Page 1

100

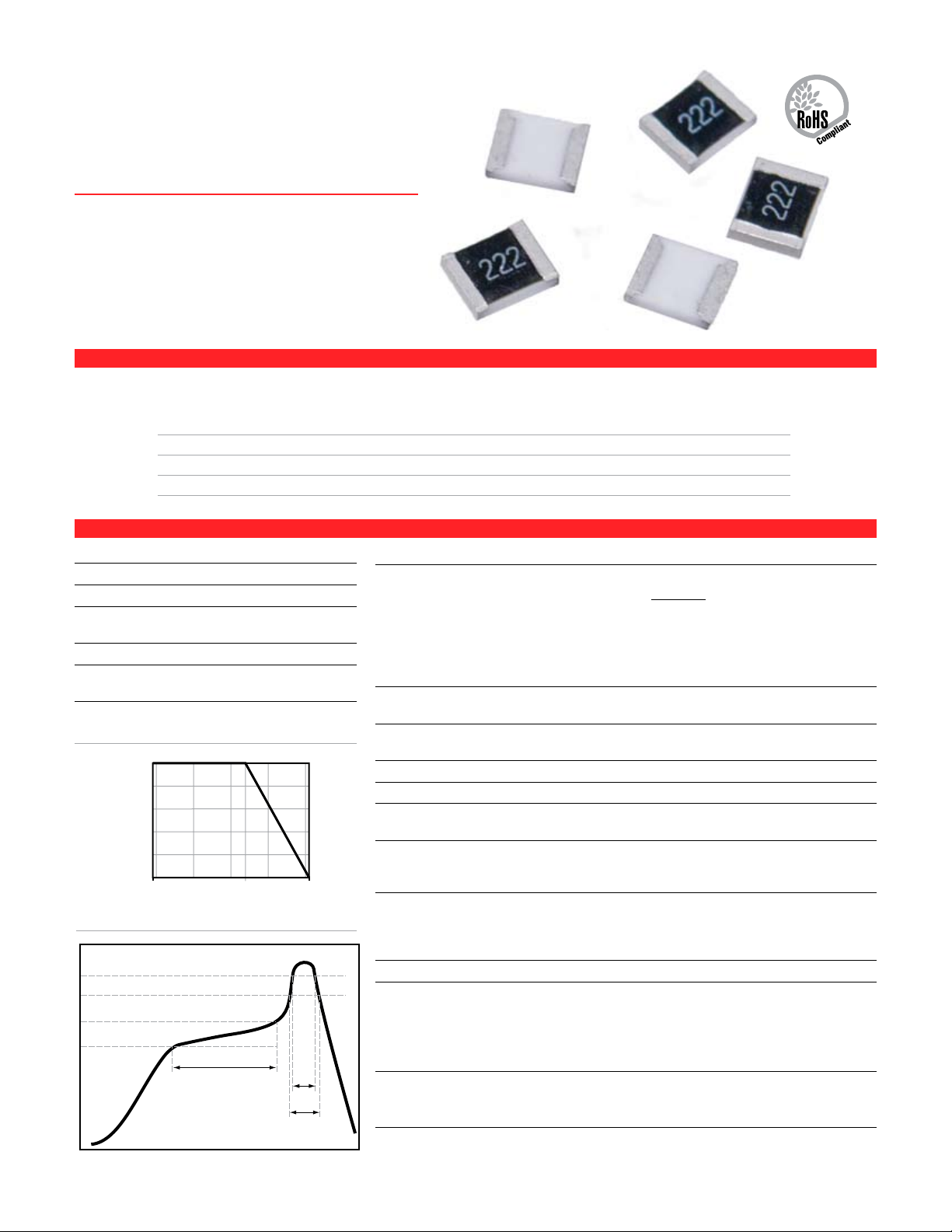

Percent Rated Power

Ambient Temperature, °C

60

20

0

80

40

050 100 15570-55

Temp. (°C)

Time (sec.)

217°

235°~255°C

180°

150°

Peak: 260°C max.

Pre-heating

90s ~ 120s

Soldering 20~40s

Liquid 60~80s

AS Series

Anti-surge Thick Film Chip Resistors

FEATURES

• Smallsizeandlightweight

• Suitableforbothwaveandreflowsoldering

• Canwithstandhighsurge

• Reductionofassemblycosts

SERIES SPECIFICATIONS

Power Max Max Dielectric

Rating Working Overload Withstanding Resistance

Type at 70°C Voltage Voltage Voltage Range

AS08 (0805) 0.33W 150V 300V 500V 1Ω~10MΩ

AS12 (1206) 0.5W 200V 400V 500V 1Ω~10MΩ

AS25 (2512) 1.5W 500V 500V 500V 1Ω~20MΩ

CHARACTERISTICS

-55°C ~ +155°C

E-24 values

Thick film

Silver, copper, nickel,

and tin, non-SAC alloy

Matte tin

±5% standard; ±10%

and ±20% available

Test ΔR Test Methods (JIS C 5201-1 )

Temperature

Soldering Heat

Temperature

withstanding

Derating

Reflow

6

Std. Oper. Temp.

Standard Values

Construction

Terminal material

Solderable finish

Tolerance

Coefficient

Short Time

Overload

Terminal

Bending

Single Pulse

Humidity

Load Life in

Humidity

Load Life

Solderability

Cycling

Dielectric

voltage

1Ω-10Ω: ≤ ±400PPM/°C

(±200 PPM can be provid-

ed on a case to case basis)

11Ω-10MΩ: ≤ ±100PPM/°C

±(1.0% + 0.1Ω) max. Permanent ΔR after the application of a

±(1.0% + 0.05Ω) max. Twist of Test Board: Y/X = 3/90 mm for

±(1.0% + 0.05Ω) max. 260°C±3°C for 10 ±1 sec.

±(1.0% + 0.1Ω) max. See graph on next page.

±(3.0% + 0.1Ω) max. Temporary ΔR after 240 hr. at 40 ±2°C

±(3.0% + 0.1Ω) max. ΔR after 1,000 hr. (1.5 hr. "on", 0.5 hr.

±(3.0% + 0.1Ω) max. ΔR change after 1,000 hr. operat-

Min. 95% coverage Wave Solder: 245°C ±3°C for 2-3 sec.

±(1.0% + 0.05Ω) max. ΔR after 5 cycles:

No evidence of flashover,

mechanical damage, arcing

or insulation breakdown

Natural ΔR/°C

R2-R1

R1(t2-t1)

R1: at room temp. (T1)

R2: at room temp. plus 100°C (T2)

Test pattern: room temp. (T1), room

temp. +100°C(T2)

potential of 2.5 times RCWV for 5 sec.

60 sec.

and 90-95% relative humidity

"off" ) at RCWV at 40 ±2°C and 90-95%

relative humidity

ing at RCWV, with duty cycle of (1.5

hours"on", 0.5 hour"off") at 70°C ±2°C

ambient

-55°C ±3°C 30 min.

Room temp. 10-15 min.

+155°C ±2°C 30 min.

4 Room temp. 10-15 min.

Clamped in the trough of a 90°C metal-

lic v-block at specified AC potential

60-70 sec.

x 106 (PPM/°C)

Page 2

AS Series

a a

b b

178 ±2

60 ±1

13 ±.5

2 ±.5

W ±1

21 ±.5

A ±.2

B ±.2

T ±.1

1.5 +0.1/-0

1.75 ±.1

3.5 ±0.05

4.0 ±.1

8.0 ±.2

Paper

Embossed

2.0 ±.05

A ±.2

B ±.2

1.0 ±.1

1.5 +0.1/-0

1.5 +0.1/-0

1.75 ±.1

3.5 ±0.05

4.0 ±.1

8.0 ±.2

2.0 ±.05

AS08J1004ET

RoHS

compliant

Ohms

First 3 digits are

significant; 4th digit

is multiplier. Values

below 100 ohms use

"R" as a decimal

holder.

examples:

1001 = 1000 ohms

1502 = 15000 ohms

Tolerance

J = 5%

standard

for E24

values

Series

AS08= 0805

AS12= 1206

AS25= 2512

TCR

T= tape and

reel: 0805 and

1206 paper

tape; 2512

embossed tape.

Single

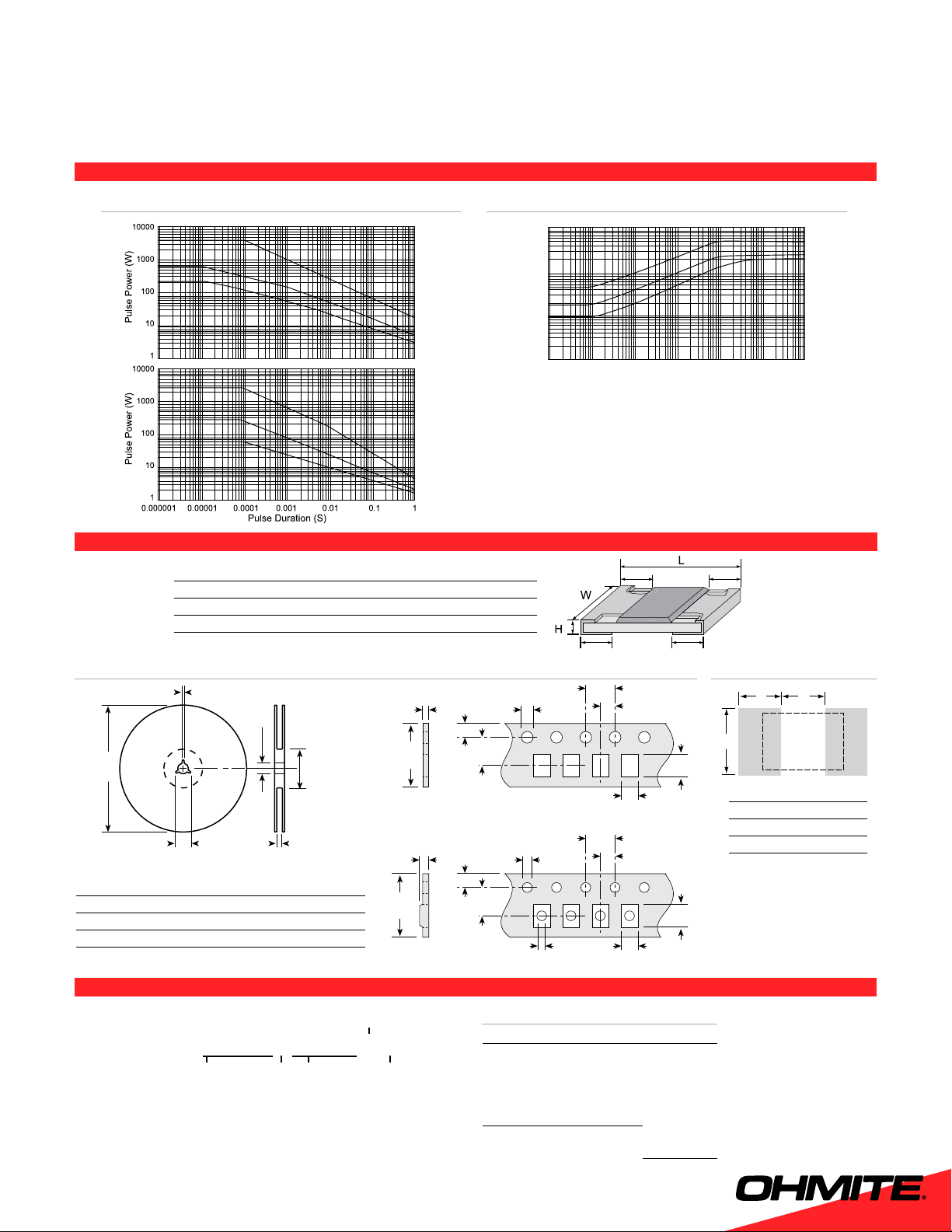

AS25

AS12

AS08

AS25

AS12

AS08

Continuous (100KΩ)

AS25

AS12

AS08

1.2/50µs Lightning Surge

Resistance (Ω)

Voltage (V)

10,000

1,000

100

10

1 10 100 1K 10K 1M100K

B C

A

Anti-surge Thick Film Chip Resistors

CHARACTERISTICS

Pulse Curve Lightning Surge

DIMENSIONS

(mm)

Series L W H a b

AS08 2.00 ±0.15 1.25 +0.15/-0.10 0.55 ±0.10 0.40 ±0.20 0.40 ±0.20

AS12 3.10 ±0.15 1.55 +0.15/-0.10 0.55 ±0.10 0.45 ±0.20 0.45 ±0.20

AS25 6.35 ±0.10 3.10 ±0.15 0.55 ±0.10 0.60 ±0.25 0.50 ±0.20

Tape and Reel Land Pattern

Series Packaging Qty./reel A B T W

AS08 Paper 5,000 pcs. 1.65 2.40 0.81 10

AS12 Paper 5,000 pcs. 2.00 3.60 0.81 10

AS25 Embossed 4,000 pcs. 3.50 6.70 1.0 13.8

rev 10/20-2

ORDERING INFORMATION

Standard Part Numbers

0805

AS08J1R00ET

AS08J10R0ET

AS08J1000ET

AS08J1001ET

AS08J1002ET

AS08J1003ET

AS08J1004ET

1206

AS12J1R00ET

AS12J10R0ET

AS12J1000ET

AS12J1001ET

AS12J1002ET

AS12J1003ET

AS12J1004ET

2512

AS25J1R00ET

AS25J10R0ET

AS25J12R0ET

AS25J15R0ET

AS25J22R0ET

AS25J1000ET

AS25J1001ET

AS25J1002ET

AS25J1003ET

AS25J1004ET

7

Series A B C

AS08 1.3 1.2 1.0

AS12 1.8 1.2 2.2

AS25 3.0 2.5 4.0

Loading...

Loading...