Page 1

TA1K & TA2K

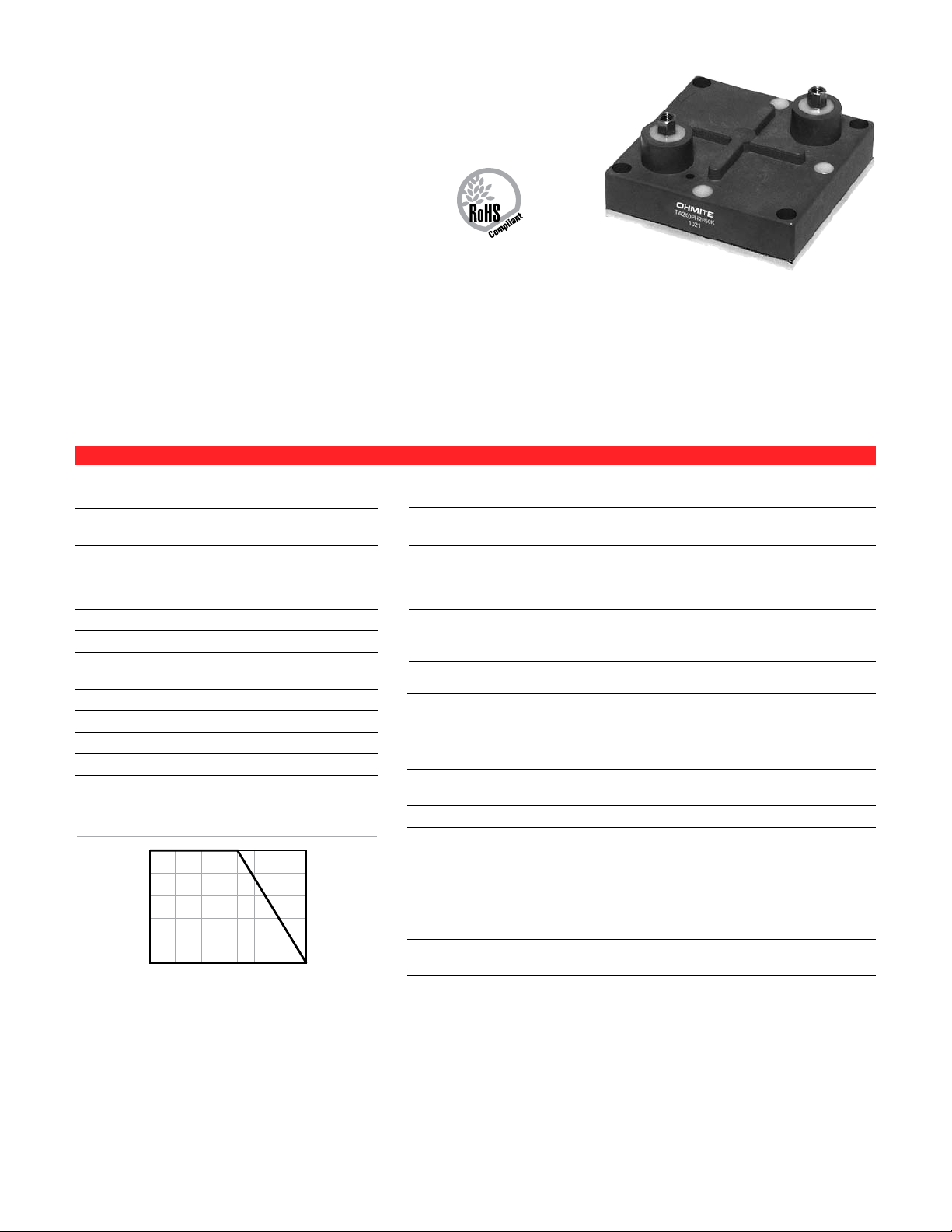

100

Percent Rated Watts

Bottom of base plate Temperature, °C

60

20

0

150

80

40

25 100 12505085

High Wattage Heat Sinkable Planar Resistor

The TAP series delivers

1000W or 2000W of continuous power when properly

mounted to a liquid cooled

heat sink (based on 85°C

mounting plate temperature)

Applications include

power conditioning, power

distribution, power conversion, and power control.

FeATures

• High Energy Rating

• Low Inductance

• Resistor Element Electrically Isolated

• High Dielectric Strength

• Small Footprint

chArAcTerisTics

ApplicATions

• Power semiconductor balancing

• Motor control

• Inrush Current Limiting

Resistor Element

Power Rating

Resistance Values

Resistance Tolerance

Max Operating Voltage

Temperature Coefficient

Dielectric Strength

Operating Temperature

Terminal Screws

Max Contacts Torque

Mounting Screws

Max Mounting Torque

Creepage Distance

Derating

Range

Thick Film on Alumina

Substrate

1000W or 2000W at

85°C mounting plate

0.5Ω to 1000Ω

+10% std.

2000VDC

± 250 PPM/°C

6KV standard

-55°C to 85°C

#10-32

10 in-lb

#8-32

15 in-lb

50mm ± 1mm (min)

Test Continuous Pulse

Rated Power, max. current and heat sink plate

temperature limited

Operating Voltage

Max. Applied Voltage, ohms law limited

Max. Current

Critical Resistance; below this resistance max

power has to be de-rated due to exceeding max

current

Test Method Maximum ∆R

Short Time

Overload

Moisture

Resistance

Thermal Shock

Vibration, elec.

Vibration, mech.

Load Life

Pulse Tolerance

Dielectric

Strength

1.14 x √P*R / 10 sec @ 70°C Max % ∆Rsto =

(TA1K0) 1000 hrs @ 40°C, 90-95% RH

(TA2K0) 1750 hrs @ 40°C, 90-95% RH

MIL-STD-202, Method 107 MIL-STD-202,

MIL-STD-202, Method 201 ±2% Resistance

MIL-STD-202, Method 201 No Loose

(TA1K0) 1000 Hrs 90 min ON / 30 min OFF

(TA2K0) 1750 Hrs 90 min ON / 30 min OFF

52µF @ 2KV / 60 sec intervals, 104J,

20,000 Pulses

6KVDC for 1 minute ≤1%

(TA1K0) 1000W

(TA2K0) 2000W

√P*R N/A

223V 2000VDC

10A 53.33A

(TA1K0) 10Ω

(TA2K0) 20Ω

Rating

±(2% + 0.05Ω)

≤1%

≤1%

Method 107

Terminal Screws

≤1%

≤1%

≤1%

(continued)

Page 2

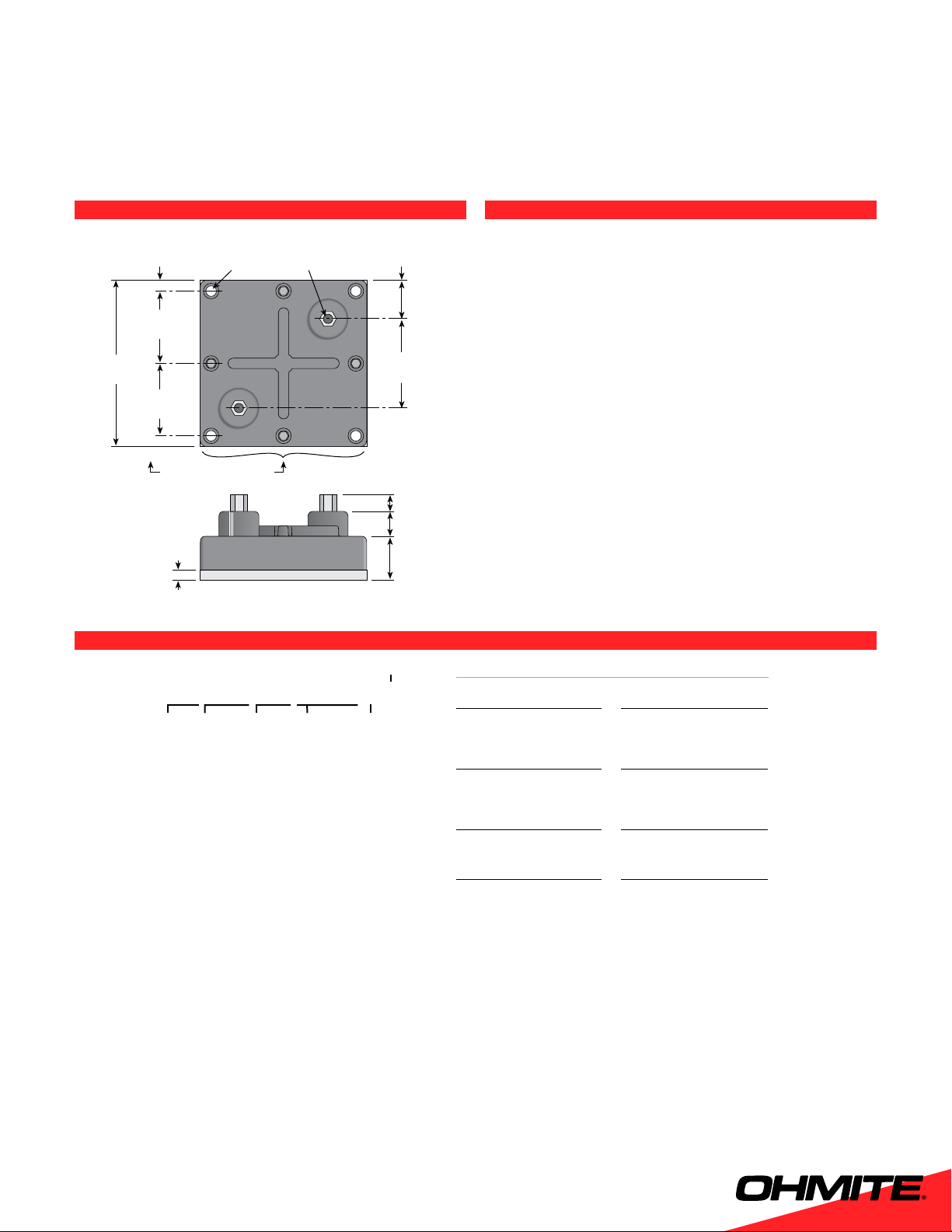

TA 1K0PH2R50KE

Style Package

Type

Resistance

2.5Ω = 2R50

50Ω = 50R0

Tolerance

K = 10% (standard)

L = 20%

Wattage

RoHS Compliant

0.798"

(20.26mm)

3.000"

(76.20mm)

ø10-32

1.308"

(33.21mm)

0.193"

(4.89mm)

1.622"

(41.20mm)

0.689"

(17.50mm)

ø0.172"

(4.37mm)

0.450"

(11.43mm)

0.300"

(7.62mm)

0.188"

(4.76mm)

1.308"

(33.21mm)

(same dimensions)

TA1K & TA2K

High Wattage Heat Sinkable Planar Resistor

(in./mm)

dimensions

ordering inFormATion

ApplicATion noTes

Proper heat sinking techniques are essential to performance of

a TAP resistor. Pleased follow these guidelines when designing

TAP system:

• Heats sink plate (base plate of the resistor) temperature

must be monitored to establish proper de-rating. Best technique is to attach a thermocouple to the side of the base

plate of the resistor. Temperature of plastic housing or heat

sink cannot be used to establish rating of the resistor. Usage

of laser thermometers should be avoided.

• To obtain a power rating of 1000W or 2000W, the bottom

case temp must not exceed 85°C. This can only be achieved

if the thermal conduction to the heatsink Rth-cs<0.025°K/W.

This value can be reached by using thermal transfer com-

pound with a heat conductivity of 1W/mK. The flatness of

the cooling plate must be better than 0.05mm overall. The

roughness of the surface should not exceed 6.4µm.

• Due to very high power density, only liquid cooled heat sinks

are recommended for applications when >300W power rating

is desired.

• Properly designed heat sink should have more than 2 cooling

pipes under the surface of the TAP resistor. The Ohmite CP4

heat sink (https://www.ohmite.com/cp4-series-chillplate/) is

an example of properly designed heat sink.

Standard Part Numbers

Ohms 10% Tolerance

1000 Watt

0.5 TA1K0PHR500KE

1 TA1K0PH1R00KE

2.5 TA1K0PH2R50KE

5 TA1K0PH5R00KE

7.5 TA1K0PH7R50KE

10 TA1K0PH10R0KE

15 TA1K0PH15R0KE

25 TA1K0PH25R0KE

50 TA1K0PH50R0KE

100 TA1K0PH100RKE

250 TA1K0PH250RKE

500 TA1K0PH500RKE

750 TA1K0PH750RKE

1000 TA1K0PH1K00KE

Ohms 10% Tolerance

2000 Watt

0.5 TA2K0PHR500KE

1 TA2K0PH1R00KE

2.5 TA2K0PH2R50KE

5 TA2K0PH5R00KE

7.5 TA2K0PH7R50KE

10 TA2K0PH10R0KE

15 TA2K0PH15R0KE

25 TA2K0PH25R0KE

50 TA2K0PH50R0KE

100 TA2K0PH100RKE

250 TA2K0PH250RKE

500 TA2K0PH500RKE

750 TA2K0PH750RKE

1000 TA2K0PH1K00KE

Loading...

Loading...