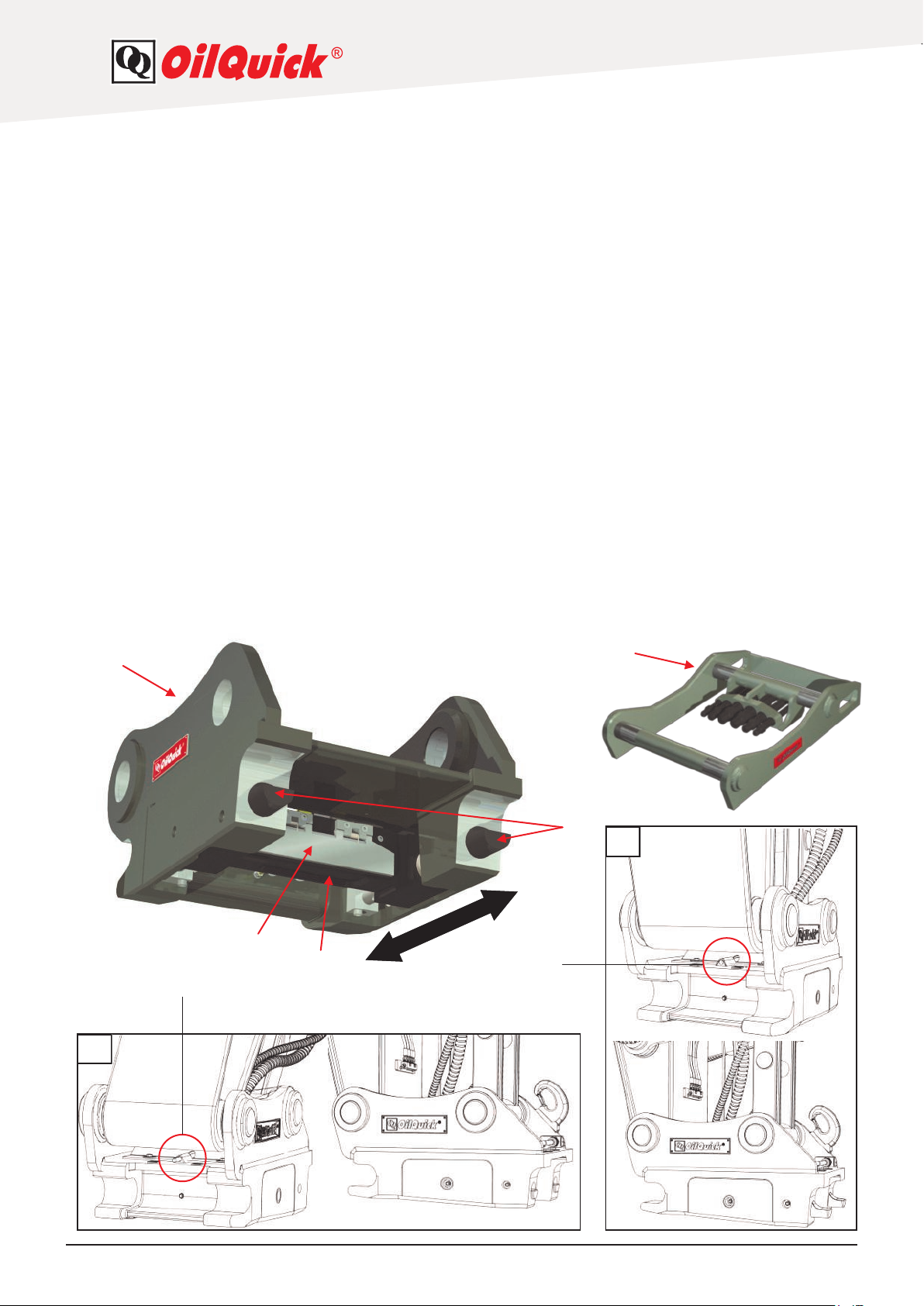

1.4 Attachment frame for hydraulic tools

15. Attachment frame

16. Coupling ramp

17. Male connector

18. Front pin

19. Rear pin

The attachment frames are available in various models for different applications, but the function is the same

as for the basic model in each case. For further details, please contact your nearest OilQuick dealer.

17

18

15

19

16

1.5 V-90 electric coupling (option)

20. Contact socket

21. Contact plug

The contact elements are 10 pin.

21

20

21

20

1.6 1/2" electric coupling (option)

22. Contact socket

23. Contact plug

The contact elements are 10 pin.

22

23

22

23

1.7 Locking hydraulic kit (option)

28

24

27

26

24. Control switch with double command function

25. Alarm

26. Electric selector valve, 4/2

27. Cable set

28. Electric connection

Use this kit when a hydraulic lock has not yet been installed on the machine or OilQuick's requirements

for hydraulic locking has not been met (see section 3).

25

Version 1.1 9 2011-06-28

2. Quick coupler functionality

The quick coupler consists of a basic coupler part (1) with the H-cylinder (2) and various accessories

mounted on it. It is attached to the excavator arm and linkage. The H-cylinder (2) and locking plungers (3) are

moved backwards and forwards (4) when oil is supplied to the H-cylinder. When the H-cylinder is located at

the front position (4:1), the locking plungers are not visible and an attachment can be connected or disconnected. When the H-cylinder is located at the rear position (4:2), the locking plungers are visible and an attachment

frame can be connected to the coupler.

The hydraulic quick couplers are located in the middle of the H-cylinder between the locking plungers.

Models OQ 70/55 and OQ 80 can be fitted with two 1/2", two 3/4" and two 1" quick couplings.

A dirt guard (5) prevents the quick couplers from becoming dirty. It is opened automatically when the

H-cylinder is at the front position (4:1) and closed automatically at the H-cylinder's rear position (4:2).

The system installed on the excavator for the hydraulic quick coupler supplies oil to the H-cylinder (2).

The operator only has to take a look at the indicator rod (6) to check the H-cylinder's position.

When the indicator rod (6) is visible, the H-cylinder (2) is at its front position and the quick coupler is

unlocked. In this case an alarm sounds and a warning light comes on in the cab.

When the indicator rod (6) is not visible, the quick coupler is closed or locked with an attachment frame.

In this case there is no acoustic signal and the warning light does not come on.

When a hydraulic tool (7) is coupled, the hydraulic quick couplers are connected and the attachment is

mechanically locked.

1

4:1

6

5

2

4

7

3

4:2

6

Version 1.1 10 2011-06-28

Loading...

Loading...