Page 1

MOX500 Series

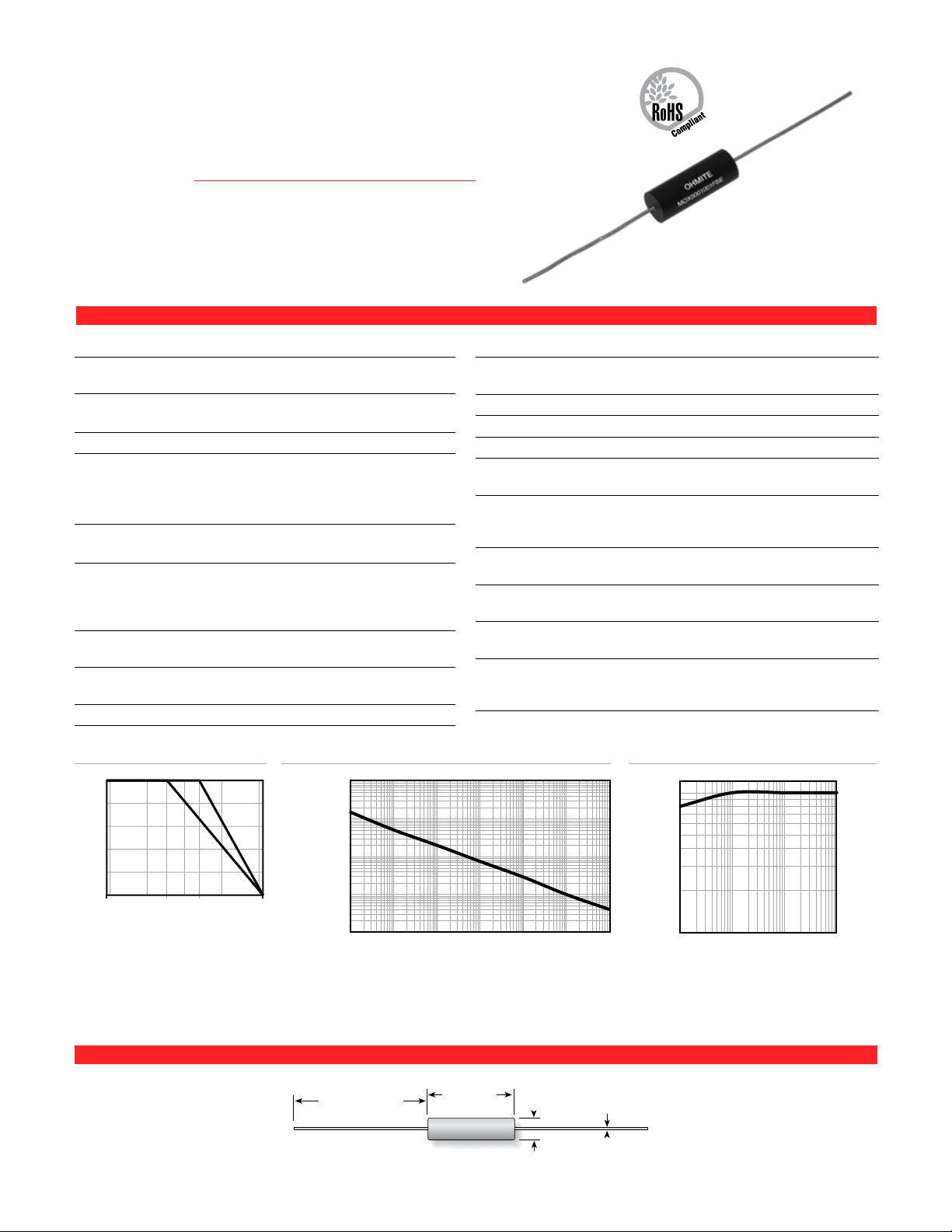

1.430" ±.075 /

36.3mm ±1.9

0.570" max. /

14.5mm

0.205" ±.010 /

5.2mm ±.3

0.032" ±.002 /

0.8mm ±.05

*Total resistor length

including leads approx. 70mm

for taped & reeled units

100

Percent Rated Power

Ambient Temperature,

2W

3W

°C

60

20

0

80

40

500 100 1557025-55

Power (watts)

Pulse duration

10

100,000

100

1,000

10,000

1µs 10µs 100µs 1ms 1s10ms 100ms

Peak Voltage (V)

Resistance (Ω)

500

5,000

1K 10K 100K 1M

Epoxy Molded, Metal Glaze-Metal Oxide Resistors

FEATURES

• MeetsMil-Std-202

• MeetsIEC61000-4-5upto2KV

• MoldedConstruction

• AvailableinE96values

CHARACTERISTICS

Resistor Type

Power Rating

Resistance Range

Tolerance

Temp. Coeff.

Resistance

Construction

Max. Working

Voltage

Diel. Width-

standing Volt.

Terminals

Oper. Temp.

Thick Film, Epoxy Molded

2W at 70°C

3W at 25°C

Metal Glaze:1.5KΩ to 5MΩ

Metal Oxide:15Ω to <1.5KΩ

1%, 2%, 5%

Metal Glaze: 100/200ppm

Metal Oxide: 350ppm

Not all tolerances and TCR values available

throughout entire resistance range

Metal glaze 100/200 ppm

Metal oxide 350 ppm

RCWV or 1000 V whichever lesser. (RCWV

= rated DC or RMS AC continuos working

voltage at commercial line frequency and

waveform (volt) )

1000 VRMS

Copper Wire, Solder Coated axial, RoHS

composition

-55º to +155ºC

Characteristic Test Method ΔR limits

Moisture

Resistance

Humidity

Shock

Vibration

Terminal

Strength

Short Term

Overload

Load Life

Temperature

Cycling

Resistance to

soldering heat

Immunity

MIL-STD-202, Method 106G ±0.20%

MIL-STD-202, Method 103, Condition B ±0.25%

MIL-STD-202, Method 213, Condition I ±0.10%

MIL-STD-202, Method 204, Condition D ±0.10%

MIL-STD-202, Method 211A, Condition

A or B

DC test potential 2.5 time the rated continuous working voltage but not exceeding twice the maximum voltage specified

1000 hrs at RCWV duty cycle 1.5hr ON,

0.5 hr OFF at 70ºC ±2ºC

-65º to +125ºC ±0.10%

Temp 350ºC ±10ºC for 3 ±0.5 sec ±1%

IEC61000-4-5, waveform 1.2/50μS, 10

Surge

Pulses applied. Does not include values

under 1KΩ.

Derating Single Impulse Test Surge Immunity Test

±0.10%

±0.5%

±2%

<±1%

in./mm

Change in resistance under 1%

DIMENSIONS

Resistors are tested in accordance with

IEC61000-4-5, waveform 1.2/50μS, 10 Pulses

applied. Limit of acceptance is a shift in resistance of less then 1% from the initial value. Graph

data shows values equal or greather than 1KΩ.

Page 2

MOX500 Series

MOX5001001FSETR

Resistor

Series

Tape & reel

TR = 1250 pcs

Tolerance

F = 1%

G = 2%

J = 5%

Ohms

First 3 digits are

significant; 4th

digit is multiplier

(# of zeros to follow).

examples:

10R0 = 10 ohms

1001 = 1000 ohms

1502 = 15000 ohms

TCR

S = 100ppm/°C

L = 200ppm/°C

K = 350ppm/°C

RoHS

compliant

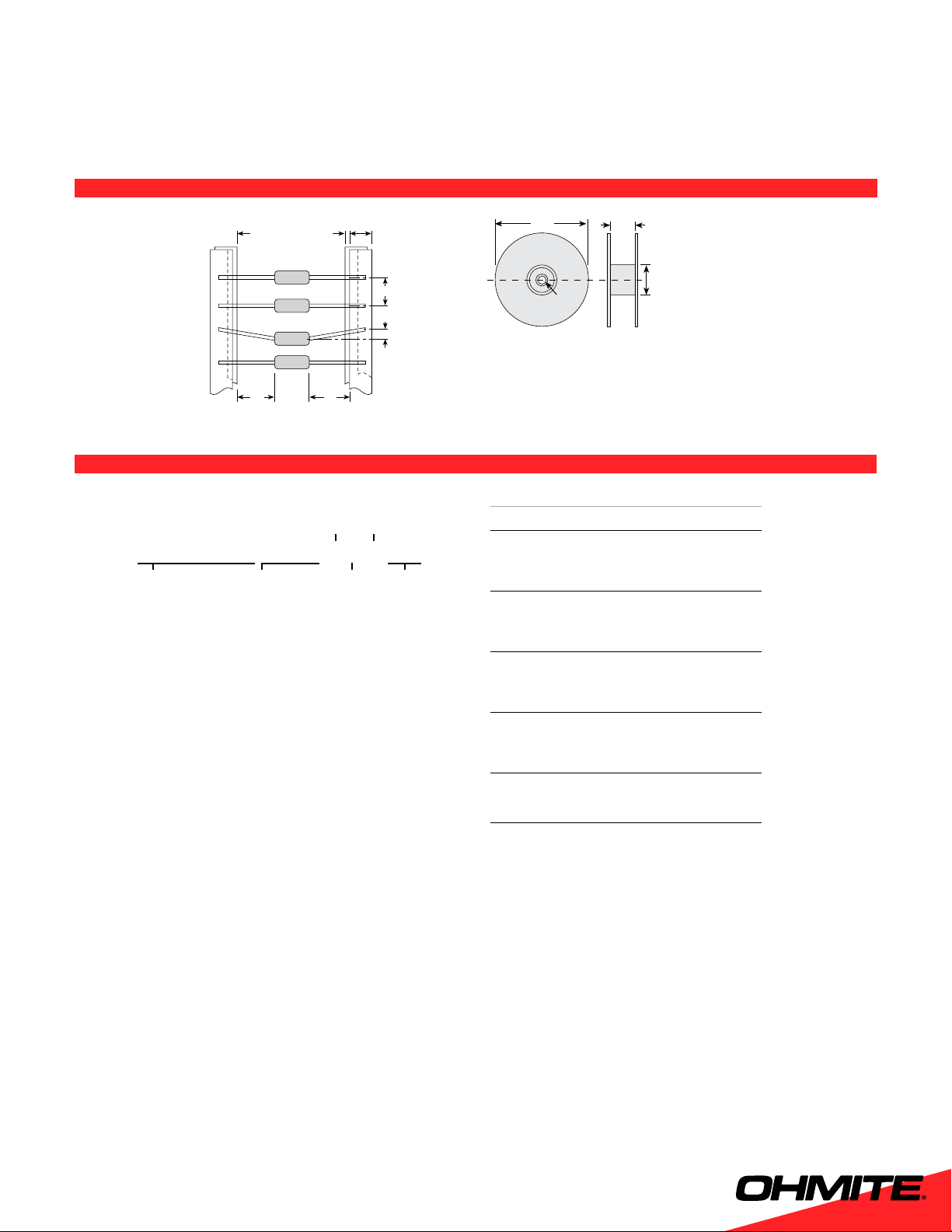

2.82" max.

14"

ø 1.13"

2.88"

6mm ±1

56.5mm ±1.5

L

1

L

2

L

1

– L

2

= 1.4mm max.

0.80mm

max.

10mm ±0.5

Epoxy Molded, Metal Glaze-Metal Oxide Resistors

TAPE & REEL

EIA-296standard

ORDERING INFORMATION

Standard part numbers for MOX500 Series

Resistance 2% tolerance 5% tolerance

100 MOX500100RJSE

150 MOX500150RJSE

270 MOX500270RJSE

1K MOX5001001JSE

1.5K MOX5001501JSE

2.7K MOX5002701GSE

3.3K MOX5003301JSE

4.3K MOX5004301JSE

6.8K MOX5006801JSE

7.5K MOX5007501GSE

10K MOX5001002JSE

15K MOX5001502JSE

18K MOX5001802JSE

20K MOX5002002GSE

27K MOX5002702GSE

33K MOX5003302JSE

47K MOX5004702GSE

66K MOX5006602JSE

100K MOX5001003GSE

150K MOX5001503GSE

220K MOX5002203GSE

270K MOX5002703GSE

330K MOX5003303GSE

1M MOX5001004GSE

7

Loading...

Loading...