Oilon GP-6.10 P, GP-6.20 P Maintenance Manual

OPERATING AND MAINTENANCE

INSTRUCTIONS

GAS BURNERS

q GP-6.10 P

q GP-6.20 P

OILON OY

P.O.Box 5

FIN-15801 LAHTI FINLAND

Tel. +358 3 85 761

Fax +358 3 857 6239

E-mail info@oilon.com 40180036GB

Table of Contents

1. Conventions in this Manual ............................................................................................................1

2. General...........................................................................................................................................2

3. Burner Technical Data ...................................................................................................................4

3.1. Technical Data .....................................................................................................................4

3.2. Basic Assembly Drawing......................................................................................................5

3.3. Parts List ..............................................................................................................................6

3.4. Burner Dimensions ..............................................................................................................6

3.5. Nozzle Table ........................................................................................................................6

4. Burner Installation ..........................................................................................................................7

4.1. Burner Mounting...................................................................................................................7

4.2. Hinged Burner Housing........................................................................................................7

4.3. Electric Connections ............................................................................................................7

4.4. Example of an Installation of Gas Supply Line ....................................................................8

4.5. Gas Pressure Regulating Assembly ....................................................................................9

5. Burner Automation .......................................................................................................................10

5.1. Time Sequence Diagram (High-Low) ................................................................................10

5.2. Time Sequence Diagram (Modulating) ..............................................................................11

5.3. Operation ...........................................................................................................................12

6. Burner Adjustments......................................................................................................................15

6.1. Capacity Regulation ...........................................................................................................15

6.2. PI-Diagram.........................................................................................................................16

6.3. Combustion Head Adjustments .........................................................................................17

6.3.1. Distance between Nozzle and Diffuser Disc and Ignition Electrode

Setting ...................................................................................................................17

6.3.2. Adjusting the Air Velocity in the Combustion Head ...............................................17

6.3.3. Setting Values of Adjustment Ring........................................................................18

6.4. Combustion Air Adjustment ...............................................................................................19

6.5. Air Cone Position ...............................................................................................................20

6.6. Flame Inspection................................................................................................................20

6.7. Pressure Switches .............................................................................................................21

6.7.1. Gas Pressure Switch.............................................................................................21

6.7.2. Differential Air Pressure Switch.............................................................................22

7. Valve Leak Tester VPS 504 (only on request) .............................................................................23

8. Control Unit LFL1.322 ..................................................................................................................24

8.1. Internal Circuitry................................................................................................................24

8.2. Control Program of the Sequence Switch..........................................................................25

8.3. Control Program under Fault Conditions and Lockout Indication ......................................26

8.4. Detector Currents and Connection of Flame Detector FE (Ionization Electrode) ..............27

8.5. Technical Data ...................................................................................................................27

9. Maintenance.................................................................................................................................28

10. Fault Conditions and Procedures .................................................................................................29

11. Notes ............................................................................................................................................32

40180036GB

1. Conventions in this Manual

Read these instructions carefully before installation, commissioning or

maintenance of the burner. The given instructions must be followed.

Throughout this manual, the following three symbols are used to point out very

important information:

DANGER! This symbol is used where there may be a danger to personnel, if the

instructions are not followed.

CAUTION! This symbol is used where there may be something that has the potential

to cause damage to component, burner, process or surroundings, if the instructions are

not followed.

1

Note!

A note points out information of special interest.

KEEP THESE OPERATING AND MAINTENANCE INSTRUCTIONS

AS WELL AS THE ELECTRICAL SCHEMES AVAILABLE NEAR THE

BURNER!

40180036GB

2. General

Oilon GP-6.10 P and GP-6.20 P -burners are fully automatic gas burners.

The burners can be used on most heating appliances such as hot water boilers, steam boilers

and air heaters.

2

Burners are tested and certified for the following gas types

· natural gas: - gases of the 2

nd

family, groups H and E (equipment categories I

2H

and I2E)

- supply pressure (=inlet pressure) at burner 20 - 100 mbar

- gas temperature to gas valve -15…+40 °C.

rd

· LPG: - gases of the 3

family, group P (equipment category I3P)

- supply pressure (=inlet pressure) at burner 30 - 100 mbar

- gas temperature to gas valve 0…+40 °C.

When using other gases or supply pressures as the above mentioned, please consult the burner

manufacturer on the suitability of the burner.

When necessary the gas pressure is reduced in the pressure regulating assembly. The quantity

of gas is regulated by means of with the gas valve (MultiBloc) equipped with gas/air ratio

controller).

A fan attached to the burner and dimensioned to provide a sufficiently high and even air

pressure for efficient combustion in modern combustion chambers supplies the required air.

Max. required combustion air: 13 m³ of combustion air for each 10 kWh.

Burner operation is controlled and supervised by control unit.

The burner capacity is controlled by boiler thermostats or pressurestats (High-Low) or by

electronic controller (high-low or modulating).

Degree of protection: IP20

Supply/control voltage: 230 V (-15 %...+10 %) 50 Hz 1-phaese

Consumption: 200 W 1,0 A

A pre-requisite for burner operation is, that the ambient temperature during burner operation is

0...+40 °C.

The following should be checked before first start-up:

· connections are correct,

· settings of boiler regulating and control devices are correct,

· boiler and its equipment is in working condition,

· burner is getting sufficient air,

· valves in supply line are open,

· gas line is filled with gas,

· leak test on gas line has been carried out,

· gas pressure is adequate.

40180036GB

3

CAUTION! The burner must be installed firmly. Vibrations may damage burner or its

components.

CAUTION! Prior to trial start the gas piping must be vented. See chapter ”Example of

an Installation of Gas Supply Line”.

DANGER! In case of gas leakage:

- do not make fire, do not touch the electrical equipment

- close the main fuel shut-off valve outside the plant

- make sure, that there is no people in the leakage area

- air the leakage area

- take appropriate actions.

In case of fire or other danger:

- switch off the main switch

- close the main fuel shut-off valve outside the plant

- take appropriate actions.

DANGER! Never use a naked flame while checking the burner or the boiler. Never

store any inflammable material in the boiler room.

DANGER! Keep the boiler door closed while starting the burner and during burner

operation.

DANGER! Wear hearing protectors, if there is noise in the boiler room.

Correct installation and adjustment together with regular servicing are the most reliable

guarantees of trouble-free burner operation.

Note!

Local regulations and requirements must be adhered to when installing or servicing

the gas burner or the gas supply line.

The burner has to be installed in such a way that the motor shaft lies horizontally; however, it is

not allowed to install the burner upside down.

Use only original spare parts. When ordering spare parts please give the burner type and serial

number indicated on the burner nameplate.

40180036GB

3. Burner Technical Data

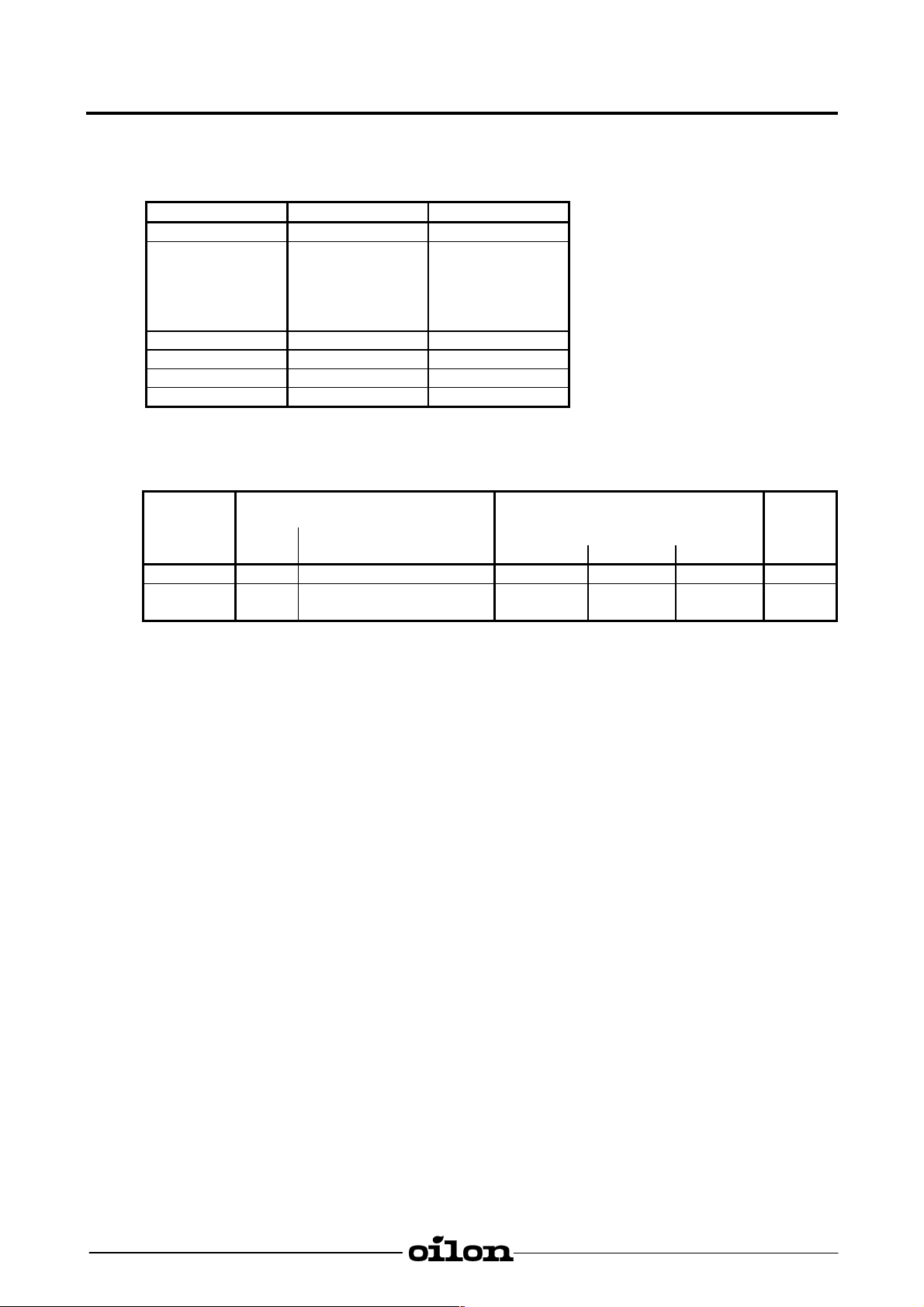

3.1. Technical Data

Burner GP-6.10 P GP-6.20 P

Capacity kW 50 - 120 60 - 160

Burner motor

Voltage 50 Hz

Output kW

Current A

Speed rpm

Control unit LFL1.322 LFL1.322

Flame detector Electrode Electrode

Servomotor SQN… SQN…

Weight kg 22 22

Effect of gas inlet pressure on burner capacity range

Burner Gas valve Burner capacity range kW *) Pmax

Conn. Gas inlet pressure pressure

size Type 20 mbar 50 mbar 100 mbar mbar

GP-6.10 P ¾" MB-VEF 407 B01 50 - 120 50 - 120 50 - 120 100

GP-6.20 P ¾"

1 ¼"

1~ 230 V

0,125

1,0

2750

MB-VEF 407 B01

MB-VEF 412 B01

4

1~ 230 V

0,125

1,0

2750

60 - 130

60 - 160

60 - 160

60 - 160

60 - 160

60 - 160

inlet-

100

100

*) The max. capacities given in the table are obtained at a boiler backpressure of 0.

40180036GB

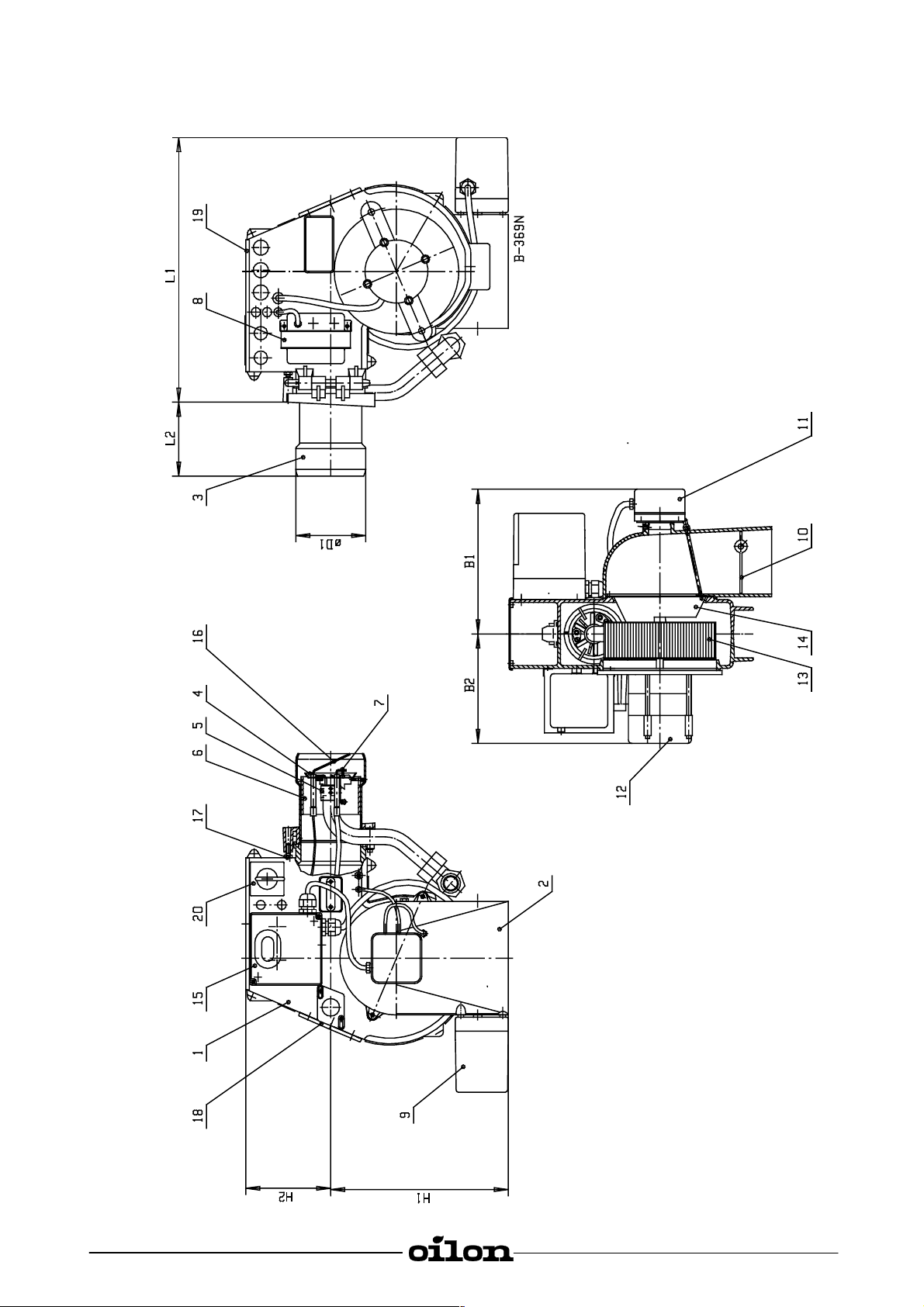

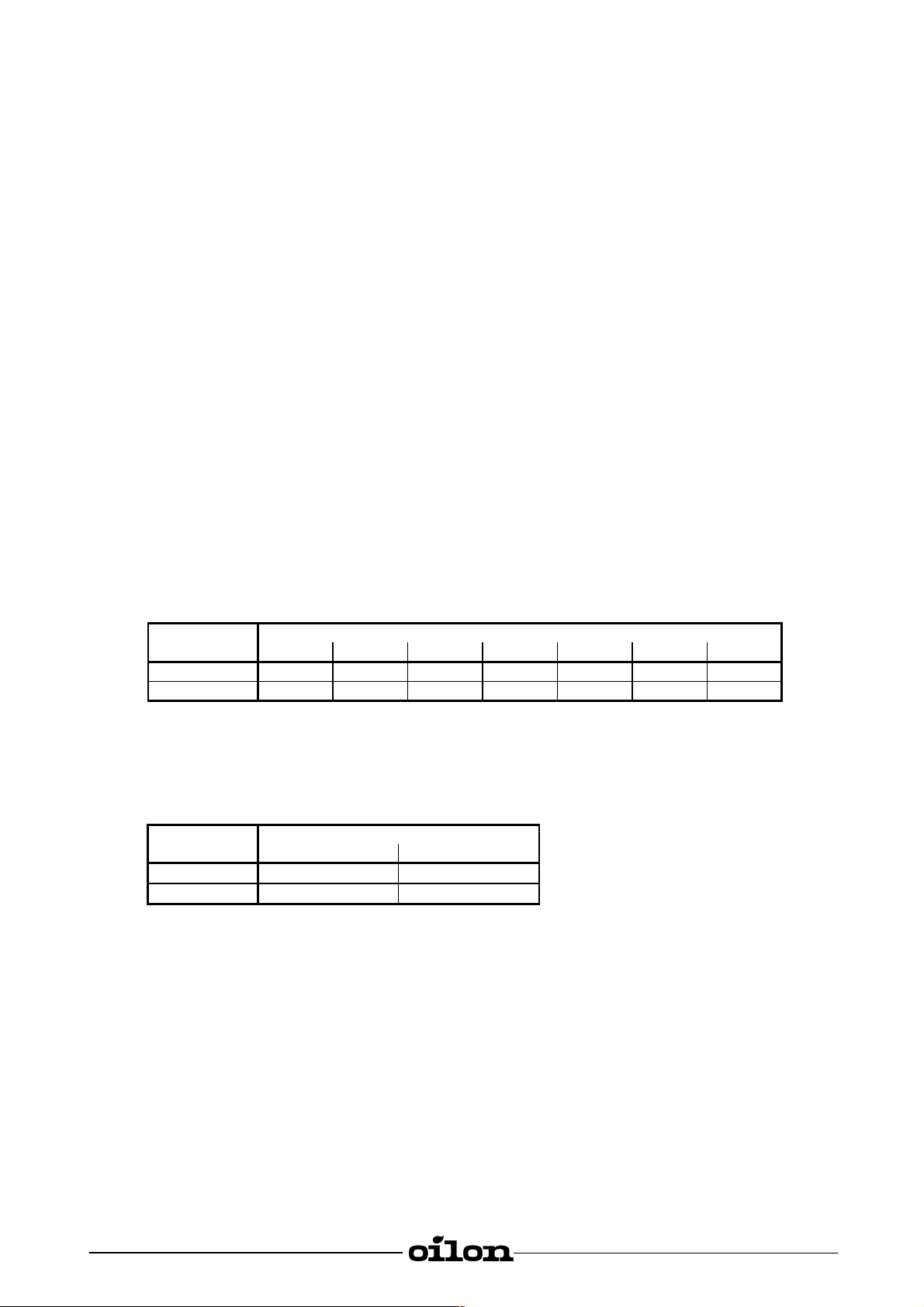

3.2. Basic Assembly Drawing

5

40180036GB

3.3. Parts List

1 Burner housing

2 Air intake

3 Flame tube

4 Diffuser disc

5 Gas nozzle

6 Adjustment ring

7 Ignition electrode

8 Ignition transformer

9 Air damper servomotor

10 Air damper

11 Differential air pressure switch

12 Burner motor

13 Fan wheel

14 Air control cone

15 Control unit

16 Ionization electrode

17 Limit switch (safety switch)

18 Sight glass

19 Protective cover

20 Control switch

6

3.4. Burner Dimensions

Burner Measures in mm

L1 L2 H1 H2 B1 B2

GP-6.10 P 400 110 255 120 210 180 95

GP-6.20 P 400 110 255 120 210 180 100

3.5. Nozzle Table

Burner Nozzle (pcs x hole size)

Natural gas LPG

GP-6.10 P

GP-6.20 P

8 x Æ 4,0 8 x Æ 2,8

8 x Æ 4,0 8 x Æ 2,8

Æ D1

40180036GB

4. Burner Installation

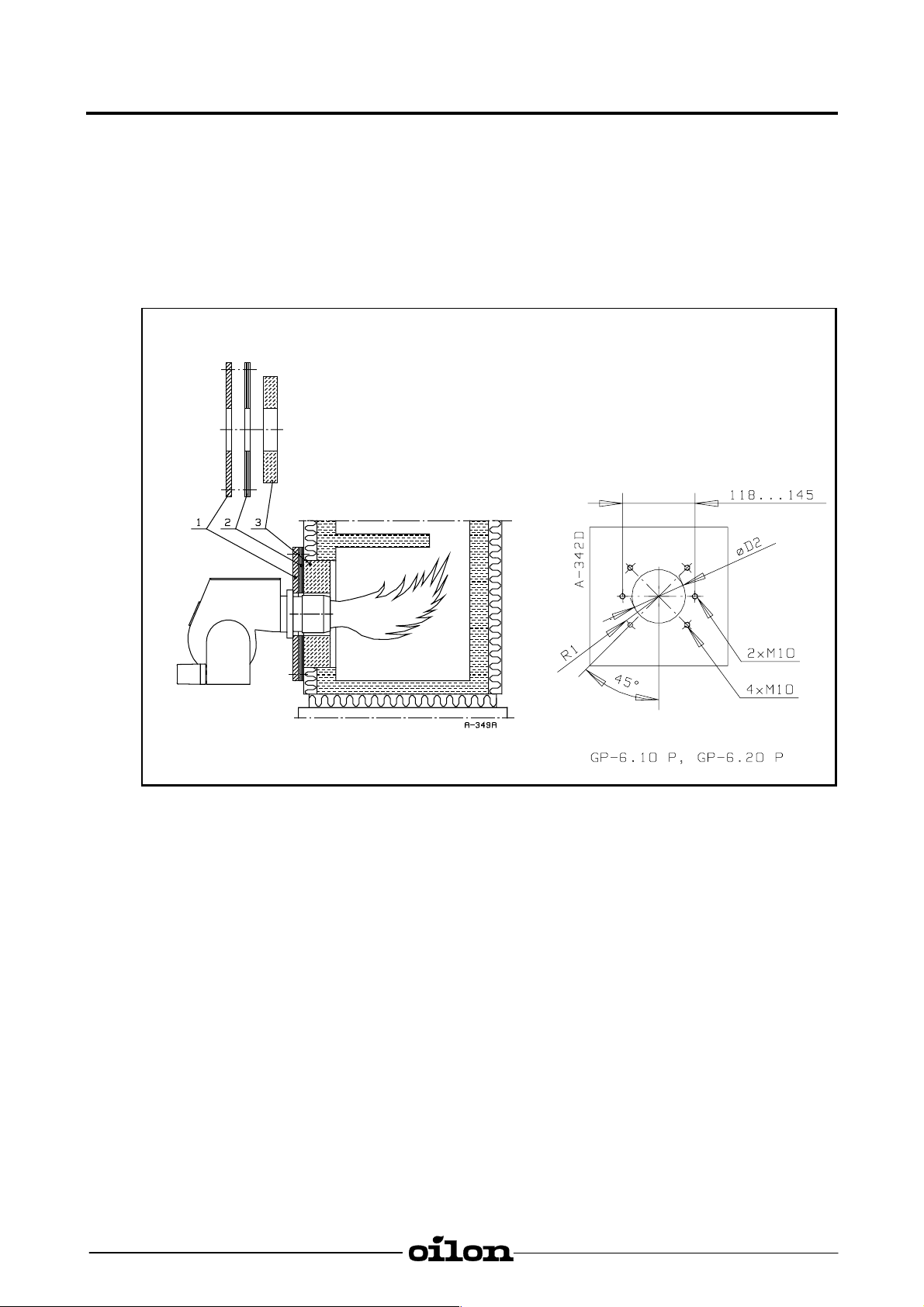

4.1. Burner Mounting

The furnace which has a flame-shaped design does not require refractory. Boilers without

bottom cooling require refractory to prevent heat from reaching boiler foundations.

The flame must at no point come into contact with the furnace walls. If this cannot be avoided,

such points must be covered with refractory. This applies especially to the refractory at the back

wall of short furnaces.

7

1 Mounting plate

2 Gasket plate

3 Thermal insulation

Burner Æ D2 R1

GP-6.10 P 100 70 - 74

GP-6.20 P 105 70 - 74

The mounting plate must have 2 or 4 pcs M10 threaded holes for the mounting of the burner

according to the drawing.

4.2. Hinged Burner Housing

On standard version the burner can be hinged to the left.

4.3. Electric Connections

The burner must be connected according to the electrical diagrams delivered together with the

burner. General and local standards and regulations as well as requirements of electrical

equipment on electrical connections must be adhered to.

40180036GB

8

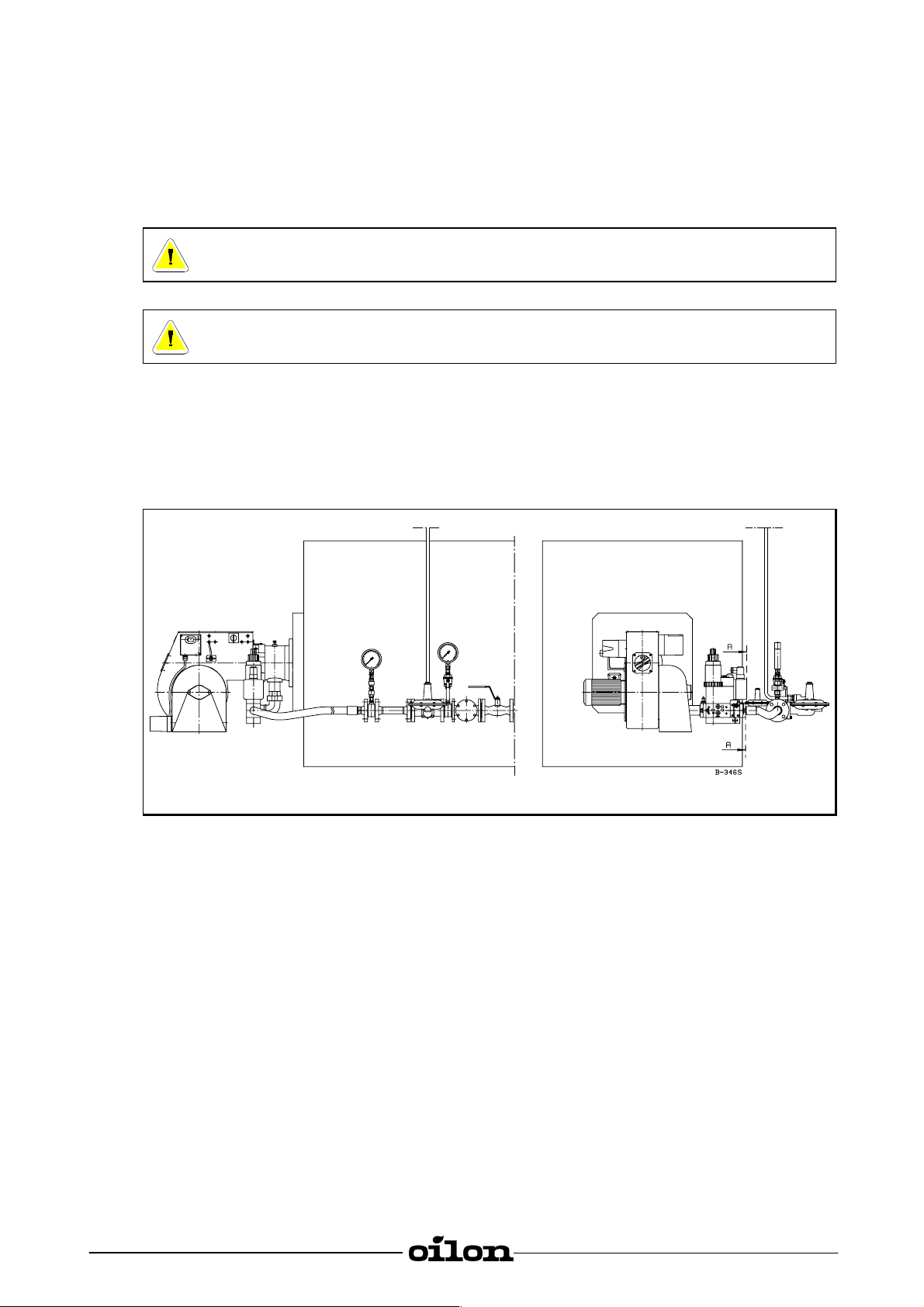

4.4. Example of an Installation of Gas Supply Line

The gas supply line after the pressure regulator must be of the same size or one size larger than

the valve train size.

As standard the gas connection to the burner is from the right side.

Note! A hand-operated shut-off valve must be fitted before the gas valve train.

CAUTION! A separate filter must be fitted before the gas valve train.

CAUTION! The gas valve must be mounted tension free.

Gas pipe venting

A pipe or hose is connected, leading into the open from the measuring connection of inlet

pressure in the gas valve, to discharge the air. For venting open slowly the ball valve in the

supply line and fill the piping with gas. After this close measuring connection.

A - A delivery limit

40180036GB

Loading...

Loading...