Page 1

EBW Series

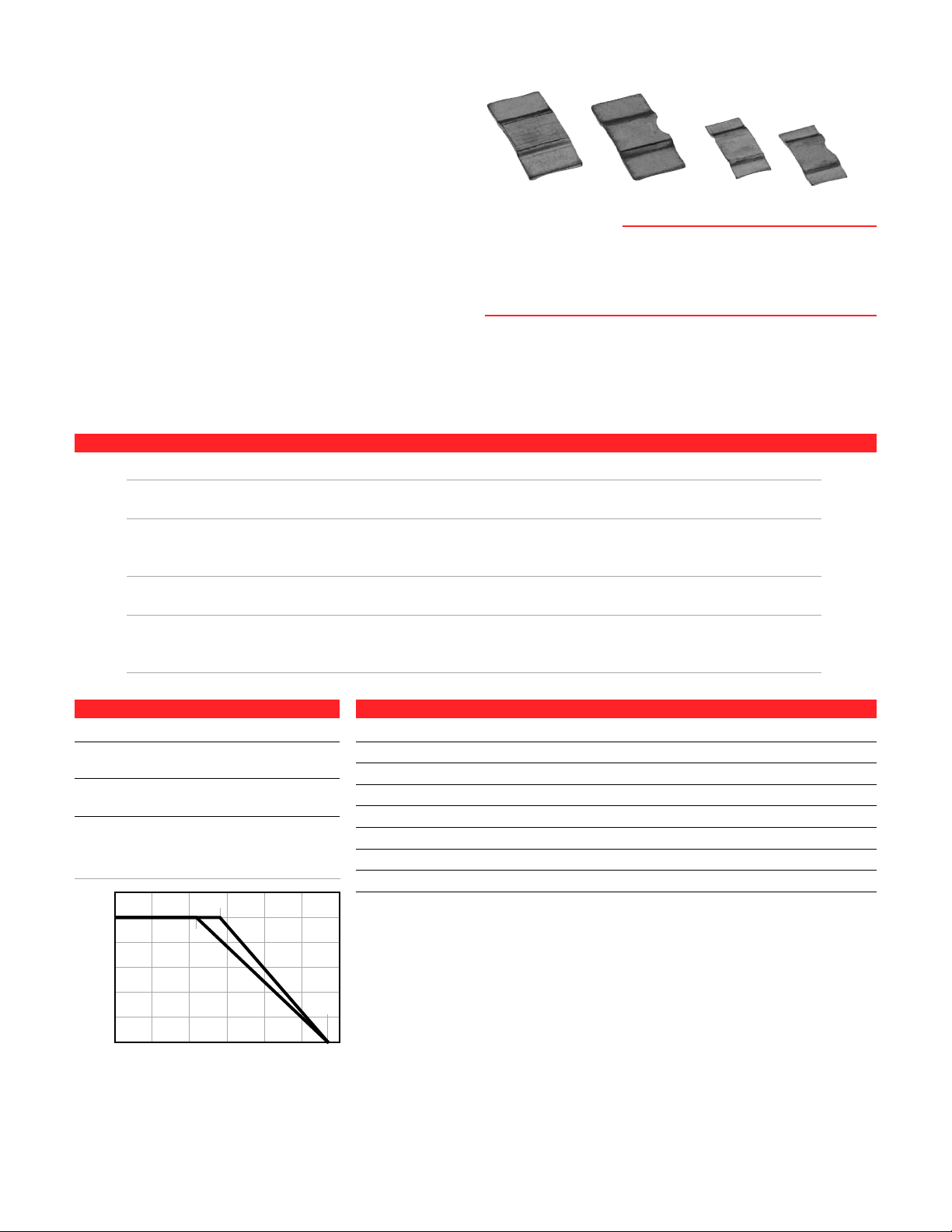

% Rated Power

Resistor Surface Temp., oC

180

170°

(EBWB) 65°

85° (EBWA)

0 6030 90 120 150

40

0

60

80

20

100

Manganin/Aluchrom Alloy Current Sense

The EBW Series are manufactured using electron

beam welding technology. This allows the joining of

different alloys with great accuracy and tolerance.

The EBW Series have heavy copper connectors,

excellent long term stability and low inductance.

These components can tolerate soldering temperatures of 350C for 30 seconds or 250C for 10min.

These can be mounted using re-flow soldering or

welding on copper. The EBWA can handle a power

of 5W up to 100A at 0.5mΩ. The EBWB can handle

a constant power of 7W at 0.2mΩ and a continuous

load of 180A at 0.2mΩ.

SERIES SPECIFICATIONS

Model Power (W) Resistance (mΩ) Material TCR (20°C - 60°C) Weight (g)

EBWA-M 5 0.5 Manganin ±70ppm/°C 0.4081

4 1 Manganin ±50ppm/°C 0.1994

EBWA-N 4 2 Aluchrom Alloy ±50ppm/°C 0.2726

3 3 Aluchrom Alloy ±50ppm/°C 0.1832

2.5 4 Aluchrom Alloy ±50ppm/°C 0.1363

EBWB-M 7 0.2 Manganin ±100ppm/°C 1.5138

6 0.5 Manganin ±75ppm/°C 0.5652

EBWB-N 6 1 Aluchrom Alloy ±50ppm/°C 0.8573

4 2 Aluchrom Alloy ±50ppm/°C 0.4287

3.5 3 Aluchrom Alloy ±50ppm/°C 0.2858

CERTIFICATIONS

BN ES ISO 9001: 2008

ISO/TS 16949: 2009

APPLICATIONS

• Currentsensorsforhybridpowersources

• Frequencyconverters

• Highcurrentautomotiveapplications.

CHARACTERISTICS

Tolerance

TCR

Operating

Temperature

Derating

±1%(F), ±5%(J)

20°C-60°C

Max. ±200ppm/°C

-55°C to 170°C

PERFORMANCE DATA

Thermal Shock

Short Time Overload

Resistance to Soldering Heat

Moisture Resistance

High Temperature Exposure

Vibration High Frequency

Inductance

Load Life

-65°C, 25°C, 125°C, 25°C 25cycles

Rated Power X 5 for 5 secs. ±0.2%

350°C 30 sec. or 250°C 10 min. ±0.2%

90~98%RH,+25°C,+65°C,-10°C 10 cycles ±0.2%

140°C for 250 hours ±0.2%

15g 10 to 2000Hz 36 cycles ±0.2%

90 min “ON” 30 min “OFF” for 2000 hours ±1.0%

±0.1%

<3nH

Page 2

EBW Series

0.220"

5.6mm

0.630"

16mm

0.344" / 8.75mm

(0.244" / 6.2mm)

L

A

W

T max.

trimming area

electron

beam

welding

0.020"

0.5mm

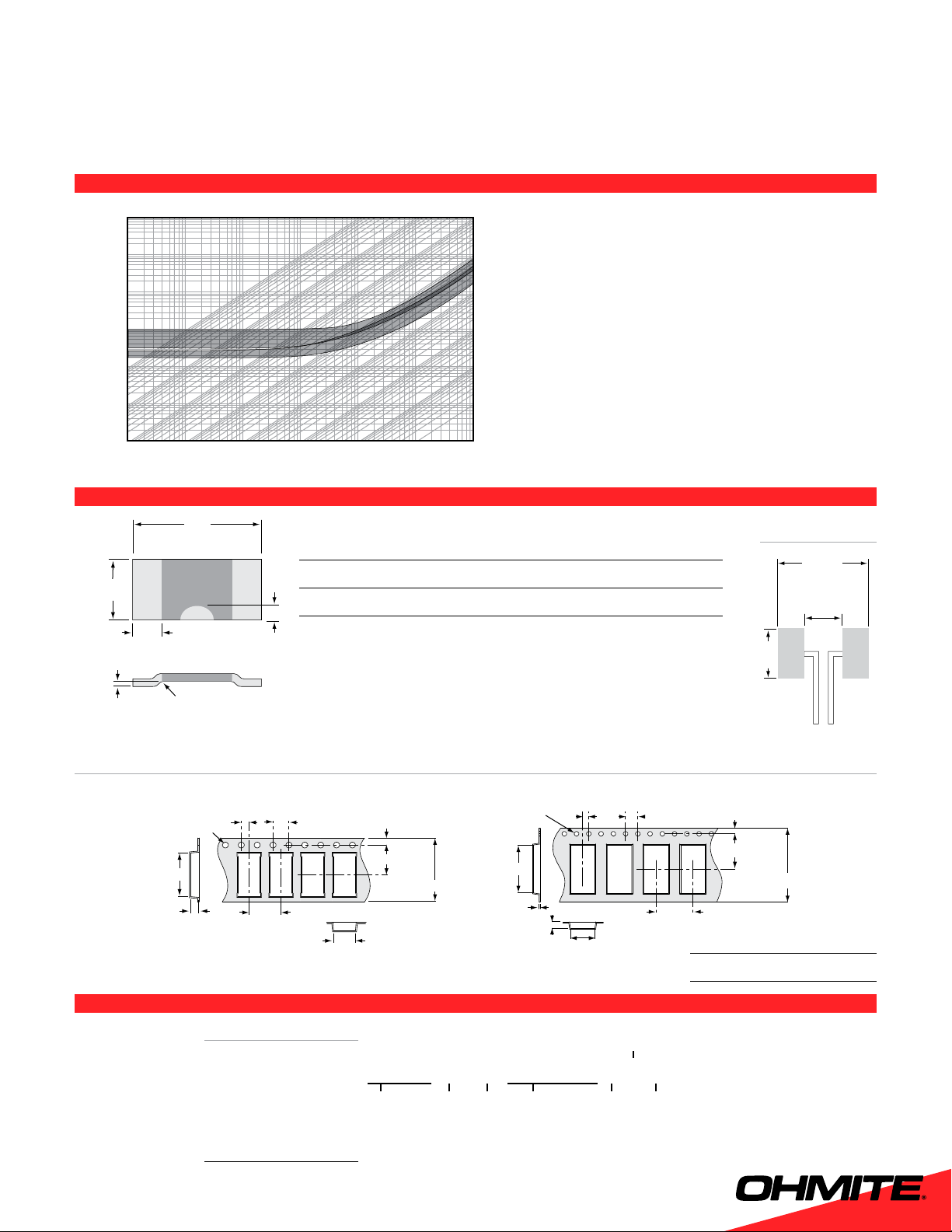

Pulse Energy (J)

Power (W)

Time (msec.)

EBWB

EBWA

1

0.01

10

100

0.1

1000

10,000

0.01

0.0001

0.1

1

0.001

10

100

1,00010,000

0.010.0001 0.1 10.001 10 100

EBWA-MR0020FET

Series

Electron

Beam Weld

Size Alloy

M = Maganin

N = NiCr

Resistance Tolerance

F = 1%

J = 5%

Tape and reel

EBWA: 3000 pc/reel

EBWB: 2000 pc/reel

RoHS Compliant

15.70mm ±.10

11.00mm ±.10

0.30mm ±.10

2.00mm ±.10

2.00mm ±.10

1.75mm ±.10

1.75mm ±.10

11.50mm ±.10

7.50mm ±.10

12.00mm ±.10

24.00mm ±.30

16.00mm ±.30

10 pitch cumulative

tolerance on tape ±0.2

4.00mm ±.10

10 pitch cumulative

tolerance on tape ±0.2

4.00mm ±.10

Ø1.50mm +10/-0

Ø1.50mm +10/-0

8.00mm ±.10

8.00mm ±.10

EBWA EBWB

5.50mm ±.10

2.10mm ±.10

2.10mm ±.10

Manganin/Aluchrom Alloy Current Sense

PULSE ENERGY/POWER FOR CONTINUOUS OPERATION

DIMENSIONS

(in. / mm)

L W A T

EBWA 0.394" 0.205" 0.079" 0.024"

EBWB 0.591" 0.305" 0.165" 0.039"

10mm +.3/-.2 5.2mm +.3/-.2 2mm +0/-.5 0.6 max.

15mm ±.2 7.75mm +.3/-.2 4.2mm +.1/-.7 1.0 max.

EBWA: Max. curve is only valid for the resistance value 0.5m. The

min. curve is only valid for the resistance value 4m. For other resistance values the area in between the max. and the min. curve is valid

EBWB: Max. curve is only valid for the resistance value 0.2m. The

min. curve is only valid for the resistance value 2m. For other resistance values the area in between the max. and the min. curve is valid

Land Pattern

Tape and Reel

Standard Part Numbers

EBWA-MR0005FE

EBWA-MR0010FE

EBWA-NR0020FE

EBWA-NR0030FE

EBWA-NR0040FE

EBWB-MR0002FE

EBWB-MR0005FE

EBWB-NR0010FE

EBWB-NR0020FE

EBWB-NR0030FE

ORDERING INFORMATION

5

Reel: ~12.95" (329mm)

Qty. per reel: EBWA: 3000pcs

EBWB: 2000pcs

Loading...

Loading...