Page 1

Surface Mount

Flexible

J-bend

Standard

pedestal mount

Recessed-base

mount

Power

RC Series: carbon composition (1/4 & 1/2 watt)

RC Series: ceramic composition (above 1/2 watt)

RF Series: metal film

RW Series: wirewound

RP Series: power film

RM Series: high voltage thick film

FEATURES

• Tolerance 1%, 5%, 10%, depending on construction

• Twelve wattage ratings

• Seven package sizes

• Two mounting designs to accommodate your soldering process

• Five power resistor technologies to optimize your operating performance:

1. Carbon and Ceramic composition for surge and low inductance

2. Metal film for high ohmic value and low T.C.

• Flexible J-bend terminations

• Working Temperature Range: -55°C to +150°C

Part Number (watts)* voltage 1% tol. 5% tol. 10% tol. 0.1Ω–1Ω 1Ω–10Ω 10Ω+ Withstanding 13” reels per reel

RC0S2CA––––– 0.25 250 — — 2.2Ω–5.6M — ±400 ±400 1000V 16mm 1500

RC0R5DB––––– 0.50 350 — — 2.2Ω–20M — ±400 ±400 1000V 24mm 1000

RW0S6BB––––– 0.6 50 0.010Ω–1K 0.005Ω–1K ±90 ±50 ±20 1000V 12mm 2500

RF0S8BA––––– 0.8 200 1Ω–5M — — ±100 ±100 1000V 12mm 2000

RW1S0BA––––– 1.0 50 0.005Ω–1K 0.005Ω–1K ±90 ±50 ±20 1000V 12mm 2000

RF1S0CA––––– 1.0 350 10Ω–1M 1Ω–10M — ±200 ±100 1000V 16mm 1500

RC1R0EA––––– 1.0 500 3.3-100K (10% tol only) -1300 1000V 32mm 750

RP1S3CA––––– 1.25 350 — 1Ω–1M — ±250 ±250 1000V 16mm 1500

RW1S5CA––––– 1.5 75 0.005Ω–1.5K 0.005Ω–1.5K ±90 ±250 ±250 1000V 16mm 1500

RP1S5CB––––– 1.5 350 — 1Ω–1M — ±250 ±250 1000V 16mm 1000

RP1R5CB–––––

RW2S0CB––––– 2.0 100 0.005Ω–5K 0.005Ω–5K ±90 ±50 ±20 1000V 16mm 1000

RW2R0CB–––––

RP2S0DA––––– 2.0 500 — 1Ω–1M — ±250 ±250 1000V 24mm 1000

RP2R0DA–––––

RW2S0DA––––– 2.0 100 0.005Ω–5K 0.005Ω–5K ±90 ±50 ±20 1000V 24mm 1000

RW2R0DA–––––

RP2R5DB––––– 2.5 500 — 1Ω–1M — ±250 ±250 1000V 24mm 1000

RW3R0DB––––– 3.0 200 0.005Ω–13K 0.005Ω–13K ±90 ±50 ±20 1000V 24mm 1000

RP3R0EA––––– 3.0 750 — 1Ω–1M — ±250 ±250 1000V 32mm 750

RW3R5EA––––– 3.5 350 0.005Ω–25K 0.005Ω–25K ±90 ±50 ±20 1000V 32mm 750

RM0R7EA––––– 0.75 2500 1KΩ–1000M 1KΩ–1000M — — ±50 1000V 32mm 750

3. Wire element for inrush current combined with low ohmic values.

Resistance values as low as 0.005Ω

4. Power film for high ohmic value and high wattage

5. High Voltage thick film for high voltage applications

SERIES SPECIFICATIONS

Power Maximum Resistance range Temp. Coefficient Dielectric Tape Size Quantity

*25°C ambient. E24 values standard; contact Ohmite for custom values.

(continued)

Page 2

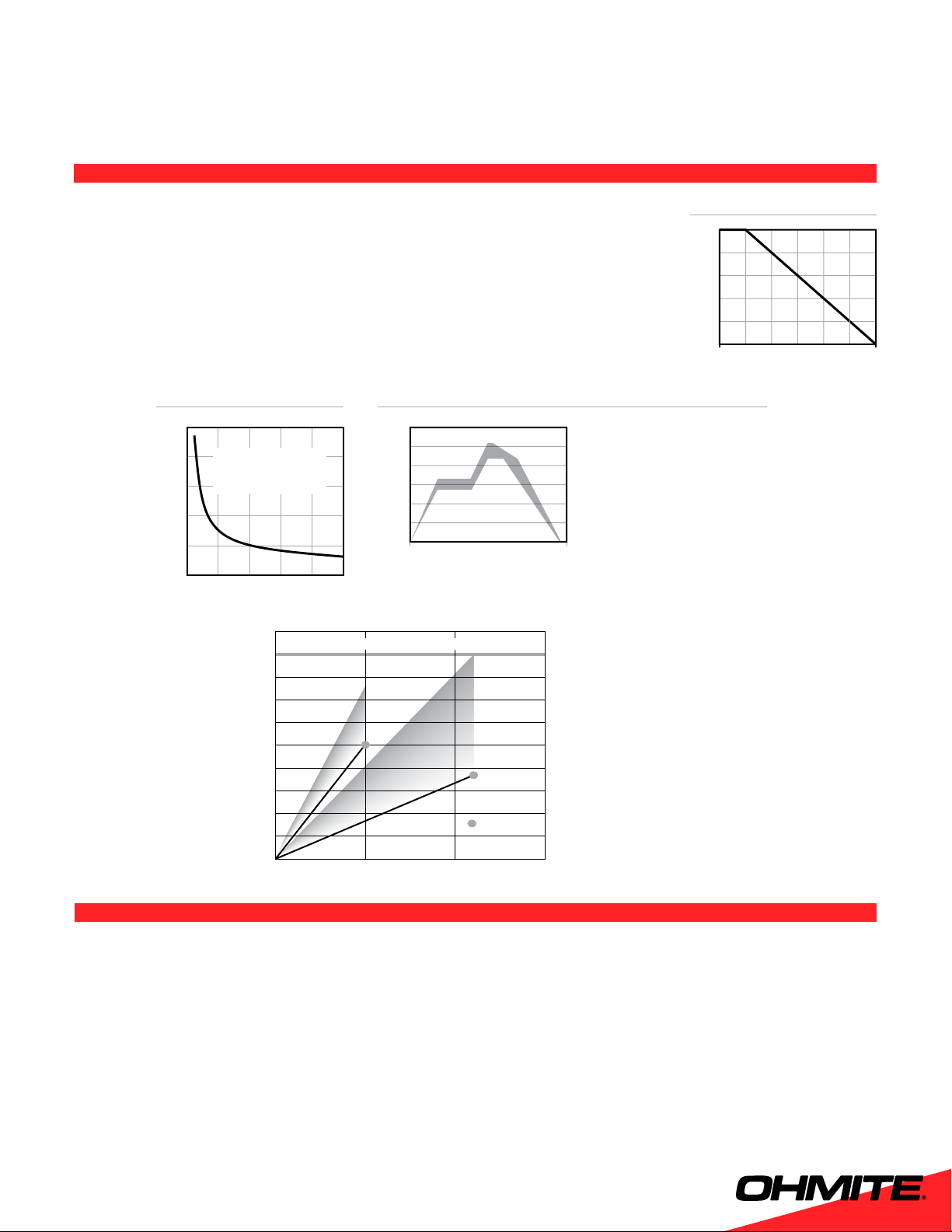

100% 200% 300%

200

180

160

140

120

100

80

60

40

20

Temperature rise, ϒC

Percent Rated power

Alumina

Solder joint

FR4

Package limit hot spot temperature rise

100

Percent Rated Power

Ambient Temperature, ϒC

60

20

0

80

40

25 50 100 150750 125

0.02

500

400

300

200

100

Ohms

0.04 0.06 0.08 0.10

Typical TCR for

less than 0.1Ω SMD

resistors (PPM/°C)

Surface Mount Power

300

Temperature °C

Time (sec.)

Preheating

120 sec.

Soldering

Cooling

200

50

500 100 150 250200

0

250

100

150

60 sec.

10 sec.

PERFORMANCE DATA

Temp. cycle Load Life Immersion

(-55°C to 125°C, (1000 hours (260°C for Momentary

Construction 1000 cycles) at 25°C) 10 sec.) Overload

RC Carbon/Ceramic Comp. ±4.0%+.05Ω ±10.0%+.05Ω ±3.0%+.05Ω 6.3x rated power for 5 sec.

RF Metal Film ±0.5%+.05Ω ±0.5%+.05Ω ±0.1%+.05Ω 2x rated power for 0.1 sec.

RW Wirewound ±0.5%+.05Ω ±3.0%+.05Ω ±0.1%+.05Ω 5x rated power for 5 sec.

RP Power Film ±3.0%+.05Ω ±5.0%+.05Ω ±0.5%+.05Ω 2x rated power for 0.1 sec.

RN Wirewound, Non-inductive ±0.5%+.05Ω ±3.0%+.05Ω ±0.1%+.05Ω 5x rated power for 5 sec.

ALL models: Leaching (260°C Solder immersion, 60 sec.)....................... No visible leaching

Thermal Shock (Units at -55°C, then rated power applied).. No mechanical damage

Flammability ......................................................................... UL Material rating, UL94V0

Derating

TCR

Recommended Solder Profile

Preheating: 145°C ±15°, max. 120 sec.

Soldering: min. 220°C, max. 60 sec.

Max. Temp.: 260°C ±5°, 10 sec.

(RC only: 250°C ±5°, 3 sec.)

The temperature rise graph

data was obtained by a

selection of test substrate

size and trace width for

each resistor size to limit

operating temperatures to

safe values.

The operating temperature

safe rises are either 100°C

substrate temperature rise

or 180°C package hot spot

temperature rise at 25°C

ambient.

FR4: 0.062 in. thick; 0.062

in. traces

Alumina: 0.040 in. thick;

0.010 in. traces

Molding material rated at

205°C continuous.

RC SERIES ONLY C. Cautions

A. Heat Treatment

110°C ±10°C

15 hours

RC SERIES: BAKE PROCEDURE

B. Frequency of

heat treatment

1 time only

Solderability: may be affected due to oxidization of lead wire

Resistance value: some units may not completely recover to origi-

nal value.

Soldering heat: some treated product may have substantial resis-

tance change during soldering operation. It is recommended that

parts be tested to evaluate soldering heat effects.

Page 3

Surface Mount Power

J

I

C

B

K

=0.006 Ref.

D

A

E

G

H

Note 1

F

=0.005 ±.001

Note 2

L

O

M

P

N

Recommended

for glue dot

application

A

0.795*

20.2

min.

0.512 ±.008

13.0 ±.200

C

B

1.973

50

min.

0.059*

1. 5

min.

Full

Radius

Tape Start Slot

Measured

at Hub

0.098 /

2.5

min. width

0.394 /

10

min. depth

DIMENSIONS

(in./mm)

Packages A B C D G I J L M N O P

BA (in.) 0.246±.020 0.136±.005 0.133 REF 0.110±.010 0.047 ±0.020 0.054±.012 0.136±.005 0.150 0.346 0.098 0.126 0.050

(mm) 6.248±.508 3.454±.127 3.378 REF 2.794±.254 1.194 ±0.508 1.372±.305 3.454±.127 3.81 8.79 2.49 3.20 1.27

CA (in.) 0.394±.020 0.159±.005 0.156 REF 0.220±.010 0.062 Nom. 0.064±.012 0.159±.005 0.256 0.524 0.134 0.126 0.060

(mm) 10.008±.508 4.039±.127 3.962 REF 5.588±.254 1.575 Nom. 1.626±.305 4.038±.127 6.50 13.31 3.40 3.20 1.52

CB (in.) 0.407±.020 0.226±.005 0.222 REF 0.260±.010 0.062 Nom. 0.084±.012 0.222±.005 0.276 0.537 0.131 0.126 0.093

(mm) 10.338±.508 5.74±.127 5.639 REF 6.604±.254 1.575 Nom. 2.134±.305 5.639±.127 7.01 13.64 3.33 3.20 2.36

DA (in.) 0.455±.020 0.240±.005 0.236 REF 0.260±.010 0.062 Nom. 0.115±.012 0.226±.005 0.317 0.585 0.134 0.155 0.093

(mm) 11.557±.508 6.096±.127 5.994 REF 6.604±.254 1.575 Nom. 2.921±.305 5.740±.127 8.05 14.86 3.40 3.94 2.36

DB (in.) 0.625±.020 0.273±.005 0.268 REF 0.417±.010 0.062 Nom. 0.115±.012 0.226±.005 0.474 0.742 0.134 0.155 0.093

(mm) 15.875±.508 6.934±.127 6.807 REF 10.592±.254 1.575 Nom. 2.921±.305 5.740±.127 12.040 18.85 3.40 3.94 2.36

EA (in.) 0.811±.020 0.273±.005 0.268 REF 0.572±.010 0.093 Nom. 0.115±.012 0.273±.005 0.611 1.000 0.195 0.155 0.093

(mm) 20.599±.508 6.934±.127 6.807 REF 14.529±.254 2.362 Nom. 2.921±.305 6.934±.127 15.52 25.4 4.95 3.94 2.36

BB (in.) 0.202±.010 0.10±.010 0.095 REF 0.079±.010 0.050 Nom. 0.065±.012 0.135±.005 0.078 0.328 0.125 0.126 0.026

(mm) 5.140±.508 2.54±.127 2.41 REF 2.00±.254 1.280 Nom. 1.640±.305 3.420±.127 1.98 8.33 3.18 3.20 0.66

Note 1: Packages BA and CA are only available with a pedestal base. Packages CB and DA are available in either pedestal or recessed base. Packages DB and EA

are only available in a recessed base.

Note 2: Test point is .020 above PCB.

Note 3: Tape and reel dimensions per EIA 481 A except “EA” size which is 12 mm component pitch versus 16mm pitch.

Package Outline Dimensions PC Board Land Pattern

Land pattern dimensions are for reference only

Reel Dimensions

Size A nom. B C max. Quantity

12mm 13” 0.488" +0.078, –0.00 0.724" 2000 pcs. BA or

16mm 13” 0.646" +0.078, –0.00 0.882" 1500 pcs. CA or

24mm 13” 0.961" +0.078, –0.00 1.196" 1000 pcs. DA or DB

32mm 13” 1.276" +0.078, –0.00 1.52" 750 pcs. EA

All reels are compatible with major pick-and-place machines

and made in accordance with EIA 481 A (except EA size,

which is 12mm component pitch versus 16mm pitch).

12.4mm +2.0, –0.0 18.4mm 2500 pcs. BB

16.4mm +2.0, –0.0 22.4mm 1000 pcs. CB

24.4mm +2.0, –0.0 30.4mm

32.4mm +2.0, –0.0 38.4mm

(continued)

Page 4

Component type

R = resistor

Component Modifier

C = carbon/ceramic

composition

F = film

P = power film

W = wire

N = wirewound, non-inductive

Wattage

Examples:

1S3 = 1.25W

2S0 or 2R0 = 2.0W

3R5 = 3.5W

Type of Base

S = standard

R = recessed

Package

B = 12mm

C = 16mm

D = 24mm

E = 32mm

Package Modifier

A, B sequential

Resistance Value

R = Decimal

K = 1,000

M = 1,000,000

Tolerance

F= 1%

G= 2%

H= 3%

J= 5%

K=10%

Examples:

R249 = 0.249 ohms

24R9 = 24.9 ohms

2K49 = 2,490 ohms

T = Tape

and Reel

(optional)

E = RoHS compliant

Available Jan. 2006

Surface Mount Power

ORDERING INFORMATION

(For example, the part

number shown is a wirewound resistor, 3.5 watt,

recessed base, 32mm tape

size, first case size [A],

1000 ohms 1% tolerance.)

Standard Part Numbers for Surface Mount Power Resistors

Wirewound

Package style

Base: standard

or recessed

Wattage

BA CA CB CB DA DA DB EA BB EA

S S S R S R R R S R

1.0 1.5 2.0 2.0 2.0 2.0 3.0 3.5 0.6 1.0

Part No.

Prefix

Suffix Tolerance suffix: F = 1% J = 5% K=10%

Ohmic value

RW1S0BA–––

RW1S5CA–––

RW2S0CB–––

RW2R0CB–––

RW2S0DA–––

RW2R0DA–––

RW3R0DB–––

RW3R5EA–––

0.005 –––R005– J J F/J

0.010 –––R010– F/J J J F J J J F

0.015 –––R015– F/J J F

0.020 –––R020– J J F J J F

0.025 –––R025– J

0.027 –––R027– J

0.030 –––R030– F J J J F

0.033 –––R033– J

0.036 –––R036– J

0.050 –––R050– F/J J J F J J F

0.056 –––R056– J

0.075 –––R075– J F

0.080 –––R080– J J

0.100 –––R100– F/J J J F J J J F

0.150 –––R150– J J J

0.200 –––R200– J J J

0.220 –––R220– J

0.240 –––R240– J J F

0.300 –––R300– J J

0.330 –––R330– J

0.400 –––R040– J

0.400 –––R400– J

0.470 –––R470– J J J F

0.500 –––R500– J J J J

0.750 –––R750– J F

1.00 –––1R00– F/J J J J J F

2.00 –––2R00– F

RW0S6BB–––

Wirewound

Package style

Base: standard

or recessed

Wattage

BA CA CB CB DA DA DB EA BB EA

S S S R S R R R S R

1.0 1.5 2.0 2.0 2.0 2.0 3.0 3.5 0.6 1.0

Part No.

RC1R0EA–––

Prefix

Suffix Tolerance suffix: F = 1% J = 5% K=10%

Ohmic value

RW1S0BA–––

RW1S5CA–––

RW2S0CB–––

RW2R0CB–––

RW2S0DA–––

RW2R0DA–––

3.30 –––3R30– K

4.70 –––4R70– K

5.00 –––5R00– F

5.60 –––5R60– J

6.80 –––6R80– K

7.50 –––7R50– J F

10.00 –––10R0– J J J F K

15.00 –––15R0– J J F K

20.00 –––20R0– J

22.00 –––22R0– F K

24.90 –––24R9– F

33.00 –––33R0– F K

36.00 –––36R0– F

47.00 –––47R0– J J F K

50.00 –––50R0– J

51.00 –––51R0– J

68.00 –––68R0– K

82.00 –––82R0– J

100.00 –––100R– J F K

120.00 –––120R– J

180.00 –––180R– J

300.00 –––300R– J

470.00 –––470R– J

1K –––1K00– J K

4.7K –––4K70– J

5K –––5K00– J

RW3R0DB–––

RW3R5EA–––

RW0S6BB–––

RC1R0EA–––

35

Loading...

Loading...