Page 1

FC4T Series

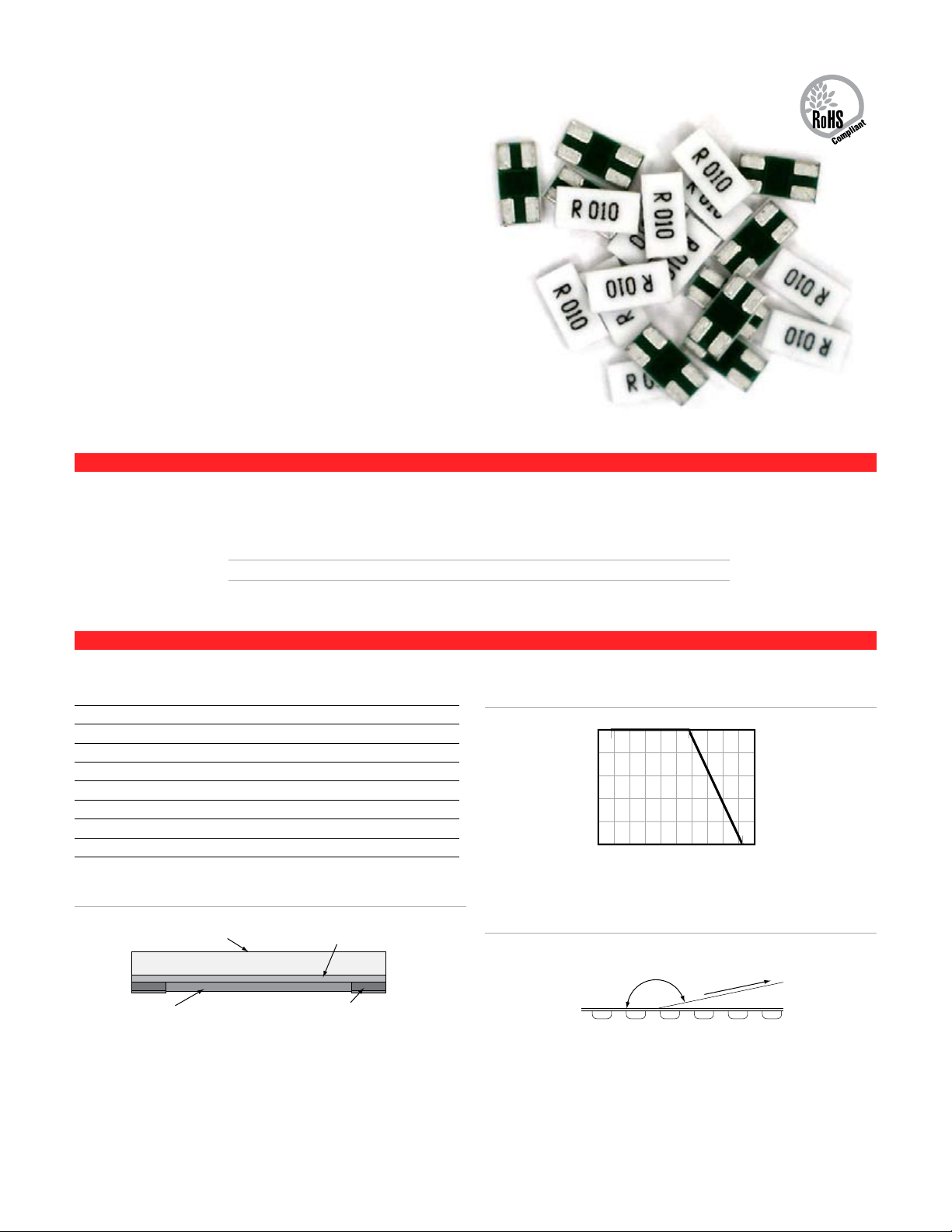

100

Percent Rated Power

Ambient Temperature, °C

60

20

0

80

40

0

-55°

70°

155°

150175°50-75 -50 100

Alumina Substrate

Electrode (Cu+Ni+Sn)Epoxy resin

protection coat

Epoxy resin marking

Cu-alloy resistor

165°~180°

F

Metal Foil Low Value Chip

The FC4T chip features four terminals, also known

as a “Kelvin” configuration. This configuration

enables current to be applied through two opposite

terminals and a sensing voltage to be measured

across the other two terminals, eliminating the resistance and temperature coefficient of the terminals

for a more accurate current measurement. Ohmite’s

proprietary Metal Foil technology offers an excellent

Temperature Coefficient of Resistance (TCR) even

for very low resistance values ( down to 50ppm).

SERIES SPECIFICATIONS

Power Resistance

Pkg. Rating Range TCR

Series Size (W @70°C) (Ω) (ppm/°C) Tolerance

FC4T 1206 0.5W 0.005-0.100 50ppm 0.5%, 1%

Construction

12

Resistance

Operating Temp. Range

Rated Power

Resistance Tolerance

Temperature Coefficient

Coating Material

Terminals

Max. Current

Res. of Electrodes

CHARACTERISTICS

0.005-0.100

-55°C to +155°C

0.5 watt

0.5% and 1% standard

within ±50ppm, ±100ppm for 5mΩ

Epoxy resin

Cu/Ni/Sn

√(Max. power÷ Resistance value)

<5mΩ

Derating

Peeling Strength of Seal Tape

F = Peel-back force: 0.1 - 0.7N (10 - 71gf)

(continued)

Page 2

FC4T Series

W

1

A

N

A

B

P

P

2

D

0

E

F

W

D

1

P

T

K

T

1

Direction

of feed

W

a

g

b

c

d

e

L

t

f

FC4TR010DER

Series

Tolerance

F= 1%

D=0.5%

Ohms

Tape & Reel

5000/reel

RoHS Compliant

V = sensing terminal

(voltage)

I = current terminal

VV

II

Metal Foil Low Value Chip

PERFORMANCE CHARACTERISTICS

Test Items Performance Test Methods

Short time overload

High Temp. Exposure

Low Temp. Storage

Moisture Load Life

Thermal Shock

Load Life at 70ºC

Solderability

Resistance to Solder Heat

Mechanical Shock

Substrate Bending

(mm ±0.2)

±(1.0%+0.5mΩ) P= 2.5Pr; T=25 ±2ºC, t=5sec.; IEC60115-1 4.13

±(1.0%+0.5mΩ) T=+170 ±2ºC; t=1000h; IEC60115-1 4.25

±(1.0%+0.5mΩ) T=-55 ±2ºC; t=1000h; IEC60115-1 4.25

±(2.0%+0.5mΩ) Vtest=Vmax; T=60 ±2ºC; RH=95%; t= 90min ON, 30min OFF, 1000h; IEC60115-1 4.25

(60℃, 95%RH)

±(1.0%+0.5mΩ) -55ºC 30min. / R.T. 3min. / +150ºC 30min. / R.T. 3min ], 100cycles; IEC60115-1 4.19

±(2%+0.5mΩ) Vtest=Vmax; T=70 ±2ºC; t=90min ON; IEC60115-1 4.25

The covered area >95% Dip into solder at T=245 ±5ºC, t=3 ±0.5sec.; IEC60115-1 4.17

±(1.0%+0.5mΩ) Through Reflow T=275 ±5ºC, t=20 ±1sec.; IEC60115-1 4.18

±(1.0%+0.5mΩ) a=100G, t=11ms, 5 times shock; IEC60115-1 4.21

±(1.0%+0.5mΩ) Span between fulcrums 90mm; bend width 2mm; test board glass-epoxy;

Thickness=1.6mm; IEC60115-1 4.33

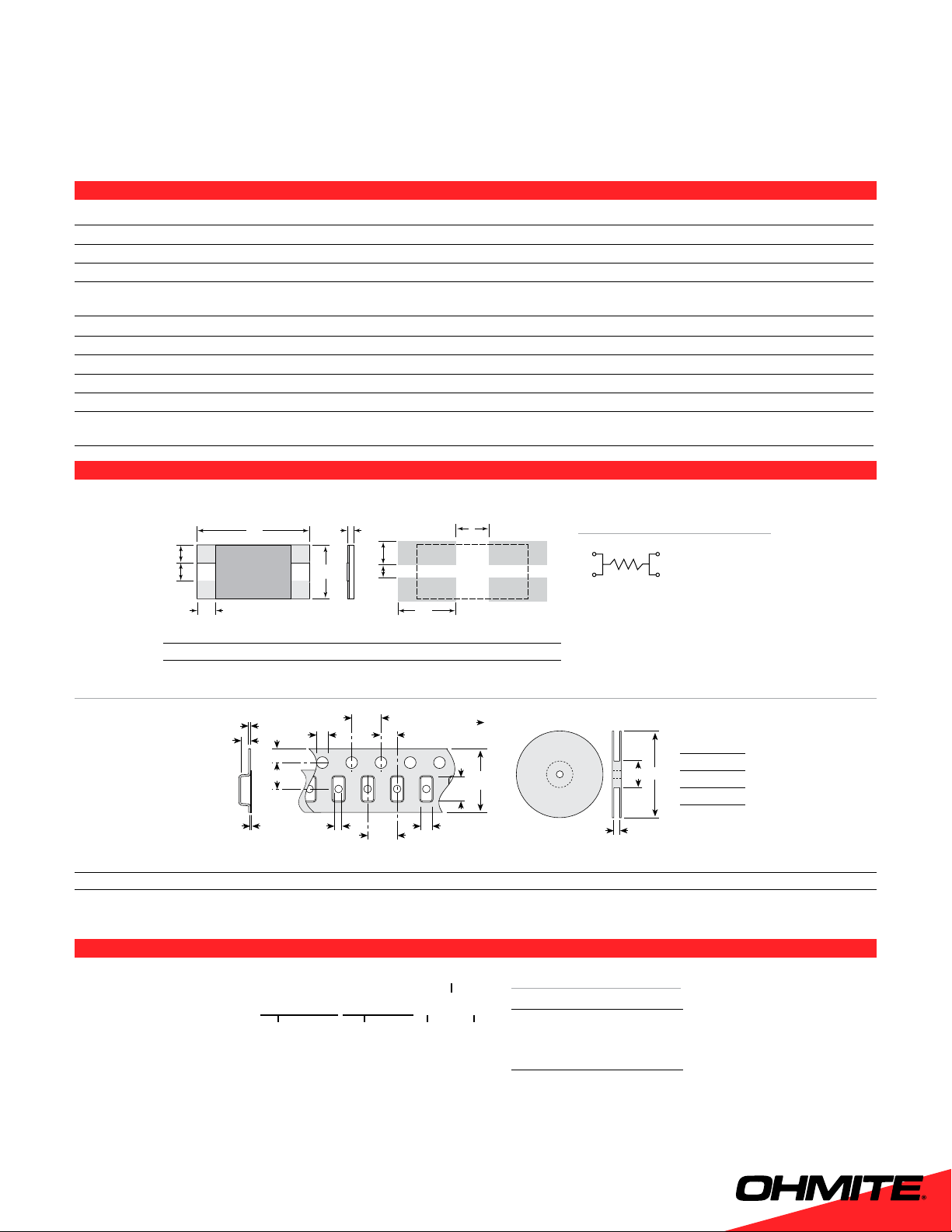

DIMENSIONS

Schematic

Layout for

illustration only,

part can be

rotated 180°

without effect to

the circuit.

Part L W a b c t d e f g

FC4T 3.2 1.6 0.6 0.55 0.3 0.6 1.10 0.30 1.2 1.8

Tape and Reel

A 178 ±5

N 60 ±2

W1 9 ±1

Part W P P2 A B D0 F E T T1 K

FC4T 8.00 ±0.30 4.00 ±0.10 2.00 ±0.10 2.05 ±0.20 3.65 ±0.20 1.50 ±0.10 3.50 ±0.10 1.75 ±0.10 0.20 ±0.10 Max. 0.1 0.85 ±0.20

ORDERING INFORMATION

Standard Part Numbers

1%

FC4TR005FER

FC4TR010FER

FC4TR015FER

FC4TR050FER

FC4TR100FER

0.5%

FC4TR010DER

FC4TR015DER

FC4TR050DER

FC4TR100DER

rev 1/18-3

13

Loading...

Loading...