Page 1

TBH Series

25 Watt TO220 Package Thick Film Power

Ohmite’s TBH25 TO220 style

resistors are designed for a

variety of uses that require

intermediate heatsinkable

power at an economical price.

Engineered for industrial

applications, these resistors

deliver reliable performance

to traditional high-quality

Ohmite standards.

Resistor

Terminals

Derating

Dielectric Strength

Max. Mounting

Torque

Operating

Temperature Range

Temperature

Coefficient

Thermal Resistance

Tolerance

Power

Resistance Range

Max. Operating

Voltage

Thick film element above 1Ω, Ni-Cu metal element below 1Ω

High Temperature Plastic

Case

Solder coated phospher bronze

100% @ 25°C to 0% @ 150°C curve referenced to case temperature

1000 VDC

0.9Nm

-55°C to +150°C

0.1-10Ω @ ±200ppm

11Ω-10KΩ @ ±50ppm

5°C/W

5%

25 Watts. Rating based on 25°C case temperature. The case temperature is to be used

for the purposes of establishing the applied

power limit. The case temperature must be

made with thermocouple contacting the center of the component’s mounting tab mounted

on designated heat sink.

0.1Ω - 10KΩ. Standard values listed at left,

others available upon special request.

350V

FEATURES

• 25Watts,@25°Ccasetemperature

• Non-InductivePerformance

• LowThermalResistance

• Anti-statictubepackaging

available

• Economicallypriced

• Resistanceelementiselec-

trically insulated from metal

heat sink mounting tab

CHARACTERISTICS

Solderability

Thermal Shock

APPLICATIONS

• PowerSupplies

• IndustrialControls

• AutomotiveSteering

Test Condition Result

Load Life

Moisture

Resistance

Short Time

Overload

Terminal

Strength

Vibration

(1000hrs @ rated power) max. ∆R ±1%

(MIL-STD-202, method 106) max. ∆R ±0.5%

(2x rated power, not to exceed

1.5x max. operating voltage)

(MIL-STD-202, method 208)

(MIL-STD-202, method 107,

cond. F)

(MIL-STD-202, method 211,

cond. A (pull test) 2.4N)

(MIL-STD-202, method 204,

cond. D)

• Pre-load/Damping

• Snubber/Bleeder

• CurrentSensing

max. ∆R ±0.3%

max. ∆R ±0.3%

max. ∆R ±0.2%

max. ∆R ±0.2%

146

(continued)

Page 2

Series Tolerance

J = 5%, standard

Ohm Value

Example:

R100 = 0.1Ω

10R0 = 10Ω

1K50 = 1500Ω

TBH25P2R00JE

RoHS compliant

Non-RoHS version unavailable

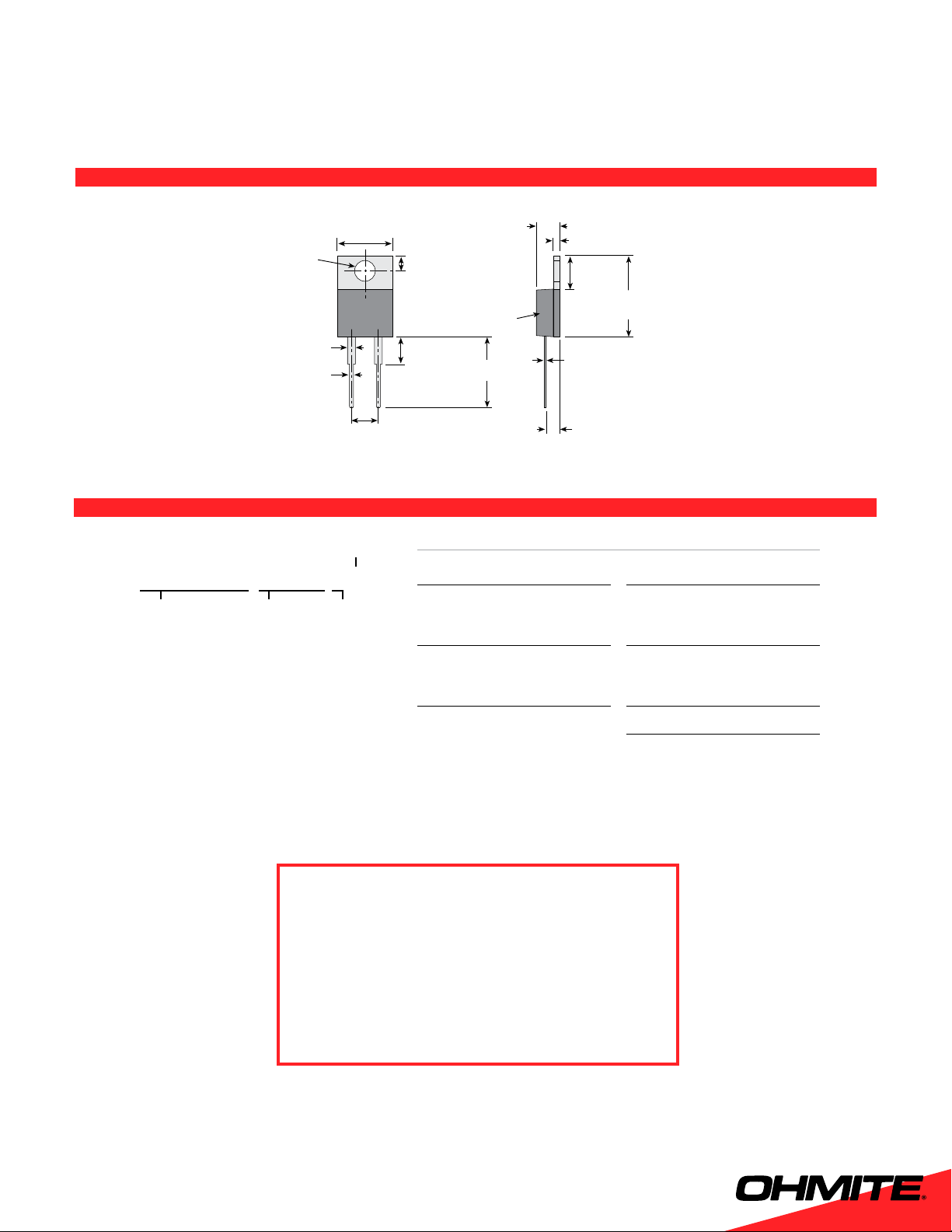

9.91 ~ 10.41mm

2.65 ~ 3.05mm

3.55 ~

3.95mm

1.17 ~

1.37mm

0.70 ~ 0.86

4.83 ~ 5.33mm

1.20 ~ 1.40mm

5.85 ~

6.35mm

4.06 ~ 4.82mm

14.50 ~

15.00mm

4.00mm max.

0.40 ~ 0.70mm

Molding

2.05 ~ 2.52mm

12.70 ~ 14.70

TBH Series

25 Watt TO220 Package Thick Film Power

DIMENSIONS

(mm)

Note: These dimensions apply to TBH products manufactured after June 10, 2016

ORDERING INFORMATION

Standard Part Numbers

Ohms 5% Tolerance

10 TBH25P10R0JE

15 TBH25P15R0JE

22 TBH25P22R0JE

30 TBH25P30R0JE

33 TBH25P33R0JE

47 TBH25P47R0JE

51 TBH25P51R0JE

75 TBH25P75R0JE

Part Number

2 TBH25P2R00JE

7.5 TBH25P7R50JE

Ohms 5% Tolerance

100 TBH25P100RJE

150 TBH25P150RJE

220 TBH25P220RJE

240 TBH25P240RJE

330 TBH25P330RJE

470 TBH25P470RJE

510 TBH25P510RJE

1000 TBH25P1K00JE

1500 TBH25P1K50JE

2000 TBH25P2K00JE

2700 TBH25P2K70JE

10,000 TBH25P10K0JE

Part Number

THIS PRODUCT IS DESIGNED FOR

USE WITH PROPER HEATSINKING.

Maximum base plate temperature of the resistor must

be monitored and kept within specified limits to establish the power rating. Best technique is to attach a

thermocouple to the side of the base plate of the resistor. Temperature of plastic housing or heat sink cannot

be used to establish rating of the resistor.

147

Loading...

Loading...