Page 1

TDH Series

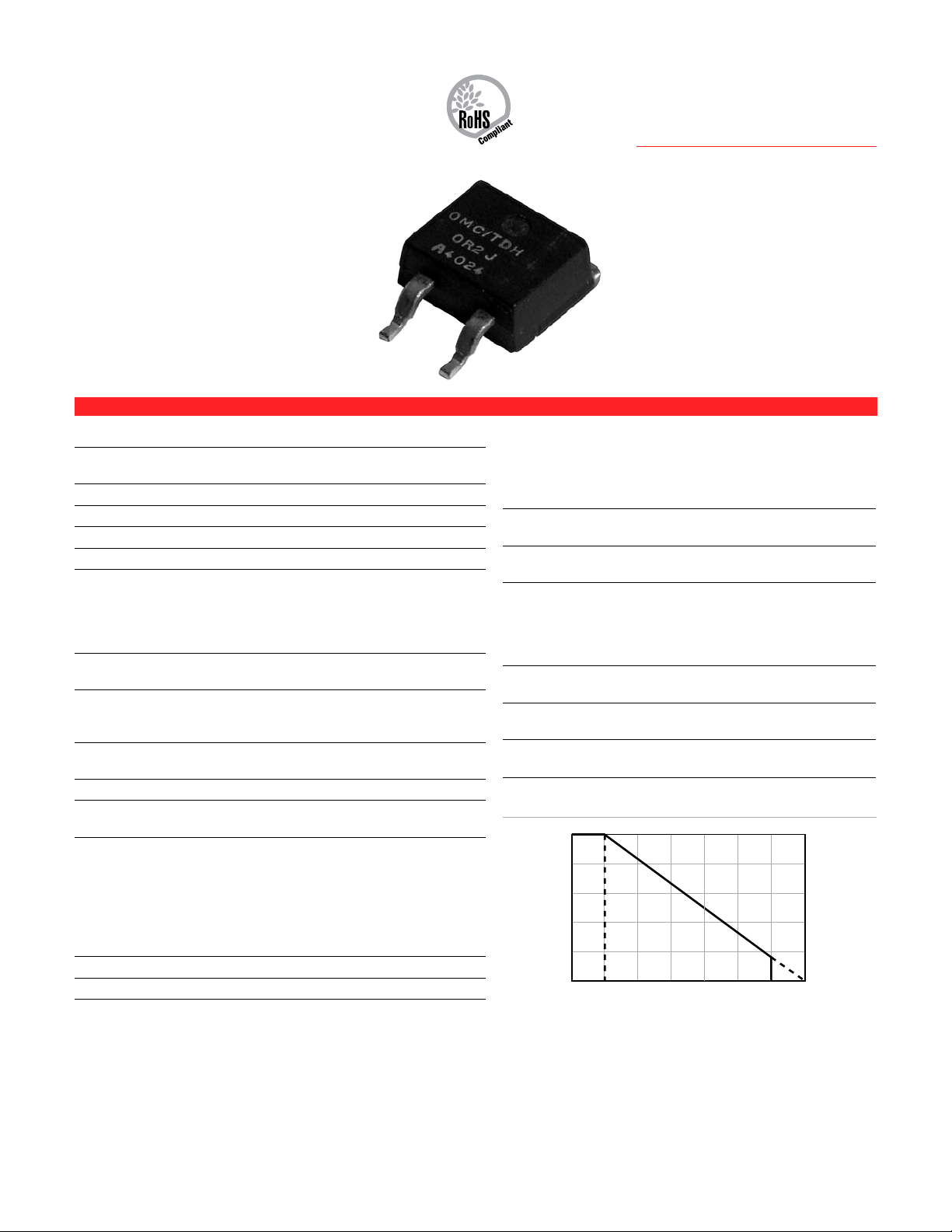

100

Percent Rated Power

Bottom of base plate Temperature, °C

60

20

0

050 10025 75 125

80

40

150 175

35

21

7

0

28

14

Rated Power, W

35 Watt D2PAK Package

Thick Film Power Surface Mount

Ohmite’s TDH resistor is an economical solution to intermediate power

application design requirements.

TDH’s reliable thick film on alumina

substrate construction can be easily

heat sinked for higher power performance. TDH resistors are ideal for

pulse-loading, pre-charge, bleeder,

and snubber applications.

CHARACTERISTICS

Terminal

Terminal Plating

Resistance Range

Tolerance

Max. Operating Voltage

Insulation Resistance

Power Rating

Working Temperature

Range

Solder Process

Derating

Dielectric Strength

Operating Temperature

Range

Temperature Coefficient

Inductance

Flatness

Copper

Terminals- SnAg,

Thermal Header- German Silver/Nickel Silver

0.05Ω to 10KΩ other values on request

±1% to ±10% (0.5% on request)

350V

10GΩ min.

Depends upon case temperature. See derating curve.

D2PAK style power package for surface

mounting applications; 35W power rating at

25°C case temperature.

-55°C to +175°C

The TDH35P cannot exceed 215°C (260°C

for the TDH35H) for more than 10 seconds

during soldering process.

100% @ 25°C to 0% @ 150°C curve referenced to case temperature

1,800VAC

-55°C to +150°C

Referenced to 25°C, ∆R taken at +105°C

10Ω and above: ±50 ppm°C

For under 10Ω:

3R to 9R9: 100ppm

1R to 2R9: 300ppm

0R1 to 0R99: 700ppm

0R05 to 0R09: 1000ppm

less than 20 nanohenries

less than 0.1mm tolerance

FEATURES

• 35Wattpowerratingat25°C

• SMD-D2PAKpackagecon-

figuration

• Heatresistancetocooling

plate:Rth<4.28°C/W

• Amoldedcaseforenviron-

mental protection.

• Resistorelementiselectrically

insulated from the metal sink

tab.

Soldering note: During surface mount soldering the soldering

temperature profile must not cause the metal tab of this device to

exceed 220°C (260°C for the TDH35H)!

Test Condition Result

Load Life

Moisture

Resistance

Short Time

Overload

Thermal Shock

Terminal

Strength

Vibration, High

Frequency

Derating

MIL–R–39009, 2,000 hours ∆R ±(1.0%

+0.01Ω)

MIL–Std–202, Method 106 ∆R =(0.5%

+0.01Ω) max.

2 times rated power with

applied voltage not to exceed

1.5 times maximum continuous operating voltage for 5

seconds

MIL–Std–202, Method 107,

Cond. F

MIL–Std–202, Method 211,

Cond. A (Pull Test) 2.4N

MIL-Std-202, Method 204,

Cond. D

∆R ±(0.3%

+0.01Ω) max.

∆R =(0.3%

+0.01Ω) max.

∆R =(0.2%

+0.01Ω) max.

ΔR =(0.2%

+0.01Ω) max.

38

Derating(thermalresistance):0.23W/°C(4.28°C/W).The

case temperature is to be used for purposes of establishing

the applied power limit. The case temperature measurement

must be made with a thermocouple contacting the center of

the component mounted on the designed heat sink. Thermal

grease should be applied propperly.

(continued)

Page 2

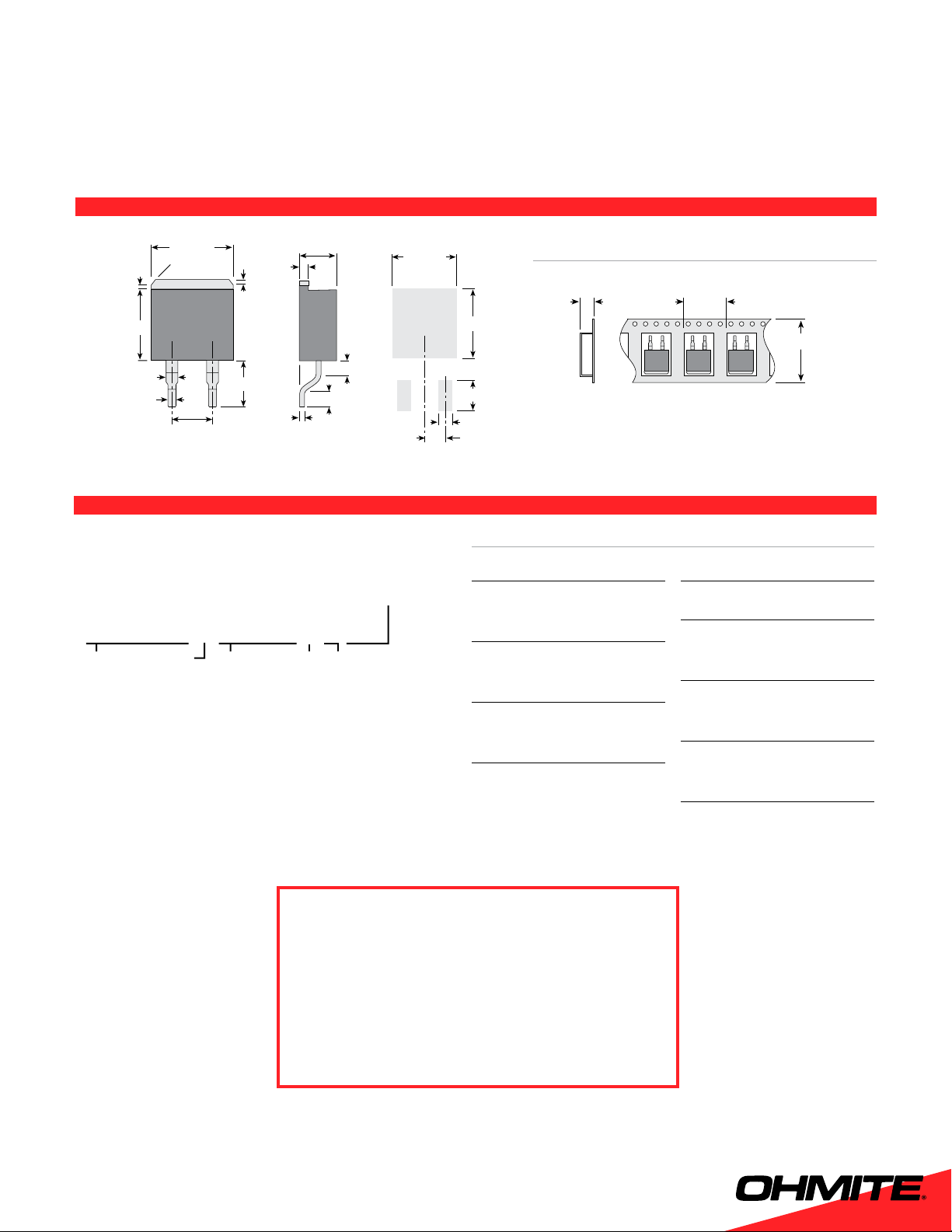

TDH35PR100JE-TR

Style Ohms

R = Decimal

Example:

R100 = 0.10

1R00= 1.0

10K0= 10,000

Tolerance

F = 1%

J = 5%

K = 10%

RoHS Compliant

Non-compliant

version unavailable

Tape and reel

(optional)

750 per reel

Package

Modifier

P = low temp.

H = high temp.

10.1mm

0.9mm

5.08m

Tol. ±0.2mm unless otherwise noted

m

1.1mm

±

0.5

45°

4.5mm

1.5mm

±

0.5

0.6mm

1.5mm

±

0.5

0.5mm

8.6mm

0.5mm

4.8mm

1.4mm

7.87mm

8.51mm

2.63mm

3.81mm

2.54mm

1.65mm

Land

Pattern

16mm4.95mm

24mm

TDH Series

35 Watt D2PAK Package

Thick Film Power Surface Mount

DIMENSIONS

ORDERING INFORMATION

Tape Dimensions

750pc./reel

Standard Part Numbers

Ohms 5% Tolerance

0.10 TDH35PR100JE

0.15 TDH35PR150JE

0.20 TDH35PR200JE

0.25 TDH35PR250JE

0.30 TDH35PR300JE

0.36 TDH35PR360JE

0.47 TDH35PR470JE

0.50 TDH35PR500JE

0.75 TDH35PR750JE

1.0 TDH35P1R00JE

2.0 TDH35P2R00JE

3.0 TDH35P3R00JE

5.0 TDH35P5R00JE

7.5 TDH35P7R50JE

10 TDH35P10R0JE

15 TDH35P15R0JE

20 TDH35P20R0JE

Part Number

Ohms 5% Tolerance

25 TDH35P25R0JE

33 TDH35P33R0JE

39 TDH35P39R0JE

47 TDH35P47R0JE

68 TDH35P68R0JE

75 TDH35P75R0JE

100 TDH35P100RJE

150 TDH35P150RJE

200 TDH35P200RJE

250 TDH35P250RJE

300 TDH35P300RJE

500 TDH35P500RJE

750 TDH35P750RJE

1000 TDH35P1K00JE

1500 TDH35P1K50JE

2500 TDH35P2K50JE

3000 TDH35P3K00JE

5000 TDH35P5K00JE

Part Number

THIS PRODUCT IS DESIGNED FOR

USE WITH PROPER HEATSINKING.

Maximumbaseplatetemperatureoftheresistormust

be monitored and kept within specified limits to establish the power rating. Best technique is to attach a

thermocouple to the side of the base plate of the resistor. Temperature of plastic housing or heat sink cannot

be used to establish rating of the resistor.

39

Loading...

Loading...