OilGear PVM-011, PVM-014, PVM-046, PVM-022, PVM-065 Service Manual

...

Bulletin 947070-B

OILGEAR TYPE “PVM” PUMPS -

-011/-014/-022/-025/-034/-046/

-064/-065/-075/-076/-098/-130

SERVICE INSTRUCTIONS

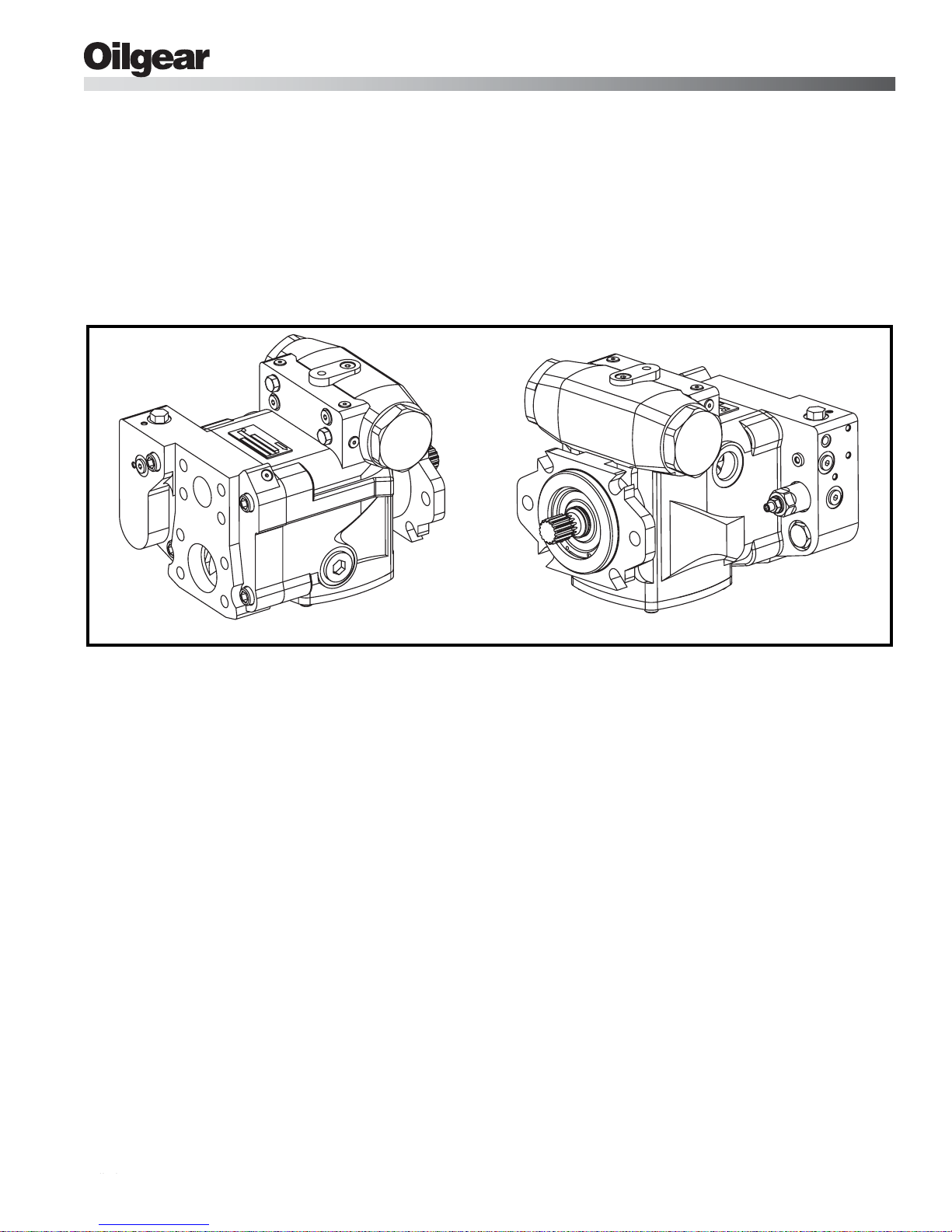

Figure 1. Typical Oilgear “PVM” Open Loop Pump

PURPOSE OF INSTRUCTIONS

These instructions will simplify the installation,

operation, maintenance and troubleshooting of

Oilgear type “PVM” pumps.

REFERENCE MATERIAL

Fluid Recommendations.....................................................................................Bulletin 90000

Contamination Evaluation Guide.........................................................................Bulletin 90004

Filtration Recommendations...............................................................................Bulletin 90007

Piping Information...............................................................................................Bulletin 90011

Installation of Vertically Mounted Axial Piston Units ...........................................Bulletin 90014

PVM Open Loop Pumps Sales Brochure........................................................Bulletin 47070-B

OILG0173

Become familiar with the construction, principle of

operation and characteristics of your pump to help

you attain satisfactory performance, reduce shutdown and increase the pump's service life. Some

pumps have been modified from those described in

this bulletin and other changes may be made

without notice.

Bulletin 947070-B THE OILGEAR COMPANY 1

Revised November, 2004

THE OILGEAR COMPANY

2300 South 51st Street

Milwaukee, Wisconsin 53219

Bulletin 947070-B

Safety First

Read and understand this entire instruction sheet

before repairing, or adjusting your Oilgear product.

Those who use and maintain this equipment must

be thoroughly trained and familiar with the product.

If incorrectly used or maintained, this product and

its equipment can cause severe injury.

SAFETY SYMBOLS

The following signal words are used in this

instruction sheet to identify areas of concern where

your safety may be involved. Carefully read the text

and observe any instructions provided to ensure

your safety.

DANGER

! !

THIS SIGNAL WORD INDICATES AN IMMINENTLY HAZARDOUS SITUATION WHICH,

IF NOT AVOIDED, WILL RESULT IN DEATH

OR SERIOUS INJURY.

WARNING

!

This signal word indicates a potentially

hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION

This signal wor d indicate s that a pote ntiall y

hazardous situation exists which, if not

avoided, may result in damage to

equipment or minor personal injury.

NOTE

While not directly relevant to the topic being

discussed, the NOTE is used to emphasize

information provided, or provide additional

information which may be of benefit.

WARNING

!

This service information is designed for

the maintenance of your Oilgear product.

It contains the information on the correct

procedures determined by Oilgear for the

safe manner of servicing. Always keep

this instruction sheet in a location where it

is readily available for the persons who

use and maintain the product. Additional

copies of this instruction sheet are

available through the Oilgear Company.

Or visit our website: www.oilgear.com.

Please contact us if you have any

questions regarding the information in

this instruction bulletin.

NOTE

The cleanliness of working on this pump or

the hydraulic system is extremely

important to the safety and reliability of the

pump and the system. Always make sure

the fittings are clean on the outside before

removing them from their connections, are

capped and plugged when removed and

placed in a clean rag or container until they

are reinstalled.

WARNING

!

Some service operations may require

special tools or equipment. If you require

information on these items, please contact

Oilgear before attempting these repairs

and service operations.

WARNING

!

Read, understand, and follow the safety

guidelines, dangers, and warnings

contained in this instruction sheet to

promote reliable operation and prevent

serious personal injury.

WARNING

!

DO NOT attempt to service this machinery

in an environment where safety regulations

are not established and in place.

WARNING

!

DO NOT operate the hydraulic system if a

leak is present. Serious injury may result.

WARNING

!

Hydraulic systems operate under very high

pressure. Hydraulic fluid escaping from a

pressurized system can penetrate

unprotected body tissue. DO NOT inspect

for hydrauli c leaks with ba re hands or o ther

exposed body parts. As a minimum, wear

leather gloves prior to inspecting for leaks

and use cardboard or wood. If leaks are

present, relieve pressure and allow system

to cool prior to servicing. If injured by

escaping hydraulic oil, contact a physician

immediately. Serious complications may

arise if not treated immediately. If you have

questions regarding inspecting for

hydraulic leaks, please contact Oilgear

prior to servicing.

2 THE OILGEAR COMPANY Bulletin 947070-B

© 1993 THE OILGEAR COMPANY - ALL RIGHTS RESERVED

Safety First

WARNING

!

Hydraulic hoses and tubing must be

inspected on a daily basis for leaks, cuts,

abrasions, damage and improper

clearance along any mounting frame for

hidden damage before the unit is put into

service. Replace damaged hoses or hoses

you suspect are damaged before the

system is returned to service! Hoses must

be replaced every two years. Failure to

properly inspect and maintain the system

may result in serious injury.

WARNING

!

Hydraulic systems are hot. DO NOT

TOUCH! Serious personal injury may

result from hot oil. When you have

completed working on the hydraulic

system, thoroughly clean any spilled oil

from the equipment. Do not spill any

hydraulic fluids on the ground. Clean any

hydraulic fluids from your skin as soon as

you have completed maintenance and

repairs. Dispose of used oil and system

filters as required by law.

WARNING

!

Hydraulic cylinders can be holding a

function in a certain position when

thepump is OFF. An example of this is a

function being held in the lift or partial lift

position by the cylinders. If a hydraulic

line is removed or the hydraulic circuits or

controls are being worked on, gravity may

allow the function being held in position to

drop. All workers and personnel must

remain clear of these areas when working

on or operating the hydraulic system.

Block and secure all devices and

functions which apply before beginning

work or operation. Failure to comply with

this can result in serious injury or death.

WARNING

!

Any hydraulic pipe which is replaced must

conform to SAE J1065 specifications. If

incorrect hydraulic pipe is installed, the

hydraulic system may fail, causing

serious injury. Damaged or leaking

fittings, pipes or hoses must be replaced

before the system is returned to service.

WARNING

!

Use correct hoses, fittings, and adapters

with the correct SAE rating when

replacing hoses to prevent possible

serious injury. Always replace hoses,

fittings, and adapters with replacements

that have a proper, suitable, working

pressure rating. Replacement hoses must

be of the correct length and must comply

with the hose manufacturer’s and

Oilgear’s installation guidelines and

recommendations.

WARNING

!

Hydraulic hoses have the SAE ratings

marked on the hose to assist you in

selecting the correct hose. The same manufacturer must supply any replacement

hydraulic hoses and fitting assemblies. As

an example: Brand “X” hose and brand “Y”

fitting will not normally be compatible. No

“Twist” is allowed in the hydraulic hoses.

“Twist” may result in premature hose

failure. This can cause serious injury.

Please contact Oilgear for assistance when

required.

WARNING

!

DO NOT heat hydraulic pipe. The carbon

content of this steel tube is such that if

heated for bending, and either water or air

quenched, the pipe may lose its ductility

and thereby be subject to failure under

high pressure or hydraulic chock

conditions. Serious injury can result.

Damaged or leaking pipes must be

replaced before the system is returned to

service. Please contact Oilgear if you

require assistance or have questions.

WARNING

!

All hydraulic pressure must be relieved

from the hydraulic system prior to re moving

any components from the system. To

relieve the hydraulic pressure from the

hydraulic system, turn off the motor and

operate the control panel with the key in the

ON position. Failure to comply can result in

serious injury. If you have any questions

concerning relieving the hydraulic pressure

from the system, please contact Oilgear.

Bulletin 947070-B THE OILGEAR COMPANY 3

Safety First

WARNING

!

Hydraulic components can be heavy. Use

caution while lifting these components.

Serious personal injury can be avoided

with proper handling of the components.

WARNING

!

Please contact Oilgear if you require

assistance, when performing hydraulic

test procedures, use the proper hydraulic

gauges. Installing an incorrect test gauge

could result in serious injury if the gauge

fails. Use properly rated hydraulic hoses

to allow the test gauge to be read away

from moving parts and functions.

WARNING

!

Increasing hydraulic pressure beyond the

recommendations may result in serious

damage to the pump and system or

serious personal injury and may void the

Oilgear Warranty. If you have questions

concerning hydraulic pressures or testing

procedures, please contact Oilgear before

attempting the test procedures or making

adjustments.

WARNING

!

Any Oilgear pump safety decals must be

replaced anytime they are damaged,

missing, or cannot be read clearly. Failure

to have proper decals in place can result

in serious injury or death. (If you require

safety decals, please contact Oilgear for

replacement safety decals, at no charge.)

WARNING

!

Be sure everyone is clear of the area

around the hydraulic system before

operating after servicing. Remain attentive

at all times when operating to check your

work until you are completely sure it is

safe to return to service. Failure to heed

this warning may result in serious

personal injury or death.

WARNING

!

Wear the proper protective clothing when

operating, servicing or maintaining the

hydraulic system or the Oilgear pump. Wear

the correct protective gear, safety glasses,

gloves, and safety shoes. Serious injury

can result without proper protective gear.

WARNING

!

An Oilgear pump must not be modified in

any way without authorization from

Oilgear. Modifications may not comply

with safety standards, including ANSI

safety standards, and may result in

serious personal injury. Please contact

Oilgear if you require assistance.

WARNING

!

DO NOT enter under hydraulic supported

equipment unless they are fully supported

or blocked. F ailure to follow this procedure

can result in serious injury or death.

WARNING

!

Make sure to keep hands and feet and

other parts of your body clear of revolving

or moving parts. Failure to comply can

cause serious injury.

WARNING

!

DO NOT wear watches, rings, or jewelry

while working with electrical and mechanical equipment. These items can be hazardous and can cause serious and painful

injuries if they come into contact with electrical wires, moving parts, or hydraulic

equipment.

4 THE OILGEAR COMPANY Bulletin 947070-B

Service Instructions

PREPARATION AND

INSTALLATION

MOUNTING

Pump Without Reservoir - The pump can be

mounted in any position. But, the recommended

mounting position is with the driveshaft on a

horizontal plane. Secure the pump to a rigid

mounting surface.

Pump With Reservoir - These pumps are usually

fully piped and equipped. It may be necessary to

connect to a super-charge circuit when used.

Mount reservoir on level foundation with the

reservoir bottom at least six inches above floor

level to facilitate fluid changes.

PIPING AND FITTINGS

Refer to the referenced Oilgear Piping Information

Bulletin 90011 and individual circuit diagram before

connecting the pump to the system. Inlet velocity

must not exceed 5 fps (1,5 mps). Inlet should be

unrestricted and have a minimum of fittings.

NOTE

Horizontal Mounting - Arrange line from the highest

“case drain” or “alternate case drain” so the case

remains full of fluid (non-siphoning). Case pressure

must be less than 25 psi (1,7 bar). For higher case

pressures and the special shaft seals required,

contact our Customer Service. Each drain line

must be a separate line, unrestricted, full sized and

connected directly to the reservoir below the lowest

fluid level. Make provisions for opening this line

without draining (siphoning) reservoir.

Vertical Mounting - Refer to referenced Oilgear

“Installation of Vertically Mounted Axial Piston

Units,” Bulletin 90014.

DO NOT use an inlet strainer.

WARNING

!

Running the pump in NEUTRAL position

(zero delivery) for extended periods

without a supercharge circuit can damage

the pump. The system and pump must be

protected against overloads by separate

high pressure relief valves. Install bleed

valve(s) at the highest point(s) in system.

POWER

Power is required in proportion to volume and

pressure used. Motor size recommendations for

specific applications can be obtained from The

Oilgear Company. Standard low starting torque

motors are suitable for most applications.

CAUTION

DO NOT start or stop unit under load

unless system is approved by Oilgear. It

may be necessary to provide delivery

bypass in some circuits.

DRIVE

V erify rotation direction plate on the pump 's housing.

Clockwise pumps must be driven clockwise and

counterclockwise pumps must be driven

counterclockwise. Use direct drive coupling. Size

and install coupling per manufacturer's instructions.

CAUTION

DO NOT drive the coupling onto the pump

driveshaft. If it is too tight, it may be

necessary to heat coupling for installation.

Refer to manufacturer's instructions.

Misalignment of pump shaft to driver's shaft should

not exceed 0.005 inches (0,13 mm) Total Indicator

Readout (TIR) in any plane.

Bulletin 947070-B THE OILGEAR COMPANY 5

FILTRATION

Keep the fluid clean at all times to ensure long life

from your hydr aulic system. Ref er to the ref erenced

Oilgear Filtration Recommendations bulletin 90007

and Oilgear Contamination Evaluation Guide

Bulletin 90004. Oilgear recommends use of a filter

in the pressure or return line. Replace filter

element(s) when the filter condition indicator

reaches change area at normal fluid temperature.

Drain and thoroughly clean filter case. Use

replacement element(s) of same beta 10 ratio

(normally a ratio of 4 with hydraulic oils).

FLUID COOLING

When the pump is operated continuously at the

rated pressure or frequently at peak load, auxiliary

cooling of the fluid may be necessary. Fluid

temperature should not exceed limits specified in

the referenced Oilgear Fluid Recommendations

Bulletin 90000.

AIR BREATHER

On most installations, an air breather is mounted

on top of fluid reservoir. It is important for the

breather to be the adequate size to allow air flow in

and out of reservoir as fluid level changes. Keep

the breather case filled to the “fluid level” mark.

About once every six months, remove cover, wash

screen in solvent and allow screen to dry, clean

and refill case to level mark and install screen.

Refer to the manufacturer's recommendations.

FLUID, FILLING AND STARTING

RECOMMENDATIONS

Refer to instruction plate on the unit, reservoir,

machine and/or reference, Fluid Recommendations

bulletin. Fire resistant fluids and phosphate ester

fluids can be used in accordance with fluid

manufacturer's recommendations .

1. Pump all fluid into reservoir through a clean

(beta 10 ratio of 4 or more) filter. Fill reservoir

to, but not above, “high level” mark on the sight

gauge.

2. Remove case drain line and fill pump case

with hydraulic fluid.

3. Turn driveshaft a few times by hand with a

spanner wrench to make sure parts rotate.

With pump under “no load” or with pump control at

NEUTRAL:

4. Turn drive unit ON and OFF several times

before allowing pump to reach full speed. The

system can usually be filled by running the

pump and operating the control.

5. The fluid level in the reservoir should decrease.

Stop the pump. DO NOT allow the fluid level to

go beyond the “low level.” If the level reaches

“low level” mark, add fluid and repeat step.

NOTE

With differential (cylinder) systems, the fluid

must not be above “high level” when the

ram is retracted or below “low level” when

extended. Bleed air from the system by

loosening connections or opening petcocks

at the highest point in the system. Close

connections or petcocks tightly when solid

stream of fluid appears.

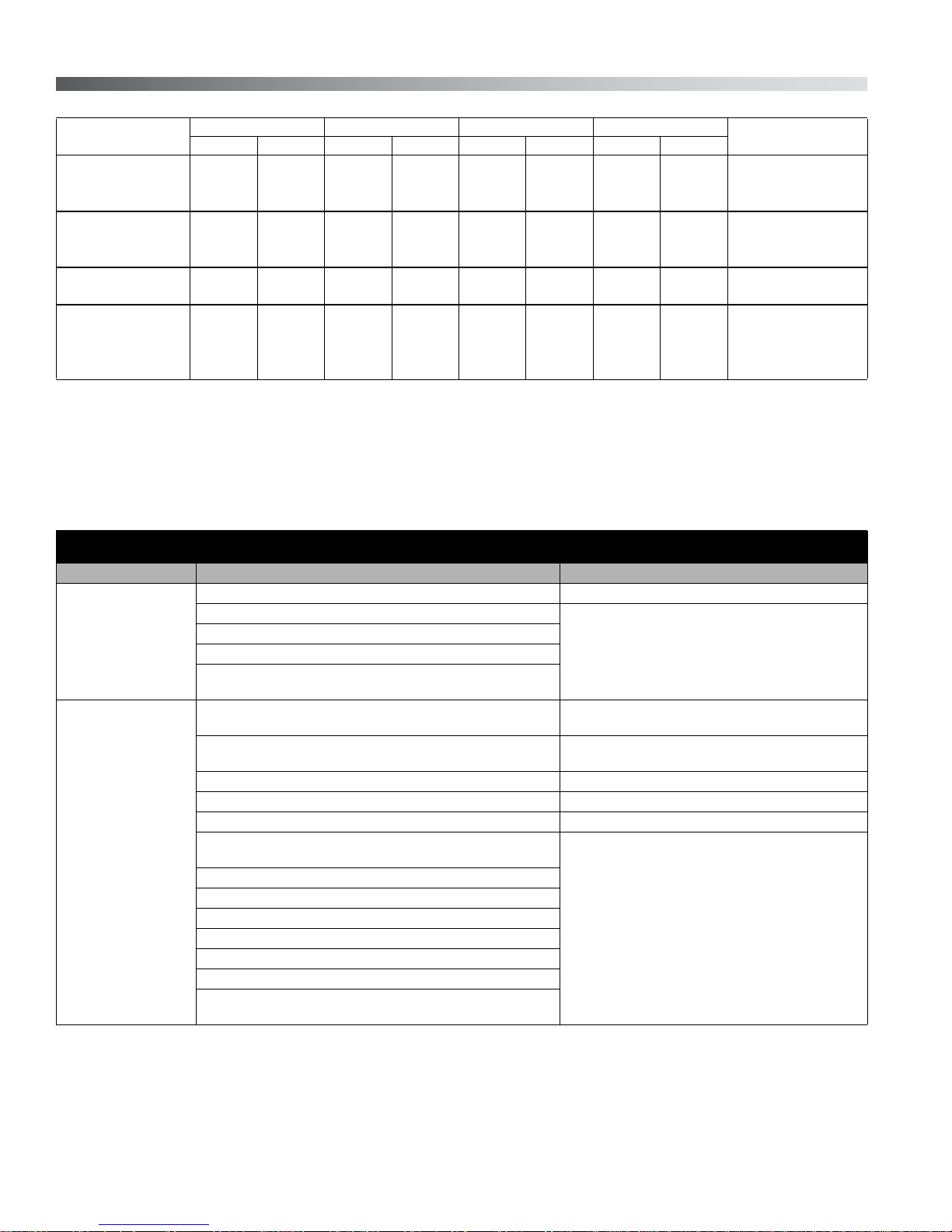

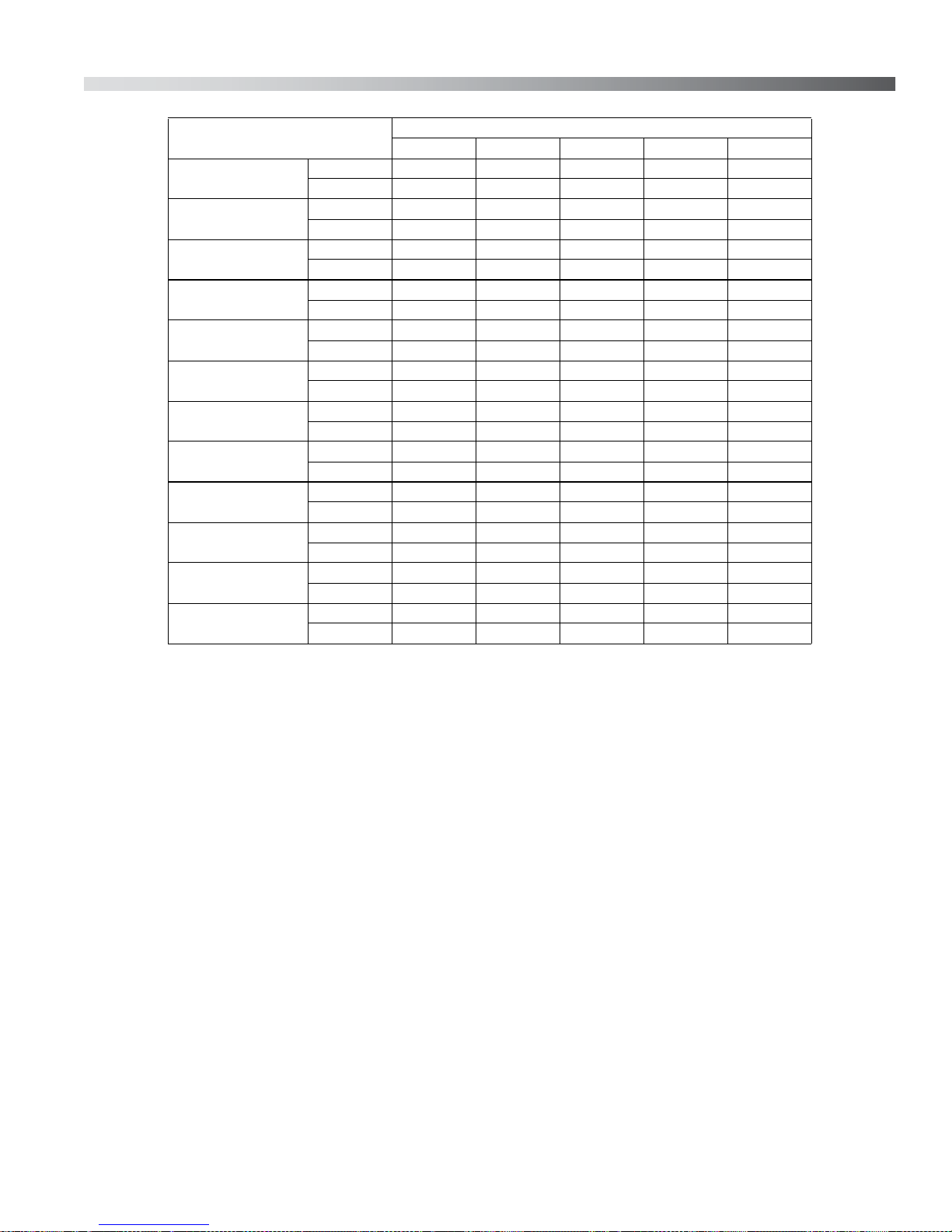

Unit PVM-011/-014/-022 PVM-025/-034/-046/-065/-075 PVM-064/-076/-098/-130

Approximate torque

to turn driveshaft

15-25 in•lb

(1,7-2,8 N•m)

6 THE OILGEAR COMPANY Bulletin 947070-B

120-180 in•lb

(13,7-20,5 N•m)

Table 1. Torque to Turn Shaft

180-260 in•lb

(20,5-29,6 N•m)

CONSTRUCTION

See Figures 11, 12 and 13.

1. A driveshaft (21) runs through the center line of

pump housing and valve plate (45) with the

pump cylinder barrel (38) splined to it.

2. A bearing (26) supports the outboard end of

the driveshaft and a bushing supports the

inboard end. (The bushing is part of valve pla te

assembly.)

3. The pump cylinder barrel is carried in a

hydrodynamic (journal type) cylinder bearing

(35).

4. The port plate (43) has two crescent shaped

ports and is located on a valve plate (45) that

has matching crescent shaped ports.

5. The pumping piston/shoe assemblies (39) in

the cylinder barrel are held against a

swashblock (29) by a shoe retainer (40).

6. The shoe retainer is held in position by the

fulcrum ball (41) which is forced outward by the

shoe retainer spring (42).

7. The spring acts against the pump cylinder

barrel, forcing it against the valve plate while

also forcing the piston shoes against the

swashblock.

8. The semi-cylindrical shaped swashblock limits

the piston stroke and can be swiveled in arc

shaped saddle bearings (30).

9. The swashblock is swiveled by a control piston

(19). Refer to PRINCIPLE OF OPERATION.

SPECIFICATIONS

NOTE

Refer to reference material, pump control

material and individual application circuit

for exceptions.

FLOW RATE

THEORETICAL

UNIT

011 0.66 10,8 3750 258,6 4250 293,1 4.3 16,3 5.6 (0,39) 8.1 (0,56) 17.2 (1,19) 3600 12.8 9,5

014 0.86 14,1 3750 258,6 4250 293,1 5.8 22,0 5.5 (0,38) 7.8 (0,54) 17.2 (1,19) 3600 16.4 12,1

022 1.35 22,1 3750 258,6 4250 293,1 9.5 36,0 8.6 (0,60) 11.4 (0,79) 23.7 (1,63) 3600 26.1 19,5

025 1.55 25,4 3750 258,6 4250 293,1 10.1 38,2 6.5 (0,45) 11.5 (0,80) - 2700 28.8 21,5

0342.06 33,8 3750 258,6 4250 293,1 14.1 53,4 5.7 (0,40) 11.0 (0,76) - 2700 37.7 28,1

046 2.83 46,4 3750 258,6 4250 293,1 19 .7 74,6 5.7 (0,40) 8.1 (0,56) - 2400 51.9 38,7

064 3.88 63,6 3750 258,6 4250 293,1 2 6 .6 100,7 7.3 (0,50) 11.4 (0,79) - 2400 70.2 52,4

065 4.00 65,5 3750 258,6 4250 293,1 27 .9 105,6 6.2 (0,43) 1 0.2 (0,70) - 3000 71.0 53,0

075 4.61 75,5 3750 258,6 4250 293

076 4.67 76,5 3750 258,6 4250 293,1 32.4 122,6 8.2 (0,57) 13.4 (0,92) - 2400 85.7 63,9

098 6.00 98,33750 258,6 4250 293,1 41.2 156,0 8.3 (0,57) 12.1 (0,83) - 2400 109.2 81,4

1307.94130,2 3750 258,6 4250 293,1 57.8 218,8 8.7 (0,60) 14.9 (1,03) - 2400 150.8 112,5

Case pressure should be less than 25 psi (1,7 bar). For hi gh er pressure, consult factory. Higher speeds availab le - consult factory.

MAXIMUM

DISPLACEMENT

in 3/rev ml/rev psi bar psi bar gpm l/mi 1800 rpm 2400 rpm 3600 rpm rpm hp kw

RATED

CONTINUOUS

PRESSURE

MAXIMUM

PRESSURE

1800 rpm rated

continuous

pressure and

14,7 psia (bar abs)

inlet condition

,1 31.3 118,5 6.5 (0,45) 10.6 (0,73)- 3000 83.8 62,5

at

MINIMUM INLET PRESSURE

psia (bar abs)

MAXIMUM

SPEED

POWER

INPUT at

rated

continuous

pressure &

1800 rpm

Table 2. All data is for ISO 46 mineral-based oil at 125°F (160 SSU).

Bulletin 947070-B THE OILGEAR COMPANY 7

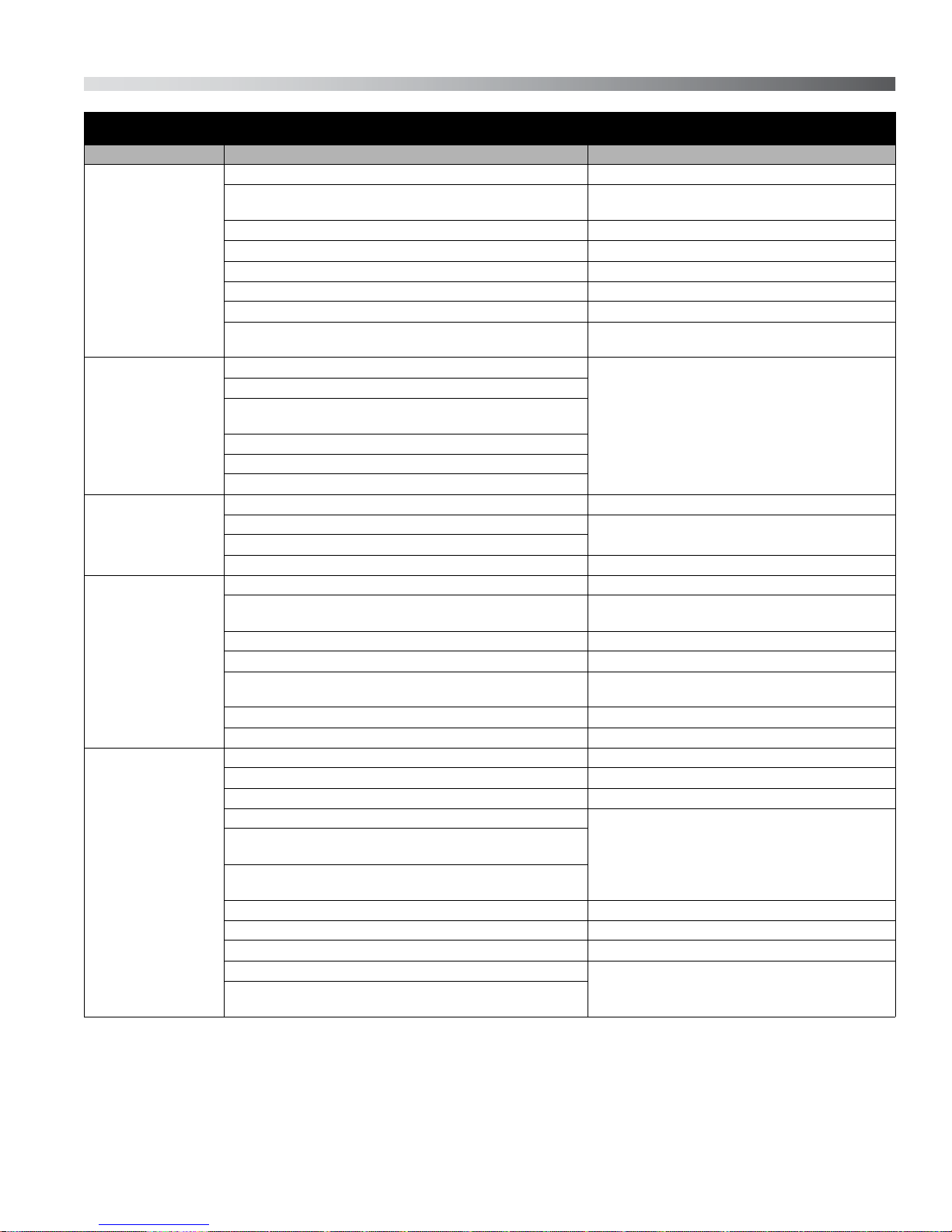

Unit

PVM-011

PVM-022

PVM-025

PVM-046

PVM-065

PVM-075

PVM-064

PVM-076

PVM-098

PVM-130

Length Width Height Weight*

inches mm inches mm inches mm lbs. kg

7.95 201,9 7.28 184,9 6.63 168,4 37.5 17,0 SAE "A" 2 BoltPVM-014

9.51 241,5 9.00 228,6 8.88 225,6 73.0 33,1 SAE "B" 2/4 BoltPVM-034

10.00 254,0 9.03 229,4 8.88 225,6 75.0 34,0 SAE "B" 2/4 Bolt

11.91 302,5 10.73 272,5 10.45 265,4 136.0 61,7 SAE "C" 2/4 Bolt

For detailed dimensions, contact your Oilgear Representative.

* Weight with rear port valve plate and without maximum volume stop.

Table 3. Nominal Dimensions and Weights.

Refer to installation drawings for more detailed dimensions and port configurations.

TROUBLESHOOTING

PROBLEM CAUSES REMEDY

Plugged stability orifice (OP2). Inspect. Clean out if contaminated.

PC control cartridge (55) damaged.

Unresponsive or

Sluggish Control

Insufficient Pump

Volume

Swashblock saddle bearings (30) worn or damaged.

Control piston (19) or sequence spool (54) binding in bore.

Control piston spring (20) broken, sequence valve spool spring

(53) broken.

High load sense differential pressure.

PC control cartridge damaged, stuck open.

Delivery limited by stroke limiter screw (70). Adjust stroke limiter CCW.

Obstructed suction circuit or insufficient supercharge volume. Inspect for obstruction and verify supercharge.

Insufficient drive motor speed. Check drive speed.

Worn or grooved cylinder barrel (38) and/or port plate (43) mating

surfaces.

Worn or damaged piston shoe or swashblock (29).

Worn or sticking control piston (19).

Port plate not seated against valve plate.

Worn hydrobearing (35).

Worn or broken saddle bearing (30).

O-rings leaking on plug (84) or control cartridges (55) or (83).

Worn or damaged piston and shoe assemblies (39) or piston

bores in cylinder (38).

Inspect components. Replace.

Verify that load sense differential pressure is less than

pump control setting.

Inspect. Clean out if contaminated. Replace if

necessary.

Inspect components. Replace.

Face Mounting

8 THE OILGEAR COMPANY Bulletin 947070-B

TROUBLESHOOTING

PROBLEM CAUSES REMEDY

Fluctuating load sense differential pressure. Check system flow control valve/orifice.

Irregular or

Unsteady Operation

Loss of Pressure

Excessive or High

Peak Pressure

Excessive Noise

Excessive Heating

Faulty control piston (19), sequence valve (54) or PC control

cartridge (55) operation.

Fluid level in reservoir is low or supercharge is insufficient. Verify fluid level and/or supercharge.

Air entering hydraulic system. Inspect system for leak.

Low viscosity fluid used. Increase size of OP2. Refer to Table 4.

Remote PC setting close to pump PC setting. Increase pump PC setting.

Worn axial piston pump. Inspect components. Replace.

Faulty output circuit components (cylinder, motors, valves or

other related components).

Worn piston pump.

Worn hydrobearing.

Worn or grooved cylinder barrel (38) and/or port plate (43)

mating surfaces.

Worn piston/shoe assemblies (39) or piston bores in cylinder.

Worn or broken saddle bearing (30).

Faulty output circuit components.

Faulty output circuit components. Check the relief valves.

Faulty PC control cartridge (55) operation.

Seized control piston (19).

Worn or broken saddle bearing (30). Inspect components. Replace.

Pump stopped or started incorrectly under load. Verify operation procedure of pump.

Low fluid level in reservoir or insufficient supercharge causing

cavitation.

Air entering hydraulic system. Inspect system for leak.

Fluid too cold or viscosity too high. Verify fluid temperature and/or type.

Suction line problem i.e.; obstructions in line, line too long, line

diameter too small or too many bends and/or loops in line.

Broken or worn piston/shoe assembly (39). Inspect components. Replace.

Pump rotating in wrong direction. Inspect operation direction of pump.

Operating pump above rated or peak pressure. Verify pump limitations.

Low fluid level in reservoir or insufficient supercharge. Verify fluid level and/or supercharge.

Air entering hydraulic system. Inspect system for leak.

Worn piston pump.

Worn or grooved cylinder barrel (38) and/or port plate (43)

mating surfaces.

Faulty output circuit components (continuous blowing relief v alves

or "slip" through valves, cylinder or other components.

Insufficient cooling provision or clogged coolers. Inspect for obstruction.

Insufficient case fluid level (wrong drain port). Use highest drain port.

OP2 too big or missing causing excessive case drain. Decrease size of OP2.

Sequence spool seized.

Sequence spool leaking (if heating occurring during

compensating).

Inspect components. Replace.

Inspect components. Replace.

Inspect components. Replace.

Inspect components. Replace.

Verify fluid level and/or supercharge.

Inspect line and for obstruction.

Inspect components. Replace.

Inspect, replace spool and valve plate if necessary.

Bulletin 947070-B THE OILGEAR COMPANY 9

Table shows the orifice plugs OP2 (item 68).

Unit Application

PVM-011

PVM-014

PVM-022

PVM-025

PVM-034

PVM-046

PVM-065

PVM-075

PVM-064

PVM-076

PVM-098

PVM-130

Standard (fluid viscosity of 100 SSU or

greater)

High Temperature or thin oil (fluid

viscosity less than 100 SSU)

Standard (fluid viscosity of 100 SSU or

greater)

High Temperature or thin oil (fluid

viscosity less than 100 SSU)

Standard (fluid viscosity of 100 SSU or

greater)

High Temperature or thin oil (fluid

viscosity less than 100 SSU)

Standard

Orifice Size*

0.032 dia. 240971-018

0.040 dia. 240971-002

0.047 dia. 240971-022

0.062 dia. 240971-003

0.062 dia. 240971-003

0.076 dia. 240971-004

Oilgear Part Number

* Pumps delivered from the factory are equipped with the standard application orifice unless specified for high temperature

or thin oil.

Table 4. PVM Stability Orifice Sizing

10 THE OILGEAR COMPANY Bulletin 947070-B

PRINCIPLE OF OPERATION

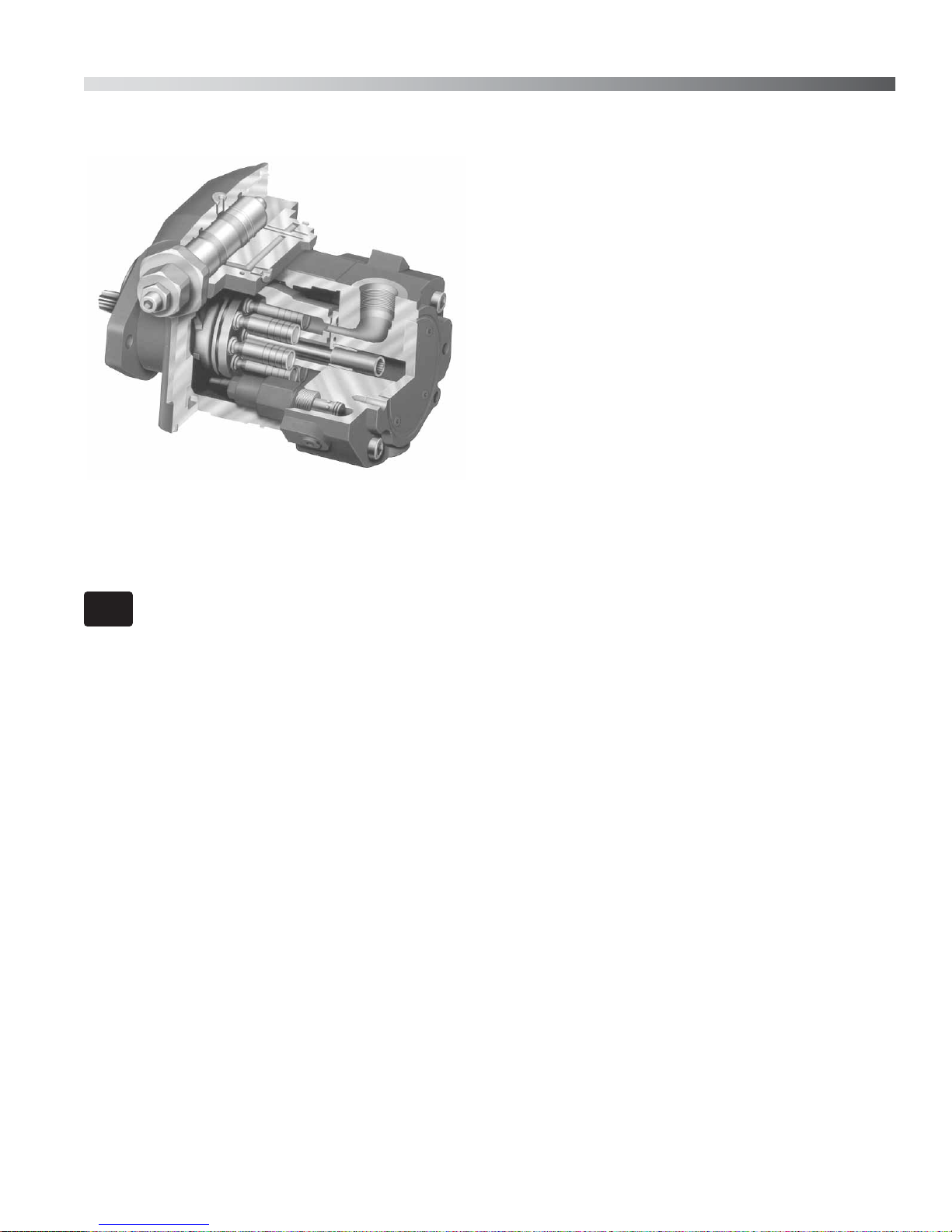

OILG0020

Figure 2. Cut-a-way of a Typical “PVM”

Pump (01010)

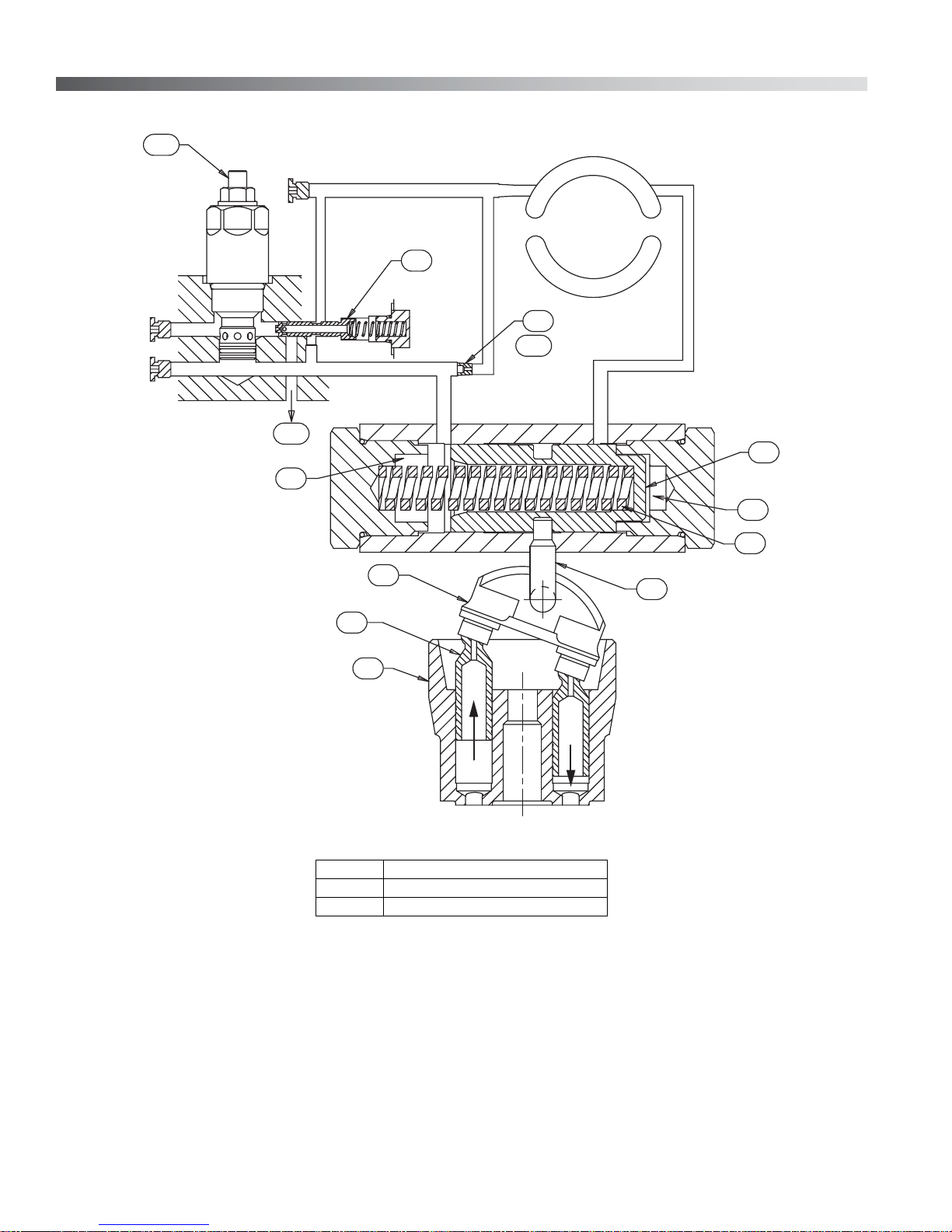

Full Stroke Operation - Figure 3

NOTE

The control piston (19) positions the control pin

(31) and pump swashblock (29) so the pump will

deliver maximum volume to raise pressure in the

system.

Raising Pressure

Pump delivery (and resultant pressure) is fed to

both sides of the control piston (19). Pressure to

the unloading side (C) of the control piston is

direct. Pressure to the bias side (D) of the control

piston is maintained by the respective control.

Numbers in parentheses represent item

number in parts list and drawings.

The areas on either end of the control piston are

the same and the pressure acting on either end is

the same. The resultant hydraulic forces on the

ends of the control piston cancel each other out

(the control piston is balanced), and the force of the

control piston spring (20) controls the control piston

position (19).

Rotating the driveshaft turns the splined cylinder

(38), which contains the pumping pistons (39).

When the cylinder rotates, the pistons move in and

out within their bores as the shoes ride against the

angled swashblock (29).

As the cylinder rotates, the individual piston bores

are connected, alternately, to the crescent shaped

upper (P) and lower (S) in the valve plate. While

connected to the lower side (suction) S, each

piston moves outward OUT, drawing fluid from S

into the piston bore until its outermost stroke is

reached. At this point, the piston bore passes from

the lower crescent S to the upper crescent P.

While rotating across the upper crescent port, each

piston moves across the angled swashblock face

and then each piston is forced inward IN. Each

piston then displaces fluid through the upper

crescent to P until its inner most stroke is reached.

At this point, the piston bore passes from the upper

to the lower crescent again and the cycle is

repeated.

The angle of the swashblock determines the length

of the piston stroke, (the difference between

outermost and innermost position) which

determines the amount of delivery from the pump.

If the stroke angle is one-half of the stroke, the

piston stroke is one-half and the pump delivery is

one-half.

Note that the flow through the PC control cartridge

(3-1) is blocked.

Bulletin 947070-B THE OILGEAR COMPANY 11

3-1

HP

RP

3-3

D

LS

P

54

S

68

3-2

19

C

20

29

39

38

OUT

(3-1) PC Control Cartridge

(3-2) Stability Orifice

(3-3) Into Case

Figure 3. Full Stroke Operation

31

IN

OILG0119

12 THE OILGEAR COMPANY Bulletin 947070-B

4-1

Relatively small variations in system flow

LS

P

requirements can be accommodated for in the

mentioned operational mode. When pump outlet

54

HP

RP

4-3

53

S

68

4-2

19

pressure decreases below the preset pressure

setting of the PC Control Cartridge, the PC Control

Cartridge closes. The sequence spool spring (53)

repositions the sequence spool to open the flow

path. This provides for an unobstructed flow path to

the bias side of the control piston so the pump will

be responsive to increased system flow demand.

20

D

(4-1) PC Control Cartridge

(4-2) Stability Orifice

(4-3) Into Case

OILG0115

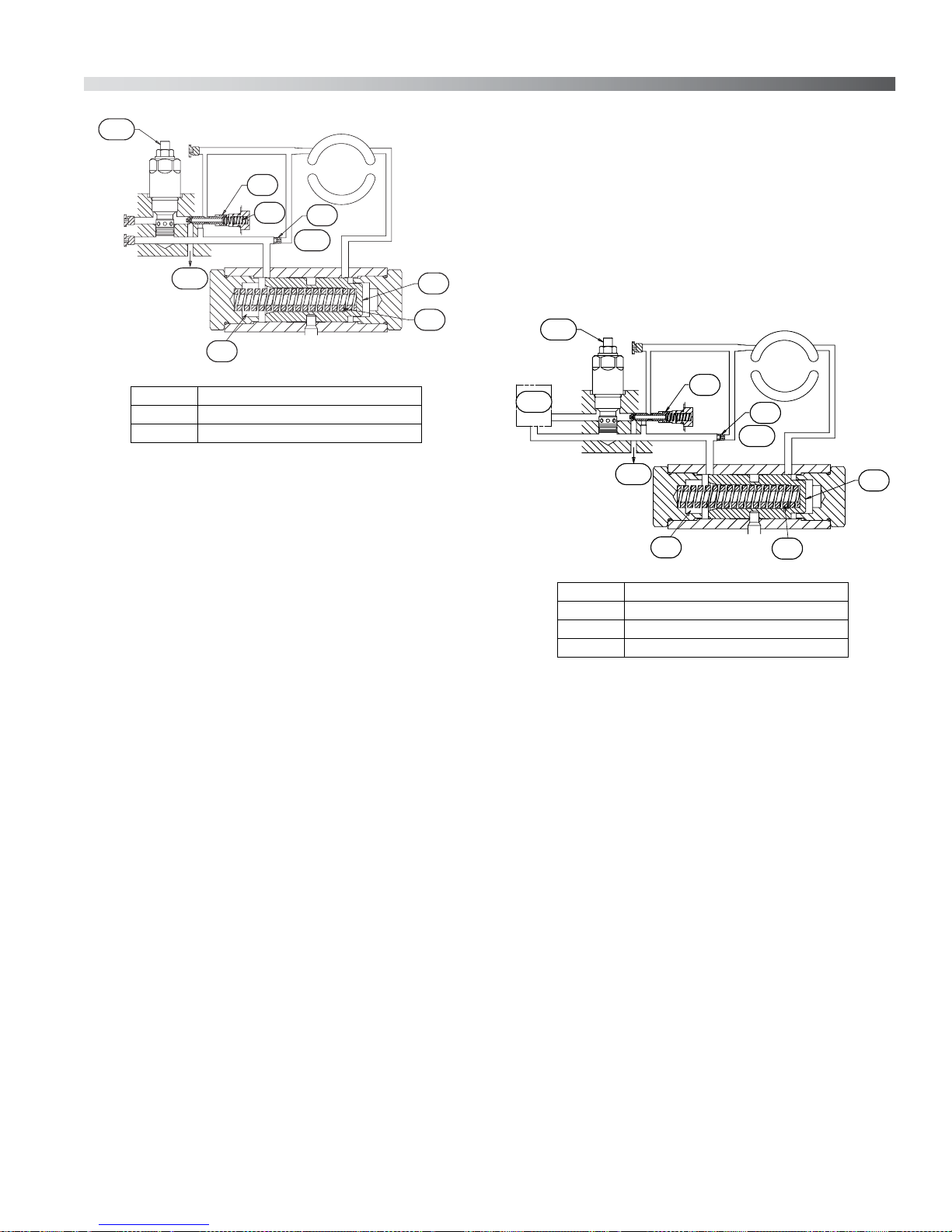

Figure 4. Pressure Compensating

Pressure Compensating - Figure 4

When pump outlet pressure reaches the preset

pressure setting of the PC Control Cartridge, bias

pressure D (pressure on the spring side of the

control piston) is relieved by the PC Control

Cartridge. Exhaust flow from the PC Control

Cartridge is ported to the pump case via the

sequence spool (54). The resulting pressure drop

across the sequence spool due to the exhaust flow

moves the spool to block the flow path. All flow to

the PC Control Cartridge is now provided via the

stability orifice OP2 (68).

Blocking the flow path and requiring all control flow

to pass through OP2 minimizes case drain leakage

and provides a means of stability adjustment for a

wide range of system requirements. The decrease

in bias pressure results in a pressure differential

across the control piston (19). The control piston is

no longer balanced and the pressure on the

unloading side of the control piston forces the

control piston to compress the control piston spring

(20). The control piston moves the control pin and

shifts the swashblock to a position that provides

less flow output from the pump. Flow output from

the pump is then controlled to maintain the preset

pressure setting of the PC Control Cartridge. When

the outlet port of the pump is blocked, the

swashblock is positioned so the pump delivers just

enough volume to provide for internal losses and

required control flow.

5-1

5-2

HP

RP

(5-1) PC Control Cartridge

(5-2) Remote Pressure Control Valve

(5-3) Stability Orifice

(5-4) Into Case

5-4

LS

54

D

5-3

68

20

P

S

19

OILG0116

Figure 5. Remote Pressure Compensating

Remote Pressure Compensating - Figure 5

Principal of operation for remote pressure

compensating is the same as the integral pressure

compensating except another pressure control

valve is placed in parallel with the PC Control

Cartridge.

The supply port of the remote pressure control

valve needs to be ported to the RP port on the

valve plate (43). The exhaust from the remote

pressure control valve needs to be ported to the

HP port on the valve plate. When pump outlet

pressure reaches the preset pressure setting of the

remote control valve, bias pressure D [pressure on

the spring side of the control piston (19)] is relieved

by the remote control valve. Exhaust flow from the

remote control valve is ported to the pump case via

the sequence spool (54). The resulting pressure

drop across the sequence spool due to the exhaust

flow mov es th e spool to block the flow path. All flow

to the remote control valve is now provided via the

stability orifice OP2 (68). Blocking the flow path

and requiring all control flow to pass through OP2

Bulletin 947070-B THE OILGEAR COMPANY 13

minimizes case drain leakage and provides a

means of stability adjustment for a wide range of

system requirements.

6-1

6-6

69

LS

P

The decrease in bias pressure results in a pressure

differential across the control piston (19). The

control piston is no longer balanced and the

pressure on the unloading side of the control piston

forces the control piston to compress the control

piston spring (20). The control piston moves the

control pin and shifts the swashblock to a position

that provides less flow output from the pump. Flow

output from the pump is then controlled to maintain

the preset pressure setting of the remote pressure

control valve. When the outlet port of the pump is

blocked, the swashblock is positioned so the pump

delivers just enough volume to provide for internal

losses and required control flow.

Relatively small variations in system flow

requirements can be accommodated for in the

mentioned operational mode, but, when pump

outlet pressure decreases below the preset

pressure setting of the remote control valve, the

remote control valve closes. The sequence spool

spring (53) repositions the sequence spool to open

the flow path. This provides for an unobstructed

flow path to the bias side of the control piston so

the pump will be responsive to increased system

flow demand. If the setting of the remote pressure

control valve exceeds the setting of the PC Control

Cartridge, the pump will control to the setting of the

PC Control Cartridge.

NOTE

Failure to port the exhaust of the remote

pressure control valve to the HP port will

result in significantly higher case drain

leakage.

6-2

68

20

S

19

OILG0118

HP

RP

6-5

(6-1) PC Control Cartridge

(6-2) Stability Orifice

(6-3) Bias D

(6-4) Outlet C

(6-5) Into Case

(6-6) Load Sense Port

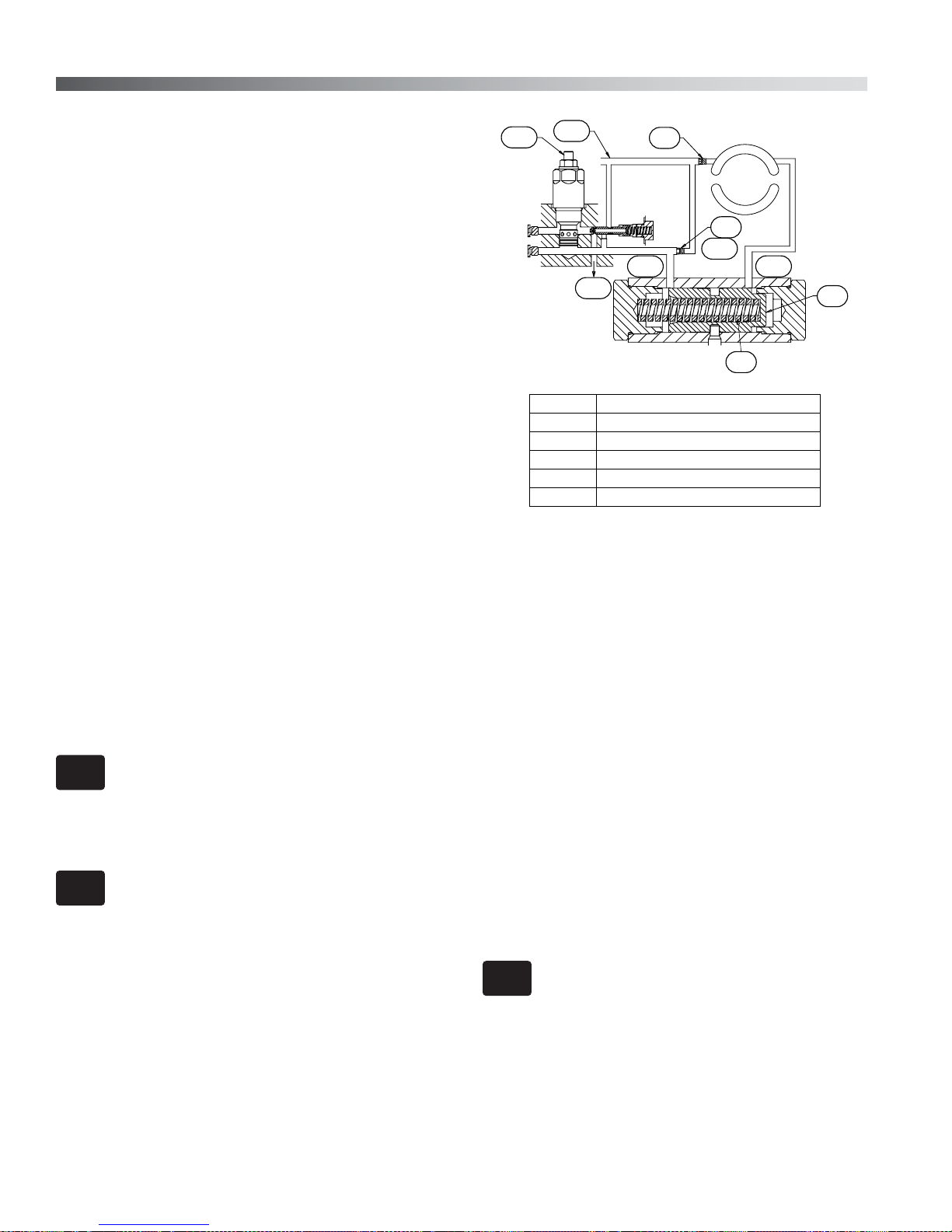

Figure 6. Standard Load Sensing with Pressure

Compensating Override

6-3 6-4

Standard Load Sensing with Pressure

Compensator Override - Figure 6

The parts configuration for the Standard Load

Sense control is similar to the Pressure

Compensator control except for the installation of a

plug. All other components are unchanged. A 1/16

inch pipe plug is supplied with all new pumps. The

plug is installed in a blind hole next to the LS port

for all pumps originally shipped as a Pressure

Compensator control or Adjustable Load Sense

control. The plug (69) is already installed in the

correct location (and the blind hole is empty), if the

pump was originally shipped as a Standard Load

Sense.

NOTE

The RP lines of multiple pumps cannot be

tied together for unloading or controlling

with a common remote pressure control

valve. Each pump requires a dedicated

valve.

14 THE OILGEAR COMPANY Bulletin 947070-B

To convert to a Standard Load Sense from a

Pressure Compensator control, install the pipe plug

(69) deep into the LS port of the valve plate as

shown in Figure 6.

NOTE

The pipe plug threads start approximately

1.7 inch (0.043 mm) from the port spotface.

Standard Load Sense control requires the load

sense line (pressure signal from downstream of an

orifice or flow control valve) be attached at the LS

port on the valve plate assembly. Load sense

pressure is ported via the sequence spool and

stability orifice to the bias side of the control piston

(19). The pressure differential across the system

flow control is therefore equal to the pressure

differential across the control piston; when the

pressure differential reaches the non-adjustable

preload force of the control spring, the control

piston moves toward the neutral position. The

control piston moves the control pin and shifts the

swashblock to a position that reduces pump

delivery to maintain a constant, preset pressure

differential across the flow control v alv e . The preset

pressure differential is 150 to 210 psi (10,3 to 14,5

bar). If the pressure differential across the flow

control valve is decreased, t he control piston spring

(20) moves the control piston in the full stroke

direction until pump delivery is increased

sufficiently to reach the preset load sense

differential pressure. When the pump outlet is

blocked and the load sense pressure is allowed to

go to drain pressure, the swash is positioned so

that the pump delivers just enough volume to

provide for internal losses and required control flow

at a standby pressure equal to the preset pressure

differential of 150 to 210 psi (10,3 to 14,5 bar).

The pressure compensating function will override

the load sense control and, if necessary, further

reduce pump delivery when the load sense

pressure reaches the preset pressure of the PC

Control Cartridge.

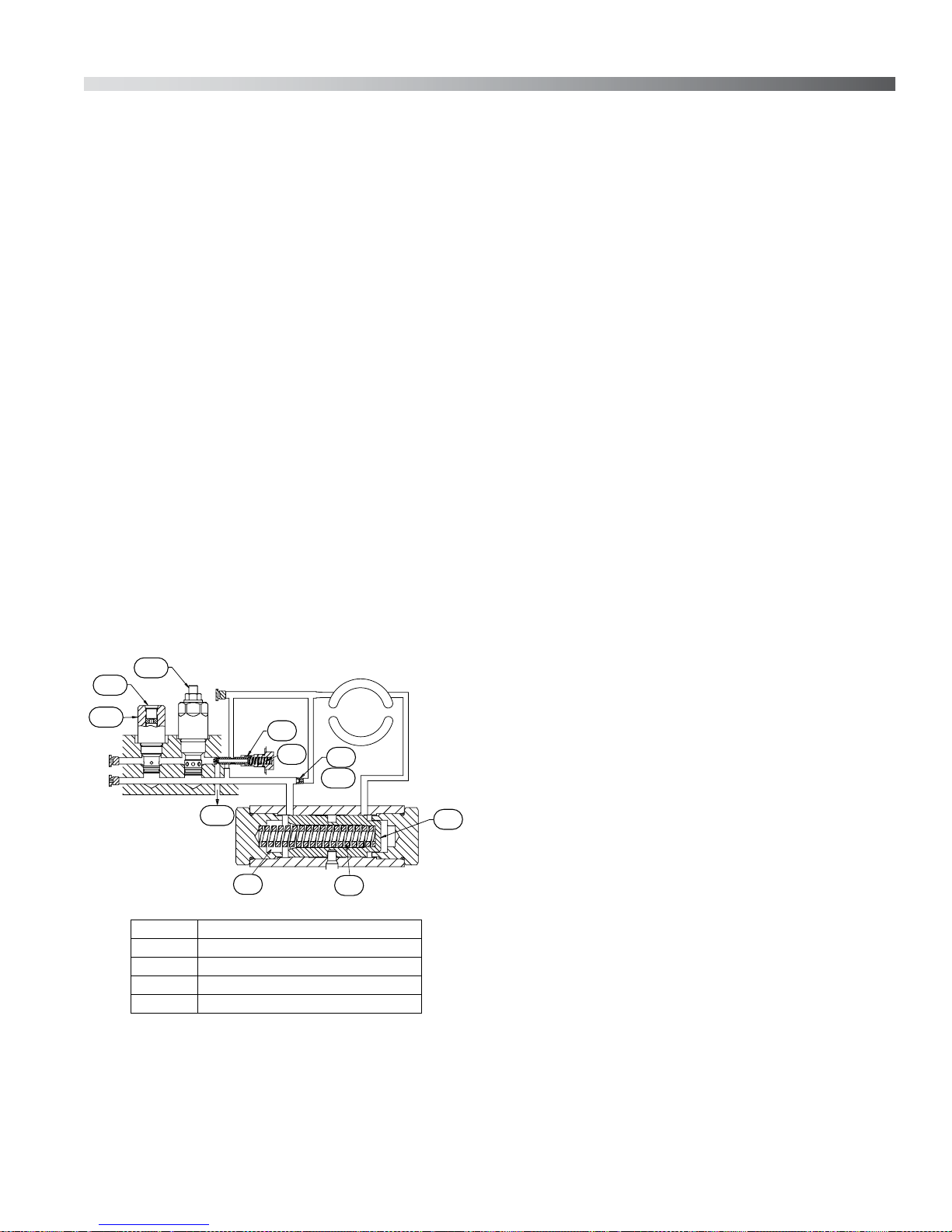

7-1

7-4

7-5

Figure 7. Adjustable Load Sensing with Pressure

LS

HP

RP

(7-1) PC Control Cartridge

(7-2) Stability Orifice

(7-3) Into Case

(7-4) Load Sense Port

(7-5) Adjustable Load Sense Cartridge

LS

54

53

7-3

D

Compensating Override

68

7-2

20

P

S

19

OILG0117

Adjustable Load Sensing w/ Pressure

Compensator Override - Figure 7

The Adjustable Load Sense control functions

similar to the Standard Load Sense control except it

is adjustable from 150 to 600 psi (10,3 to 41,4 bar).

The Adjustable Load Sense Cartridge is located

adjacent to the PC Control Cartridge on the valve

plate. The Adjustable Load Sense does not require

the installation of the 1/16 inch pipe plug in the

standard load sense port as previously described.

The standard load sense port should be plugged

with an SAE #4 plug. Adjustable Load Sense

control requires the load sense line [pressure

signal from downstream of an orifice or flow control

valve] be attached to the end of the Adjustable

Load Sense Cartridge.

When load sense pressure differential reaches the

preset pressure setting of the Adjustable Load

Sense Cartridge, bias pressure D [pressure on the

spring side of the control piston (19)] is relieved by

the Adjustable Load Sense Cartridge. Exhaust flow

from the Adjustable Load Sense Cartridge is

ported to the pump case via the sequence spool.

The resulting pressure drop across the sequence

spool (54) due to the exhaust flow moves the spool

to block the flow path. All flow to the Adjustable

Load Sense Cartridge is now provided via the

stability orifice OP2 (68). Blocking the flow path

and requiring all control flow to pass through OP2

minimizes case drain leakage and provides a

means of stability adjustment for a wide range of

system requirements.

The decrease in bias pressure results in a pressure

differential across the control piston (19). The

control piston is no longer balanced and the

pressure on the unloading side of the control piston

forces the control piston to compress the control

piston spring (20). The control piston moves the

control pin and shifts the swashblock to a position

that provides less flow output from the pump. Flow

output from the pump is then controlled to maintain

the preset pressure differential setting of the

Adjustable Load Sense Cartridge. When the outlet

port of the pump is blocked, the swashblock is

positioned so the pump delivers just enough

volume to provide for internal losses and required

control flow at a standby pressure equal to the

differential pressure setting of the Adjustable Load

Sense Cartridge.

Bulletin 947070-B THE OILGEAR COMPANY 15

Relatively small variations in system flow

requirements can be accommodated for in the

mentioned operational mode, but, when pump

outlet pressure decreases below the preset

differential pressure setting of the Adjustable Load

Sensing Cartridge, the Adjustable Load Sensing

Cartridge closes. The sequence spool spring (53)

repositions the sequence spool to open up the flow

path. This provides for an unobstructed flo w path to

the bias side of the control piston so the pump will

be responsive to increased system flow demand.

The pressure compensating function will override

the load sense control and, if necessary, further

reduce pump delivery when the load sense

pressure reaches the preset pressure of the PC

Control Cartridge.

Electronic Proportional Pressure Compensator

with Override - Figure 8

The Electronic Proportional Pressure Compensator

functions the same as the Pressure Compensating

Control (refer to Figure 4) except the PC Control

Cartridge is electrically controlled. An electrical

signal is used to proportionally increase or

decrease the pressure compensator setting with

increasing current. A manually adjustable PC

Override Valve enables the user to set the

maximum desired pressure compensator setting.

NOTE

An Adjustable Load Sense control is also

available with a bleed-off feature. This

cartridge internally vents load sensing

pressure to case via an orifice in the

cartridge and the sequence spool when the

control is not active or the system is

shutdown.

8-2

8-1

LS

HP

RP

LS

8-8

8-9

8-7

8-3

P

S

8-4

8-5

8-6

(8-1) PC Override Cartridge

(8-2) Electronic Proportional Control Cartridge

(8-3) Sequence Spool

(8-4) Stability Orifice (OP2)

(8-5) Control Piston

(8-6) Control Pin

(8-7) Cylinder Barrel

(8-8) Piston

(8-9) Swashblock

(8-10) Into Case

Figure 8. Electronic Proportional Pressure

16 THE OILGEAR COMPANY Bulletin 947070-B

OILG0170

Compensator with Override

TESTING AND ADJUSTING

WARNING

!

Shut the pump OFF and release pressure

from the system before disassembling

components. Failure to comply with these

instructions could result in personal injury

or death. Blocking the pressure line

between the pump and the system (or

pump) high pressure relief valve will result

in damage and could result in serious

personal injury.

PISTON PUMP

To check for a worn piston pump, make a leak

measurement test from the case drain while the

pump is under pressure. After the unit is warm,

either install a flow meter in the drain line or have

the flow from the drain line directed into a large

container or reservoir. The pump case must remain

full of fluid during this test.

CAUTION

DO NOT run a pump on stroke against a

blocked output unless it is protected by a

high pressure relief valve and then run no

longer than necessary to check slip. Limit

discharge to prevent dropping reservoir

fluid below low level.

With an accurate high pressure gauge in the

pressure line, start the pump and stall (or block)

output device to raise system pressure to

maximum (as set by system relief valve). Read the

measurement on the flow meter or time and

measure the case drain flow used to fill a known

size container and calculate the flow rate in terms

of cubic inches per minute (cipm). The leakage

should conform to Table 5.

NOTE

Additional leakage indicates wear, but

does not become critical until it impairs

performance.

DISASSEMBLY

Refer to

pump.

NOTE

DO NOT attempt to remove or install any

components or assembly while the pump

and system is running. Always stop the

pump, shut OFF the power and release

pressure from the system before servicing

or testing. Be sure provisions have been

made so the case drain line can be

disconnected from the unit without

causing the line to drain (siphon) the

reservoir.

1. Disconnect case drain line(s).

2. Drain pump case. If drain pump case plugs are

Figures 9 through 15

The cleanliness of working on this pump or

the hydraulic system is extremely important

to the safety and reliability of the pump and

the system.

When disassembling or assembling the

pump, choose a clean, dry, dust and sand

free area where no traces of abrasive

particles are in the air which can damage

the pump and system. DO NOT work near

welding, sandblasting, grinding benches or

similar conditions.

Always make sure the fittings are clean on

the outside before removing them from

their connections. Make sure they are

capped and plugged when removed. Place

them on a clean surface and in a clean rag

or container until they are reinstalled.

When cleaning parts which have been

disassembled, it is important to use

CLEAN cleaning solvents and parts are

allowed to dry. All tools and gauges should

be clean prior to working with the system

and use new, CLEAN lint free rags to

handle and dry parts.

WARNING

!

inaccessible, it may be necessary to remove

the pump from the mounting and drive motor

before draining it.

for your series of

Bulletin 947070-B THE OILGEAR COMPANY 17

(continued)

DISASSEMBLY (Continued)

CAUTION

WARNING

!

Seek assistance from others and use of a

hoist and/or proper lifting techniques to

prevent personal injury.

NOTE

3. After removing the pump from the mounting

NOTE

VALVE PLATE GROUP

If another pump is coupled with a thru-shaft pump

or other device coupled to the rear of the pump, it

will be necessary to remove that unit and O-ring

(59). If thru-shaft convertible cover (63) is used,

remove the socket head cap screws (64) and

O-ring (62). Also remove screw (61) and thru-shaft

coupling spacer (60).

Tag similar par ts (particularly screws, plugs

and O-rings) during disassembly to make

sure they don't become confused with

similar parts and to ensure they will be

returned to their original location. Do not

remove (locator) roll pins unless they are

deformed or need to be replaced.

and before disassembly, cap or plug all ports

and clean the outside of unit thoroughly to

prevent dust from entering the system.

Depending on what part or par ts are to be

inspected, it may not be necessary to

completely take apart all assemblies.

Do not damage the faces of the port plate

and the matching faces of both the valve

plate and cylinder barrel.

1. Block the unit on bench with driveshaft

horizontal.

2. Remove valve plate assembly (45) by removing

four socket head cap screws (50 and 56) and

the valve plate assembly. When used, shaft

coupling (57) with retaining rings (58), if used,

will come with valve plate assembly. The port

plate (43) is located on the valve plate

assembly by a dowel pin. Remove the port

plate from the valve plate assembly.

The control sequence valve can be removed, if

necessary by:

(A) Removing the sequence valve spool plug

(51) with the O-ring (52).

(B) Withdrawing sequence valve spool spring

(53) and sequence valve spool (54).

The PC control cartridge (55) can also be

unscrewed from the valve plate if necessary. The

rear shaft bearing (67 or 77) is pressed into the

valve plate.

18 THE OILGEAR COMPANY Bulletin 947070-B

Frame Unit - Size

SAE “A” PVM-011

SAE “A” PVM-014

SAE “A” PVM-022

SAE “B” PVM-025

SAE “B” PVM-034

SAE “B” PVM-046

SAE “B” PVM-065

SAE “B” PVM-075

SAE “C” PVM-064

SAE “C” PVM-076

SAE “C” PVM-098

SAE “C” PVM-130

Case Slip at Full Stroke and Indicated Pressure

500 psi 1000 psi 2000 psi 3000 psi 3750 psi

cipm 25.0 40.0 75.0 110.0 160.0

lpm0,410,661,23 1,80 2,62

cipm 35.0 50.0 80.0 120.0 170.0

lpm0,570,821,31 1,97 2,79

cipm 55.0 90.0 145.0 210.0 300.0

lpm0,901,472,38 3,44 4,92

cipm 75.0 115.0 185.0 270.0 360.0

lpm 1,23 1,88 3,03 4,42 5,90

cipm 70.0 105.0 175.0 255.0 340.0

lpm 1,15 1,72 2,87 4,18 5,57

cipm 70.0 105.0 180.0 280.0 365.0

lpm 1,15 1,72 2,95 4,59 5,98

cipm 95.0 135.0 205.0 300.0 400.0

lpm 1,56 2,21 3,36 4,92 6,55

cipm 140.0 190.0 290.0 450.0 650.0

lpm 2,29 3,11 4,75 7,37 10,65

cipm 90.0 135.0 230.0 345.0 460.0

lpm 1,47 2,21 3,77 5,65 7,54

cipm 90.0 145.0 245.0 390.0 580.0

lpm 1,47 2,384,016,399,50

cipm 125.0 180.0 280.0 560.0 860.0

lpm2,082,954,599,1814,09

cipm 135.0 210.0 370.0 580.0 810.0

lpm 2,21 3,44 6,06 9,50 13,27

Table 5. NOMINAL CASE SLIP versus High Pressure at 1800 rpm

[All data is for ISO 46 mineral-based oil at 125°F (160 SSU)]

Bulletin 947070-B THE OILGEAR COMPANY 19

ROTATING GROUP

WARNING

!

The rotating group may be heavy. Be

careful not to damage cylinder wear

surface which mates against the valve

plate, bearing diameters or piston shoes.

Use proper lifting techniques and

assistance from others to prevent

personal injury.

-011/-014/-022

5. Remove cylinder barrel retaining ring (37) and

pull the hydrodynamic cylinder bearing (35) and

roll pins, if necessary, from the housing.

-025/-034/-046/-064/-065/-075/

-076/-098/-130

5. Remove the hydro-bearing retaining ring (37).

1. Remove O-rings (13 and 14) from the pump

housing (1). Do not remov e roll pins (12) unless

they are damaged.

2. Remove the rotating group by turning the

driveshaft (21) slowly, while pulling the cylinder

barrel (38) from the housing.

3. Identify (number) each pump piston shoe

assembly (39) and its respective bore in the

cylinder barrel (38) and shoe retainer plate (40)

for easy reassembly.

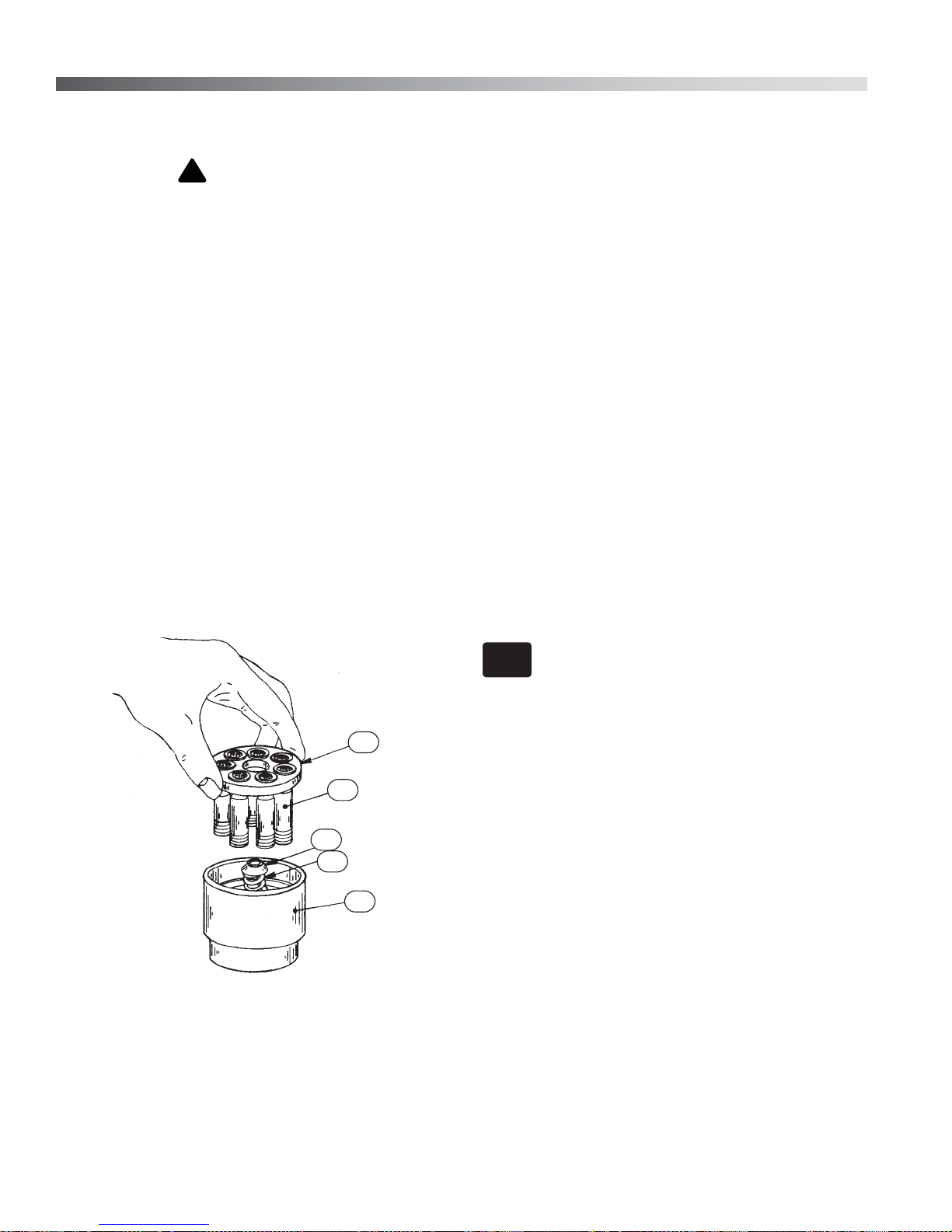

4. See Figure 9. Lift out shoe retainer (40) with

pistons (39) and remove the fulcrum ball (41)

and shoe retainer spring (42).

40

39

41

42

38

6. Remove socket head screw (36) and lock

washer (5).

7. Pull hydrodynamic cylinder bearing (35) from

housing.

DRIVESHAFT GROUP

1. Remove the drive key (22 or 23), if used and

the driveshaft bearing retainer ring (28).

2. Grasp outboard end of driveshaft (21) and pull

it out of the pump housing.

3. Remove shaft seal retainer (25). Remove

driveshaft seal (24) from housing ONLY if

necessary.

NOTE

If the seal is removed it can not be reused.

It must be replaced.

SWASHBLOCK GROUP

1. Remove the socket head cap screws (34), the

housing cover (33) and O-ring (32).

2. Reach into the housing through the opening

and pull out the swashblock (29), along with

control pin (31).

The saddle bearing (30) is seated in the housing by

an integral pintle that engages a hole in the

housing.

Figure 9. Rotating Group Disassembly

20 THE OILGEAR COMPANY Bulletin 947070-B

OILG0023

3. Pull the saddle bearing (30) back (parallel to

driveshaft axis) until the pintle disengages from

the housing, then pull the saddle bearing out in

the same manner the swashblock was

removed.

Loading...

Loading...