Page 1

TAP600 Series

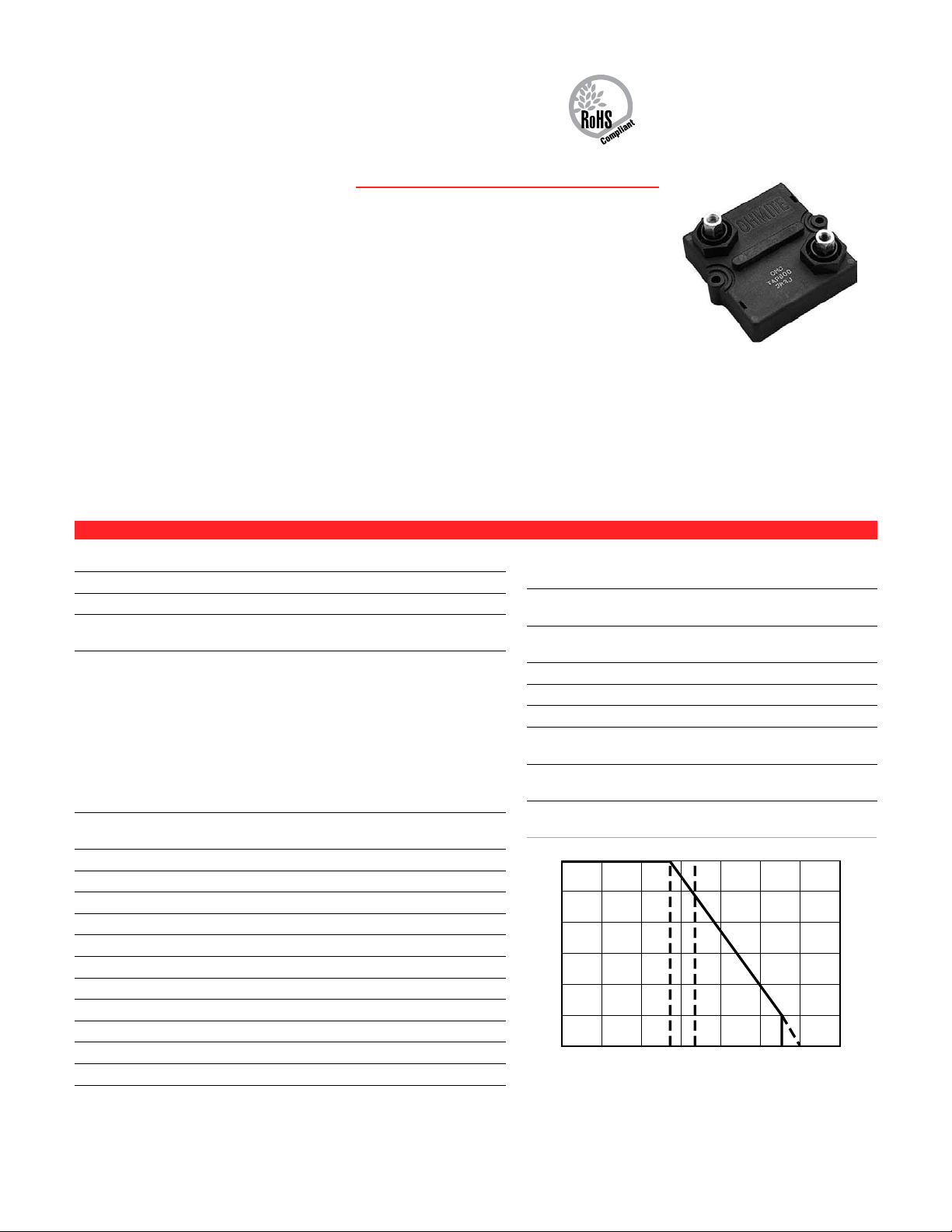

Percent rated power

Bottom of base plate Temperature, °C

0255075 100 125 150 175

40

0

60

80

120

20

100

Rated power, watts

240

0

360

480

720

120

600

600 Watt Heat Sinkable Planar

Ohmite’s TAP600 delivers 600

watts of reliable power to a

variety of power conditioning,

power transmission, and power

FEATURES

• Dielectric Strength up to 12KV

• Special Design for Low Inductance and

Capacitance Values

control applications. These resistors can be designed for liquid

or air cooled heat sink systems.

Applications include variable

speed drives, power supplies,

robotics, motor control, and other

control devices.

• Contacts allow for easy load connection with M5 screws (not included)

available with M4 as special request.

Thread depth 7mm

• Encapsulated with a special resin filled

epoxy casing with a large creepage

distance to mass, large air distance

between terminals, and a high insula-

tion resistance (CTI 600).

• Materials meet the requirements of

UL94-V0

CHARACTERISTICS

Resistance Values

Resistance Tolerance

Temperature Coefficient

Maximum Working Voltage

Power Rating

Dielectric Strength Voltage

Single Shot Voltage

Insulation Resistance

Creeping Distance

Air Distance

Inductance

Capacitance/Mass

Capacitance/Parallel

Operation Temperature

Max. Torque for Contacts

Max. Torque for Mounting

Derating (thermal resist.)

0.25Ω to 100KΩ

±10% Std., 5% available on request.

±150ppm/°C (others upon request)

5,000V DC, higher voltage on request, not

exceeding max. power

600W at 70°C heat sink temperature or

85°C bottom case temperature. This value

is only valid by using a thermal conduction

to the heat sink Rth -cs<0.025°C/W.

The value can be reached by using thermal

transfer compound with a heat conductivity

of 1w/mk. The flatness of the cooling plate

must be better than 0.05mm overall. The

roughness of the surface should not exceed

6.4µm.

7K Vrms, 50Hz, 1min standard; up to 12k

Vrms available

Up to 12KV Normwave (1.5/50 µsec)

10GΩ min. at 500V

42mm min.

14mm min.

≤80nH

≤110pF

≤40pF

-55°C to +150°C

2 Nm

1.8 Nm

8.33W/°C (0.12°C/W) element to case

Test Method

Short Time

Overload

Humidity Steady

Temp. Cycling

Shock

Vibrations

Load Life 1,000

Cycles

Terminal Strength

of Contacts

1000 W/10 Sec. @

70°C

56 Days/40°C/ 95°C 0.25%

State

-55/+125/5 Cycles 0.20%

40g/4,000 Times 0.25%

2 - 500Hz/10g 0.25%

Pn 30 min. ON/30

min. OFF

200N 0.05%

Derating

Typical

Results - ∆R

0.4%

0.40%

138

(continued)

Page 2

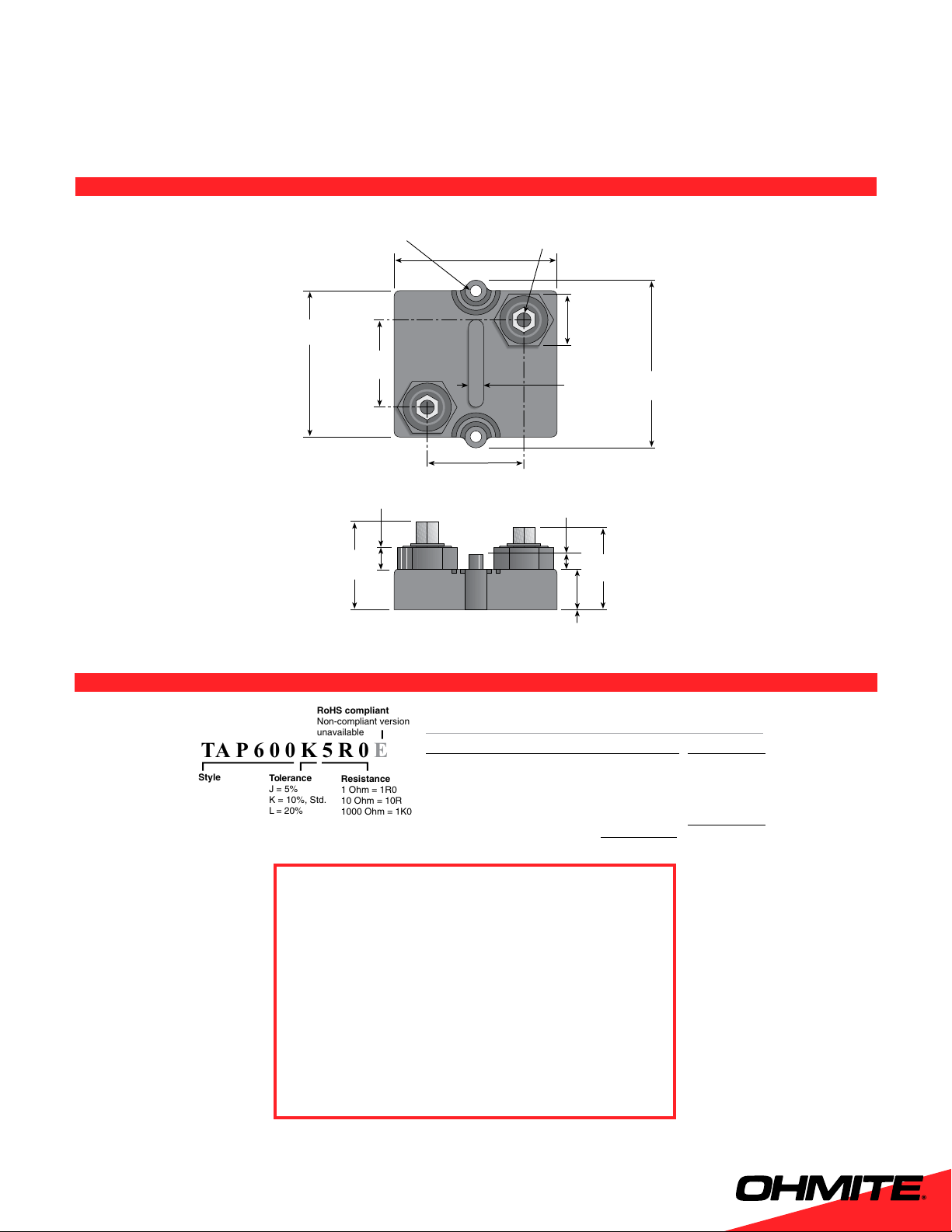

*Also C to C

dimension for

mounting holes

LL

ø0.159–0.169"

(4.05–4.3mm)

0.689–0.728"

(17.5–18.5mm)

2.56" ±0.031

(65mm ±0.8)

1.331–1.346"

(33.8–34.2mm)

*2.244" ±0.02

(57mm ±0.5)

1.409–1.425"

(35.8–36.2mm)

2.36" ±0.031

(60mm ±0.8)

øM5

occ. Din

0.177–0.216"

(4.5–5.5mm)

1.26" ±0.02

(32mm ±0.5)

*

*Dimensions are taken while part is

mounted to a proper heatsink

1.181" ±0.02

(30mm ±0.5)

*

0.571–610"

(14.5–15.5mm)

*

0.177–0.216"

(4.5–5.5mm)

0.295–0.335"

(7.5–8.5mm)

Tolerance

J = 5%

K = 10%, Std.

L = 20%

Style

Resistance

1 Ohm = 1R0

10 Ohm = 10R

1000 Ohm = 1K0

TA P 600K5R0 E

RoHS compliant

Non-compliant version

unavailable

TAP600 Series

600 Watt Heat Sinkable Planar

DIMENSIONS

(iin./mm)

ORDERING INFORMATION

Standard Values

10% tol.

0.10 1.0 15 500

TAP600KR25E

TAP600KR33E

TAP600KR50E

THIS PRODUCT IS DESIGNED FOR

TAP600K100E

TAP600K10KE

TAP600K10RE

TAP600K1K0E

TAP600K1R0E

TAP600K4R0E

TAP600K40RE

TAP600K20RE

TAP600K200E

TAP600K22RE

TAP600K2R0E

TAP600K3R0E

TAP600K50RE

USE WITH PROPER HEATSINKING.

Maximum base plate temperature of the resistor must

be monitored and kept within specified limits to establish the power rating. Best technique is to attach a

thermocouple to the side of the base plate of the resistor. Temperature of plastic housing or heat sink cannot

be used to establish rating of the resistor. The Ohmite

CP4 (https://www.ohmite.com/cp4-series-chillplate/) is

an example of properly designed heat sink.

TAP600K5R0E

TAP600K7K5E

TAP600K7R5E

TAP600K75RE

TAP600K750E

TAP600K30RE

TAP600K500E

139

5% tol.

TAP600J1R0E

TAP600J10RE

TAP600J50RE

TAP600J100E

TAP600J500E

TAP600J1K0E

Loading...

Loading...