Ohmite 33Jxxx Series, 35Jxxx Series, 30Jxxx Series, 825JxxxH Series, RH3R0DBxxxJ Series Data Sheet

Page 1

High Energy Wirewound

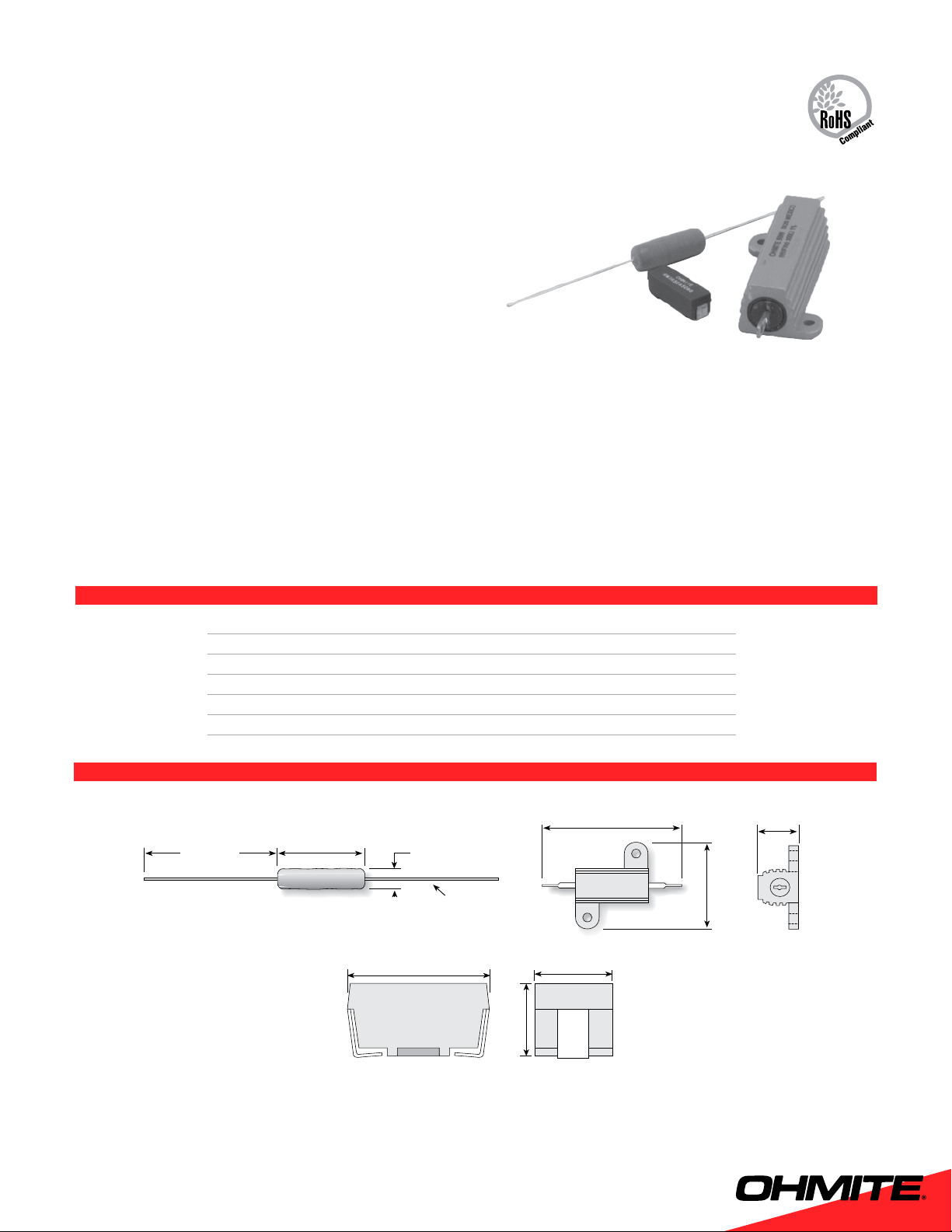

1.5 / 38.1

33J: 0.593 / 15.1

35J: 1.000 / 25.4

30J: 1.900 / 46.8

33J: 0.218 / 5.5

35J: 0.343 / 8.7

30J: 0.406 / 10.3

33J: 20 ga.

35J: 18 ga.

30J: 18 ga.

RH3R0DBxxxJ: 0.612 / 15.545 0.273 / 6.934

0.226 / 5.740

825JxxxH: 1.938 / 49.23

1.080 / 27.43

0.546 / 13.87

in. / mm

Axial Terminal / Surface Mount / Heat Sinkable Packaging

Ohmite Manufacturing’s family of High Energy

Wirewound Resistors employ special winding techniques to maximize the effective joule rating of each

resistor. Most wirewound resistors are wound with

the objective of meeting the stated power (wattage) rating and keeping cost low through the use

of automatic winding equipment. Typically, manufacturers will allow substitution of resistance wire,

depending on material availability. On tight tolerance

wirewounds some type of abrasive adjustment to the

resistance wire is often used to maximize production

yields. Both of these procedures can adversely affect

the joule rating and fusing current of a wirewound

resistor, and this is often the reason that the manufacturer does not publish a fixed joule rating.

Ohmite High Energy Wirewounds are wound so

as to maintain the tightest possible pitch (space

between windings) and thereby maximize the mass

of the resistive element. Since no wire substitutions

are allowed, and no abrasive adjusting is permitted

in this family, Ohmite can publish a fixed joule rating and fusing current for each part number in the

series.

This technique can be applied to any wirewound

product. In order to provide the broadest selection of

packaging, Ohmite has developed standard offerings

in three different package types-axial, SMD, and heat

sinkable. Other sizes and types can be quoted on

request, such as tubular power resistors.

SERIES SPECIFICATIONS

Series Type Watts Tolerance Voltage

33Jxxx Axial 3 5% 200

35Jxxx Axial 5 5% 460

30Jxxx Axial 10 5% 1000

825JxxxH Heat Sinkable 25 5% 520

RH3R0DBxxxJ Surface Mount 3 5% 200

DIMENSIONS

61

Page 2

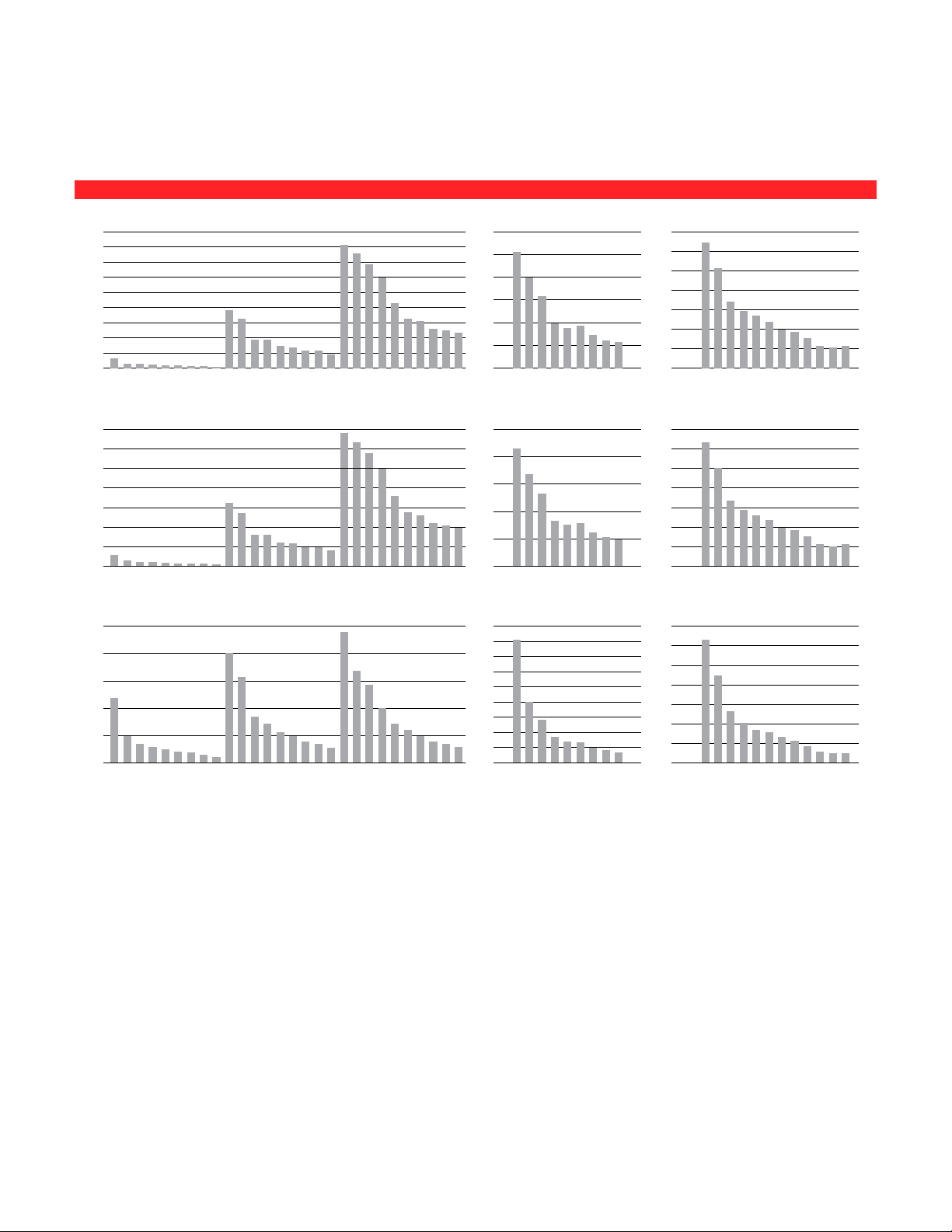

Energy (J)

0

33J1R0

33J5R0

33J10R

33J15R

33J20R

33J25R

33J30R

33J50R

33J100

35J1R5

35J2R5

35J7R5

35J12R

35J18R

35J22R

35J36R

35J47R

35J75R

30J2R0

30J4R7

30J6R8

30J15R

30J27R

30J33R

30J50R

30J82R

30J100

30J150

20

40

60

80

100

120

140

160

180

Fusing Energy (J)

0

33J1R0

33J5R0

33J10R

33J15R

33J20R

33J25R

33J30R

33J50R

33J100

35J1R5

35J2R5

35J7R5

35J12R

35J18R

35J22R

35J36R

35J47R

35J75R

30J2R0

30J4R7

30J6R8

30J15R

30J27R

30J33R

30J50R

30J82R

30J100

30J150

100

200

300

400

500

600

700

Fusing Current (A)

0

33J1R0

33J5R0

33J10R

33J15R

33J20R

33J25R

33J30R

33J50R

33J100

35J1R5

35J2R5

35J7R5

35J12R

35J18R

35J22R

35J36R

35J47R

35J75R

30J2R0

30J4R7

30J6R8

30J15R

30J27R

30J33R

30J50R

30J82R

30J100

30J150

10

20

30

40

50

Energy (J)

0

-1R0H

-5R0H

-10RH

-25RH

-36RH

-47RH

-75RH

-100H

-150H

Fusing Energy (J)

825J-

Energy (J)

0

-R500J

-1R00J

-2R70J

-4R70J

-6R80J

-7R50J

-10R0J

-15R0J

-25R0J

-47R0J

-68R0J

-75R0J

RH3R0DB-

0

-1R0H

-5R0H

-10RH

-25RH

-36RH

-47RH

-75RH

-100H

-150H

825J-

Fusing Energy (J)

0

-R500J

-1R00J

-2R70J

-4R70J

-6R80J

-7R50J

-10R0J

-15R0J

-25R0J

-47R0J

-68R0J

-75R0J

RH3R0DB-

Fusing Current (A)

0

-1R0H

-5R0H

-10RH

-25RH

-36RH

-47RH

-75RH

-100H

-150H

825J-

Fusing Current (A)

0

-R500J

-1R00J

-2R70J

-4R70J

-6R80J

-7R50J

-10R0J

-15R0J

-25R0J

-47R0J

-68R0J

-75R0J

RH3R0DB-

10

20

30

40

50

60

50

100

150

200

250

5

10

15

20

25

30

35

40

45

2

4

6

8

10

12

14

0

10

20

30

40

50

60

5

10

15

20

25

30

35

High Energy Wirewound

Axial Terminal / Surface Mount / Heat Sinkable Packaging

PERFORMANCE CHARACTERISICS

62

(continued)

Page 3

High Energy Wirewound

Axial Terminal / Surface Mount / Heat Sinkable Packaging

ORDERING INFORMATION

Standard Part Numbers

Part Number Ohms Power (J) Energy (J) to fuse (A) fuse (W)

33J1R0 1 3 12.70 53.26 23.93 572.60

33J5R0 5 3 6.25 26.20 10.03 502.96

33J10R 10 3 4.94 20.73 7.08 501.70

33J15R 15 3 4.66 19.55 5.95 531.47

33J20R 20 3 3.91 16.40 5.00 500.45

33J25R 25 3 3.07 12.89 4.20 441.79

33J30R 30 3 2.97 12.46 3.92 460.80

33J50R 50 3 2.43 10.20 2.97 440.68

33J100 100 3 1.92 8.07 2.10 439.58

35J1R5 1.5 5 76.55 321.19 40.32 2438.48

35J2R5 2.5 5 64.65 271.23 31.59 2494.75

35J7R5 7.5 5 37.66 158.01 16.90 2141.89

35J12R 12 5 37.90 158.99 14.20 2420.25

35J18R 18 5 28.80 120.84 11.13 2228.50

35J22R 22 5 27.48 115.29 10.03 2213.02

35J36R 36 5 22.78 95.59 7.86 2222.93

35J47R 47 5 23.22 97.42 7.08 2358.00

35J75R 75 5 18.77 78.77 5.55 2309.77

30J2R0 2 10 162.30 680.93 47.98 4603.79

30J4R7 4.7 10 150.86 632.92 33.88 5395.94

30J6R8 6.8 10 137.27 575.91 28.47 5513.41

30J15R 15 10 119.76 502.47 20.11 6065.77

30J27R 27 10 85.27 357.74 14.20 5445.56

30J33R 33 10 65.54 274.98 11.93 4700.40

30J50R 50 10 62.45 262.03 10.03 5029.59

30J82R 82 10 51.90 217.74 7.86 5063.34

30J100 100 10 49.41 207.28 7.08 5017.03

30J150 150 10 46.61 195.54 5.95 5314.71

825J1R0H 1 25 51.04 214.12 40.32 1625.65

825J5R0H 5 25 39.92 167.49 20.11 2021.92

825J10RH 10 25 31.58 132.50 14.20 2016.87

825J25RH 25 25 19.64 82.40 8.43 1776.01

825J36RH 36 25 17.79 74.62 7.08 1806.13

825J47RH 47 25 18.71 78.49 6.60 2049.57

825J75RH 75 25 14.66 61.49 5.00 1876.69

825J100H 100 25 12.29 51.56 4.20 1767.15

825J150H 150 25 11.59 48.64 3.53 1872.00

RH3R0DBR500J 0.5 3 12.93 54.25 31.59 498.95

RH3R0DB1R00J 1 3 10.23 42.91 22.31 497.70

RH3R0DB2R70J 2.7 3 6.87 28.82 13.24 473.33

RH3R0DB4R70J 4.7 3 5.87 24.63 10.03 472.78

RH3R0DB6R80J 6.8 3 5.34 22.41 8.43 483.07

RH3R0DB7R50J 7.5 3 4.75 19.91 7.86 463.11

RH3R0DB10R0J 10 3 3.98 16.70 6.60 436.08

RH3R0DB15R0J 15 3 3.75 15.75 5.55 461.95

RH3R0DB25R0J 25 3 3.07 12.89 4.20 441.79

RH3R0DB47R0J 47 3 2.28 9.59 2.97 414.24

RH3R0DB68R0J 68 3 2.08 8.72 2.49 423.26

RH3R0DB75R0J 75 3 2.29 9.62 2.49 466.83

RoHS compliant product available; Add “E” suffix to part number to specify.

Energy Fusing Current Power to

Other values available, contact Ohmite for details.

63

Loading...

Loading...