OHTAKE OM-26M Operation Manual

NSIR MAE01

Read these instructions for the proper use of this machine.

After having read these instructions, keep them in a convenient place so you

or the operator can refer to them whenever necessary.

NSRI Type

Automatic Screw Feeder

ὀព㸟㸸www.ohtake-root.co.jp ࡀᙜ♫၏୍ࡢ HP ࢻࣞࢫ࡛ࡍࠋ

ᘢ♫ࡢྡࢆ㦄ࡿഇࢧࢺࡈὀពୗࡉ࠸ࠋ⌧ᅾࠊᙜ♫ࡣ୰ᅜᅜෆᨭᗑࡣࡈࡊ࠸ࡲࡏࢇࠋ

ྛ栦ᐈ実ὀព㸸ࠕwww.ohtake-root.co.jp ᩎྖ၏୍ⓗᐁ᪉⨒❰㸪

┠๓㸪ᩎྖᅾ୰ᅜἐ᭷≆⢬ᡤ宻ⓗ୰ᅜᐁ⨒ࠋࠖ

ATTENTION : www.ohtake-root.co.jp is the only web site associated with our company.

We do not have any branches in China.

Operation Manual

・ Read these instructions for the proper use of this machine.

・ After having read these instructions, keep them in a convenient

place so you or the operator can refer to them whenever necessary.

自動ネジ供給機

OM-26M

Type

Automatic Screw Feeder

OMM1MA02

M

(Maintenance)

-1-

Contents

1. OVERVIEW OF THIS MACHINE -------------------- 1

2. BEFORE USE -------------------------------------------- 1

3. OPERATING PRECAUTIONS ----------------------- 2

4. NAMES OF MACHINE PARTS ---------------------- 5

5.

ADJUSTMENTS AND CHECKS BEFORE USE-------- 7

6. MAINTENANCE ----------------------------------------- 16

7.

PARTS ADJUSTMENTS AND REPLACEMENTS

----- 16

8. EXTERNAL OUTPUT SIGNALS------------------- 28

9. MISCELLANEOUS ----------------------------------- 30

10. TROUBLESHOOTING ------------------------------- 32

11. SPECIFICATIONS ------------------------------------- 38

12. EXTERNAL DIMENSIONS -------------------------- 40

13. WARRANTY -------------------------------------------- 41

2.

BEFORE USE

Please check for the following accessories before operating the machine.

*

Instruction Manual 1 copy

*

AC Adapter 1 unit

*

Hexagonal Wrench 1 piece

*

Screwdriver 1 piece

*

Ground Wire 1 piece

1.

OVERVIEW OF THIS MACHINE

Thank you very much for selecting our Automatic Screw Feeder "OM-26M series ".

This machine can line up screws (Type M2 - M6) and supplies them one by one to help

the efciency of screw fastening work.

Different sizes of screws can be used by changing the rail and parts of the escaper assembly.

It can be used wherever there is a power source for an AC adapter.

Only steel screws may be used with this machine. Stainless steel or plastic screws cannot be used.

-2-

3.

OPERATING PRECAUTIONS

This manual contains safety alert symbols and signal words to help prevent injuries

to the user or damage to property.

◎

Indications

This indicates there is a chance of death, serious injury or re if the instructions

are not followed.

This indicates there is a chance of personal injury or damage to property

if the instructions are not followed.

◎

Symbols indicating type of danger and preventative measures

This indicates to stop operations.

Unplug power supply from wall outlet.

General caution.

Prohibited operation. Never do this!

Do not disassemble, modify or repair.

Do not touch with wet hands.

WARNING

CAUTION

When the earth wire is connected, loosen the screw near the mark once.

After attaching the earth wire,tighten the screw again.

the bottom of the main body

-3-

Do not disassemble the AC adapter as there is a risk of electric shock, re or malfunction.

Do not damage, alter or change the power cord. Do not place heavy objects on the cord.

Do not pull hard on the cord or twist the cord as it could be damaged, thereby causing a risk

of re or electric shock.

Do not handle the AC adapter with wet hands as it could cause an electric shock.

When using an outlet with AC100~240V, don't overload the electrical circuit.

Do not modify or remodel this machine as this may cause a re or electric shock.

Do not operate this machine near ammable liquids, gasses or materials as there could

be a risk of re or explosion.

Stop operating the machine and unplug the AC adapter from the wall outlet when you detect overheating,

smoke, a pungent odor or any other unusual condition, as there may be a risk of re or electric shock. Contact

the dealer, from which you purchased the machine, and have

it examined and repaired.

In the case of a thunderstorm, stop operating the machine, turn off the power and unplug

the AC adapter from the wall outlet. If there is lightning and thunder nearby, move away from the machine and

do not touch it or the AC adapter.

After the thunder stops, and when it is safe to do do so, check the machine. If there is any abnormality, contact

your dealer.

When performing maintenance, changing parts or when you sense an abnormality in the machine, turn the

power off and pull the AC adapter from the wall outlet.

WARNING

-4-

Do not bend, alter or damage the rail. Do not apply any oil. It is recommended that the user

clean the rail periodically.

Do not use any screw that is out of the specied range nor any screw that is oily or dirty.

When pick uping screws, do not exert excessive force or shock to the screws.

Do not allow any foreign material to enter the machine while in operation.

Do not put your ngers into the machine while in operation, otherwise an injury will result.

Use only the AC adpater supplied with this machine otherwise it may result in a re

or electric shock.

Do not install this machine in an unstable location otherwise it may fall causing damage or injury.

When moving the machine, always disconnect the AC adapter from the wall outlet or it may result in damage to

the cord, or cause a re or electric shock.

Turn off the machine and unplug the AC adapter from the wall outlet during closing hours

or if the machine will be unused for any extended period of time.

Do not operate this machine in overly humid or dusty conditions.

Keep the socket plug clean at all times otherwise it may cause a re or electric shock.

Do not operate the machine with tension on the AC adapter cord.

Keep the cord loose and untangled.

Always operate the machine with the upper cover in place, otherwise it may result in injury.

CAUTION

-5-

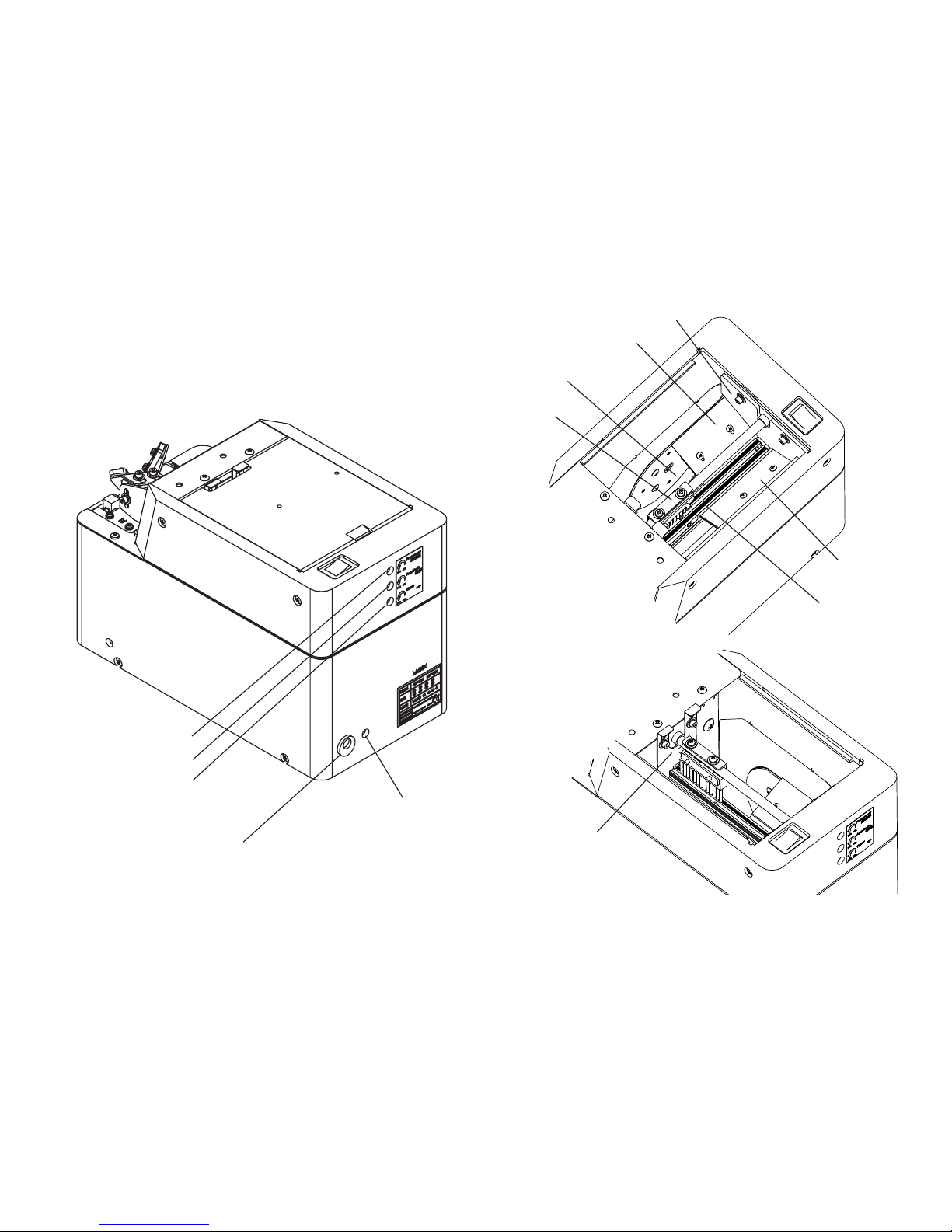

4.

NAMES OF MACHINE PARTS

Top lid

Rail xing bolt

Power switch

Front cover

Front lower

cover

LED screw indicator

Sensor bracket

Escaper assembly xing bolts

(1 left / 1 right)

Holding plate

adjusting bolt

Holding plate

xing bolt

Escaper guide-right

Holding plate

Light-emitting

sensor

Light-receiving

sensor

Bit guide

Escaper

Stopper assembly

Stopper

Bit guide bracket

Bit guide bracket

attaching plate

Right guide

Left guide

-6-

2

3

4

5

6

1

2

3

4

Passing plate

Brush

Scraper-left

Scraper-right

Rail assembly

Rear cover

Scooping hopper

DC jack

Signal line out

Timer adjusting knob

Amplitude adjusting knob

Frequency adjusting knob

-7-

5.

ADJUSTMENTS AND CHECKS BEFORE USE

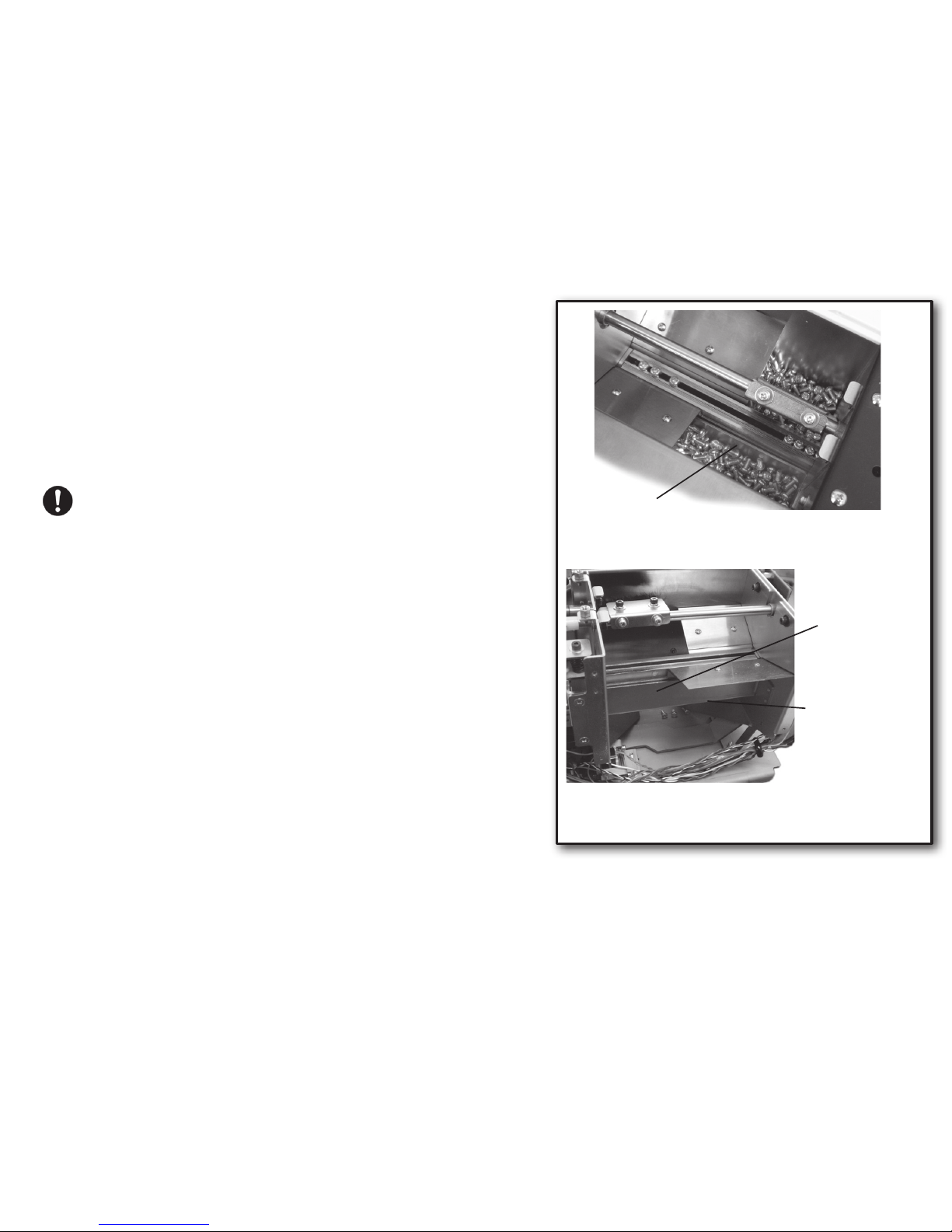

5-1.

Checking the model number of the main body

Check if the machine has the parts which match the nominal diameter of

the screws to be loaded. Check the model number of the rail, escaper,

stopper assembly, escaper guide-right,

and passing plate by referring to the following table.

Before delivery, each section of the machine is checked and adjusted

with panhead screws matching the nominal diameters of the model

ordered. Operate the machine with the screws loaded to check that the

pick up is smooth. If the height or or shape of the screw head is different

or if the operation is regarded as abnormal, each section must be

readjusted.

If this is the case, make the following checks and adjustments:

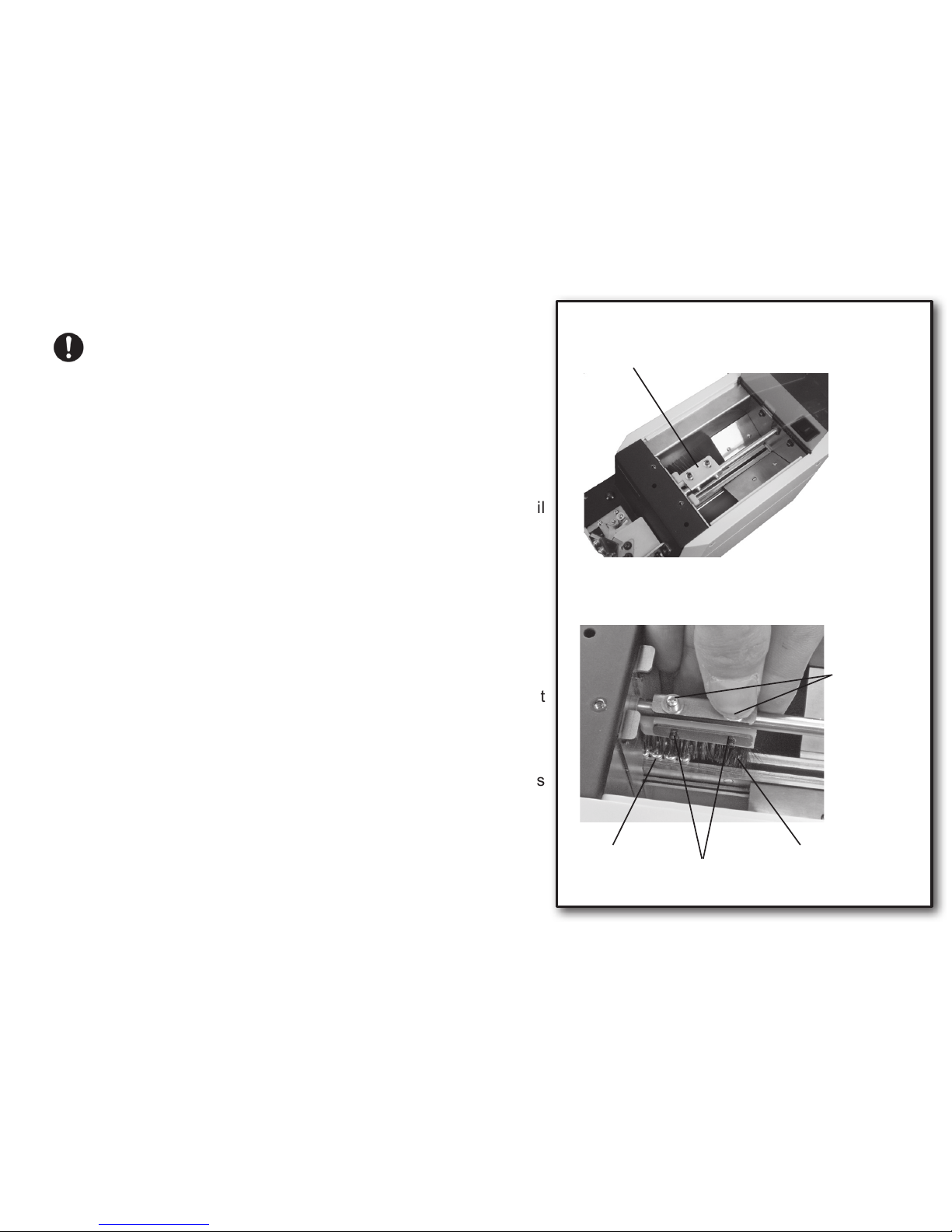

Identication stamp

※

This photo shows removal of the bit guide.

Stopper assembly

Escaper

Escaper guide-right

If the rail, escaper, stopper assembly, escaper guide-right and passing plate are replaced, screws with a different nominal

diameter can be accepted. After these parts are replaced, ne adjusting is required.

The respective adjusting procedures will be described elsewhere. Please read these procedures.

The rail identification

seal can be located

after removing the front

cover.

○ Check the screw load amount

○ Check and adjust the passing plate

○ Check and adjust the holding plate

○ Check and adjust the timer

○ Check and adjust the brush

○ Check and adjust the rail vibration

○ Check and adjust the front and rear sides of the rail

Passing plate

identication seal

㻾㼑㼒㼑㼞㼑㼚㼏㼑㻌㼠㼍㼎㼘㼑㻌㼛㼒㻌㼠㼔㼑㻌㼟㼜㼑㼏㼕㼒㼕㼑㼐㻌㼟㼏㼞㼑㼣㼟

㻿㼏㼞㼑㼣

㼒㼑㼑㼐㼑㼞

㼟㼑㼞㼕㼑㼟

㻿㼏㼞㼑㼣

㼒㼑㼑㼐㼑㼞

㼙㼛㼐㼑㼘

㻿㼏㼞㼑㼣

㼟㼕㼦㼑

㻱㼤㼏㼔㼍㼚㼓㼑㻌㼗㼕㼠

㻺㼛㻚

㻾㼍㼕㼘㻌㼙㼛㼐㼑㼘

㻺㼛㻚

㻱㼟㼏㼍㼜㼑㼞

㼙㼛㼐㼑㼘㻌㻺㼛㻚

㻿㼠㼛㼜㼜㼑㼞

㼍㼟㼟㼑㼙㼎㼘㼥

㼙㼛㼐㼑㼘㻌㻺㼛㻚

㻱㼟㼏㼍㼜㼑㼞

㻌㼓㼡㼕㼐㼑㻙㼞㼕㼓㼔㼠

㼙㼛㼐㼑㼘㻌㻺㼛㻚

㻼㼍㼟㼟㼕㼚㼓

㼜㼘㼍㼠㼑

㼙㼛㼐㼑㼘㻌㻺㼛㻚

㻿㼏㼞㼑㼣

㼟㼕㼦㼑

㻿㼏㼞㼑㼣㻌㼟㼔㼍㼒㼠

diameter(φ )

㻿㼏㼞㼑㼣

㼔㼑㼍㼐

㼐㼕㼍㼙㼑㼠㼑㼞

(φ )

㼃㼍㼟㼔㼑㼞

㼐㼕㼍㼙㼑㼠㼑㼞

(φ )

㻿㼏㼞㼑㼣

㼔㼑㼍㼐

㼠㼔㼕㼏㼗㼚㼑㼟㼟

(mm)

㻿㼏㼞㼑㼣

㼟㼔㼍㼒㼠

㼘㼑㼚㼓㼠㼔

(mm)

㻿㼑㼙㼟

㻰㼛㼡㼎㼘㼑

㼟㼑㼙㼟

㼃㼍㼟㼔㼑㼞

㼔㼑㼍㼐

㻻㻹㻙㻞㻢㻹㻞㻜 φ 㻞㻚㻜 㻻㻹㻹㻞㻜㻿㻱㼀 㻻㻹㻹㻞㻜 㻿㻵㻱㻞㻜 㻿㻵㻱㻿㻞㻜 㻿㻵㻱㻹㻞㻜 φ 㻞㻚㻜 1.9~2.1 2.4~6 2.4~10 0.35~6 2.6~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹㻞㻟 φ 㻞㻚㻟 㻻㻹㻹㻞㻟㻿㻱㼀 㻻㻹㻹㻞㻟 㻿㻵㻱㻞㻟 㻿㻵㻱㻿㻞㻟 㻿㻵㻱㻹㻞㻟 φ 㻞㻚㻟 2.2~2.4 2.7~6 2.7~10 0.35~6 2.9~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹㻞㻢 φ 㻞㻚㻢 㻻㻹㻹㻞㻢㻿㻱㼀 㻻㻹㻹㻞㻢 㻿㻵㻱㻞㻢 㻿㻵㻱㻿㻞㻢 㻿㻵㻱㻹㻞㻢 φ 㻞㻚㻢 2.5~2.7 3.0~6 3.0~10 0.35~6 3.2~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹㻟㻜 φ 㻟㻚㻜 㻻㻹㻹㻟㻜㻿㻱㼀 㻻㻹㻹㻟㻜 㻿㻵㻱㻟㻜 㻿㻵㻱㻿㻟㻜 㻿㻵㻱㻹㻟㻜 φ 㻟㻚㻜 2.9~3.2 3.5~6 3.5~11 0.35~6 3.6~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹㻟㻡 φ 㻟㻚㻡 㻻㻹㻹㻟㻡㻿㻱㼀 㻻㻹㻹㻟㻡 㻿㻵㻱㻟㻡 㻿㻵㻱㻿㻟㻡 㻿㻵㻱㻹㻟㻡 φ 㻟㻚㻡 3.4~3.7 4.0~8 4.0~11 0.35~6.5 4.1~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹㻠㻜 φ 㻠㻚㻜 㻻㻹㻹㻠㻜㻿㻱㼀 㻻㻹㻹㻠㻜 㻿㻵㻱㻠㻜 㻿㻵㻱㻿㻠㻜 㻿㻵㻱㻹㻠㻜 φ 㻠㻚㻜 3.8~4.2 4.5~8 4.5~12 0.35~6.5 4.6~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹㻡㻜 φ 㻡㻚㻜 㻻㻹㻹㻡㻜㻿㻱㼀 㻻㻹㻹㻡㻜 㻿㻵㻱㻡㻜 㻿㻵㻱㻿㻡㻜 㻿㻵㻱㻹㻡㻜 㻻㻹㻡㻜 φ 㻡 㻚㻜 4.8~5.2 5.5~10 5.5~12 0.35~7 5.6~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹㻢㻜 φ 㻢㻚㻜 㻻㻹㻹㻢㻜㻿㻱㼀 㻻㻹㻹㻢㻜 㻿㻵㻱㻢㻜 㻿㻵㻱㻿㻢㻜 㻿㻵㻱㻹㻢㻜 㻻㻹㻢㻜 φ 㻢 㻚㻜 5.8~6.2 6.5~11 6.5~12 0.35~7.5 6.6~25 ○ ○ ○ ○ ○ ○

㻻㻹㻙㻞㻢㻹

㻻㻹㻞㻜㻙㻟㻜

㻻㻹㻟㻡㻙㻠㻜

㻿㼔㼍㼜㼑㻌㼛㼒㻌㼟㼏㼞㼑㼣㻌㼔㼑㼍㼐

㻼㼍㼚㻌㼔㼑㼍㼐

㼎㼕㼚㼐

㻲㼘㼍㼠㻌㼔㼑㼍㼐

㼔㼑㼤㼍㼓㼛㼚

㼒㼘㼍㼚㼓㼑

㼎㼛㼘㼠

-8-

5-2.

Basic operations

○Loading the screws

・

Turn the power switch ON and OFF so that the brush stops vertically above

the rail.

・

Open the top cover and load screws on the left and right side of the rail

evenly.

・

Do not load screws above the surface of the rail.

・

Be sure to determine the screw load by observing the machine while it is in

operation.

Screws with a diameter larger than 5 or longer than 20mm,

under the head, should not be loaded higher than the rail bottom.

○Turning ON the power

・

Use only the adapter supplied with this machine to connect it to a wall outlet.

When you turn the power on, the switch lamp lights up, the motor rotates and

screws are scooped onto the rail.

・

The rail vibrates to deliver screws towards the end of the rail, then the

escaper rotates to deliver screws to the pick up spot. When the screws come

to the stopper, the LED indicator lights up and the escaper stops rotating.

Rail cover

(INDICATION:The maximum screw load must not be

over 30mm below the rail-groove surface.)

Disassembled state

Do not load screws

above this point.

(Rail Bottom)

Rail cover

[CAUTION]

・The type and length of screw changes the load capacity so check and adjust

the load accordingly.

・Do not overload the hopper with screws otherwise it may cause a

malfunction or damage the machine.

・This machine accepts only steel screws. Plastic or stainless screws are not

accepted.

[CAUTION] Use only the AC adapter supplied with this machine

otherwise it may cause damage to the machine.

-9-

○Pick uping Screws

・

Pick up the screws at the stopper with the electric screw driver.

Use the bit guide to put the screwdriver down vertically into the screwhead's slots,

then pull the screwdriver, horizontally, towards you as pick uping the screw.

・

When inserting the screwdriver into the screwhead slots, do not use excessive force

as it may alter the position of the escaper or cause damage to the machine.

・

To insert the screwdriver bit into the screwhead slots properly, it may be necessary to

twist the driver slightly.

・

Use a driver bit which corresponds with the screw's diameter.

○Action of the escaper

・

The escaper rotates 90° clockwise--> stops for about 0.6 seconds

--> and rotates again 90° clockwise.

When a screw is caught in the escaper and the notch position is altered, the escaper

automatically rotates to the left, as a reference point run, in order to adjust the notch

position and then returns to the right rotation.

・

This machine continues its operation when no screw is found at the screw pick up

spot. The machine continues operating with a screw at the pick up spot but will stop,

after a certain lapse of time, if the screw is not picked up. After the screw is picked

up, the machine starts operating again. This time lapse can be varied by adjusting

the timer.

・

When no screw is found at the pick up site after a certain lapse of time, the rail

vibration increases.

(The vibration sound, also, increases however, this is not a problem.)

If no screw is still not found at the pick up site, then the machine stops operating. At

this time the escaper keeps rotating. When you want to start operation again, turn

the power switch OFF and ON again.

LED screw indicator

①

②

①

Put the screwdriver

down vertically as

twisting it slightly and

insert the bit into the

screwhead slots properly.

②

Pull the screwdriver

towards you, horizontallly

and pick up the screw.

Accepting a screw.

LED screw indicator

is OFF

The screw is carried to

the pick up site.

LED screw indicator is

ON

Pick uping the screw

at the pick up site.

LED screw indicator is

OFF

The rotation of the escaper, in the opposite

direction, is a reference point run of the escaper

motor.

The rotation of the escaper, in the opposite

direction, occurs when the power is turned on and

the starting point of the escaper is not alligned

with the reference point of the escaper motor.

During regular operation, as in the gure above,

the escaper rotates clockwise.

(Reference)

○Action of the escaper

-10-

5-3.

Adjusting the brush height

Load the screws into the scooping hopper, turn ON and OFF the

power switch so that screws are alligned into the rail groove.

・

Turn ON and OFF the power switch in order to set the brush to the

left as shown in the gure on the right.

・

Move the brush by hand to check that the screws, in the rail

groove, are in slight contact with the brush bristles and if needed

make the necessary adjustments.

・

When the brush height is too high or low, this will have an adverse

effect on the screw allignment and transport.

・

If any adjustment is necessary, loosen the brush height adjusting

bolt to adjust the brush height.

・

If the plastic portion, at the front of the brush, comes into contact

with the passing plate, loosen the brush assembly mounting screw

and move the brush assembly back so there is 0 mm clearance.

・

Turn ON the power switch to check that the brush operation is

normal.

Turn OFF the power switch before starting replacement and

adjustment.

Brush

Loaded screws

Brush height adjusting bolt

Move the brush by hand to check that the screws, in the

rail groove, are in slight contact with the brush bristles

and make adjustments if necessary.

Turn On and Off the power switch to put the brush

bristles in a horizontal position towards the left side.

Brush assembly

attaching screw

-11-

5-4.

Checking and adjusting the rail vibration

The amplitude and frequency of the rail vibration can be adjusted.

The vibration has been adjusted at the factory for screws that correspond with

the rail.

Put some screws into the rail and turn the power on. If they are delivered

smoothly, there is no need for adjustment.

The screw transport feed differs depending on screw type.

For screws with a low transport speed, or screws that easily jump, an

adjustment is necessary.

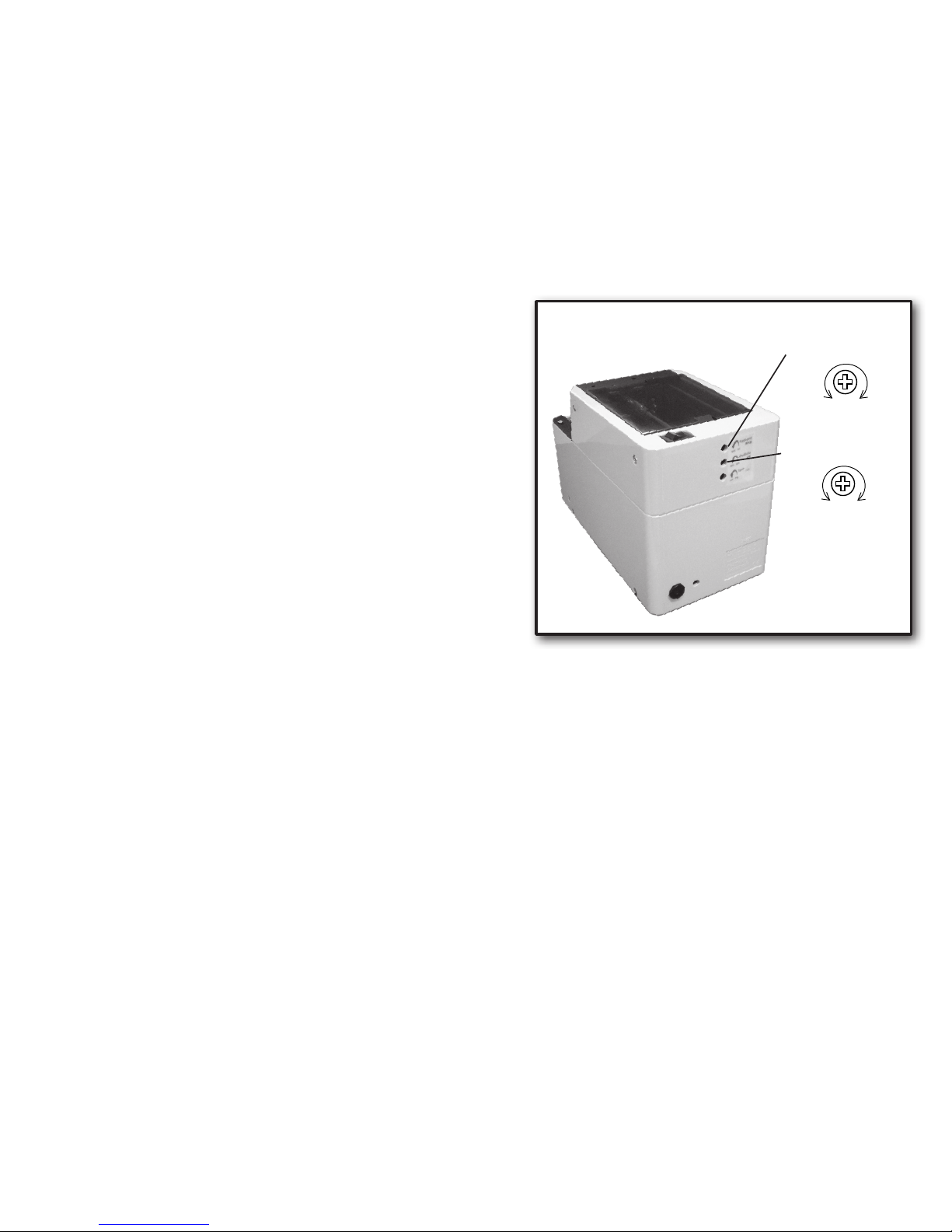

Amplitude adjusting

knob

Frequency adjusting knob

SmallLarge

LowHigh

①

Turn the frequency adjusting knob (rst hole at the top in the

back of the machine) using the accompanying screwdriver.

Find the frequency at which the rail vibrates the most.

②

Turn the amplitude adjusting knob (second hole from the top)

and nd the amplitude for which screws are delivered smoothly.

・

If the vibration is adjusted to a too large a value to increase the transport

speed, screws may jump from the rail and fall into the machine from the

clearance, failing to unload screws normally.

Adjust the vibration to a proper value that matches the loaded screws.

・

With the accompanying screwdriver, turn the knob without using excessive

force.

・

When no screws are scooped onto the rail for a certain period of time, the rail

vibration increases. If, still, no screws are scooped on to the rail, the machine

stops operating.

-12-

5-5.

Check and adjust the front and rear sides of the rail

5-6.

Check and adjust the rear hopper cover

Turn OFF the power switch before starting replacement and

adjustment.

Turn OFF the power switch before starting replacement and

adjustment.

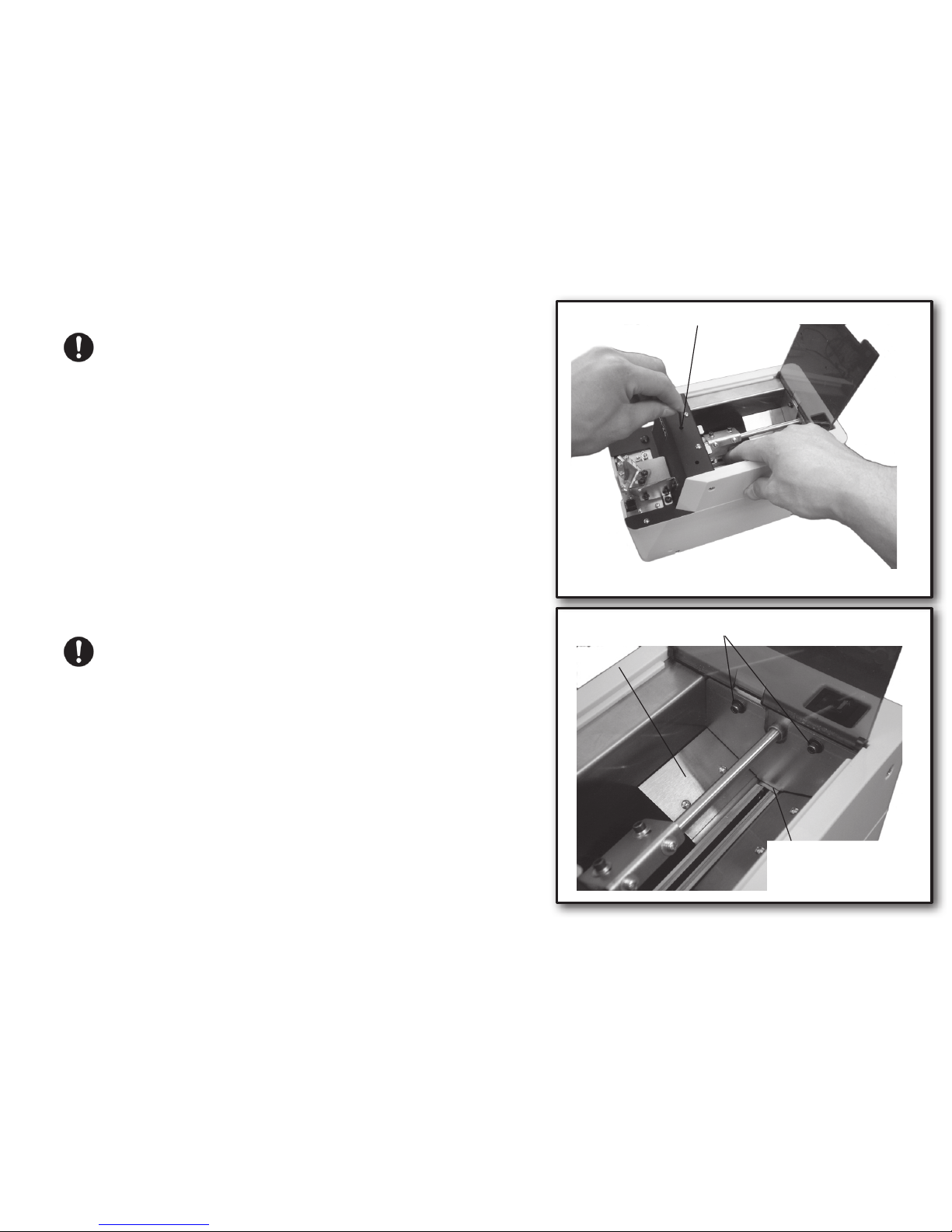

Rail xing bolt

Hold the rail groove and

adjust the rail assembly either

backward or forward.

The rear hopper cover attaching bolts

The clearance between the

rear hopper cover and the rail

assembly is about 0.2mm

Scraper

・

If the rail comes into contact with the escaper, or the clearance between the

rail and escaper is too large, loosen the rail xing bolt, hold the rail groove

and adjust the rail assembly either backward or forward.

After making an adjustment, be sure to tighten the rail xing bolt.

・

When the rail comes in contact with the escaper, the escaper disk doesn't

rotate properly. When the clearance between the rail and the escaper is too

large, screws may fall down into the machine.

・

After making an adjustment, try making a vibration readjustment by referring

to " 5-4 Checking and Adjusting the Rail Vibration".

・

Check that the clearance between the rear hopper cover and the rail

assembly is about 0.2 mm.

・

If the rail hits against the rear hopper cover, the vibration will become weak

and the screws will be delivered slowly.

If the rear hopper cover is too high, the slit between the rail and the scraper

catches screws easily.

・

If adjustment is required, loosen the rear hopper cover attaching bolts and

make an adjustment either up or down.

-13-

5-7.

Check and adjust the passing plate

5-8.

Check and adjust the holding plate

・

Check that the clearance between screws in the rail groove and the

holding plate is about 0 ~ 1mm.

・

If any adjustment is required, loosen the holding plate attaching screw

and turn the holding plate adjusting screw, to move the plate up or

down.

・

If there is no clearance, a screw will be blocked. If the clearance is too

large, screw piling or screw jump out will occur.

When the holding plate adjusting screw is turned clockwise,

the plate moves down.

When the adjusting screw is turned counterclockwise,

the plate moves up.

Turn OFF the power switch before starting replacement and

adjustment.

Up

Down

Passing plate

Passing plate

attaching bolt

Loaded

screws

The clearance should be just enough to permit the loaded screws

to pass through the passing plate.

Holding plate

adjusting screw

Holding plate attaching

screw

(inside of the hole)

・

Check that the passing plate is adjusted to a height that permits

loaded screws to pass just within the limit.

・

If the passing plate is too low, screws cannot pass.

If the passing plate is too high, it will hamper a smooth transport of the

screws.

・

If adjustment is required, loosen the passing plate attaching bolts and

adjust either up or down.

Loading...

Loading...