OHTAKE NSB2, NSB2-10, NSB2-12, NSB2-14, NSB2-17 Operation Manual

...

16,50$(

4GCFVJGUGKPUVTWEVKQPUHQTVJGRTQRGTWUGQHVJKUOCEJKPG

#HVGTJCXKPITGCFVJGUGKPUVTWEVKQPUMGGRVJGOKPCEQPXGPKGPVRNCEGUQ[QW

QTVJGQRGTCVQTECPTGHGTVQVJGOYJGPGXGTPGEGUUCT[

䠪䠯䠮䠥㻌㼀㼥㼜㼑

$XWRPDWLF6FUHZ)HHGHU

ὀព㸟㸸www.ohtake-root.co.jp ࡀᙜ♫၏୍ࡢ HP ࢻࣞࢫ࡛ࡍࠋ

ᘢ♫ࡢྡࢆ㦄ࡿഇࢧࢺࡈὀពୗࡉ࠸ࠋ⌧ᅾࠊᙜ♫ࡣ୰ᅜᅜෆᨭᗑࡣࡈࡊ࠸ࡲࡏࢇࠋ

ྛ栦ᐈ実ὀព㸸ࠕwww.ohtake-root.co.jp ᩎྖ၏୍ⓗᐁ᪉⨒❰㸪

┠๓㸪ᩎྖᅾ୰ᅜἐ᭷≆⢬ᡤ宻ⓗ୰ᅜᐁ⨒ࠋࠖ

ATTENTION : www.ohtake-root.co.jp is the only web site associated with our company.

We do not have any branches in China.

Operation Manual

Read these instructions for the proper use of this machine.

After having read these instructions,

keep them in a convenient place so you

or the operator can refer to them whenever necessary.

自動ネジ供給機

NSB²

Series

Automatic Screw Feeder

NSB2MA01

Ma

(Maintenance)

-1-

CONTENTS

1. BEFORE USE

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

2. FOR SAFE USE

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2

3. NAME OF MACHINE PARTS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

4. ADJUSTMENTS AND CHECKS BEFORE USE

・・・・・・・・・・・・・・・・

4

5. OPERATING INSTRUCTIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

6. REPLACEMENT OF CONSUMABLE PARTS

・・・・・・・・・・・・・・・・・

13

7. OTHERS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

18

8. TROUBLESHOOTING

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

18

9. SPECIFICATIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

23

10. EXTERNAL DIMENSIONS

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

25

11. WARRANTY

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

26

Cautions

Be sure to follow the cautions, or it could lead to serious damage, such as injuries.

electric shock, and damage to properties.

1)

BEFORE USE

Thank you very much for selecting our Automatic Screw Feeder “NSB² series”. Please check the following accessories before

operating the machine.

*

Instruction manual, 1 copy

*

Passage plate, 2 pieces (1 piece is already attached to the main body.)

*

AC adapter, 1 piece

*

0.35 mm gauge plate, 1 piece (used for adjusting the holding plate)

*

Hexagonal wrench, 1 piece

*

Screwdriver, 1 piece

-2-

2)

FOR SAFE USE

Read the following Cautions thoroughly for the safe use of this machine. Keep them in mind during the operation

of the machine in order to prevent injuries and damage to property.

- Installation

Caution:

Install the machine on a level, stable location that can endure it’s weight and running conditions.

If the machine falls down or turns over due to improper installation, injuries or property damage may occur.

- Operating Environment

Caution:

Do not operate this machine where ammable or corrosive gas is present. It is extremely dangerous

to use this machine under such circumstances. Do not operate this machine in environment of high humidity.

- AC adapter

Caution:

Use only the AC adapter supplied with this machine otherwise it may result in a re or electric shock.

- Rail

Caution:

Do not damage nor oil the rail.

- Screw compatibility

Caution:

Do not use screws with grease, dirty screws or any screw other than those prescribed.

- Access of screws

Caution:

Do not exert excessive or impactive force when accessing the screws.

- When machine is not in use

Caution:

Be sure to unplug the AC adapter from the wall outlet during closing hours and if the machine will be

left unattended for any extended period of time.

- Abnormalities during operation

Caution:

Stop operation and unplug immediately whenever you sense abnormalities or unusual machine

behaviors during the operation of this machine, such as a pungent odor. Turn off the power switch and

disconnect the AC adapter from the receptacle. Continued operation may cause re, electric shock,

malfunction or personal injury. Immediately contact the dealer from which you purchased the product.

- Servicing

Caution:

Do not attempt to repair, disassemble or modify this machine except where specied by this manual.

Consult your dealer for service and repair of this machine.

-3-

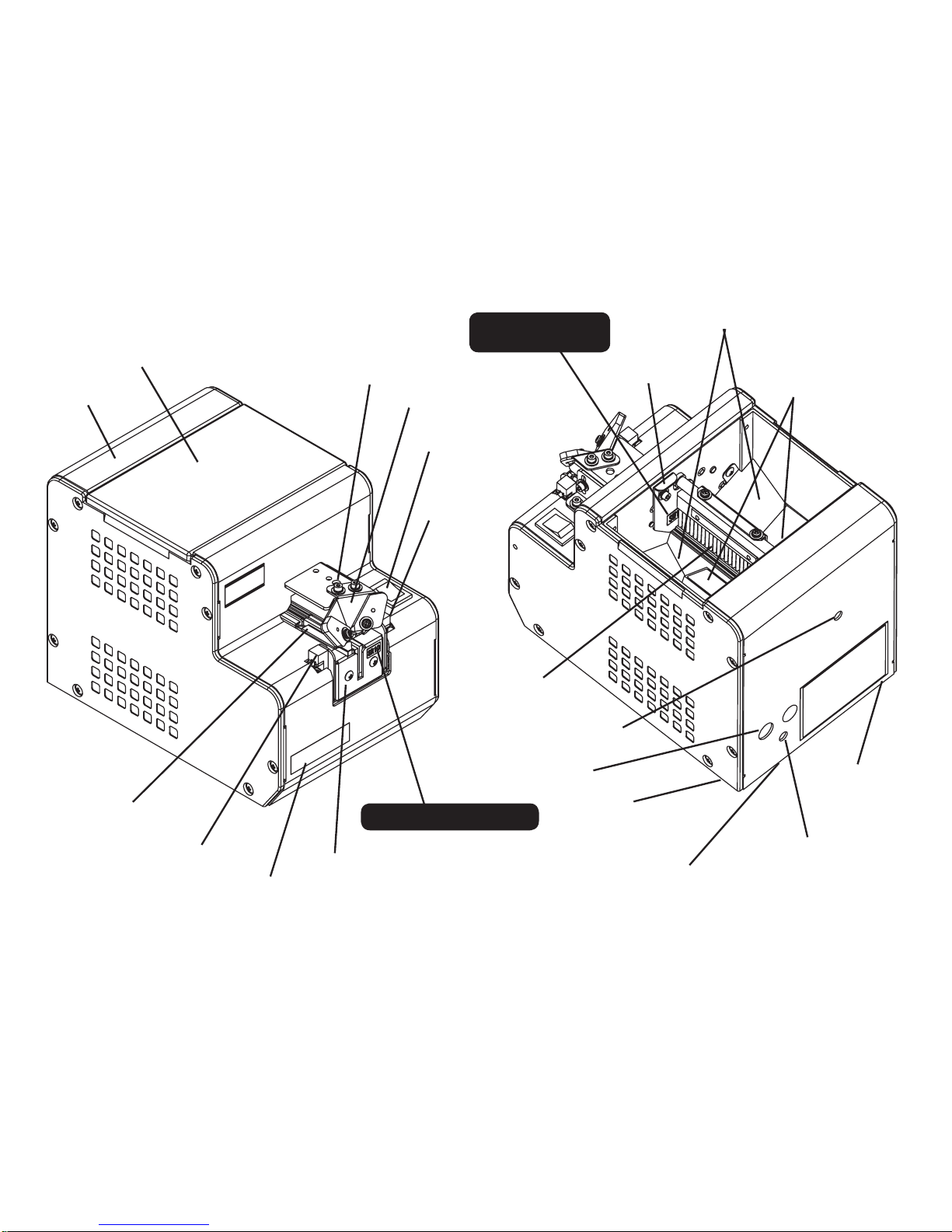

3) NAMES OF MACHINE PARTS

Upper cover

Rear cover

Rail xing bolt

Power swtich

Holding plate

Light-receiving

sensor

Light-emitting

sensor

Bit guide

Front cover

Rail assembly

Timer knob

Brush

Passing plate

Passing plate

identication seal

Scooping block

(left and right)

(moving up and down)

Scooping chamber

Rail identication seal

Tilting bolt(under

the machine

)

Vibr a tion adjus t ing

plate xing bolt

DC jack

Tilting bolt(under

the machine

)

Vibration adjusting bolt

(under the machine

)

-4-

◆ When there is no rail installed on the machine, please install the rail

before use.

- First, unfasten the rail xing bolt through the upper bit guide holder

- Insert the rail into the furthest point

- Fasten the xing bolt

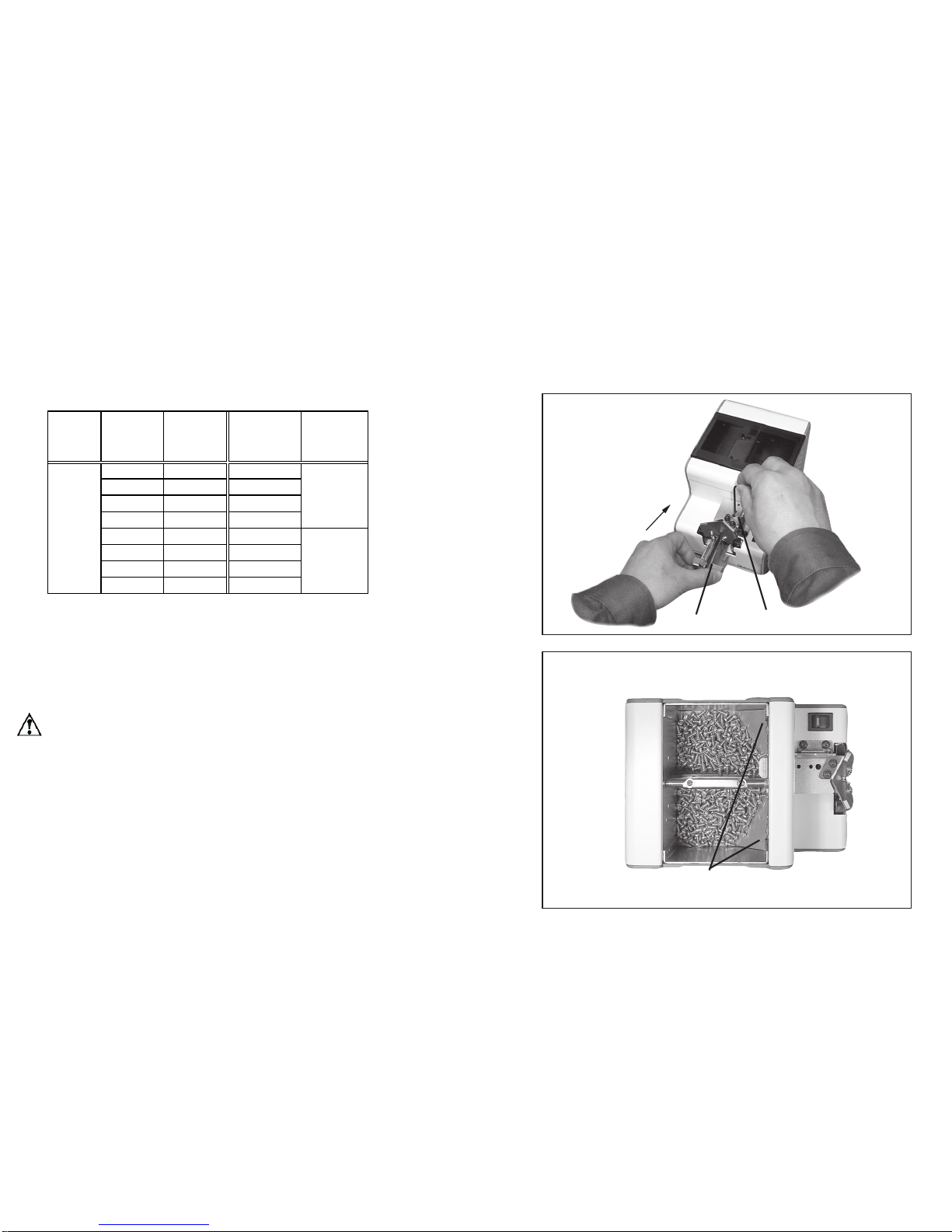

Quantity of screws thrown in

If too many screws are thrown in, orientation and transfer of the

screws will be seriously affected.See the diagram on the right for the

maximum number of throw screws in the [scooping chanber].

* Set the [scooping block] in the lowest possible position.

* Throw in screws up to a position of 2 mm to 3 mm below the rail

groove face.

* In this condition, ensure that the front inclined-face of the ramp is

not hidden by the screws.

4)

ADJUSTMENTS AND CHECKS BEFORE USE

Before using the machine, please check if the rail and components installed on the machine is suitable for the screw applied. The rail is φ1.0 to φ3.0 depending on the nominal diameter. It is determined by the identication seal on a rail

front cover. There are two kinds of passage plates, namely one for φ1.0 to φ1.7 and one for φ2.0 to φ3.0. It is deter-

mined by a identication seal afxed on a passage plate.

These parts of the inclined face of the ramp should

be

use underline.

Ensure that the rail groove face is not hidden by the screws.

(Screws should be positioned 2 to 3 mm below the rail

groove.)

Rail xing boltRail

Reference table of the specified screws

Screw

feeder

series

Screw

feeder

model

Screw size Rail model No.

Passing plate

model No.

Screw

size

Screw shaft

diameter(φ )

Screw

head

diameter

(φ )

Screw

head

thickness

(mm)

Screw

shaft

length

(mm)

Sems

Double

sems

Washer

head

NSB²-10

φ 1.0 SR10 φ 1.0 0.9~0.95 1.2~4.5 0.35~1.0 1.6~10 ○

NSB²-12

φ 1.2 SR12 φ 1.2 1.1~1.15 1.4~4.5 0.35~1.0 1.8~10 ○

NSB²-14

φ 1.4 SR14 φ 1.4 1.3~1.4 1.7~4.5 0.35~1.0 2.0~10 ○

NSB²-17

φ 1.7 SR17 φ 1.7 1.6~1.7 2.0~4.5 0.35~1.0 2.3~10 ○

NSB²-20

φ 2.0 SR20 φ 2.0 1.9~2.1 2.4~6 0.35~4.5 2.6~20 ○ ○ ○ ○ ○ ○ ○

NSB²-23

φ 2.3 SR23 φ 2.3 2.2~2.4 2.7~6 0.35~4.5 2.9~20 ○ ○ ○ ○ ○ ○ ○

NSB²-26

φ 2.6 SR26 φ 2.6 2.5~2.7 3.0~6 0.35~4.5 3.2~20 ○ ○ ○ ○ ○ ○ ○

NSB²-30

φ 3.0 SR30 φ 3.0 2.9~3.2 3.5~6 0.35~4.5 3.6~20 ○ ○ ○ ○ ○ ○ ○

NSB²

SW1017

SW2030

Shape of screw head

Pan head

bind

Flat head

Counter

sunk

head

hexagon

flange

bolt

-5-

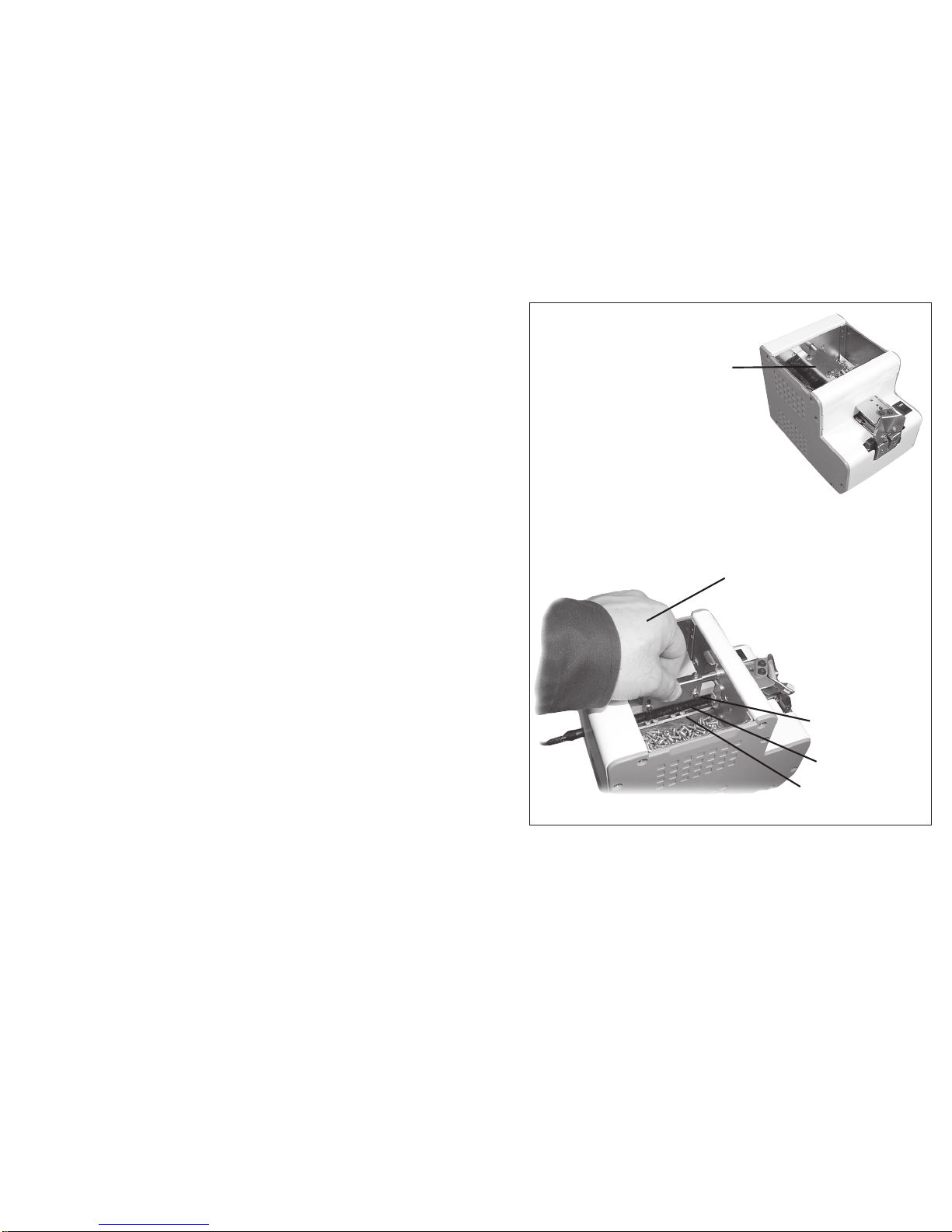

◆

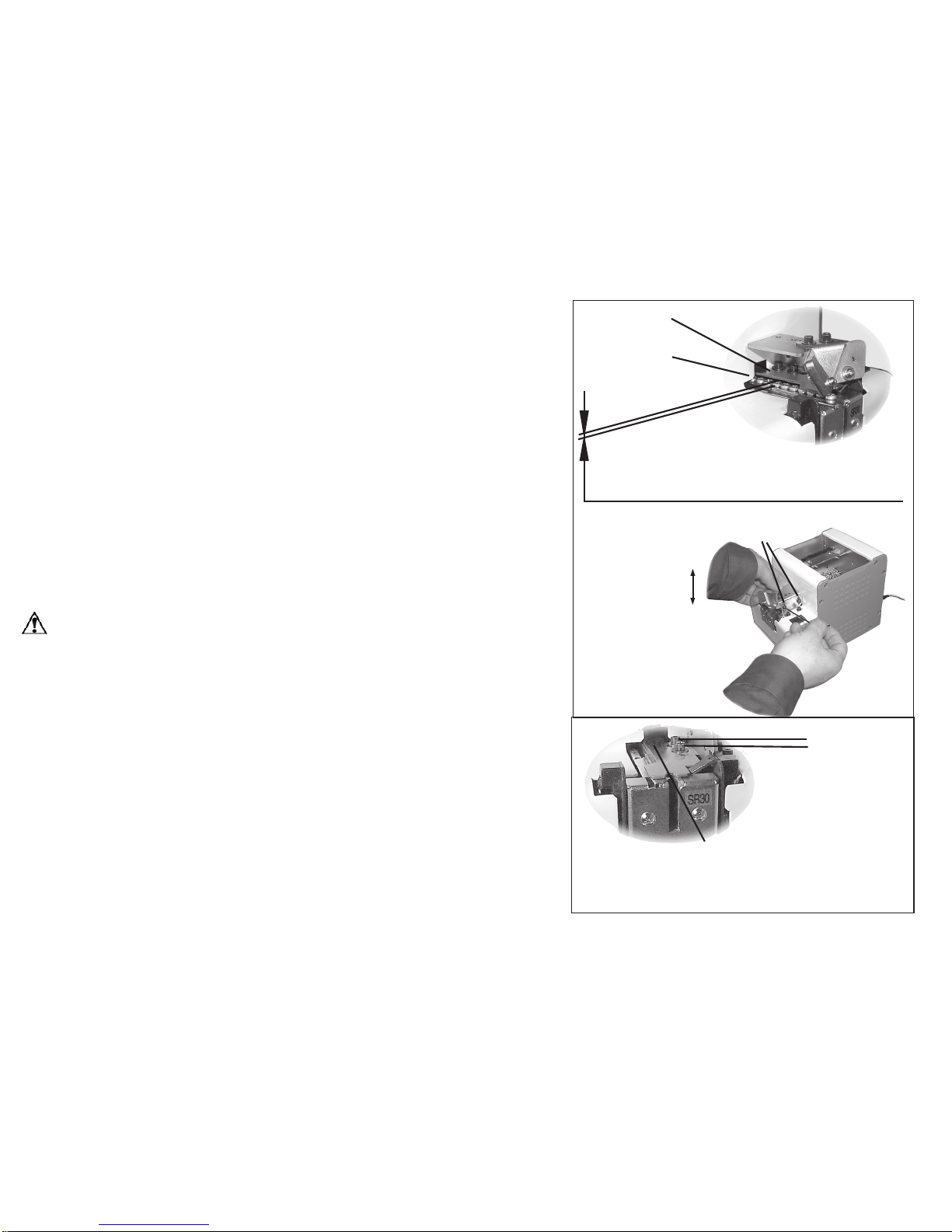

Adjustment of the brush

Check the height of the brush.

* As in the picture on the right, set the brush to an approximately level position.

* Ensure that the edge of the brush is grazing the screw’s

head.

* If the height of the brush is either too low or too high, orientation and transfer of the screws will be seriously affected.

* If adjustment is necessary, adjust it by loosening the brush

height adjusting screw.

Note:

Always unplug the AC adapter from the wall outlet be-

fore making any adjustments to avoid injury.

Turn the power switch on & off,

and set the brush on the level.

Ensure that the edge of the

brush is grazing the screw’s

head.

Adjustment screw

for the brush

Brush

Screws

-6-

◆

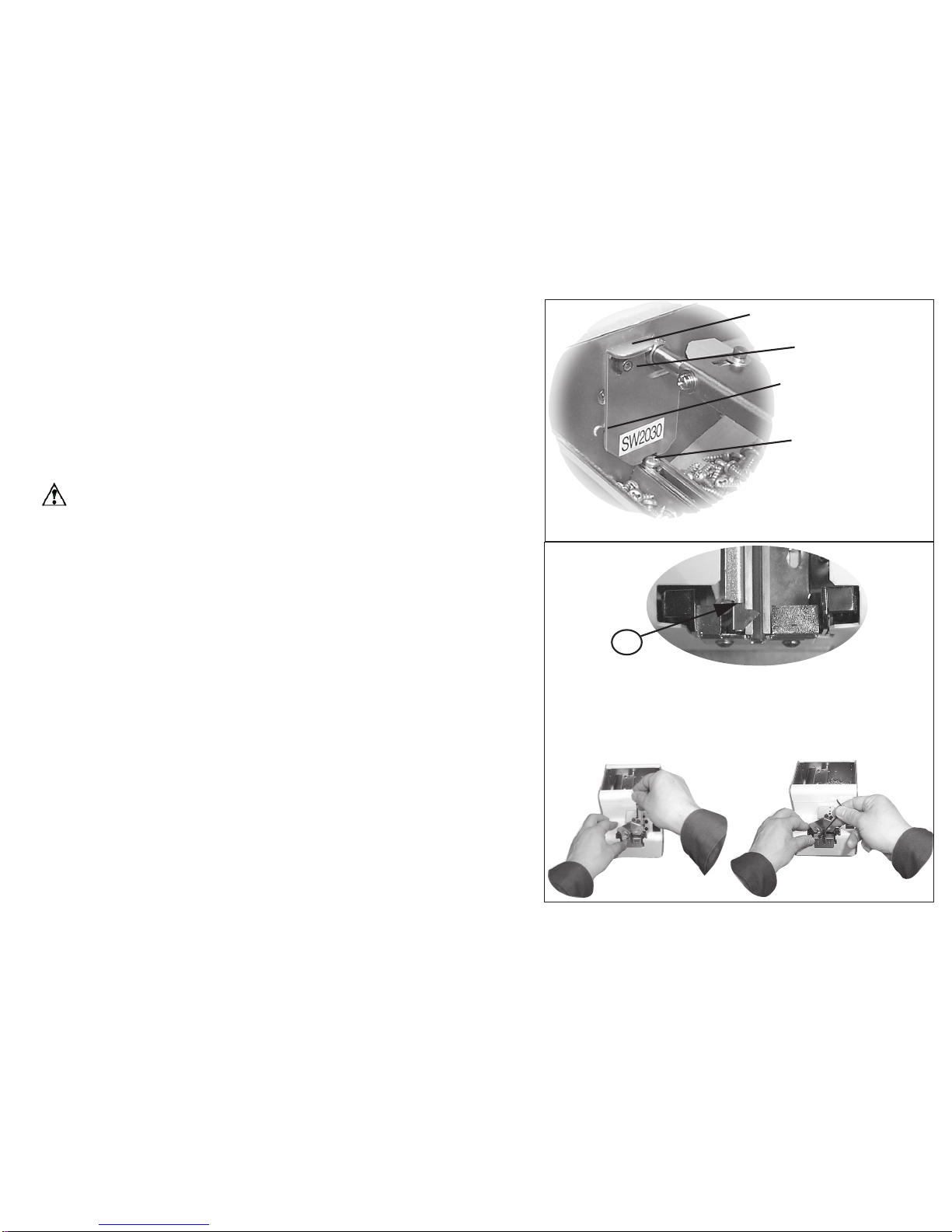

Adjustment of the holding plate

Check the position of the holding plate.

* Ensure that the gap between the head of the used screw in the rail

groove and the holding plate is approximately 0.2 mm to 1 mm.

* If there is no gap, the screw gets caught. If the gap is too large, the

screw overlaps or juts out.

* If adjustment is necessary, adjust it up or down by loosening the bit

guide bracket attaching screw.

◆

Easily adjust it by using the 0.35 mm gauge plate.

* Loosen the bit guide bracket attaching screw. Insert the gauge between screws on the rail and the holding plate. Tighten the bit guide

bracket attaching screw when the holding plate is touching the front and

the back of the gauge equally.

Caution:

Matching the center of the holding plate outlet and the rail

center may be necessary.

* Ensure that the center of the holding plate outlet matches the rail center.

* If not, adjust it by loosening the attaching screw.

Holding plate

Screws

The bit guide bracket attaching screws

Adjustment of

the height

The gap between the holding plate and the head

of screws should be 0 .2 mm to 1 mm. The

holding plate and the rail should be parallel,too.

Match the center of the holding

plate outlet and the rail.

(It’s not necessary to remove the

bit guide.)

Attaching

screws

-7-

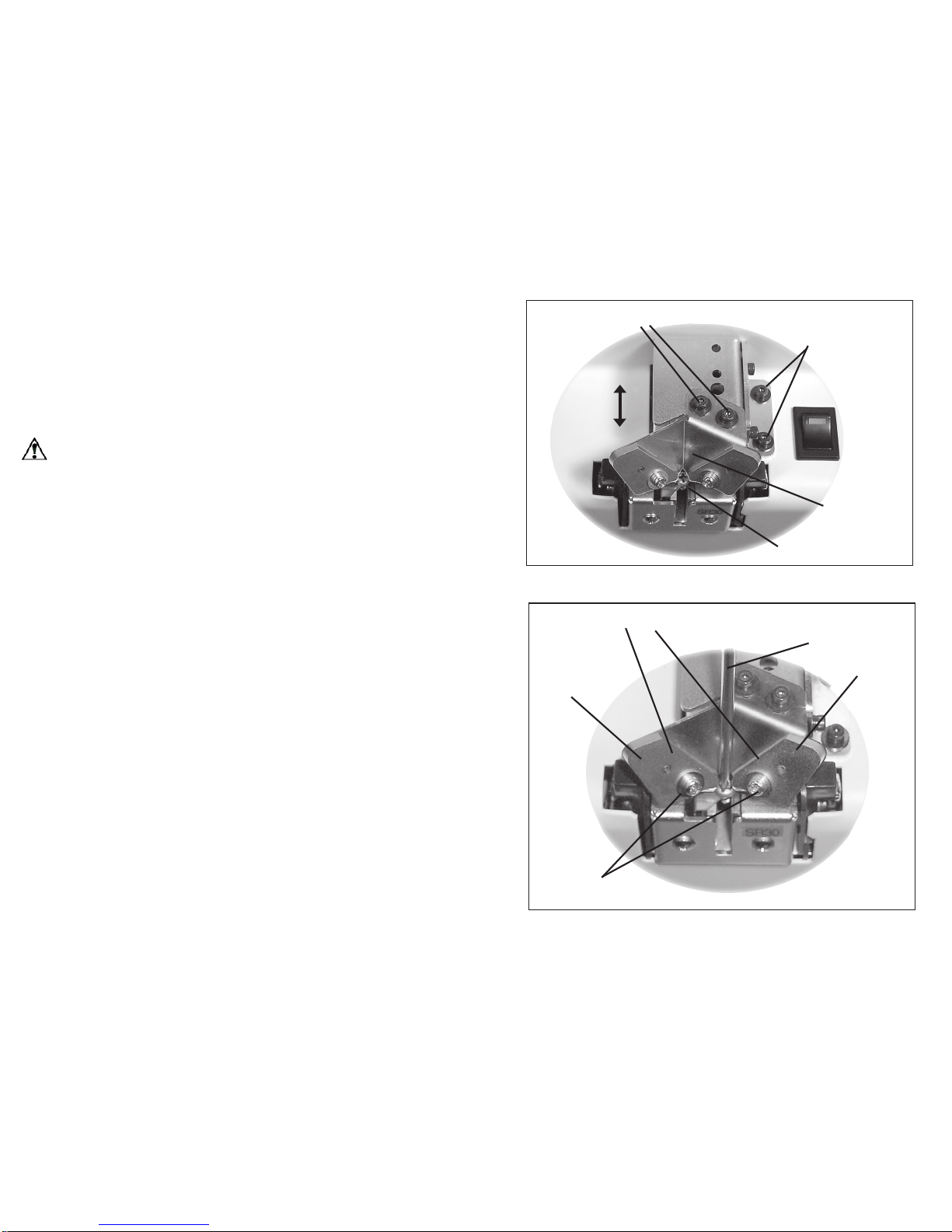

◆

Adjustment of the passage plate

Check the height of the passage plate.

* Ensure that the passage plate is adjusted at a height where the

used screw can manage to pass.

* If the passage plate is too low, the screw cannot pass, and if too

high, the screw easily gets caught.

* If adjustment is necessary, adjust it by loosening the passage

plate attaching screw.

Caution:

Slide the half blankings at both sides of the passage

plate up and down the guide.

◆

Adjustment of the rail

Check the physical relationship of the stopper and sensor.

* Ensure that the rail is xed so that “A” portion of the stopper is 0

mm to 0.5 mm ahead of the sensor optical axis.

* If adjustment is necessary, adjust it’s location by loosening the

rail attaching screw.

Halfway hole

(On both sides of the

passage plate)

Ensure the screw passes

through the window with no

extra space.

Screw

Passage plate

Passage plate

attaching screw

Looking down from the top, a portion of the stopper is

sticking out 0 to 0.5 mm more forward than the sensor’s

optical axis. (It’s necessary to remove the bit guide.)

A

Loosen the rail

attaching screw.

Adjust the rail back and

forth.

-8-

◆

Check/adjustment of the bit guide

Check the position of the bit guide.

* Adjust the bit guide to a position where a user can easily take

screws.

Actually pick up screws a few times to adjust it.

Adjust it by loosening the attaching screws.

Caution:

The rail is adjusted according to the physical relationship with the sensor as on the preceding page, so basically

the rail is not adjusted here.

◆

Adjustment of the left and right guide pieces

Please check and adjust position of the guide piece as necessary.

The bit guide is originally set at approximately 3mm at the front

opening, and shall be adjusted as needed by the user.

- Unfasten the front xing screws, insert driver-bit to be used and

adjust the slit opening, so that the bit can move freely.

- After the adjustment, try to pick up a screw and check its working

condition before turning on the power.

Guide attaching screws

Right guide plate

Left guide plate

Driver bit

Adjust the guide plate

The bit guide attaching screws

(Assy. attachiing

screws)

Adjustment

Bit guide

Screw

Loading...

Loading...