Page 1

TGH Series

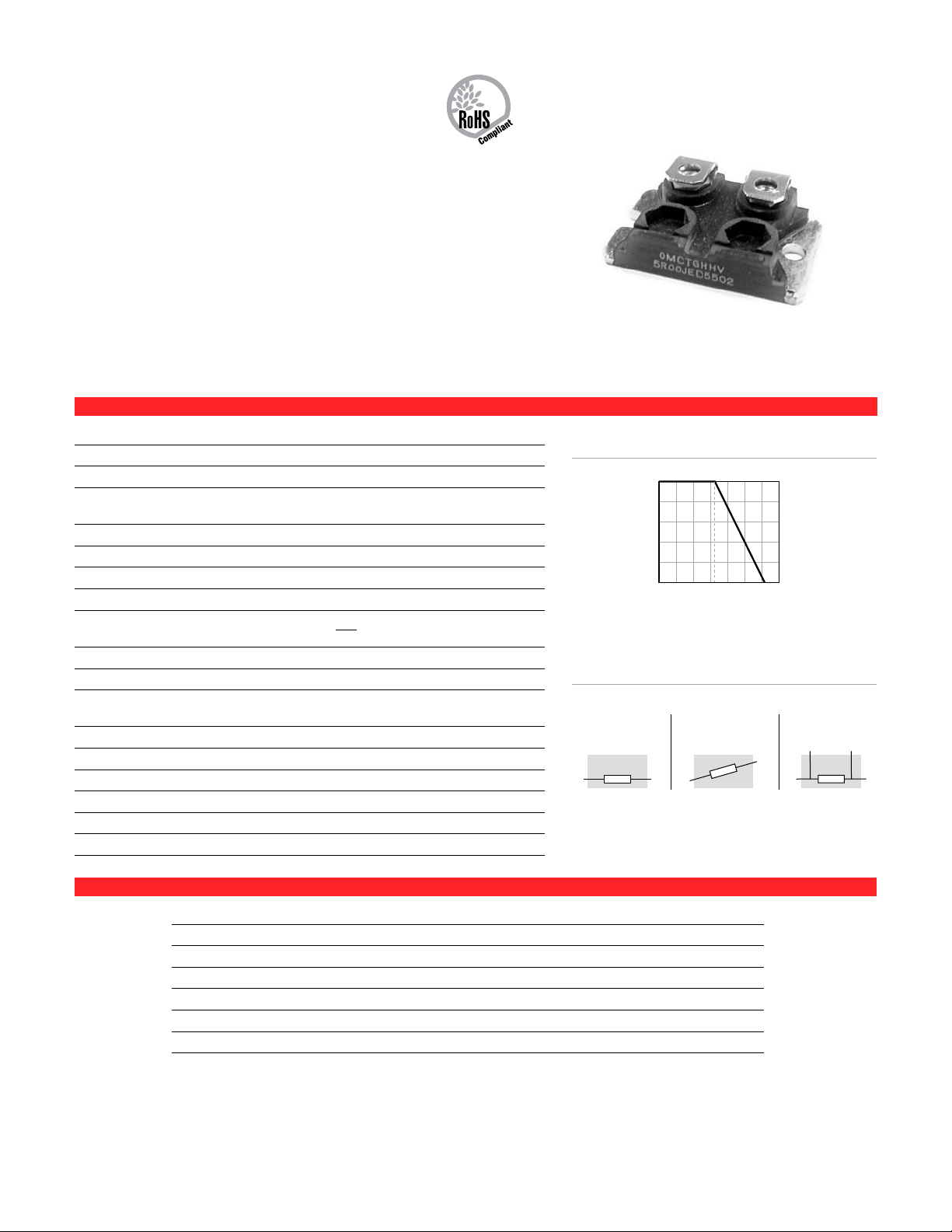

100

Percent Rated Power

Bottom of base plate Temperature, °C

60

20

0

175

80

40

25 100 125050 85

200

Rated Power, W

120

40

0

160

80

150

120

72

24

0

96

48

LHTy pe:

1

4

1 2

Config.

1 (V) Config. 2 (X)

1

3 4

2

Config.

3 (Y)

120 and 200 Watt SOT227Package

Thick Film Power

Due to their non-inductive design, these resistors are

ideally suited for high-frequency and pulse-load applications. Available in 120- or 200-watt sizes, this resistor

is designed for direct mounting onto a heatsink. Popular

applications include variable speed drives, power supplies, control devices, telecom, robotics, motor controls,

and other switching designs.

CHARACTERISTICS

Heat Sink

Contacts

Substrate

Molding Compound

Terminal Nuts

Resistance Range

Tolerance

Temperature coefficient:

Max. Working Voltage

Power Rating at 85°C

Partial Discharge

Voltage Proof

Heat Resistance to Cooling Plate

Capacitance/Mass

Working Temp. Range

Max. Torque for Base Plate (static)

Max. Torque for Contacts (static)

Derating (thermal resistance)

Nickel-plated copper

Nickel-plated copper

Al203 (96%)

High-performance epoxy, compliant to

UL94-V0

American standard 303 stainless steel

0.1Ω to 1MΩ

±5%; other tolerances available on request

±250ppm (at +105°C ref. to +25°C)

500V (1000V, not to exceed rated wattage

using √P*R

.)

120W (see derating)

up to 2,000Vrms/80 pC

Dielectric Strength up to 4,000V DC against

ground

th <0.35 K/W

R

45pF

-55°C to +155°C

1.5 Nm

1.3 Nm. M4 screws (not included)

2.86W/°K (0.35°K/W)

Derating

Best results can be reached by using a

thermal transfer compound with a heat

conductivity of better than 1W/mK

Configurations

(per package)

PERFORMANCE DATA

Test Method ΔR

Moisture Resistance

Thermal shock

Terminal Strength

Vibration, High Frequency

Requirements to be achieved under the following conditions: T

MIL-Std-202, Method 106 (0.5% + 0.001W) max

Mil-Std-202, Method 107, Cond F (0.3% + 0.01W) max

MIL-Std-202, Method 211, Cond A (pull test) 2.4N (0.2% = 0.01W) max

MIL-Std-202, Method 204, Cond D (0.2% + 0.01W) max

20 years (120,000 hours) Operating failure rate of 8.3 x 10-7 fail/hour.

Life

amb=25°C, THS=70°C, Papplied=Pn

(continued)

Page 2

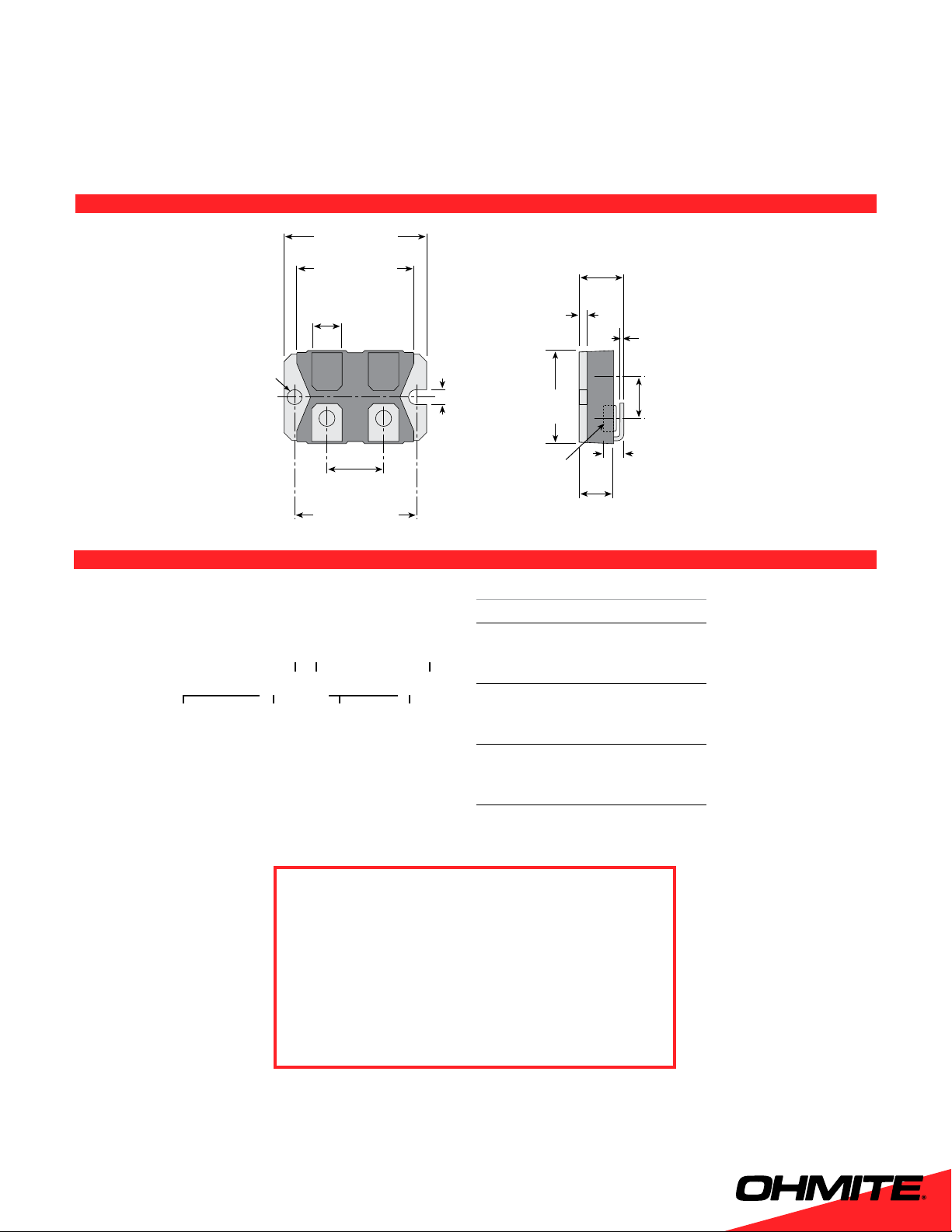

1.24" ±.02

(31.5mm ±.5)

0.315" ±.008

(8mm ±.2)

0.031" ±.002

(0.8mm ±.05)

0.472" ±.008

(12mm ±.2)

0.354" ±.004

(9mm ±.1)

0.165" ±.004

(4.2mm ±.1)

0.157" min.

(4.0mm)

diam.

0.209" min.

(5.3mm)

0.98" ±.2

(24.9mm ±.5)

0.078" ±.002

(2mm ±.05)

1.496"±.012

(38mm ±.3)

1.189" ±.004

(30.2mm ±.1)

4

3

1 2

M4

0.59" ±.008

(15mm ±0.2)

0.5" ±.02

(12.7mm ±.5)

TGH Series

TGHLVA 25R0JE

SOT 227 Series

Special Option

A = 1KV

Resistance Value

Example:

R500 = 0.500Ω

1R00 =1Ω

250R = 250Ω

1K00 = 1,000Ω

10K0=10,000Ω

Wattage

H=120W

L=200W

E = RoHS

compliant

Tolerance

J= 5%

Configuration

V = config. 1

X = config. 2

Y = config. 3

120 and 200 Watt SOT227 Package

Thick Film Power

DIMENSIONS

(iin./mm)

ORDERING INFORMATION

Standard Part Numbers

Ohms 120 Watt TGHH 200 Watt TGHL

0.1 TGHHVR100JE TGHLVR100JE

0.5 TGHLVR500JE

1 TGHHV1R00JE TGHLV1R00JE

5 TGHHV5R00JE

10 TGHHV10R0JE TGHLV10R0JE

25 TGHLV25R0JE

33 TGHHV33R0JE TGHLV33R0JE

50 TGHHV50R0JE

100 TGHHV100RJE TGHLV100RJE

150 TGHHV150RJE TGHLV150RJE

500 TGHHV500RJE TGHLV500RJE

680 TGHHV680RJE TGHLV680RJE

1K TGHHV1K00JE TGHLV1K00JE

5K TGHHV5K00JE TGHLV5K00JE

10K TGHHV10K0JE TGHLV10K0JE

THIS PRODUCT IS DESIGNED FOR

USE WITH PROPER HEATSINKING.

Maximum base plate temperature of the resistor must

be monitored and kept within specified limits to establish the power rating. Best technique is to attach a

thermocouple to the side of the base plate of the resistor. Temperature of plastic housing or heat sink cannot

be used to establish rating of the resistor.

155

Loading...

Loading...